3D printing lulzbot

LulzBot®| 3D Printers, Filament, and More

What can you do with a LulzBot?

Our legendary 3D printers have found their calling everywhere from elementary school classrooms to space exploration labs. Let us help find your LulzBot's purpose today!

Educate

Show me moreThe consistency and support from LulzBot has made achieving my goals realistic.

- FREE Curriculum

- Career Readiness

- Unparalleled Engagement

- Hands-On Experience

Explore Education

Manufacture

Show me moreWithin a day, my idea had become a physical part and put to work in production.

- Rapid Prototyping

- Just-In-Time Manufacturing

- Decentralized Manufacturing

Explore Manufacturing

Create

Show me moreAfter trying a few other brands, the LulzBot Mini was the perfect solution.

![]()

- Creative Freedom

- Versatility

- Solutions for You

Explore Creating

Request a Free Sample Print

Let us demonstrate the incredible geometries and useful shapes that are possible to 3D print with a LulzBot. We are confident the quality and versatility from our 3D printers will help you evaluate your LulzBot purchase. Request a no-risk sample 3D print to get started today!

In the News

MatterHackers forms CRADA with Naval Information Warfare Center

The Naval Information Warfare Center (NIWC) has entered into a CRADA (Cooperative Research and Development Agreement) with South-California based, LulzBot reseller MatterHackers to provide use cases to collect data on effective, low-cost, expeditionary 3D printing.

Project Time: 3D Print A Functional Continuity Tester

Learn how to 3D print a functional continuity tester in this tutorial

Boost Your STEAM Engagement This Year

It’s that time of year when educators and students return to school, opening doors to new opportunities and fresh lessons. LulzBot’s educational specialists are here with valuable experience to ensure your 3D printing setup is a success!

LulzBot’s educational specialists are here with valuable experience to ensure your 3D printing setup is a success!

Ehlers Family Farms: A Seed Plot Solution with 3D Printing

In agriculture it's common to test out a variety of seeds with your soil before determining which to plant. Planting Seed Plots is an excellent way to compare multiple varieties of seed for the next growing season. Problem is, most modern machinery has been optimized for planting one or two varieties at a time, leaving seed plots to be planted with outdated equipment in many cases, which can be very inefficient.

Better First Layers on Your TAZ SideKick

If you want to get the perfect first layer you need to make sure that your BLTouch has the proper z-offset tuned. To do this you need to follow the steps of calibrating using the Z-Offset Wizard, a feature that can be found on all LulzBot TAZ SideKicks.

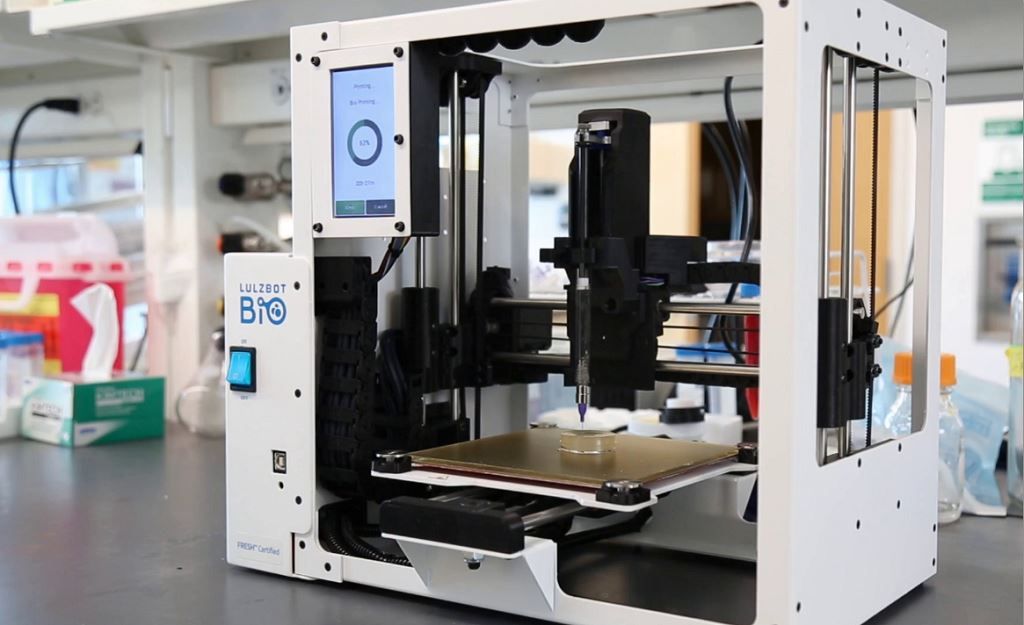

3D Printing Industry Gives the LulzBot Bio a Fresh Review

The 3D Printing Industry, a dedicated news resource in all things 3D printing, went through a LulzBot Bio 3D bioprinter recently and was able to give it a thorough inspection and run down.

TAZ SideKick 289 Awarded as Best Upgrade Printer from ALL3DP

Don’t think you have enough space for a 3d printer? LulzBot’s TAZ Sidekick is out to prove you wrong! The TAZ SideKick was recently picked by ALL3DP, The World's #1 Magazine for the Digital Maker, as the Top Upgrade Pick for the entire small/portable 3D printer category!

More articlesShop LulzBot 3D Printers & Filament

3D Printers

Award-winning LulzBot® desktop 3D printers respect your freedom to create. Enjoy industry-leading robustness, reliability, ease-of-use, and material variety to bring your ideas to life!

