Who uses 3d printers

Five Industries Utilizing 3D Printing

Learn Blog

With a plethora of companies using professional 3D printers in their production processes, we want to identify industries that we believe can benefit most from additive manufacturing. By looking at these industries, it’s easy to understand how and why professional 3D printers are changing manufacturing as a whole.

Aerospace

The aerospace industry has some of the highest standards in part performance. Aerospace parts must withstand extreme temperatures and chemicals while being subjected to repeated loading, all while remaining as light as possible. Individual part failures often result in full system failures on aircraft carrying lives and cargo — so failure is simply not an option. Since part precision is critical for aircraft, aerospace engineers have taken to 3D printing inspection tooling to reduce costs for low-volume parts.

In the last few years, additive manufacturing has advanced rapidly, and advancements in the 3D printing industry have developed better solutions for aircraft manufacturers. Professional 3D printers can now print in high-performance thermoplastics reinforced with continuous fiber reinforcement (CFR) for additional strength, such as ULTEM™ 9085 Filament. Furthermore, professional 3D printers are now able to print larger parts at faster speeds, widening the scope of possible aerospace applications for the benefits of AM.

White Paper: Why Additive, Why Now?

How has 3D printing developed in recent years? Learn what today's AM platforms are capable of, and how they are solving new problems.

Automotive

The automotive industry has been charging ahead with additive manufacturing, with high-profile companies such as Audi using 3D printers. It’s not just the Audis of the world that are using 3D printers — everything from race car teams to sub manufacturers (OEMs) for each car manufacturer are utilizing 3D printers. Initially, the value of the 3D printing industry reaching automotive manufacturers focused on building the tooling and fixtures that aide the manufacturing process. The most common parts printed by automotive manufacturers are fixtures, cradles, and prototypes, which need to be stiff and strong, as well as durable.

However, professional 3D printers are now used to print high-strength, fiber-reinforced end use parts as well. Garry Rogers Motorsport, for example, uses a professional 3D printer to print numerous end-use parts such as steering wheels.

It’s also not unheard of for some to use professional 3D printers to fabricate replacement parts for centuries-old cars. This ensures there are enough pieces to service legacy cars as well as standard maintenance, repairment, and operations.

Manufacturing

From jigs and fixtures all the way to end-of-arm tooling, industrial 3D printers are completely turning the decades-old manufacturing industry on its head. Companies are able to create custom, low-volume tooling and fixtures at a fraction of the traditional price, giving designers and engineers more time to spend on revenue-generating parts. Due to 3D printing industry advances, mall manufacturers get the same advantages with a professional 3D printer as giant, global manufacturers, to improve and expedite processing while mitigating downtime. Companies are also able to have more creative freedom while saving on labor costs and time. Metal fabrication company Lean Machine, for instance, has approached 3D printing with a design for additive manufacturing (DFAM) approach, saving them upwards of $4000 per tool.

Metal fabrication company Lean Machine, for instance, has approached 3D printing with a design for additive manufacturing (DFAM) approach, saving them upwards of $4000 per tool.

Robotics

From customizability to reduced weight, these factors make successful robotics parts match well with 3D printing capabilities. Parts like grippers and sensor mounts are expensive to fabricate and need to be custom designed for different uses. Robotics engineers utilize 3D printers for end-of-arm tooling and end-use parts, from gripper fingers to entire robot components to reduce the weight of the overall product to ensure the tools can move faster and carry heavier items. Instead of paying large amounts of money for a non-customized design, 3D printing industry technologies allow robotics companies to design and fabricate light, complex parts such as end-of-arm tooling at a fraction of the cost. Haddington Dynamics, for example, is utilizing its four printers to create 3D printed robot arms for NASA and GoogleX for 58% less than traditional manufacturing.

Haddington Dynamics, for example, is utilizing its four printers to create 3D printed robot arms for NASA and GoogleX for 58% less than traditional manufacturing.

Education

As the 3D printing industry grows, educational institutes are rushing to make sure they stay on the cutting edge of the new technology for research and education purposes. From professors printing parts for educational tools to convey the lesson plan to PhD students utilizing the printers for research, 3D printers serve a variety of purposes in colleges. Colleges like Oklahoma State University and Purdue University in Indiana have taken a great interest in teaching their students about emerging additive manufacturing materials and technology.

Want to test the strength of our parts? Request a free sample part or sign up for a demo!

*The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Demonstration from Markforged Application Engineer Ross Adams on 3D printing applications in the Aerospace industry.Customer Success Stories

NASA JPL's Team CoSTAR

NASA JPL's Team CoSTAR used their Markforged printers to print parts for field use in the DARPA Challenge

3D Printing for Education

All of the blogs and the information contained within those blogs are copyright by Markforged, Inc. and may not be copied, modified, or adopted in any way without our written permission. Our blogs may contain our service marks or trademarks, as well as of those our affiliates. Your use of our blogs does not constitute any right or license for you to use our service marks or trademarks without our prior permission. Markforged Information provided in our blogs should not be considered professional advice. We are under no obligation to update or revise blogs based on new information, subsequent events, or otherwise.

and may not be copied, modified, or adopted in any way without our written permission. Our blogs may contain our service marks or trademarks, as well as of those our affiliates. Your use of our blogs does not constitute any right or license for you to use our service marks or trademarks without our prior permission. Markforged Information provided in our blogs should not be considered professional advice. We are under no obligation to update or revise blogs based on new information, subsequent events, or otherwise.

