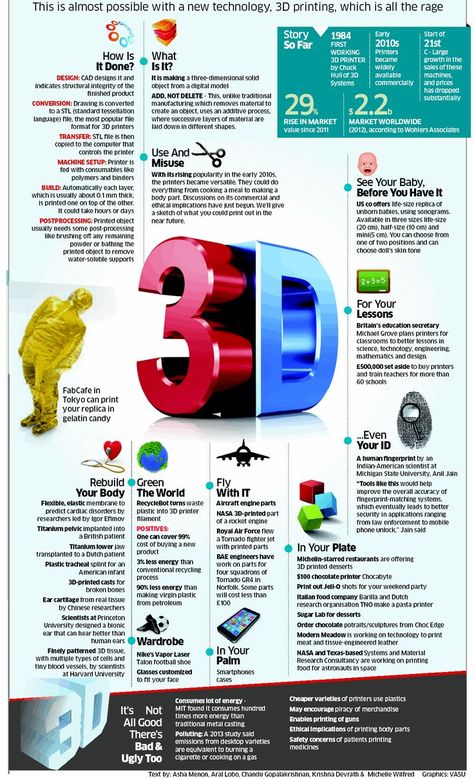

What plastic is used in 3d printers

The Plastics of 3D Printing

By Jason Griffey |

Editor's Note: This is the third of a series of posts excerpted from Jason Griffey's Library Technology Report "3D Printers for Libraries."

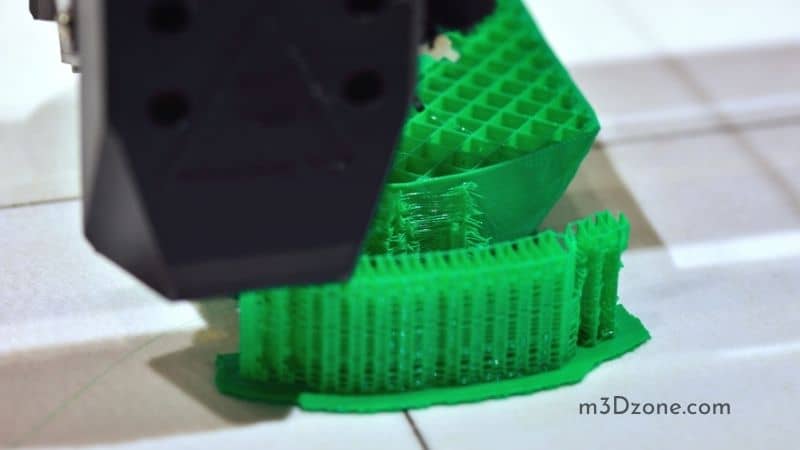

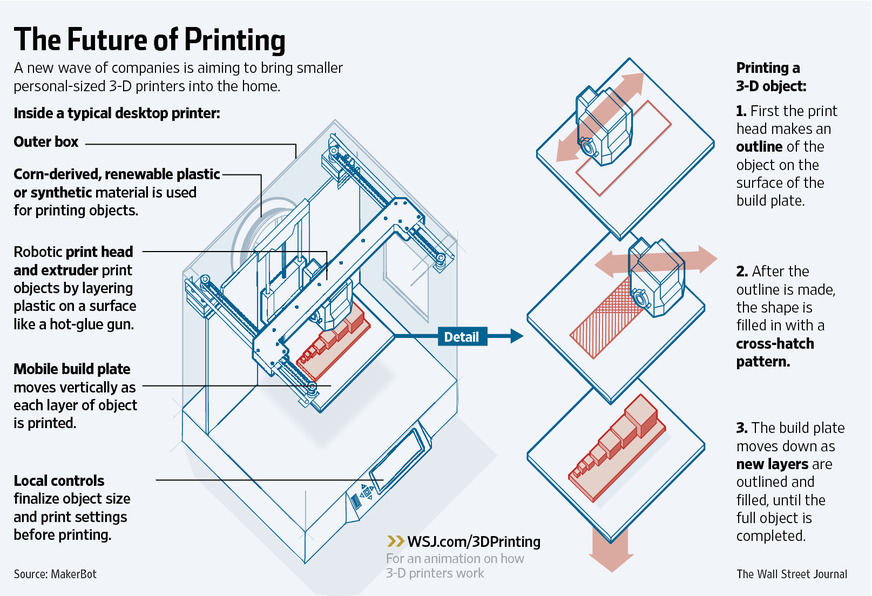

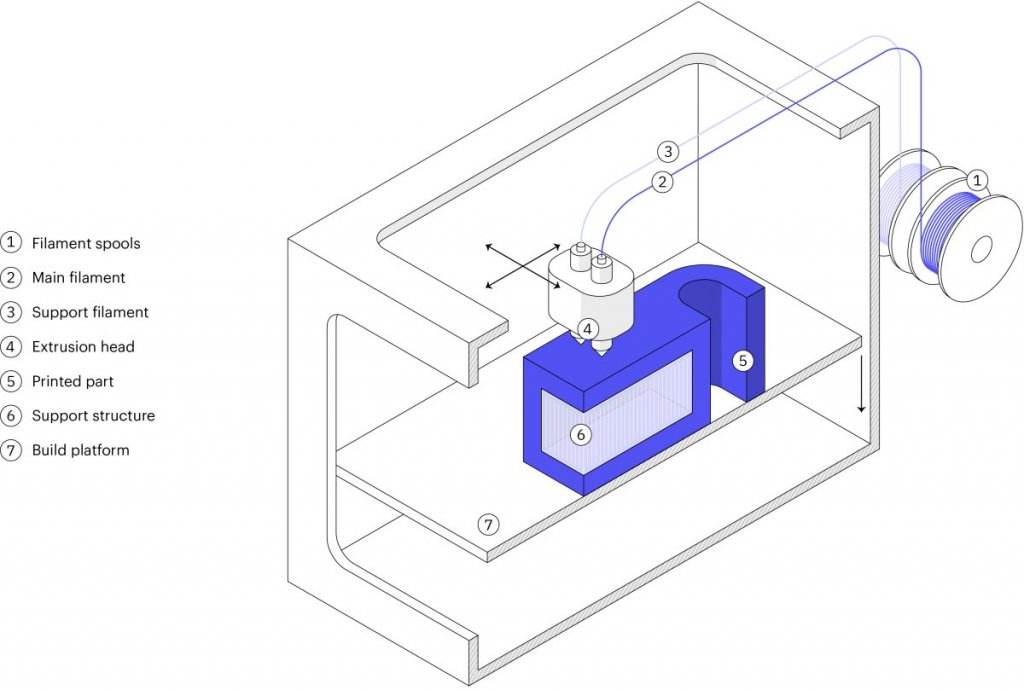

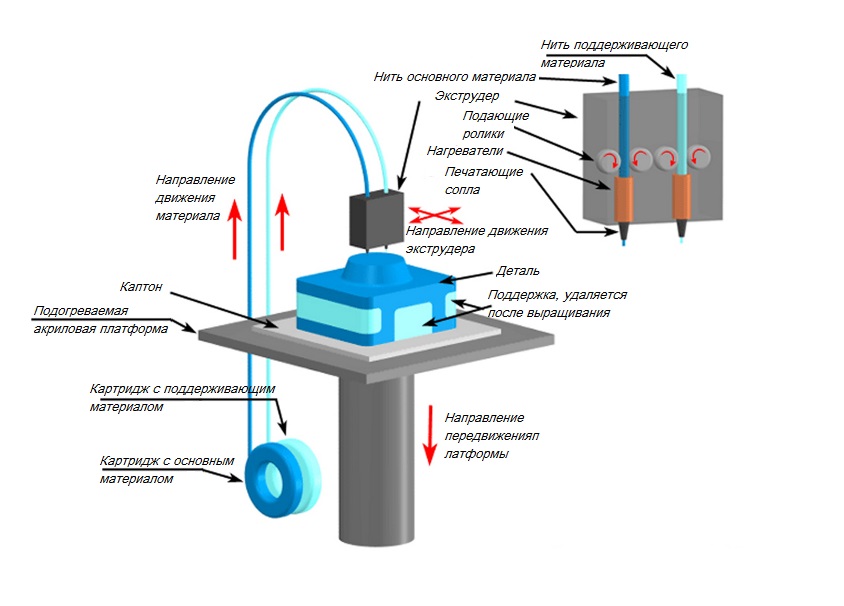

The substrate for FDM printers are almost exclusively some form of thermoplastic that is delivered in an extruded wire-like form on a spool. It is usually called “filament” in the generic. The two common diameters for use in FDM printing are 1.75mm and 3mm, and a specific diameter is called for by the print head being used for the printer in question. A printer that uses 1.75mm diameter filament won’t be able to use 3mm without retrofitting the hardware for the difference, and vice versa. Slightly more common, the 1.75mm diameter is used by Makerbot Industries, the most popular manufacturer of FDM printers.

