Mattell 3d printer

From Creepy Crawlers to 3D Printers: Mattel Resurrects the ThingMaker - 3DPrint.com

One sign that I’m getting old is that I’ve started to do the “back in my day!” thing more often than I’m entirely comfortable with. One example of this is when it comes to kids’ toys. I’ve written a bit about 3D printers for kids, which are becoming more common; I’ve also seen virtual reality headsets, tablets, and even robots designed specifically for children. “Back in my day, we played with rocks!” This is actually true: rocks made great currency, “food” for the outdoor “kitchen,” buried treasure and projectiles.

I did play with a few high-tech toys, though, which in the ’90s meant a Skip-it, a Lite Brite, a Teenage Mutant Ninja Turtles pizza shooter, Shrinky Dinks (I still have a magnet on my fridge made from a California Raisins Shrinky Dink I was very proud of) and Creepy Crawlers, the official name for which, I’m just now learning, was “ThingMaker.” The toy consisted of metal molds into which you poured a dubious, colorful chemical substance. The molds were then heated until the chemical substance solidified into wibbly-wobbly, Jello-like insects, which were NOT to be eaten. I’m not sure what their purpose was, actually, other than throwing them at your cousins, but they were fun.

ThingMaker back in my day.

Like I said, high tech! Most of my childhood toys are obsolete now, though I did just discover, to my surprise, that Shrinky Dinks are still a thing. But now comes the news that Mattel has resurrected the ThingMaker. Yes! It’s not the goopy mess it was back in my day, though – it’s now been upgraded to…a 3D printer for kids!

Yes, even Creepy Crawlers are cooler than I am now. The new and improved ThingMaker was just unveiled at Toy Fair in New York, and the noxious chemicals and metal molds have been replaced by PLA filament and, naturally, an app for iOs and Android. While the printer itself won’t be on the market until the fall, the ThingMaker Design app is live now and can be used to design items for other 3D printers. (As of Monday, you can start pre-ordering the printer on Amazon.)

(As of Monday, you can start pre-ordering the printer on Amazon.)

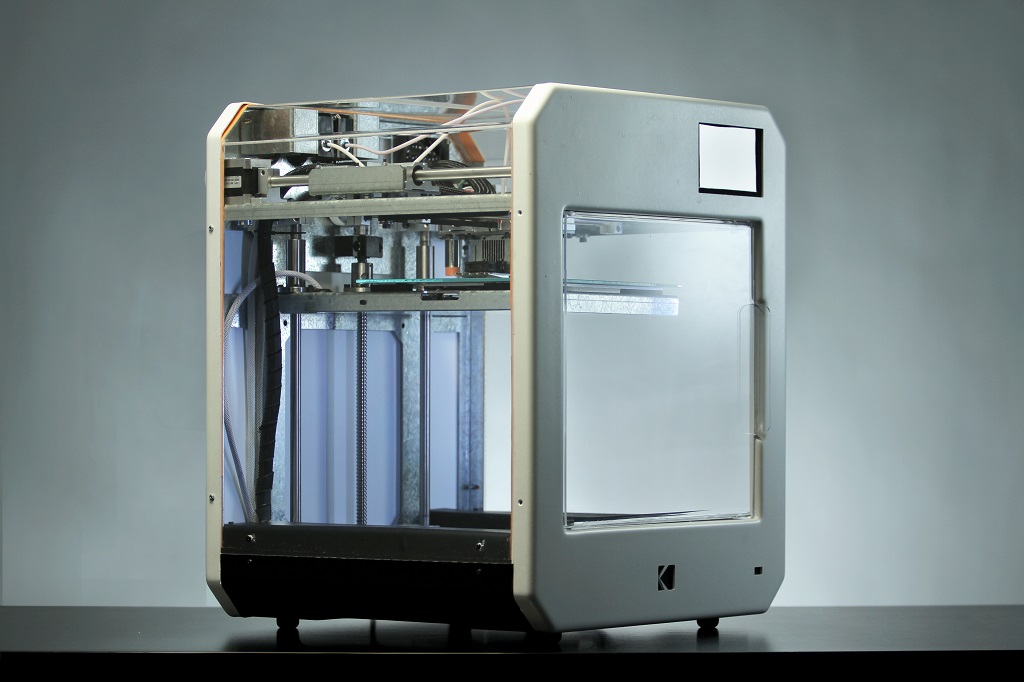

ThingMaker now.