Never miss an article

Subscribe to get new Markforged content in your inbox

required required requiredSubmit

Who Really Uses 3D Printing And Why

We’re checking which industries, professionals, and who really uses 3D printing.

Many modern professionals take advantage of using 3D printing on a permanent basis. The technology is constantly evolving, together with the number of industries in which 3D printing is used. So, let’s explore how the applicability of this technology has expanded in certain professions by today and try to answer the question about who really uses 3D printing today.

The technology is constantly evolving, together with the number of industries in which 3D printing is used. So, let’s explore how the applicability of this technology has expanded in certain professions by today and try to answer the question about who really uses 3D printing today.

Product Design

Fashion category is a relative newcomer to the commercial application of 3D printing besides prototyping products for advertising purposes. A striking example of the progress is Zante Generate, a running shoe featuring full-length thermoplastic midsole of unprecedented performance and incredible flexibility. New Balance’s product designers have used the selective laser sintering technology combined with specifically developed new powder material created in collaboration with 3D Systems.

Source: New BalanceIn contrast to the market giants, the smaller companies tend to offer fashion designers the appropriate universal desktop solutions for creative work such as ZMorph multitool 3D printer already being in use by fashion, shoe, and even jewelry designers.

In electronics, nobody would be surprised with printed quadcopter parts. But engineers now can have personal 3D printing factories at their disposals! The issue was addressed by VOXEL8 that was mentioned in MIT Technology review as "one of the 50 smartest companies of 2015". Their dedicated all-in-one 3D printer allows any developer to design and prototype next-generation 3D electronics using cloud software, innovative conductive silver ink, as well as fused deposition modeling, and pneumatic direct write technologies with 200 microns layer resolution.

[Tweet "Check out who really uses #3Dprinting and why #innovations #design"]

Environmental Engineering & Architecture

Ecological engineers, as well as civil constructors, are on the verge of the most important and timely use of mobile 3D printing solutions. A bright example is the Field Ready humanitarian organization. Right after the earthquake, two engineers used their Land Rover as a standing platform and a charger to a small desktop 3D printer which was printing a plastic fitting for local pipes. The problem seems to be not so serious, but that day only two men helped to bring water to the whole village in just 15 minutes.

The problem seems to be not so serious, but that day only two men helped to bring water to the whole village in just 15 minutes.

The progress of civil construction through 3D printing becomes more obvious with such projects as WinSun’s giant villa which was almost entirely printed by an almost 7 meters tall printer. The architects were able to create a fantastic geometry thanks to the possibilities of giant printing units and the concrete ink consisting completely of recycled materials that needed only 24 hours to dry.

Source: The Guardian / Imaginechina / CorbisArchitects can also use 3D printing technology for the creating accurate dioramas of entire cities and neighborhoods in matters of hours. In the past, such visualizations could take months to complete!. For example, all architectural modeling processes in LGM company are currently based on 3D modeling and CAD resources, starting from composite concept models and ending with full-color terrain models.

Medical industry

The future of high-dose medications takes a rapidly disintegrating form with ZipDose technology developed by Aprecia’s pharmacists. The precise powder-liquid three-dimensional layering allows creating the unique bonds system that masks the taste, simplify drugs administration, and enables prescribing individual dosages to patients.

In Brazil, a team of doctors has printed the silicone prosthesis of the part of the man's face ingested by cancer. They used Autodesk’s 123D Catch photogrammetry app and a standard desktop 3D printer just like a student from Poland who has built a rehabilitation orthosis.

3D printed rehabilitation orthosisAxial3D is the revolutionary pre-surgery diagnostic scanning platform developed by two physicians from Belgium. It analyses the data received from CT and MRI scans of patients and creates a three-dimensional model that can be quickly 3D printed.

Another medical example is dentistry which already utilized the precision of desktop 3D printers like ZMorph which can print directly from DICOM medical files, Form 2 or Objet30 OrthoDesk. The technology is slowly replacing traditional methods of casts and impressions for teeth prosthetics as well as introduces printing with specialized fillers like dental SG resin or NextDent Base that can revolutionize classical dental practices in just a few years.

