Filter for 3d printer

Building an Air Filtration System for a 3D Printer

How I used a microcontroller, a fan, and a bunch of sensors to create a smart filtration system.

Posted on January 6, 2021 by Mike Buss

I was thinking of projects to work on, and I thought, gee, it would be nice if our 3D printer didn’t kill us.

I had researched the potential health side effects of owning a 3D printer when I bought it - it turns out they can malfunction and catch fire or release harmful chemicals into the air - but I made excuses. I’m only printing in Polyactic Acid (PLA), one of the least harmful filaments - it’s probably fine. Sure, maybe it releases some tiny plastic into the air, but it’s a big room, and sometimes I keep the windows open. Our smoke detectors are brand new and well tested. We’re probably fine.

Now that we welcomed Theodore, our now 3-month-old, into the world, I wanted to be on the safe side. So, I set out to build an air filtration system and some other safety features.

The Start of an Idea

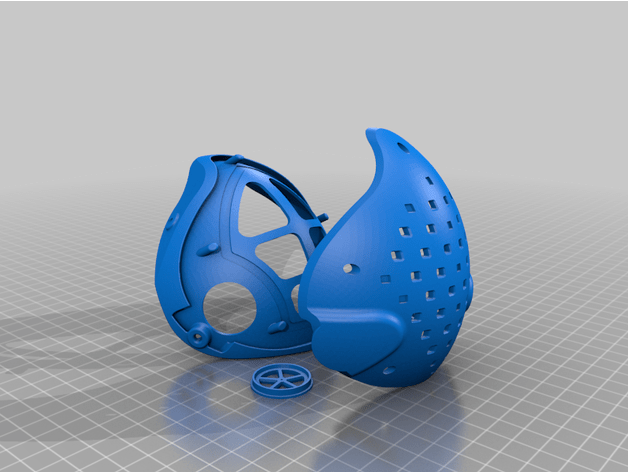

As with most of my hobby projects, it started out simple. I thought of strapping a fan to a HEPA filter and maybe adding a carbon filter for extra protection. Then I thought: wouldn’t it be cool if it turned on and off automatically when a print started? Surely that wouldn’t be too difficult to build.

And wouldn’t it be even better if the system could tell when the volatile organic compounds (VOC) levels were high and adjust the fan speed accordingly? Since the goal is to make this box less likely to kill everyone in our sleep, why not add a fire sensor and an electric cutoff?

The fan I started with: a 140mm NZXT fan for PC's.Eventually, I landed on building a totally ridiculous, completely overkill air filtration system for our 3D printer that probably wasn’t necessary in the first place. And it was lots of fun.

Here’s how I did it.

Sketching It Out

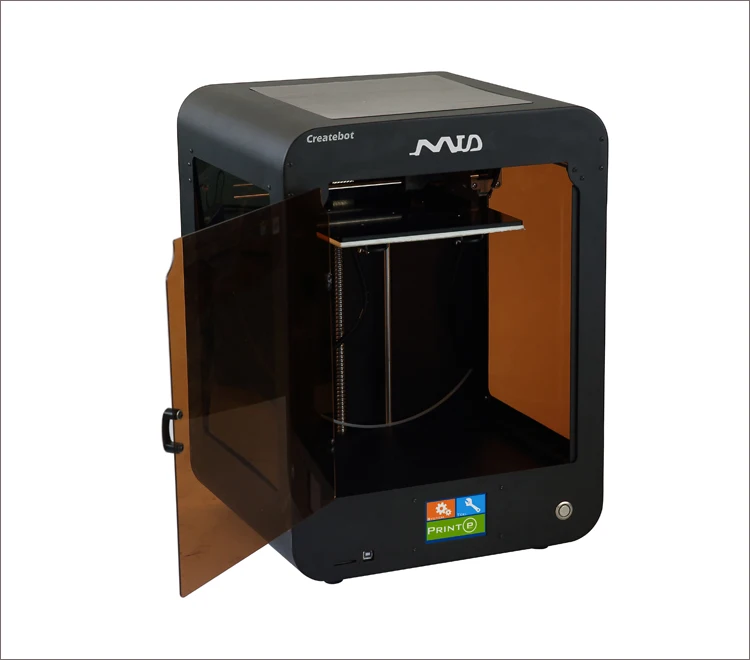

I’m a firm believer in “measure twice, cut once”, so I started with a sketch of the system. I measured my 3D printer - an Ultimaker S3 - and jotted down a plan for the top enclosure. Then, I sketched out what components I wanted to use and how they’d connect.

I measured my 3D printer - an Ultimaker S3 - and jotted down a plan for the top enclosure. Then, I sketched out what components I wanted to use and how they’d connect.

Next, I printed the parts I needed to assemble the box and the filtration panel. Isn’t it cool how a printer can print things to augment itself? Next step: Skynet.

Everything except the electronics and Lexan was printed.Building the Partial Enclosure

I bought some Lexan from Home Depot, scored the sheets with a box cutter, and snapped them off using the edge of my workbench. It worked surprisingly well.

If you plan to do this at home, wear protective gear, including glasses.

I used Lexan because it was readily available at the local Home Depot.After cutting the Lexan, I connected all the pieces with 3D-printed parts. Special thanks to Hans Peter for building something similar and releasing the designs on Thingiverse.