“We’re going to use these seven months to really learn and gain analytics of how people are using it,” said Aslan Appleman, a senior director at Mattel. “Our thought is we want to make this open to makers. What we want to highlight is the ThingMaker ecosystem.”

Image: USA Today

The easy-to-use app lets kids design toys by dragging and dropping parts from a palette into a template, where they can arrange and assemble them as they wish. Several parts are printed together in batches; kids choose the colors in the app and they are then printed one color at a time. The door automatically locks once printing starts – a safety feature common to most kid-friendly printers.

The printer and app were designed in conjunction with Autodesk, who announced an official partnership with Mattel last year for the purpose of marketing 3D printing and technology apps to kids, and they look like they’ll be a good way for children to start grasping how 3D design works. While the drag-and-drop format isn’t exactly CAD, it still helps kids to understand how a digital design can be turned into a physical object.

While the drag-and-drop format isn’t exactly CAD, it still helps kids to understand how a digital design can be turned into a physical object.

“All the physical behaviors are as it would be when it was actually printed out, so you can get an idea for how it is going to mechanically move and what the limits of all the joints and sockets that you create are,” said Dan Pressman, creative director at Autodesk.

Still a bit creepy, actually.

The ThingMaker printer, which will retail for $299.99, is listed as being for kids ages 13 and older, but the toys you can print out are safe for children as young as 3. For kids too young to use a 3D printer themselves, I imagine it could still be a great parent-child project.

Although this ThingMaker bears little or no resemblance to the ThingMaker of my childhood, keeping the name is a nice shout-out to ’90s kids, many of whom have children of their own now. (“Back in my day, all my ThingMaker could make was fake Jello bugs!”) How do you think apps like this will affect the world of toy manufacturing in the future? Discuss in the ThingMaker 3D Printed Toys forum over at 3DPB. com.

com.

[Images: Mattel / ThingMaker / USA Today]

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d design app for kids • 3d printed games and toys • 3d printed toys • 3d printed toys and games • 3d printer for children • 3d printer for kids • autodesk • Creepy Crawlers • mattel • ThingMaker • ThingMaker 3d printer • ThingMaker Design

Please enable JavaScript to view the comments powered by Disqus.

Mattel Innovates the Toys of Tomorrow with MakerBot 3D Printers

Mattel’s Product Innovation team uses 3D printing to support toy research, design, and development

Mattel, a leading global toy company and owner of one of the strongest catalogs of children’s and family entertainment franchises in the world, is on a mission to empower the next generation to explore the wonder of childhood and reach their full potential. The company facilitates that through high quality innovative products that are constructed with the highest consumer safety in mind and are accessible to many.

The company facilitates that through high quality innovative products that are constructed with the highest consumer safety in mind and are accessible to many.

A critical part of that is the research and development of the toys of tomorrow, a responsibility of Jack Peach, key lead innovation engineer at Mattel, and the Product Innovation team. Jack and his team support all of Mattel’s portfolio of iconic brands, including Barbie, Hot Wheels, Fisher-Price, American Girl, Thomas & Friends, UNO, Masters of the Universe, Monster High and MEGA. From simple mechanical features to researching and prototyping toys of tomorrow, the Product Innovation team helps Mattel brands execute their vision based on consumer insight.

