What to use 3d printers for

25 (Unexpected) 3D Printing Use Cases

For years, hype around 3D printing captured audiences in the mainstream press. With visions of a future including a 3D printer in every home, these predictions were light on details and ultimately most did not come to fruition. However, the possibilities of 3D printing were undeniable, despite the youth of the technology and the relatively low number of use cases that were viable in the past.

The initial hype masked legitimate and growing business applications for 3D printing. With a proliferation of high-performance desktop and benchtop machines being introduced into the market, we are now seeing a broader variety of businesses expanding their product offerings and delivering better results to customers.

What can you do with a 3D printer? Read on to discover 25 (often unexpected) 3D printing use cases that show the broad scope of possible applications for the technology.

Report

A new industry report that compares how recent and early adopters are using 3D printing for their business, and explores future trends of the technology.

3D printing can add enormous value to supply chains, unlocking a broad spectrum of production applications. The technology is growing more workable and affordable, with companies able to bring additive manufacturing in-house to support processes on the factory floor. New, resilient 3D printing materials are opening opportunities for the production of high precision, functional 3D prints that can stand in for final parts, offering customization opportunities that help designers radically push the boundaries of high-performance cars. Industrial design studio Vital Auto has put all of this technology to work creating high-fidelity prototypes and concept cars, rapidly working through iterations using a variety of advanced tools, including a large fleet of in-house 3D printers.

“We've used 3D printing from day one. We wanted to introduce it to our manufacturing processes, not only to reduce costs, but to give the customer more diversity with their designs and their ideas,” said Design Engineer Anthony Barnicott.

The automotive industry has seen the value additive manufacturing can add to multiple touch points in the creation of automobiles. This means going well beyond rapid prototyping to include:

- Creating custom, complex, and high-performance parts

- Producing tooling and manufacturing aids

- Manufacturing replacement parts and spare parts on demand

- Cutting costs and lead times by up to 90% compared to outsourcing

See How Concept Cars Are Created

Recent advancements in 3D printing technology have started to fundamentally change the audio industry, meaning that digital printing of custom fit ear devices for the audiology, noise protection, and consumer audiology industries has never been so affordable. In recent years, 3D printing manufacturers have brought skin-safe biocompatible materials to market, allowing for in-house production of ear models and headphone tips.

Custom fit offers a unique individual listening experience built around the earphone fitting exactly in the customers ear. This gives a secure fit that removes any possibility of earphones falling out of the ear, in addition to improved comfort and noise isolation.

This gives a secure fit that removes any possibility of earphones falling out of the ear, in addition to improved comfort and noise isolation.

“We are very excited about the concept of custom fit to deliver a custom experience to further enhance immersive listening. Formlabs shares Sennheiser’s drive for innovation – and improving the customer experience through this prototype is a testament to that mindset.”

Sennheiser Director AMBEO Immersive Audio, Veronique Larcher

The challenges that come with customized manufacturing can be overcome through the combination of Formlabs' disruptive printing technology and mobile scanning coupled with machine learning. This means customers can have easy access to custom fit earphones, with lead times reduced from four days to next day delivery or even same day.

Learn More About 3D Printing in Audiology

restor3D tools being printed, along side their final form.

Ten years ago, few people were talking about the huge impact 3D printing would have on the medical industry, from helping create advanced medical devices to patient-specific surgical guides. One company no one saw coming was restor3d, who leverages 3D printing capabilities to drastically improve surgical care by printing procedure-specific polymer instrumentation tailored to cervical spine implants.

One company no one saw coming was restor3d, who leverages 3D printing capabilities to drastically improve surgical care by printing procedure-specific polymer instrumentation tailored to cervical spine implants.

With a fleet of over 25 Formlabs 3D printers in its production line, restor3D is already printing the next generation of surgical tools. For surgeons using these tools, this procedure-specific, single packed sterile instrumentation system results in:

- Replacement of large, expensive surgical trays.

- Ability to iterate designs and quickly introduce new tools or features based on surgeon preferences.

- Dramatic reduction of supply chain and sterilization costs for hospitals.

Read How restor3d Is Creating Next Generation Tools

As much as 3D printing technology has developed in the past few years, there are even more high-impact, use cases currently in development. 3D printed organs is one of them.

Being able to easily create new organs has for decades been a dream for scientists working in regenerative medicine. While it remains in its early stages, the use of the 3D workflow to produce organic tissue eligible for transplant is bearing early fruit.

While it remains in its early stages, the use of the 3D workflow to produce organic tissue eligible for transplant is bearing early fruit.

Dr. Sam Pashneh-Tala from the University of Sheffield is leading the way. His research uses high-precision desktop stereolithography (SLA) 3D printing to enable the production of tissue-engineered blood vessels with a variety of geometries. This will allow for patient-specific vascular graft designs, improved surgical options, and provides a unique testing platform for new vascular medical devices for those suffering from cardiovascular disease—which is currently the number one cause of death worldwide.

“My differentiator is that I’m able to create blood vessels with geometries that are more closely matched to those found in the body. This offers the potential for improved surgical options and even patient-matched blood vessel designs. Without access to high-precision, affordable 3D printing, creating these shapes would not be possible, ” said Dr. Pashneh-Tal.

Pashneh-Tal.

Read About Tissue Engineering

The reconstruction of the three cities in the two different time periods consisted of over 650 segments, which were printed using Formlabs White Resin, each measuring 12x12cm.

As an industry already based on geometric design, prototyping, and modeling, architecture stands to gain enormously from advances in 3D printing technology.

On top of saving time during model production, the 3D printed models allow architects to anticipate the effects of certain design features with much greater certainty, e.g., by seeing a model produced with a fuller complement of materials, an architect can measure aspects such a light flow through the structure with higher precision.

But 3D printing’s use case goes beyond a single model: some firms are recreating entire towns. Institute of Architecture at the Hochschule Mainz - University of Applied Sciences. The result is an extraordinary exhibition that showcases six large-scale models of the cities, in the years 800 and 1250 AD. The models consist of over 650 parts, all of which were created using SLA 3D printing technology.

The models consist of over 650 parts, all of which were created using SLA 3D printing technology.

Learn About the Reconstruction of Medieval German Cities

The 990S TripleCell and the FuelCell Echo Triple.

The sport-footwear industry has long relied on technology to optimize the performance of their products, and with the digital workflow they have more options than ever in customization.

Large brands like New Balance, Adidas, and Nike, having recognized the power of additive manufacture, intend to mass produce custom midsoles made from 3D printed materials. As in other industries, the digital workflow will augment traditional methods of manufacture here—critical, highly-customized components of each product will be entrusted to the 3D printing, and the rest left to traditional means.

Given the unique properties required for footwear, New Balance worked with Formlabs to create a custom printing material which could resist the daily wear and tear faced by an athletic shoe. Shoe materials experience a variety of environments, with the additional need to withstand various levels of pressure thousands of times per day. Designed to create springy, resilient lattice structures, Rebound Resin has a much higher energy return, tear strength, and elongation than any other Formlabs material. Rebound Resin is strong enough to be used in gaskets, seals, and automotive interiors, but light and flexible enough for the sole of a shoe.

Shoe materials experience a variety of environments, with the additional need to withstand various levels of pressure thousands of times per day. Designed to create springy, resilient lattice structures, Rebound Resin has a much higher energy return, tear strength, and elongation than any other Formlabs material. Rebound Resin is strong enough to be used in gaskets, seals, and automotive interiors, but light and flexible enough for the sole of a shoe.

“One of the things that’s really exciting for us is that it provides a very different experience for the runner.”

Katherine Petrecca, General Manager of Footwear at the Innovation Design Studio, New Balance

See the 3D Printed New Balance Shoe

3D printing has already been integrated into the production of Hollywood films and is widely used for practical visual effects and costuming.

Whereas the creation of film's most fantastic creatures once required meticulous handcraft, the increased deadline pressure and time demands of modern moviemaking have made a quicker method of creating practical effects vital. Effects studios like Aaron Sims Creative now use a hybridized approach, practical effect-making enhanced by the digital workflow, to create new opportunities for collaboration and cut lead times on bringing ideas to life.

Effects studios like Aaron Sims Creative now use a hybridized approach, practical effect-making enhanced by the digital workflow, to create new opportunities for collaboration and cut lead times on bringing ideas to life.

“The Demogorgon was one of the first prints that we did using our Formlabs 3D printers, and we were amazed. Before that, we had always outsourced printing. So to be able to grow it in-house, and see a design that we helped create from the very beginning printed right in front of us, was kind of an amazing thing. It was like going back to the days when we used to sculpt with clay,” said Aaron Sims.

Read About How Aaron Sims Creative Builds Their Worlds

3D printing's artistic potential is not limited to physical artwork. It also has the power to bring entirely new dimensions to forms like dance and music. Given the design freedom inherent in 3D printing, even the most complex or unique instruments can be modified or created from scratch, at a fraction of the price of traditionally made instruments.

Having been around for centuries and barely changing, the violin’s form is recognizable to all. Violin music has evolved to such a high level that the instrument has attained an almost legendary status in our culture. But Formlabs engineer Brian Chan challenged himself to create a fully-functional acoustic violin, using a 3D printer and Formlabs White Resin.

Get an Inside Look at Design Process

3D scanning, CAD, and 3D printing have been used to restore the works of some of history's most famous artists, returning works by the likes of Michelangelo and da Vinci to their former glory.

Art restoration projects can be enhanced by combining 3D printing and 3D scanning, two powerful technologies that allow builders to take physical objects, turn them into three dimensional shapes, make changes or restorations, and re-print the parts.

Mattia Mercante uses 3D replication to replace lost pieces of sculptures and fine artworks at the world-renowned Opificio institute in Florence, allowing museum visitors to experience the art as the artists intended.

For one 17th-century reliquary, Mercante scanned intricate frame details from elsewhere on the piece using an HP 3D Structured Light Scanner, and then replicated the missing pieces on a Formlabs 3D printer. The prints were painted to appear identical to the original decorations. Best of all, the restoration required minimum CAD modeling, and was fast and affordable compared to hand craft.

