Best lube for 3d printer

How to Lubricate Your 3D Printer Like a Pro – Best Lubricants to Use – 3D Printerly

Being able to maintain your 3D printer properly with care usually involves lubrication in the moving parts of your machine. Light machine oils or silicone lubricant is widely used in the 3D printing world.

This article will be a guide on which lubricants are popular to use with 3D printers, and what techniques people use to get the best results. Keep on reading through this article to get the up-to-date advice on 3D printer maintenance.

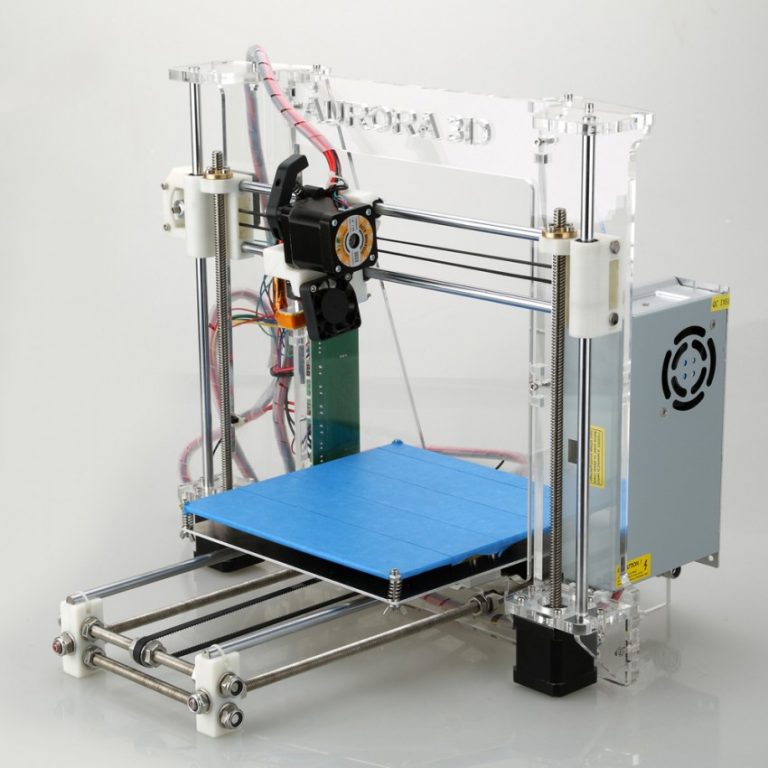

What Parts of a 3D Printer Needs to Be Lubricated?

Simply put, all moving parts, i.e. any surface that moves against another surface needs to be lubricated to have a smoothly working printer. In all of this, the following areas of a printer have to be lubricated from time to time.

