M400 3d printer

EOS M 400 – the metal 3D printer for large parts

12_laserIncreased productivity thanks to 1000-watt laser power

11_modularityModular platform with process and set-up station

52_construction_spaceBuild volume of

400 x 400 x 400 mm

1000-watt laser power increases productivity with higher build rates and thicker layers. Ideal for serial manufacturing of large metal parts.

Coating both sides with powder material reduces production downtime. A circulating air filtering system with automatic cleaning means fewer filter changes and longer service life.

A comprehensive collection of materials is available, from light metals to stainless steel, tool steels and super alloys.

| Construction Volume | 400 x 400 x 400 mm (15.8 x 15.8 x 15.8 in) (height incl. build plate) | |

| Laser Type | Yb-fiber laser; 1,000 W | |

| Precision Optics | F-theta-lens | |

| Scan Speed | up to 7.0 m/s (23 ft/s) | |

| Focus Diameter | approx. 90 µm (0.0035 in) | |

| Power Supply | 50 A | |

| Power Consumption | max. 50,2 kW / typical 16,22 kW 50,2 kW / typical 16,22 kW | |

| compressed air supply | 7,000 hPa; 20 m³/h (102 psi; 706 ft³/h) | |

| Machine Dimensions (W x D x H) | 4,181 x 1,613 x 2,355 mm (164.6 x 63.5 x 92.7 in) | |

| Recommended Installation Space | min. 6,500 x 6,000 x 3,300 mm (256 x 236 x 130 in) | |

| Weight | approx. 4,635 kg (10,218 lb) | |

| Software | EOSPRINT 2, EOSTATE, EOSCONNECT Core, EOSCONNECT MachinePark, EOSCONNECT MachinePark, Materialise Magics metal package and modules |

53_individual_production Metal Materials for the EOS M 400

EOS Aluminum AlSi10Mg

Parts printed using EOS Aluminum AlSi10Mg offer strength, hardness and dynamic properties as well as excellent thermal properties and low weight.

EOS Maraging Steel MS1

Parts have excellent mechanical properties and are heat-treatable using a simple thermal age-hardening process to obtain superior hardness and strength.

EOS NickelAlloy IN718

Parts show excellent tensile, fatigue, creep and rupture strength at temperatures up to 700°C, making it ideal for many high temperature applications.

EOS Titanium Ti64

Titanium’s material characteristics make it ideal for many high-performance applications in aerospace, automotive & medical.

EOS Titanium Ti64ELI

Titanium’s material characteristics make it ideal for many high-performance applications in aerospace, automotive & medical.

EOS CopperAlloy CuCrZr

Copper alloy CuCrZr has a favorable combination of electrical and thermal conductivity accompanied with good mechanical properties.

11_modularity Material Management Metal Materials

IPM M Powder Station L

The IPM M Powder Station L is the fully-automatic and intelligent material management solution that offers a closed powder cycle in a protective gas atmosphere in just one module.

13_automation Software

EOSPRINT 2

EOSPRINT is an intuitive, open and productive CAM tool for EOS systems that enables the assignment and optimization of build parameters for your CAD data. Together with data preparation software like SIEMENS NX or Magics, it offers an extensive additive manufacturing CAM environment for a smooth 3D printing process.

Together with data preparation software like SIEMENS NX or Magics, it offers an extensive additive manufacturing CAM environment for a smooth 3D printing process.

EOSTATE Monitoring

EOSTATE is the modular solution for seamless monitoring of all production and quality-relevant data in industrial 3D printing. EOSTATE comprises 4 modules that can be used individually or in combination.

EOSCONNECT Core

EOSCONNECT Core is the connectivity solution for monitoring production. EOS systems are IIoT-capable and can be integrated into existing IT infrastructures via EOSCONNECT Core. EOS offers an open interface for this.

EOS systems are IIoT-capable and can be integrated into existing IT infrastructures via EOSCONNECT Core. EOS offers an open interface for this.