Learn More About Art Restoration

3D printing has as much potential utility in reconstruction as it does in production. The work of a forensic artist is often made difficult by incomplete evidence. Digital technologies can be of tremendous use in legal investigations and can augment the abilities of forensic artists to reconstruct accurate models of persons of interest or victims.

The digital workflow here involves turning CT scans into 3D prints to aid in identification. For instance, when investigators find just part of a skull as evidence, a printer can model and replicate the complete sample.

Reconstructions of the appearance of crime victims have already played a key role in attaining justice, proving once again the utility of 3D printing beyond considerations of design and productive efficiency.

Just like 3D printing can be used for preoperative planning, CT scans of crime victims can help detectives get up-close to bones. Digital CT scan and X-ray data of remains can be used to produce 3D-printed replicas of various body parts. Then, the pathologist can determine the full circumstances of a crime, from the number of participants to the nature of the weapon used.

Learn More About Solving Crime

3D printing's impact is not limited to improving workflows or enabling rapid prototyping. It can also change lives directly. With 30 million people worldwide in need of artificial limbs and braces, there is hope that 3D printing can provide new solutions where cost and specification have traditionally been hurdles.

3D printing can provide an affordable alternative that, like many related advances in medicine, can provide therapy that is much more closely tailored to a patient's needs. The affordability and customizability of 3D printing techniques can profoundly alter the quality of life for the better for those suffering from injury or disability, as we saw in this story of a father and son.

The affordability and customizability of 3D printing techniques can profoundly alter the quality of life for the better for those suffering from injury or disability, as we saw in this story of a father and son.

We saw this type of innovation first hand with Matej’s and Mateja’s son Nik, who was suffering from cerebral palsy. Matej set out with a simple goal: to enable Nik to walk. Months of research and development followed, resulting in a custom-made, 3D printed orthosis that provides support and correction exactly where Nik needs them, which finally helped him take his first steps independently. Watch the full video above and read their story.

Beyond prosthetics which return lost function to a user’s body, it is possible to 3D print devices which are, in some ways, even better than the limbs they are replacing. With 3D printing, this is no longer a future possibility about bionetic, robo-cop like body parts, but part of the latest in cutting-edge prosthetic production. Some firms, such as Psyonic, are already delivering advanced prosthetics.

Arm Wrestling With A Bionic Hand

Maybe people think of 3D printing as producing smaller items which you can hold. In recent years, firms have been exploring manufacture-scale additive workflows that can produce much larger functional components. In the last few years, various initiatives have gotten underway to create houses and larger structures that are entirely the product of 3D printing, opening new frontiers in sustainable living and construction.

3D printing technique gives freedom of form to architects, even with previously less malleable building materials like concrete. More broadly speaking, it allows fully sustainable and energy-efficient homes to be built that also meet modern comfort standards. Construction by this means could be entirely waste-free, as well as less expensive and environmentally costly as traditional methods.

While you will not be moving into a 3D printed house on the near horizon, you can experience 3D printed construction projects today. The MX3D Bridge in Amsterdam is currently open to foot traffic. According to dezzen.com, the “structure used 4,500 kilograms of stainless steel, which was 3D-printed by robots in a factory over a period of six months before being craned into position over the canal this year.”

The MX3D Bridge in Amsterdam is currently open to foot traffic. According to dezzen.com, the “structure used 4,500 kilograms of stainless steel, which was 3D-printed by robots in a factory over a period of six months before being craned into position over the canal this year.”

Source: www.dezeen.com

Read More About the 3D Printed Bridge

With one of the highest barriers-to-entry of any industry in the world, space travel is ripe for 3D printing innovation. Lowering prototyping costs for expensive, space-specific tools and machines will lower costs and allow smaller companies to help innovate in space.

Aerospace startup Relativity has tested the creation of aluminum rocket engines using additive manufacturing. If successful, this application would sharply reduce the costs and practical difficulties of space travel, opening up the field to new business and to a vast potential for growth.

Masten Space Systems is another changemaker for 3D printing in the aerospace industry: founded in 2004, the company specializes in vertical takeoff and vertical landing rocketry. The company is launching a mission to the moon in 2022 as part of the NASA Commercial Lunar Payload Services (CLPS) Project. Using Formlabs 3D printers, Masten produced plastic rocket engines for R&D testing.

The company is launching a mission to the moon in 2022 as part of the NASA Commercial Lunar Payload Services (CLPS) Project. Using Formlabs 3D printers, Masten produced plastic rocket engines for R&D testing.

The company has experience in 3D printing in both plastics and metals--they’ve even helped develop new custom metals for their NASA Tipping Point project. “We really like 3D printed rocket engines because they enable you to do a lot of things that you can't do in a traditional manufacturing process. In our goal to drive down costs and increase our effectiveness, we started looking at how we could use the Stereolithography printers, particularly once Ceramic Resin and High Temp Resin were released. Those have some rather attractive engineering properties for seeing if we could actually use them in a rocket,” Matthew Kuhns, chief engineer at Masten, said.

Formlabs’ High Temp Resin and Rigid 10K Resin are examples of materials with optimal engineering properties for aerospace applications. High Temp Resin is designed for functional prototyping in high heat applications while Rigid 10K Resin is the stiffest material in our engineering portfolio, making it suitable for industrial-grade prototypes.

High Temp Resin is designed for functional prototyping in high heat applications while Rigid 10K Resin is the stiffest material in our engineering portfolio, making it suitable for industrial-grade prototypes.

Read More About Masten Space Systems

Origin Labs, within the Innovation Hub, will have a space dedicated to 3D printing for students and the broader community.

Most institutions of higher education are focused on preparing their students for the workforce of the future. The Pennsylvania State University is focused on the current workforce as well and has recently invested millions of dollars into building the Eric J. Barron Innovation Hub, which serves the public as well as the University community.

The Appalachian mountain range in western and central Pennsylvania has historically been the center of the nation’s coal mining industry, and enjoyed a solid and prosperous economy in the first half of the twentieth century because of it. As global and domestic economies shifted away from coal, the Appalachian region suffered, with a higher rate of joblessness and one of the lowest household income rates in the country, as reported by the Appalachian Regional Commission.

Over the last two decades, leadership at the local and state levels have sought to change that through investments in manufacturing, education, and technology. The Appalachian Regional Commission offers $1 million grants to “support educational opportunities and institutions, especially by connecting skill development and workforce training with local and regional business interests and opportunities.”

As additive manufacturing rapidly expands in a wide range of businesses (as seen in this blog post!), hiring managers are looking for employees trained in working in digital spaces and fluent in CAD. Universities are looking to address this market lead by creating large and well funded innovation hubs.

See the Investment the Pennsylvania State University is Making

Besides training tomorrow’s workforce in CAD and 3D printing, universities are starting to see the benefits of deploying 3D printers across a wide range of educational disciplines.

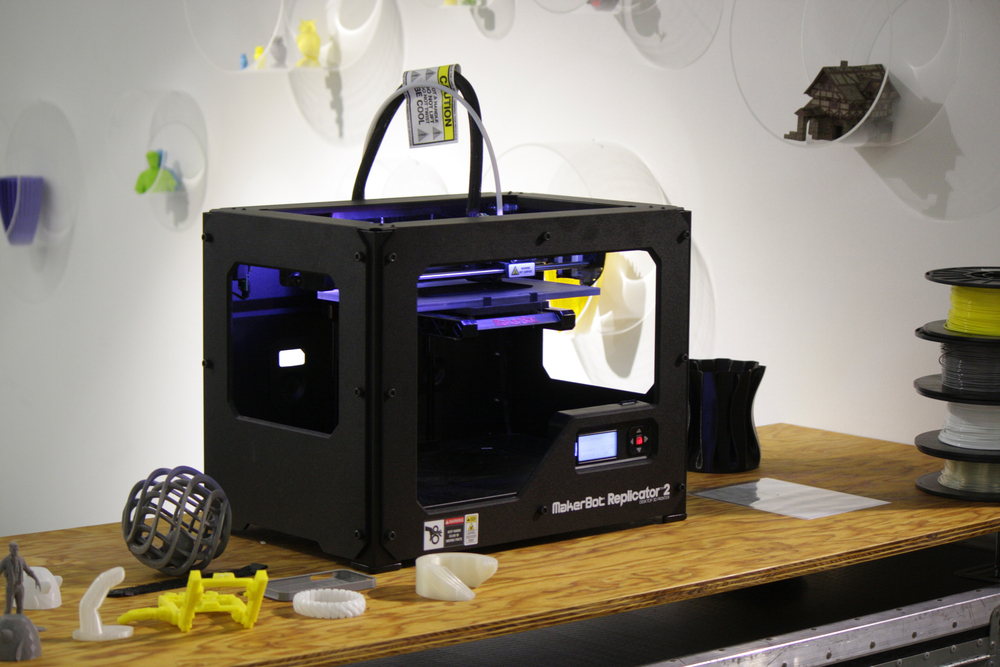

At UMass Lowell, that meant modernizing its sculpting and 3D design courses for the 21st century. Enter Yuko Oda, who joined the university in 2017 and got started by ordering a multitude of 3D printers, including a Formlabs SLA machine.

Enter Yuko Oda, who joined the university in 2017 and got started by ordering a multitude of 3D printers, including a Formlabs SLA machine.

Yuko is able to take her passion for art and technology into the classroom, currently teaching sculpture, 3D modeling and animation, and interactive media. Most students know that they’re required to understand 3D animation and 3D modeling for future careers in various fields, including sculpture design for cinema. For studio artists, 3D modeling has become an essential skill.

“Students sculpt a 3D model, import it into Zbrush, then print in various resins, including Clear Resin. The ability for Formlabs machines to show intricacies that were modified in Zbrush is unparalleled when compared to other printers in the lab.”

Yuko Oda

One of the most promising new developments in sculpture is the integration of 3D printing and Virtual Reality (VR). This is especially salient for students intimidated by 3D design. VR is rapidly reducing barriers for 3D design, allowing artists and students to create with their hands in programs such as Oculus Medium. Yuko has taught 8th graders how to create a 3D object in 30 minutes in VR, and then print the artwork on a 3D printer. Even for seasoned sculptors, VR reduces the time it takes to go from an idea to a physical object, potentially opening up new areas of experimental art.