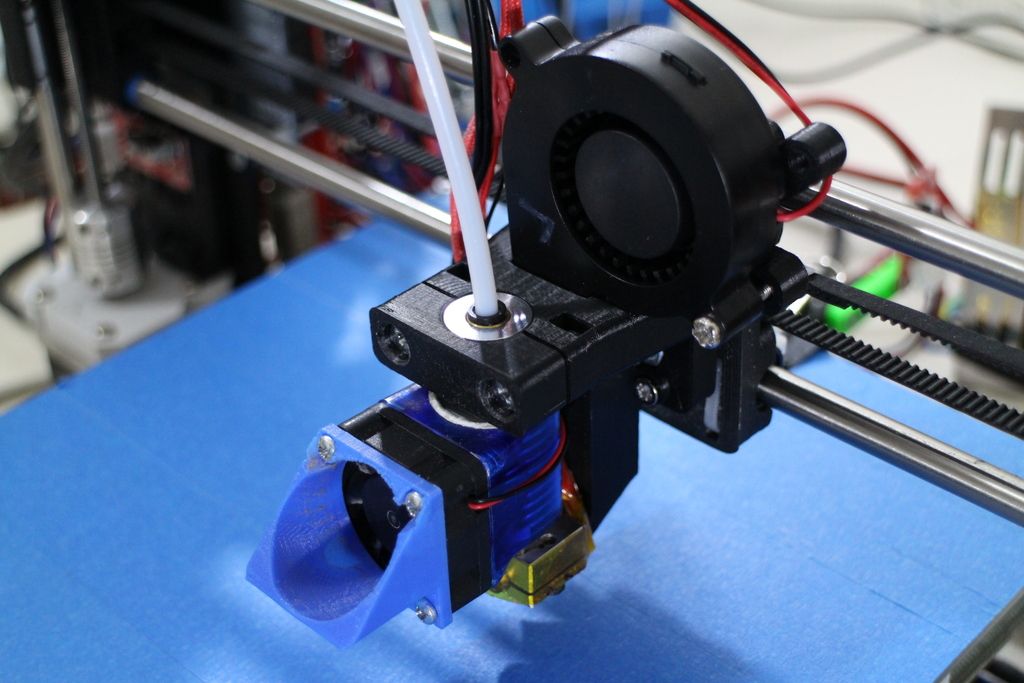

The X, Y and Z axis: these moving parts of the 3D printer determine where the nozzle is moved to, and so they are constantly being moved around.

The Z-axis which moves vertically and the X and Y which moves horizontally are constantly moving when the machine is on. Wear and tear may occur if they are not lubricated regularly.

These coordinates determine the position of the hot end nozzle, which is moved around by different rails and driving systems.

Guide rails: these help to support the Z-axis as they move. The bearings on the railing can either be metal on metal or plastic on metal.

Many 3D printers will use simple threaded steel rods or lead screws, which are essentially extra-long bolts. These parts also need to be lubricated.

Stepper motors don’t need any maintenance or lubrication since they are a brushless motor which doesn’t have brushes that need to be replaced or anything.

How Do You Lubricate & Maintain a 3D Printer?

No matter the kind of lubrication being used, the steps to carrying out the lubrication is the same. Follow these steps for correct lubrication of your printer.

The first step in lubrication is cleaning. Clean all parts that require lubrication thoroughly. This will ensure that remnants of former lubricants do not get it the way when you are applying the new one.

You can use rubbing alcohol to wipe down moving parts such as the belt, rods and rails. Do not use acetone as it is corrosive and may likely eat through the plastic. Give the parts some time to dry out from the alcohol.

The next thing is to apply the lubricant. Depending on the type being used, space out the lubricants at equal distances and take note not to apply too much of it. With the aid of an applicator, spread the lubricant.

It’s a good idea to use some rubber gloves while you do this so the lubricator doesn’t touch your skin since some lubricants can cause slight irritation.

Once the lubricant has been totally spread on all the moving parts, move the parts from one side to the other to ensure that there is no friction. You can do this manually or make use of the motor controls located in the 3D printer.

Make sure you cannot see excess lubricant while moving the parts because this usually indicate that you have applied too much lubricant. This can do the exact opposite of what it’s supposed to do and make it hard for the parts to move.

If you noticed that you have applied too much lubricant, gently wipe off the excess with paper towels and run the parts along its axes again to make sure everything is smooth.

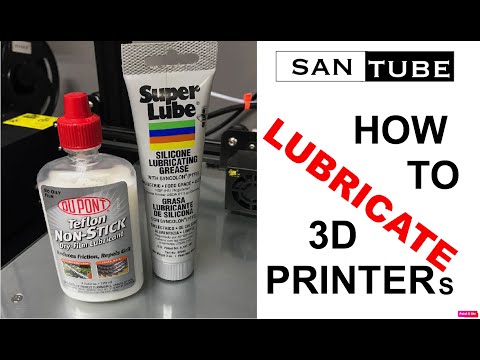

Find more information about how to lubricate your 3D printer in the video below.

Best Lubricants You Can Use For Your 3D Printer

As easy as lubricating a 3D printer is, the difficult part is figuring out the right lubricant to select. Of course, many new 3D printers now come with maintenance tips and advice on what lubricants to use.

