Can you 3d print gold

Can You 3D Print Gold? The Complete Guide to Gold & Gold Filament 3D Printing

3D printing gold is in theory no different to any other type of metal printing. In practice however, there is more to be considered.

Gold’s properties make it unsuitable for some of the more reliable and accessible metal 3D printing techniques. However, these same difficult properties make it suitable for methods previously considered too specialist or expensive.

Whilst yes, you can 3D print gold using the same techniques as you would to 3D print any other metal, as you’re about to see, some will produce far better results than others.

However, hobbyists have more recently taken to mimicking gold with gold filaments that retain the metallic aesthetic and shiny gold color. This gets you most of the look, but without the cost or difficulty.

This article both explains how you can 3D print precious gold metal with metal 3D printing, as well as these more accessible alternatives.

So, with that in mind, how exactly can you 3D print gold?

A 3D printed gold pendant, available for purchase3D Printing With Gold Filament

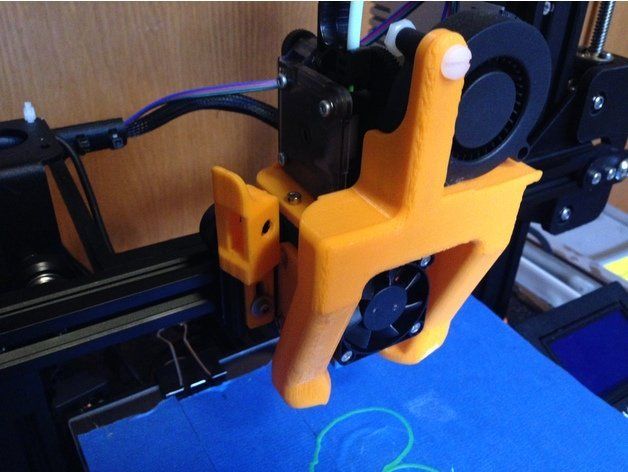

Metal filaments, also known as metal-filled filaments, are perhaps the most accessible way of 3D printing metal. These filaments are made from a mixture of metal powders and a polymer — usually PLA filament.

Mixing the metal with polymers means that even at high concentrations, metal filaments can be extruded through most FDM 3D printers. Additionally, these prints have similar properties to solid metal. They can be polished, magnetic, and even patinaed.

Metal-filled Pokémon 3D printsAny metal can be used to create a metal filament, including gold. However, doing so is very impractical.

As a precious metal, one of gold’s defining features is its expense. Whilst it is true that gold filament can be made, doing so is simply too expensive to try. For example, if a manufacturer produced 1kg of gold filament, and used enough gold powder to make it resemble solid gold, then the resulting single spool would cost tens of thousands of dollars.

The current price of gold is around $58,000 per kilo. Standard filament mixes are usually around 30% of the mixed material, and 70% PLA. The cost of the gold, not including any work to mix it into the filament, would therefore cost over $17,000.

The result is that gold-filled filaments are essentially unavailable for purchase. Even if a customer was willing to buy the product, no company is currently manufacturing it. In fact, the closest we’ve ever gotten was an April fool’s joke. In 2019, XYZprinting announced their new “24 carat gold filament,” with a pre-order price of $50,000 per 1kg spool.

What About “Gold Colored” Filaments?

For people still keen on using an FDM printer, there is the option of using gold colored metal filaments. These are usually mixtures of bronze or copper powders with colored polymers.

They’re great for fun maker projects designed to resemble and mimic gold, though they won’t help those striving to 3D print precious metals.

A gold colored PLA filament and print.So, with gold-filled filaments ruled out, printing gold rings on your home FDM printer is a non-starter.

However, there are ways around this. As our next method demonstrates, you can still 3D print your own gold, you’ll just need a more specialized 3D printer.

DMLS 3D Printed Gold

Direct Metal Laser Sintering (DMLS) is the closest we have to a true “gold 3D printer.”

The process again uses metal powders, but rather than being held in a polymer solution, lasers are instead used to fuse the powders together into a 3D object.

The process begins with the DMLS machine’s print bed being coated with a layer of gold powder. Lasers then fuse this powder into the object’s first layer. The print bed is then lowered, another layer of powder is applied, and the process is repeated. Once complete, the final object can be retrieved from the unsintered gold poweder it is submerged in.

DMLS 3D printed gold cufflinksReusing 3D Printed Gold Powder

DMLS stands out as a more efficient way of 3D printing gold. Unlike metal filaments, DMLS prints are solid gold and therefore aren’t diluted with polymers.

