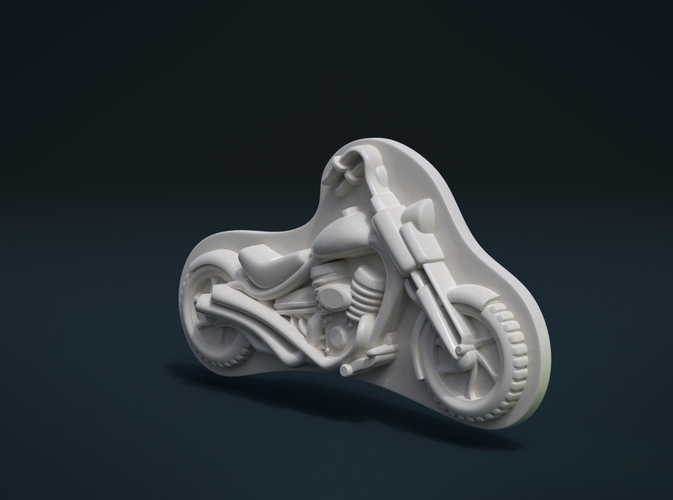

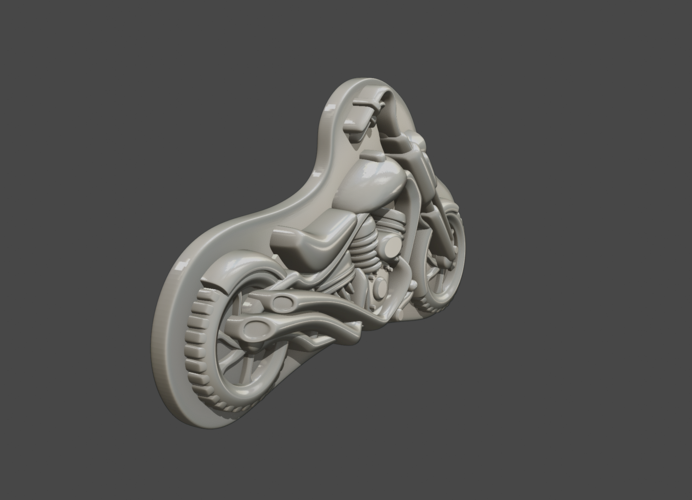

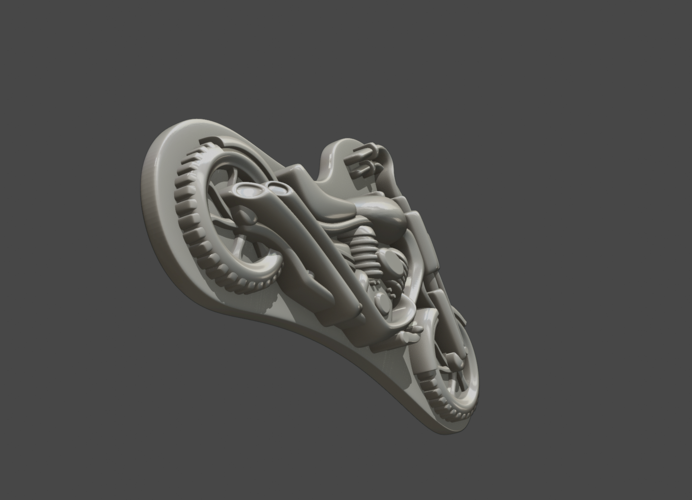

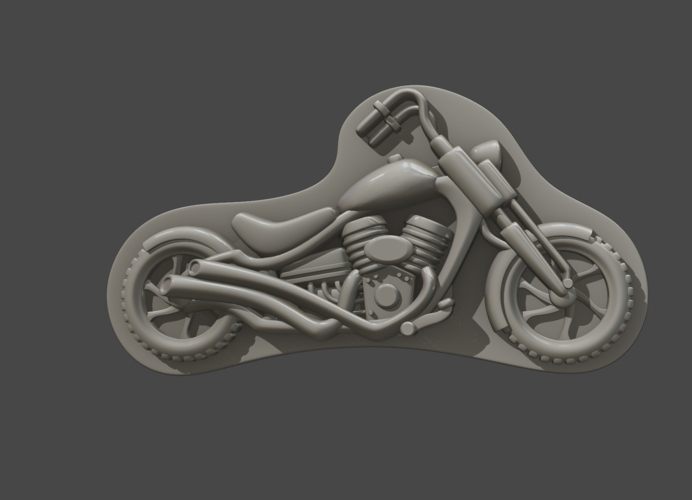

Motorcycle 3d print

🏍️ Best 3D print files for bikes and motorbikes・Cults

🏍️ Best 3D print files for bikes and motorbikes

Download 3D print motorcycle files

Designers who are passionate about motorcycles have managed to model in STL models that are true replicas of existing machines. Some of these 3D objects even have the ability to be remote controlled. In this collection you will find everything: racing bikes, vintage bikes, motocross bikes, etc.

