Who is buying 3d printers

Who buys consumer-level 3D printers?

Who buys consumer-level 3D printers? | IDTechEx Research ArticleMärz 09, 2015 Dr Jonathan Harrop

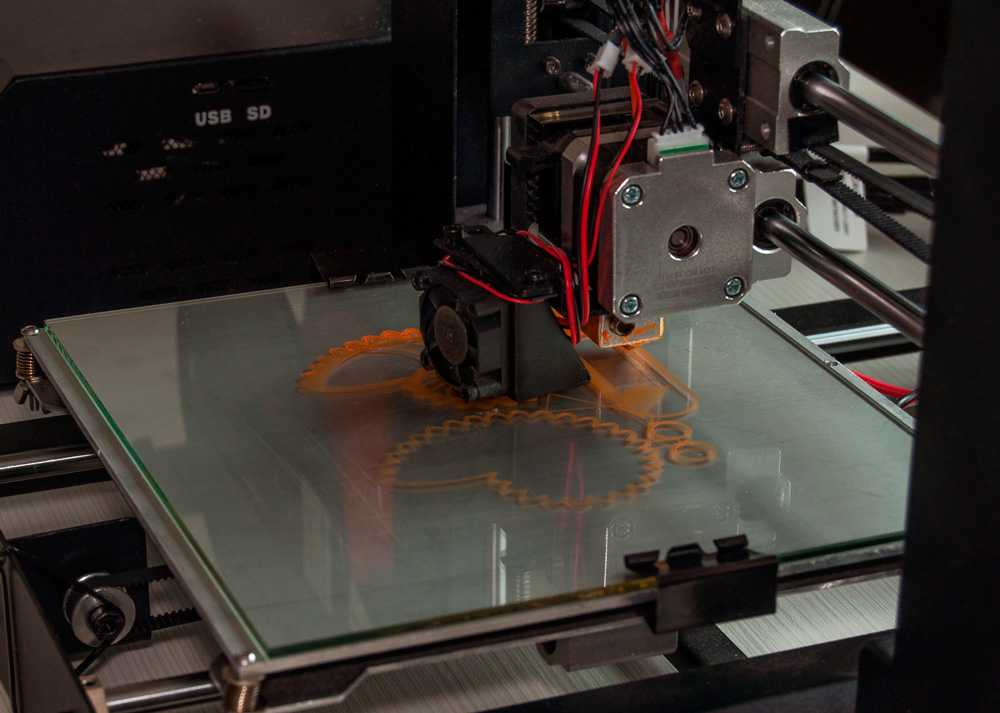

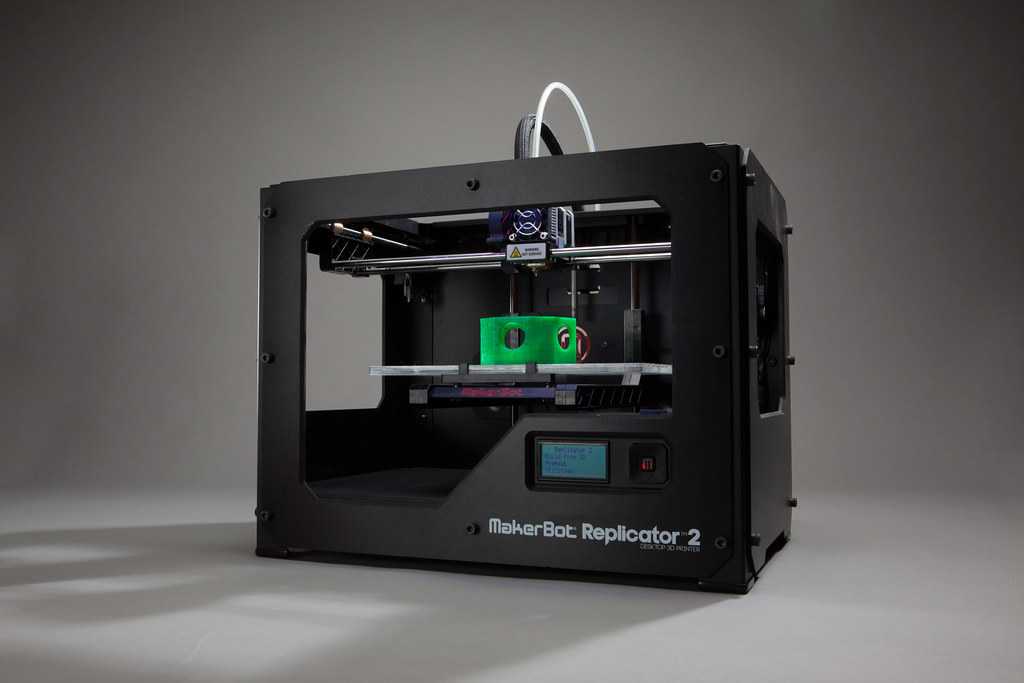

Since the first consumer-level 3D printers came on the scene six years ago their sales have grown substantially. Around 100,000 of these printers were sold last year. Despite 20 years of industrial 3D printer legacy, Makerbot went from nothing to the most popular 3D printer brand in the world. Given the dramatic growth many are predicting ever greater sales in the future and potentially a 3D printer in every home. But few have stopped to ask "who buys consumer-level 3D printers"? IDTechEx have studied this and, with the help of several major players in 3D printing, compiled the following graph showing the proportion of sales to consumers as a function of price:

Full disclosure is given in the IDTechEx report 3D Printing 2015-2025: Technologies, Markets, Players

With most consumer-level 3D printers selling around the $2,000 price mark this market research shows that only around a half of all consumer-level 3D printers are actually being sold to consumers. Printers under $500 sell entirely to consumers and printers costing $4,000 only sell 5% to consumer. This obviously raises the question of who else is buying all of these printers.

Several other groups are responsible for the other half of sales of consumer-level 3D printers. The largest other group is currently professionals. Many professionals are buying consumer-level 3D printers for use in labs, workshops and even offices to make small plastic objects. This work ranges from mundane repairs to exploratory study of how 3D printing might affect different businesses. The education sector, schools and universities, are also buying significant numbers of consumer-level 3D printers. Many 3D printer vendors have noticed this and are targeting schools with projects such as Makerbot Academy and Ultimaker Create. The UK added 3D printing and robotics as mandatory subjects to be studied by all eight year olds this academic year. However, despite best efforts such ventures are meeting significant resistance due to inevitable constraints such as funding and teacher training.