Gold powder is still expensive though, and not all the powder used in DMLS ends up in the final object. Instead, much of the powder is simply unused, with the lasers fusing around them each layer.

This could be a significant issue. Wasted gold powder ultimately results in wasted money. However, depending on the DMLS machine used, wastage isn’t necessarily a problem.

Although material loss can occur, most precious metal specific DMLS machines are designed to preserve as much unused material as possible.

Product artist, Lionel T Dean, addressed this whilst revealing his collection of 3D printed jewelry in 2015:

“when we started off, we were using a regular laser sintering machine, but this has a lot of cavities and places where powder can get trapped and lost. Obviously with the high value of gold powder, it’s important to capture every speck of material.”

Lionel T Dean

So, DMLS results in solid gold prints and doesn’t waste gold powder. However, despite how effective DMLS could be for 3D printing gold, it is too expensive for most gold uses.

Disadvantages Of DMLS Gold Printing

DMLS machines are large and industrial 3D printers. They cannot simply be ordered online like a typical FDM 3D printer. Instead, conversations with the manufacturer will have to be arranged, and lead times can be long.

They cannot simply be ordered online like a typical FDM 3D printer. Instead, conversations with the manufacturer will have to be arranged, and lead times can be long.

Prices aren’t readily available as manufacturers will usually tailer their quotes specifically to their clients. But as a guide, DMLS machines rarely cost less than $50,000 and can cost up to $1 million depending on the operation’s scale.

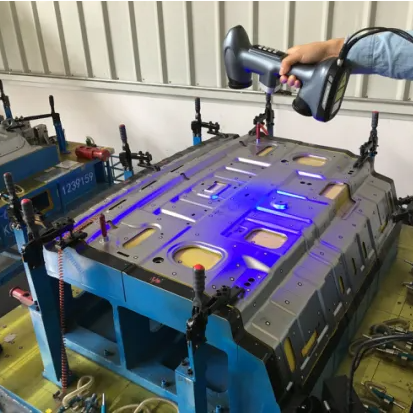

A precious metal DMLS machineThis makes purchasing a DMLS machine unrealistic for most individuals wanting to 3D print their own gold. However, the technique has seen success as a gold printing service instead.

We also have a buyer’s guide for metal 3D printers

DMLS and Gold 3D Printing As a Service

The process of using a gold 3D printing service is like any other. Customers design their model in 3D modeling software, the file is sent to the 3D printing company, they provide a quote, and if accepted, they 3D print the object in gold.

Although a service fee must be paid, using a DMLS service remains an affordable and practical way for individuals to turn their designs into gold.

But what if you want to produce your design yourself? Perhaps you prefer more control over the final piece, or want the satisfaction of 3D printing your own gold? Well, there is one final option.

Lost Wax Casting

Lost wax casting is an ancient method of forming precious metals. The technique is potentially as old as recorded history, with some archaeological finds believed to be lost wax cast in 3700 BC.

An ancient lost wax cast amulet from the Indus Valley civilizationRemarkably, the technique has changed little throughout the centuries, and is still used by professional jewelers today. But this doesn’t mean that the introduction of 3D printing hasn’t created new opportunities for the process.

The Process

In general, lost wax casting begins with a design sculpted in wax. Wax sprues are then attached to the sculpt. The sculpt is then molded in plaster, but the end of the sprues are left exposed in the bottom of the mold.

The mold is then heated, melting the wax but leaving the plaster intact. Because the sprues were connected to an opening in the bottom of the mold, as they melt they become channels that the rest of the wax and any trapped gases can flow out of.

Because the sprues were connected to an opening in the bottom of the mold, as they melt they become channels that the rest of the wax and any trapped gases can flow out of.

With the wax gone, the plaster mold will be left with a negative impression of the original design. This mold can then be flipped, with the channels now serving as funnels for the molten gold to be poured into.

The gold will flow into the negative impression, creating a positive golden cast of the original wax design. Once the gold has set, the plaster can either be broken open, or dissolved in water, leaving behind a golden object. Once polishing or other finishing has been applied, the piece is complete.