Harley Davidson

Free

2016 Suzuki GSX-RR MotoGP RC Motorcycle

Free

2016 Suzuki GSX-RR 1:8 Racing RC MotoGP Version 2

Free

Joe Bar Team Paulo les gazs

Free

Peugeot 104

Free

2016 Ducati Draxter Concept Drag Bike RC

Free

Harley Davidson Ashtray

Free

Harley Davidson

Free

Jawa 250

Free

Motorcycle cafe racer 2D

Free

motorcycle coaster quartararo

Free

KTM Motorcycles Sign

Free

Jawa 250

Free

Handle for 1966 HD M50S

Free

Sportster Harley Davidson

Free

MT-09 Protection of handlebar end cap -motorcycle handlebars cap

Free

SPORTSTER HARLEY DAVIDSON V2

Free

Motorcycle ToolBox

Free

Shoei Keychain motorcycles

Free

Motorbike Agusta Bestiale

€7. 42

Motorcycle helmet fan - motorcycle helmet dryer "dual" fan

€7.50

handlebar mirror support

Free

Motorcycle helmet fan - motorcycle helmet dryer single

€5

Buell American Motorcycles Pegasus Logo Sign

Free

skull helmet support

€13

Super Bike

€0.50

motorcycle key ring

Free

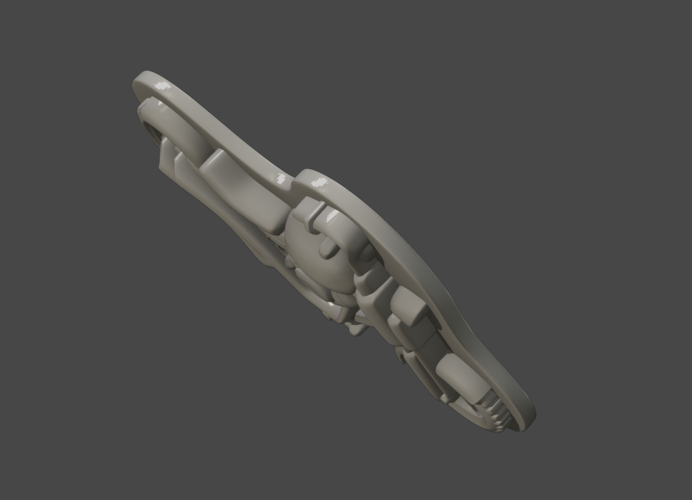

1988 Suzuki DR 750 Chain Guide

Free

Motorcycle helmet holder hook hanger

€2.50

Mobile phone holder - phone holder

€1

Yamaha XSR 700 Gauge relocation

€2

Yamaha motorcycle phone mount

€3

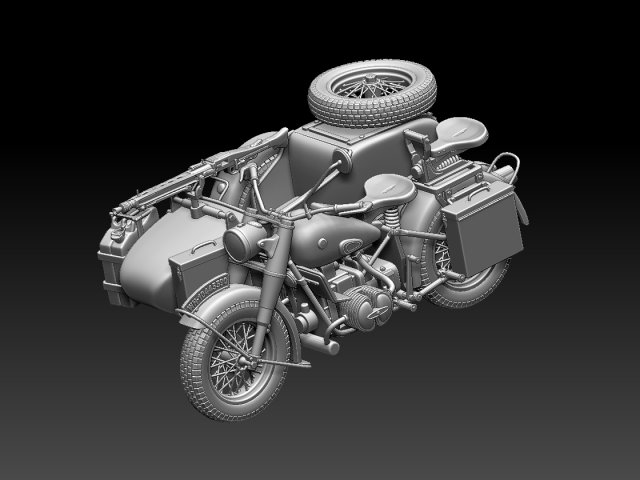

Zündapp KS 750 scale 1:48

€7.09

BMW motorcycle mirror extender

€1. 66

66

Super Motorcycle Keyring

€0.50

Harley-Davidson Softail Slim S

€3.33

motorbike cutter

€1.93

Motorcycle Helmet Devil Horn

€13

Model Harley Davidson Bike

€50.64

Junak 123 motorbike phone mount

€2

motorbike with sidecar

€2.50

"Stay True" Motorcycle and Rider

€6.61

Phone Holder Universal

€1.60

Naked bike V-twins Ducati style

€5

AfricaTwin XRV650

€49.95

Yamaha dt175

€8.23

DeskCycles Simply Z Model

€4.05

Harley Harley-Davidson Fender Trim

€3

Check out our selection of the best 3D print files for 3D printer in the motorcycle world. All these STL files are easily 3D printable, so just download them, fire up your 3D printer and play with them. This collection was made by selecting the best creations from the Cults 3D library.

All these STL files are easily 3D printable, so just download them, fire up your 3D printer and play with them. This collection was made by selecting the best creations from the Cults 3D library.