VR is rapidly reducing barriers for 3D design, allowing artists and students to create with their hands in programs such as Oculus Medium. Yuko has taught 8th graders how to create a 3D object in 30 minutes in VR, and then print the artwork on a 3D printer. Even for seasoned sculptors, VR reduces the time it takes to go from an idea to a physical object, potentially opening up new areas of experimental art.

Learn How How UMass Lowell Integrates Art and Technology

While caretakers at ZooTampa were performing a routine check-up on a 25-year-old great hornbill, they found a lesion at the base of the bird’s casque, the yellow helmet-like growth on top of the head. Further examination determined that the bird, named Crescent, was suffering from life-threatening cancer.

The cancer, located near the bird's skull, couldn't be removed because it housed part of the bird's sinuses. The team wanted to know if they could remove the casque, and replace it with a 3D printed replica designed specifically for this bird. Patient-specific prosthetics and devices have been used before in human procedures, but never for a great hornbill. Would it be possible, and if so, which materials would be safe for the bird?

Patient-specific prosthetics and devices have been used before in human procedures, but never for a great hornbill. Would it be possible, and if so, which materials would be safe for the bird?

ZooTampa says the successful 3D-printed “replacement beak,” was created using BioMed White Resin. This material is an opaque white material for biocompatible applications requiring long-term skin contact or short-term mucosal contact. Special among Formlabs SLA 3D printing materials, this medical-grade material is validated for short-term tissue, bone, and dentin contact.

3D Printing and Veterinary Medicine

During the COVID-19 pandemic and following supply chain crises of 2021/22, many firms turned to 3D printing to help keep machines online and products rolling off the factory floor. The expanded use of in-house 3D printing to create end-use parts, such as replacement parts for machines, has made additive manufacturing a key tool to address supply chain problems.

Formlabs commissioned the 2022 3D Printing Applications Report to better understand what, if anything, has changed recently among 3D printing users. The report demonstrates the shift in attitudes around 3D printing from an R&D and prototyping tool to an invaluable manufacturing technology needed to meet evolving consumer preferences and overcome supply chain challenges. Whether working to ease supply chain constraints, creating limited run products, or personalizing devices, businesses have been forced to rethink how they produce goods to meet customer demand.

The report demonstrates the shift in attitudes around 3D printing from an R&D and prototyping tool to an invaluable manufacturing technology needed to meet evolving consumer preferences and overcome supply chain challenges. Whether working to ease supply chain constraints, creating limited run products, or personalizing devices, businesses have been forced to rethink how they produce goods to meet customer demand.

End-use parts printed on the Fuse 1.

An IR sensor purge printed on the Fuse 1 in Nylon 12 Powder.

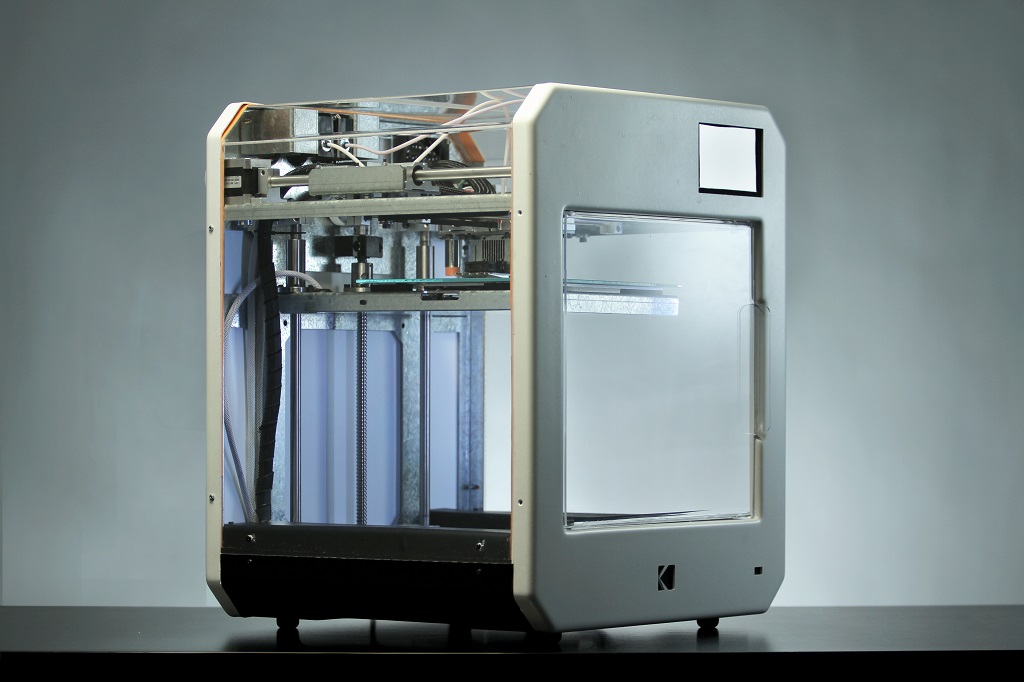

Building 3D printers is always an engineering challenge. Packing industrial-grade performance into an affordable, sleek desktop machine requires years of engineering and design work. This was especially true of Formlabs’ much anticipated selective laser sintering (SLS) 3D printer, the Fuse 1.

One of the tools Formlabs engineers used to prototype parts was the Fuse 1 itself. But the use of 3D printing didn’t stop at prototyping. Today, every single Fuse 1 unit shipped to customers contains multiple production parts printed directly on a Fuse 1 using Nylon 12 Powder.

Using the Fuse 1 SLS printer to prototype and create end-use parts offered three main advantages, according to Seth Berg, the engineer program manager overseeing the Fuse 1:

- The design freedom to create complex parts without internal support structures.

- Reducing supply chains by prototyping and creating end-use parts in-house.

- Eliminating outsourcing to achieve an affordable solution for small-batch production with a proven, versatile Nylon 12 material.

To see how the team did this, and which end-use parts on the 3D printer and 3D printers, watch the video below.

In May of 2020, Forbes ran an article titled: How 3D Printing Test Swabs Will Help Fulfill America's Shortage. They noted that the 3D printing industry has come together to tackle the COVID-19 swab shortage head on, with Formlabs, HP, Origin, Carbon, Desktop Metal and more working to ramp up swab production.

The impact of the COVID-19 pandemic required a global, concerted response. Through collaborating with USF and Northwell, Formlabs enabled a solution that has been deployed worldwide. With the accessible design, affordable equipment, and validated processes, the swab design enabled over forty million COVID tests in twenty five countries. Over the last year, Formlabs 3D printers have continued being used by governments and healthcare providers to improve patient testing and care. This global solution is just one example of how the agility of 3D printing can benefit the public good.

Through collaborating with USF and Northwell, Formlabs enabled a solution that has been deployed worldwide. With the accessible design, affordable equipment, and validated processes, the swab design enabled over forty million COVID tests in twenty five countries. Over the last year, Formlabs 3D printers have continued being used by governments and healthcare providers to improve patient testing and care. This global solution is just one example of how the agility of 3D printing can benefit the public good.

We saw this happen dramatically in Singapore, where Eye-2-Eye Communications ramped swab production to over 30,000 swabs per day to help keep the city safe.

“It has not only been an excellent opportunity to showcase the advantages of 3D printing for rapid design and development but it has also shown Formlabs effectiveness in being able to mass produce products in very short timeframes. Also, as we see spikes in cases across the globe it is reassuring to know we can scale our production relatively easily to meet demand if required,”said Chief Executive Officer of Eye-2-Eye Communications, Miles Podmore.

One controller with buttons printed on the Fuse 1 (left), and another with buttons injected molded (right).

One problem with creating custom aftermarket parts is these orders are typically low volume, and need to evolve in response to product updates by the original manufacturers. But with the rise of in-house 3D printing, custom manufacturing has sprouted in multiple industries.

Battle Beaver Customs is focused on delivering a premier gaming experience through custom gaming controllers. Their modifications make the controllers more responsive and more competitive, allowing players to increase their gaming potential and reach peak performance across a range of games. Rapid prototyping with the Fuse 1 SLS 3D printer allows Battle Beaver Customs to quickly change their mount and button designs. When building custom consumer products, quick turnaround times can pay dividends for businesses looking to stay ahead of their competitors. According to Head of Research and Design at Battle Beaver Customs, Michael Crunelle, the “Fuse 1 has been great for being able to make changes quickly, from concept to end-use part. Our competitors can’t keep up with us."

Our competitors can’t keep up with us."

JetBoatPilot, a marine parts and accessories manufacturer, has built a reputation as an authority in the industry by creating aftermarket products that improve the performance and low speed handling of jet powered boats.

JetBoatPilot utilizes the Form 3 SLA and Fuse 1 selective laser sintering (SLS) 3D printers to prototype and manufacture aftermarket parts. A newly designed and now top performing product, the Lateral Thruster 2.0, was designed and manufactured on the Fuse 1. Equipped with the Fuse 1 and Nylon 12 Powder, JetBoatPilot was able to cut costs by 6x compared to their previous manufacturing methods.“I probably would have made that (aluminum version) retail price somewhere in the $400 dollar range, maybe even $600 dollar range, if I really had pushed it. I wouldn't have sold nearly as many at $600. But now I'm selling it for $199 and the customer is happy as they can be. And I'm twenty times the cost of goods,” says JetBoatPilot founder Will Owens.

With 928 stores spanning across 48 countries, Lush Cosmetics is a retailer known globally for making creative and crowd pleasing products such as Massage Bars, Body Butters, Bath Bombs and more, attributes its success to being able to respond quickly to trends and customer demand.

To bring new, industry defining, highly-detailed cosmetics to life, Lush needed to turn to 3D printing for much more than prototyping new shapes. They’ve invested in a next-generation additive manufacturing center for mold creation, tooling, and end-use parts.

The Lush Cosmetics team vacuum forms using 3D printed molds in-house.

“We use our Formlabs 3D printers for a mix of mold creation, custom tooling, and end-use parts. We’re a reactive business and having this capability in-house means we don’t need to share designs externally as we own everything in the product development process,” said Damien Carter, Innovation Lab Manager at Lush Cosmetics.