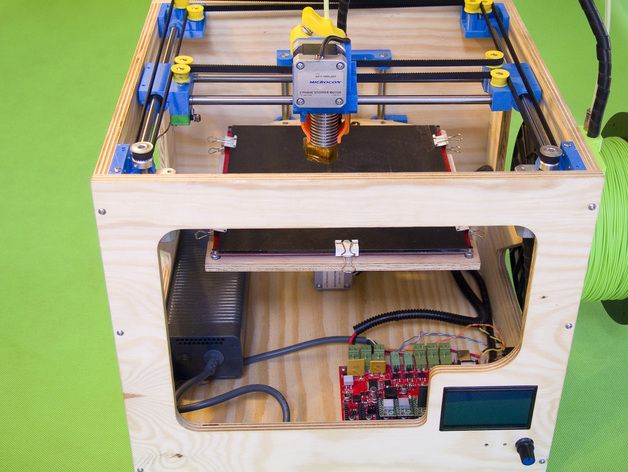

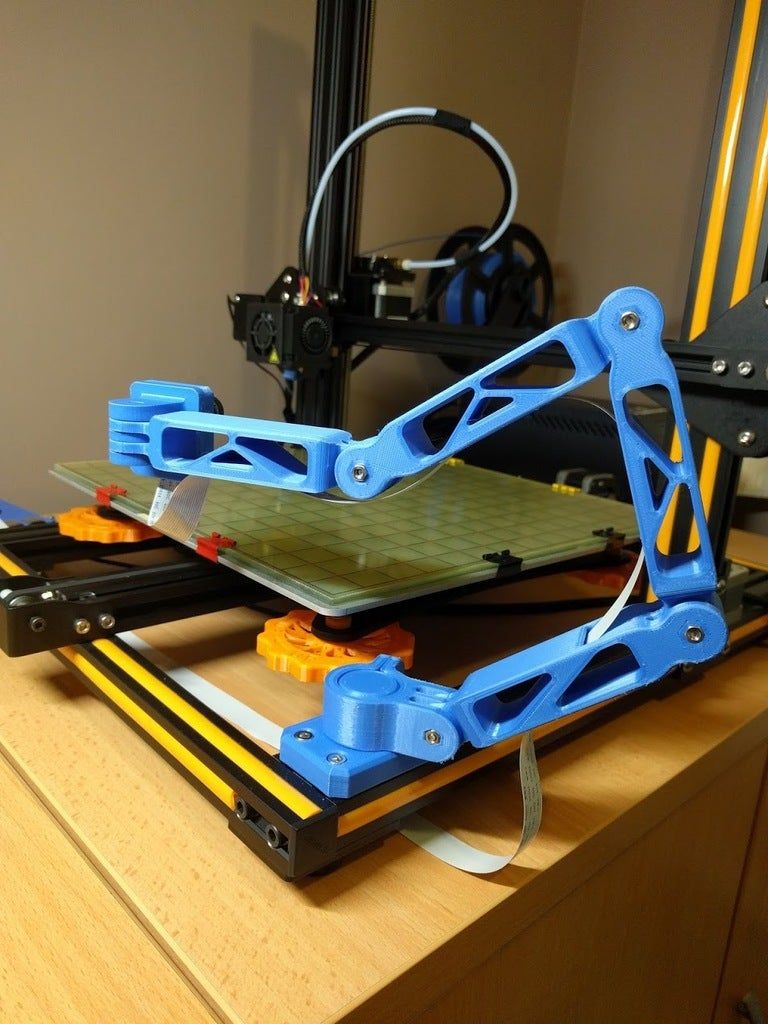

The METHOD platform has streamlined prototyping for Jack and his team.

Jack has been working in the toy industry for over 15 years, having previously worked at a toy invention company. His passion for invention combined with a love of learning, and the joy of seeing children experience new toys have pushed him to be more creative as he designs new features and components.