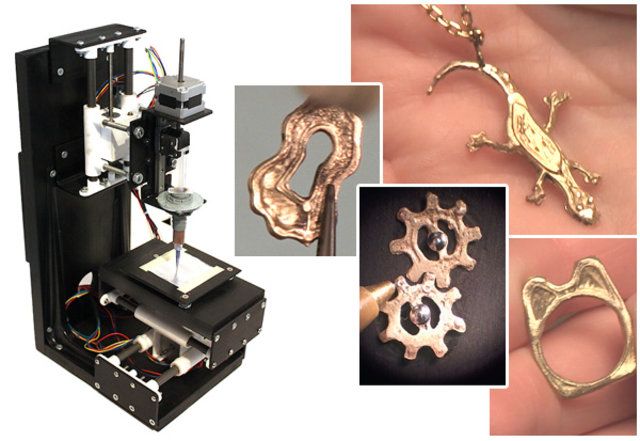

A small scale lost wax casting operationNot only does lost wax casting produce solid gold objects, but it also does so without expensive machinery. In fact, the equipment needed to cast gold rings can easily cost less than $100 (excluding the gold and a 3D printer), meaning that individuals can easily begin lost wax casting.

Resin 3D printers capable of 3D printing jewelry are cheaper than ever before. Though not as accurate as more expensive printers, you can now buy LCD printers with adequate precision to create detailed wax molds, costing just $200.

Check out our buyer’s guide for resin 3D printers

We also have a buyer’s guide for 3D printers for jewelry

The Impact of 3D Printing of Gold and Precious Metal Production

3D printing’s involvement in the process is minimal, but still offers valuably opportunities.

Instead of manually sculpting an original wax design, the initial sculpt can instead be 3D printed in wax. This is perhaps less useful for artists who can already manually sculpt.

However, for designers already familiar with software sculpting, it’s an opportunity to turn their original models into gold. Additionally, it opens the door for any 3D printable object to be cast in gold, without needing expensive equipment or expertise.

3D printed rings, and their lost wax castsMore generally, another implication of 3D printing is the increased accessibility of the entire jewelry making process.

3D printing gold: for entrepreneurs

A growing trend is for individuals to start their own jewelry businesses. However, instead of renting factories or workshops, these individuals will outsource all the labor other than the original wax 3D print.

You can also check out our guide to starting your own 3D printing business

These entrepreneurs use local jewelry districts to cast their own 3D designs and create custom gold or other precious metal pieces on-demand, and without owning any equipment.

As gold retains its value when processed into jewelry, such a venture is relatively low risk, as unsold products can still be sold as metal for only a small loss. Additionally, because the various services within jewelry districts are in competition, labor prices are generally fairly cheap.

LA’s Jewelry District3D printing the wax models makes the process even more accessible. These entrepreneurs once had to design or commission their pieces. But now, 3D printing allows them to instead print wax models ready for casting, saving them valuable time and money.

With suitable 3D printers starting at $200, and stunning 3D jewelry models buyable online for around $30, 3D printing has become an essential part of these entrepreneur’s processes.

Is Lost Wax Casting for You?

Despite this, 3D printing hasn’t revolutionized the process. Lost wax casting remains a slow and labor-intensive way of 3D printing gold.

A lost wax cast gold ring, still attatched to its supportsLarge or complex objects can take days to complete, though a gold ring can be made in a few hours. Additionally, and like any skill, it requires practice to get reliable results, with every cast being affected by the jeweler’s skill.

Ultimately, lost wax casting is a great opportunity for individuals and small businesses to try 3D printing their own gold. However, for operations large enough to justify the expense of a DMLS machine, lost wax casting will largely be overlooked for its consistent and automatic production.

Which Method Should You Use?

Regardless of the method used, 3D printing with gold will always remain an expensive prospect. Not because the technology available is lacking, but rather because working with gold will always be expensive.

Not because the technology available is lacking, but rather because working with gold will always be expensive.

Having said that, if your operation is big enough to justify it, DMLS machines will serve you well. Otherwise, consider using a gold 3D printing service, or if you’re brave enough, lost wax casting your own 3D printed gold.

Gold 3D Printing Explained: Technology, Material, Tips | 3D Printing Blog

Begin typing your search above and press return to search. Press Esc to cancel.

by Fabian | January 8, 2020 | Materials

Gold 3D Printing Explained: Technology, Alloys, Colors, Design Tips

by Fabian | January 8, 2020

3D printing is changing the way goldsmiths work and design. More and more people are asking us how 3D printed jewelry items in gold look and feel. In this article, we explain how gold items are created, the difference between 14k and 18k, its various colors, and how to model your 3D design to get the perfect gold 3D print!