If you do not have this information about your printer, you can visit their website to ensure that you are using the right lubricant. The following are the best printers for your 3D printers.

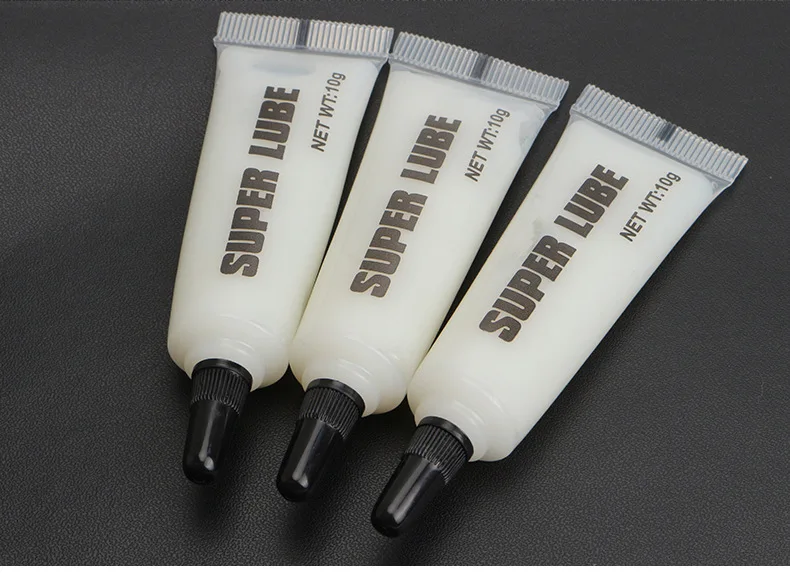

Super Lube 51004 Synthetic Oil with PTFE

Many 3D enthusiasts use a great product called Super Lube Synthetic Oil with PTFE, a staple lubricant for your 3D printer.

It is a premium, synthetic oil with suspended PTFE particles that bond to surfaces of moving parts providing protection against friction, wear, rust and corrosion.

Product that contains PTFE are types of lubricants which are solid substances usually suspended in a medium such as alcohol or any other similar spirit. They can be sprayed on the printer parts that needs to be lubricated.

The viscosity is similar to that of cooking oils such as canola or olive oil. It adheres to almost any surface and prevents dust and corrosion of metal parts.

3-In-One Multi-Purpose Oil

Another great option that is used in the 3D printing community is the 3-In-One Multi-Purpose Oil.

One user who purchased this oil used it for their motors and pulleys, and it quickly solved their issues. The value of the product is one of the highlights because it is very affordable while getting the job done.

The value of the product is one of the highlights because it is very affordable while getting the job done.

This oil is actually used in the manufacturing of some 3D printers because it works so well, and can even give immediate results for noise reduction. Another benefit is how there is little to no odor unlike some other lubricants out there.

You can also use it successfully on your linear bearings for great results in your prints, while giving extra life and durability to your 3D printer. Most experts recommend using oil regularly for maintenance.

Get yourself some 3-In-One Multi-Purpose Oil from Amazon today.

White Lithium Grease LubricantYou’ll hear plenty about White Lithium Grease if you are looking for a suitable lubricant for your 3D printer, or even other general items that require some maintenance. Permatex White Lithium Grease will work very well for lubricating your machine.

It is an all-purpose lubricant which has metal-to-metal applications, as well as metal-to-plastic. Moisture isn’t a problem for this lubricant and it can easily withstand high heats too.

Moisture isn’t a problem for this lubricant and it can easily withstand high heats too.

Permatex white lithium grease makes sure that surfaces and movements are friction-free, allowing you to get that top quality from your 3D printer. You want to use it all around your 3D printer, especially on the lead screw and the guide rails.

You can also use it with door hinges, garage doors, latches and much more.

The White lithium grease is a great, weather-resistant lubricant, and it can also be easily removed and replaced when it’s time to replace it.

Many people who chose this lubricant over something like WD40 saw amazing results, especially to stop squeaks and screeches that occur.