In later postss, when I write on the different printer types and manufacturers, I’ll note what type of filament they are capable of printing, because that turns out to be a major limitation and purchasing decision factor.

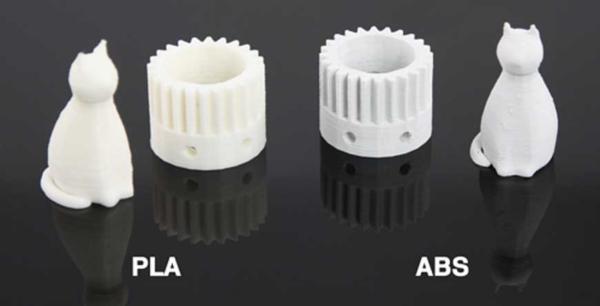

ABS

The original fused deposition printers almost exclusively used ABS (Acrylonitrile butadiene styrene) as their substrate for printing. ABS is nearly ideal from a material property point of view for rapid prototyping in plastic, as it’s strong, slightly flexible plastic, which extrudes cleanly at between 220° and 240° celsius. ABS is the type of plastic used in Lego bricks, and is one of the most commonly used industrial/commercial plastics.

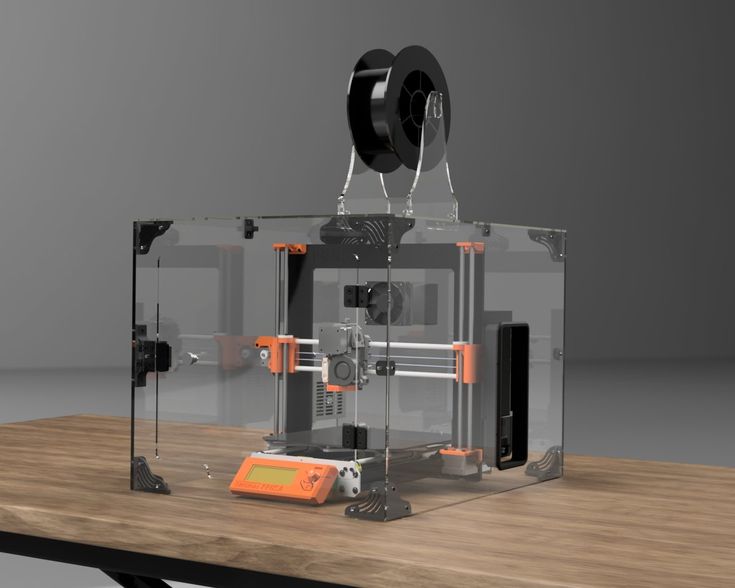

For FDM printing, ABS requires a heated print bed to ease the thermal shock for printing. Heating the print build plate aids the plastic in both adhering to the plate for stability, and in preventing cooling too quickly, which leads to thermal deformation, or a sort of curling separation. ABS is sensitive enough in this arena that many people who print ABS learned early on that enclosing the printer was a way to increase the stability of prints because it regulated the temperature around the printer. I soon discovered in my printing experiments with an early Makerbot printer (Replicator 1) that even a strong breeze blowing in the wrong place (across the print bed) could wreak havoc. Higher end printers will have an enclosed print area, while less expensive ones don’t.One of the advantages of ABS is that it dissolves in acetone. Acetone dissolves ABS completely, but used sparingly it can act as a glue to fuse two ABS printed pieces together permanently. Acetone is also used to make a “glue” for print beds, to help in making the print bed sticky for the initial printed layers. Acetone vapor is heavier than air, and some people have used this to build acetone vapor baths that act to smooth the edges of layers of an FDM ABS print.ABS has caught some bad press recently, as the potential effects of off-gassing of the heated plastic and microparticulate effects are studied. As a petroleum based plastic, ABS does produce a distinctive stink when printing. Fumes have been reported to cause headaches, and studies link ABS fumes to olfactory loss; one study that found ABS printing released high volumes of ultrafine particles that could be dangerous when inhaled.

I soon discovered in my printing experiments with an early Makerbot printer (Replicator 1) that even a strong breeze blowing in the wrong place (across the print bed) could wreak havoc. Higher end printers will have an enclosed print area, while less expensive ones don’t.One of the advantages of ABS is that it dissolves in acetone. Acetone dissolves ABS completely, but used sparingly it can act as a glue to fuse two ABS printed pieces together permanently. Acetone is also used to make a “glue” for print beds, to help in making the print bed sticky for the initial printed layers. Acetone vapor is heavier than air, and some people have used this to build acetone vapor baths that act to smooth the edges of layers of an FDM ABS print.ABS has caught some bad press recently, as the potential effects of off-gassing of the heated plastic and microparticulate effects are studied. As a petroleum based plastic, ABS does produce a distinctive stink when printing. Fumes have been reported to cause headaches, and studies link ABS fumes to olfactory loss; one study that found ABS printing released high volumes of ultrafine particles that could be dangerous when inhaled. These are preliminary studies. Most haven’t been repeated, and the science is still rough on the health effects here. But if you need to print with ABS, it may be a good idea to take venting into account.

These are preliminary studies. Most haven’t been repeated, and the science is still rough on the health effects here. But if you need to print with ABS, it may be a good idea to take venting into account.

PLA

PLA (Polylactic acid) is the second most popular printing substrate for FDM printers. A bioplastic, PLA is made from corn, beets, or potatoes. It is compostable in commercial compost facilities (the heat and bacterial action isn’t high enough in home composting to break it down). It melts at a much lower temperature than ABS (150-160°C), but is typically extruded at a higher temperature, anywhere from 180-220°C depending on the PLA itself. Because of it’s lower temperature, it’s not suitable for uses that involve high temperatures and direct sunlight. PLA is also very different than ABS in term of fragility. Far more crystaline, PLA shatters or cracks more readily than ABS, whih instead will deform under pressure.

However, Makerbot and other major manufacturers are now starting to go with PLA as their primary printing plastic. PLA doesn’t require a heated bed for adhesion or thermal curling reasons, which lowers the price of the printers that use it. As well, it’s far more thermally stable during printing than ABS, and much less likely to warp or curl due to errant breezes. It is possible to reliably print PLA without needing to enclose your printer, which can be a huge benefit in many circumstances.

PLA doesn’t require a heated bed for adhesion or thermal curling reasons, which lowers the price of the printers that use it. As well, it’s far more thermally stable during printing than ABS, and much less likely to warp or curl due to errant breezes. It is possible to reliably print PLA without needing to enclose your printer, which can be a huge benefit in many circumstances.

The other significant advantage is that PLA is far more pleasant when printing than ABS. Because it is a bioplastic, when heated it smells like waffles or syrup, and not like an oil spill. It also hasn’t been linked to any types of medical issues from being heated, although the study of all these plastics is young when it comes to 3d printing specifically.

One of the other advantages of PLA is that it’s available in dozens and dozens of colors, including both opaque and partially transparent, as well as a couple of colors of glow-in-the-dark. It also is available in a flexible form, which can produce prints that are almost rubber-like in consistency.

If you are printing in a library setting, I would suggest focusing on PLA. Between the reliability and the ease of working with it, it’s a far better choice than ABS for printing in a public space.

Other Filament

Once you get beyond ABS and PLA, you’re in the realm of specialized plastics that are used for specific properties rather than for general 3D printing. More of these appear every day, practically, but generally they fall into a couple of categories: dissolvable support material, specific material qualities that are needed, or non-plastic powder suspended in a thermoplastic resin. I’ll describe the most common of these below.

HIPS

High Impact Polystyrene or HIPS is a plastic filament used for dissolvable support structures in FDM printers. It extrudes at around 235°C and has a set of material properties that make it similar to ABS. The main difference is that HIPS is completely soluble in a liquid hydrocarbon called limonene. This means that if you have an FDM printer with more than one print head, you can extrude ABS from one and HIPS as a support material from the other, and sit the final printed model in a bath of Limonene. The HIPS will dissolve away, leaving only the ABS behind, thus allowing for nearly impossible geometries to be printed, including moving ball bearings and more.

This means that if you have an FDM printer with more than one print head, you can extrude ABS from one and HIPS as a support material from the other, and sit the final printed model in a bath of Limonene. The HIPS will dissolve away, leaving only the ABS behind, thus allowing for nearly impossible geometries to be printed, including moving ball bearings and more.