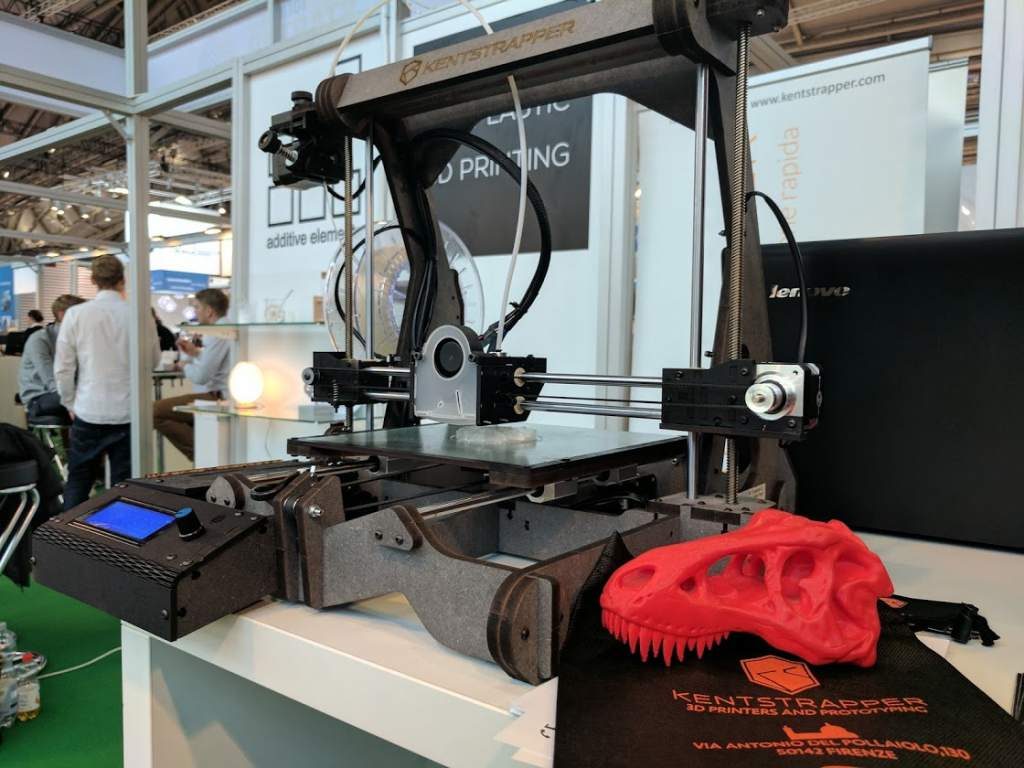

Skull model in Voxelizer softwareAutomotive Industry

Have you ever dreamed that someday you’ll be able to make not only car parts but the whole car using a 3D printer? Well, the creators of STRATI just have translated these dreams into reality and it symbolically took place in Detroit!

Source: Local MotorsThe world's first printed car was described by Local Motors CEO as "a small electric two-seater". Its actual significance for the car industry lies in the extreme low-cost technology and fully recyclable materials used such as carbon-fiber-reinforced plastic. The whole structure takes only 44 hours to print and leaves no waste products. Of course, the engineers didn’t yet move the stuffing of the car to plastic so the electric components such as motor, battery, and powertrain were not printed.

Its actual significance for the car industry lies in the extreme low-cost technology and fully recyclable materials used such as carbon-fiber-reinforced plastic. The whole structure takes only 44 hours to print and leaves no waste products. Of course, the engineers didn’t yet move the stuffing of the car to plastic so the electric components such as motor, battery, and powertrain were not printed.

Companies like Ford, Volvo, and BMW really uses 3D printing for rapid prototyping, experimental parts, and creating jigs and fixtures for manufacturing. Mercedes-Benz which is currently pioneering this niche among other truck producers, and makes more than 100 000 printed prototypes each year. They also provide their clients with unique spare parts even if their cars are no longer produced. The parts available online include high-quality plastic covers, spacers, spring caps, air and cable ducts, clamps, mountings and control elements.

Source: Mercedes-BenzFood Industry

Chefs and restaurateurs are just fans of such novelties like Foodini. This compact machine can create a fresh and healthy dish in the fastest and most incredible way. Foodini is an innovation that could be used just like a microwave in the next five years. Natural Machines engineers provided it with an open capsule model that makes this appliance even more convenient and multipurpose than competitors' devices.

This compact machine can create a fresh and healthy dish in the fastest and most incredible way. Foodini is an innovation that could be used just like a microwave in the next five years. Natural Machines engineers provided it with an open capsule model that makes this appliance even more convenient and multipurpose than competitors' devices.

Veterans of food industry appear to be NASA scientists, who have been exploring additive manufacturing of food for years. One of the developers of NASA 3D food program, Anjan Contractor, today uses the earlier developments to print fresh pizza with a BeeHex desktop robot. Even more traditional desktop 3D printers like ZMorph can be equipped with a thick paste extruder able to 3D print with various foods.

Food 3D printed with ZMorph's Thick Paste extruderMusic Industry

Musicians around the world suddenly really uses 3D printing as a cheap way to get high-quality original instruments. Among the most extraordinary, we should point out a metal saxophone printed by enthusiast Olaf Diegel after his previous experiments with Duraform nylon guitar and drum set. The new instrument was printed using ITRI's Optical Engine technology and a titanium alloy powder. The basis of this technology is individual hardness variability of various sections of a solid alloy, as well as high precision printing (up to 50 μm).

The new instrument was printed using ITRI's Optical Engine technology and a titanium alloy powder. The basis of this technology is individual hardness variability of various sections of a solid alloy, as well as high precision printing (up to 50 μm).

Next musician literally stands on the brink of the future of electronic MIDI instruments. Onyx Ashanti is not only a virtuoso in his custom controllers for hands and feet Beatjazz and Exo-Foot respectively but also makes them from scratch using the desktop version of RepRap 3D printer and nylon filament and EcoFlex PLA from Formfutura.

Source: 3D Printing IndustryArtists

Instead of listing a bunch of 3D printed drums, violins, cellos, guitars, and even restored vinyl records along with playing music servomotors, let’s check other applications of 3D printing in a wider array of arts. Mark Wilson’ latest work borders with a creation of a new life. The Chromatose is not only a masterpiece but also a responsive living synthetic organism! Such novelties as varying color and rigidity as well as the resolution of just 16 micron (!) became possible due to the latest 3D printing technology innovations.