“Being an inventor, I’m most excited to see the sparkle in a kid’s eye when a toy does something unexpected, something “magical”. It is a shared experience driving imagination at their level and mine, encompassing ‘What if? Why Not?’,” said Jack.

INNOVATING THE TOYS OF TOMORROW

Mattel, which recently was named to Fast Company’s Best Workplaces for Innovators list two years in a row, uses the same tools and processes as some of the largest tech companies. It has access to some of the most cutting-edge design tools and machine shops. For Mattel, creating innovative products and experiences that inspire, entertain, and develop children through play is serious business.

Jack and his team use a wide range of professional digital design software and hardware tools for sketching and rough model layout, mechanical feature design and simulation, virtual model (VR and AR) visualization and electronic hardware/software development. For fabrication, they have access to hand tools and power tools to build prototypes to prove out rough size and function.

To build out his toy workshop in his home office, Jack added two 3D printers to the mix – the MakerBot METHOD® and MakerBot METHOD X®. While he was familiar with operating CNC machines at his previous company, it wasn’t until he started working at Fisher-Price that Jack learned about the advantages of industrial 3D part fabrication.

“In early 2020, I decided to invest in a 3D printer that offered high resolution, high repeatability and was super easy to use. When I started using the METHOD 3D printers, I realized 3D printing parts at home at the industrial level with industry standard material was amazing,” said Jack. “Our team’s focus is to share innovative product features with the brand team and help bring them to market. When physical models are needed, our team can rely on industrial-grade 3D printing materials like ABS-R or Nylon Carbon Fiber because they are durable enough to prove out form and function.”

Digital design and development are key at Mattel for unlocking efficiencies and innovation internally and working with outside vendors. Through an iterative process, concepts can be shared with its brand partners, the Fisher-Price™ Play Lab and the Mattel® Imagination Center for toy testing and consumer insights for feedback. The design is then updated, fabricated as needed, and shared again.

Through an iterative process, concepts can be shared with its brand partners, the Fisher-Price™ Play Lab and the Mattel® Imagination Center for toy testing and consumer insights for feedback. The design is then updated, fabricated as needed, and shared again.

“Brainstorming and concept sketching is where it all starts. Minimal deco changes to last years’ products might be approved with visuals in the digital space. But if we’re trying to prove out a mechanical function/feature or appropriate sizing for a child, fabricating a model is essential. The prototype can reveal unforeseen issues that need to be resolved or you might discover a new use case or feature that elevates the product,” he continued. “With a 3D printer, you don’t have to re-fabricate the entire prototype by hand. You can make a few adjustments digitally, send it to the printer, and have a new part printed quickly. This process makes modifications, testing, and reviewing so much easier and quicker.”

Jack prototyped the Fisher-Price Soothe & Glow Rainbow Sound Machine in ABS-R.

METHOD printed a functional prototype of the toy, which included several complex pieces.

3D printing enabled Jack to test mechanical and electrical functions sooner than before.

CHANGING THE GAME

Before having a 3D printer at his fingertips, Jack relied solely on the machine shop at the office to support his prototyping needs. Since other teams also utilized the machine shop, sometimes it would take days before he received his part back. If additional adjustments needed to be made to the original design, he would have to send back a new design and wait some more for a new part, extending his project lead time.

“With the METHOD and METHOD X, I can quickly produce a concept and get it into a physical form. Years ago, it would have taken longer. But with a 3D printer in my workshop, I have more control over the process and timeline,” Jack noted. “Having a high-quality desktop 3D printer in-house opens new doors, allowing me to fabricate and test mechanical functions sooner, sometimes shaving off days. Complex parts and assemblies are often ready overnight, ready for review with a cup of coffee in the early hours of the morning. I can inform the team with results at the morning meeting.”

Complex parts and assemblies are often ready overnight, ready for review with a cup of coffee in the early hours of the morning. I can inform the team with results at the morning meeting.”