Here you will find different types of 3D printed motorcycles, there are models to build yourself, functional motorcycles that don't need any work afterwards, but also 3D models for fans of modeling. By adding various elements and a motor you can 3D print your own remote control motorcycle. There are really incredible examples that you can use directly on a track!

These replica motorcycles are suitable for both children and adults. Many motorcycle manufacturers and brands use 3D printing to produce some parts of their machines, but rare are the 100% 3D printed projects. This selection might make you want to create a real 100% 3D printed motorcycle! All the fans of Honda, Suzuki, KTM and Triumph will be able to enjoy these beautiful creations.

Motorcycle best STL files for 3D printing・Cults

Skip to contentGPS motorcycle mount

€3

Kawasaki KZ1000P

€6 -50% €3

Kawasaki Ninja 300

€6 -50% €3

Kawasaki Ninja Z250

€6 -50% €3

Kawasaki Ninja h3

€6 -50% €3

Kawasaki Z1000

€6 -50% €3

Wandhalterung für Sena Docking-Station / Wall Mount Sena Docking

€4. 99

99

Generic Trigger 50 SM Motorcycle gas tank cap

€5

Acerbis Handguards

€5.06

Cafe Racer

Free

Cush Drive Spacer

Free

Akaso EK7000 Pro Case (Motorcycle Edition)

Free

KLR 650 Rear Axle Spacer (Sprocket)

Free

Motorcycle Helmet Fins

Free

DUCATI CAM CAM BELT LOCK TOOL 1098 1198 848 821

€1.99 -30% €1.39

DUCATI Cam Belt Tool 1098 1198 848 821

€1.99 -30% €1.39

Reflector Holder Yamaha MT09 , 48mm Fork

Free

Motorcycle throttle lock - Textured

Free

Roadbook

€12. -20% €10 50

50

Samsung A52 Aprilia RSV4 Case

€1.50

50mm Fork Gauge Mount (Right Side)

€5.06

MOTORCYCLE CENTERPIECE

Free

50mm Fork Gauge Mount (Left Side)

€5.06

Motocross piston Compressor 250cc 77mm

Free

Dash for Suzuki DRZ-400S. May fit other bikes.

Free

CROSS ARM MOTOCROSS MOTORCYCLE RIDER / MOTOCROSS MOTORCYCLE RIDER

€5.83

Zündapp ks750

Free

mens motorcycle tyre ring size T

€28.55

VFR 750 R / RC 30 1988 – Printable motorcycle model

€9.40

Motorcycle and bike Phone holder

€5

Motorcycle water cup holder

€5

Adaptateur clignotant fourche US

Free

Sportster License Plate bracket

Free

Valentino Rossi MotoGP

€26

Route 66 Lamp

€2. 87

87

Harley Davidson logo Lamp

€2.87

Motorcyclist Harley

€2.87

US fork flasher adapter

Free

Molto motorcycle baby carry handle

Free

MOTORCYCLE CRUISE CONTROL 30MM.