EOSCONNECT MachinePark

Expand the capabilities of your EOS system. Increase your productivity with EOS Web Apps and monitor your entire EOS machine park from anywhere in an intuitive dashboard. Receive automatic notifications on machine status and print jobs.

Large and ultra-fast 3D Printer with 4 laser

05_incr_productivityUp to 4x more productivity

12_laserFour precise 400-watt fiber lasers

52_construction_spaceBuild volume of

400 x 400 x 400 mm

With a build volume of 400 x 400 x 400 mm and four lasers, the EOS M 400-4 platform achieves up to four-times higher productivity, making it perfect for industrial applications. Four precise 400-watt fiber lasers work over an area of 250 x 250 mm each, with 50 mm overlap.

Four precise 400-watt fiber lasers work over an area of 250 x 250 mm each, with 50 mm overlap.

With its intuitive user interface, flexible software tools and diverse accessories, the system meets every usage requirement of an industrial production environment. Highly automated procedures and processes guarantee ease of operation.

A broad portfolio of materials is available, from light metals to stainless steel, tool steels and super alloys. Any process from the EOS M 290 can be transferred to the EOS M 400-4 to achieve equivalent part properties.

| Construction Volume | 400 x 400 x 400 mm (15.8 x 15.8 x 15.8 in) (height incl. build plate) | |

| Laser Type | Yb-fiber laser; 4 x 400 W | |

| Precision Optics | 4 F-theta-lenses; 4 high-speed scanners | |

| Scan Speed | up to 7. 0 m/s (23 ft/s) 0 m/s (23 ft/s) | |

| Focus Diameter | approx. 100 µm (0.004 in) | |

| Power Supply | 3 x 50 A | |

| Power Consumption | max. 45 kW / typical 22 kW | |

| compressed air supply | 7,000 hPa; 20 m³/h (102 psi; 706 ft³/h)" | |

| Machine Dimensions (W x D x H) | 4,181 x 1,613 x 2,355 mm (164.6 x 63.5 x 92.7 in) | |

| Recommended Installation Space | min. 6.500 x 6.000 x 3.300 mm (256 x 236 x 130 in) | |

| Weight | approx. 4,835 kg (10,659 lb) 4,835 kg (10,659 lb) | |

| Software | EOSPRINT 2, EOSTATE PowderBed, EOSCONNECT Core, EOSCONNECT MachinePark, Materialise Magics Metal Package and modules |