Nylon

There are at least 4 types of nylon currently available for use in FDM printers: Nylon 618, Nylon 645, Nylon 680 and Nylon 910. These vary in their color from medium transparency to fully opaque white, and all are extraordinarily strong as compared to other FDM substrates. They are also very resistant to solvents and such, although they are dyeable with acid-based dyes for coloring.

Nylon as an FDM printing material is more expensive than PLA or ABS. The major reason for using them would be for specific material properties (resistance to specific chemicals) or due to the need for FDA approved materials, as both Nylon 680 and 910 are undergoing FDA approval for use, something rare in the 3D printer world.

T-Glase

T-Glase is a brand name for a filament composed of Polyethylene terephthalate. Of all 3D printer filaments, it is the most glass-like. Nearly transparent, especially at small sizes, it could easily be mistaken for glass. At larger sizes it is still very light-transmissive, if not fully transparent. T-Glase prints at around 221°C, on a heated bed, but is very stable and resistant to curling.

LayBrick & LayWood

Another type of printing material for FDM printers, these fall squarely in the experimental realm. They are made by a single manufacturer, and are both a sort of hybrid filament, with a powdered material being supported inside a resin. In the case of LayWood, fine wood particles are suspended in a thermoplastic resin, and in the case of LayBrick, it would be very finely crushed chalk and other minerals suspended in the resin.

Both LayBrick and LayWood have the interesting property of variability in appearance depending on the temperature at which they are printed. LayBrick can range from a very smooth, almost ceramic feel, to very rough sandstone, just by increasing the heat of extrusion. For very smooth, you print at a low temperature (165°C to 190°C) and then going up from their to around 210°C will render the printed part more and more rough. For LayWood, the difference is in the appearance of the final product. By increasing the temperature, you get darker and darker wood grain from the output, so you can actually vary the look from light to dark wood (or, if you have a printer that supports variable temperatures during a single print, you can get different colors in a single print by varying the temperature).

LayBrick can range from a very smooth, almost ceramic feel, to very rough sandstone, just by increasing the heat of extrusion. For very smooth, you print at a low temperature (165°C to 190°C) and then going up from their to around 210°C will render the printed part more and more rough. For LayWood, the difference is in the appearance of the final product. By increasing the temperature, you get darker and darker wood grain from the output, so you can actually vary the look from light to dark wood (or, if you have a printer that supports variable temperatures during a single print, you can get different colors in a single print by varying the temperature).

One of the risks, however, with both of these is that the filament isn’t uniform in construction, which means that it’s possible to clog your extruder if the nozzle opening is smaller than the particulate in the filament itself. FDM printers nozzle openings range from .35 to .5mm, and on the lower end of that, especially with the LayWood (organic particles are harder to ensure regular sizes than inorganic particulate) you risk clogging a nozzle. I know 3D printers that have clogged even at .4mm nozzle using LayWood. For printing these sorts of filaments, the larger the nozzle the better.

I know 3D printers that have clogged even at .4mm nozzle using LayWood. For printing these sorts of filaments, the larger the nozzle the better.

Polypropylene

Still very experimental, polypropylene (PP) offers the possibility of food-grade 3D prints. Polypropylene should work with any FDM printer, at an extrusion temperature of 201°C and a heated print bed set to 90°C. It looks like PP is only really available in black.

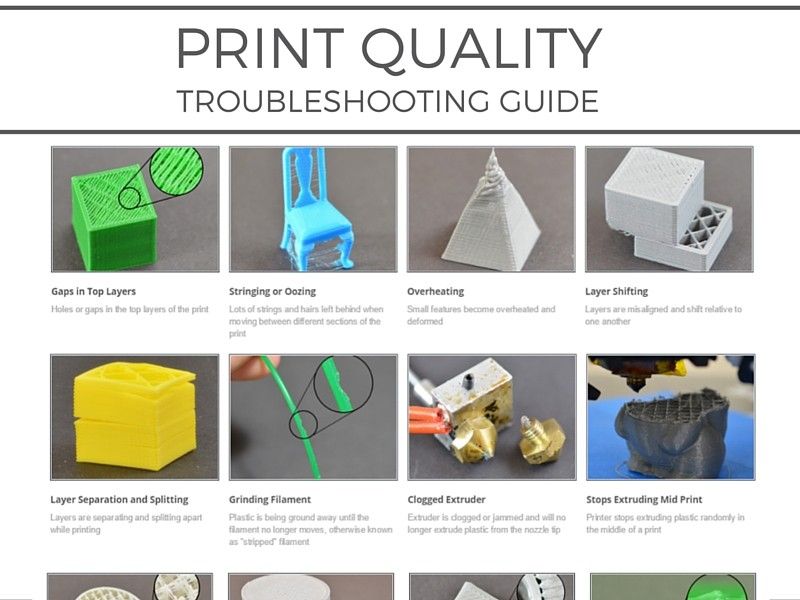

Challenges with Fused Deposition Modeling

Most of the issues with FDM printing are related to the fact that it’s a very mechanical process, and tuning the printer is key. The most sensitive aspect of the process is the relationship between the extruder and the build plate. Because the printhead has to extrude an even layer of plastic onto the build plate, it’s necessary that the build plate be perfectly flat relative to the nozzle. If there is any warp or uneven-ness, you’ll get uneven attachment to the plate or other forms of print failure. This is the most common issue with FDM printing, especially with new operators. The first question to ask if a print fails is: “Is my build plate level/”

This is the most common issue with FDM printing, especially with new operators. The first question to ask if a print fails is: “Is my build plate level/”

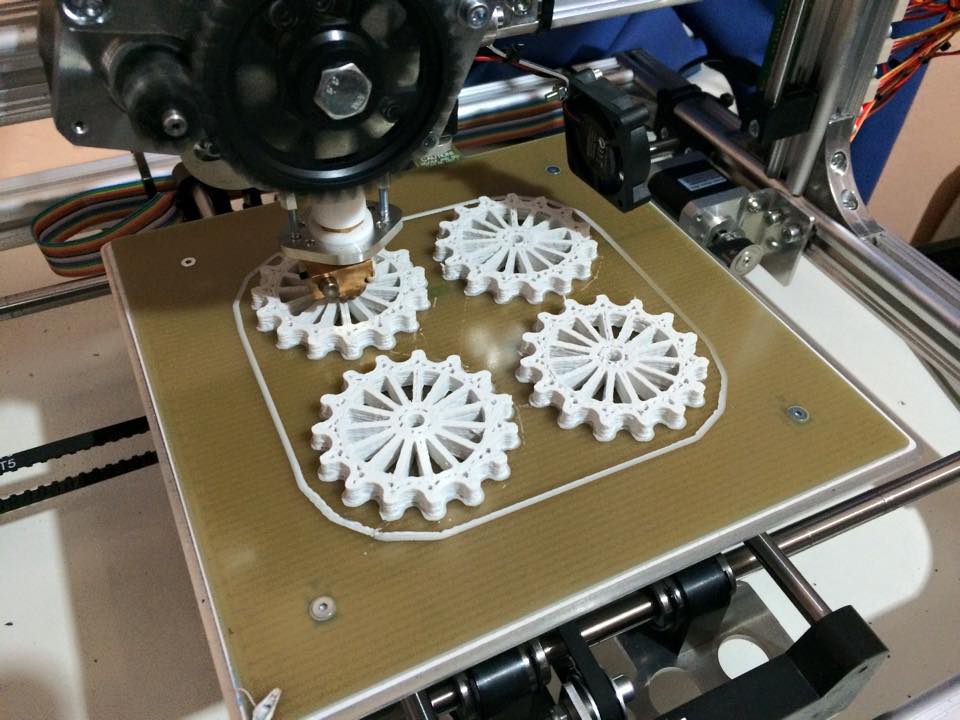

And prints will fail. FDM printing is a complicated mechanical process, and while you can tune a FDM printer to be very reliable, at some point you will have a failure and will come back to a print that looks like someone poured plastic spaghetti on your build plate. This is normal. Recalibrate, re-level, and try again.

3D Printing Materials Guide: Plastics

Published on June 8, 2020 by Alexandrea P.

A plastic is a material made of synthetic or semi-synthetic compounds that has the property of being malleable (capable of changing its shape). Most plastics on the market are completely synthetic (most commonly derived from petrochemicals). However, given the growing environmental concern, plastics derived from renewable materials such as Polylactic Acid (PLA) are also popular on the market. Due to their low cost, ease of manufacture, versatility and water resistance, plastics are used in a multitude of products and sectors. In the AM sector, 3D printing plastics are also very popular.

Due to their low cost, ease of manufacture, versatility and water resistance, plastics are used in a multitude of products and sectors. In the AM sector, 3D printing plastics are also very popular.