€3.27

LED Helmet Display

€3.54

Hagrid's motorcycle

€5 -25% €3.75

Shoei NXR(II) GoPro Chin Mount

Free

Motocross rider Motorcycles / motocross rider motorcycle

€4.58

Paddock stand bobbin M8

Free

Helmet wall bracket

€0.66

Motorcycle

Free

Motorcycle kickstand extension

€3

SLS 3D Printed Electric Motorcycle / Sudo Null IT News

E-moto AGH, a team of students from the Polish Academy of Mining and Metallurgy. Stanisława Staszic (hereinafter AGH), designed and built an electric off-road motorcycle. The students not only wanted to prove the benefits of alternative energy sources, they also learned how to apply the latest solutions, such as the Sinterit Lisa Pro desktop SLS 3D printer. Basically, the motorcycle was created in the laboratory of the academy.

Stanisława Staszic (hereinafter AGH), designed and built an electric off-road motorcycle. The students not only wanted to prove the benefits of alternative energy sources, they also learned how to apply the latest solutions, such as the Sinterit Lisa Pro desktop SLS 3D printer. Basically, the motorcycle was created in the laboratory of the academy.

“We spend most of our time in the workshop,” says team leader David Senko. — Our project is the creation of electric motorcycles. Two motorcycles are already ready: with a capacity of eight and thirty kilowatts.

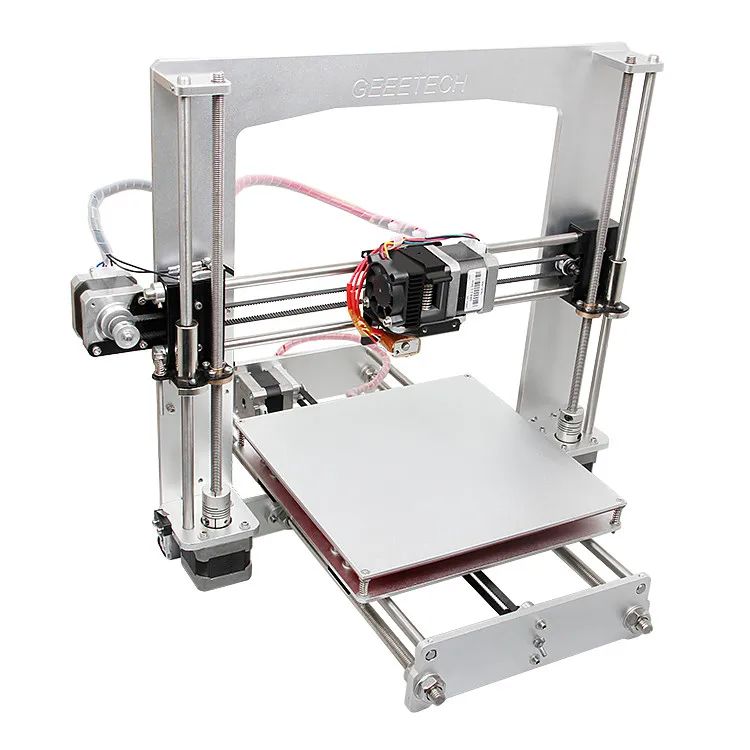

The E-moto AGH team creates their bikes from start to finish. Many parts are made by hand, for example, using vacuum forming or machining. The rest of the parts are 3D printed. Students use several printers, mostly FDM type. But there was a special task for which the technology of selective laser sintering SLS (Selective Laser Sintering) was used.

“We needed to print a heatsink housing, and SLS is the best fit for this purpose, because prints are durable and some parameters are more predictable than FDM,” says Jakub Sobański. “It is also very important that a wide range of powders is used for SLS.”

“It is also very important that a wide range of powders is used for SLS.”