If you are getting vibrations or feedback from the joints in your Z-axis, you can see much better elevation control after using this grease.

Get yourself some Permatex White Lithium Grease from Amazon.

DuPont Teflon Silicone Lubricant Aerosol Spray

Silicone lubricants are more popular among 3D enthusiasts as they are cheaper, easy to apply and non-toxic. A great one to go for which is easier to apply than the lubricants above is the DuPont Teflon Silicone Lubricant Aerosol Spray.

A great one to go for which is easier to apply than the lubricants above is the DuPont Teflon Silicone Lubricant Aerosol Spray.

One user described this silicone spray as exactly what they needed for their 3D printer. This clean, light-duty lubricant is excellent for all types of materials and provides a great protection, as well as lubricant for your machine.

It helps prevent rust and corrosion too.

Get the DuPont Teflon Silicone Lubricant Aerosol Spray from Amazon.

3D printer lubrication: Everything you need know

Consumer 3D printers are delicate machines crafted from metal and plastic. And as such, they are best kept in correct working order through routine servicing, cleaning and maintenance. In this article, we will be looking at a very important aspect of 3D printer maintenance: Lubrication.

Disclosure: This post contain affiliate links, we may earn advertising commissions for sharing products we know and love.

The parts that needs to be lubricated on a 3D printerIn a nut-shell, all the parts that move against another surface require at least some lubrication in order for the printer to operate smoothly, without friction-related wear and operational errors.

Most important of all, is the Z-axis threaded rod and nut used to move the print-head in terms of height from the print bed. The other lubricant hungry parts are the X-Y guide-rails for the print-head and print bed, as well as the bearings fastened along the railings for movement.

Almost all consumer 3D printers have a metal-on-metal contact on the Z-axis between the rod itself and the nut. Whereas the X-Y guide rails are generally made from metal, the surface of bearings used tends to be of varying types. This may lead to either kind of contact, either metal on metal, or plastic on metal.

The type of contact dictates the kind of lubricant that would be effective.

Suitability of lubricants for 3D printersThe suitability of a lubricant for 3D printers depends on two things:

- How well it prevents direct metal-on-metal or plastic-on-metal contact; and

- How it affects smooth movement of the parts

A heavy lubricant would create a thicker barrier between the contact layers and would stay intact under heavy load. However, heavier lubricants also have a tendency to inhibit movement. Whereas a light lubricant is great for movement, but it does not provide the same sort of protection as a heavy lube does.

However, heavier lubricants also have a tendency to inhibit movement. Whereas a light lubricant is great for movement, but it does not provide the same sort of protection as a heavy lube does.

For 3D printers then, a goldilocks solution becomes necessary. The ideal choice should bend towards lightness for smooth movement under load.

Should you use WD-40 on a 3D printerStandard WD-40 is more akin to a solvent, and NOT a proper lubricant. Nor should it be used as such. It is designed to eat through rust and inhibit further rusting. Its use on 3D printers has been known to cause irreparable damage to rods being eaten away over time due to excessive misuse of this multi-product.

With that out of the way, let’s look at the different types of lubricants that do work.

Best lubricants to use and the parts of the 3D printer to use them on:1.

PTFE lubricantPTFE (Polytetrafluoroethylene, also known as TEFLON) lubricants are the ideal lubricant for 3D printer parts such as threaded rods for X, Y or Z axis. PTFE lubricants are available in oil, grease and solvent (dry) bases.

PTFE lubricants are available in oil, grease and solvent (dry) bases.

Depending on the particular requirements, any or all of the above 3 form lubricants can be used. However, go with oils whenever possible. PTFE has one of the lowest drag coefficients of all the available lubricants and is suitable for both plastic-on-metal as well as metal-on-metal contacts. Drag coefficients is a measure of how high or low the surface friction of a compound is.

Super lube lubricantThe most popular brand of PTFE lubricant that is often used amongst the 3D printing industry is known as Super Lube, an ISO grade synthetic lubricant with multi-purpose applications. The PTFE particle containing in Super Lube adheres to any surface the oil comes into contact with. The particles helps to prevent corrosion (rust) and wear from friction.