Source: Václav Jirásek

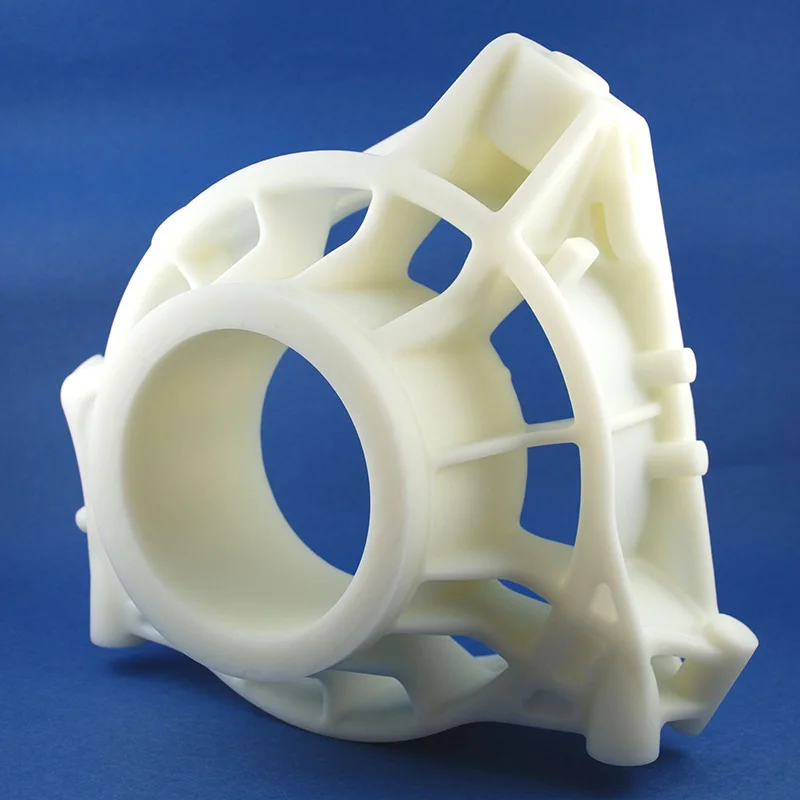

3D lattice palms ready for microwelding

Challenge:

Bring a goldsmith’s creation to life by printing an intricate and luxurious life-size 3D lattice face mask and palms, to which jewels could be micro welded.

Source: One3D

One3D facility in Mohelnice with EOS M 400-4

Solution:

- One3D AM Engineers

- EOS M 400-4

- EOS StainlessSteel 316L

Source: Václav Jirásek

Post-processed 3D lattice palms

Results:

- Design, print and post-processing of complex parts in just 5 days

- Complete design freedom for artist and One3D engineers

- Rapid printing of 207 cm3 build volume enabled highly detailed and considered 3D lattice palms ready for post-processing

53_individual_production Metal Materials for the EOS M 400-4

EOS Aluminum AlSi10Mg

Parts printed using EOS Aluminum AlSi10Mg offer strength, hardness and dynamic properties as well as excellent thermal properties and low weight.

EOS NickelAlloy IN718

Parts show excellent tensile, fatigue, creep and rupture strength at temperatures up to 700°C, making it ideal for many high temperature applications.

EOS NickelAlloy HX

Parts show high strength and oxidation resistance also at elevated temperatures up to 1200°C making it ideal for applications in aerospace, gas turbines, etc.

EOS NickelAlloy HAYNES® 282®

This material is a precipitation strengthened nickel-base superalloy with a unique combination of high temperature strength, thermal stability, and fabricability. The alloy was developed for high temperature structural applications.

EOS Maraging Steel MS1

Parts have excellent mechanical properties and are heat-treatable using a simple thermal age-hardening process to obtain superior hardness and strength.

EOS StainlessSteel 316L

Parts show a high level of corrosion resistance, toughness and ductility as well as a high resistance to acids.

EOS Titanium Ti64

Titanium’s material characteristics make it ideal for many high-performance applications in aerospace, automotive & medical.

EOS Titanium TiCP grade 2

Titanium’s material characteristics make it ideal for many high-performance applications in aerospace, automotive & medical.

11_modularity Material Management Metal Materials

IPM M Powder Station L

The IPM M Powder Station L is the fully-automatic and intelligent material management solution that offers a closed powder cycle in a protective gas atmosphere in just one module.

13_automation Software

EOSPRINT 2

EOSPRINT is an intuitive, open and productive CAM tool for EOS systems that enables the assignment and optimization of build parameters for your CAD data. Together with data preparation software like SIEMENS NX or Magics, it offers an extensive additive manufacturing CAM environment for a smooth 3D printing process.

Together with data preparation software like SIEMENS NX or Magics, it offers an extensive additive manufacturing CAM environment for a smooth 3D printing process.

EOSTATE Monitoring

EOSTATE is the modular solution for seamless monitoring of all production and quality-relevant data in industrial 3D printing. EOSTATE comprises 4 modules that can be used individually or in combination.

EOSCONNECT Core

EOSCONNECT Core is the connectivity solution for monitoring production. EOS systems are IIoT-capable and can be integrated into existing IT infrastructures via EOSCONNECT Core. EOS offers an open interface for this.

EOS systems are IIoT-capable and can be integrated into existing IT infrastructures via EOSCONNECT Core. EOS offers an open interface for this.