The MakerBot 3D printers are mostly used to print early prototype models to prove out an electromechanical function. Jack uses a mix of 3D printing materials depending on the application. Since most of his team’s work is for demonstration of a new feature or function, he typically uses a material that can withstand hundreds of cycles. Recently, they started to use ABS-R for housings and structural features due to the material’s high impact resistance and durability, and Nylon Carbon Fiber for gears.

Printing high-quality custom parts on demand has enabled the team to provide dimensionally accurate assemblies that are very similar to injection molded production assemblies, helping to prove out a toy’s features quicker and with high confidence of success.

In one recent example, Jack and his team worked on a project for a brand team, where they were asked to brainstorm a new feature for a particular line. After pitching a few concepts, the team built a rough mockup of one of the user-interfaces that included lights and sounds that played when a joystick was moved FORWARD/REVERSE/LEFT/RIGHT. The joystick was an off-the-shelf version and was too large to fit into the toy.

After pitching a few concepts, the team built a rough mockup of one of the user-interfaces that included lights and sounds that played when a joystick was moved FORWARD/REVERSE/LEFT/RIGHT. The joystick was an off-the-shelf version and was too large to fit into the toy.

A digital model of the toy was modified, and the team quickly designed a smaller joystick that was then integrated into the toy. After verifying the direction with the brand team, they 3D printed out the parts, assembled the model, added the electronics, and shot a demo video. The feature received great reviews from the brand team and is now scheduled for production.

“The hit and miss ratio in the toy invention business is crazy. If one out of a hundred of your ideas makes it to the market, you’re doing good,” said Jack. “The MakerBot METHOD and METHOD X have been game changers enabling me to put form to the creation and bring joy and imagination to the next generation of Makers.”

Photo courtesy of Mattel.

To learn more about how Jack designs and engineers the latest and greatest toys, check out our workshop tour and get an insider's peek at his process: https://www.makerbot.com/stories/engineering/webinar-recording-a-look-inside-a-mattel-engineers-3d-printing-workshop/

Mattel's 3D Printer Will Print Any Child's Toy

?Previous Entry | Next Entry

The3D printer is only $300 and makes it easy to create your own toys.