Explore 3D Printers

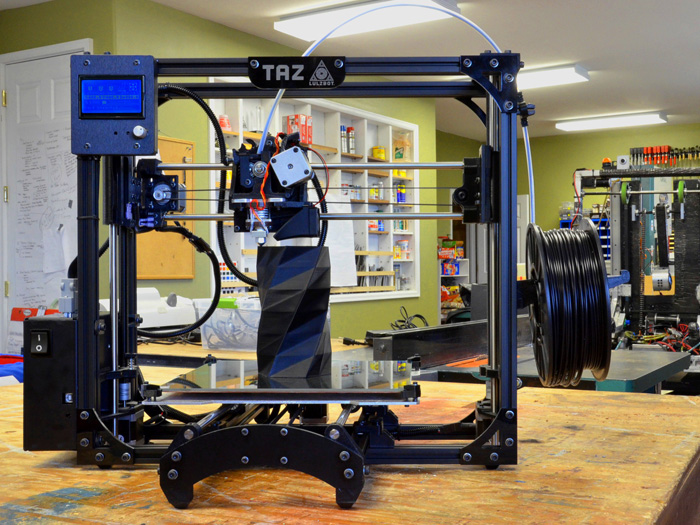

LulzBot TAZ Workhorse

Bigger. More Reliable. Easier Than Ever.

A name earned over seven years and millions of printing hours, the LulzBot TAZ Workhorse is a ready-to-print powerhouse that builds on the unmatched reliability and print quality of its predecessors while offering more material options than ever before.

- LulzBot TAZ Workhorse Introduction Video ➡

- Need a TAZ Workhorse ABS+ Enclosure? Find it here ➡

3D Printers

$ 2,950 00

2950.0

LulzBot TAZ Pro

Professional Results.

The new LulzBot TAZ Pro is an industrial desktop 3D printer that provides large, multi-material and soluble support printing with LulzBot’s award-winning reliability. Create large functional prototypes, manufacturing aids, and print-on-demand parts with easy, professional results.