Photo: Andrzej Rusinowski / KSAF

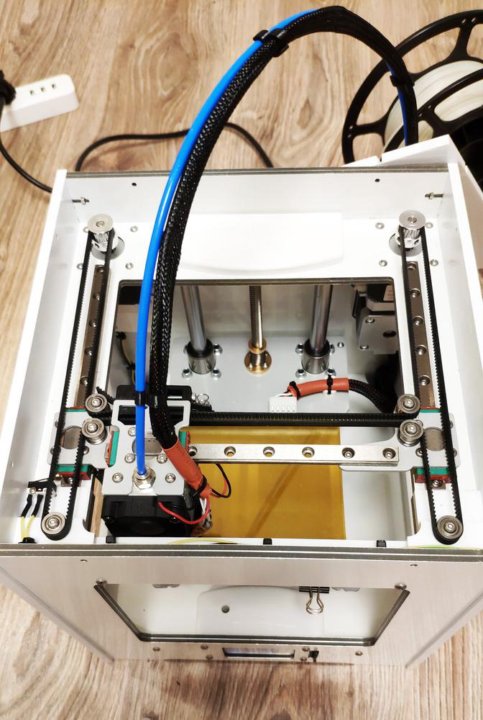

The E-moto AGH team, as already mentioned, used a Sinterit Lisa Pro desktop SLS 3D printer to print the radiator case. One of the advantages of SLS technology is that it will allow very complex designs to be printed. Students printed parts with a honeycomb structure. The air baffles have been designed to keep the radiator from getting clogged with dirt and gravel.

“The printout came out so good and elastic that although the bike fell several times, the part was not damaged,” says Jakub Sobański.

How affordable is SLS 3D printing?

There are two types of SLS 3D printers on the market: industrial and desktop. They differ in the volume of the printing chamber, the degree of automation of the process and the range of materials.

Benchtops are great for research work, rapid prototyping and even small series production. The huge potential of SLS lies in new materials with individually selected properties, which can include conductivity, heat resistance, water repellency - the list is endless.

The huge potential of SLS lies in new materials with individually selected properties, which can include conductivity, heat resistance, water repellency - the list is endless.

And most importantly, desktop SLS-3D printers are several times cheaper than industrial ones.

AGH students learned how to make the most of advanced 3D printing technology, selective laser sintering, and printed functional parts for motorcycles on the Sinterit Lisa Pro, with which they took part in the Smart Moto Challenge in Spain.

“The choice of printer was also related to the choice of printed material. When choosing the Sinterit Lisa Pro 3D printer, we took into account the maximum coolant temperature, which is 60 degrees Celsius. PA12 powder, the main printing material for SLS 3D printers, was a very good fit for our project,” added Jakub Sobański.

SLS 3D printers are ideal for R&D applications. SLS technology goes far beyond prototyping, even functional ones. The quality and durability of the printouts are so good that, under certain circumstances, SLS 3D printers can successfully print final products.

Photo: Andrzej Rusinowski / KSAF

Smart Moto Challenge Championship in Barcelona

The E-moto AGH team installed 3D printed radiator housings on their bikes and took them to the Smart Moto Challenge.

The international championship has been held for eight consecutive years. Student teams from different countries come there. Each team, for a maximum of three years, designs and manufactures its own electric motorcycle. First, the commission evaluates the technical documentation and business plan of each project.

Then they check how the motorcycle endures rain, how the headlights and brakes work, etc.

Finally, dynamic tests are carried out: acceleration, energy consumption of batteries are evaluated. Motorcycles participate in slalom, cross-country, endurance race.

Both motorcycles built by the E-Moto AGH team passed all tests. Now the students are developing a new version for next year's championship.

Prototyping for the automotive industry requires technologies that guarantee high fidelity and durability. That is why selective laser sintering is the choice of many research groups and manufacturing companies. This technology is reliable and is now available to small and medium businesses, universities and schools.

This is especially important for technical universities that train future engineers and inventors. If the workshops of universities have the best tools and machines in their class, students will be able to study and master the newest and most advanced technologies.

Source: www.sinterit.com

Specifications:

- Operating system: Windows;

- Power supply: 220-240V AC, 50/60 Hz, 7A;

- Dimensions, mm: 690 x 500 x 880;

- Weight, kg: 90;

- Software: Sinterit Studio 2018;

- File formats: STL, OBJ, 3DS, FBX, DAE, 3MF;

- Camera: integrated;

- Laser: IR 5W;

- Minimum wall thickness: 0.

4 mm;

4 mm; - Power input: 1.8 kW;

- Working chamber: 150 x 200 x 260 mm;

- Chamber temperature: 192°C;

- Print technology: SLS;

- Layer thickness: from 75 µm;

- XY print accuracy: 50 µm;

- Media: PA11, PA12 Smooth, Flexa;

- Display: 7" color;

- Interfaces: Wifi, Usb.

Read more about 3D printing on the Top 3D Shop Blog.

3d printer helps improve race bike design

Implementation stories

Automotive

Rapid prototyping

Author: Viktor Naumov

Author: Viktor Naumov

3D printing and motorcycle racing: when every detail matters | Drilling templates | Footboard attachment | Air intake | results

The idea of using 3D printing is based on its technological features (such as the possibility of customization and reproducibility of the object), which allow the development of innovative solutions for the creation of racing motorcycles. Motorcycle racing is a highly competitive field where even the smallest detail can affect the result and lead you to victory.