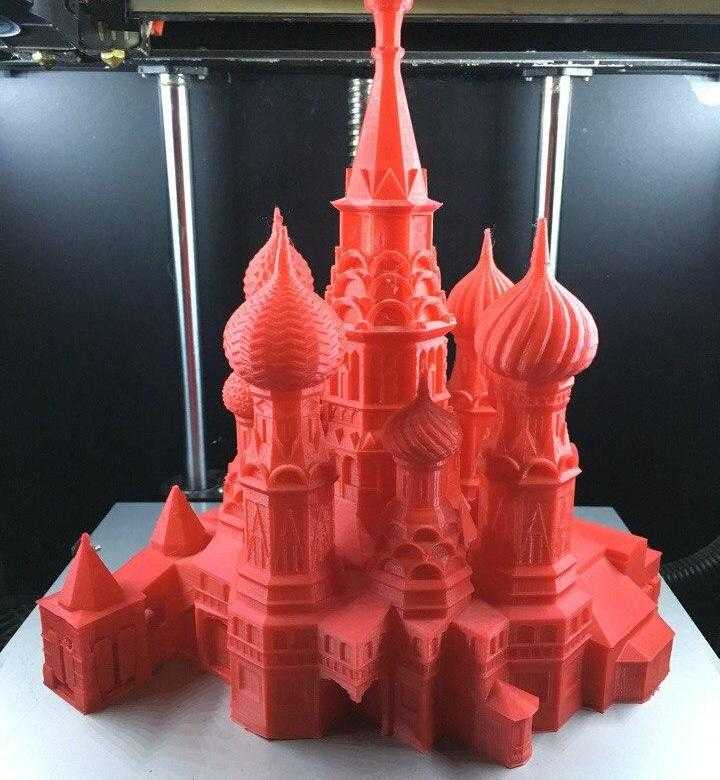

And what of the future? At IDTechEx, we believe current technology is not capable enough to warrant having a 3D printer in every home. In fact, we see consumer 3D printers as being more like power tools than office equipment. They often live in the garage. Consumables are usually bought from third parties rather than the equipment vendor. Most practical applications fall under the remit of miscellaneous tinkering. Therefore, regarding the consumer 3D printer market as part of the global home power tool market we forecast that the current meteoric rise in sales of consumer printers will slow down very rapidly. Specifically, that the 100% growth seen in recent years will fall to just 20% growth by 2025. In this hare and tortoise race, the professional and educational sectors prove to be the tortoise with a slower start but larger addressable markets means sustainable growth for at least the next decade.

For our complete analysis of the current market and players with a ten-year forecast covering bioprinting, aerospace, automotive, dental, medical, consumer products, oil and gas, jewelry and other sectors please read the IDTechEx report 3D Printing 2015-2025: Technologies, Markets, Players

Also attend the IDTechEx 3D Printing Europe 2015 event, in Berlin on 28-29 April - see www. IDTechEx.com/3DP-Europe.

IDTechEx.com/3DP-Europe.