Mark Wilson’ latest work borders with a creation of a new life. The Chromatose is not only a masterpiece but also a responsive living synthetic organism! Such novelties as varying color and rigidity as well as the resolution of just 16 micron (!) became possible due to the latest 3D printing technology innovations.

A legend of modern abstract sculpture, Bruce Beasley, used Autodesk to create and then print his latest Coriolis series, which was printed with a large state-of-the-art industrial 3D printer using liquid plastic.

Source: Bruce BeasleyInterior designers are on the rise of using 3D printing in creating the decorative patterns. Like the elegant and stylish decorative tile made by Michail Georgiou and his students using ZMorph multitool 3D printer.

One of the 3D printed patterned landscapesSo, who really uses 3D printing and why?

Our list of who really uses 3D printing clearly shows that the technology has long passed the innovation stage. Professionals, both from large and small companies, artists, scientists, designers, engineers, and architects, choose this technology not only to try something new and different. They choose it because of less expensive non-waste production, simplified manufacturing processes, the possibility of using recyclable materials, simplicity and mobility, environmental friendliness, and unlimited shapes and sizes of products.

Professionals, both from large and small companies, artists, scientists, designers, engineers, and architects, choose this technology not only to try something new and different. They choose it because of less expensive non-waste production, simplified manufacturing processes, the possibility of using recyclable materials, simplicity and mobility, environmental friendliness, and unlimited shapes and sizes of products.

3D printing became a tool that enables creating things that were previously unimaginable. became a tool that enables creating things that were previously unimaginable.

Expand Your Manufacturing Knowledge

ZMorph Materials Library is a comprehensive guide to all materials compatible with Zmorph VX and Fab All-in-One 3D Printers. This resource will give you an extensive outlook on a wide range of additive and subtractive fabrication materials supported by the machine.

Discover endless manufacturing possibilities with materials divided into three categories: 3D printing, CNC milling, and laser cutting and engraving.

instruction how to work from scratch for beginners and dummies, how

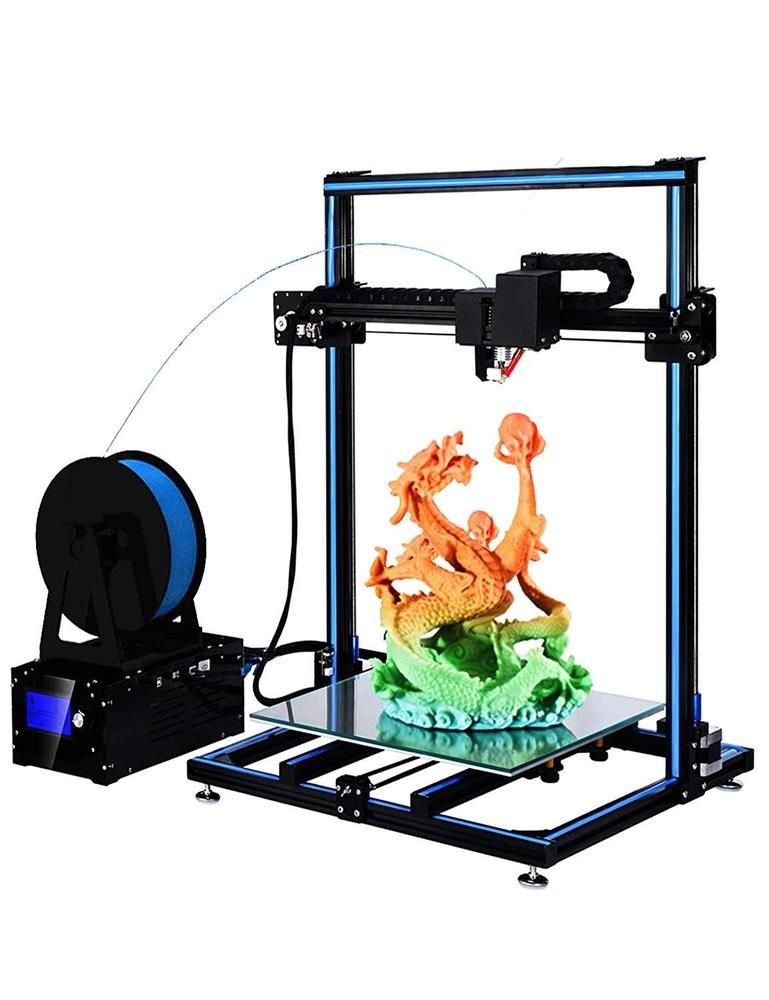

looks likeThree-dimensional printing has become increasingly introduced into our daily lives. Thanks to new technologies, it has become possible to easily print from a small detail to a large building. The range of products is also pleasing - today you can find a lineup that includes both affordable devices and more expensive ones. But how to work with a 3D printer? This is a completely normal question that any beginner will have, it is for this reason that we will try to answer it as simply and accessible as possible.

What is a 3D printer and how does it work?