Now that I had the shell, it was time for the guts: the electronics.

Wiring Everything Up

The first rule of wiring electronics is don’t accidentally put 12V into a pin that expects 5V. You’ll get lots of smoke and heat and generally feel bad. After you’ve learned that rule, continue reading.

No electronics project would be complete without a prototype that looks like a rat's nest (top right). I cleaned this up later!I managed to assemble a gaggle of electronics that all needed power. Some needed 12V to work. Others needed 3.3V. Some were controlled with pulse width modulation, others with I2C. Getting them powered and conducting a symphony of functions was, in my opinion, the best part of this project.

I started with a 12V 3A power supply. This, wired into my Arduino Nano 33 IoT, a relay, and (via the relay) the fan, gave life to the essential components. I could now turn the fan on and off through the Arduino, but only at full speed.

I could now turn the fan on and off through the Arduino, but only at full speed.

To control the fan’s speed, I connected its PWM pin to a PWM pin on the Arduino. It took some math to change the Arduino’s built-in PWM frequency to 25 kHz, but the slower fan speed significantly reduced noise.

Now that the Arduino could control the fan, I wanted to have it start and stop automatically. To do this, I used the built-in WiFi module poll the Ultimaker S3’s API periodically.

The Ultimaker S3 comes with an excellent API.Then, because everyone loves data, I added some logging to my creation. I equipped the inside and outside of the chamber with sensors that measure temperature, humidity, and VOC levels. This data is sent over WiFi to a server running on my NAS (a Synology DS918+). Eventually, I’d like to use this data in real-time to control the fan speed, but for now, it’s just filed away along with information on what was printed and when.

Adding two temperature sensors was a little tricky, considering they share the same hardcoded I2C address. Because of this, the Arduino can’t address them individually. My solution was to use an I2C multiplexer to let me switch between sensors and query them individually.

While all of this is happening, the Arduino is also checking a flame sensor that hovers over the printer. If this sensor detects a fire, the power to the Ultimaker is immediately shut off, and a piezo alarm starts blaring. It’s not as cool as those automatic fire suppression kits you can buy, but the alarm can be heard throughout the house.

The flame sensor (left) will report if it detects a fire in the print chamber. This photo was taken when I was still breadboarding the prototype.Filtration

The fan pulls air out of the chamber, through a HEPA filter and a carbon filter, and then out the back. You can find all the parts I used here.

You can find all the parts I used here.

Future Improvements

The fan I have probably isn’t pushing as much air as I’d like through the two filters. I’d like to upgrade it to something better in the future.

All said and done, this project was fun to build and gives my wife and me some peace of mind. If you’ve created something similar, I would love to hear about it!

Share:

Welcoming Our First

Today, my wife and I welcomed Theodore Frederick Buss into the world!

Fixing the Worst USB Hub in the World

Hewlett Packard makes the world's worst USB hub. No, really. It's truly awful.

Mike Buss is a software engineer from Ohio who works primarily in the healthcare space. His work has been featured on Apple.com and helped hundreds of thousands of patients. In his spare time, he writes about software development and more.

Follow @michaeltbuss on Twitter as he continues to document his software development journey.

Why you won’t find a HEPA filter hanging on the back of our enclosures – Printed Solid

First we should talk about 3D printer enclosure designs and why you may want one. Enclosures serve three main purposes. 1) It helps keep heat in and prevent drafts over your build volume. 2) It keeps pets and hands away from hot ends and beds and pinch points. 3) It can help control VOC’s (volatile organic compounds)

- Keeping the heat in is what most people think of when they think of enclosing a 3D printer. This can be a factor to some degree but too much heat is also a problem for a lot of materials and printers. There are lots of designs for 3D printers which try to completely seal in a printer and insulate it and people try to add heating elements to make it even hotter inside. If you look at your printer it most likely have some or even a lot of plastic parts to it. Even if you have an all metal printer you might still have plastic fans, wire components, belts and so forth.

Plastic gets weaker as it gets warmer, long before it gets to the melting point. So if your printer has any mechanical or structural components in it made of plastic then they can wear out or fail if it gets too warm inside a completely sealed enclosure. So heat is a friend and an enemy at the same time. Another problem with too much heat is that most extruders have a passive fan cooling the heat sync part. So if that gets too warm then you face heat creep and your extruder jams. So our enclosures have intentional openings on them to allow excess heat to escape while still preventing drafts over the build plate. It’s a delicate balance of retaining heat and releasing heat. A great example is a competitor out there completely seals up a Ultimaker printer top completely. Then as a user prints higher temp materials for a long time the plastic clips on the gantry soften and then entire XY axis drops out of the printer. Causing damage that if you weren’t watching it would be extremely expensive to repair.

Plastic gets weaker as it gets warmer, long before it gets to the melting point. So if your printer has any mechanical or structural components in it made of plastic then they can wear out or fail if it gets too warm inside a completely sealed enclosure. So heat is a friend and an enemy at the same time. Another problem with too much heat is that most extruders have a passive fan cooling the heat sync part. So if that gets too warm then you face heat creep and your extruder jams. So our enclosures have intentional openings on them to allow excess heat to escape while still preventing drafts over the build plate. It’s a delicate balance of retaining heat and releasing heat. A great example is a competitor out there completely seals up a Ultimaker printer top completely. Then as a user prints higher temp materials for a long time the plastic clips on the gantry soften and then entire XY axis drops out of the printer. Causing damage that if you weren’t watching it would be extremely expensive to repair. We have seen Prusa printers completely melt inside a hot box and even Raise3D recommends removing their hood while printing PLA so you don’t get heat creep on your extruder and it jams. So a little heat is ok but a lot is bad.