Top image: The Form 1 3D Printer, Formlabs

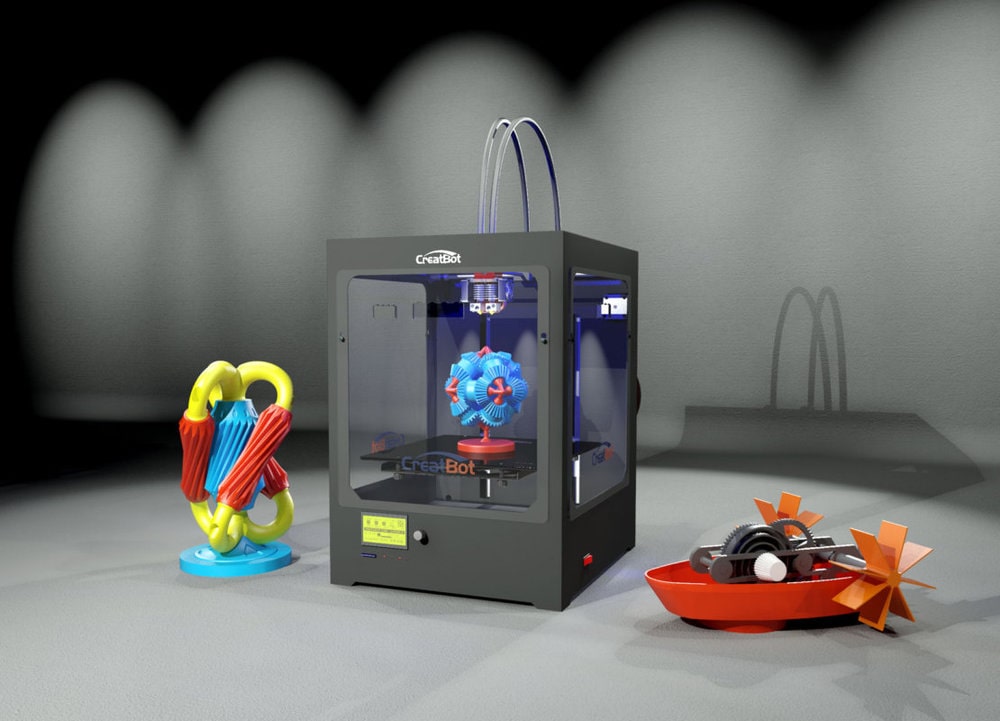

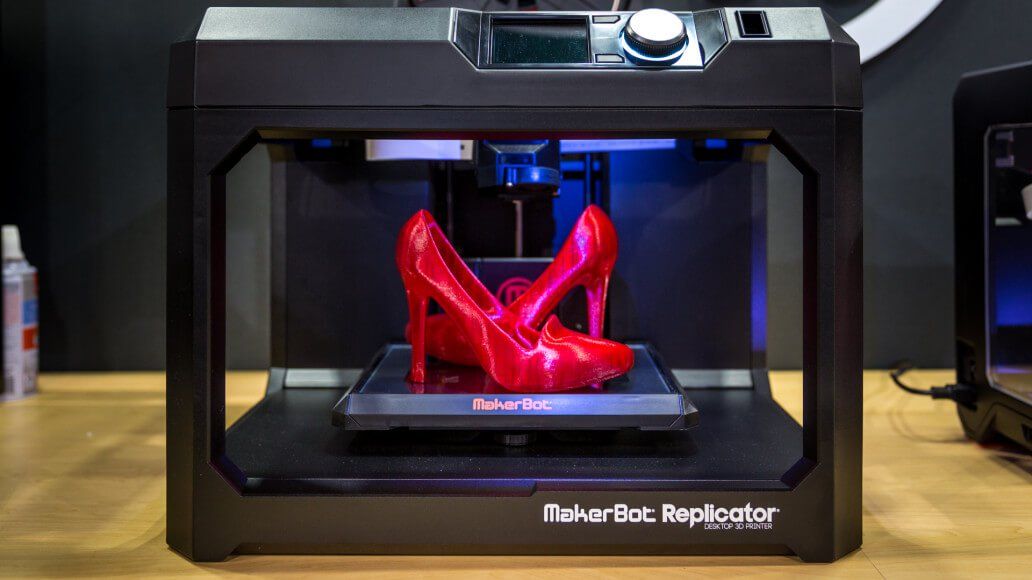

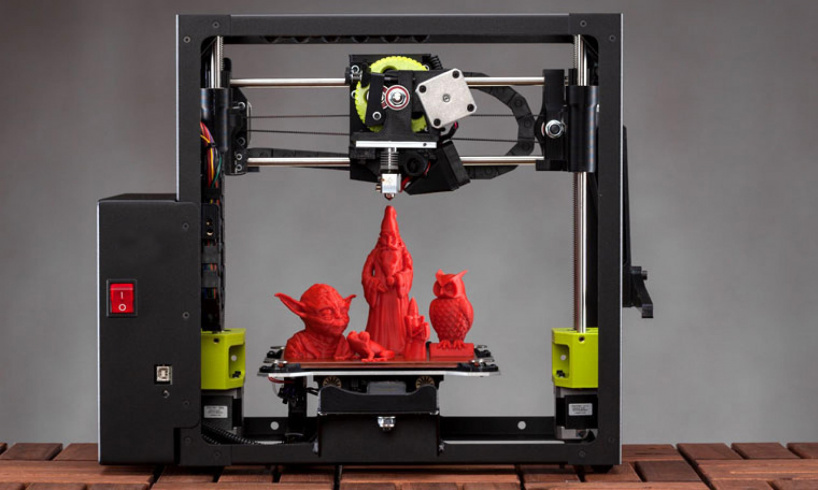

Best 3D Printer 2022 - The Ultimate Buying Guide [WINNERS]

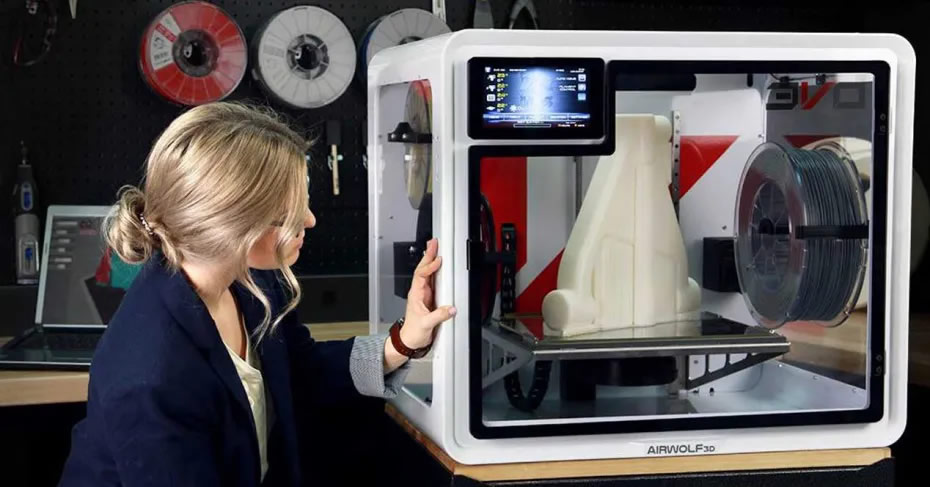

]3D printers grant you the ability to generate anything you can possibly dream of. However, as they’re fairly complex pieces of kit it’s often hard to decide which one is best for your needs.

That’s where we come in. We’ve researched some of the best 3D printers on the market and broken them down by category. No matter your needs or budget, we’re positive that there’s a 3D printer right here for you!

Table of ContentsShow

Zoom Out: The 15 Best 3D Printers For 2022

In the short buyer’s guide below we’ll explain a few things to look out for. This will help ensure that you find a printer that fits your needs and prevents you from feeling ripped off or otherwise disappointed in your new product. Now, before you spend any money, it’s important to know what the 3D printer’s specifications mean.

We know, we know, it’s a little boring but it CAN save you hundreds of dollars and a whole lot of buyer’s remorse, so taking a little extra time to compare different products is of grand importance.

Build Area

This one is really simple. The build area of a 3D printer refers to the maximum size of an object you can create.

Now, 3D printers come in all shapes and sizes, so some might have a taller or wider build area than others. You can still use most of the templates you’ll find online but you might have to rotate them first.

Generally speaking, bigger is better when it comes to the build area. Unfortunately, larger areas usually mean a higher price tag, so you should try and strike a balance between creating huge items and saving money in the long term.

Materials

Essentially, 3D printing works by heating a filament until it’s malleable and remolding it in the shape you need. However, there are several different filament materials on offer and not every printer can use every type.

The most commonly used filaments are ABS and PLA. These make durable, temperature resistant items, but there are many other types available. If you want to use one, in particular, make sure the printer supports it before buying.

There are even 3D printers that can use other materials, like clay or Sugru. The problem with these printers is that they’re usually less reliable than standard filament-based models. If you’re an artist or want to use a printer for experimental use then have at it, but most people will be better suited towards a standard printer.

Print Speed

Here’s the bad news: 3D printing is still very slow despite its many advancements.

Generally, most low-budget printers go at a rate of around 50mm per second. This means that larger models can take a long time to create. There’s another problem: very fast printers create thicker, more obvious layers in the final product. This proves that usually, slow and steady is the better option.

Some printers allow you to add an additional extruder (essentially a nozzle) to speed up the printing process. These have another upside too – you may even be able to use multiple materials at the same time. If this is something that you think you’d like, consider purchasing a dual-extruder model.

These have another upside too – you may even be able to use multiple materials at the same time. If this is something that you think you’d like, consider purchasing a dual-extruder model.

Best Budget 3D Printers

While 3D printers still aren’t particularly cheap, there are several that come with a relatively low price tag. We’ve located and thoroughly researched three of the best budget 3D printers on the market so that you don’t have to.

Take a look!

Monoprice Select Mini

Our first recommendation is the Monoprice Select Mini. At a little over $200, this model is an excellent choice for people looking to dip their toes into the world of 3D printing.

It has a 4.7” build area. This isn’t huge, but it’s still large enough to create models or little things for around the home. With a printing speed of 55mm/s, it’s slightly faster than others in this price range. Need a bracket for that cupboard door? No problem, just wait a few hours.

With its WiFi capability, MicroSD slot, and simple, intuitive interface, this product offers far more than you expect. Also, its price makes it an absolute bargain.

New Matter MOD-t

Next, let’s take a look at the New Matter MOD-t. This is a futuristic looking printer that comes with lifetime tech support and wireless printing functionality.

It uses PLA filament and can print at up 80mm/s, although its speed is adjustable. This allows you to spend a little longer to create a smoother, more professional looking product or just get the job done quickly depending on the situation. Good, right?

It has a slightly larger build area than the Monoprice, and accordingly, costs a little more money. That said, we believe that the versatility of this product more than offsets the increase in price.

XYZprinting da Vinci Jr.

Lastly, in this category, we have the XYZprinting da Vinci Jr. This model has a 5.9” build area and a maximum printing speed of 100mm/s, making it larger and faster than the two others we’ve seen.

So what’s the catch?