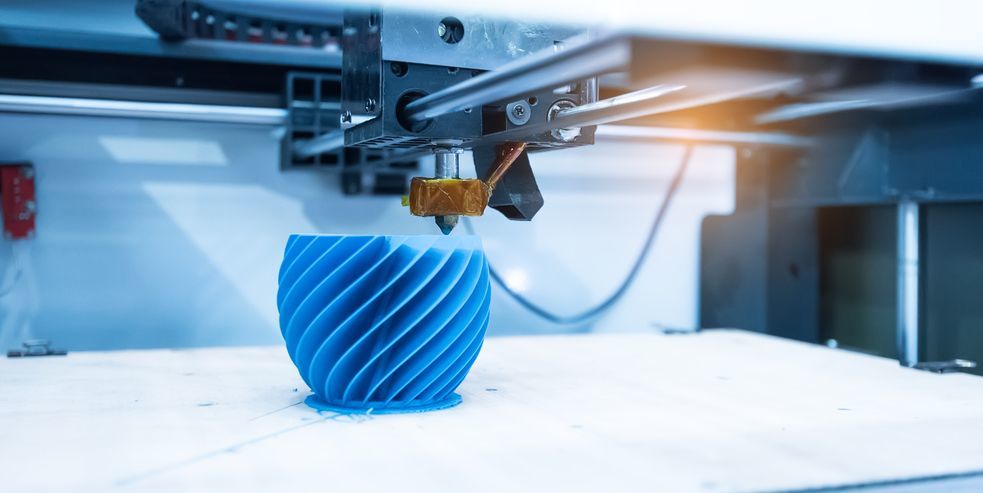

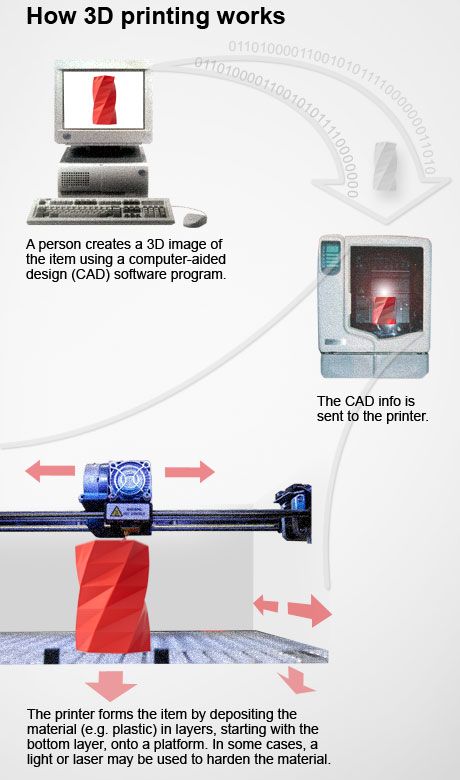

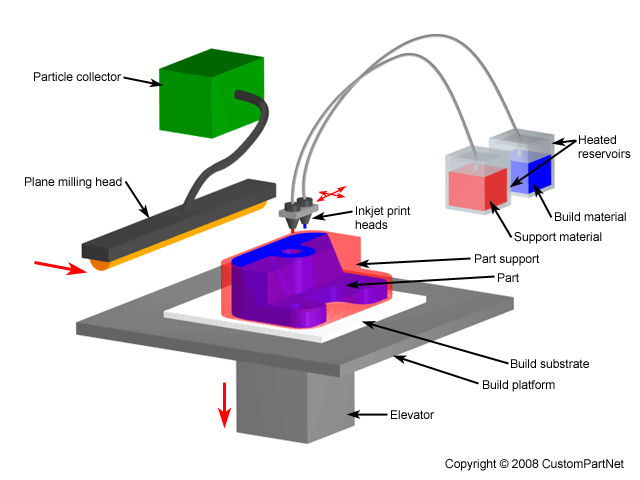

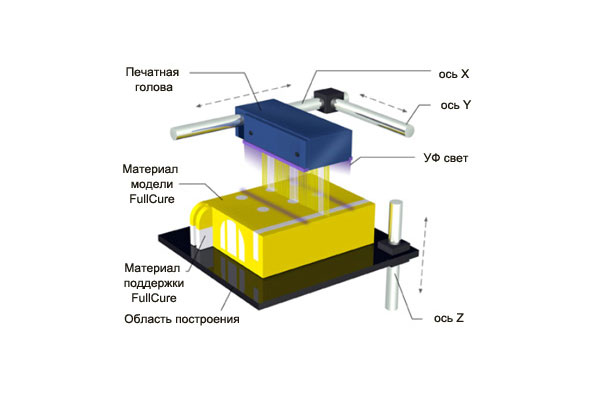

In the following guide, we will take a look at the most common 3D printing plastics. As you may know, the most popular and affordable 3D printing process, FDM, produces parts through the extrusion of plastic filaments. However, the precision on FDM machines is not the same as other AM processes such as SLS or SLA. Plastics are often used with this technology to create prototypes. Therefore, for industrial and end-use parts, manufacturers might decide to opt for SLS (using plastic powders) or SLA (using plastic resins) technologies that offer more accuracy and part quality. Two other technologies that can print with plastics are Material Jetting and Multi Jet Fusion.

What plastics can be used in additive manufacturing? In filament or powder form, the plastic should melt to form the object you are printing layer by layer. In resin form, it should solidify to form the object. Each plastic will require different 3D printing parameters during the building process, and will give parts varying properties.

In resin form, it should solidify to form the object. Each plastic will require different 3D printing parameters during the building process, and will give parts varying properties.

ABS

ABS filament is the most commonly used 3D printing plastics. It is used in the bodywork of cars, appliances, and mobile phone cases. It is a thermoplastic which contains a base of elastomers based on polybutadiene, making it more flexible, and resistant to shocks. ABS can also be found in powder form for powder bed processes such as SLS, and liquid form for SLA and PolyJet technologies.

ABS is used in 3D printing when heated between 230ºC and 260ºC. It is a tough material, able to easily withstand temperatures of -20ºC to 80ºC. In addition to its high strength, it is a reusable material and can be welded with chemical processes. However, ABS is not biodegradable and shrinks in contact with air, so the printing platform must be heated to prevent warping. Moreover, it is recommended to use a closed chamber 3D printer to limit particle emissions when printing with ABS. Learn more about ABS in our dedicated guide.

Learn more about ABS in our dedicated guide.

PLA

Known as polylactic acid, or PLA, this material has the benefit of being biodegradable, unlike ABS. PLA is manufactured using renewable raw materials such as corn starch. PLA is one of the easiest materials to print, though it does have a tendency to shrink slightly after 3D printing. You don’t require a heated platform when printing in PLA, unlike with ABS. PLA also prints at a lower temperature than ABS, between 190ºC to 230ºC.

PLA is a more difficult material to manipulate due to its high cooling and solidification speed. It is also important to mention that models can deteriorate when in contact with water. However, the material is consistent, simple to use, and comes in a wide variety of colors, making it suitable for FDM 3D printing. Learn more about PLA in our dedicated guide.

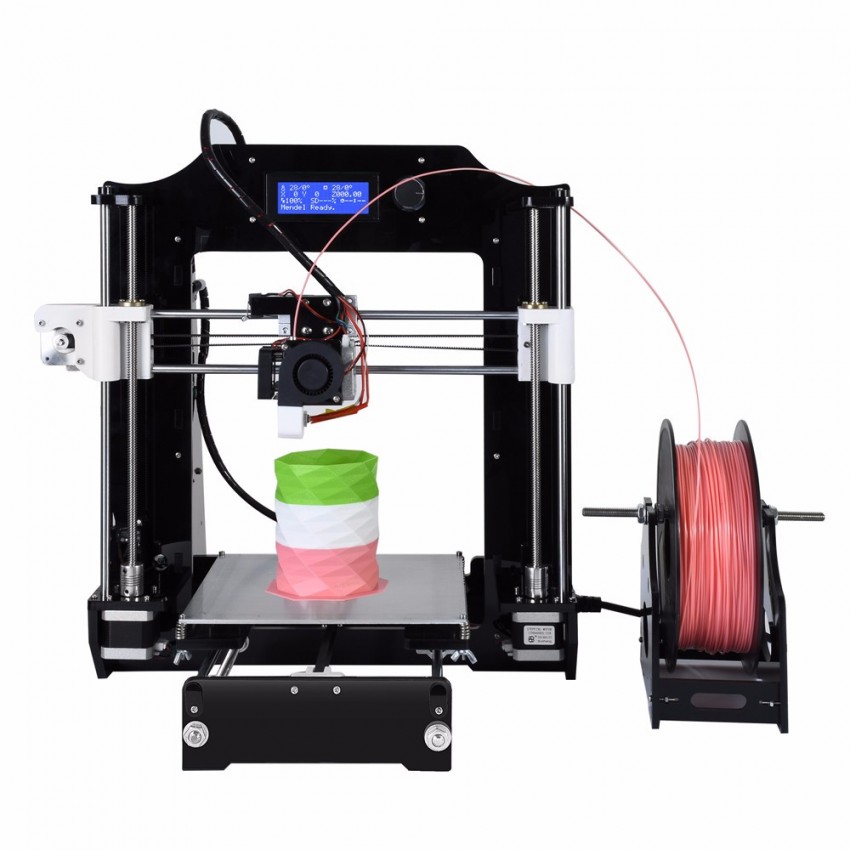

PLA 3D printing filament spools

ASA

ASA is a material that has similar properties to ABS, but has a greater resistance to UV rays. As with ABS, it is advised to print the material with a heated bed platform to prevent warping. When printing with ASA, similar print settings are used to ABS, but extra care must be taken to print with a closed chamber due to styrene emissions.