We have seen Prusa printers completely melt inside a hot box and even Raise3D recommends removing their hood while printing PLA so you don’t get heat creep on your extruder and it jams. So a little heat is ok but a lot is bad. - Keeping pets and little fingers out of the printer. It’s a minor concern but one to think about none the less. Your cat will like the warmth of the heated bed and may even think it’s a moving toy to swipe at. With the hot parts and moving parts it could hurt your curious pets if they go snooping around. The same is true for kids. However with kids it has an additional factor. At home or in school people will bring kids right up to the machine so they can see the magic of 3D printing. As close range a tiny hand sticks out at touches the hot end and now you have a crying child to deal with.

- Volatile Organic Compounds. Even the words sound scary. There have been lots and lots of studies about it so we don’t have to go into the fine science of the issue.

One thing that is not mentioned and is commonly misunderstood is VOC’s and HEPA. So lets get some simple numbers out there. HEPA ratings matter but you would be surprised by how much they don’t matter. Confused? That is the way they want it. Basically a 99.97% HEPA filter will capture a .3 micrometer particle, also called a h24 class filter. At the low end you have a 85% HEPA filter which is 85% or E10 rating. At the extreme high end you get into ULPA filters up to 99.9999% or U17 rating. OK, I said I would keep it simple and I haven’t, so I’m sorry for that. Let me try again and simplify these numbers even more for you. Most HEPA filter options are from 85% to 99.97% and capture particles down to .3 micrometers. The closer to 99.97% you get then the fewer amount of those particles get through the filter. You will rarely find a higher filter rating above 99.97% that won’t cost less than a car and require almost monthly replacement but those filters get you down to .1 micrometer particle sizes.

One thing that is not mentioned and is commonly misunderstood is VOC’s and HEPA. So lets get some simple numbers out there. HEPA ratings matter but you would be surprised by how much they don’t matter. Confused? That is the way they want it. Basically a 99.97% HEPA filter will capture a .3 micrometer particle, also called a h24 class filter. At the low end you have a 85% HEPA filter which is 85% or E10 rating. At the extreme high end you get into ULPA filters up to 99.9999% or U17 rating. OK, I said I would keep it simple and I haven’t, so I’m sorry for that. Let me try again and simplify these numbers even more for you. Most HEPA filter options are from 85% to 99.97% and capture particles down to .3 micrometers. The closer to 99.97% you get then the fewer amount of those particles get through the filter. You will rarely find a higher filter rating above 99.97% that won’t cost less than a car and require almost monthly replacement but those filters get you down to .1 micrometer particle sizes.

A quick summary: Most HEPA filters capture around .3 micrometer particle sizes and the better quality ones let fewer .3 micrometer particles get through.

Now to quickly shorten up all of those research papers for you about VOC’s and 3D printing.

- The particle size of the emissions from a 3D printer are between .1 and .3 micrometers.

- The amount varies depending on what material you print with.

- Most HEPA only filters will only capture the largest of these particles.

- An open window or well ventilated room will drop the levels below safety standards.

What about those particles smaller than .3 micrometers?

Well you can get one of those filters that cost as much as a car every month or you can used activated carbon. Activated carbon comes in many flavors and some of the facts can be misleading but to simplify it I will keep the scope limited. Basically the size of the activated carbon matters, smaller the size of the carbon the better. Then the amount of activated carbon matters. More is better. Activated carbon works using adsorption. No that is not a misspelling, I said adsorption which is different than absorption. Basically activated Carbon holds those VOC’s to its surface. So the size of the activated carbon matters because the smaller it is then the more surface area it has and the more VOC’s it can trap. Then there is the amount. Small amounts trap less than large amounts. The worse activated carbon filters out there are the woven mat filters like you find on a fish tank filter. They weigh nothing and are usually a plastic or cloth mesh covered in a thin coat of activated carbon and you can see light pass right through it. So even if they captured every particle passing through them then it would fully adsorption all of the VOC’s in a week or two.

Then the amount of activated carbon matters. More is better. Activated carbon works using adsorption. No that is not a misspelling, I said adsorption which is different than absorption. Basically activated Carbon holds those VOC’s to its surface. So the size of the activated carbon matters because the smaller it is then the more surface area it has and the more VOC’s it can trap. Then there is the amount. Small amounts trap less than large amounts. The worse activated carbon filters out there are the woven mat filters like you find on a fish tank filter. They weigh nothing and are usually a plastic or cloth mesh covered in a thin coat of activated carbon and you can see light pass right through it. So even if they captured every particle passing through them then it would fully adsorption all of the VOC’s in a week or two.

Finally! Why we don’t put a small HEPA filter hanging off the back of our enclosures.