Well, this printer uses a uniquely sized filament. It’s a little less expensive than you might think, but your options for buying filament are very restricted. This can, in turn, lead to slightly more expensive refills.

That said, in terms of performance, this product far outshines the others we’ve seen so far. It’s unfortunate that you can’t use standard filament with this model, but if this doesn’t bother you then the da Vinci Jr. would be an excellent choice.

Best Commercial 3D Printers

At some point, a standard 3D printer just isn’t going to meet your needs. Maybe you’re considering starting a printing business or just have exceptionally high demand. Whatever you need, we’re positive that one of the two following models will fit the bill.

Lulzbot TAZ 6

The Lulzbot TAZ 6 is very well-known in the 3D printing community, but it comes with a substantial $2500 price tag. So what does this product do to justify it?

Well, keep reading to find out.

Firstly, it has a massive build area of almost 11 square inches. Secondly, with the TAZ 6, you aren’t limited to just the standard materials. In fact, it can handle more than 30 different types of filament including wood, metal, and stone composites.

Not only that but this model has a self-leveling and self-cleaning print head. This takes the hard work away and leaves you free to enjoy the design and printing process.

So is it still as slow as all the rest? Well, it’s dual extruder compatible. This means that you can hypothetically halve the time it takes to complete a model, although of course, as we’ve mentioned above, this will affect the overall look of the finished result.

All things considered, we think that this printer will likely be too expensive and too high-tech for most people’s needs, but for commercial printers or organizations who plan to use it a lot, it’s actually very reasonably priced.

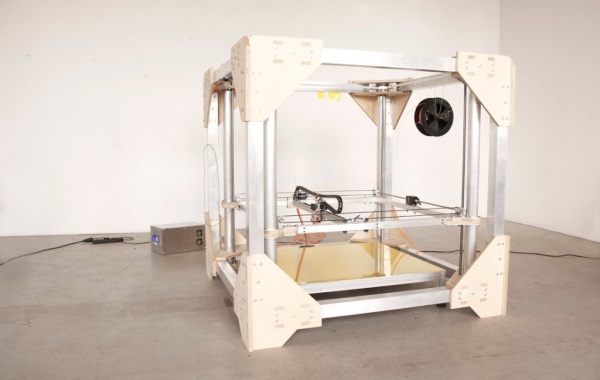

HICTOP Creality CR-10

The second commercial printer we’ve found is the HICTOP Creality CR-10. This is far less expensive than the TAZ, at around $500, yet provides an even larger build area.

This is far less expensive than the TAZ, at around $500, yet provides an even larger build area.

This is due to this printer’s open design. It’s not constrained by the same hardware and can freely create things much larger than most of its rivals could handle. This simple design means that this printer can be broken down into just three parts for easy assembly. What else is good?

This printer has a variable printing speed. At its base rate, it can run at 80mm/s but this can be boosted as high as 200mm/s if you’re in a hurry. Layers can be as thick as 0.4mm or as thin as 0.5mm so there’s a good degree of creative freedom with the CR-10.

You might expect the CR-10 to be a compromise considering its far more palatable price. However, nothing could be farther from the truth. It’s a solid, fast 3D printer that can handle anything you throw at it.

Ultimately, if you don’t care about using anything except PLA then there’s no reason to spend any extra money on a fancy printer. Simply put, this model has everything you need.

Simply put, this model has everything you need.

If you work in a creative field, you’ll probably have been asked to create a rapid prototype of something. What if you could remove the hassle from this and create an even higher quality item while you were away doing other things?

Well, you can. The following 3D printers are packed full of features that make them invaluable to designers and we’re confident that you’ll find one you like.

FlashForge Creator Pro

First up we have the FlashForge Creator Pro. This is a pretty pricey printer but it supports printing with a huge range of different materials including wood and nylon. So how is it to use?

It does have a fairly small build area, but this is offset by its high speed. This means that you can create several smaller items and combine them later at the same time that creating a larger object would have taken.

This printer supports tetherless printing via SD card, but there’s no WiFI functionality. Considering it’s the kind of product that would be best suited to a computer lab, this really isn’t as big of an issue as it appears at first.

Considering it’s the kind of product that would be best suited to a computer lab, this really isn’t as big of an issue as it appears at first.

Overall, while the FlashForge can seem a little overpriced considering its small build area, it’s actually pretty good at what it does. We particularly liked its wide material support – this is something usually only found in far more expensive models and something we’re sure will come in handy.

QIDI TECHNOLOGY

There’s also a reasonably priced 3D printer from QIDI TECHNOLOGY. It costs around $400 and has a 5.5” build area. This is a pretty small chamber but considering this is a mid-budget pick, that’s to be expected.

So what is this printer’s best feature?

One of the things we really liked about this printer is its ultra-simple interface. 3D printing can get pretty technical so having something that’s easy to understand is a breath of fresh air and will help less experienced users feel more at home.

This printer supports both simple and advanced materials, although there are limits. You won’t be able to print with wood, for example, but less common plastic composites will work just fine.

All in all, the QIDI printer is a decent middle ground between the functionality of an advanced model and the price of a budget one. For that reason alone, it’s a strong choice, but when you take the versatility into account, this printer becomes a no-brainer for any designer.

Best 3D Printer For Hobbyists

Maybe the products we’ve seen thus far are way more than you’re looking for. Maybe you only want a 3D printer for occasional use or to help facilitate another one of your hobbies.

That’s okay too!

However, since you’re not going to be a heavy user, it doesn’t make sense to spend a lot of money. Below, you’ll find two 3D printers that are as versatile as they are inexpensive.

XYZPrinting Mini

First up is another entry in XYZPrinting’s da Vinci line. The XYZPrinting Mini is, as you might expect, a tiny little printer. It stands just 24” tall, 18” wide, and 15.5” deep. This makes it nice and easy to put away in a closet when you aren’t using it.

The XYZPrinting Mini is, as you might expect, a tiny little printer. It stands just 24” tall, 18” wide, and 15.5” deep. This makes it nice and easy to put away in a closet when you aren’t using it.

It has a build area that’s a reasonable size given this model’s sub-$200 price and 5.9” is plenty of space to create most of the things you’ll want, plus you can always combine components if you want to make something larger. So, let’s talk filament.

Like the da Vinci Jr., the Mini only uses a proprietary XYZPrinting filament. This is fairly standard PLA material but it’s a little narrower than other brands’. This does mean that filament is slightly more cost-intensive, but infrequent users will find that they don’t have to buy extra filament all that often anyway.

There’s a lot to like here. This product has an incredibly simple interface: it’s a single button with LED lights to indicate print status. This helps make the Mini an excellent choice for people looking to experiment with 3D printing for the first time.

This printer takes the stress out of setup by automatically calibrating itself and with a maximum speed of 120mm/s, it’s more than capable of getting things done quickly when necessary.

So it’s perfect, right? Well, not exactly.