The Super Lube we use on our printers, seen here: Super Lube with PTFE, is usually quite affordable and also contains PTFE.

Another type of lubricant often containing PTFE is Lithium Grease lubricant. Lithium grease, referred to as white lithium grease, is another lubricant commonly applied to 3D printer rods and guide rails. It is generally made with lithium soap and some other mixture of oil and additives.

Lithium grease, referred to as white lithium grease, is another lubricant commonly applied to 3D printer rods and guide rails. It is generally made with lithium soap and some other mixture of oil and additives.

2.

Silicone lubricantSilicone lubricants are a popular choice as they are readily available, non-toxic, and easy-to-use. Most silicone lubricants are silicone oils. Greases are available, but oil-based silicone lubricants are by far the most popular. The silicone lubricant by Super Lube seen here: Super Lube silicone lubricating grease, is also a good choice. It also contains PTFE.

While silicone is a good choice for plastic and rubber surface contacts, it can also be used for plastic or rubber on metal contact.

Silicone lubricants are not, by any means, suited for metal-on-metal contact. So, while depending on the exact make of the XY axles/guiderails, this lube may or may not be used. For the Z-axis, this lubricant is simply not suited at all.

3.

Graphite powder lubricantGraphite powder lubricants are also suspensions, in either oil, grease or solvent bases. The most popular graphite-based lubricants are easily the dry lubricants, available in volatile solvents. Graphite itself is a good lubricant. Graphite further helps in the process by adding strength to the lubricated parts. It should be note, however, that graphite powder can penetrate plastic parts and may cause weakening in those joints of the 3D printer.

Graphite powder lubrican. Photo credit: RUIVALAFurther, its carbon black color, as well as electrical conductivity means that it should only be used where the black coloring is not an issue, either aesthetically or in terms of color contamination of a part during printing. It’s also important to make sure that it is not used in any place with direct or indirect contact with the wiring or electronic circuitry of the 3D printer.

4. Molybdenum Disulphide (MolyD) lubricantMolyD is not electrically conductive. In all other respects, however, it is very similar to graphite lubes. While MolyD is used by some 3D printer users, it is by no means a popular choice owing in part to its increased price as compared with other lubes, and also because like graphite, this solid additive may weaken plastic parts of a 3D printer.

In all other respects, however, it is very similar to graphite lubes. While MolyD is used by some 3D printer users, it is by no means a popular choice owing in part to its increased price as compared with other lubes, and also because like graphite, this solid additive may weaken plastic parts of a 3D printer.

WS2 is not a general consumer-grade lubricant. This is purely due to the fact that it is very expensive. WS2 was developed by NASA to provide the best possible lubrication to its space bound equipment. It is one of the few compounds to have a lower drag coefficient than PTFE.

While it is not a necessity to use such an expensive lubricant, for the prosumers out there who want to take care of their 3D printers in the best possible way, WS2 is probably as good as it gets.

Oils VS grease VS dry lubricantsOil based lubricants are often touted as the ideal form of lubrication. They are not as heavy as grease and are not as light as dry (solvent-based) lubricants. And in many ways, this is true. Oil based lubricants come with a variety of additives, such as the solid lubricants discussed above as well as anti-corrosion, water, dirt and oxidation resistant agents. Oils are not as bad as grease in picking up stray particles such as dust and UFPs from the ambient surroundings, but they still can accumulate their fair share of goop on the shafts.

They are not as heavy as grease and are not as light as dry (solvent-based) lubricants. And in many ways, this is true. Oil based lubricants come with a variety of additives, such as the solid lubricants discussed above as well as anti-corrosion, water, dirt and oxidation resistant agents. Oils are not as bad as grease in picking up stray particles such as dust and UFPs from the ambient surroundings, but they still can accumulate their fair share of goop on the shafts.