Those tiny fans with “HEPA” filters hanging off the back of some enclosures or printers do almost nothing and even less after a week of being on. It’s great marketing for sure and that is it. They barely move enough air to pull VOC’s through the filter. A total build volume of a printer is around 2 cubic feet. The recommended exchange rate at that size would 30 CFM after the filter. So those tiny filters that say 30 CFM fans are saying the fan moves 30 CFM but after the filter that number can drop to under 5 CFM. So not only do those small filter not capture enough particles, wear out in a week or two but they don’t even move enough air to actually move the particles through the filter to be captured.

It’s great marketing for sure and that is it. They barely move enough air to pull VOC’s through the filter. A total build volume of a printer is around 2 cubic feet. The recommended exchange rate at that size would 30 CFM after the filter. So those tiny filters that say 30 CFM fans are saying the fan moves 30 CFM but after the filter that number can drop to under 5 CFM. So not only do those small filter not capture enough particles, wear out in a week or two but they don’t even move enough air to actually move the particles through the filter to be captured.

Another issue is that a one way filter like those negate the entire purpose for an enclosure. The filaments with the highest particle emission’s like ABS, Polycarb, Nylon are the ones that need a warm enclosure. So if you are filtering air out of your printer then where is the new air coming from to fill the void? You’re not creating a vacuum so air is coming into the printer from somewhere. Cold air from outside the printer is being drawn into the printer and creating cold drafts across the print area and creating warping and de-lamination of your prints. Or worse those small filters are pulling cold air from gaps near the filter and not your print area and not capturing any particles, making you believe you are being safe and actually not filtering anything.

Or worse those small filters are pulling cold air from gaps near the filter and not your print area and not capturing any particles, making you believe you are being safe and actually not filtering anything.

This is why we teamed up with BOFA and their line of filters. With the Print Pro 3 you get a true 88 CFM after the filter rating and a 3 stage filter with a pre-filter to capture 5 micrometer particles, then a true 99.997% HEPA filter and over 4 lbs of activated carbon to capture the .3 micrometer particles and VOC’s instead of just an ounce or two on the other solutions. On top of that it also has a supply and return hose to get the heated air back into the chamber without creating cold drafts over your print area. Then to top it off it has a warning indicator to tell you when to replace the filter. We searched high and low and found the BOFA units to be the only solution out there in this price range. While the science is still out on how the VOC’s might affect users over long time exposure, we don’t want to offer a solution that is just a placebo. We wanted a solution that actually addressed the issue. Since most consumer’s don’t have a way to test for VOC’s and UFP’s to find out if a filter is actually working we want to make sure the ones we sell actually do it.

We wanted a solution that actually addressed the issue. Since most consumer’s don’t have a way to test for VOC’s and UFP’s to find out if a filter is actually working we want to make sure the ones we sell actually do it.

Need to clean plastic for 3D printer

Today we will talk about the need to clean plastic for printing. Sooner or later, everyone who prints a lot on a 3D printer faces this problem. Plastic can be different, it can be stored and delivered to you in different ways, but one day it will fall into your hands exactly that coil of plastic, from the farthest and dustiest end of your supplier’s warehouse, which will clog the nozzle of your 3D printer in a matter of minutes. But let's go in order.

When the plastic is clean, it passes through the extruder without problems, heating up and melting near the nozzle through which it is extruded. If the plastic is dusty, then, accordingly, all the dust will end up in the nozzle, where it will begin to accumulate, at first practically not affecting the print quality. But this is only at first ... After a while (depending on the degree of contamination of the plastic), there will be enough dirt in the nozzle to clog the outlet, which is rather small. Now all our problems begin, as high-quality printing stops at this moment. The plastic from the nozzle either stops flowing at all, or comes out intermittently and in the wrong volume. It is very problematic to notice this right away, since few people vigilantly control the printing process, but even in the opposite case, it is extremely difficult to detect underextrusion until the printer “runs” a couple of new layers with defects. And by this time the printed part will most likely be damaged and everything will have to be started all over again. As a result, we lose both time and plastic, but that's not all - now we are the owners of a clogged nozzle!

But this is only at first ... After a while (depending on the degree of contamination of the plastic), there will be enough dirt in the nozzle to clog the outlet, which is rather small. Now all our problems begin, as high-quality printing stops at this moment. The plastic from the nozzle either stops flowing at all, or comes out intermittently and in the wrong volume. It is very problematic to notice this right away, since few people vigilantly control the printing process, but even in the opposite case, it is extremely difficult to detect underextrusion until the printer “runs” a couple of new layers with defects. And by this time the printed part will most likely be damaged and everything will have to be started all over again. As a result, we lose both time and plastic, but that's not all - now we are the owners of a clogged nozzle!

What to do now? - clean the nozzle. There are many ways that we won't go into detail, suffice it to mention that any of them most likely involves dismantling the nozzle, heating it and physically removing all the contents of the nozzle (and old cooled plastic and dust). You can either burn out everything inside the nozzle with prolonged heating, or use a special plastic for cleaning, which is fed into the hot nozzle and all the dirt sticks to it. In any case, we are wasting time and nerves. Is it possible to protect yourself from this?

You can either burn out everything inside the nozzle with prolonged heating, or use a special plastic for cleaning, which is fed into the hot nozzle and all the dirt sticks to it. In any case, we are wasting time and nerves. Is it possible to protect yourself from this?