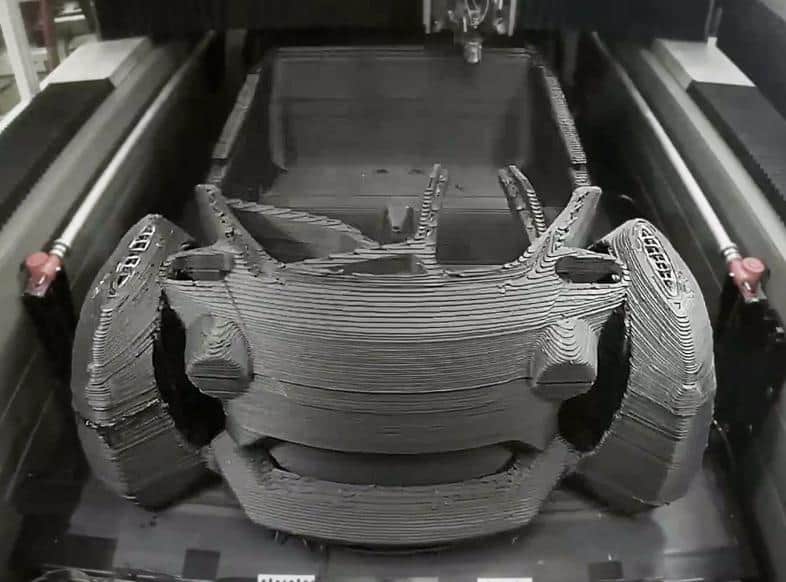

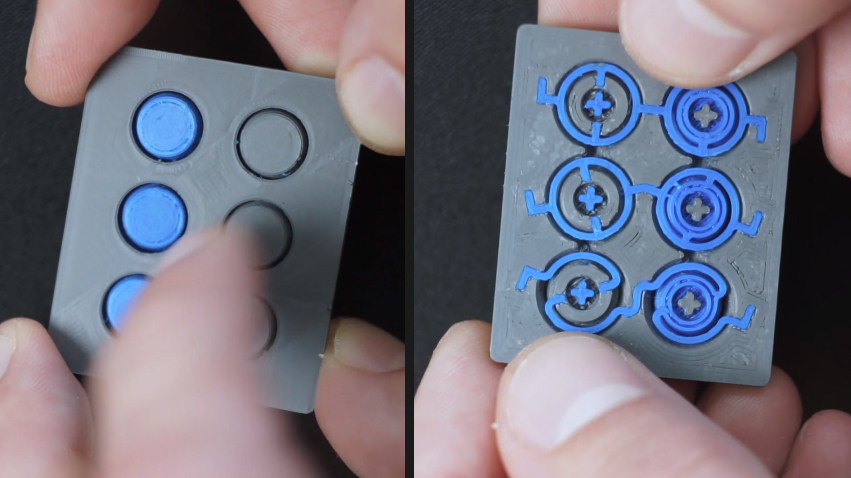

The Technology: It’s All Based on WaxInstead of printing your gold item directly, we use wax 3D printing and lost wax casting to build your design. The wax printing process is a type of Stereolithography that uses a wax-like resin. Support structures are printed along with the model to make sure the item does not fall apart. These support structures are automatically generated and then manually removed after the printing process.

The wax printing process is a type of Stereolithography that uses a wax-like resin. Support structures are printed along with the model to make sure the item does not fall apart. These support structures are automatically generated and then manually removed after the printing process.

The wax cast is subsequently covered in a fine plaster. When the plaster solidifies, it is put in an oven until the wax is completely burned off. The gold is then poured into the empty cast, thus creating a 3D printed gold item. In the final step of this process, the item is polished and finished manually.

Wax 3D printing and lost wax casting are used to create a gold item.

14k or 18k: The Amount of Gold MattersA pure gold item (composed of 100% gold) is too soft for durable jewelry. With this in mind, jewel makers and goldsmiths usually mix pure gold with other metals, typically silver, copper, or zinc, in order to make it stronger.

The karat (often just written as “k”) indicates the amount of pure gold in the metal: the higher the karat, the larger the percentage of pure gold in the metal. For instance, 100% of pure gold is equal to 24k. However, as already pointed out, an object made of 24k would be too soft. This is why the amount of gold needs to be reduced: while 18k contains 75.2% pure gold, which is the standard in Europe, 14k gold only contains 58.5% of pure gold and is somewhat less expensive. In fact, 14k gold is the most popular choice for gold jewelry in the United States.