As with ABS, it is advised to print the material with a heated bed platform to prevent warping. When printing with ASA, similar print settings are used to ABS, but extra care must be taken to print with a closed chamber due to styrene emissions.

PET

Polyethylene terephthalate, or PET, is commonly seen in disposable plastic bottles. PET is the ideal filament for any pieces intended for contact with food. Moreover, the material is fairly rigid and has good chemical resistance. To obtain the best results when printing with PET, print between 75 – 90ºC. PET is commonly marketed as a translucent filament, with variants such as PETG, PETE, and PETT also sold. Advantages of PET include that the material doesn’t release any odours when printing, and is 100% recyclable.

PETG

PETG, or glycolized polyester, is a thermoplastic widely used in the additive manufacturing market, combining both the simplicity of PLA 3D printing and the strength of ABS. It is an amorphous plastic, which can be 100% recycled. It has the same chemical composition as polyethylene terephthalate, better known by its acronym PET. Glycol has been added to reduce its brittleness and therefore its fragility. Learn more about PETG in our dedicated guide.

It has the same chemical composition as polyethylene terephthalate, better known by its acronym PET. Glycol has been added to reduce its brittleness and therefore its fragility. Learn more about PETG in our dedicated guide.

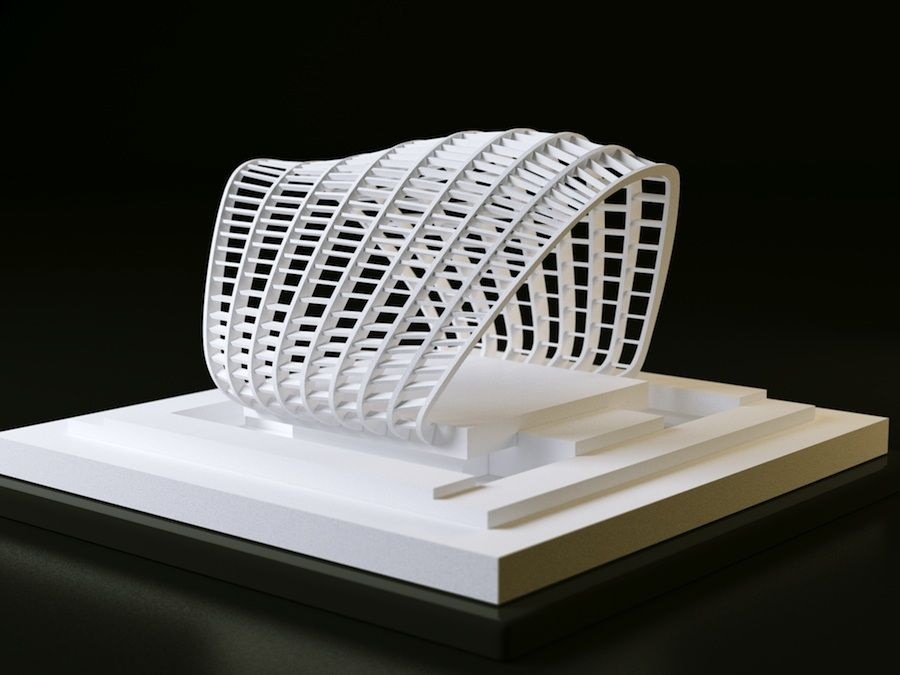

Polycarbonate (PC)

Polycarbonate (PC) is a high strength material designed for engineering applications. The material has good temperature resistance, able to resist any physical deformation up to around 150ºC. However, PC is prone to absorbing moisture from the air, which can affect performance and printing resistance. Therefore, PC has to be stored in airtight containers. PC is highly valued by the AM industry for its strength and transparency. It has a much lower density than glass, making it particularly interesting for designing optical parts, protective screens or decorative objects. Learn more about PC in our dedicated guide.

A 3D printed part made from PC

High Performance Polymers (PEEK, PEKK, ULTEM)

The evolution of 3D printing technologies has led to extensive research work on printing materials, enabling the development of a whole range of high-performance filaments with mechanical characteristics similar to those of metals. There are several types of high-performance 3D printing plastics such as PEEK, PEKK or ULTEM – they are distinguished by family such as polyaryletherketones (PAEK) or polyetherimides (PEI). These filaments have a very high mechanical and thermal resistance, are very strong and at the same time much lighter than some metals. These properties make them very attractive in the aerospace, automotive and medical sectors.

There are several types of high-performance 3D printing plastics such as PEEK, PEKK or ULTEM – they are distinguished by family such as polyaryletherketones (PAEK) or polyetherimides (PEI). These filaments have a very high mechanical and thermal resistance, are very strong and at the same time much lighter than some metals. These properties make them very attractive in the aerospace, automotive and medical sectors.

Due to their characteristics, high performance polymers cannot be printed on all FDM machines on the market. Indeed, the 3D printer must have a heating plate capable of reaching at least 230°C, an extrusion at 350°C and a closed chamber. Today, about 65% of these materials are printed with FDM technology, but they are also found in powder form, compatible with SLS technology. Learn more in our dedicated guides on PEEK and PEKK.

Image via VisionMiner

Polypropylene (PP)

Polypropylene is another thermoplastic widely used in the automotive sector, professional textiles sector, and in the manufacturing of hundreds of everyday objects. PP is known for its resistance to abrasion and its ability to absorb shocks, as well as relative rigidity and flexibility. However, drawbacks of the material include its low temperature resistance, and sensitivity to UV rays which can cause it to expand. Due to this, several manufacturers have developed alternative types of PP, simili-propilenos, that are stronger both physically and mechanically.

PP is known for its resistance to abrasion and its ability to absorb shocks, as well as relative rigidity and flexibility. However, drawbacks of the material include its low temperature resistance, and sensitivity to UV rays which can cause it to expand. Due to this, several manufacturers have developed alternative types of PP, simili-propilenos, that are stronger both physically and mechanically.

Nylon

Objects made from polyamides (nylon) are usually created from a fine, white, granular powder with SLS technology. There are however some variants of the material such as nylon that are also available in filaments used in fused deposition modeling (FDM). Due to its biocompatibility, polyamides can be used to create parts that come into contact with food (except foods that contain alcohol).

Constituted of semi crystalline structures, polyamides have a good balance of chemical and mechanical characteristics that offer good stability, rigidity, flexibility, and shock resistance. These advantages mean that the material has many applications across sectors and offers a high level of detail. Due to its high quality, polyamides are used in the manufacture of gears, parts for the aerospace market, automotive market, robotics, medical prostheses, and injection molds. You can learn more in our dedicated guide on Nylon.

These advantages mean that the material has many applications across sectors and offers a high level of detail. Due to its high quality, polyamides are used in the manufacture of gears, parts for the aerospace market, automotive market, robotics, medical prostheses, and injection molds. You can learn more in our dedicated guide on Nylon.