Motorcycle racing is a highly competitive field where even the smallest detail can affect the result and lead you to victory.

Andrea Pirazzini, founder and director of Help3D, a 3D service provider, has a passion for racing and competes in the Velocità CNV Motoasi Italian Championship for 100 octane pit bikes. In Andrea's opinion (and we fully agree with him), the advantage of additive technologies is the ability to create unique shapes from technical materials is exactly what you need to work on prototypes and models of racing motorcycles.

Another big advantage of 3D printing, according to Andrea, is the variety of materials that can be used. The world of additive manufacturing is constantly evolving and there is a need to develop technical materials with advanced performance characteristics to create better and more efficient parts. That is why 3D printing can be applied to any manufacturing process, streamlining and streamlining prototyping.

Andrea has already used a Sharebot 3D printer to print plastic prototypes for racing bikes and has worked with the Quarto di Litro team at the University of Pavia on parts for the concept bike.

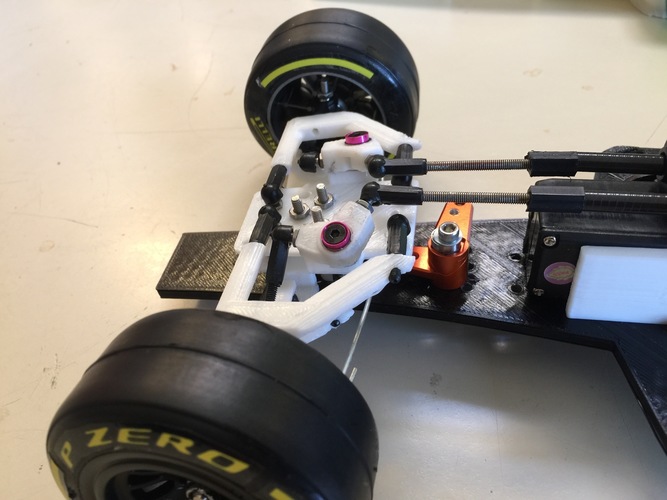

All parts were made on Sharebot Q and Sharebot 42 3D printers (modified version - Sharebot 43). For example, a multi-component fork assembly that was printed on the Sharebot 42 in just 20 hours using PLA plastic, or spacers and links made from thermoplastic polyurethane (TPU). The choice of these elastic materials is due to the high load that they must withstand. The printed part was tested and no problems were found as a result.

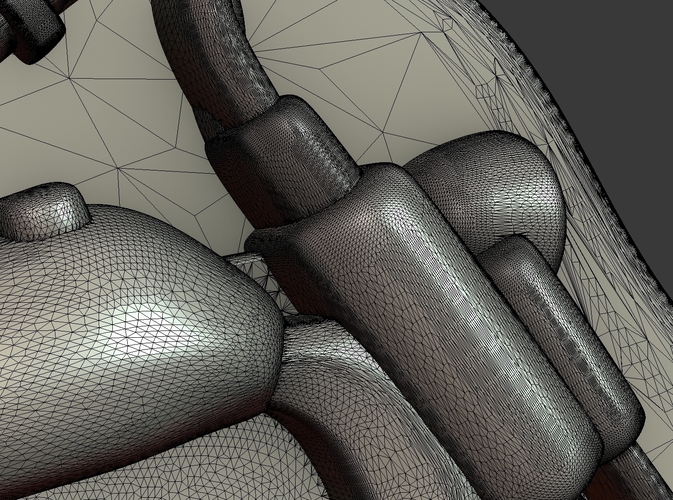

One of the most interesting prototypes is a 1:1 printed pit bike body (23 hours of work). Thanks to 3D printing, Andrea Pirazzini was able to reproduce every technical and aerodynamic detail with the highest precision and resolution. He also created the air intake and spigot from high-strength polybutylene terephthalate (PBT).

iQB Technologies experts recommend article: Plastic works wonders: how a 3D printer imitates human organs

3D printing and motorcycle racing: when every detail matters

MotoGp is the world championship in road racing, the main competition in its class. At an event of this caliber, every detail counts, and the bike's continuous optimization helps the rider lap a few precious tenths of a second faster.