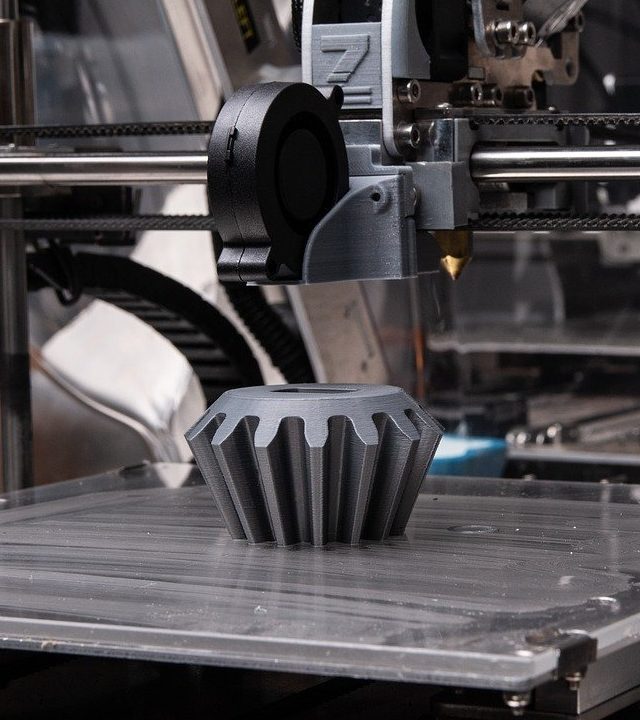

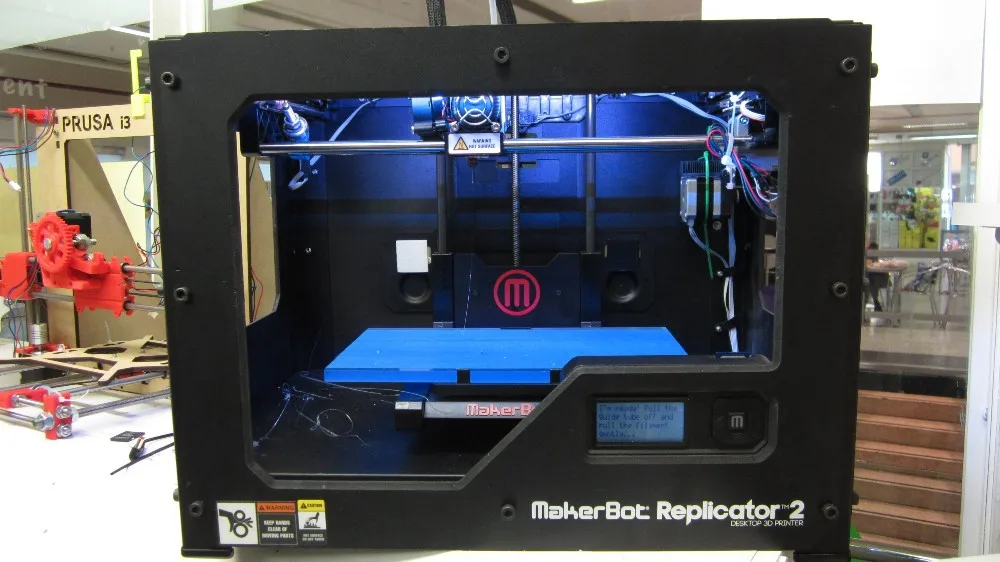

The 3D device consists of the printer itself and a computer that controls all processes. The principle of operation of such a design is to create 3D models by superimposing layers of liquid material. There are a large number of printer models - from large industrial ones to compact ones, but they all have the same principle of operation and component parts:

- Extruder - the print head through which the thread passes.

The head heats the thread to a semi-liquid state and evenly supplies the material to the working surface.

The head heats the thread to a semi-liquid state and evenly supplies the material to the working surface. - Work surface - a printing platform on which a 3D model is formed.

- Motors - mechanisms responsible for the accuracy of movement and speed of printing.

- Sensors are electronic devices that limit moving parts to specified coordinates.

- The frame is the structure that connects all parts of the printer.

How a 3D printer works: features

Work with the aim of building a three-dimensional model begins with a sketch, which is created in a special program. After that, the software independently generates a plan for the movement of the print head and a print sequence. The 3D model is reproduced by strongly heating the plastic and distributing it evenly.

3D printers are used in many areas. Let's list some of them:

- Architecture - creation of models of buildings.

- Medicine - dental prosthetics, making models of organs for study.

- Construction - production of houses using 3D printing technology.

- Education - a visual aid for learning 3D printing.

- Automotive - creation of tuning parts, prototype layouts and other products.

This is a small list of industries where 3D printing is actively used. Today, almost every entrepreneur and just an enthusiastic person can afford a printer.