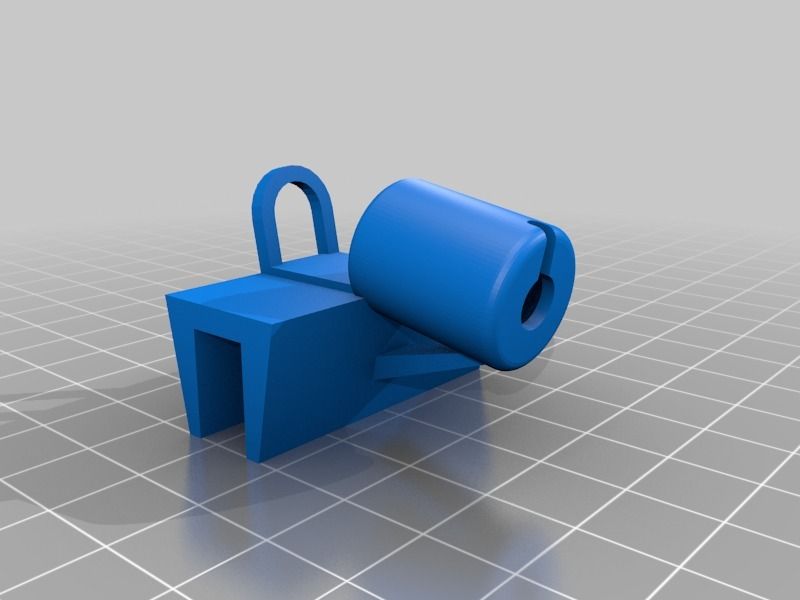

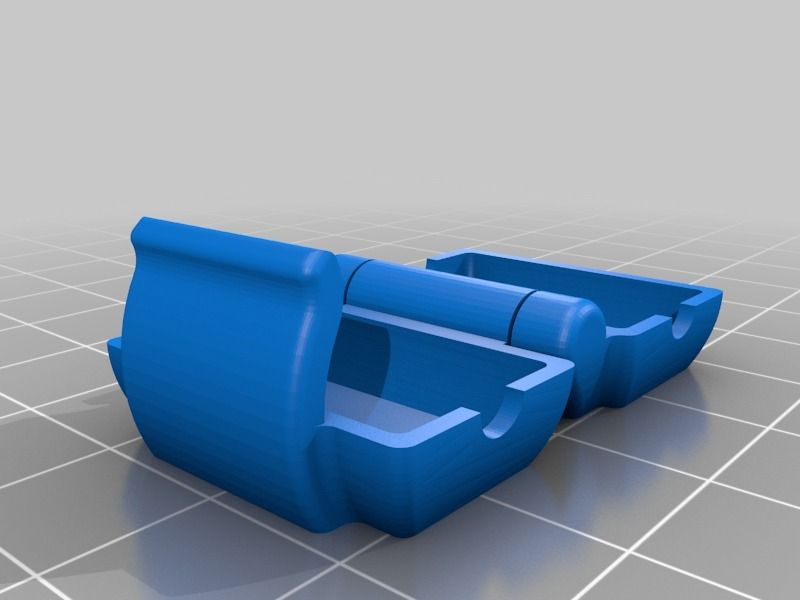

Filter for 3D printer

Open filter for 3D printer

Of course, and quite easily. A small filter will help us (see the picture to the left), which will clean all the plastic fed into the extruder. And you don’t have to invent anything, this filter can be printed on a 3D printer in half an hour, then insert a filter element (most often foam rubber) into it and put it on a plastic thread. That's all. The filter should be placed between the spool of plastic and the tube that feeds the plastic into the extruder. Now the plastic will first enter the filter, where the foam rubber will remove all the dust from its surface and then nothing will interfere with the printing process. You should not forget to periodically clean our filter, or at least check the amount of dust inside it, because you can do this without even removing the filter from the filament and without stopping printing (if you use the filter design from this article)!

For example, here is a photo of an open filter after five hours of printing with obviously dusty plastic:

Dirty 3D printer filter

we all already know.

We should also briefly dwell on the rules for storing plastic. In the ideal case, plastic from the very beginning (when it was wound on a coil at the factory) and until the moment the coil is fully used should be stored in a place inaccessible to sunlight and in an airtight bag. The package will protect your plastic not only from dust, but also from moisture, since in some types of plastic, when stored in a place with high humidity, microcracks form, from which the plastic becomes brittle. Sunlight is also detrimental to plastics, especially colored or phosphorescent ones.

You can download the 3D filter model here. And next time we will discuss the issue of heating and cooling parts during printing. It will be interesting!