See How Lush Cosmetics Operates

3D printing is unleashing new possibilities and business opportunities, such as mass customization. What used to be too complex, prohibitively expensive, or impractical to produce with traditional methods is available at no extra cost with digital technologies, giving full control to designers and opening the door for fully customizable consumer products to become a reality.

What used to be too complex, prohibitively expensive, or impractical to produce with traditional methods is available at no extra cost with digital technologies, giving full control to designers and opening the door for fully customizable consumer products to become a reality.

A good example of this is Gillette’s Razor Maker™, which gives customers the opportunity to customize the handle of their razor by picking various designs, colors, or adding custom text.

“For Gillette, piloting Razor Maker™ represents a crucial step in our customization journey where new technology and new business models must come together in order to deliver products that are as unique as our consumers,” said Donato Diez, global brand manager for Gillette and Razor Maker™

Learn How Gillette Uses 3D Printing to Unlock Consumer Personalization

White Paper

This guide will provide manufacturers with insights into the different approaches to customization, how to choose the most applicable approach, and more.

Download the White Paper

Dentistry has also been one of the most prominent drivers of 3D printing investment, desktop 3D printers are an increasingly common sight in dental labs and practices. As a matter of fact, the popular clear aligners, thermoformed on 3D printed molds, are possibly the single most successful use of 3D printing we've seen to date.

Over the past ten years, 3D printing has so advanced in dental that now no new dental labs are opening without using some form of digital dentistry. With materials so good they can 3D print permanent crowns, full dentures, and more.

3D printing technologies thrive in an environment where our unique bodies require custom solutions. As a result, the dental industry is going through a rapid digital transformation with digital workflows bringing increased efficiency, consistently high quality, and lower costs to dental labs and practices.

Five Ways 3D Printing Has Redefined the Dental Industry

Next time you’re out for a night on the town, keep your eyes peeled for our next unexpected 3D printing use-case: 3D printing is coming to custom glasses frames.

Marcus Marienfeld AG set themselves apart from conventional glass frames, using different and unique production techniques to create their frames. Recently they started integrating selective laser sintering (SLS) 3D printing into the production line for frames in their Swiss workshop for printing end-use parts and rapid tooling for forming titanium.

“You get very inventive and imaginative when you have a 3D printer in-house. I can do things with little effort that I wouldn't otherwise try," said Marcus Marienfeld.

See the 3D Printed Glasses

Visualizing 3D printing-driven changes in the way things are made does not require the feats of imagination it once did. As workflows have developed over the last several years and gained footholds in various industries, we are beginning to see that revolutionary potential demonstrated.

From dentistry and across healthcare to consumer goods, architecture, and manufacturing, the public is interacting more and more with the end products of 3D printing. Making custom parts cost-efficient, cutting lead times and overheads, and empowering customers by bringing them closer to the products they want—we can only expect the influence of 3D printing to continue expanding.

Making custom parts cost-efficient, cutting lead times and overheads, and empowering customers by bringing them closer to the products they want—we can only expect the influence of 3D printing to continue expanding.

Explore Formlabs 3D Printers

12 Uses for 3D Printers at Home

- Author

- Recent Posts

Martin

Besides many test devices, Martin now has his fourth own 3D printer running and prints as a hobby for friends, family and himself. He is happy to share his experience with each new article.

Latest posts by Martin (see all)

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

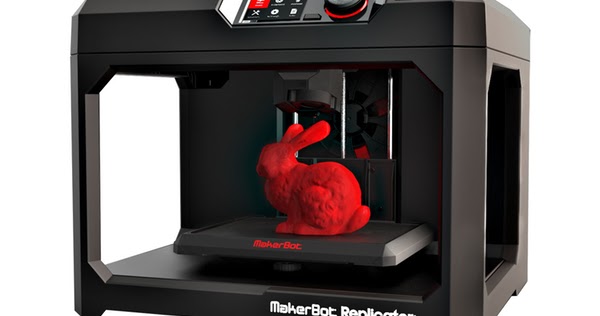

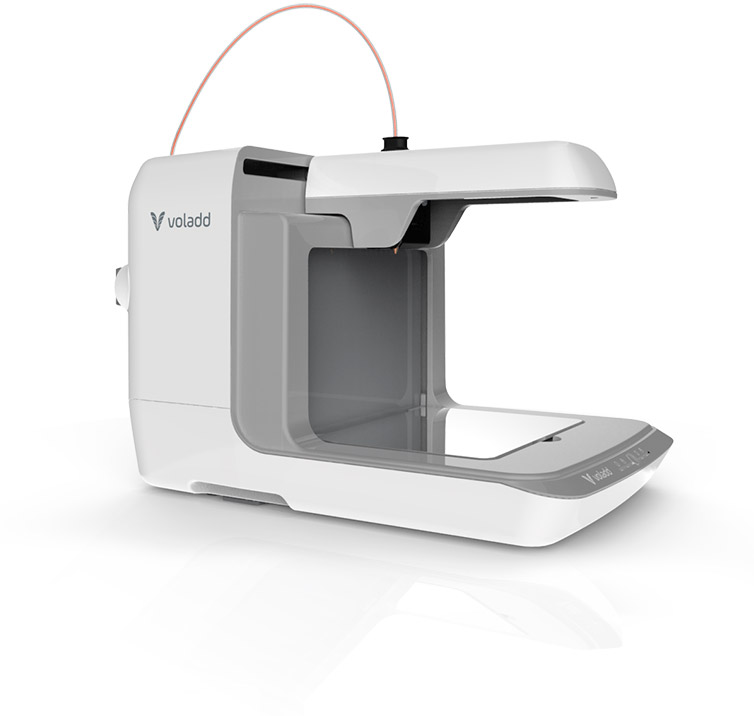

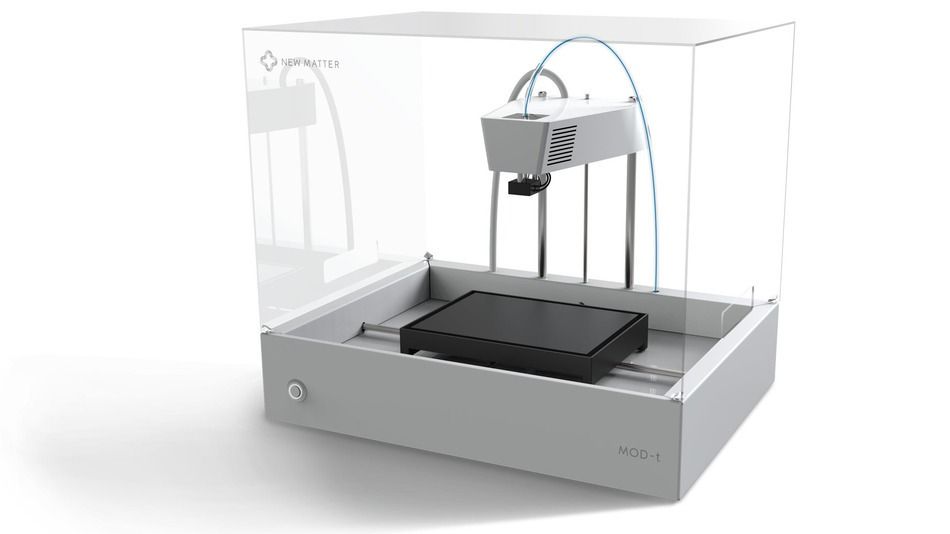

3D printers are taking private households by storm. This is partly due to the fact that the prices for entry-level models have dropped dramatically and you can now buy high-quality models for $200 to $300. The number of 3D models online you can print is also growing steadily. The many reasons that speak for a 3D printer at home, lead to ever-higher sales figures for the manufacturers.

The many reasons that speak for a 3D printer at home, lead to ever-higher sales figures for the manufacturers.

If you need more reasons to buy a 3D printer than the promise of a creative hobby with endless possibilities, check out this article for 12 more.

And if you’re wondering which printers would be best for you as a beginner, check out our guide on the best 3D printers for beginners.

Table of Contents:

- 1 Having Fun

- 2 3D Printed Practical Things

- 3 3D Printed Toys and Fan Articles

- 4 3D Printed Gifts

- 5 Save Time

- 6 Save Money

- 7 Earn Money

- 8 Educate Children

- 9 Experience the Future

- 10 Boost Your Creativity

- 11 Protect the Environment

- 12 Learn New Skills

- 13 Conclusion: 3D Printers Are Worth It!

Having Fun

Whether you’re printing miniatures for your tabletop, toys for your kids, your own action figures, or just decorative items for your home, the many uses for 3D printers at home give you plenty of room to express your creativity!

The endless possibilities of 3D printing offer you always new things you can learn and try. For inspiration, you have your own creativity as well as that of many other hobbyists. On websites like Thingiverse you can find numerous objects that you can print.

For inspiration, you have your own creativity as well as that of many other hobbyists. On websites like Thingiverse you can find numerous objects that you can print.

There are also countless filaments you can try:

- TPU: An elastic filament that can be used to print many interesting objects.

- Wood*: Filaments with wood fibers are especially popular for decorative items.

- transparent filaments: some filaments, like PETG, are available in transparent form.

- ABS: After PLA, the most popular filament for 3D printing. It is very tough and well suited for functional objects.

Especially when you venture into unknown territories and try new things, a sense of achievement is not long in coming. Of course, a certain amount of frustration is also pre-programmed, as there are many minor problems in 3D printing.

But for these problems, there is always at least one simple solution. And especially the overcoming of such problems brings you a sense of achievement and therefore a lot of fun.

And especially the overcoming of such problems brings you a sense of achievement and therefore a lot of fun.

As you can see, you probably won’t get bored with this hobby. The endless creativity of the community always provides you with new 3D objects that you can try out. There will also always be new interesting 3D printers that raise your interest.