For instance, 100% of pure gold is equal to 24k. However, as already pointed out, an object made of 24k would be too soft. This is why the amount of gold needs to be reduced: while 18k contains 75.2% pure gold, which is the standard in Europe, 14k gold only contains 58.5% of pure gold and is somewhat less expensive. In fact, 14k gold is the most popular choice for gold jewelry in the United States.

Tulip Shell Pendant by Vulcan Jewelry. Printed in 14k red gold.

Rod of Asclepius Pendant Mini by Marcus Ritland. Printed in 14k yellow gold.

Yellow, White, and Red Gold: The Amount of Silver, Copper, and Zinc MattersSince neither 14k nor 18k gold contains 100% pure gold, the metals we choose to strengthen pieces of jewelry (silver, copper, and zinc) have an impact on the color of the final item. As a result, gold can be offered in several colors: white, yellow, and red.

Take a look at the following examples of the color difference depending on the amount of pure gold as well as the amount and type of metal alloy:

Our three gold color options: yellow gold, red gold, and our updated white gold.

The term ‘white gold’ is used very loosely in the jewelry industry to describe karat gold alloys with a whitish hue. The term ‘white gold’ covers a large spectrum of colors that borders or overlaps with pale yellow, tinted brown, and even very pale rose.

To create a white color effect, nickel is often added to the alloy. Since 1 out of 8 people have allergic reactions to nickel, and in order to comply with a European regulation called REACH, we didn’t want to go this way and preferred a slightly yellowish look.

The jewelry industry often conceals these off-white colors by using rhodium plating. It is a common misconception that the color of the rhodium plating, which is seen on many commercial pieces, is actually the color of white gold. In reality, however, rhodium plating will inevitably wear off. So you would need to ask your local jewelry shop to apply a rhodium plating to whiten your model each time it wears off.

Since neither nickel nor rhodium plating were acceptable options, we decided to add palladium, a rare and lustrous silvery-white metal, to the alloy.

- Wall thickness: For most models in gold, the minimum wall thickness is 0.5 mm. However, when making something small, such as the band of a ring, the wall thickness should be at least 1 mm. If the model is too thin, the fragility of the gold might cause the ring to break when you wear it.

- High definition: The resolution of the wax-printing process is very high, so it is important to create and export your model with enough definition to cover the triangles of the original design.

- Hollow models: Gold can also be used to print hollow models. However, keep in mind that you need to incorporate holes or slots, so we can get rid of the unprinted wax resin and make sure that the casting plaster is sufficiently supported. Without these holes, you will not be able to cast your model properly. To prepare your model for casting, make as many holes or slots as possible (at least two holes or slots for each side), each with a minimum diameter of 1.

5 mm.

5 mm.

For more essential tips & tricks for designing your gold model, please visit our gold design guide. You can also learn more about 3D-printed jewelry in our blog posts about Desmond Chan’s stunning jewelry collection, Czech jewelry label blueberries, and our ultimate jewelry style guide.