Grease on the other hand, is the worst offender when it comes to creating a dirty mess over time. Properly applied grease, however, will also provide the smoothest operation of all three bases. Lithium grease with PTFE is also the most suited for relubricating bearings when needed.

Lastly, are dry lubricants. Dry lubricants are solid lubricant particles suspended in alcohol or a similar spirit. They are available either in spray cans or can be “painted” on the parts. Dry lubricants completely eliminate the issue of lubricants collecting dust, dirt or UFPs on the 3D printer rods.

PTFE dry lubricants are quite popular as they provide great lubrication without the mess of oils or greases. Dry lubricants need to be reapplied more often because of the lack of tackiness that oils and grease provide. They also are slightly more expensive, but not egregiously so. Dry lubricants also are often combined with dirt, corrosion and oxidation resistant compounds in spray can form.

How to lubricate a 3D printerNo matter which lubricant one chooses, the lubrication process remains unchanged:

- To start off with, thoroughly clean the 3D printer rods or guide rails, and any other moving parts, such as belts, that need lubrication. It is a good idea to clean the system with rubbing alcohol with a cleaning cloth and paper towels. Acetone is not recommended as it is corrosive and eats through plastic like acid. For the threaded rod, use a toothbrush with rubbing alcohol. Wait for everything to dry.

- Next, apply the lubricant directly on the surface at equal distances, like putting a drop at every 5 or 6 inches or so, taking care to not apply too much the first time.

- Spread the lubricant evenly with an applicator or a rubber glove. It is better to not use your bare hands, as an additive in even a nontoxic lubricant may cause some irritation.

- Once applied, move the parts either manually or via the motor controls of the 3D printer. “Jog” the printhead along the complete length of the axes a few (2-4) times to make sure that the lubricant is spread out evenly and gets into all the nooks and crannies.

- If at this point, you can visibly see the lubricant, then it is probably excessive. Too much lubricant will also strain the motors by inhibiting movement of the parts, so clean any excess off with paper towels or a cloth.

- Rerun the printer along its axes to make sure that everything is still smooth as required.

As is evident from the above instructions, the most difficult part of lubricating a 3D printer is selecting the right lubricant. Many 3D printer manufacturers nowadays offer maintenance guidance, including what lubricants are best suited. As a best practice, try to check with the manufacturer’s support page or the manual that came with the 3D printer.

As a best practice, try to check with the manufacturer’s support page or the manual that came with the 3D printer.

Still, it is equally true that manufacturer recommendations are often designed to cater to the lowest common denominator of potential customers. So, if you want to experiment with giving your printer a more comprehensive servicing, that will serve you well in the long run.

As mentioned above, old grease that’s been applied and expose to the environment tend to collect dust and debris. Ideally, you will want to clean and reapply lubrication every so often depending on the type of environment.

Though it may be excessive in most cases to reapply lubrication each month, doing a monthly preventative maintenance check is not a bad idea. If a printer is making a squeaky sound while it runs, then the next lubrication application is obviously past due. We hope that this little guide helps in making that monthly servicing for your printer that much simpler and more beneficial.

Tags: 3D printergraphite lubricantLithium GreaseLubricantsMaintenancePTFESuper Lube

Which lubricant is suitable for the printer?

Moving and heating parts of printers are subject to the most rapid wear and destruction. High speeds, friction, and improper operation will adversely affect parts, resulting in increased maintenance frequency and repair costs.

The most loaded friction units of the printer must be periodically lubricated. For these purposes, special lubricants are used for the printer, which can operate at high temperatures, do not interact with inks and toners, and do not affect the printing result. nine0003

Lubricant for EFELE printers is the best choice for servicing all types of printers and office equipment. It works effectively at high temperatures on thermal shafts, reduces the friction of the units and the load on the shaft bearings, and allows you to extend the life of the entire equipment as a whole.