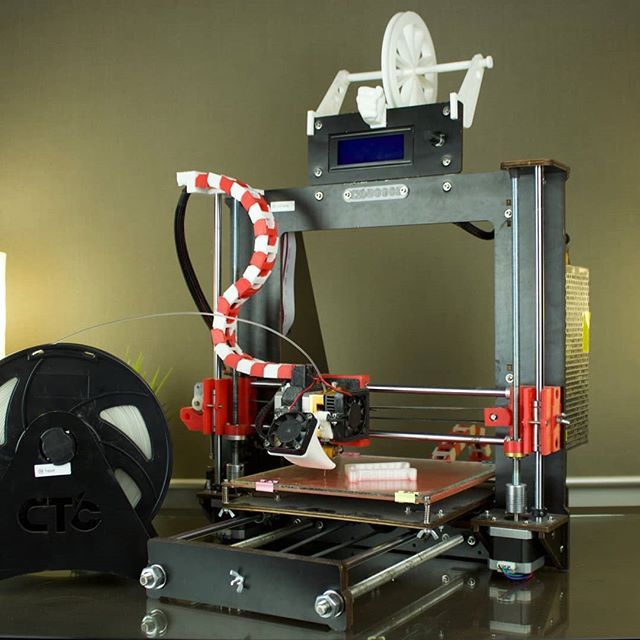

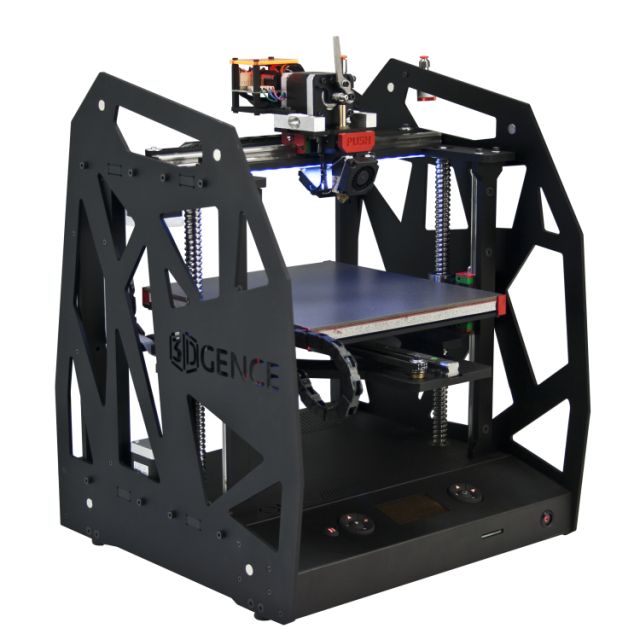

A very interesting aspect of the 3D printing hobby is upgrading your own 3D printer. For example, the extremely popular Ender-3 from Creality* offers countless upgrade options, allowing you to transform it from an extremely affordable entry-level model into a capable 3D printer for your own use.

It’s also a lot of fun to get friends and family involved in your hobby. The enthusiasm for 3D printing is highly contagious and you can have a lot of fun with gifts or joint projects.

3D Printed Practical Things

Stackable Battery Holders by adoniram made by iceekbAs already mentioned, there is an almost infinite number of 3D printing templates that you can find online. Among them are not only toys or fan articles, but also many practical objects.

Among them are not only toys or fan articles, but also many practical objects.

These include, for example, tea dispensers, stylish shelves, speakers, sanding blocks or mini purses. Self-created decorative objects are also very popular. There are numerous templates for plant pots, lamps and other stylish objects for your home.

Many things you need in your household can be 3D printed. This saves you the trip to the hardware store or the purchase on the Internet. This saves you time and money and you even have fun making the object.

Often you need to repair small things in the household and do not have the right part at hand. The resulting improvisation usually looks suboptimal and is in need of repair after a short time. If you 3D print the part to fit exactly, you won’t have these problems.

For many projects, it can be practical to design the objects yourself. This way you have full control over how the object will look and what function it will perform. But you don’t have to worry about needing half an engineering degree or having to deal with complicated CAD programs. There are now very simple online services like TinkerCAD that make designing objects very easy.

There are now very simple online services like TinkerCAD that make designing objects very easy.

An example of a successful DIY project is printing a replacement part for my dishwasher. One of the wheels for the lower basket of my dishwasher was broken. I simply measured an intact wheel and replicated it in TinkerCAD. Then all I had to do was print it out with my 3D printer and mount it (I used ABS* as filament so it could withstand the temperatures in the dishwasher).

3D Printed Toys and Fan Articles

Cute Mini Octopus by McGybeer made by m0g0d0nOf course, it is exciting to produce practical things with a 3D printer to create real added value. But more often, 3D printers are used in the private sector for fun things like fan articles or toys. Often there are also combinations of practical things and fan items like a Minecraft lamp or a Baby Groot planter.

Other examples of popular fan articles:

- Iron Man Mask

- Link Sword and Shield

- Baby Yoda (Grogu)

- Lightsaber

- Draft Punk Planter

- Hand of the King pin from GoT

If you buy official fan merchandise, it’s usually quite expensive due to its license. 3D printed items can look similarly good and cost only a fraction.

3D printed items can look similarly good and cost only a fraction.

Attention: You are not allowed to sell the fan articles printed at home, otherwise you will get into copyright trouble. But they are very good for decoration or as a gift.

Besides fan merchandise, actual toys are also very popular. And this doesn’t just mean toys for kids, but also for adults. Here are a few examples of popular toys for kids that you can 3D print:

- Flexi Rex (T-Rex made of several, movable links)

- Spinning Top

- Penny Balista

But there are also things for adults like tabletop terrain or figures. Here are a few examples:

- 3D Settlers of Catan

- Fantasy Figures

- Watchtower

- Dice Tower

3D Printed Gifts

Curved honeycomb vase by eggnot made by Oscar_PeralesFinding the right gift for someone is often not easy. Many options are boring or impersonal. The search for an individual gift is often stressful and unsatisfying. To find a good gift you have to invest a lot of time in the search.

To find a good gift you have to invest a lot of time in the search.

With a 3D printer, however, you have the choice to create anything your creativity can come up with in no time. There are many possibilities to create a personalized gift for friends or family members through 3D printing.

A gift from the 3D printer is always unique and the recipient is usually very happy about it. With a self-made gift, it is obvious that you have dealt with the person and thought about how you can make him or her happy with a gift.

The search for a suitable gift is also very simple. Everyone has a special area of interest or things that they love. If you search for these things on the online databases for 3D print templates, you will find a lot that fits into this niche.

Is your friend or relative interested in a particular movie series, such as Star Wars? Does he or she like to build remote control cars? Or maybe a nice decorative object is just the thing?

For every field of interest or hobby, there are creative ideas that you can 3D print. And even your own creativity limits you here only limited because you can fall back on the creativity of many other hobbyists.

And even your own creativity limits you here only limited because you can fall back on the creativity of many other hobbyists.

Save Time

With 3D printers, you can produce any geometry in a very short time. This is one of the great strengths of this technology that makes it interesting not only for hobbyists but also for industry and science.

If you need to make a quick repair at home and you’re missing a spare part, you can simply 3D print it. You don’t have to wait for long delivery times and can solve the problem directly.

I mentioned above that this is how I fixed my dishwasher. Had I not printed the broken wheel myself, I would have either had to live with the defect or wait weeks for the replacement part, if it had been available at all.

Depending on what kind of 3D printer you have, smaller parts are ready within 20 to 30 minutes and even complex and large objects after a few hours. I have often saved myself a trip to the hardware store by simply printing the part myself.

Even in the hobby area, you can save a lot of time with your 3D printer and save yourself eternal waiting times. Are you missing a part in a board game? Just print it. Did your kid break a toy? Just print a new one. Want to upgrade your 3D printer but don’t want to wait 4 weeks for a power supply cover? Just print it yourself.

Even with 3D printing itself, you will save more and more time as the process becomes more efficient. With time you will know exactly which settings you need to pay attention to. You will be able to create or find new objects faster and faster and print them with the right settings.

Save Money

We spend far too much money on the little everyday things. Here a new doorstop, there a new plant pot and a kitchen roll holder is also missing.

Especially such small household items add up to a big pile of money over time. But the price of such items in the store or online consists mainly of logistics and profit margin. The actual manufacturing costs are usually only pennies!

If you print such things from a cheap filament, you will save a lot of money in the long run, which you can invest in other, more useful things.

The trend to make your own objects will increase more and more in the future. At some point, it could be that everyone makes their own everyday objects at home.

At the moment it is only possible to print with plastics in the hobby area. But this material alone offers millions of items you can make yourself. This doesn’t mean that the big factories in East Asia will disappear anytime soon, but more and more will happen at home.

Need a new cover for your smartphone? You can print countless designs yourself and not only save delivery times and their costs – you also do something good for the environment because this small plastic item no longer has to be shipped halfway around the world but is produced directly at your home.

Earn Money

3D Printed Products on etsy.comThe production of objects exactly to customer dimensions is a specialty of 3D printing. Few manufacturing methods can deliver similar results so cost-effectively and quickly.

Injection molding, for example, is only worthwhile for objects that you want to produce thousands or even millions of times. But if someone only needs a prototype, injection molding is much too expensive and much too slow. To produce a suitable tool for this alone costs several $1000, engineers and a lot of time. Making a CAD model of the prototype and printing it within a few minutes or hours is much faster and cheaper.

But if someone only needs a prototype, injection molding is much too expensive and much too slow. To produce a suitable tool for this alone costs several $1000, engineers and a lot of time. Making a CAD model of the prototype and printing it within a few minutes or hours is much faster and cheaper.

But not only in this professional context, you can earn money with 3D printing, also private persons can earn some money on the side or even start their own business.

There are many startups that make themselves independent with self-designed objects. On Kickstarter, for example, there are regularly new projects that support the launch of tabletop figures. Mostly they are very successful and offer the startup a possibility to make their ideas come true.

You can also offer your self-designed and manufactured products on platforms like ebay or Etsy and sell them directly to customers.

But you don’t only have to have profit in mind. You can continue to feed your hobby with the money you earn from it. If you sell a few items online in between, you can eventually buy a better printer with the profit. This opens up a whole new world of possibilities.

You can continue to feed your hobby with the money you earn from it. If you sell a few items online in between, you can eventually buy a better printer with the profit. This opens up a whole new world of possibilities.

Also, the whole process around the topic of making money with 3D printing can be turned into money. There are now many online portals like udemy where you can offer self-created online courses.