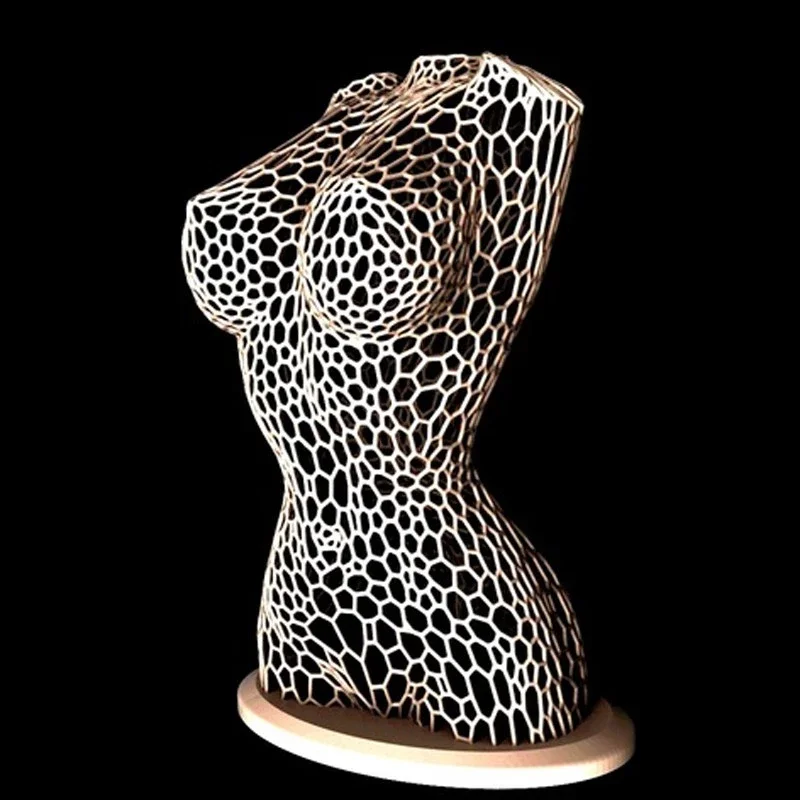

Use of a 3D printer in jewelry

The design of modern fashion jewelry requires innovative approaches in production technology, and here 3D printing comes to the rescue. Rings, bracelets, pendants, brooches and more can now be easily modeled in a special 3D program and printed on a 3D printer. The design can be the most daring. The range depends only on the imagination of the creator.

With photopolymer printing, designers and jewelers can create custom-made pieces easier, faster and cheaper. In addition, a prototype made on a 3D printer allows you to see how the final product will look like, make any adjustments in a timely manner and ensure the most comfortable fit. nine0003

nine0003

The owner of the jewelry company told us more about how he uses advanced 3D technologies in his work « GOLD S.S.A.M. » and our esteemed client Sargis Machkalyan . GOLD S.S.A.M. started in Buenos Aires, Argentina. But in 2002, Sargis decided to develop his business in Armenia.

- Sargis, please tell us how you came to use 3D printing?

I had this idea a long time ago, but we started working with 3D printing about 2 years ago. Basically, we make products by hand, according to individual orders. We make a lot of wedding rings. We also do casting. With the help of a 3D printer, we print products that cannot be made by hand or take a very long time.

- Were there any difficulties in the transition to digital?

There were no difficulties with the transition itself, and finances, thank God, allowed it. There are problems with the fall in production due to the coronavirus and military operations, unfortunately. It is not easy in Armenia now. nine0003

It is not easy in Armenia now. nine0003

- Do you see the advantages of technology over traditional methods?

There are benefits. Manufacturing has become much easier. It is not required to attract a large number of jewelers. Increased work speed. And design - you can produce whatever you want, so to speak. And most importantly, the advantage for the client is that the products look much better, much more beautiful and more modern.

- Does 3D printing save money and time? nine0018

Time yes. I would not say that you can save a lot of money on 3D printing, because it also requires its own costs.

- Do private individuals or businesses apply to your company?

We work with everyone: both companies and individuals.

- How long does it take to produce a 3D decoration?

It depends on the model itself. There are models that are made quickly: you can assemble a model in half an hour or an hour in a modeling program, and printing will take 3 hours. More complex models can be assembled in two hours, printing takes the same 3 hours. nine0003

More complex models can be assembled in two hours, printing takes the same 3 hours. nine0003

- What 3D equipment do you currently have at your disposal?

PCs and Phrozen Shuffle Lite 3D printer only. There is also an excellent Phrozen Shuffle 4K, but it is currently under repair.

- What resin do you print with?

We print on ESUN, X10 burn-out resin and recently started using HARZ Labs.

- Do you see the modern jewelry industry without 3D technology? nine0018

No, I don't.

On behalf of the Tsvetnoy Mir company, we would like to wish Sargis success in his future work, do not stop there, continue to make customers happy thanks to the unusually beautiful and modern designs and the consistent quality of his products. In the photo you can see prototypes made of photopolymer resin, printed on a 3D printer, and final products made of gold, created by burning the former.

nine0003

3D printed products

Ultimate gold jewelry

Sargis Machkalyan at work

You can read more about the technology of 3D printing of jewelry on our website at the link: 3D printing of jewelry

3D printing with gold thread: properties and uses

Author Kirill Sokolov Reading 7 min. Views 90 Published by

Views 90 Published by

Gold, with its characteristic color and luster, has always been a highly valued metal throughout almost the entire history of mankind. Often used in the jewelry industry, the ability to work with gold and create custom pieces remains a valuable and exclusive skill set. Those with 3D printers might ask: Can 3D printing technology be used to create custom designs that are made of gold or mimic the look of gold? nine0003

Both of these questions are still answered. . As you might expect, budget comes into play. What options do you have if you want to 3D print your own gold jewelry?