EOSCONNECT MachinePark

Expand the capabilities of your EOS system. Increase your productivity with EOS Web Apps and monitor your entire EOS machine park from anywhere in an intuitive dashboard. Receive automatic notifications on machine status and print jobs.

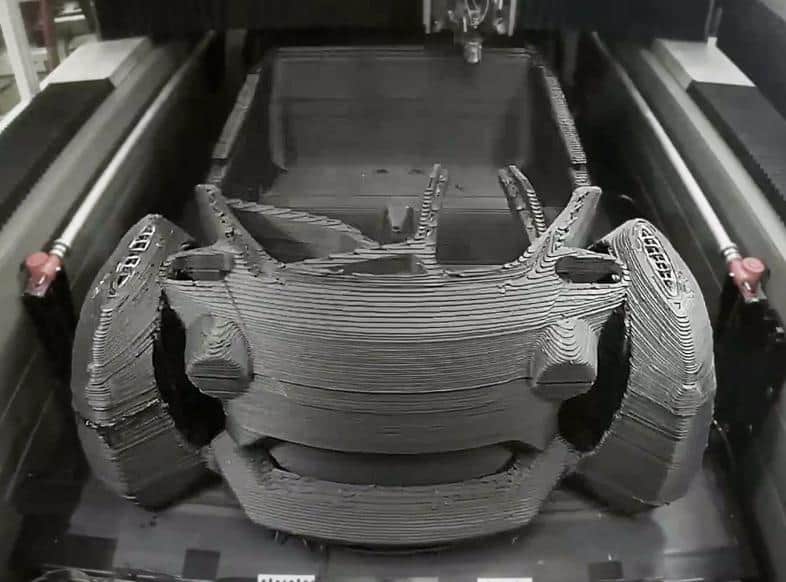

The prospect of using 3D printing technology in construction

Attempts to use the latest technologies in construction, similar to the increasingly popular 3D printing, is experiencing a real boom. As positive aspects of the application of this technology, the possibility of implementing large-scale projects and the implementation of complex configurations of concrete products with minimal time and cost is emphasized.

As positive aspects of the application of this technology, the possibility of implementing large-scale projects and the implementation of complex configurations of concrete products with minimal time and cost is emphasized.

So, in the recent past, it was announced the start of cooperation between the British Loughbrough University, the architectural firm Foster + Partners and the Swedish construction company Skanska, whose goal is to introduce technologies, develop a working set of equipment and further commercial use of 3D printing technologies from concrete of various grades. nine0003

British specialists provide access to the results of research work carried out over a number of years, which will quickly create modern devices for volumetric "printing" of objects from high-strength and stable concrete.

It should be noted that a group of researchers has achieved notable success in this field, having accumulated a considerable number of interesting and promising developments. These include a printer built on the basis of digital manipulators and a gantry crane. The device extrudes a liquid concrete mixture, applying it in several layers to the prepared base, the design parameters are set by a digital 3D model. nine0003

These include a printer built on the basis of digital manipulators and a gantry crane. The device extrudes a liquid concrete mixture, applying it in several layers to the prepared base, the design parameters are set by a digital 3D model. nine0003

What is the uniqueness of 3D printing technology in construction

The technology is unique in that the output is a ready-made building block with precisely defined shape and characteristics, suitable for use as an assembly component for structures of any complexity. The docking of the components obtained in this way is not difficult.

The creators of the device claim that its use will allow the production of any parts of buildings and structures, including those that cannot be obtained using even the most modern technologies currently used on construction sites. For example, it is possible to create wall structures with properly implemented engineering communications, which will significantly reduce the time for further preparation of structures for commissioning. nine0003

nine0003

Additional benefits of the project, the developers call the reduction of time to create complex structures from weeks to hours. A significant reduction in construction time can contribute, according to British experts, and the high mobility of the device.

No less interesting from the point of view of commercial use was the development of a 3D printer-manipulator presented by the Dutch company CyBe Additive Industries.