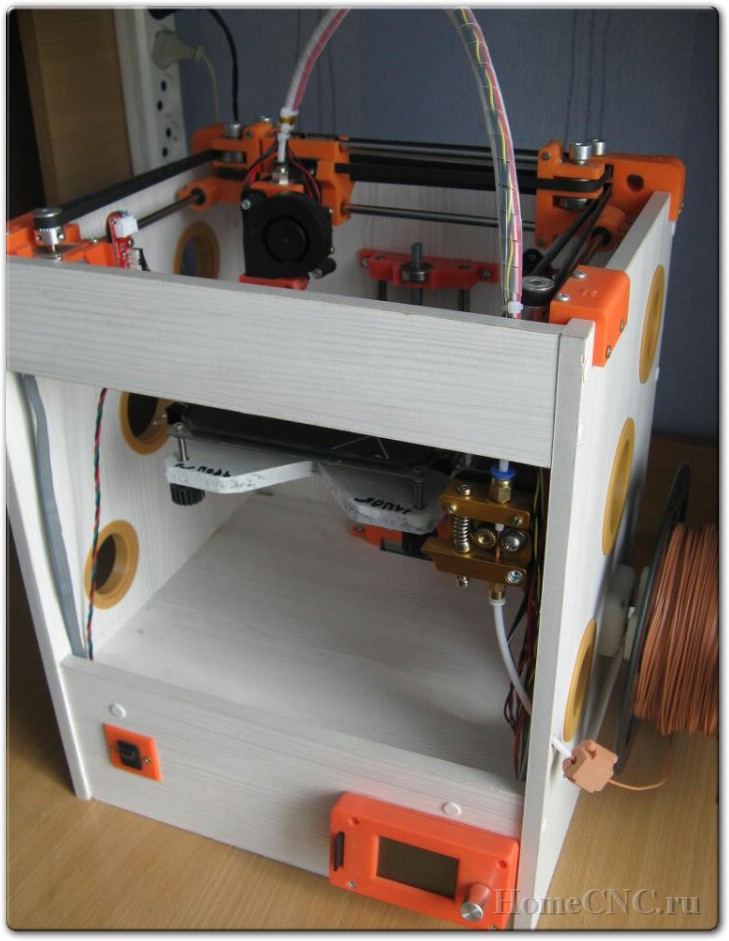

In the 1960s, Mattel's ThingMaker gave children the ability to create their own toys by pouring molten plastic into metal moulds. But today you will not surprise anyone with this, so the world's largest toy manufacturer decided to adapt the device to the modern requirements of the current century, using 3D printing technology.

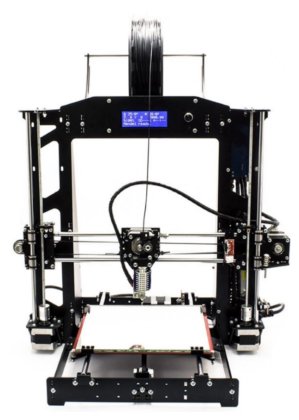

1. Mattel 'ThingMaker' 3D Printer

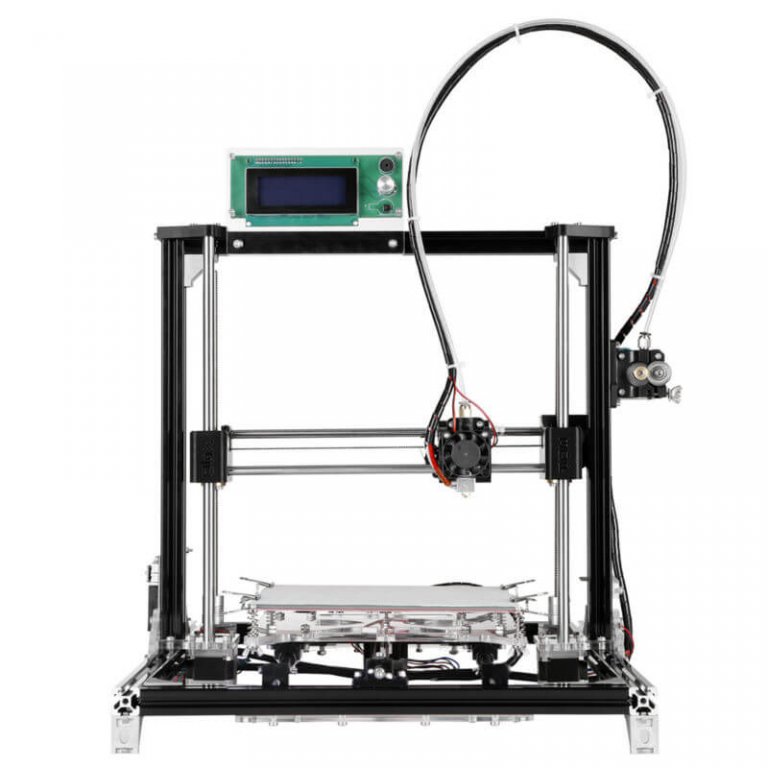

Reimagining what is essentially a relatively affordable 3D printer (as low as $300) compatible with iOS and Android mobile devices. The main target audience for Mattel's new 3D printer is still children (as well as their parents). Using a smartphone or tablet, or rather a companion mobile app, they can create all sorts of figurines and send them over the air directly to a printer for printing.

The main target audience for Mattel's new 3D printer is still children (as well as their parents). Using a smartphone or tablet, or rather a companion mobile app, they can create all sorts of figurines and send them over the air directly to a printer for printing.

According to Toyland, the app contains a database containing many basic blueprints, including rings, necklaces, scorpions, dinosaurs, and skeletons. In addition, users can customize the toys by printing new components to them, which are attached via conventional ball joints.