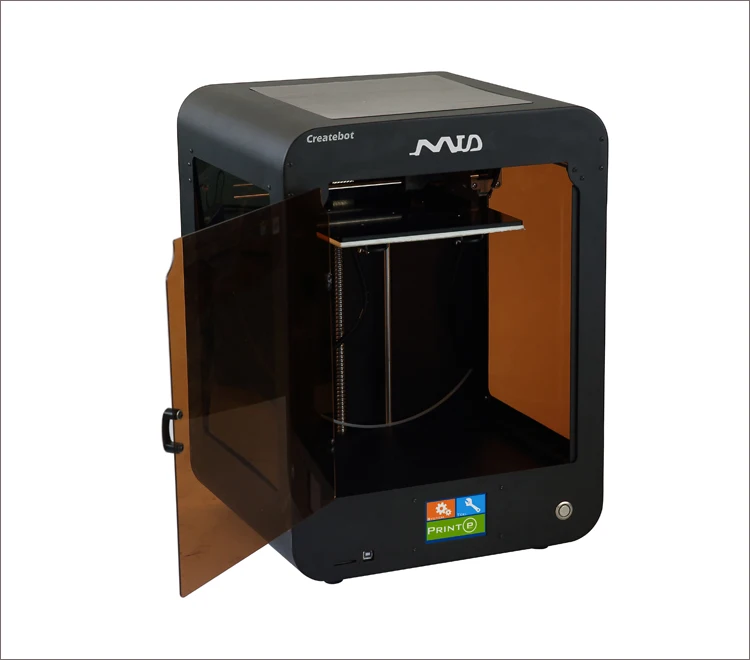

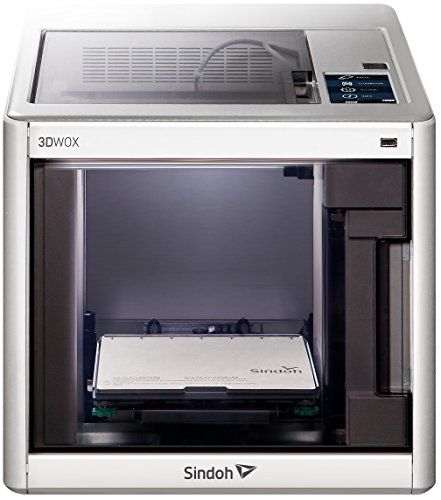

The following printers are distinguished by design features:

- RepRap - self-reproducing printers that can create their own copies.

- DIY-kit - the device comes disassembled with instructions, the assembly of which will take a sufficient amount of time.

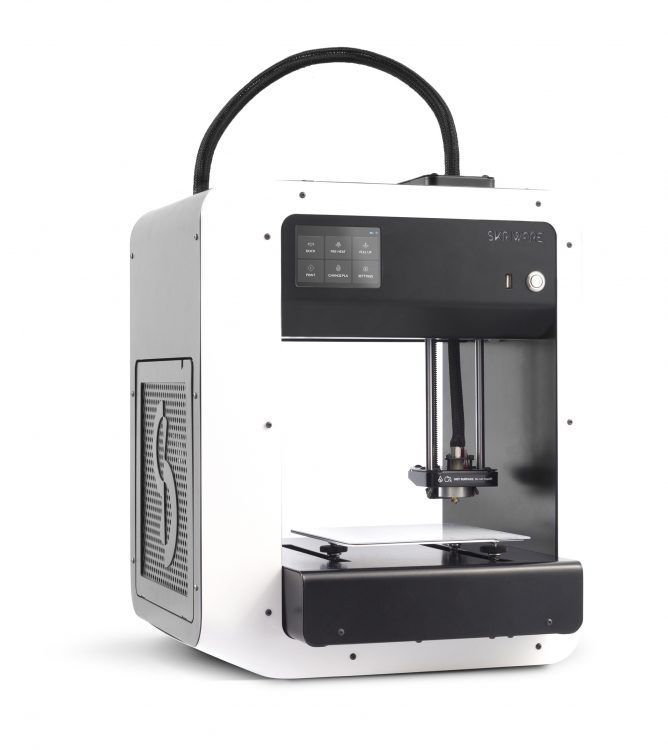

- Completed - Models are delivered assembled and ready to use.

- Commercial and Industrial - devices capable of printing metal, concrete, polymers and other materials.

How to use a 3D printer: tips for beginners, where to start

Mastering the technique of 3D printing is not difficult if you follow the recommendations and tips. Especially for those who plan to learn the basics of 3D modeling, an up-to-date list of questions and detailed answers to them has been prepared.

Especially for those who plan to learn the basics of 3D modeling, an up-to-date list of questions and detailed answers to them has been prepared.

Printer Installation

To begin, you will need to carefully unpack the box and remove any stops. The next step is to install the printer on the surface using the building level. This will allow you to place the device as evenly as possible, which will provide better printing.

Note. Some 3D printers come with a level for installation.

Next, you will need to connect the printer to your computer and install the necessary drivers. The software disc comes with the 3D device.

Preparation for work

To get started, you need to calibrate the working surface - without this, printing quality products is impossible. This process is carried out automatically or manually. The attached instructions have detailed information on how to perform manual calibration.