Educate Children

Children learn best when they can try things out for themselves and enjoy the activity. 3D printers are a perfect example of how hands-on technology can support learning new skills.

Building a 3D printer yourself and holding a self-printed object in your hand promotes the technical competence of children enormously. Also, the sense of achievement to hold something self-made in your hands contributes strongly to the development of the child. To get only dry theory through monotonous lectures or boring books is not very effective. Many schools and universities have noticed this by now.

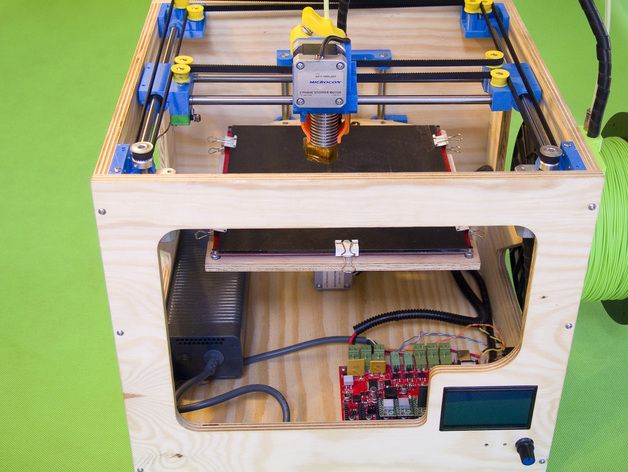

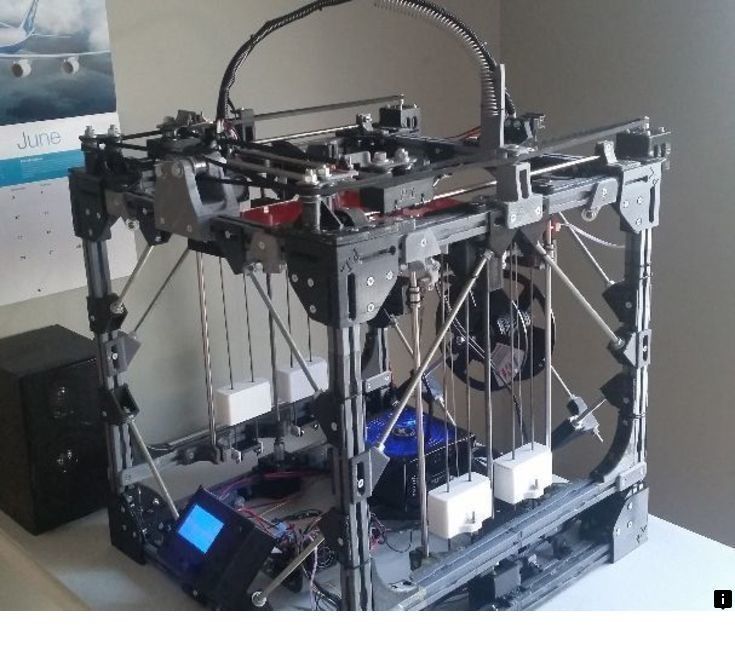

There are now many educational institutions that use 3D printers in their teaching. Especially DIY 3D printers are advantageous because they promote problem-solving. The learning effect is even greater when you have solved a problem while printing in a team and can hold the perfect result in your hand at the end.

In today’s world, it is increasingly important that children learn how to use technology. Once they lag behind, they can hardly catch up with the others.

3D printers cover many areas of modern technology that should be learned. The perfect combination of touchable technology, entering settings in the 3D printer program and operating the 3D printer via touch screen, is the perfect mix of digital and analog technology.

If you are looking for a 3D printer for children, you have to make sure that it is safe to use. Also, children should only use filaments that do not release toxic gases.

Experience the Future

Large-Scale 3D Printer (source: forcetechnology)3D printing is still in its infancy. The technology will continue to evolve over time and take over more and more areas of our lives. The technology will not only spread in the industry, but it will also influence our everyday life immensely.

The technology will continue to evolve over time and take over more and more areas of our lives. The technology will not only spread in the industry, but it will also influence our everyday life immensely.

While 3D printing is still a gimmick or an interesting hobby for many at the moment, it will be indispensable in the future. With many technical gadgets, we have justified doubt before buying whether it is worthwhile to invest in this technology at all or whether it is just an entertaining fashion and quickly becomes boring.

With 3D printing, however, you are actively participating in a future technology that will continue to develop over time. This is not only exciting but also practical, as you are one of the first to benefit from the advantages of 3D printing.

It is also very exciting for children to learn about this technology as it will have even more importance in their future. In 20-30 years, when every household is printing its own everyday items, these children will be able to say that they were there at the beginning.

Just as it sounds inconceivable to kids today when you tell them you’re older than Google, this will eventually be the case with 3D printing. When it is taken for granted that you can print a new coffee mug or a new chair, it will be unimaginable for many that they had to have these objects sent to their homes from manufacturers around the world.

So when you invest in a 3D printer, you make sure that you don’t get stuck in the past and join a conversation when it comes to future technologies. The ever-growing topic will continue to develop and thus remain endlessly exciting.

Boost Your Creativity

3D printing is like magic! And just like magic, 3D printing is only limited by your creativity.

And it’s not just about what you should print next but also how you solve problems. Like so many things in life, the journey itself is the destination. While 3D printing is all about holding a specific object in your hand at the end, it’s also about getting to grips with the 3D printer, its settings and the associated software, especially when it comes to the hobby.

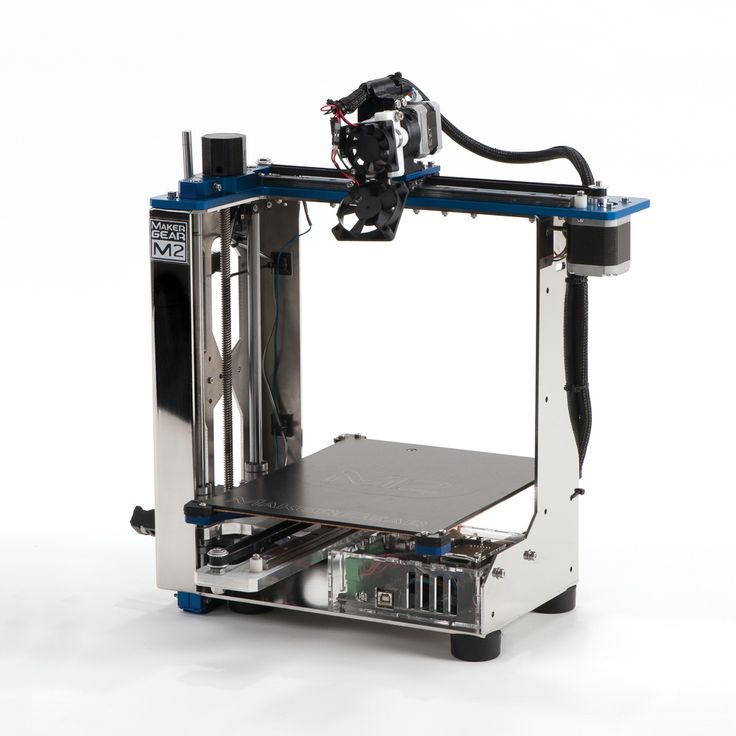

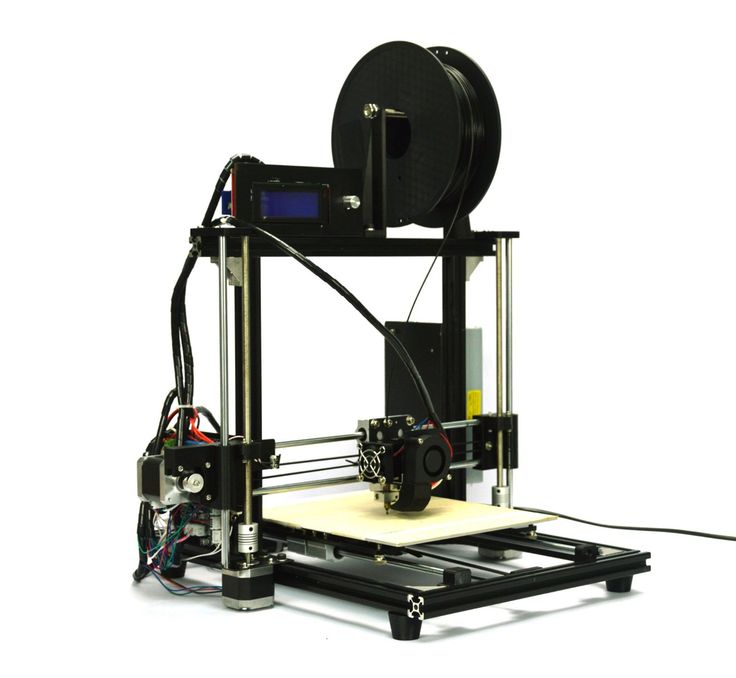

Depending on which aspect of this hobby you want to focus on, you can either buy a 3D printer kit or a ready-made high-end 3D printer.

With a kit, you have to do a lot more tinkering on your own. With a ready-made 3D printer of high quality, it is actually only necessary to download the appropriate 3D object and press a few buttons in the 3D printing software and on the 3D printer itself.

But you don’t need to be afraid of such DIY kits – there are now countless tutorials in video and text form that explain everything about such kits. In addition, there are many specialized forums where you can address problems and think about solutions together.

Indulging in a creative hobby can bring you a lot of joy and be a meaningful pastime. There are far too many distractions to get lost in these days that don’t add value in the end. Social media is depressing, but a creative hobby makes for lasting happiness as long as it doesn’t get boring. And with the endless possibilities of 3D printing, this hobby can’t get boring!

Protect the Environment

PolyTerra*, the Environmentally Friendly 3D Printing Filament (source: 3dnatives)The environmental footprint of 3D printers can be much smaller than that of conventional manufacturing processes.

For 3D printing, you need filament which is manufactured and shipped in one spool. All the objects you make from this one spool do not need to be shipped or made.

Most manufacturing processes require a lot of energy and several steps to produce the final product. With 3D printing, this is only one step and only some electricity. And even this electricity you can get from sustainable sources.