- LulzBot TAZ Pro Introduction Video ➡

- Need a TAZ Pro ABS+ Enclosure? Find it here ➡

3D Printers

$ 4,950 00

4950.0

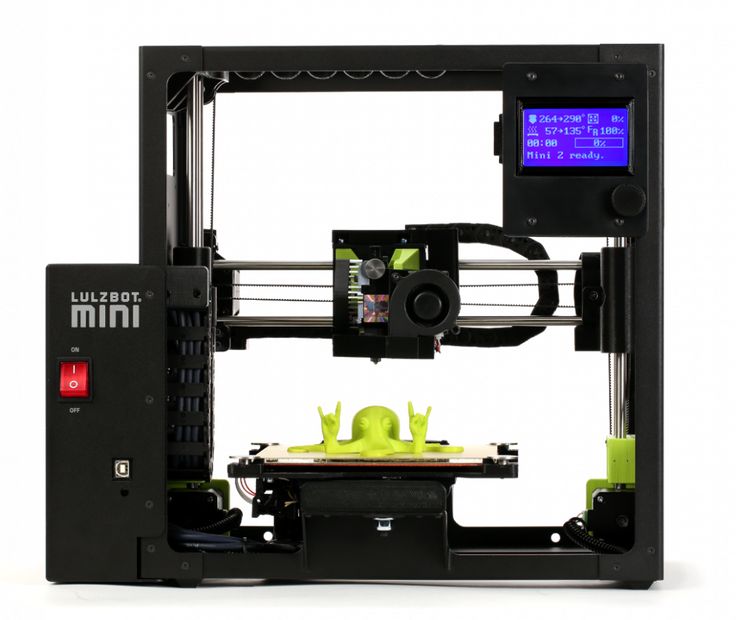

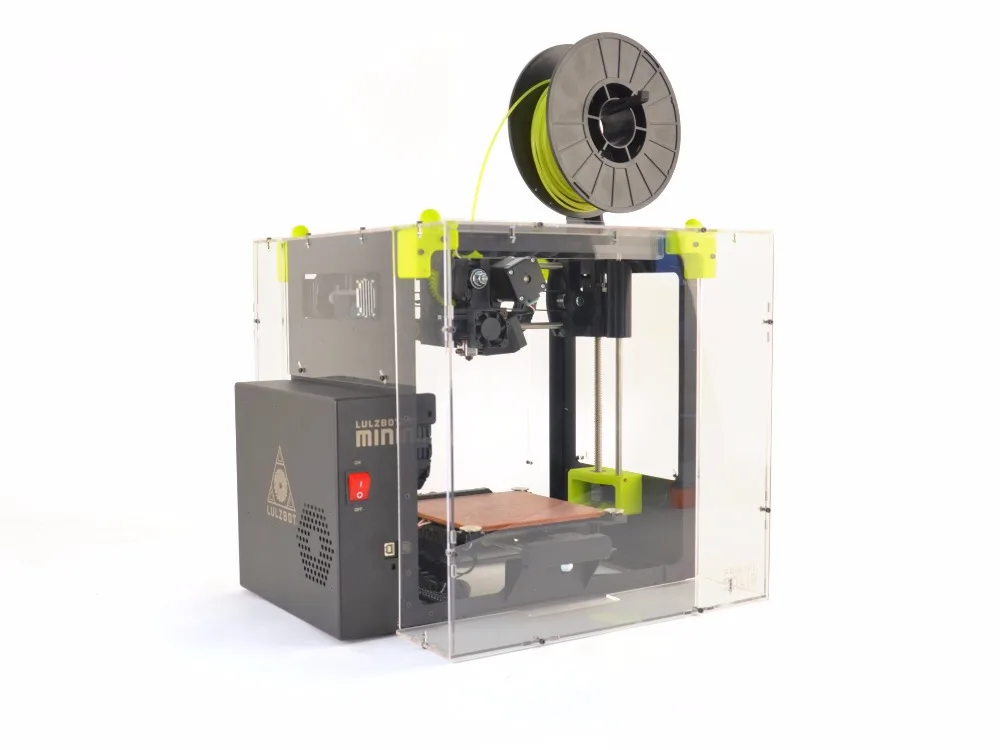

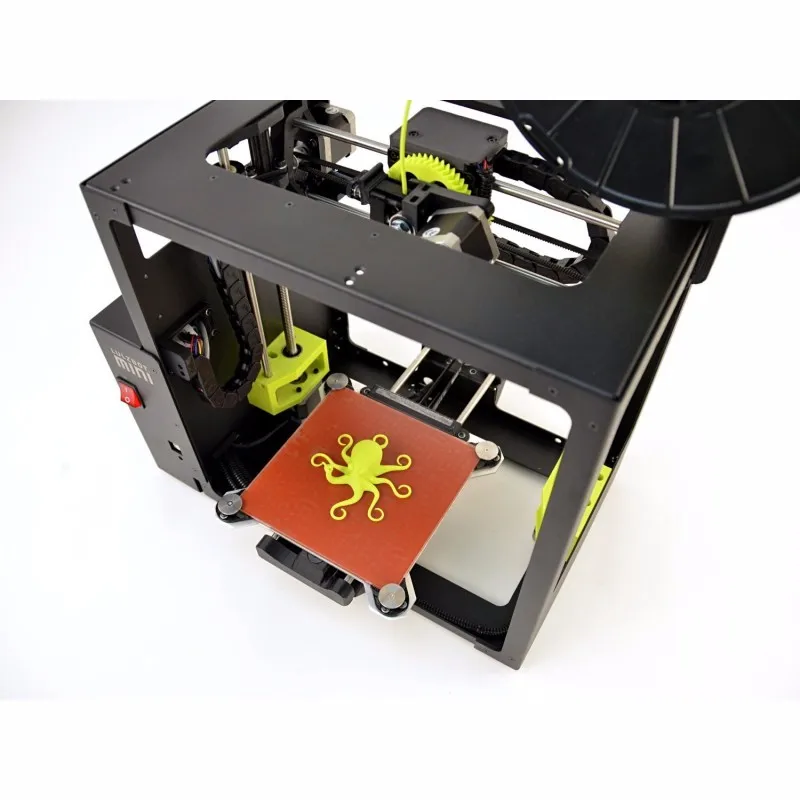

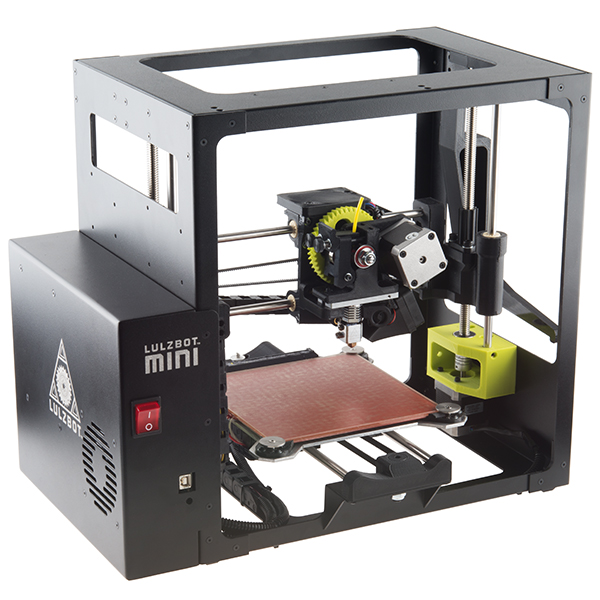

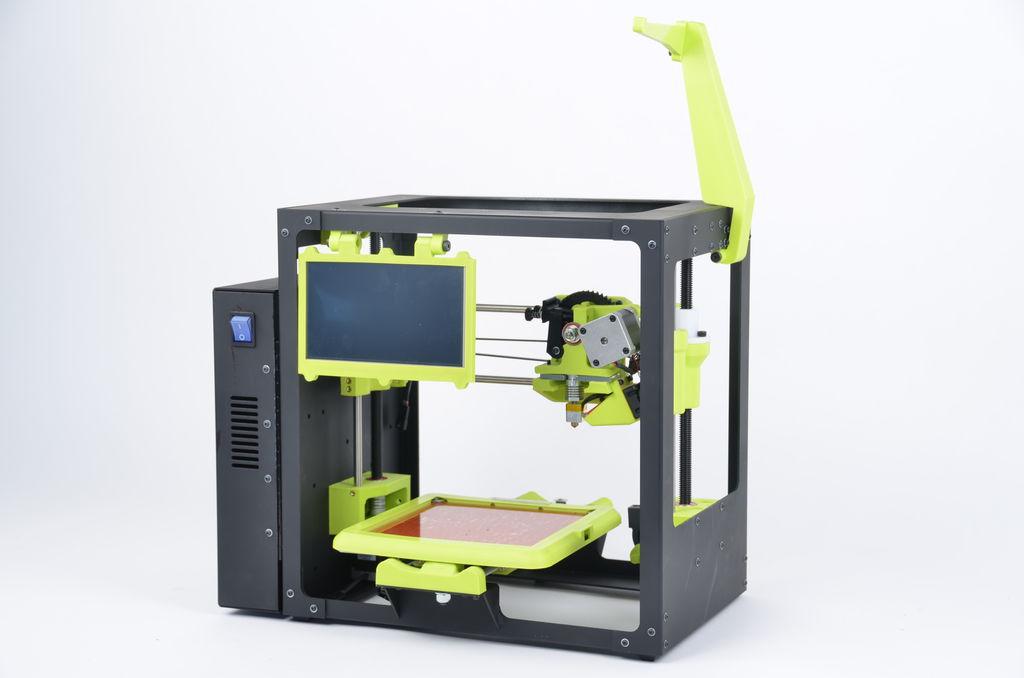

LulzBot Mini 2

Less show pony, more work horse.