A special lubricant is used and is equally effective for laser, dot matrix and inkjet printer assemblies. It works well at high temperatures, does not oxidize, does not dry out and does not break down. Lubricant for EFELE printers does not destroy the thermal film of laser printers, does not lead to its deformation. nine0003

This versatile material is white. If grease gets on the paper, it will not affect print quality or stain documents. It is also safe for humans; in case of accidental contact and skin contact, it does not cause allergic reactions.

EFELE grease is suitable not only for shafts and metal parts, it is also compatible with plastics and elastomers, does not cause their premature destruction. Lubricant for printers and office equipment EFELE compares favorably with analogues also in the following characteristics: nine0003

-

It has the best value for money.

-

Suitable for metal and plastic elements.

-

At high temperatures, the material does not change its original properties.

-

Does not react with toners, inks and chemically aggressive environments.

nine0024 -

Works well at high loads and speeds.

-

Provides long service life.

-

Prevents jamming of shafts and movable carriages of printers.

Lubricant is available in dispensers of 10 grams. A convenient form of release allows you to simplify the application process and economically consume the material. nine0003

For thermal film laser printers

Thermal roller and thermal film are the most important elements of laser printers. With their help, the toner is melted and fixed on paper. Thermal film damage due to improper use or normal wear and tear is one of the most common problems. To avoid it, you need to use a lubricant.

The lubricant for thermal film and thermal roller must meet two basic conditions: be resistant to heat and not deform plastic parts. Unsuitable types of lubricants burn out, dry out, or vice versa become liquid and flow out. nine0003

Unsuitable types of lubricants burn out, dry out, or vice versa become liquid and flow out. nine0003

Printer lubricant for use up to +260°C, compatible with most plastics. Lubrication must be applied to the surface of the shaft along the entire length, which has been previously cleaned of stuck toner and contaminants.

For gears

Many printer lubricants are not universal. That is, for different parts of the equipment it is necessary to use different lubricants. This increases the range of service materials and maintenance costs. nine0003

Printer lubricant can be used on metal and plastic parts. It does not destroy gears and does not change the geometry of the teeth. The lubricant creates a protective barrier that reduces friction and extends the life of plastic parts in printers and office equipment.

For bushings

Bushings are rolling and sliding bearings in the printer. They work in conditions of high speeds and friction with metal parts. This leads to premature wear of parts, the appearance of extraneous noise, jamming and equipment failure. nine0003

This leads to premature wear of parts, the appearance of extraneous noise, jamming and equipment failure. nine0003

Universal printer grease can be used on metal and plastic bushings. During maintenance, the bearings are pre-cleaned of dirt, old lubricant, ink or toner, and a thin layer of lubricant is applied.

Special heat-resistant printer lubricants are the best and reliable choice for maintenance and repair of equipment. The versatility of such materials allows it to be used for any friction units, preventing premature wear and failure of office equipment. Universal lubricants replace a wide range of other lubricants, reduce the cost of equipment maintenance. nine0011