It is unbelievable how many items ordered online are transported across our oceans. It’s a seemingly endless series of massive container ships blowing their exhaust fumes into our environment. Some of this could be saved if we made more items at home. Besides, it could save you a lot of time!

It is now even possible to recycle and reuse filaments. This way you could reduce the impact on our environment even more. There are also a variety of eco-friendly materials available for 3D printing.

The most popular filament for 3D printing is PLA. This plastic is biodegradable and can be produced in an environmentally friendly way. So if it’s important to you to protect the environment, you should use materials that don’t harm our planet even more.

So if it’s important to you to protect the environment, you should use materials that don’t harm our planet even more.

Learn New Skills

From the idea to the finished 3D printed object, you have to go through a few processes. All these processes are very different and require different skills.

Not only do you need to be comfortable with digital media, but you also need some dexterity and technical understanding. And if any of these aren’t your strengths, 3D printing is a perfect way to turn that weakness into a strength!

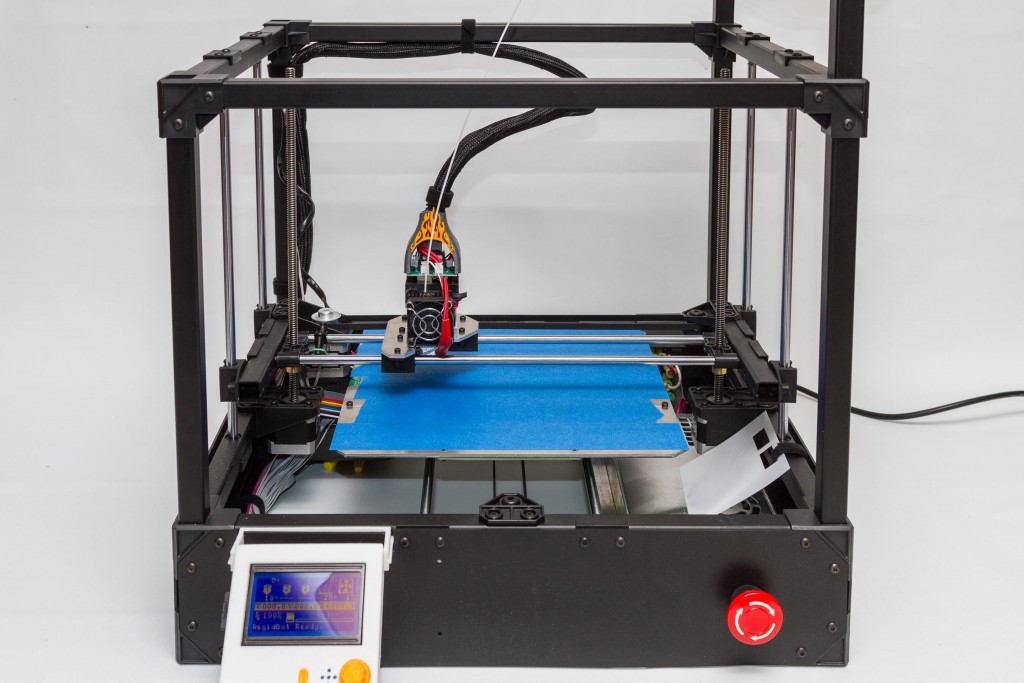

3D printer assembly: right at the beginning you train your technical understanding when you assemble the 3D printer. Some 3D printers, especially those in the lower price segment, are delivered in a half-assembled state. Here you have to do it yourself and make sure that everything is connected correctly.

Upgrading a 3D printer: Many 3D printers can be upgraded. There are many purchasable upgrades that you just need to install. But there are also many printable upgrades, such as a more efficient housing for the hot end or a filament holder.

But there are also many printable upgrades, such as a more efficient housing for the hot end or a filament holder.

Create 3D models: If you want to create your own CAD models, you’ll learn a lot of skills that can be useful in other fields. The intuitive handling of new software is also extremely important for almost every career or job.

Solving problems: A variety of problems can arise during 3D printing. Sometimes the filament throws bubbles (“blobs“), small threads appear on the print object (“stringing“) or the first layers curl up (“warping“). For all these problems there are solutions that have to be found and applied. You will not only learn a lot about 3D printing – your ability to solve problems, in general, will be promoted.

Conclusion: 3D Printers Are Worth It!

3D printing has successfully found the home user. Entry-level 3D printers are more affordable than ever, and usability is improving all the time.

The entry hurdle is getting lower and lower and it is no longer a big investment to dedicate yourself to this hobby. The only requirements you need to bring for the hobby are curiosity, a PC and internet access. If you have all this, you will very quickly find pleasure in being able to hold your own creations in your hands.

The only requirements you need to bring for the hobby are curiosity, a PC and internet access. If you have all this, you will very quickly find pleasure in being able to hold your own creations in your hands.

As you’ve seen in this article, there’s almost no limit to the things you can print. You’ll also save time and money in the process.

If you are interested, these articles are the next step:

- Best 3D Printers for Beginners

- Best 3D Printer DIY Kits

- Best 3D Printers under $300, $500 and $1000

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.

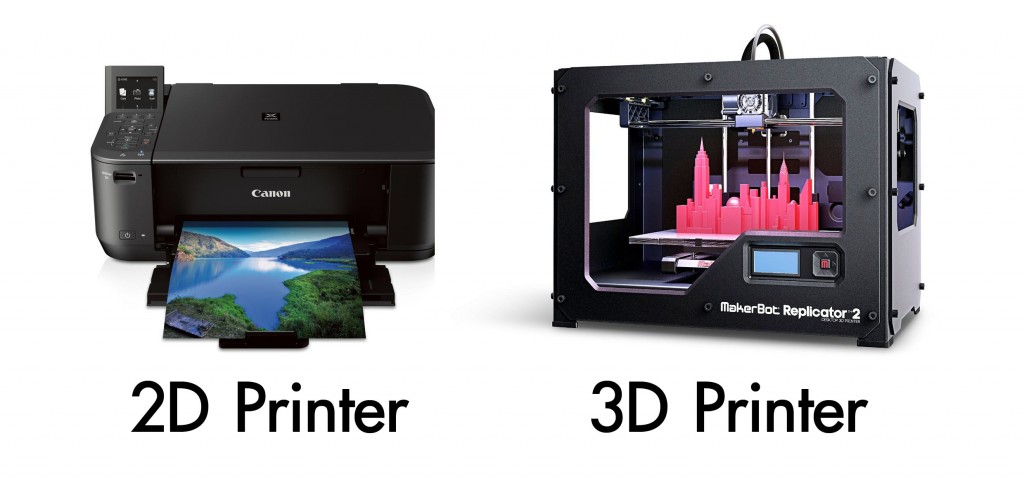

What is a 3D printer and why is it needed? / Amperka

Additive technologies have been going to the masses for a long time: institutes and research centers have been closely involved in them since the 80s, and now the moment has come when you can touch high-tech and master 3D printing right at home. You don’t even have to break the bank to do this: the prices of 3D printers have caught up with average smartphones. We understand how it works and what opportunities open up for makers and DIY enthusiasts!

You don’t even have to break the bank to do this: the prices of 3D printers have caught up with average smartphones. We understand how it works and what opportunities open up for makers and DIY enthusiasts!

Everything for 3D printing ❯

Why you need a 3D printer

The printer is very useful for do-it-yourself engineers. You no longer have to look for a universal case for the project, and then drill additional holes in it. 30 minutes of design, a few hours of printing - and you already have a case that is perfect for your device. Assembly of 5 shields does not fit anywhere? Forget about such problems.

The printer is sure to help you repair gizmos around the house. Everyone has had a situation in life when a thing had to be thrown away, although only one plastic part was broken in it. With the help of 3D printing, you can easily replace rare plastic parts in appliances that are difficult to find separately.

Until you learn how to model plastic parts yourself, you can simply download them on the Internet. There are many sites with millions of ready-made free models that are freely exchanged by users. We devoted a separate article to the search for models.

There are many sites with millions of ready-made free models that are freely exchanged by users. We devoted a separate article to the search for models.

Types of 3D printers

There are several main types of 3D printers that differ fundamentally in terms of how they work.

FDM (Fused Deposition Modeling)

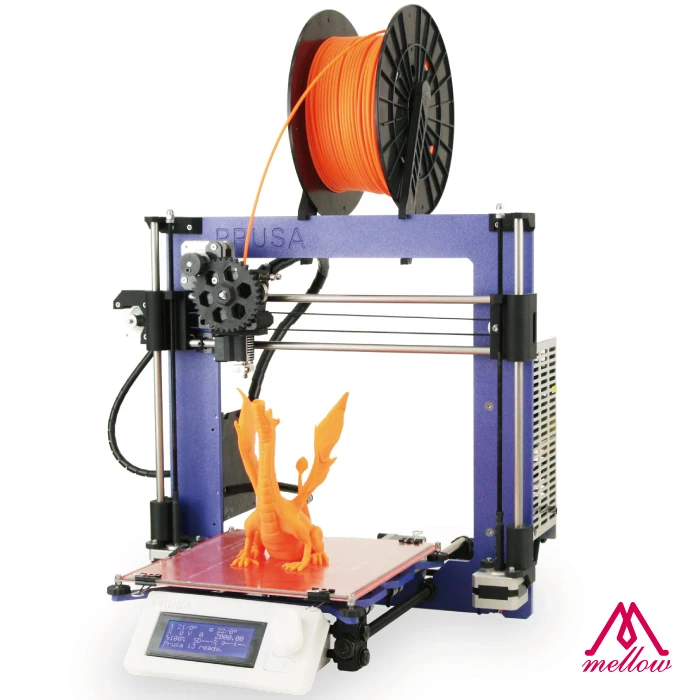

FDM printers are the most common type. They work due to a movable print head with a heating element. Plastic is fed into it in the form of a rod, which melts and is squeezed out in liquid form onto the printing table. At the same time, the plastic is blown by a fan and instantly freezes, and the head begins to squeeze out a new layer over the frozen one.