Contents

- Option 1: Silk Gold PLA Filament

- Option 2: 3D SoluTech Real Gold PLA Filament

- Option 3: GizmoDorks Gold ABS Filament

- Is there a technology for real gold 3D printing?

- Closing thoughts

Option 1: Silk Gold PLA Filament

This Silk Gold PLA Filament from CC3D is one of the most popular options for those who want to try their hand at 3D printing something that looks like gold. The average reason for the popularity of this thread is that it is very cheap. This is just another way of saying that the filament does not contain real gold.

The average reason for the popularity of this thread is that it is very cheap. This is just another way of saying that the filament does not contain real gold.

This filament uses gold colored silk filaments embedded in a PLA matrix. The use of silk is an amazing idea that makes the material reflective enough to mimic the sheen of real gold. Prints made with this filament naturally come out shiny and glossy, although a little sanding and polishing won't hurt to get rid of the layer lines. nine0003

Besides the low cost of the filament, another advantage of using silk instead of metal particles is that the filament is not exclusively abrasive. Using the standard brass nozzle of most solid filament 3D printers is always problematic as solids tend to wear down brass materials fairly quickly. This is not a problem for silk threads.

Silk Gold PLA filament prints at normal PLA printing temperatures - ranging from 195 to 230°C. As with regular PLA, a heated bed is not a strict requirement when working with Silk Gold PLA, although a bed heated to around 60°C is still ideal. Silk Gold PLA is a relatively simple and beginner-friendly filament that provides visually pleasing results.

Silk Gold PLA is a relatively simple and beginner-friendly filament that provides visually pleasing results.

Since the filament does not contain solids, you will miss the characteristic mass of 3D printed projects. made from solid thread. This weight gives 3D prints a certain level of premium quality. A print made from PLA Silk Gold looks good, but you're not going to fool anyone that it's made from real gold. nine0003

Option 2: 3D SoluTech Real Gold PLA Filament

This real gold filament from 3D SoluTech is another viable and inexpensive option if you want your prints to be elegant. Even though the thread's marketing used "real gold", nothing could be further from the truth. This is a standard solids-free color PLA, which is both a good and a bad thing.

The absence of any metallic particles in this true gold filament means it is no more difficult to print than standard PLA. You can print at low temperatures and without a heated bed without worrying about layer sticking or warping issues. You can also safely use the standard nozzle without worrying about wear. nine0003

Since almost everyone who has tried 3D printing knows how to work with PLA, this might be the easiest way to add some gold to your 3D prints.

However, in this case, quality takes a backseat to ease of use. Prints made with Real Gold filament look more like brown bronze than gold. The closest metallic analogue of a thread made of real gold will be copper. Because it does not contain any naturally shiny materials, a full range of finishing techniques, from sanding and polishing to priming, will be required to achieve the "shine" of the finished print. nine0003

Despite its shortcomings, the SoluTech Real Gold Filament is still a compelling choice for 3D printer hobbyists who want to get a little creative but don't want to work with complex filament material. The filament still looks great and "pops out" when properly tuned. This is an inexpensive filament that is easy to work with and requires no modification to your standard 3D printer. Just met your expectations, as it can not be like "real gold" in any way. nine0003

Just met your expectations, as it can not be like "real gold" in any way. nine0003

Option 3: GizmoDorks Gold ABS Filament

Famous 3D filament brand GizmoDorks uses their ABS based gold filament instead of PLA. This should be a good choice for those who want their gold prints to have an extra factor of strength and heat resistance. Naturally, GizmoDorks gold filament comes with the usual difficulties of ABS printing.

Like SoluTech Gold Thread, GizmoDorks Gold Thread does not contain solids, but is simply colored ABS. This simplifies the whole technique of 3D printing this gold filament, especially if you are already used to working with ABS. Compared to PLA, ABS printing is slightly more stable in terms of chemical and thermal resistance. It's also robust enough for limited functional use, although we assume you'll be using this thread to build display elements. nine0003

The finish of this gold thread is also somewhat dull, but closer to toffee yellow than bronze. The bright finish looks great even without any trim. However, this thread is a great opportunity to practice ABS finishing techniques using an acetone steam bath. This technique melts a very thin layer of plastic onto an ABS print, giving it a perfectly smooth and shiny surface.

The bright finish looks great even without any trim. However, this thread is a great opportunity to practice ABS finishing techniques using an acetone steam bath. This technique melts a very thin layer of plastic onto an ABS print, giving it a perfectly smooth and shiny surface.

