3D scanner for sale south africa

Professional 3D Scanning

You are here: Home / Professional 3D Scanning

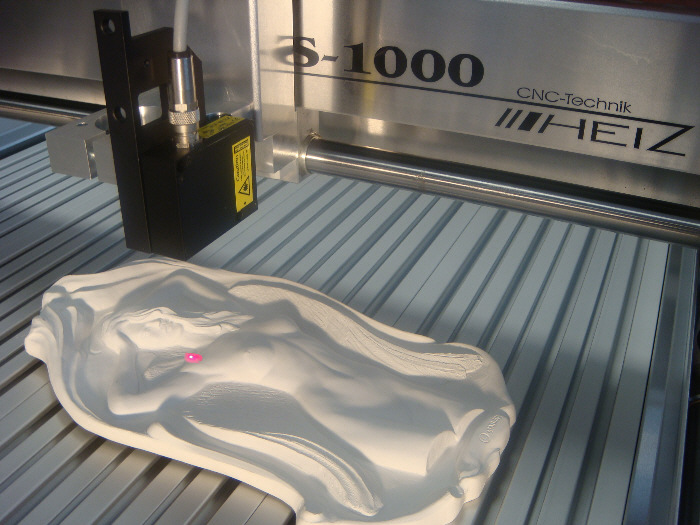

Reverse engineering is paramount to multiple industries such as manufacturing, automotive, aerospace, and healthcare. Professional-grade 3D scanning has a broad range of applications, including product improvement and reconstruction, design augmentation, generative design and simulation, and many others. The world today would not be the same without it.

Whether it be an out-of-production car part or a detailed tooling insert, the capabilities of high-end 3D scanning technology have changed the way we approach digital fabrication.

For the 3D printing industry, 3D scanners have become an essential part of the process of designing and modeling parts and components. There are different types of 3D scanners, each designed to meet different needs. Applications vary in requirements; usually, it is a combination of higher accuracy, resolution, or capture speed.

What really matters when choosing a 3D scanner?

Choose the appropriate scanner for the type of object you wish to scan and the result you wish to achieve. For example, if you need to scan something very small, choose a 3D scanner that is able to capture the small details of the object in high resolution. If you need to 3D scan something from a distance, choose a long-range scanner. Another criterion is the software, which is an integral part of 3D scanning.

Often, we see customers jump into 3D scanning without fully understanding the entire workflow required. Regardless of whether it’s reverse engineering, preparation for part reproduction via 3D printing, or even metrology-level inspection — if you do not consider the tools, both hardware and software, required to complete the job, you may find yourself with an expensive 3D scanner that only partially solves your problem.

The Rapid 3D team will walk you through this minefield … before you make a purchase decision.

We find that structured light systems are best for 3D scanning objects where both the colour and texture data are important, as well as the underlying 3D geometry. By contrast, laser scanners tend to be faster and a better option when speed and details are the key criteria for a scan.

By contrast, laser scanners tend to be faster and a better option when speed and details are the key criteria for a scan.

Rapid 3D is the only certified Artec 3D partner in Southern Africa. Achieving this official certification required demonstrating ‘exceptional’ practical and complex 3D scanning and software knowledge and capability. The certification gives you the security of knowing that we can provide effective support.

Here’s our Artec 3D Official Partner Certificate.

Akhani 3D, our 3D print service bureau sister company has given our engineers lots of experience with 3D scanning and processing a wide range of objects.

Artec 3D are a multi-award winning 3D scanning vendor. Going head-to-head with over a dozen world-renowned 3D scanner companies, Artec 3D won the 2019 3D Scanning / Metrology Company of the Year award from the leading 3D tech publication 3D Printing Industry. That after Artec’s most cutting-edge 3D scanner, the Artec Leo won yet another significant award; the Golden Mousetrap Award for the best device in the Test & Measurement category.

Thanks to their high precision, Artec 3D scanners have a wide range of applications in industrial design and manufacturing. Commonly used during various stages of product design development and implementation, these powerful 3D scanning tools significantly speed up the workflow, making it easier to get the required object data and create customized automated capturing solutions.

While all the Artec 3D scanners are great for reverse engineering and quality control, the best industrial 3D scanner, the Artec Space Spider, is used for capturing small objects and complex geometry with the highest precision. The Artec Eva is able to 3D scan larger objects with both speed and accuracy. Neither scanner requires the user to stick targets on the object.

Neither scanner requires the user to stick targets on the object.

Seamless export of the 3D models to a variety of widely used CAD and CAM programs allows users to conduct a large variety of tests for quality control, acquire necessary measurements and other data for reverse engineering, object integration, and more.

Learn about industrial 3D scanning applications

- How one foundry uses “crazy efficient” Artec Eva to slash up to 75% off production time, cut losses, and more.

- Hyundai – Quality control of automobile seats.

- Improved Manufacturing Process with Artec 3D and Geomagic Control X.

Talk to us about your 3D scanning applications

FARO Laser Scanner - Small size 3D Scanners and Freestyle3D Scanners

The Focus

S Series consists of three laser scanners with different ranges: FocusS 350 for long-range measurements up to 350m, FocusS 150 for mid-range measurements up to 150m and the newest member FocusS 70, perfectly suitable for short-term measurements up to 70m.