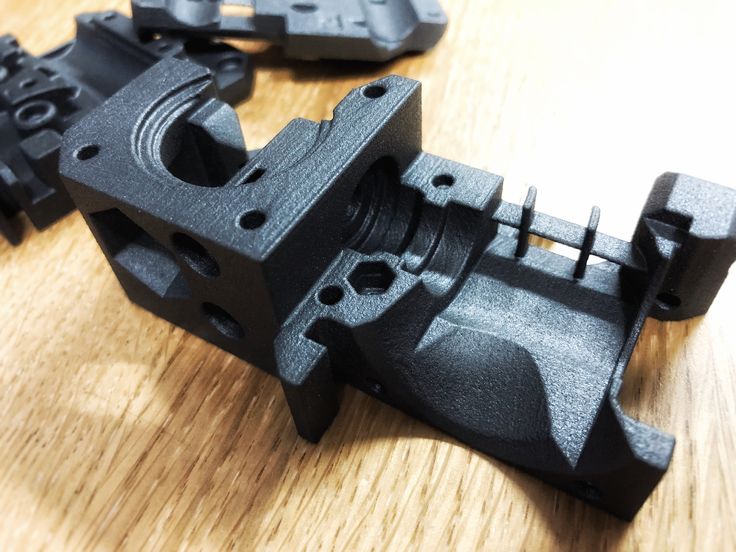

Image via Sculpteo

Composites

Composites are extremely beneficial when making lightweight yet strong parts. The fibers add strength to a part without adding weight, which is why we also refer to composites as fiber reinforced materials. There are two types of reinforcements, short fiber or continuous fiber. In the first case, chopped fibers, which consist of segments less than a millimeter in length, are mixed into traditional 3D printing plastics to increase the stiffness and to a lesser extent the strength of components. Chopped fibers can be mixed with thermoplastics such as nylon, ABS or PLA.

Alternatively, the fibers can be added to the thermoplastics continuously to arrive at a stronger part. The main fiber used in the 3D printing sector is carbon fiber, but there are also other fibers such as glass fiber or Kevlar. You can find more information in our dedicated guide.

The main fiber used in the 3D printing sector is carbon fiber, but there are also other fibers such as glass fiber or Kevlar. You can find more information in our dedicated guide.

Carbon fiber reinforced filament spool

Hybrid Materials

There are a variety of hybrid materials that mix base plastics with powders to give them a new color, finish or additional material properties. Often based on PLA, these materials are usually made of 70% PLA and 30% hybrid material. For example, wood-based filaments ranging from bamboo, cork, wood dust, and more are available. These wood-based materials mixed with PLA give the hybrid filament a more organic texture. Additionally, some hybrid materials incorporate metal powders to work with FDM-based technologies, to give parts a metal finish. They can be based on copper, bronze, silver, and more.

3D filaments based on wood.

Alumide

Alumide plastic objects are manufactured from a combination of polyamides and aluminium powder using the SLS process. The material has a large, slightly porous surface and a gritty, grainy appearance offering great strength and good temperature resistance (up to 172°C). However, some post-processing treatments are necessary, such as grinding, sanding, coating, or milling.

The material has a large, slightly porous surface and a gritty, grainy appearance offering great strength and good temperature resistance (up to 172°C). However, some post-processing treatments are necessary, such as grinding, sanding, coating, or milling.

Alumide is used for complex models, design pieces, or for small series production of functional models that need high rigidity and an appearance similar to aluminium. This technique involves few geometric limits.

Soluble Materials

Soluble materials are materials printed with the intention of being dissolved in a future stage of the manufacturing process. The two most common soluble filament materials are HIPS (High Impact Polystyrene) and PVA (Polyvinyl Acetate). HIPS is associated with ABS, and can be dissolved with limonene, whereas PVA is associated with PLA and can be dissolved using just water.

There are also BVOH filaments which are becoming increasingly popular, especially in dual extruder printers. This is because the material is soluble in water, and according to experts has a higher solubility than PVA.

This is because the material is soluble in water, and according to experts has a higher solubility than PVA.

Flexible Materials

A newer type of filament, and one of the most successful, are flexible filaments. They are similar to PLA, but usually made out of TPE or TPU. The advantage of using these filaments for 3D printing is they allow for the creation of deformable objects, widely used in the fashion industry. Generally, these flexible filaments have the same printing characteristics as PLA, though they come in a variety of ranges based on their stiffness. It is worth finding out which type of extruder is best suited to the material to avoid jams when 3D printing.

Flexible materials are widely used in fashion and design

Resins (for photopolymerization-based 3D printing)

3D printing technologies based on photopolymerization use UV-sensitive resins to create objects layer by layer. In other words, they use a light source such as a laser or LCD screen to solidify a liquid photopolymer. Technologies include SLA, DLP, and even Material Jetting (PolyJet). Creating parts using resins results in high detail and smooth surface objects, nevertheless, the color range is still quite limited using this process. What differentiates resins from FDM filaments is that it is impossible to mix resins to obtain different results quite easily.

Technologies include SLA, DLP, and even Material Jetting (PolyJet). Creating parts using resins results in high detail and smooth surface objects, nevertheless, the color range is still quite limited using this process. What differentiates resins from FDM filaments is that it is impossible to mix resins to obtain different results quite easily.

Standard resin has properties similar to ABS: the surface finish of the part will be good given the photopolymerization process, however mechanical properties will be moderate. More advanced resins do exist for technical applications such as in dentistry (also need to be biocompatible), or engineering. Additionally, flexible resins that offer greater flexibility and deformation can be used to make jewelry. Over the years, manufacturers have expanded their range of liquid photopolymers to answer manufacturing needs from various sectors. Therefore, you should be able to find resins that have high-temperature resistance, can withstand large impacts, or that have high elongation properties.

The 3D printing resin is poured in a tank

What do you think of our explanation of these 3D printing plastics? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

90,000 types of plastic for 3D printerContent

-

- Pla

- ABS

- HIPS

- PVA

- Petg

- SBS 9000

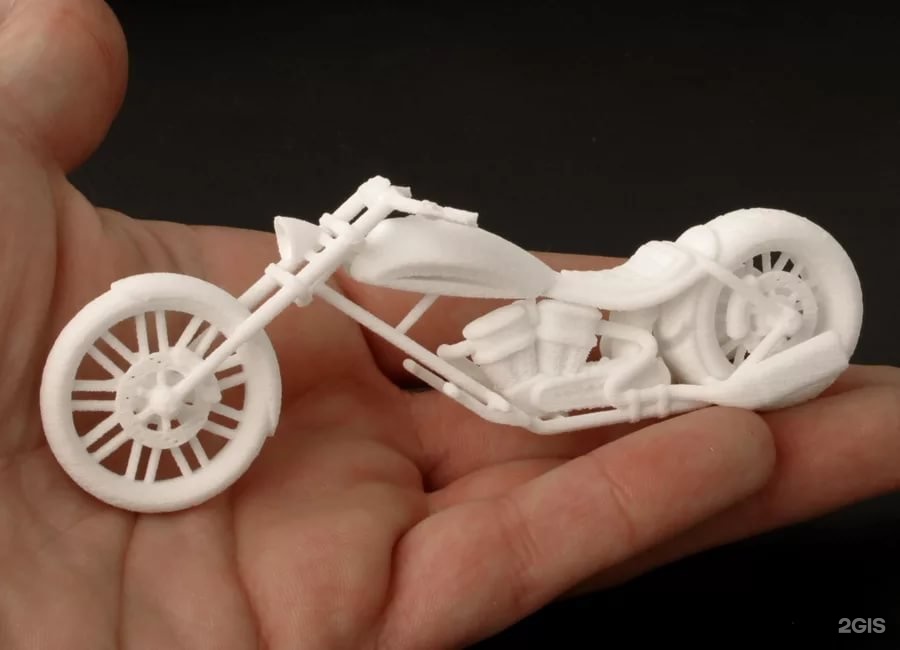

Every year 3D printing becomes more popular and accessible. Previously, a 3D printer was more like a complex CNC machine, but now manufacturers are meeting users. Simplified and automated settings that many beginners drove into a stupor. Despite this, it can be difficult for a novice user to understand the variety of constantly appearing plastics for a 3D printer. nine0003

The choice of plastic for a 3D printer is very important, especially when the goal is to print a functional model with certain properties. It will be a shame if the printed gear breaks almost immediately, or the decorative model quickly loses its beauty.

It will be a shame if the printed gear breaks almost immediately, or the decorative model quickly loses its beauty.

It is important to understand whether the printer will be able to work with the selected plastic. Some materials (most often engineering) require certain conditions for successful printing.

First, decide which model you want to print. What properties should it have? Does the model need to be durable? Or is it a master model for further replication, in which the quality of the surface is important? nine0003

90% of 3D printers use 1.75 diameter filament. 3mm diameter is rare, but it is better to check in advance which size is used in your printer.

PLA

PLA (Polylactide) is the most popular and affordable 3D printer plastic. PLA is made from sugar cane, corn, or other natural raw materials. Therefore, it is considered a non-toxic, biodegradable material.

Extruder temperature - 190-220 degrees. Table heating is not needed, but if the printer's table has a "heater" for better adhesion, you can heat it up to 50-60 degrees. PLA is very easy to work with. The only requirement is to blow the model. There is practically no shrinkage in this material. When printed, it is practically odorless, and if it smells, it smells like burnt caramel.