We did find that the Mini is a little loud, but that’s to be expected at this price range. If you’re planning to print overnight, we’d recommend placing this product as far from the bedroom as possible because even if it seems quiet at first, it can quickly become distracting enough to keep you awake.

Apart from its noisy operation, the da Vinci Jr. is an exemplary little 3D printer. It comes with everything you need to get started and is unhampered by the extensive setup and configuration process that more advanced printers are.

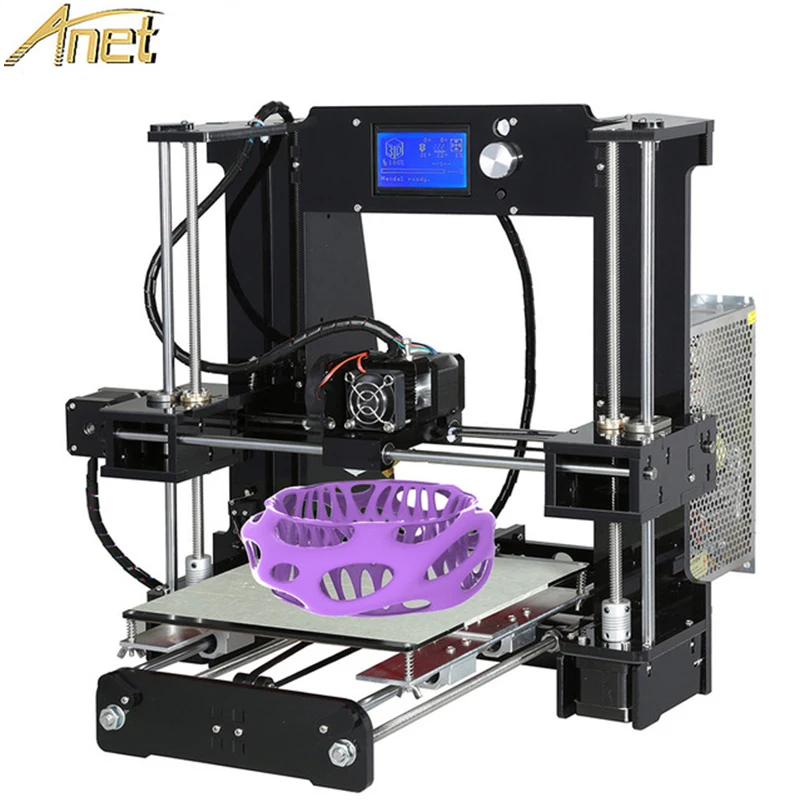

ALUNAR 3D Printer

If the Mini’s reliance on specific materials annoys you, you might be better suited to the ALUNAR 3D printer. It’s capable of using any standard filament plus some more advanced ones like wood or conductive materials.

This printer is a touch more expensive at around $210. That said, it comes with a 1000 hour motor guarantee, so you can expect it to work for a long time. So far, so good.

Now, a word of warning. This printer requires some assembly. For the most part, this is very simple but it does require some degree of common sense. For example, you’ll have to switch the voltage to either 100V or 220V depending on your input.

We really liked that this printer lets you pause your work at any time. This allows you to quiet it down after hours or catch any mistakes before they’re set in stone (possibly literally). You’ll have to be quick, though: this printer can go as high as 100mm/s.

Again, the ALUNAR has a slightly more complex user interface than the Mini. It has five buttons and an LCD display for navigating its menu system. Rather than complicating things, this actually makes the user feel like they have more control, and with this new wave of tech, that’s a benefit that can’t be understated.

This is a printer that provides the best of both worlds. On one hand, it offers far more creative freedom than its rivals, and on the other, it does require some construction. Nonetheless, we still recommend it.

Best Mid-Budget 3D Printers

The products above are great but let’s say you don’t fit neatly into any of our categories and just want to know what’s available. Well, you’re in luck! We’ve created a list of the best all-around 3D printers in the mid-budget range to help you out.

FlashForge Finder

Let’s take a look at the FlashForge Finder. It costs around $400 and has a 5.5”3 build area. But that’s far from all this product has to offer.

This printer is exactly what you imagine when someone says “3D printer”. It looks futuristic and sleek, featuring a small 3.5” LCD touchscreen interface. This keeps operation nice and simple while providing enough flexibility to navigate menus with ease.

The Finder offers two ways to import files. The first is the standard SD care and flash drive support, but it also features WiFi functionality for tetherless printing. This can be especially useful if your computer is somewhere out of the way and you don’t fancy running cables through your home.

The first is the standard SD care and flash drive support, but it also features WiFi functionality for tetherless printing. This can be especially useful if your computer is somewhere out of the way and you don’t fancy running cables through your home.

The only issue with this printer is that it’s designed to work only with FlashForge PLA filament. That said, it’s also possible to use Hatchbox filament if you run it in from outside. Either way, your filament options are limited which may lead to slightly increased costs down the line.

One of the things we really liked about this model is its filament refill alert. It automatically detects when you’re running low so you never find yourself halfway through a print and having to buy extra filament.

QIDI TECHNOLOGY 3DP-QDA16-01

Our second pick is the QIDI TECHNOLOGY 3DP-QDA16-01. What it lacks in a catchy name, it makes up for in terms of functionality.

First up, it has a slightly wider than average build area at 8. 8”. This gives you the freedom to create ever larger items and given its price (around $650) this size is excellent. So what else does it offer?

8”. This gives you the freedom to create ever larger items and given its price (around $650) this size is excellent. So what else does it offer?

Well, it’s almost entirely metal. This not only looks good but lends the printer added stability and structure. This is more important than you might think – with temperatures up to 280° you need all the stability you can get.

It features a dual-extruder setup. This means that you can print models up to twice as fast as other models. There is very little range in terms of layer size, however. It ranges from 0.1-.2mm and while you might think that this makes layers noticeable, it’s actually not that bad.

We really liked that this model comes with 24-hour tech support and a turbofan cooling function to let you grab your items as soon as possible after it’s done.

Files can be transferred either via SD card or USB stick, and while there’s no WiFi capability, this is just a bonus and isn’t all that necessary.

Robo R1+

Lastly, in this category, we have the Robo R1+. Sounds fancy, right? Well, you’ll be pleased to hear that its functionality lives up to its futuristic name.

Sounds fancy, right? Well, you’ll be pleased to hear that its functionality lives up to its futuristic name.

This printer has a quick-change extruder system and fast-feed filament setup. Finally – a printer that can keep up with the fastest print speeds, In many ways, it’s designed for professionals – with maintenance this simple, it’s no longer a chore.

Believe it or not, it gets better. This printer has an absolutely huge build area. For around $500 you can create items up to 10” x 9” x 8” in size. That’s incredible, but wait, there’s more.

Let’s say you run into trouble using the R1+. No problem – just use the free 24-hour tech support. Ah but wait, what if the problem is your hardware itself? Relax! The R1+ is covered by a six-month parts warranty, so you can have it fixed at no additional cost. Good, right?