With their sealed design, all S Laser Scanner models are certified via the industry standard Ingress Protection (IP) Rating, and classified in Class 54 for environmental protection. The devices are built to safeguard against intrusions such as dirt, dust, fog and rain as well as other outdoor elements which typically occur in challenging scanning conditions. An extended temperature range allows scanning in extreme environments, like desserts. An addition the laser scanners offer a future-proof interface to connect additional accessories to the scanner and provide a specific on-site compensation routine.

For scan data processing users have unrestricted freedom of choice to leverage the software tools most beneficial to their own workflow. The point cloud data captured with FARO Laser Scanners can be used with various software packages including FARO SCENE or 3rd party software such as Autodesk ReCap.

All scanner types offer the possibility to perform scanning even in bright sunlight. Remote scanning as well as almost limitless scan data sharing via SCENE Webshare Cloud make the laser scanning solution truly mobile.

Remote scanning as well as almost limitless scan data sharing via SCENE Webshare Cloud make the laser scanning solution truly mobile.

Important FARO links

FARO Focus

S 350The FARO FocusS 350 is specially designed for outdoor applications due to its small size, extra light weight and extended scanning range. The FocusS 350 provides scanning results even in challenging environments, narrow job-sites, dusty or humid areas, in rain or direct sunlight applications. An on-site compensation tool allows data quality optimization on-site. Integrated GPS & GLONASS receiver enable easy positioning. HDR imaging and HD photo resolution ensure true-to-detail scan results with high data quality.

- Distance accuracy up to ±1mm

- Range from 0.6m up to 350m

- IP Class 54

- On-Site Compensation

- Accessory Bay

- HD photo overlay up to 165 megapixel color

FARO Focus

M 70The ultra-portable FocusM 70 enables fast, straight-forward and accurate measurements of construction sites, small-scale facades, complex structures, production and supply facilities and crash and crime scenes. The 3D scan data can easily be imported into all commonly used software solutions for architecture and construction, forensics and accident reconstruction or industrial manufacturing

The 3D scan data can easily be imported into all commonly used software solutions for architecture and construction, forensics and accident reconstruction or industrial manufacturing

- Distance accuracy up to ±3mm

- Range from 0.6m up to 70m

- IP Class 54

- HD photo overlay up to 165 megapixel color

- Extended Temperature Range

- Best Value for Money

Measuring method

Distance

The laser scanner transmits a laser beam, which is reflected by an object back to the scanner. The distance is measured with millimetre precision by means of the phase difference between the transmitted and received beams.

The distance is measured with millimetre precision by means of the phase difference between the transmitted and received beams.

Vertical angle

The mirror directs the laser beam through the space in a vertical direction. The angle is recorded at the same time as the distance measurement.

Horizontal angle

The laser scanner turns horizontally through 360° while scanning. The horizontal angle is recorded at the same time as the distance measurement.

Defining the 3D coordinates

Distance, vertical angle and horizontal angle result in polar coordinate (d, α, β), which are converted into cartesian coordinates (x, y, z).

About Shining 3D | EinScan

- About Us

- Contact Us

About Us

Founded in 2004, SHINING 3D has been developing 3D printing and 3D printing technology for over 14 years. SHINING 3D develops, manufactures and commercializes a wide range of 3D technologies, including 3D scanners for various industries and applications, 3D printers for both consumer and additive manufacturing, 3D materials. It also offers 3D design and manufacturing services and an online 3D cloud platform. It is the first company to offer a fully integrated 3D workspace and ecosystem.

SHINING 3D develops, manufactures and commercializes a wide range of 3D technologies, including 3D scanners for various industries and applications, 3D printers for both consumer and additive manufacturing, 3D materials. It also offers 3D design and manufacturing services and an online 3D cloud platform. It is the first company to offer a fully integrated 3D workspace and ecosystem.

As a China-listed OTC company in the 3D digitizing and printing industry, SHINING 3D is an industry leader in terms of market stability, sales volume, technology, high quality service, etc. SHINING 3D has a strong position on the market, demonstrating the ability to handle high sales volumes by offering high quality 3D technologies and qualified service support.

SHINING 3D's mission is to make all 3D imaging and production technologies available to the public, both for home use by amateurs and for large multinational corporations around the world. By providing "3D Digitization - Smart Design - Additive Manufacturing" solutions for precision medicine, personal consumption, innovative education and industrial manufacturing, SHINING 3D promotes 3D digital solutions on a large scale.

SHINING 3D, headquartered in Hangzhou, China, owns and operates subsidiaries in key strategic geographic markets in Stuttgart, Germany and San Francisco, California, USA, enabling SHINING 3D to work more closely with its customers and partners. As the leader among Chinese 3D printing companies, SHINING 3D has now greatly strengthened its international influence, having managed to win customers in more than 70 countries in Asia-Pacific, North and South America, Europe, Africa and the Middle East.