Tsar3D company blog | Page 4 of 5

Posted on

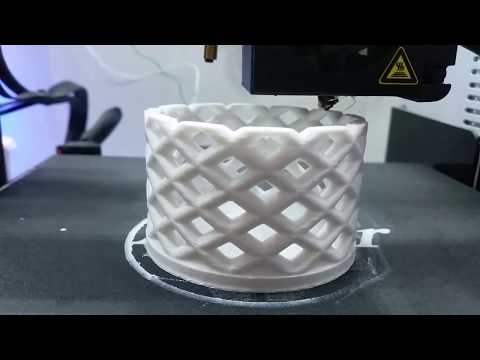

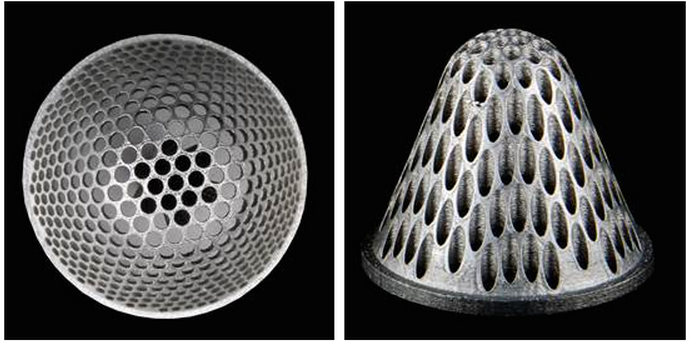

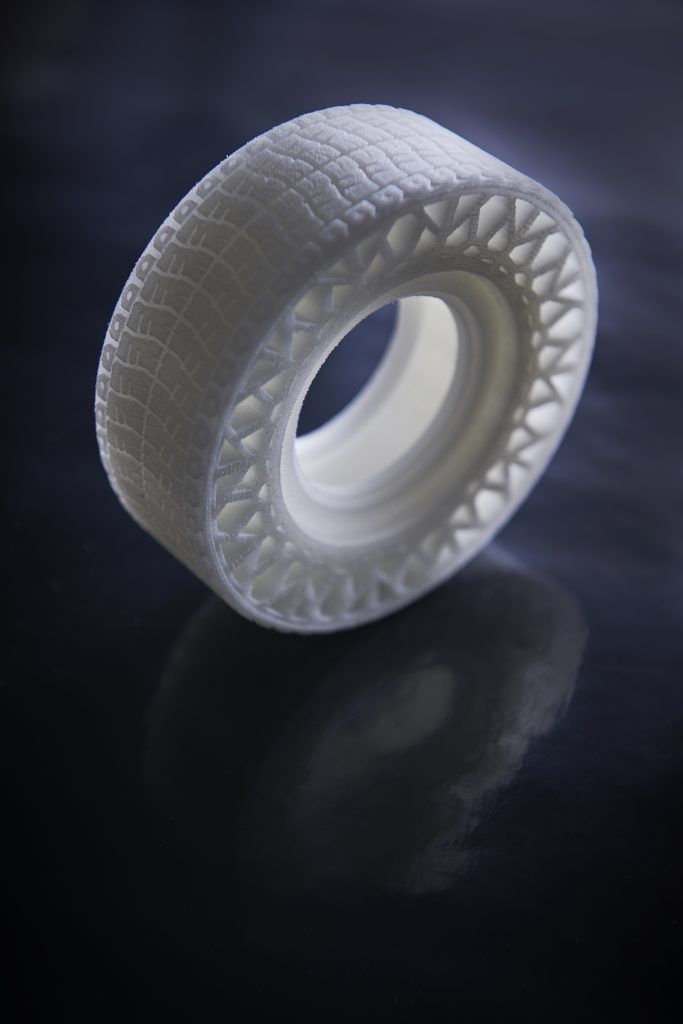

One of the most efficient applications of a 3D printer is the production of mesh filters. Also, these products include various calibration and sorting meshes with cells, a sieve, in the designs of various separators.

Also, these products include various calibration and sorting meshes with cells, a sieve, in the designs of various separators.

The advantages of 3D-printed filters include:

- Obtaining a filter with an arbitrary cell size

- Ability to print fasteners (for example, threads) directly on the filter

- Ability to create the desired mesh structure inside the volumetric filter

- Minimum terms production, no need for other equipment and manual labor

- Low cost allows you to create disposable filters

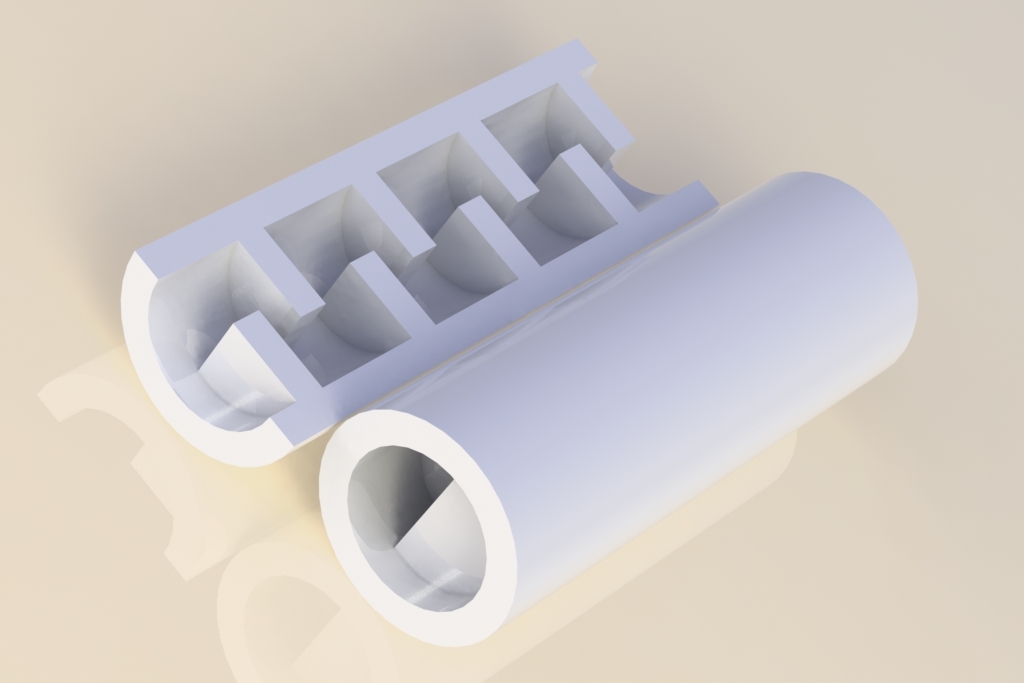

Printing housings for existing filters is the same highly efficient enterprise, simplifying the interfacing of different housings, structures and piping, which ultimately eliminates the need for expensive parts manufacturing by milling, welding or purchasing expensive components.