Table heating is not needed, but if the printer's table has a "heater" for better adhesion, you can heat it up to 50-60 degrees. PLA is very easy to work with. The only requirement is to blow the model. There is practically no shrinkage in this material. When printed, it is practically odorless, and if it smells, it smells like burnt caramel.

Pros:

-

Does not shrink. This makes it easy to build prefabricated or huge models without changing dimensions. nine0003

-

There are no specific requirements for a 3D printer. Any working 3D printer will do. PLA doesn't need a heated table or a closed case.

-

Non-toxic. Due to this, during printing it does not smell or has a barely perceptible aroma of burnt caramel.

-

Diverse color palette.

nine0051 Cons:

-

PLA is poorly sanded and machined.

-

It begins to deform already with a slight heating (about 50 degrees).

-

Fragility. Compared to other materials, PLA is very brittle and breaks easily.

-

Decomposes under the influence of ultraviolet radiation. Of course, it will not fall apart into dust, but it can become more brittle and fade. nine0003

PLA is perfect for making dimensional or composite models. For example, decorative interior items, prototyping, electronics cases, etc.

Recently, PLA+ has appeared on the market. It may differ from conventional PLA in improved performance. For example, more durable, with improved layer adhesion.

Dummy turbine

Decorative coasters

ABS

ABS (acrylonitrile butadiene styrene) is the second most popular plastic for 3D printing due to its properties, availability and low price.

Extruder temperature - 220-240 degrees. The temperature of the table is 80-100 degrees. For printing, a heated table is required at the printer. It is desirable to have a closed chamber, because ABS "does not like" drafts. Due to a sharp temperature drop, it can “unstick” from the table or crack in layers. ABS can smell bad when printing, so it is recommended to use the printer with a closed chamber and filters, or print in a well-ventilated area. nine0003

For printing, a heated table is required at the printer. It is desirable to have a closed chamber, because ABS "does not like" drafts. Due to a sharp temperature drop, it can “unstick” from the table or crack in layers. ABS can smell bad when printing, so it is recommended to use the printer with a closed chamber and filters, or print in a well-ventilated area. nine0003

Pros:

-

Good strength characteristics allow the production of functional prototypes from ABS.

-

Simple mechanical and chemical processing. ABS is easy to sand and drill, and with an acetone bath you can achieve a perfectly smooth surface.

-

It is currently the most inexpensive type of plastic for 3D printing. nine0003

-

Large selection of colors and shades.

Cons:

-

High shrinkage. Because of this, it can be problematic to manufacture overall products.

-

Printing requires a heated bed and a closed chamber.

nine0008 Without this, the ABS may peel off the table or crack in layers.

Without this, the ABS may peel off the table or crack in layers. -

During the printing process, ABS can smell bad. Therefore, it is recommended that you print in a ventilated area or use the printer with a sealed chamber and filter.

ABS is an engineering plastic. It is suitable for the manufacture of simple functional products.

ABS after chemical treatment in an acetone bath

nine0003

RU model made of ABS

ABS+ differs from conventional ABS in improved strength characteristics (elasticity, rigidity, hardness), less shrinkage and sometimes resistance to certain oils and solvents (eg gasoline).

HIPS

HIPS (high impact polystyrene) - originally conceived as a soluble support plastic for materials with high printing temperatures. For example for ABS or Nylon. nine0003

The extruder temperature is 230-260 degrees. The temperature of the table is 80-100 degrees. It is desirable to have a closed camera for a 3D printer.

The temperature of the table is 80-100 degrees. It is desirable to have a closed camera for a 3D printer.

Pros:

-

Less shrinkage than ABS.

-

Ease of machining.

-

The matte surface looks very advantageous on decorative products. nine0003

-

Food contact allowed (but be sure to check with a specific manufacturer for certificates)

Cons:

-

For printing, you need a printer with a heated table and a closed chamber.

-

More flexible and less durable than ABS. Because of this, it will not be possible to produce functional products. nine0003

-

Small palette of colors.

Most often, HIPS is used for its intended purpose for printing on 2x extruder printers as a support for ABS. It dissolves perfectly (though not very quickly) in limonel.

Sometimes HIPS is used as an independent material. Products from it are not very durable, but this plastic is loved for easy post-processing. HIPS can be used for models that will subsequently come into contact with food (not hot). nine0003

Products from it are not very durable, but this plastic is loved for easy post-processing. HIPS can be used for models that will subsequently come into contact with food (not hot). nine0003

Using HIPS as a Soluble Support

Decorative vase made of HIPS

PVA

PVA (polyvinyl alcohol) is a material that was developed as a water-soluble support for PLA.

Extruder temperature - 190-210. Table heating is not required. PVA is a slightly "capricious" material, it is not recommended to overheat it and print at high speeds. nine0003

PVA is very hygroscopic and dissolves in plain water. Therefore, it is only used as a support for PLA or other plastics with print temperatures close to PVA.

Soluble PVA Support

Add to compare

Item added to compare Go

| Manufacturer | Tiger3D | nine0265

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

Add to compare

Product added to compare Go nine0003

| Manufacturer | Esun |

PETG

PETG (polyethylene terephthalate) combines the best properties of PLA and ABS. It is easy to work with, it has a low percentage of shrinkage and excellent sintering of the layers.

It is easy to work with, it has a low percentage of shrinkage and excellent sintering of the layers.

Extruder temperature - 220-240 degrees. Table temperature - 80-100 degrees. During the printing process, the model must be well blown.

Pros: nine0003

-

Excellent sinterability of layers.

-

PETG is very strong and wear resistant. Good impact resistance.

-

Virtually no smell when printing.

-

Non-toxic.

-

Little shrinkage.

nine0029 -

slight shrinkage

-

Transparency. After treatment with solvent, limonel or dichloromethane, beautiful transparent products with an almost smooth surface can be obtained.

nine0005 -

Allowed contact with food.

-

High strength and wear resistance.

nine0008 -

High slip factor.

-

Heat resistance compared to other 3D printing plastics.

-

High resistance to many solvents.

-

Good for mechanical processing.

Perfectly polished and drilled.

Perfectly polished and drilled. -

Some fillers (eg clay) are abrasive. For such plastics, the standard brass nozzle cannot be used. Will have to buy a harder steel nozzle.

-

Some decorative plastics can clog the small nozzle (0.4 or less). For them, you need to use a “thicker” nozzle. nine0003

-

Hardness and strength.

-

Low flammability or non-combustibility.

-

High precision due to low shrinkage.

nine0029 - PLA (PLA) or polylactide. Organic and short lived. Suitable for 3D printing of decorative products, but not able to withstand high mechanical loads;

- ABS (ABS) or acrylonitrile butadiene styrene.

It has a long life and excellent mechanical properties. Heat-resistant and used for industrial purposes. Shrinks on cooling. It is recommended to print in ventilated areas; nine0008

It has a long life and excellent mechanical properties. Heat-resistant and used for industrial purposes. Shrinks on cooling. It is recommended to print in ventilated areas; nine0008 - PVA (PVA) or polyvinyl alcohol. A water-soluble material that is used as a support;

- Nylone (Nylon). An alternative to ABS plastic, suitable for many engineering structures. When printing with nylon, it is recommended to ventilate the room;

- HIPS (High Impact Polystyrene). In terms of physical properties, it is a cross between PLA and ABS. May also emit toxic fumes when printed.

Cons:

PETG is perfect for printing functional models. Due to its low shrinkage, it is often used to make large or composite models. Due to its low toxicity, PETG is often used for products that will come into contact with food.

Cookie cutters and patterned rolling pin

SBS

It is a highly transparent material. At the same time, it is durable and resilient. SBS is a low toxicity plastic. It can be used to print food contact models. nine0003

SBS is a low toxicity plastic. It can be used to print food contact models. nine0003

Extruder temperature - 230 -260 degrees. Table temperature - 60-100 degrees. You can print without the closed case on the printer.

Pros:

Easily processed mechanically or chemically.

Cons:

SBS is excellent for translucent vases, children's toys and food containers. Or functional things that require transparency, such as custom turn signals for a motorcycle or car, lamps or bottle prototypes. nine0003

Vases are perfectly printed with a thick nozzle (0.7-0.8) in one pass (printing in 1 wall or spiral printing in a slicer).

Models of bottles after chemical treatment

Nylon

Nylon (polyamide) is considered the most durable material available for home 3D printing. In addition to good abrasion resistance and strength, it has a high slip coefficient. nine0003

Extruder temperature - 240-260 degrees. The temperature of the table is 80-100 degrees. Nylon is a very capricious and hygroscopic material - it is recommended to dry the coil with plastic before use. For printing, you need a printer with a heated table and a closed chamber, without this it will be difficult to print something larger than a small gear.