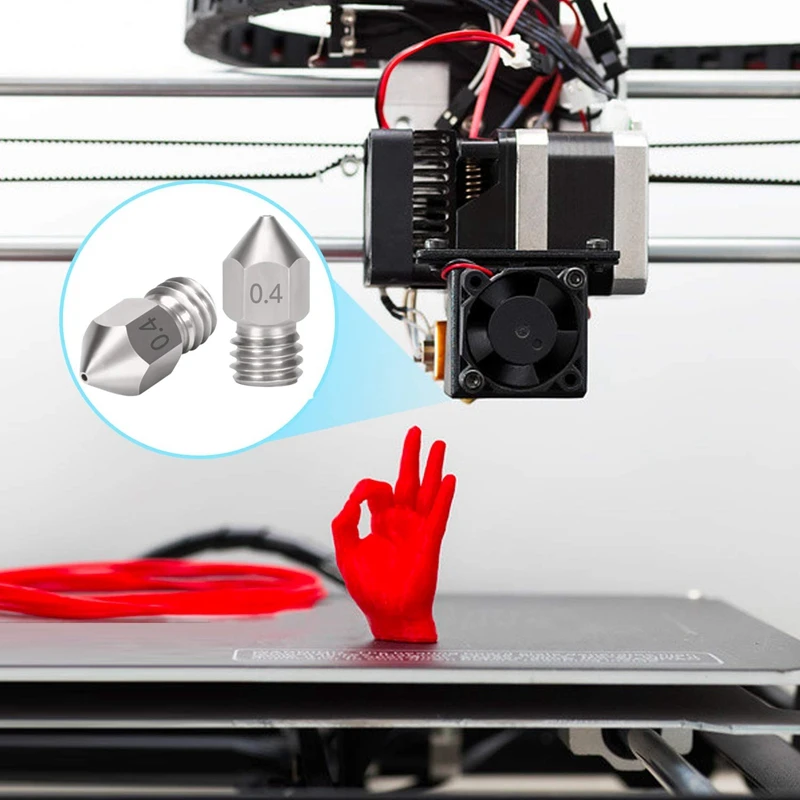

Extruder patency test

The next important step is setting up the extruder. First of all, you will need to check its nozzle. If the printer has already been used, the nozzle should be cleaned of solidified particles that will interfere with the throughput of the material. Refueling the 3D printer The thread is fed into the extruder directly from the spool. But there is one caveat - for this you must first warm it up. To thread the thread, you will have to make a small effort in order to loosen the presser mechanism.

First of all, you will need to check its nozzle. If the printer has already been used, the nozzle should be cleaned of solidified particles that will interfere with the throughput of the material. Refueling the 3D printer The thread is fed into the extruder directly from the spool. But there is one caveat - for this you must first warm it up. To thread the thread, you will have to make a small effort in order to loosen the presser mechanism.

Working with models

Models can be created using a variety of 3D modeling programs. The process of manufacturing three-dimensional parts is creative, requiring careful preparation. The better and more detailed the model is drawn, the better the 3D layout will be at the output.

Start printing

After creating the model in the program and preparing the printer for work, you need to send the file for printing and wait for the result. The print speed varies depending on the printer model and specifications, as well as the media used.

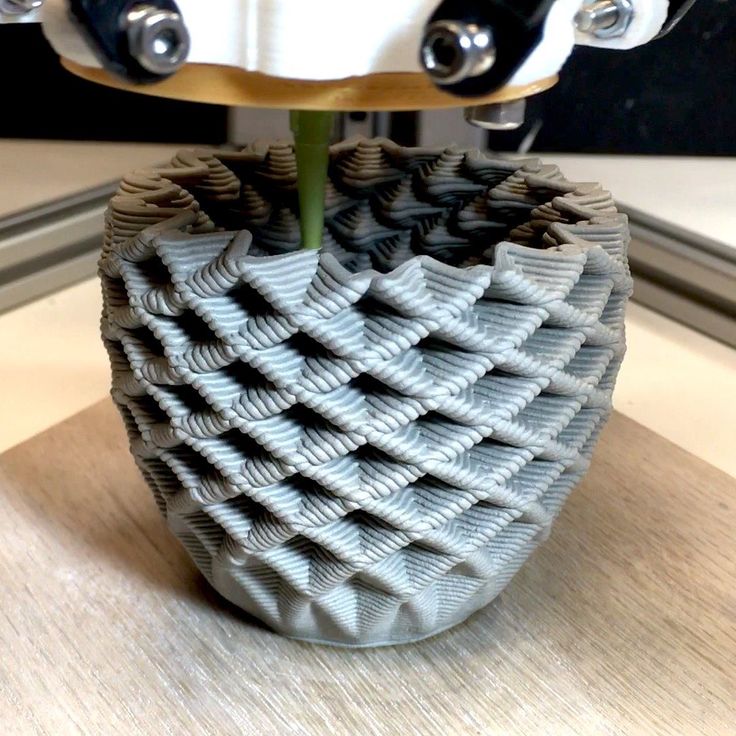

Processing the finished product

3D printed products usually do not please the user with an ideal appearance: the parts have an uneven surface. But this is typical for models of 3D printers on FDM, SLA and DLP devices, which are distinguished by higher print quality. Owners of FDM printers should not despair - a simple processing of products will give products an attractive appearance and make the surface smooth.

Several powerful ways to post-process 3D printed parts:

- Mechanical - carried out by sanding the surface with sandpaper or a special sponge for grinding.

- Chemical - Surface treatment with aggressive solvents such as acetone and dichloroethane.

- Mixed - In this case, the above two processing methods are used.

What are the possible errors and how to avoid them?

Even a novice can master the technology of 3D printing, but, despite this, the production of the first products causes excitement for the user. Simple operation, detailed instructions and recommendations on the Internet will allow everyone to deal with almost any printer model. But there are a few useful life hacks, the knowledge of which will help you avoid typical beginner mistakes:

Simple operation, detailed instructions and recommendations on the Internet will allow everyone to deal with almost any printer model. But there are a few useful life hacks, the knowledge of which will help you avoid typical beginner mistakes:

- Calibrate and test the 3D printer before starting work.