At an event of this caliber, every detail counts, and the bike's continuous optimization helps the rider lap a few precious tenths of a second faster.

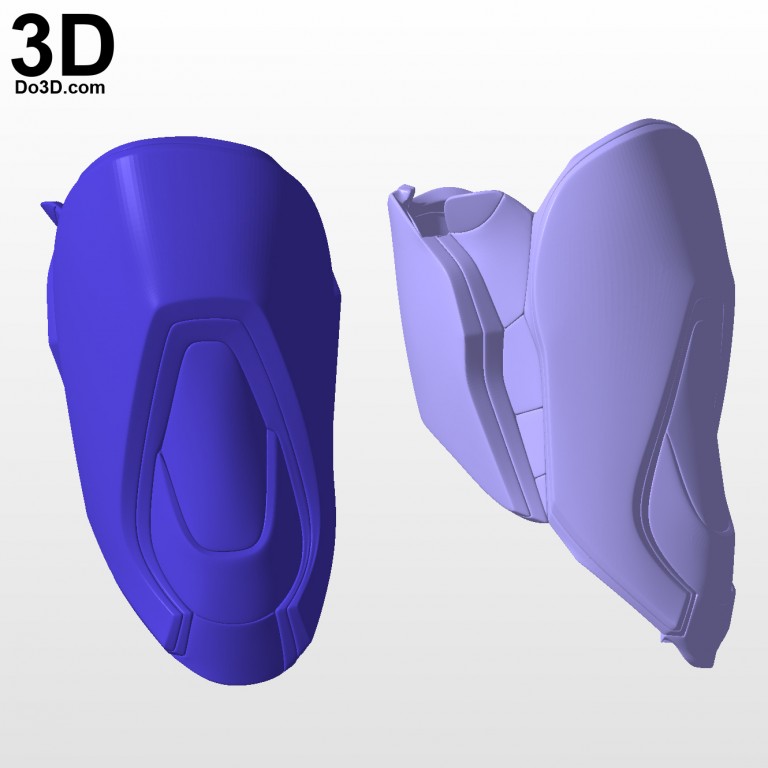

We used to think that only a better motor is enough for more speed, but in fact, everything is not so simple. Over the last few years at MotoGp, motorcycles have been getting aerodynamic fenders on the front of the fairing: at first they were thought to be just a beautiful accessory, but over the years fenders have become the basis of motorcycle aerodynamics, especially because they increase downforce, and therefore traction on asphalt, and also reduce the resistance to movement during acceleration.

Drilling templates

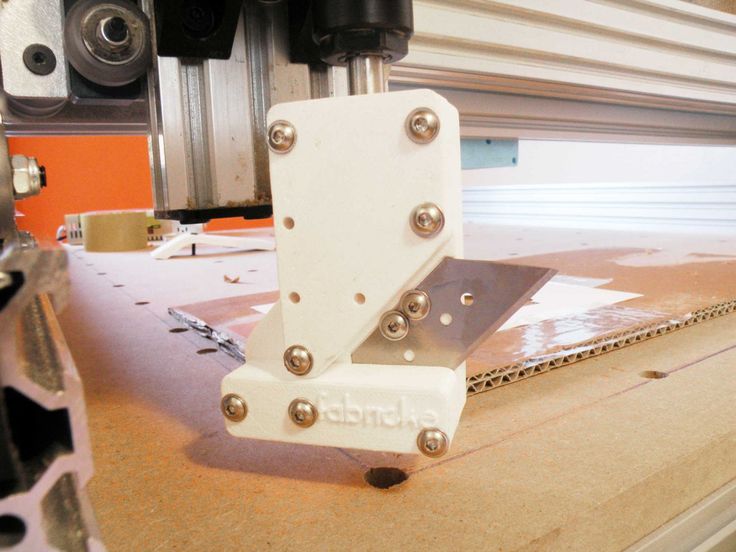

In preparation for the next racing season, the famous Italian racing motorcycle manufacturer Aprilia, using Sharebot 3D printers and Help3D technical support, has developed drilling templates for the motorcycle front fairing. The template 3D models were created directly from the fairing CAD models and then printed using the Sharebot QXXL and Sharebot 42 printers.

These templates made it possible to create holes with exceptional precision, which is not possible with classical manual template creation methods. It should be noted that the shape of the wings (made of carbon fiber) is adapted to the fairing, so it is important that the holes in the body provide a snug fit at an ideal angle.