Don't let the compact frame and easy operation fool you. The LulzBot Mini 2 Desktop 3D Printer is engineered and built to exacting standards in the USA and ships calibrated and ready to work. Whether you’re keeping pace with growing production demands, engineering mission critical components, or inspiring the next crop of global innovators in the classroom... saddle up!

- LulzBot Mini 2 Introduction Video ➡

- Need a Mini 2 ABS+ Enclosure? Find it here ➡

3D Printers

$ 1,495 00

1495.0

LulzBot TAZ Pro S

LulzBot TAZ Pro S. 1.75mm, Single Extruder.

The LulzBot TAZ Pro S is an industrial desktop 3D printer that provides large, 1.75mm material printing with LulzBot’s award-winning reliability. Create large functional prototypes, manufacturing aids, and print-on-demand parts with easy, professional results.

- Need a TAZ Pro S ABS+ Enclosure? Find it here ➡

3D Printers

$ 3,995 00

3995.0

Tool Heads

Upgrade and unleash your LulzBot® 3D Printer! Reach new layer heights for snap-fit parts and tight tolerances with the SL Micro. Make strong parts fast with the HS+. Experience 1.75mm filament printing with the M175.

Explore Tool Heads

M175 v2 Tool Head | 1.75 mm | Single Extruder | 0.5 mm

LulzBot honors your freedom to print.

Add 1.75 mm filament capability to your LulzBot 3D printer and open up an even wider variety of 3D printing materials. The M175 v2 Tool Head is here to bring the world of 1.75 mm material to your LulzBot Mini 2, TAZ Workhorse, and TAZ Pro.

Tool Heads

$ 375 00

375. 0

0

SE Tool Head | 2.85 mm | Single Extruder | 0.5 mm

Versatility and precision come standard with the LulzBot SE Tool Head, featuring the Universal Mounting System, and the industry leading Titan Aero Hot End and Extruder from E3D. This tried and true combination enables a vast palette of supported 3D printing material, both rigid and flexible. As the featured tool head on both the LulzBot Mini 2 and TAZ Workhorse 3D Printers, the SE tool head is here to bring even more performance and dependability to your already trusty LulzBot TAZ 6, TAZ 5, and LulzBot Mini 1.

Tool Heads

$ 295 00

295.0

Filament

LulzBot® 3D printers offer support for dozens of cutting edge materials, including standard plastics, nylon, metal, conductive, glow-in-the-dark, UV-reactive, polyesters, and more!

Explore Filament

IC3D ABS Filament (2. 85 mm, 1 kg Spool, Red, ABS)

85 mm, 1 kg Spool, Red, ABS)

IC3D ABS 3D printer filament is the first and only Certified Open Source Hardware 3D printer filament. IC3D has published their filament production process which includes documentation on equipment used, settings and parameters, material grade, and sources.

This transparency not only shows the drive for consistency, precision, and quality, but also a committment to furthering desktop 3D printing material technology. By choosing IC3D filament, you too can help support User Freedom in the 3D printing industry. ABS 3D printer filament is the leading thermoplastic used in consumer electronics. 3D printed ABS objects balance strength, resilience, and heat resistance.

Filament

$ 35 00

35.0

Polymaker PolyLite PLA Filament (2.85 mm, 1 kg Spool, True Black, PLA)

PolyLite™ by Polymaker offers excellent 3D printing performance, a vibrant palette of colors, and will become your affordable, go-to choice. This premium filament 3D prints reliably and has minimal warping and shrinking compared to other materials, perfect for applications featuring flat surfaces and hard angles, or requiring tight tolerances for fit.

This premium filament 3D prints reliably and has minimal warping and shrinking compared to other materials, perfect for applications featuring flat surfaces and hard angles, or requiring tight tolerances for fit.

PolyLite PLA is available in multiple weight options. Select your preference below.

Filament

$ 22 99

22.990000000000002

$ 18 39

18.392

3D-Fuel Standard PLA+ Filament (2.85 mm, 1 kg Spool, Ocean Blue, Standard PLA)

Standard PLA from 3D-Fuel® is made from NatureWorks™ 4043d Ingeo PLA

Standard PLA is a basic, entry-level PLA filament. It's available in a broad color selection and uses only virgin NatureWorks Ingeo 4043d PLA resin. No fillers or stretchers means a more predictable 3D printing experience. Because there are no fillers, the ideal print temp might be 5-10C higher than your current PLA settings.

Filament

$ 29 00

29.0

$ 21 75

21.75

Fenner Drives NinjaFlex 85A Filament (2.85 mm, 0.75 kg Spool, Snow, NinjaFlex 85A)

NinjaFlex 3D printing filament performs with an exciting combination of elongation, elasticity, and strength. Simply put, it is the stretchiest material we have ever tested. NinjaFlex comes in many colors that have a beautiful, strong sheen after being 3D printed. Like SemiFlex, NinjaFlex is a premium and high quality filament material capable of opening the door to a wide range of new applications for your LulzBot desktop 3D printer

- Shore Hardness = 85A

- 660% elongation allows for repeated movement and impact without wear or cracking

Filament

$ 64 99

64. 99

99

Accessories

Find the connection your work flow has been missing with custom LulzBot® 3D Printer enclosures, tools, and adhesives.