Our last point is a big one: this printer can use more than 30 different materials including carbon fiber PLA, rubber, and stainless steel. This provides unparalleled flexibility in terms of what you can create and frankly at this price range, that’s amazing.

Best High-End 3D Printers

Okay, we’ve covered most of the popular basic 3D printers but what if you have a little more money to spend? You’ll likely want printers with functionality that you can’t find in lower price brackets, right? The printers below offer extra features, both in terms of ease of use and printing capability.

Robo R2 3D Printer

Our first high-budget pick is the Robo R2 3D printer. This is priced at around $1500 so it’s not going to be for everyone. Those that can afford it, however, will find that it offers a lot of bang for your buck.

Did you know that this printer can print very thin layers? They range from 0.02mm to 0.3mm which is frankly crazy. This is far finer than any other printer we’ve seen and will result in a much more professional looking finished piece.

The build area is large but not as big as some due to the closed nature of the printer. Still, there’s plenty of space available for those who like to create larger items. This printer can actually save you time: models that would have to be done in parts on other printers can be done in one go with the R2.

This printer can actually save you time: models that would have to be done in parts on other printers can be done in one go with the R2.

More than 30 different materials are supported and because you can add a second extruder, you can even print two at once for a more attractive end product. If you’re not impressed yet, maybe this final point will change your mind.

The R2 comes with a year’s subscription to a professional level printing program, and there’s even 24/7 customer support, as well as a year’s warranty on parts. What’s not to like?

JGAURORA Printer

Next, we have the JGAURORA printer. It’s still considered a high-budget printer but costs about half as much as the R2. If you found the R2’s high price tag too hard to justify, perhaps this would be a better choice.

Let’s start with the basics. This printer works with any 1.75mm printing filament. That’s it – there are no other restrictions. This makes it an excellent choice for those who want to build complex, multi-material pieces without spending over a thousand dollars.

It also features a switchable voltage so be sure to alter this based on your power source. The frame is made of metal for added stability, plus the temperature can be controlled either by changing it directly or by using the built-in fan. So how is it for printing?

In a word: excellent. The layer thickness can be adjusted from 0.1-0.4mm which allows for some exceptionally high-quality models. These can be pretty large too since the build area is 11” wide, 7.9” tall and deep.

While this printer can’t connect via WiFi it does come with an 8GB SD card and reader. To be honest, WiFi connectivity would have been a bonus, but it’s hardly essential. The only difference is that files have to be transferred across. On the plus side, an SD card can load data faster than WiFi so you can get started sooner.

Sindoh 3DWOX DP200

Our final recommendation is the Sindoh 3DWOX DP200. Now, you might be thinking “how can I justify spending all this money on a product with a 7. 9×7.9×7.3” build area. Well, this printer has a number of features that make it a strong contender, and we’ll outline these below.

9×7.9×7.3” build area. Well, this printer has a number of features that make it a strong contender, and we’ll outline these below.

Take connectivity, for example. It can use Ethernet, USB, WiFi, or SD cards. Better still, it has an internal camera that can be viewed remotely. Want to check on its progress while at work? No problem!

This model makes it easier to begin printing, too. It can automatically load and unload filament and uses specialized technology to assist you during the bed-leveling process. The only way this printer could make your life even easier is if it sprouted legs and plugged itself in.

Now, this printer supports fewer material types than some of the others we’ve seen. That said, it still accepts the standard PLA and ABS filaments so the most commonly used types will work. Considering the layers can be as fine as 0.05mm, you’ll be able to create truly stunning, professional looking items.

Overall, we believe this printer to offer a good middle ground between performance and affordability. Although it has only basic material support, no other product on this list offers a camera or as many connectivity options.

Although it has only basic material support, no other product on this list offers a camera or as many connectivity options.

Who buys consumer grade 3D printers?

03/13/2015

Since the first consumer-grade 3D printers hit the market six years ago, sales have grown significantly. About 100,000 of these printers were sold last year alone. Despite a 20-year history in the 3D printing industry, Makerbot has grown from its inception to become the world's most popular 3D printer brand. Given the rapid growth of the industry, many predict more and more sales in the future and perhaps a 3D printer in every home. But only a few have bothered to ask who is buying consumer grade 3D printers. IDTechEx has looked into this issue and, with the help of several major players in the 3D printing industry, has come up with the following graph showing the share of sales to consumers by price:

For full details, see the IDTechEx report "3D Printing 2015-2025: Technologies, Markets, Players" (www. IDTechEx.com/3d).

IDTechEx.com/3d).

Since most consumer-grade 3D printers sell for $2,000, this market research shows that only about half of them are actually sold to consumers. Printers under $500 are sold exclusively to consumers, while those under $4,000 only end up with consumers 5% of the time. This fact obviously leads to the question of who else is buying these printers.

Several other groups are responsible for the second half of consumer-grade 3D printer sales. The largest of them at the present time are specialists. They buy consumer-grade 3D printers to use in labs, workshops, and even offices to print small plastic items. The use of printers ranges from home repairs to research into how 3D printing can impact different areas of business. The education sector, schools and universities are also buying a significant amount of consumer grade 3D printers. Many manufacturers of these devices have noticed this trend and are targeting schools in projects such as Makerbot Academy and Ultimaker Create. This year, the UK introduced two new compulsory subjects - 3D printing and robotics. However, despite all the efforts made, there are many obstacles, namely, insufficient funding and pedagogical training.

This year, the UK introduced two new compulsory subjects - 3D printing and robotics. However, despite all the efforts made, there are many obstacles, namely, insufficient funding and pedagogical training.

What does the future hold for us? IDTechEx believes that current technology cannot guarantee 100% availability of a 3D printer in every home. We actually see the consumer 3D printer as a mechanical tool, not office equipment. They are often placed in garages. Consumables are usually purchased from third parties and not from the equipment supplier. The situation is similar with applications. Thus, regarding the consumer 3D printer market as part of the global home tools market, we predict that the current rapid growth in consumer printer sales will slow down very quickly. In particular, the 100% growth we have seen in recent years will drop to 20% by 2025. It's like Aesop's fable of the hare and the tortoise, when the professional and educational sectors turn out to be a tortoise with a slower start but larger target markets, meaning steady growth for at least the next decade.