2.

The printer itself, according to USA Today, has an age rating of 13 years and older and features a number of security features.

For example, automatic door lock during printing. In addition, in sleep mode, the print head of the printer is safely hidden from prying eyes, which prevents the possibility of burns due to touching the hot nozzle from which molten plastic is fed.

3.

The manufacturer claims that the device works with all standard plastic threads. In addition, the company will offer branded coils.

In addition, the company will offer branded coils.

Many varieties of these reels could be seen at the recent New York Toy Fair event, although the company has yet to reveal a full list of available colors and prices. But it is known that one kilogram of such threads should be enough to create 20 figurines, 30 jewelry or 100 rings.

4.

The mobile printer app is already available in the official iOS and Android app stores, pre-orders for the device itself will start accepting on Amazon today, and the start of shipments is scheduled for this fall.

Right now, the ThingMaker looks like an easy-to-use 3D printer at a reasonable price, but Mattel could connect it to the vast toy universe by giving users the option to print out a new Barbie or Hot Wheels accessories. According to Mattel CEO Aslan Appleman, in the next 7 months the company plans to conduct a deep analysis of the demand market for the printer, to establish who uses it and for what purposes.

Today you can use the possibilities of 3D printing at any time, and now you can print almost everything. Professional 3D printing of any complexity will help you most effectively distinguish your business from competitors. With the help of 3D printing, not only toys and models of various buildings are created, but also complex engineering and architectural models.

Source: https://nashideti.temaretik.com/247058585347372115...aet-lyubuyu-detskuyu-igrushku/

Original post and comments on LiveInternet.ru

Powered by LiveJournal.com

Mattel 3D printer will print any children's toy

Zefirka > Gadgets > Mattel's 3D printer will print any children's toy

The 3D printer costs only $300 and makes it easy to create your own toys.

In the 1960s, Mattel's ThingMaker gave children the ability to create their own toys by pouring molten plastic into metal moulds. But today you will not surprise anyone with this, so the world's largest toy manufacturer decided to adapt the device to the modern requirements of the current century, using 3D printing technology.

1.

Mattel "ThingMaker" 3D Printer

A reimagining of what is essentially a relatively affordable 3D printer (as low as $300) compatible with iOS and Android mobile devices. The main target audience for Mattel's new 3D printer is still children (as well as their parents). Using a smartphone or tablet, or rather a companion mobile app, they can create all sorts of figurines and send them over the air directly to a printer for printing.

According to Toyland, the app contains a database containing many basic blueprints, including rings, necklaces, scorpions, dinosaurs, and skeletons. In addition, users can customize the toys by printing new components to them, which are attached via conventional ball joints.

2.

The printer itself, according to USA Today, has an age rating of 13 years and older, and features a number of security features.

For example, automatic door lock during printing. In addition, in sleep mode, the print head of the printer is safely hidden from prying eyes, which prevents the possibility of burns due to touching the hot nozzle from which molten plastic is fed.

3.

The manufacturer claims that the device works with all standard plastic threads. In addition, the company will offer branded coils.

Many varieties of these reels could be seen at the recent New York Toy Fair event, though the company has yet to reveal a full list of available colors and pricing. But it is known that one kilogram of such threads should be enough to create 20 figurines, 30 jewelry or 100 rings.

4.

The mobile printer app is already available on the official iOS and Android app stores, pre-orders for the device itself will begin to be accepted on Amazon today, and the start of shipments is scheduled for this fall.

Right now, the ThingMaker looks like an easy-to-use 3D printer at a reasonable price, but Mattel could connect it to the vast toy universe by giving users the ability to print out a new Barbie or Hot Wheels accessories. According to Mattel CEO Aslan Appleman, in the next 7 months the company plans to conduct a deep analysis of the demand market for the printer, to establish who uses it and for what purposes.