Explore Accessories

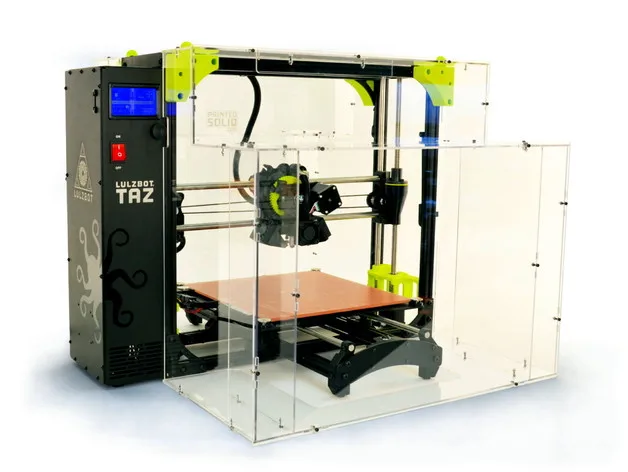

TAZ Pro/Workhorse ABS+ Enclosure

Use this ABS acrylic 3D printer enclosure with your LulzBot TAZ Pro or Workhorse to minimize warping and cracking caused by printing in cold and drafty environments, while keeping curious hands and paws away from the heated and moving parts of your 3D printer. This new 3D printer enclosure features a strengthened design with ABS panels, LulzBot branded laser-etched acrylic, and comes ready to assemble with all components provided (no 3D printing required).

Perfect for:

- Cold and/or drafty environments

- Printing materials with high shrink rates, like ABS, Nylons (Polyamides), and Polycarbonates

- Classrooms, libraries, and high-traffic areas with curious hands

Accessories

$ 350 00

350. 0

0

LulzBox by Repkord (Complete RepBox Package)

The filament management system you've been waiting for!

Holds up to six 1kg spools all in an attractive LulzBot themed RepBox.

Comes in addition to your LulzBox:

Upgraded seal kit

Humidity Hunter kit

Wall mounting kit

Does not come with filament.

Accessories

$ 295 00

295.0

Parts

Customize to your heart’s content, build your own DIY printer from the ground up, or keep your tried and true printers running with exclusive LulzBot® 3D Printer upgrades, spare parts, and more!

Explore Parts

100k Semitec NTC Thermistor

Manufactured by Semitec, this glass thermistor for 3D printers is encapsulated with a stainless steel jacket by E3D to improve heat transfer and to add strength and stability for secure installation into a hot end heater block.

Parts

$ 18 00

18.0

5 Amp Nano Polyfuse (x3)

These fast acting 5 amp nano polyfuses serve as the first line of defense for the full-sized RAMBo control electronics used in the LulzBot TAZ by protecting against potential damage caused by shorting. This three pack of LulzBot 3D printer fuses provides a full replacement set for the hot end/logic fuse, the stepper drivers fuse, with one additional fuse to be held in reserve as further backup.

Parts

$ 10 00

10.0

Mini 2/SK 289 Glass/PEI Print Surface, Retail

The LulzBot Modular Print Bed System ensures your LulzBot Mini is going strong for years to come with improved ease-of-maintenance, increased versatility, and better heat uniformity across the bed surface. The system is an easy and smart upgrade to any existing LulzBot Mini 3D Printer.

The system is an easy and smart upgrade to any existing LulzBot Mini 3D Printer.

This 3D printer glass and PEI bed surface is the upper half of the Modular Print Bed System and features a PEI (Polyetherimide) sheet laminated to a borosilicate glass plate.

Works with: LulzBot Mini 2, LulzBot Mini 1

Parts

$ 40 00

40.0

Beefy Idler Assembly, Retail

Redesigned to be stronger and more reliable, this Beefy Idler Assembly is a direct replacement for the extruder idler used on the LulzBot TAZ 6 and the LulzBot Mini 3D printer, and is compatible with previous LulzBot 3D printer models. Order this part for your LulzBot 3D printer today!

Works with: LulzBot Mini 1, LulzBot TAZ 6, LulzBot TAZ 5, LulzBot TAZ 4, LulzBot TAZ 3, LulzBot TAZ 2 or 1

Parts

$ 10 00

10. 0

0

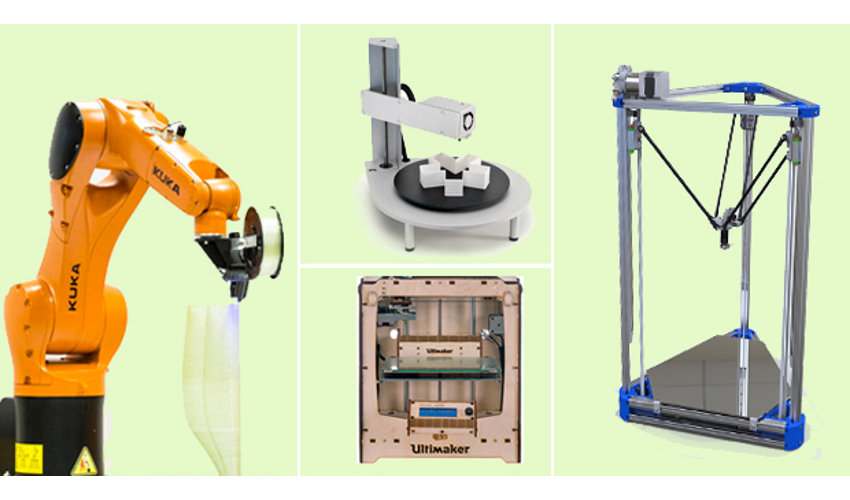

How different is printing on 3D printers for $2200 and for $200000 / Sudo Null IT News The list of materials for printing is gradually increasing. The time is not far off when it will be possible to print metal and glass products at home, and not just plastic ones.