Source

Please rate the news:

Share:

Back to news

Subscribe to receive the latest news

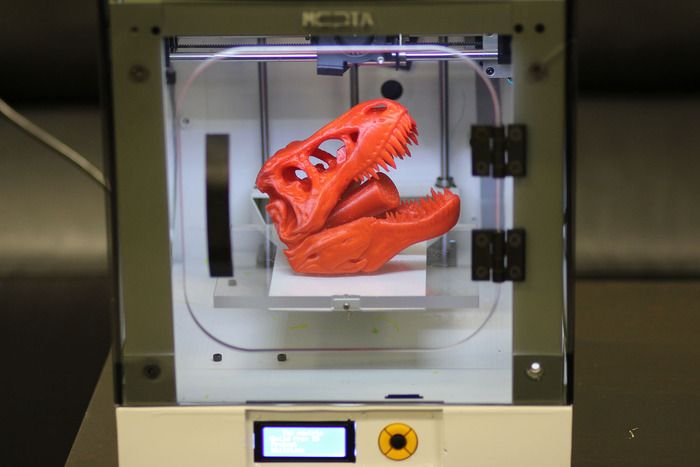

As a beginner I bought a 3D printer. Choosing, setting up, problems and solving practical problems / Sudo Null IT News

A few months ago, I was thinking about purchasing such a device because I wanted to print a broken part of my robot vacuum cleaner. About a month ago I bought a device I liked on eBay. That's what was important to me when choosing a 3D printer.

Which printer was needed?

Considering that I knew almost nothing about 3D printers (except for a few articles read here on Habré), the important points were:

- Printer performance out of the box. I have seen several articles describing how long it takes to set up a "simple Chinese printer". It needs to be assembled from a large number of parts, and it is not a fact that there will not be defective ones among them.

Once assembled, you can mess around with the device for a couple of days, and then it turns out that for some reason it does not work. In short, I needed a printer that didn't need to be assembled and that could work right out of the box.

Once assembled, you can mess around with the device for a couple of days, and then it turns out that for some reason it does not work. In short, I needed a printer that didn't need to be assembled and that could work right out of the box. - It shouldn't be too expensive. Seriously, I'm new, I was not sure that after a couple of days I would not abandon the device. And a printer for 500-600 euros would be too expensive a toy. So I was willing to spend a couple of hundred, no more.

- It should not be too big. Before buying, I allocated a little space for installing the printer, somewhere around 50 * 50 cm. Therefore, the printer had to stand on the allocated area without any problems.

- It shouldn't be too difficult to maintain. This point is closely related to the first. I didn’t want to spend a lot of time on operation and maintenance work - there is sorely not enough time, so constantly eliminating emerging glitches is not an option.

- I wanted to get a printer with WiFi, it was not critical, but important.

What did I end up buying?

Model Geeetech E180. It was shown by Google after the query “3D printer for beginners”. There were other models in the search results, but this one was liked by the design and the presence of WiFi.

The developers of this printer raised money for it with the help of Kickstarter and a couple of years ago it appeared on the free market. Its price is from 200 to 350 euros, depending on the company that sells it and the store.

Bought on eBay, starting price was 200 euros, but the seller agreed to drop 50 euros, so the total price is 150.

Printer specifications:

- Print technology: FDM

- Working space dimensions: 130 x 130 x 130 mm

- Printing accuracy: 0.05 mm

- Positioning accuracy: X / Y 0.11 mm, Z 0.0025 mm

- Print speed: 80-110 mm/s

- Thread diameter: 1.75 mm

- Nozzle diameter: 0.4 mm

- Supported material: manufacturer claims PLA, but may work with other materials

- Operating system: Windows

- Management software: EasyPrint 3D

- File format: .

STL, G-code

STL, G-code - Maximum extruder temperature: 230 °C

- Power supply: DC 12V 6A

- Connectivity: WiFi, USB, TF card (offline printing support)

- Display: 3.2" full color touch screen

- Chassis: metal plate + injection molding (portable console 3D printer)

- Work table: aluminum alloy plate

- XYZ Rods: wear resistant, stainless steel screw and lead (Z axis)

- Stepper motors: 1.8 degree stepped angle with 1/16 micro stepping

Unpacking and setup

Before setting up, I looked at several reviews and tests of the printer. If not for them, I would not have done it myself, the explanation in the instructions is slurred. The setup is simple, but not for a beginner.

The printer "wound up" as soon as I connected it to power and a laptop. I calibrated the position of the table - it turned out to be simple - inserted a microSD card into the slot, found the contents through the menu on the printer screen, inserted the fiber into the channel and started printing. The printer made a noise and started printing. Or rather, I thought that he started typing, in fact it was not so.

The printer made a noise and started printing. Or rather, I thought that he started typing, in fact it was not so.

Problems

The printhead moved, the temperature reached 205 degrees Celsius, but there was almost no plastic - in the first few seconds, a few plastic “hairs” came out and that was it. The printer continued to work, but the plastic was not squeezed out of the head.

I wasted several Saturday hours trying to figure out why. I tried to look for an explanation on the net, but solutions to similar problems did not suit me.

The joy of buying disappeared in the first couple of hours of fuss. I wanted a printer that “just works”, but it didn’t work out. As a result, I realized that the fiber was not being fed - the feed mechanism hidden under the plastic cover simply did not work. It did not work because the constituent elements did not rotate. There was no movement at all.

I have decided that the printer has a defective electric motor that is responsible for feeding, and I cannot repair it. The next step is to click the Return to Seller button on eBay. After clicking the button and describing the problem, I decided to pack the printer for shipping. Before sealing it in a foam box, just in case, I decided to carefully examine those “insides” that are visible through the holes in the case.

The next step is to click the Return to Seller button on eBay. After clicking the button and describing the problem, I decided to pack the printer for shipping. Before sealing it in a foam box, just in case, I decided to carefully examine those “insides” that are visible through the holes in the case.

And the reason was immediately found - the assembler at the factory simply forgot to connect the power supply to the engine. Seriously, the cable just dangled inside the case. I connected it to the right connector with tweezers without disassembling the printer. Then I turned on the device again and this time everything was fine, the plastic feed worked as it should.

Then a few more minor problems arose:

- Misaligned table. This caused the table to skew and the print head was pressed against the surface in one place. As a result, the plastic could not be squeezed out of the head, which led to solid print defects;

- Models downloaded from the Internet cannot be directly printed.

Being a beginner, I thought that everything works like with a regular printer - I downloaded a document, sent it to print. It turns out that slicing is also needed. I will not repeat what it is and why it needs to be perfectly described in this article on Habré;

Being a beginner, I thought that everything works like with a regular printer - I downloaded a document, sent it to print. It turns out that slicing is also needed. I will not repeat what it is and why it needs to be perfectly described in this article on Habré; - Slicers are not compatible with the printer model. Slicer needs to set printer desktop size. Some slicers for some reason did not want to work with the dimensions of my printer (13*13*13 cm). Some even crashed (including the printer's native application), some did not "understand" the dimensions. As a result, I settled on ideaMaker;

- No WiFi. As it turned out, there are two varieties of E180 - one with an integrated WiFi module, the second - without a module, you need to buy it in addition. At the seller, the inscription "need a separate module" was applied to one of the photos of the printer, small and in French (everything else was in English). Not a scam, but close to it. The module decided not to buy more, it is not really needed;

- Long printing time.