Back to the list

5 ways to keep your 3D printer running

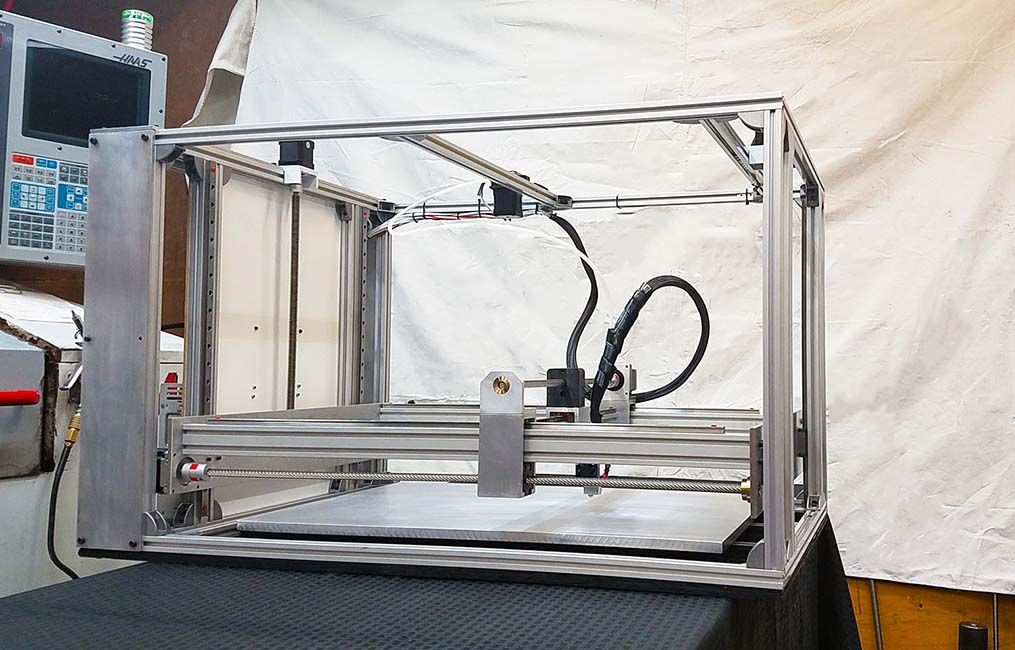

Despite their impressive design, most 3D printers have a few technically unreliable components. All of them are somehow connected with the mechanism of carriage movement in different planes, bar feed, temperature and calibration sensors.

As a rule, 3D printers are not equipped with a built-in protection against breakage of such mechanisms. If, for example, the wiring from the axis calibration sensor falls off, then due to the lack of a signal from it, the carriage will not be able to stop in the right place and will rest against the origin of the coordinate axis. Such problems can cause the printer to stretch or break the belt or break other parts of it with the power of the stepper motor. nine0003

In order to prevent damage to the 3D printer, it is necessary to periodically conduct a technical inspection and eliminate defects in time.

1. Check for lubrication on the drive axles

In all machines, moving parts need regular lubrication. The friction of metal objects against each other causes heating and abrasion, and small metal chips can jam the entire mechanism as a whole.

On the Internet, people often describe situations where their printer suddenly starts to spoil the printed parts. This is due to layer shifts in printed prototypes. One of the reasons is the poor sliding of the bushing along the axles. Another is dirt from old grease. Clean the shafts of dirt and apply special grease over a new one. nine0003

This is due to layer shifts in printed prototypes. One of the reasons is the poor sliding of the bushing along the axles. Another is dirt from old grease. Clean the shafts of dirt and apply special grease over a new one. nine0003

2. Clean the nozzle to remove any jammed filament

There are situations when the filament stops feeding during printing. The fault is not the feed mechanism, but the slag that clogged the nozzle. Before you start printing, you need to check how the plastic passes through the hotend. To do this, heat the nozzle to the desired temperature and try to programmatically feed 10-20 mm of plastic. If the bar does not feed in a straight line, but ripples or curls up, this is the first sign that the nozzle is clogged. nine0003

At very high temperatures, the plastic begins to vitrify. To clean the nozzle from slag, special cleaning kits for the hot end, drills, knitting needles of different diameters and needles are used. One way to clean the nozzle is to heat it up to the melting temperature of the plastic. After that, you can clean it from the back with a drill of the appropriate diameter.

After that, you can clean it from the back with a drill of the appropriate diameter.

3. Watch the plastic feed mechanism

This problem is closely related to the previous one and is more common for those who use small diameter nozzles. If the printer has a nozzle with a diameter of less than 0.4 mm, there is a high chance of the bar jamming or bending in the mechanism, as well as its “gnawing” by the drive gear. In this case, you should try lowering the print speed. nine0003

It is less common for the feed gear fixing bolt to loosen. Then the motor shaft starts to rotate. To prevent such an incident, periodically check the tightness of the drive gear using hexagons.

4. Check the reliability of the entire structure

Another common problem related to physics. The printer is a dynamic thing, when the head of the hot end moves, critical vibrations occur, they loosen the nuts and bolts of the mechanisms. When using the printer for a long time, the tensioners from the belts may sag, and the structure may be slightly warped from loosening the screws.