The photo shows a sample of the internal filling of products.

Published by

The creators of the German 3D printer, the company Kühling & Kühling, recently tested a part printed from ABS plastic, made to the dimensions of a chain link. The essence of the test was to hang a load weighing 800 kg through this link, with which the datal coped without any damage. It will probably support even more of that weight.

The essence of the test was to hang a load weighing 800 kg through this link, with which the datal coped without any damage. It will probably support even more of that weight.

This shows how durable the parts after 3D printing are, which allows them to be used in work and in industry as functional ones.

Published

Today we will talk about how 3D printing can be used on a specific example - the manufacture of metal parts by casting using 3D printed models.

The metal that we will use for products - IChKh12GZM - cast iron.

Briefly about the technology, which is called "casting into cold-hardening mixtures (CTS)". This technology is similar to the traditional one (metal casting in sand-clay molds), only artificial resins are used as a binder for sand mixtures. Purge of core boxes with various tertiary amines is used to cure resins.

Purge of core boxes with various tertiary amines is used to cure resins.

Casting technology in XTS ensures high quality of the casting surface, absence of gas defects and blockages in the casting

The process of manufacturing metal products by casting in XTS

First, we print models on a 3D printer - the main model and a printed detachable mold for making sand cores.

And go to the model area.

Models are placed on the slab and sprinkled with graphite to prevent sand mixture from sticking. Under-model plate with models:

A flask (metal box) is installed:

We fill in our mixture, lightly tamp.

Turn over and remove the model plate.

This is what we see after the coup. Sprinkle with graphite.

The second flask and gate run are installed, metal will be poured through it.

Fill the flask with our mixture.

Level and lightly tamp.

Along the way, we make rods from the same sand mixture. We use a two-part printed form for this.

They are needed in order to create holes in the future product. We will insert them into the mold before pouring.

In the meantime, 5-10 minutes have passed and we separate our 2 flasks and take out the models. Then a non-stick coating is applied to the inner surface.

So we got 2 flasks. Then the rods are inserted into these holes, the two halves are connected again and the metal is poured through the sprue.

The mold itself, after pouring the metal, is destroyed by temperature, but there is enough time for the metal to take shape. After that, the received models are freed from sand and it goes back to work.

This is what the product looks like after casting and rough machining:

As you can see, the casting process is not complicated. Receiving models with a 3D printer saves a lot of money and time, which leads to increased profits and increased opportunities for the foundry.

Receiving models with a 3D printer saves a lot of money and time, which leads to increased profits and increased opportunities for the foundry.

Our large 3D printer solves the problem of creating models without the use of skilled manual labor and expensive milling equipment.

Thanks to our colleague Anatoly for the photo and description of the process.

Published

On July 18 and 19, 2015, the VKontakte Festival was held in St. Petersburg.

This large-scale action captured the vast territory of the 300th Anniversary Park, located near the Gulf of Finland.

Visitors had an incredibly large number of active entertainment (more than 300), 2 huge stages, where a large number of famous artists performed.

We do not know the number of visitors, but there were at least 40 thousand people, there were several thousand participants and organizers alone.

The Tsar 3D project is located in the Innovation zone, next to virtual reality glasses, a virtual reality chair and a retailer of desktop 3D printers.

We were with the Axiomlab project. Unusual lamps printed on Tsar 3D equipment and specifically on the Tsar printer were presented.

In a simplified form, you can feel emotions from the festival on this video:

Link to the meeting of the VKontakte event: https://vk.com/fest

Published

According to our rough estimates, 95% of the population does not understand anything about the use of 3D printing, only a few have an idea about 2-3 printing technologies, and a very small percentage of people who are aware of the possibilities, nuances and efficiency of 3D printing. Therefore, we will continue to educate interested people, now in the format of blog posts.

If you approach the question fundamentally, then first you should find out what types of 3D printing are, what are their pros and cons, what is the price, etc., but most people are looking for specific numbers - the necessary investments, payback , costs, profits. We will give the numbers in the following articles, but for starters, I will discuss how you can generally make money on 3D printing.

First of all, I would like to note that 3D printing does not allow you to get finished products. The main application of 3D printing is the production of product prototypes. The vast majority of products nowadays are designed in a 3D environment, so before starting production, any manufacturing company has to get the first test products in physical form. But mass production is designed in such a way that single products will cost the company as much as several thousand products, so 3D printing comes to the rescue - for all its high cost, it turns out to be cheaper.

The second place in the applicability of 3D printing is the production of master models, that is, molds that are later used to obtain molds for, for example, cold casting of plastic or polyurethane. In jewelry, these are wax products, later burned out in a mold where the metal is poured.