I thought it would take several tens of minutes to print. I was not ready for the fact that large models can be printed for 6-8 hours. This is my own fault - I did not carefully look at the reviews.

I thought it would take several tens of minutes to print. I was not ready for the fact that large models can be printed for 6-8 hours. This is my own fault - I did not carefully look at the reviews.

Practical use

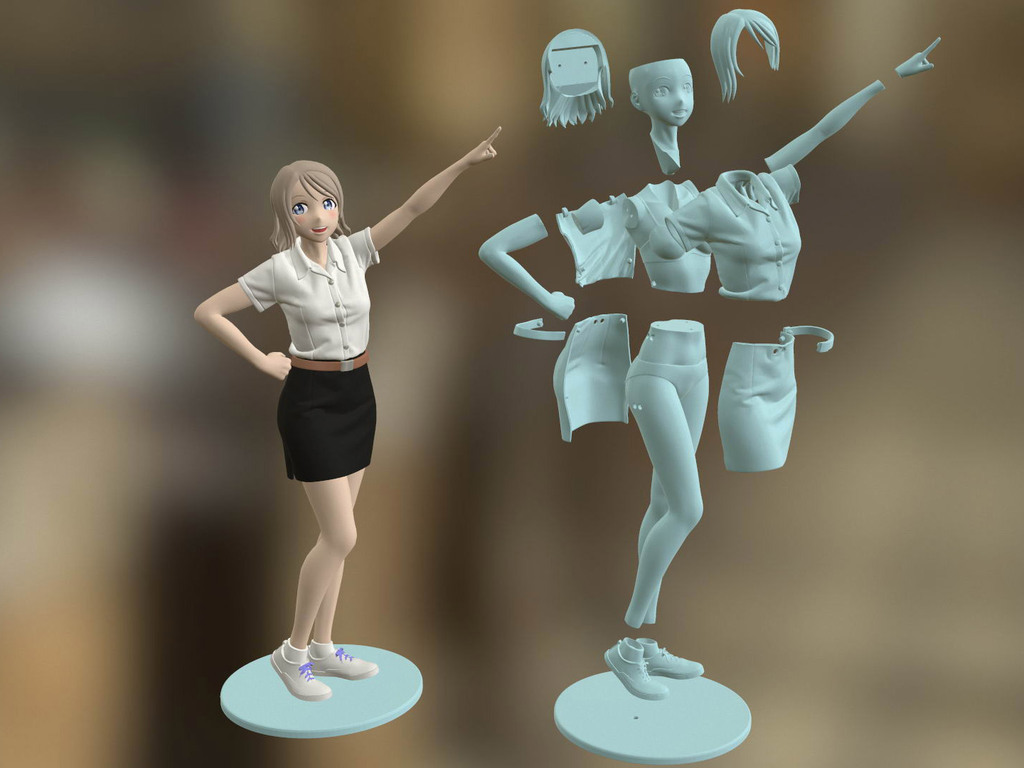

I didn’t buy a printer for a game, I wanted to get a device that would allow me to create things I need in everyday life, and not run to the store. Before buying, I outlined what I wanted to create:

The lever for separating the water tank in the iRobot Scooba robot vacuum cleaner, the repair review of which I published on Habré. His native pen broke, he did not want to spend money on buying a new one (they are relatively rare, since Scooba is no longer produced and expensive).

Finally found a suitable model on Thingiverse and printed it. To my surprise, everything fell into place the first time, the pen still works quite normally (it's been about a month since this part was printed).

Chinese electron microscope stand. I needed it for soldering small parts. I do not want to buy a professional microscope for 400 euros, since I myself do not do repairs very often. A Chinese microscope connected to a laptop is quite an option. But his native tripod is just terrible. Therefore, I wanted to make a new, normal one with my own hands.

I needed it for soldering small parts. I do not want to buy a professional microscope for 400 euros, since I myself do not do repairs very often. A Chinese microscope connected to a laptop is quite an option. But his native tripod is just terrible. Therefore, I wanted to make a new, normal one with my own hands.

Soldering iron stand. You just need a comfortable stand, from which the soldering iron will not fall, like from a Chinese stand that I once bought.

Paste tube squeezer. Yes, the thing is not the most necessary, but practical.

iPhone stand. Convenient, there is a hole for the cable, sound amplification.

Toys for children. Why buy another small doll or dollhouse piece when some things can just be printed out?

Stylus for Nintendo DS Lite. I had a game console bought at a flea market for a long time. The stylus was lost and I (and my daughter) played using the PDA stylus. Recently I found a stylus model for the console, printed it out - it turned out perfectly. It fits into the connector like a factory one.

It fits into the connector like a factory one.

Extractor for printed parts stuck to the table. Nearly every part sticks to the printer's desktop backing. You can’t do without a special device - an ordinary knife will scratch and cut a special sticker. I found a model that is compatible with the blades of a standard utility knife - works great.

The printer lived up to my expectations. It was possible to print almost everything that is indicated above. All these things fulfill their purpose, and most importantly, I am not afraid that any of them may fail. You can always print a new one.

There are a lot of ready-made models on the net. If you need some detail or thing, in 90% of cases you can find everything you need.

Troublesome little things

Printed parts are far from perfect. In some cases, deformation of some elements occurs and it is necessary to “finish” manually, using a knife and, in fact, a file. It doesn't happen that often, but I wish the printed part didn't need to be reworked (yes, I know you can get it by buying a professional 3D printer).

It doesn't happen that often, but I wish the printed part didn't need to be reworked (yes, I know you can get it by buying a professional 3D printer).

Sometimes details are printed, but for some reason the actual and declared size do not match. So, I tried several times to print different dispensers for AA and AAA batteries, but for some reason the ready-made dispensers did not fit. The diameter of the holes into which the batteries are inserted was always somewhat smaller than the diameter of the batteries themselves. I still do not understand whether the problem is on my part, or the model is problematic. As a solution, you can simply increase the scale of the part in the slicer, by 10 percent. But it’s a pity for the spent plastic - after all, you can find out whether a quality part will turn out or not only after a solid part of it is ready.

It takes a long time to print a part. Some printouts take hours to complete, so making a basic phone holder for a car can take half a day.

In order to develop something of your own, you need knowledge of CAD , at least at an elementary level. Otherwise, you will have to look for ready-made objects on sites that host models created by someone. In the end, I never found a battery cover for one of the remotes. I am not able to develop it myself - there is almost no time to master CAD.

The desktop size of my printer is small . Not all objects that I would like to print can be implemented. In particular, I wanted to get a different microscope stand model. But it did not work out, because it is larger than the printer table. The same problem with the handle of a robot vacuum cleaner (not the one in the photo, another one).

Fin

Am I satisfied, as a beginner, with the printer? Yes very. It met my expectations almost completely. True, it must be borne in mind that I got the printer relatively inexpensively. If I had bought it for, say, 300-400 euros, I would have been less satisfied with the purchase.