If you have worked with ABS before, you probably know that it is not easy to print with it. The high printing temperature required for ABS, combined with its thermal shrinkage index, makes it especially prone to warping. Achieving the perfect combination of bed temperature, print speed, and nozzle temperature takes a bit of work. The consistency and quality of this thread from GizmoDorks is pretty good, so it should help you eventually improve your technique. nine0003

Is there a technology for 3D printing with real gold?

The only thing that all of the above options have in common is that none of them uses real gold. Unlike other metals such as brass or copper, gold is very expensive even in small quantities. A 1kg spool of filament impregnated with real gold would likely cost tens of thousands of dollars, which is not very suitable for a process that requires repetitive cycles of trial and error. nine0003

A 1kg spool of filament impregnated with real gold would likely cost tens of thousands of dollars, which is not very suitable for a process that requires repetitive cycles of trial and error. nine0003

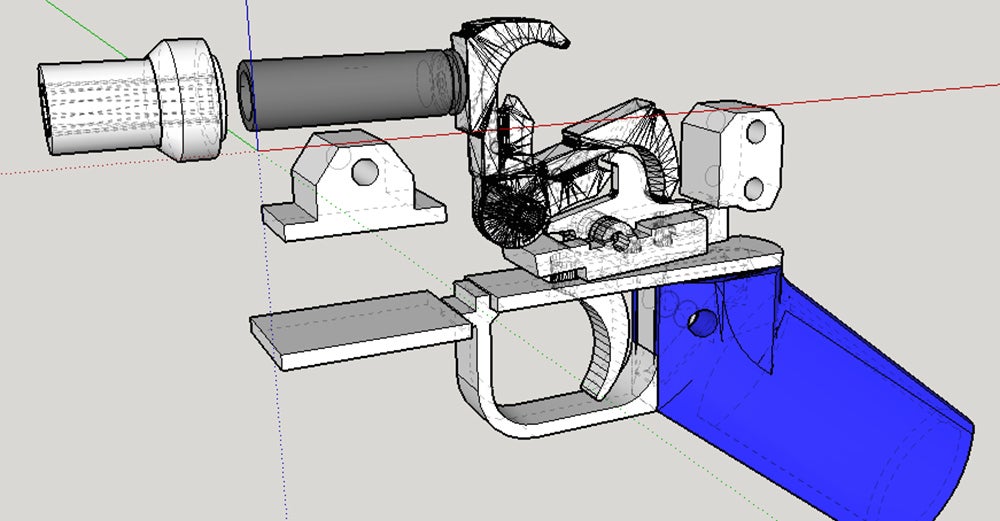

way to turn 3D models into solid gold objects, but they rely on different 3D printing technologies. The most commonly used are direct metal laser sintering (DMLS) and investment casting. Sintering is carried out using a laser to cure the powdered raw material, similar to the selective laser sintering (SLS) process.

Lost wax casting is a more indirect way of using 3D printing to work with gold. Instead of printing in gold, this method starts by using a 3D printer to create a wax model. An impression is made of the model, usually enveloping it with plaster. When the mold hardens, the bottom of the mold is pierced and subjected to high temperatures to allow the wax to run off. The mold is then filled with liquid metal—in this case, gold alloy. nine0003

Unfortunately, none of these methods can be done at home. A DMLS machine can cost up to $150,000 and houses aren't quite equipped to handle molten metal. Think about how valuable gold is and how technically complex and expensive the equipment is, it is best to entrust this work to specialists. Gold 3D printing services are offered by professional 3D printing companies such as i.materialise and Cookson Gold.

A DMLS machine can cost up to $150,000 and houses aren't quite equipped to handle molten metal. Think about how valuable gold is and how technically complex and expensive the equipment is, it is best to entrust this work to specialists. Gold 3D printing services are offered by professional 3D printing companies such as i.materialise and Cookson Gold.

Closing thoughts

3D printing in gold will be a dream come true. many manufacturers of jewelry and decorations. The sheer versatility of 3D printing, combined with the value and manufacturability of gold, will open up many opportunities for more imaginative uses of one of the most precious metals in human history.

However, 3D printing technology is not. not quite there yet. You can create faux gold 3D printer designs using filaments that mimic the look of gold, but real gold will use more traditional methods. 3D printing is still used in the art of gold working, but in a more indirect way, such as in the production of a wax model for lost wax casting.