In jewelry, these are wax products, later burned out in a mold where the metal is poured.

Thus, the main income from 3D printing is to provide printing services - their range and quality depend on the amount of equipment you purchased. The competition in this market is not very strong, but high prices make the technology available only to large customers, because. the most expensive industrial 3D printers are quite expensive and there are only a few of them in the country.

The best option is to create a business that uses 3D printing as a competitive advantage. That is, to use the main benefit of 3D printing - the creation of a complex shape without the participation of a highly qualified person and sophisticated equipment. As an example - casting souvenir soap or candles - a model is printed on a 3D printer, from which a silicone mold is removed, into which wax or soap is then poured. This form will be reusable and will allow you to receive hundreds of products. The main advantage is to quickly get a form made by any hired person anywhere in the world, or even downloaded for free.

The main advantage is to quickly get a form made by any hired person anywhere in the world, or even downloaded for free.

Our printer allows you to get large products without the use of complex manual labor and expensive equipment that requires a professional operator. Today, such devices are not available in Russia, so you have the advantage of starting a niche business right now.

As an example, a sculpture and a sink cast from concrete in a silicone mold.

We will write in more detail about working with the help of casting, the necessary conditions and means in the following articles.

Published

St. Petersburg hosted Geek Picnic, the largest popular science festival dedicated to modern technology, science and creativity.

We have been participating in this event for the 4th year in a row and have seen how it has grown from a small idea to gather outdoors into a giant festival. It has become a really exciting positive event where everyone can try a lot of entertainment and learn a lot of new things.

It has become a really exciting positive event where everyone can try a lot of entertainment and learn a lot of new things.

The festival occupies for 2 days the vast territory of the park on Elagin Island and is divided into several zones - science, art, technology. Interesting educational lectures are continuously held in several tents, and various activities for visitors and master classes are scattered everywhere. There is also a lot of food and just green lawns and sun.

We, the Tsar 3D company, brought a pre-production Tsar 3D printer and printed large letters of the name of the event. At the time of the event, this is the largest available FDM 3D printer in Russia and Europe. The printer has stood up to work in extreme conditions in the open air perfectly. Thanks to all the guests for interesting questions and photos.

Link to the event: https://vk.com/geekpicnic

comparison of the largest 3D printer and the usual ultimaker 2

The company published the post-processing process and examples in its new video:

Posted

A few years ago, when mentioning 3D printers, jokes about printing a car or a bumper were popular. But now it's reality!

The Oak Ridge National Laboratory (USA) was able to print an exact copy of the rare Shelby Cobra sports car. Representatives of the laboratory demonstrated their creation in Detroit at the International Auto Show 2015. The entire process of creating a car (from concept development to production) took only six weeks. This copy clearly showed the advantages and prospects of creating prototypes with the help of 3D printing.

The body parts were directly 3D printed and then standard alignment and paint work followed.

The machine is completely identical to the original Shelby Cobra. The car weighs 635 kg, and only a digital display mounted on the dashboard gives its “modernity”. And of course, more than 200 kg of parts produced from start to finish using 3D printing technology. Carbon fiber was used as a material for decorative elements, passenger compartment, frame and body elements.

Focusing on the success of our American colleagues, in the near future we will begin testing parts printed on the Tsar Printer, which in the future will allow us to design and print vehicles. But we will write about this later.

Published

Are you interested in cement printing? Our company is exploring the market for 3D printing with building mixtures and ceramics in Russia.

We have experience in several types of pumps for viscous mixtures, pastes and solutions that can be used for such 3D printing. This will make 3D concrete printing available in the Russian Federation.

What is it for? To create small architectural forms and interior elements, buildings and unique design solutions.

Contact us and we will solve your problem.

Very interesting video of printing with cement from the American Andrey Rudenko:

.

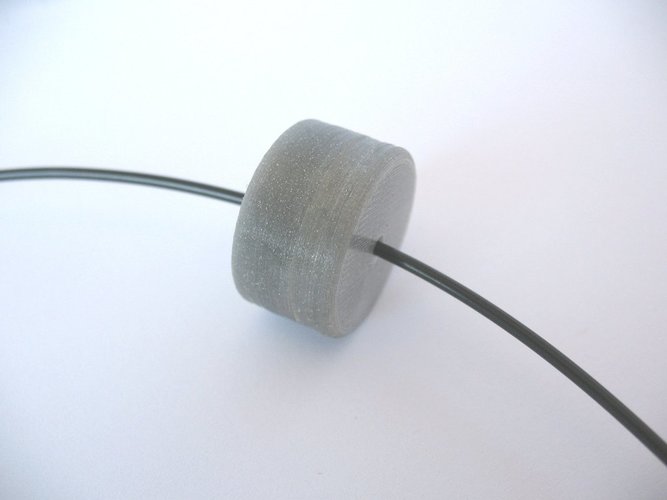

In the first week of 2015, we finally managed to do the first tests of the new extruder on the printer.

The result is a cylindrical part with an external diameter of 60 mm. Weight 40 grams. It turned out to be a very durable product that cannot be broken by anything, even with a hammer!

We don't publish the parameters of the extruder yet, but this part is printed with a nozzle with a diameter of 5 mm from ABS plastic.