SLA technology (Stereolithography Apparatus)

SLA printers work on the basis of stereolithography: instead of plastic, a special photopolymer resin is used, which cures under the influence of ultraviolet rays. For printing, the resin is filled into a tray, below which there is a display with ultraviolet pixels. A drawing of the lower layer of the model is displayed on it for several seconds. In this case, the resin above the display solidifies in the form of a displayed pattern and then sticks to a special movable table from above. After that, the table with the first layer rises, and the next layer polymerizes in the resin.

A drawing of the lower layer of the model is displayed on it for several seconds. In this case, the resin above the display solidifies in the form of a displayed pattern and then sticks to a special movable table from above. After that, the table with the first layer rises, and the next layer polymerizes in the resin.

SLS (Selective Laser Sintering) Technology

SLS printers use selective laser sintering technology, which uses a special plastic powder. During the printing process, a thin layer of powder is poured, and the printer processes it with a laser so that the layer hardens according to the model. Then the next layer of powder is poured and fused with the previous one - and so on in a circle. At the end, it remains only to clean the finished part from the remnants of the powder, which can then be reused.

Technology comparison

Each type of 3D printer has its advantages and disadvantages.

- SLS printers are large and require expensive raw materials.

They are often used in high-tech industries for piece parts.

They are often used in high-tech industries for piece parts. - SLA printers are much more widespread. The UV display improves accuracy, but working with toxic photopolymer resin at home is difficult.

- FDM printers are the most popular among hobbyists. A plastic rod is much cheaper than a special powder or photopolymer resin. However, to print complex geometry on such a printer, you will have to take care of auxiliary support. And the print speed is on average lower than on other technologies. But FDM printers are the easiest and safest to maintain.

How to prepare a print

The process from the conception of an idea to the production of a finished plastic part is simple - a schoolboy can handle it. We've broken it down in a 3D printing guide using the Flying Bear Ghost 5 printer as an example, but here we'll show you the general principle.

Initial model

First you need to create or download a 3D model of the future part. As a rule, sources are stored in the STL format, which describes the polygonal structure of the model as a set of triangles. But it will not be possible to immediately send such a file to the printer: for successful printing, you first need to break a detailed 3D model into layers that the printer can handle.

But it will not be possible to immediately send such a file to the printer: for successful printing, you first need to break a detailed 3D model into layers that the printer can handle.

Slicing

The program for cutting models (slicer) will require you to enter the model of your printer and set the print settings: layer thickness, percentage of internal filling of the part, auxiliary supports and the like. Based on this data, the slicer will automatically prepare a special code for the printer - G-Code, which describes how to move the print head, to what temperature it should be heated, and at what speed to extrude plastic in order to get the desired model layer by layer. Then it remains to load this code into a 3D printer and be patient until the end of printing.

The whole process of model preparation is clearly illustrated by the program and provided with intuitive tips for novice users. In general, slicing is not as scary as it is painted!

Finishing

After the model is ready, it can be further processed with sandpaper or a chemical solution. This will smooth out the unevenness between the layers, and the part will look just like the factory. There are a lot of life hacks on the Internet that will help minimize the flaws of the model and give it an improved look.

This will smooth out the unevenness between the layers, and the part will look just like the factory. There are a lot of life hacks on the Internet that will help minimize the flaws of the model and give it an improved look.

Printing consumables

The properties of the printed item largely depend on the raw material. As we said before, FDM 3D printers use plastic filament as a consumable, and you have a lot of room to experiment with different types of plastic.

- PLA is highly extrudable and allows complex shapes to be printed at relatively low head operating temperatures of 190°C. The biodegradability of PLA plays into the hands of the environment, but at the same time, things from it are not very durable.

- PETG plastic is stronger than PLA, but also well suited for printers with temperatures around 200 °C. Varieties of PET plastic are well known to you from bags and plastic soda bottles.

- ABS plastic is more durable than other types.

However, your printer will need an elevated extrusion temperature of around 250°C and a heated bed up to 120°C to print quality ABS plastic, so not every model aims to support it.

However, your printer will need an elevated extrusion temperature of around 250°C and a heated bed up to 120°C to print quality ABS plastic, so not every model aims to support it. - HIPS plastic is close in temperature properties to ABS, but has low caking with it and is easily removed with an organic solvent. Because of this, HIPS plastic is often used for printing composite models and supports for ABS models.

- Wood plastic is produced with the addition of wood dust. Finished models from it imitate wood not only in their appearance, but also in smell.

Plastic spools are everywhere - you can easily choose the right consumables and combine different properties and colors of parts when printing.

In conclusion

Home 3D printing is easier than you think. With a 3D printer at hand, you can create any plastic parts you can think of: cases, mock-ups, figurines, and more. Do not forget that you have at your disposal a huge library of models that are shared on the Internet. Broken vacuum cleaner nozzle or window opening limiter? No problem! Having your own 3D printer, you just need to take the finished model from the Internet, run it through the slicer program in a couple of clicks and send it to print.

Broken vacuum cleaner nozzle or window opening limiter? No problem! Having your own 3D printer, you just need to take the finished model from the Internet, run it through the slicer program in a couple of clicks and send it to print.

Useful Links

- Where to Download Free 3D Models of

- Flying Bear Ghost 5 3D Printing Manual

- Creality Ender-3 V2 3D Printing Manual

what a 3D printer can do

The possibilities of 3D printing

Unfortunately, the current level of awareness in 3D technologies leaves much to be desired. It happens that even with a basic knowledge of 3D printers, the actual application of 3D printing remains incomprehensible to a number of users. To avoid such situations, we have prepared this article and will consider in detail all the possibilities of 3D printing.

Application of 3D printing

When it comes to the application of 3D printing, it is worth considering not only the existing possibilities, but also the prospects. Already today, the application of 3D printing technology is extremely extensive and does not stop expanding. Of course, in the future we expect a large-scale distribution of additive techniques, but the practical application of 3D printing is available to everyone today. We will not delve into narrowly specific aspects of technology, such as 3D food printing, or bioprinting. Instead, let's talk about how 3D printing technology can be used by ordinary users with desktop 3D printers.

Already today, the application of 3D printing technology is extremely extensive and does not stop expanding. Of course, in the future we expect a large-scale distribution of additive techniques, but the practical application of 3D printing is available to everyone today. We will not delve into narrowly specific aspects of technology, such as 3D food printing, or bioprinting. Instead, let's talk about how 3D printing technology can be used by ordinary users with desktop 3D printers.

1. Prototyping

The best way to use 3D printing is for its intended purpose. Rapid prototyping is not only the second name of the technique, but also the original goal of its development. Creating prototypes using 3D printing significantly reduces production time and costs. And thanks to the possibilities of 3D modeling, the range of designed parts is practically unlimited. Prototyping allows you to visually assess the possible shortcomings of the product at the design stage and make significant changes to the design of the part even before its final approval.

2. Small-scale production

For small-scale production, 3D printing is a godsend. The properties of many materials allow the production of finished components at minimal cost. Compared to traditional production methods, small-scale production using 3D printing is very profitable from a financial point of view. The manufacture of molds, for example, is a lengthy and costly process. At the same time, injection molding itself takes a lot of time. On a 3D printer, you can print a batch of the necessary products in a matter of hours. This application of 3D printing is extremely relevant for frequent orders for small batches of parts.

3. Repair and restoration

Another application of 3D printing is the repair and restoration of damaged parts. For these purposes, 3D printing is ideal. You can carry out such a procedure both independently, with the appropriate skills and equipment, and in specialized 3D printing services, such as 3DDevice. First, a correct 3D model is built on the basis of the damaged product. 3D scanning can also be used to simplify design. Next, the finished model is sent to print and reproduced on a 3D printer in the required number of copies. Repair and restoration of damaged parts using 3D printing is fast, and the presence of a digital model of the component allows you to reprint it at any time.

3D scanning can also be used to simplify design. Next, the finished model is sent to print and reproduced on a 3D printer in the required number of copies. Repair and restoration of damaged parts using 3D printing is fast, and the presence of a digital model of the component allows you to reprint it at any time.

4. Production of functional models and finished components

One of the industrial applications of 3D printing is the production of functional models and finished components. Making products on a 3D printer from a transparent material allows you to see the work of a functional part “from the inside”, which is very useful when developing various engineering samples. In addition, a wide range of different materials for 3D printing turns it into a full-fledged production tool. Industrial 3D printers are gradually becoming a part of every industry, allowing the production of durable metal components.

Other questions and answers about 3D printers and 3D printing:

- Opportunities What is the future of 3D printing?

- Finance How to choose the right 3D printer?

5.

Household items

Household items Need an office organizer? Or a knife holder? Any household items can be printed on a 3D printer. The advantage of this application of 3D printing is that there are no restrictions when developing 3D models. That is, if you want to show imagination and create something original - all the cards are in your hands. Thanks to 3D printing, your home can be decorated and made more functional easily and inexpensively.

6. Toys and souvenirs

Having a 3D printer makes it very easy to make a child happy – just make cute 3D toys. There are already some pretty interesting projects of collective 3D printed games, and in the future this list will only expand. This application of 3D printing will please not only children, but also enthusiastic collectors, because on a 3D printer you can print figures of any characters and attributes of computer games and films. And color 3D printing will make it possible to produce exclusive full-color souvenirs - miniature figurines of real people. To do this, a digital model of a person is formed on the basis of 3D scanning data. In this case, all textures and color data are preserved. Everyone will definitely like such a gift, because getting a tiny copy of yourself is so unusual.

To do this, a digital model of a person is formed on the basis of 3D scanning data. In this case, all textures and color data are preserved. Everyone will definitely like such a gift, because getting a tiny copy of yourself is so unusual.

7. Design products

For creative people, there is another use for 3D printing. 3D technology in general is a unique opportunity to show your talent in the most unusual way. Artists, sculptors, fashion designers and designers from all over the world use 3D printing to create exclusive pieces of art that would be impossible to produce with standard methods. Such designer pieces impress with their beauty and originality, often fusing digital and traditional art. In addition, 3D printing techniques for clothing and footwear are being actively developed. Some models have even gone on sale, but it's too early to talk about mass production.

8. Capabilities of a 3D printer

We have listed the main capabilities of a 3D printer, but they do not end there.