The ProTo R 3DP was designed to work with specialized concrete and has outstanding performance. Thus, the range of action is at least 3 m in each of the available directions, and the speed of dispensing the mixture with one extrusion head with a diameter of 30 mm can reach 175 mm / s. In this case, the device can be equipped with several printing modules, as a result of which the output speed can be increased up to 4000 mm/s. nine0003

At the same time, not even the equipment itself is of particular interest, but the material used by it for printing concrete structures.

The company introduces its CyBe concrete mix, which has been shown by device tests to have a setting time of a few minutes and complete the mix hydration process in as little as 24 hours. Outstanding performance allows you to make the printing process really fast, and the performance of the device can exceed all known analogues. In addition, according to company representatives, CyBe concrete is environmentally friendly, since when using it, carbon dioxide emissions into the atmosphere are reduced by almost a third, and the mixture is also 100% -1 recyclable. nine0003

Does 3D "building" technology have a future?

However, the outstanding results of these and similar devices do not cause euphoria among construction professionals. The fact is that, according to many authoritative voices in the field of building technologies, the supply of concrete through extrusion heads is not an invention of today, but has long been successfully used at the stages of erection of concrete structures. In addition, the installation of concrete structures is not an independent work process, but only the final in a long series of technological processes, among which an important place is occupied by the preparation of mixtures and its transportation to work sites. At the same time, installation can account for 20 to 50% of the cost of the entire cycle. nine0003

In addition, the installation of concrete structures is not an independent work process, but only the final in a long series of technological processes, among which an important place is occupied by the preparation of mixtures and its transportation to work sites. At the same time, installation can account for 20 to 50% of the cost of the entire cycle. nine0003

Thus, the use of new devices and technologies will not be a revolutionary breakthrough in terms of the speed and cost of erecting structures, and may even significantly increase the cost of the process, due to rather expensive equipment, and, of course, the high cost of concrete mixtures with special characteristics.

Offline industrial 3D printing system tested in Germany

News

0003

5

Electro Optical Systems (EOS), one of the leading manufacturers of industrial laser 3D printers, announced the success of the NextGenAM pilot project aimed at fully automating additive manufacturing processes, including robotic maintenance of additive installations.

The NextGenAM (Next Generation Additive Manufacturing) program is run by EOS with industry partners Premium AEROTEC, an aerospace component manufacturer primarily supplying Airbus, and Daimler AG, an automaker. The goal of the pilot project was to develop a next-level digital manufacturing model that would significantly reduce the cost of aluminum components for the automotive and aerospace industries. As Premium AEROTEC's experience shows, the new manufacturing platform allows savings of up to 50% compared to traditional additive manufacturing. nine0003

The project is based on the idea of a scalable additive manufacturing chain with maximum automation of workflows, up to the sawing off of printed parts from the working platforms of 3D printers. Manual labor from the moment of transfer of digital models to the receipt of finished products is practically not required: the system itself prepares machine code, replenishes supplies of consumables, prints, heat treats, monitors quality and stores finished products. The heart of the platform is EOS M 400-4 industrial four-laser powder 3D printers, and the role of operators is performed by unmanned transport platforms and robotic arms that ensure the smooth operation of the production line. Materials used include Scalmalloy, a high-strength aluminium-magnesium-scandium alloy developed by Airbus. nine0003

The heart of the platform is EOS M 400-4 industrial four-laser powder 3D printers, and the role of operators is performed by unmanned transport platforms and robotic arms that ensure the smooth operation of the production line. Materials used include Scalmalloy, a high-strength aluminium-magnesium-scandium alloy developed by Airbus. nine0003

The entire production platform is managed by a single autonomous control center. The digital data is sent to the center, where requests are sorted and queued. You can track the execution of tasks at any time and from anywhere using mobile devices. After work cycles are completed, the center receives and stores production reports that allow you to evaluate the quality of the received products, compare the results with the original digital twins, and trace any problems back to the source. nine0003

A pilot production line at the Premium AEROTEC site is already producing parts for Daimler according to in-house serial production standards.