SHINING 3D production system strictly adheres to ISO9001, ISO14001, ISO13485, OHSMS18000 standards. Most products are CE, FDA, UL, FCC or RoHs certified, which ensures the stability of standard and large-scale production, quality assurance system, consistent quality requirements and production efficiency.

Contacts

APAC and Global Headquarters

SHINING 3D Tech Co., Ltd.

Hangzhou, China 1398, Xiangbin Road, Wenyan, Xiaoshan, Hangzhou, Zhejiang, China, 311258

Tel: +86-571-82999050

Email: sales@shining3d. com

com

Skype: shining3d_sales

Website: www.shining3d.com

Region EMEA

SHINING 3D Technology GmbH.

Stuttgart, Germany

Breitwiesenstraße 28, 70565 Stuttgart, Germany

Tel: +49-711 28444089

Email: [email protected]

Americas Region

SHINING 3D Technology Inc.

San Francisco, USA

1740 César Chávez St. Unit D. San Francisco, CA 94124

Tel: +1415 259 4787

Email: [email protected]

Support

Email: [email protected]

Skype: einscan_support 9008 to submit a support request.

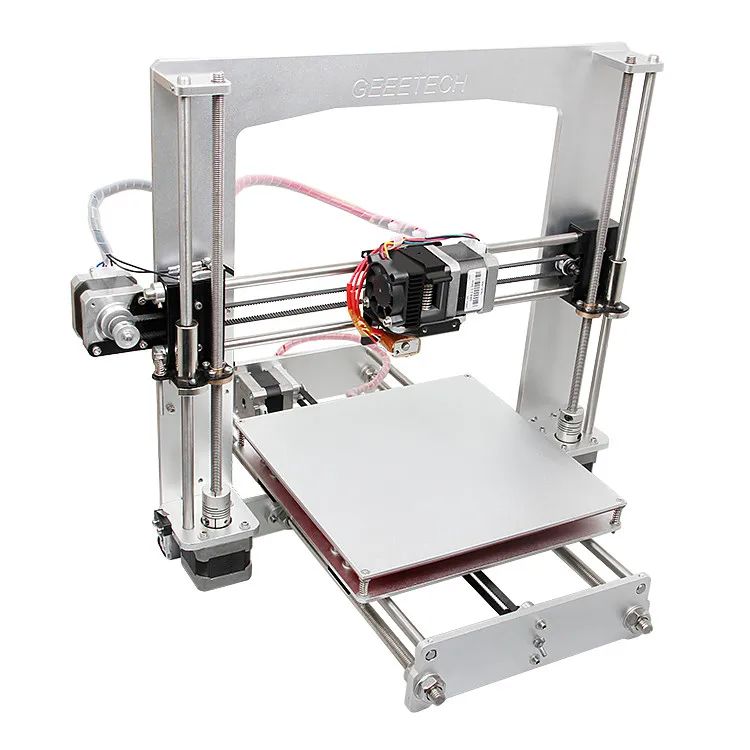

Einstart 3D Printer

Email: [email protected]

Marketing & Media

Email: [email protected]

SHINING 3D offers AutoScan-DS-EX Pro dental 3D scanner

SHINING 3D, China's leading developer and manufacturer of 3D scanning and 3D equipment - printing, opened a representative office in the United States and demonstrated the latest AutoScan-DS-EX Pro 3D dental scanner.

SHINING 3D continues to actively develop its own sales network by opening a third office in San Francisco in addition to the headquarters in Hangzhou and a representative office in Stuttgart, responsible for sales and technical support in Europe, the Middle East and Africa . The new office will serve customers in North, Central and South America.

“The new US office is a logical extension of SHINING 3D's globalization policy. The San Francisco location gives us access to California's cultural, commercial and technology hub, thereby attracting professional talent and providing a high level of service to distributors and end customers,” said Oscar Mesa, SNINING 3D Vice President of International Trade.

The company celebrated the opening of a new office with the presentation of the latest digital solution for the dental and orthodontic industries - an upgraded version of the AutoScan-DS-EX 3D scanner, first announced in August last year. The compact device with structured white or blue light technology is based on an open architecture with a modular design. Replacing individual modules ensures timely hardware updates without the need to purchase a new device. Compared to the original, AutoScan-DS-EX Pro provides better performance and accuracy.

Replacing individual modules ensures timely hardware updates without the need to purchase a new device. Compared to the original, AutoScan-DS-EX Pro provides better performance and accuracy.

AutoScan-DS-EX Pro supports in-articulator scanning, triple scanning (top, bottom and dental impression) and texture digitizing. The resolution of the cameras is 1.3 megapixels. The size of the scanned area reaches 100x100x75 mm, and it takes from 8 (per bite) to 70 (per imprint) seconds to digitize a model with an accuracy of at least 10 microns. Due to its modest dimensions and weight, not exceeding 260x270x420 mm and 5 kg, the device easily fits into cramped working spaces and is easily transported. Detailed information about the AutoScan-DS-EX 3D scanner is available on the official website of the manufacturer at this link.

About SHINING 3D

Founded in 2004, SHINING 3D soon became China's first digital technology company in the OTC market. Business lines include 3D scanning, 3D printing, consumables, 3D design, manufacturing services, and cloud platform enhancements.