- Be sure to use the correct file extension for quality printing.

- Do not remove the finished product from the printer immediately after it has been processed: this may damage the part and cause defects.

- If errors occur during the 3D printing process, try restarting the device - this usually helps.

- If restarting the printer still does not help, try changing the settings or re-entering the model.

- When assembling the 3D printing devices, follow the enclosed instructions carefully.

- Use only the correct materials for your 3D printer.

- Subscribe to useful 3D printing channels and articles.

Following the above tips will allow you to set up your 3D printer, get it ready for operation and, most importantly, print your first 3D products. Choose a model according to your budget and capabilities, and it will not be difficult to master the basics of 3D modeling and get the first details if you follow the instructions and recommendations.

Choose a model according to your budget and capabilities, and it will not be difficult to master the basics of 3D modeling and get the first details if you follow the instructions and recommendations.

- March 21, 2021

- 5919

Get expert advice

How a 3D printer works, what can be printed on a 3D printer

The 3D printer is a technology that allows you to create real objects from a digital model. It all started in the 80s under the name "rapid prototyping", which was the goal of the technology: to create a prototype faster and cheaper. A lot has changed since then, and today 3D printers allow you to create anything you can imagine.

Contents:

- What is 3D printing?

- How does a 3D printer work?

- What can be printed?

The 3D printer allows you to create objects that are almost identical to their virtual models. That is why the scope of these technologies is so wide.

That is why the scope of these technologies is so wide.

What is 3D printing?

3D printing is an additive manufacturing process because, unlike traditional subtractive manufacturing, 3D printing does not remove material, but adds it, layer by layer - that is, it builds or grows.

- In the first step of printing, the data from the drawing or 3D model is read by the printer.

- Next is the sequential overlay of layers.

- These layers, consisting of sheet material, liquid or powder, are combined with each other, turning into the final form.

With a limited number of parts, 3D printing will be faster and cheaper. The world of 3D printing does not stand still and therefore there are more and more different technologies competing with each other on the market. The difference lies in the printing process itself. Some technologies create layers by softening or melting the material, then they provide layer-by-layer application of this same material. Other technologies involve the use of liquid materials, which acquire a solid form in the process under the influence of various factors.

Other technologies involve the use of liquid materials, which acquire a solid form in the process under the influence of various factors.

In order to print something , you first need a 3D model of the object, which you can create in a 3D modeling program (CAD - Computer Aided Design), or use a 3D scanner to scan the object you want print. There are also easier options, such as looking for models on the internet that have been created and made available to other people.

Once your design is ready, all you need to do is import it into the Slicer, a program that adapts the model into codes and instructions for a 3D printer, most of the programs are open source and free. The slicer will convert your project into a gcode file ready to be printed as a physical object. Simply save the file to the included SD card and insert it into your 3D printer and hit print.

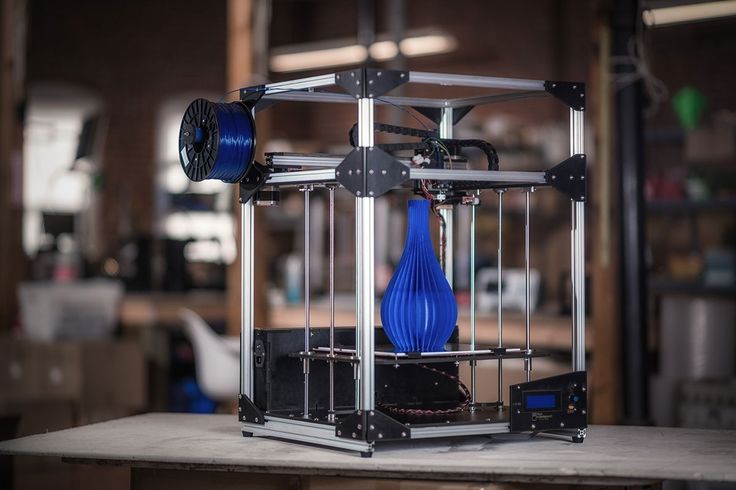

The whole process can take several hours and sometimes several days. It all depends on the size, material and complexity of the model. Some 3D printers use two different materials. One of them is part of the model itself, the other acts as a prop that supports parts of the model hanging in the air. The second material is subsequently removed.

It all depends on the size, material and complexity of the model. Some 3D printers use two different materials. One of them is part of the model itself, the other acts as a prop that supports parts of the model hanging in the air. The second material is subsequently removed.

How does a 3D printer work?

Although there are several 3D printing technologies, most create an object by building up many successive thin layers of material. Typically desktop 3D printers use plastic filaments (1) which are fed into the printer by the feeder (2) . The filament melts into the print head (3) which extrudes the material onto the platform (4) creating the object layer by layer. Once the printer starts printing, all you have to do is wait - it's easy.

Of course, when you become an advanced user, playing with the settings and tweaking your printer can lead to even better results.

What can be 3D printed?

The possibilities of 3D printers are endless and they are now becoming a common tool in fields such as engineering, industrial design, manufacturing and architecture.