3D printing promises to make an even bigger revolution in industry and construction. Now 3D printers are almost universally used for prototyping, and in the future, mass production of high-quality products will certainly begin. nine0003

As home "hobbyist" 3D printers get better and better, an interesting question arises: how different is home print quality from industrial print quality? This is exactly the question asked by American engineer and 3D printing enthusiast Mike Skrzypczak. For a sample, he went to the production laboratory of Caterpillar, one of the leading corporations for the production of large special equipment.

The laboratory has a very expensive Stratasys Fortus 380 MC printer costing approximately $200,000. This 2 meter high printer is designed to produce durable prototypes that meet the characteristics of the final product, as well as various production tools and production parts that withstand high pressure. nine0003

This 2 meter high printer is designed to produce durable prototypes that meet the characteristics of the final product, as well as various production tools and production parts that withstand high pressure. nine0003

Stratasys Fortus 380 MC Printer

Industrial printer prints seven types of thermoplastics: ABS-M30; ABS-M30i; ABS-ESD7; A.S.A.; PC-ISO material in white and translucent; PC; FDM Nylon 12. According to official specifications, the layer thickness is 0.330 mm, 0.254 mm, 0.178 mm or 0.127 mm.

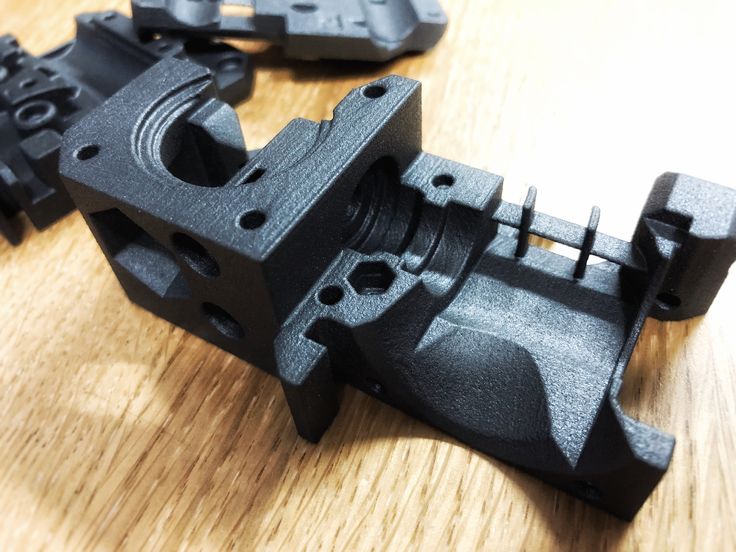

For the print sample, Mike took a real part - an auxiliary device for laying cables in the manufacture of electronic equipment. Previously, such forms were made on a press by molding, but now 3D printing is excellent for this. nine0003