Pros:

nine0051 Cons:

Nylon is perfect for making wear-resistant parts - gears, functional models, etc. Sometimes nylon is used to print bushings.

Nylon gear

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

Add to compare

Product added to compare Go nine0003

| Manufacturer | Bestfilament |

Soft plastics

FLEX (TPU, TPE, TPC) is a material similar to silicone or rubber. It is flexible and elastic, but at the same time tear-resistant. For example, TPE is a rubbery plastic, while TPU is more rigid.

FLEX are printed at a temperature of 200-240 (depending on the material). A heated table is not required. On printers with direct material feed (feed mechanism on the print head), there are usually no problems with printing. On a bowden feeder (the feed mechanism is located on the body), printing with very soft plastics can be difficult. Usually it is necessary to additionally adjust the clamping of the bar. The main nuance is the very low print speeds - 20-40mm. nine0003

Pros:

Cons:

Depending on the type of FLEXa, the models can be flexible or rubber-like. This material, depending on its softness, can be used to print gaskets, insoles, belts, tracks or other models that require flexibility or softness.

FLEX belt

nine0102 Trainers with flexible soles

Wheel for switchgear model

Decorative plastics

Decorative plastics are PLA plastics with various fillers (wood or metal shavings). Or with dyes selected to imitate different materials. Since the base of the plastic is PLA, it is very easy to print.

Or with dyes selected to imitate different materials. Since the base of the plastic is PLA, it is very easy to print.

Extruder temperature - 200-220 degrees (depending on the manufacturer). A heated table is not required. nine0003

Pros:

Cons:

Depending on the filler, different material properties are obtained. Plastics that use only dye do not require additional processing. Materials with "fillers" may sometimes require additional post-processing.

Plastics with metal fillers after printing must be processed with a metal brush. Then the Metal content will show through and the model will resemble a metal casting.nine0043

Plastics with metallic powder

These plastics are often used for printing key chains, decorative models and interior details.

If the plastic has a high content of wood dust, then it is recommended to use a larger nozzle diameter (0.5 or more), a smaller nozzle can quickly become clogged during printing.

Wood-filled plastic ground

Plastic key rings with copper dust

Engineering plastics

These are nylon-based plastics with fillers that improve strength, heat-resistant and other characteristics, help to achieve less shrinkage of the material. For example - carbon fiber, carbon fiber or fiberglass.

Extruder temperature - 240-300 degrees (depending on the manufacturer). Table temperature - 90-110 degrees. Since plastics are based on nylon, the requirements for printing are similar. This is a heated table and a closed printer case.

Pros:

Cons:

3D printers use brass nozzles, some plastics can quickly “waste” it during printing. For such materials it is recommended to use steel nozzles.

These are highly specialized plastics used for a specific task, depending on the filler. For example, functional parts that do not lose their shape when heated, are resistant to many solvents, etc. nine0003

Functional Carbon Fiber Composite Prototype

Composite frame

Polycarbonate ashtray

Totals

This is of course not the whole list of materials for 3D printing. There are many highly specialized engineering and decorative plastics for specific tasks.

nine0003

Manufacturers are constantly trying to replenish the range of materials for 3D printing. Already familiar materials are improved for more comfortable printing. There are many interesting decorative plastics imitating different materials - ceramics, clay, wood, metals.

And of course, the assortment of engineering plastics is constantly updated. Now there are many interesting materials for highly specialized tasks - for example, burnable plastic with a low ash content for subsequent casting in metal. nine0003

Burnout plastic

Before buying a coil, read the information on the website of the manufacturer or seller. There you can find some nuances of printing for a particular plastic. The manufacturer indicates the recommended temperature range on the box. Sometimes, for quality printing, it is recommended to print several tests to adjust the temperature settings, retract, etc.

Try to store the started coil in silica gel bags.

It is recommended to additionally dry high-temperature plastics before printing to remove excess moisture. nine0003

Add to compare

Product added to compare Go

Manufacturer Tiger3D Add to compare

Product added to compare Go

Manufacturer Esun Add to compare

Product added to compare Go nine0003

Manufacturer Esun Add to compare

Product added to compare Go

Manufacturer FlashForge What is the best plastic for 3D printing? Let's figure it out together!

Plastic for 3D printing

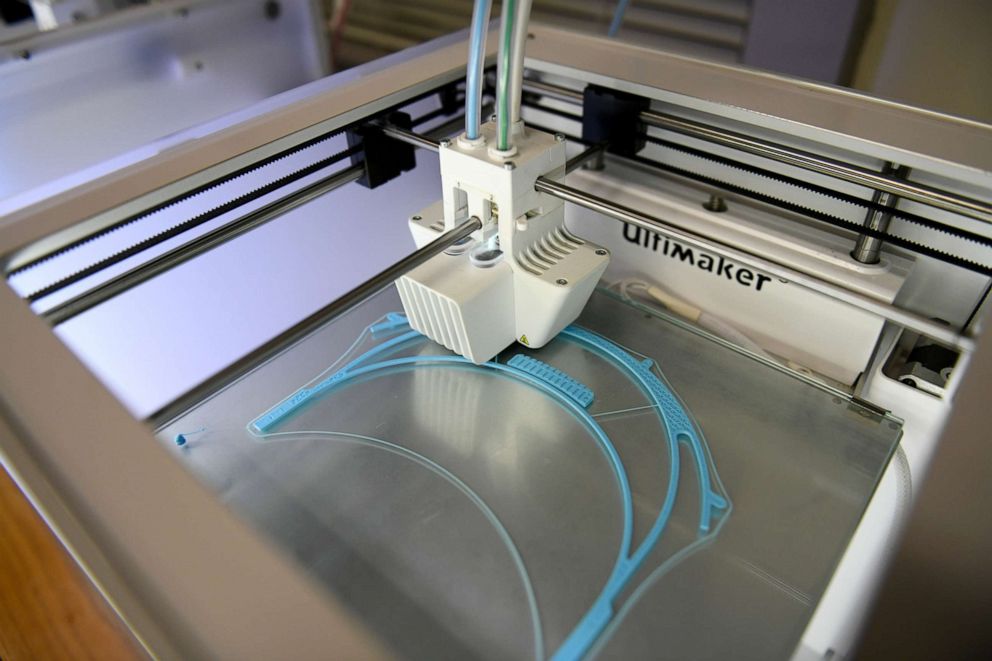

After purchasing your own FDM 3D printer, as well as in the course of choosing it, it becomes necessary to choose the right plastic for 3D printing. But how to do this if you are new to 3D printing and have little to no understanding of this issue? Plastic for printing on a 3D printer is in most cases the main component of successful product reproduction.

Therefore, we will not save on knowledge, and will tell you how to choose the best plastic for 3D printing. nine0003

Types of plastic for a 3D printer

First of all, you need to consider the types of plastic for a 3D printer. Plastic for 3D printing, or filament, is produced in the form of a thin thread with a diameter of 1.75 mm and 3 mm. Most often, filaments with a thickness of 1.75 mm are used in the basic configuration, but some manufacturers of 3D printers provide the ability to install a 3 mm plastic feed system. Plastic for 3D printing has many varieties, among which the most common are ABS and PLA plastic. nine0003

Plastic for 3D printing: varieties

By popularity in the Ukrainian market, the following types of plastic for 3D printing can be distinguished:

Other questions and answers about 3D printers and 3D printing:

What is the best plastic for a 3D printer?

In fact, there are many more types of plastic for 3D printing. This can include flexible, fluorescent and luminescent filament, wood and metallized materials. But in practice, such consumables are rarely used and are needed for narrowly specific purposes. Metallized plastics are interesting in their own right, but they are at the initial stage of development and are inferior in performance to ordinary reinforced materials.

“And what plastic is best for a 3D printer?” - you ask. You should choose based on specific goals. If you intend to print decorative elements that will not be subject to payload, you can look at PLA plastic. If your goal is to print gears, structural parts and other things, look at reinforced materials for 3D printing. nine0003

What kind of plastic to print?

Please note that not every printer supports the full range of 3D printing materials. Before buying a specific filament, check the specifications of your own device to avoid wasting money. The rest is up to you and your imagination. A huge range of colors and shades of plastic is available for sale, matte and glossy, semi- and fully transparent materials. Such a variety will allow you to make almost any product to your taste. nine0003

Remember that if you need to buy plastic for 3D printing - 3DDevice store is at your service! We offer a wide range of different materials in all possible color options and are ready to provide advice when choosing a filament.

Learn more