Footrest attachment

It's no secret that a rider on a motorcycle should sit "like a glove." It's not just about a comfortable posture, but also about optimizing the rider's aerodynamics on the bike.

The kickstand plays a vital role in the rider's riding position: it is more rearward and higher than in a road bike. If it is the wrong size, then the rider may feel discomfort, and in this position he will be uncomfortable.

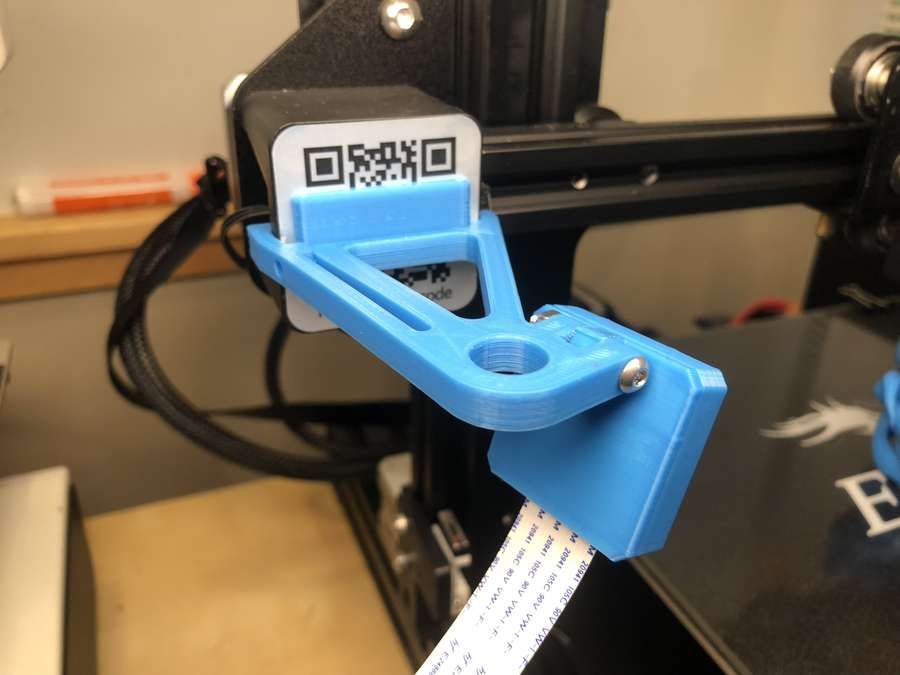

Sharebot 3D printers allowed the Aprilia Racing team to create a series of PLA footpeg mounts to see which model would work best for the team's riders. After analyzing different solutions and selecting the ideal model for each rider, the parts were made on a CNC milling machine.

With this solution, Aprilia has been able to reduce the design time and, above all, the production costs for each footpeg, while at the same time creating the optimal model for each rider.

Air intake

Engine performance also depends very much on how and how efficiently it "breathes". Sizing an air intake for a MotoGp requires careful study of the flow and turbulence created within the design. The air intake uses lightweight and ultra-strong carbon fiber. The downside is that a mold is required to make the part: thin sheets of carbon fiber pre-impregnated with epoxy are placed in a mold and then placed in an autoclave to complete the catalysis process and eliminate air bubbles.

In preparation for the season, the Aprilia Racing team created a series of PLA gearbox prototypes on the Sharebot QXXL 3D printer. By simulating various adapters and reducers, the sports division technicians were able to test different volumes on the test rig, starting with just the air intake.

This approach made it possible to determine the optimal air intake geometry without the need to first create a mold and exfoliate the carbon fiber, thereby saving time and money. The printed reducer can be tested on the bench, simply replacing one model with another, without removing the air intake each time. After determining the optimal geometry, one final mold was made to create the air intake.

Results

Let's summarize the 3D printing projects using Sharebot FDM printers, which allowed us to optimize the design and aerodynamics of motorcycles for the MotoGp World Championship.

-

Drilling templates for front fairing: 3D template models are created directly from fairing CAD models, then 3D printed. This solution made it possible to make holes with exceptional accuracy, which is unattainable using traditional methods.

-

Motorcycle Footrest Mounts: A series of parts are printed in PLA plastic to choose the most suitable for each of the team's riders, then the final products are produced by a CNC milling machine.

Learn more