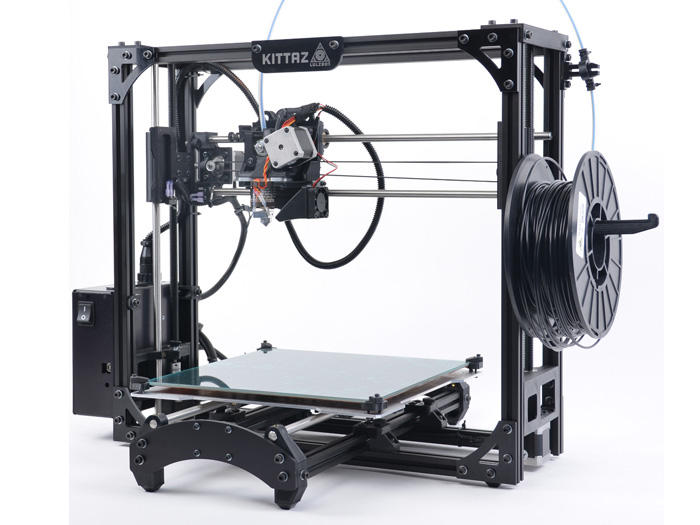

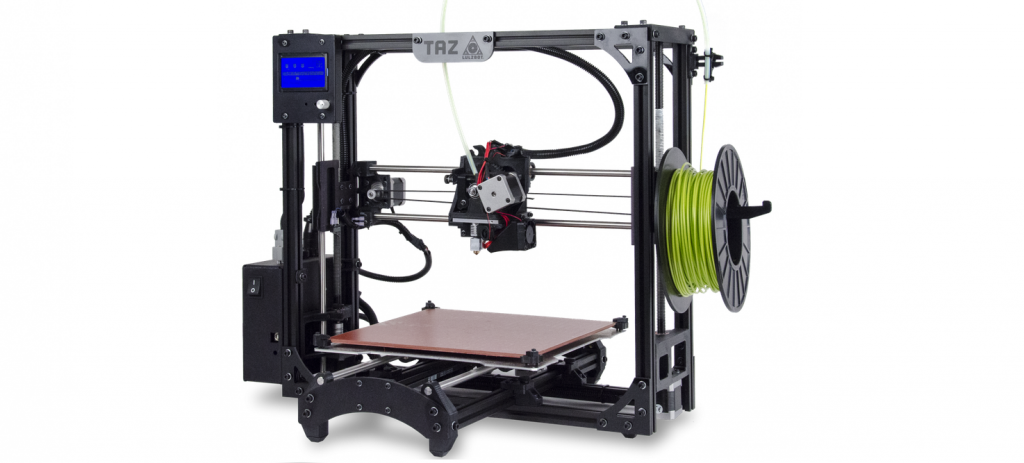

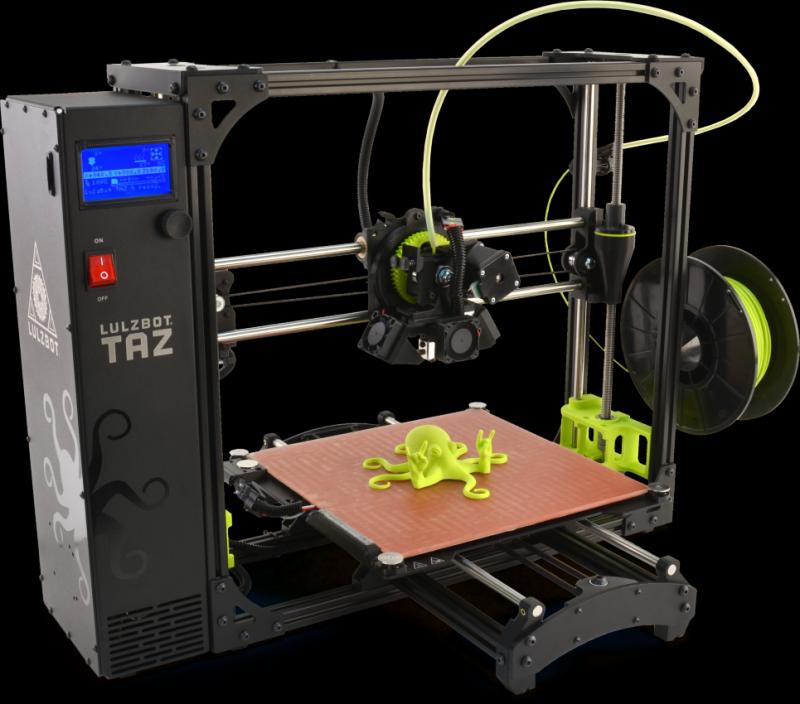

So, Lulzbot Taz 5 3D with a retail price of about $2200 will try to compete with the industrial monster.

The Lulzbot Taz 5 3D

Stratasys Fortus 380 MC printed an ABS plastic part, with 100% infill, at standard layer thickness and normal default settings. Mike says the factory didn't allow him to go directly to the machine, so he can't go into all the details about print options. The laboratory just made this detail at his request, well, thanks for that. nine0003

Mike says the factory didn't allow him to go directly to the machine, so he can't go into all the details about print options. The laboratory just made this detail at his request, well, thanks for that. nine0003

Engineer used HIPS filament on home printer, printed with 0.5mm nozzle, 0.1mm layer thickness, 25% coverage, four top and bottom hard layers, 45mm/s print speed and standard acceleration, temperature extrusion 240°C. working surface temperature 110°C and extrusion width 0.6 mm.

It is unlikely that such a test can be called absolutely correct. We do not know the exact parameters for printing on an industrial printer. In addition, for some reason the engineer used a different HIPS filament, although a home printer can print with the same ABS, and 25% infill instead of 100%. In general, this is a very superficial comparison, but still quite interesting. nine0003

The product took 18 hours to print on both machines. So what happened?

In the photographs, the two parts are easy to distinguish because the industrial part is black. The experimenter cleaned the details of excess materials as much as possible - and began to photograph.

The experimenter cleaned the details of excess materials as much as possible - and began to photograph.

If you look closely, the difference still becomes noticeable. The Stratasys Fortus 380 MC is slightly better, but the difference is not as drastic as you might think. nine0003

Mike Skshipczak carefully examined the individual elements of the two pieces. For example, a mounting protrusion on the edge of a form. The enthusiast sprinkles ashes on his head because there is not adequate support for such protruding parts that he printed on a home printer. Therefore, the mounting ledge on the part from the home printer was not completely printed. But its upper part, which printed normally, is not inferior in quality to a part from an industrial printer.

Another fragment that he examined in detail is the mounting holes and the surrounding part of the parts. Here you can see that in the "home" version around the mounting hole there are small tears in the upper layers of the print. He says that if he were to print the part again, he would make twice as many hard top and bottom layers to eliminate this artifact. It's just that the layers are too thin, so four, as we see, was not enough.

He says that if he were to print the part again, he would make twice as many hard top and bottom layers to eliminate this artifact. It's just that the layers are too thin, so four, as we see, was not enough.

In general, in the above photographs, the difference in the quality of the details is not very different and is not critical. nine0003

The part of the part where the biggest difference in print quality is the bottom surface that is in contact with the support. 3D printing enthusiasts are well aware that support spoils the surface that comes into contact with it, so it is advisable to minimize its amount (see the article “10 Rules for Preparing a Model for 3D Printing”).

So, an amateur printer makes a support from the same material from which the part itself is made, with all the ensuing consequences: a lot of burrs and uneven areas that remain on the surface. In the Stratasys Fortus 380 MC Professional Printer, the support is made from a separate, biodegradable material. It dissolves in a special saline solution and is simply washed off. Here we see big difference in product quality .

It dissolves in a special saline solution and is simply washed off. Here we see big difference in product quality .

Regardless of the quality of the print itself, it is the method of chemical removal of support made from a different material that provides the best quality on certain parts of the surface of the part.

A part from a hobby printer, apparently, needs to be carefully sanded to achieve the same quality in these areas. Or make a small upgrade. The Lulzbot Taz 5 3D printer comes with a printhead for about $500 that can also print support from soluble material. Five thousand dollars is, of course, a considerable amount, but still it does not compare with $ 200,000 for a professional Stratasys machine. nine0003

And on the “amateur” part, the engineer found one defect that is absent on an industrial printer. Separate fragments of the workpiece did not stick together normally: the photograph shows a horizontal line between them.

Despite this, both parts can normally perform their function, that is, they can be used for laying cables in the manufacture of electronic equipment.

Of course, if you look at the photos of individual fragments, the difference in quality is obvious, and someone can say that a professional printer prints is much better than . But in practice, these are not such significant differences, says Mike Skshipchak.

It is likely that a more experienced craftsman could print the same part in much better quality than Mike's did.

Yes, he himself admits that if he changed the print settings a little and applied a couple of tricks, he could achieve a better quality of the product and eliminate the defects that appeared. That is, here again, a lot depends not only on the printer, but on the even hands and experience of the master who prints the part. This skill comes with experience. nine0003

Although the part didn't work out very well, Mike emphasizes that in real work both parts are exactly the same, that is, it makes no difference to him which one to use with electronics cables. Thus, both printers did an excellent job and are excellent for use in the workplace, that is, for the manufacture of original parts. If there's not much difference here, then it's hard to come up with an excuse to buy a printer that's about 90.9 times more expensive.

If there's not much difference here, then it's hard to come up with an excuse to buy a printer that's about 90.9 times more expensive.

The engineer is now planning to run some more comparative tests on to the coordinate measuring machine and check whether the two parts are geometrically accurate. There are suspicions that it is in this test that an industrial printer will show why it costs so much.

In general, even from this experiment, we can conclude that "amateur" printers are not so far behind in terms of print quality from professional industrial machines, which are a hundred times more expensive. Much depends on the experience and skill of the engineer who knows how to print a particular part in the best way, how to avoid the most likely defects. nine0003

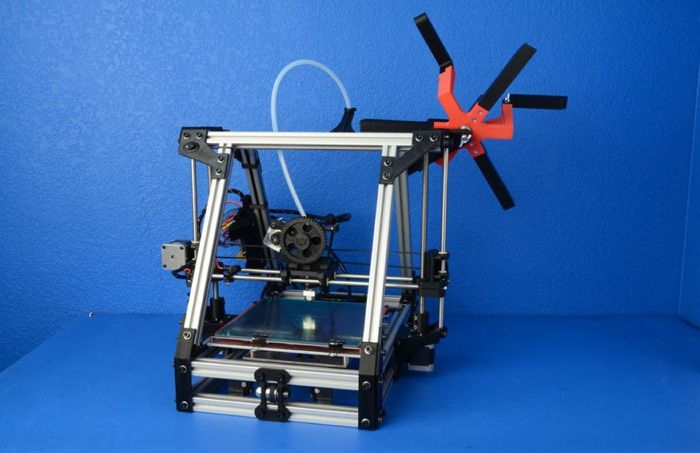

"Sad Bot"

"Sad Bot" is a self-collection based on Re-D-bot (CORE XY). The project uses aluminum profiles 2020 and 2040 of different lengths, wheels, printed parts. Additionally, a modification was used to install Chinese rails and a titan aero extruder, and I also introduced crooked hands and my own modifications of printed parts based on my strange logic into the project. RuRamps4d and Arduino DUE are used to control the printer.

RuRamps4d and Arduino DUE are used to control the printer.

Initially there was a desire to get a printer with a large print volume and print large parts on it as a whole, without gluing them together. For this, the Re-D-bot project was chosen. The printed field should have turned out to be 300x300 and the height was also about 300. An aluminum profile was ordered in Russia and loose on Ali. After receiving all the parts, the first iteration of the Sad Bot was assembled, on which parts for the author's modification were printed. nine0003

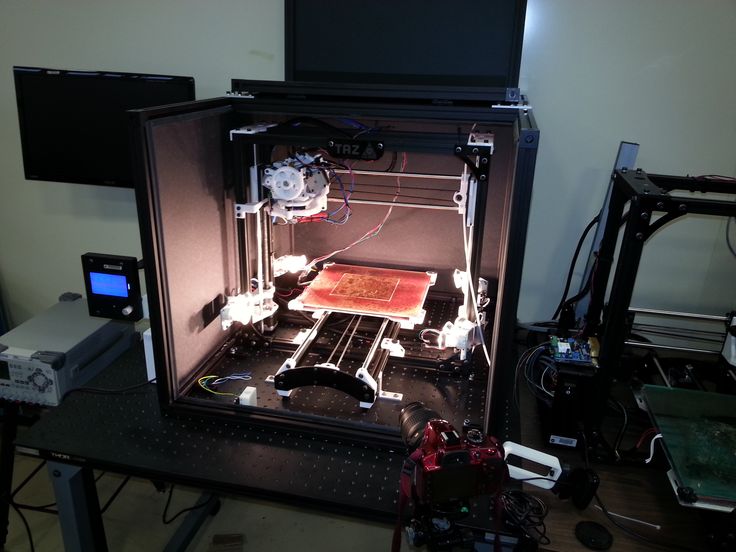

Finally, let's take a look at the printer.

Dimensions: 580*540*600mm

Printing area: 220*220mm. It so happened that having assembled a frame for a table 300 * 300, I installed a table 220 * 220. Initially, it was installed as a temporary option, due to the fact that I got it for inexpensive. But there is nothing more permanent than temporary. It turned out that 220*220 is enough for my needs.

Advantages over 300*300:

- Less heating energy required.

nine0120

nine0120 - Worth less than 300*300.

- Easier to find, more suppliers.

The disadvantage is a lot of free space inside the printer, since the frame is assembled under 300*300.

On top of a heated table, in a glass workshop, a pair of ordinary glasses 5 mm thick was ordered and purchased (they deceived, actually 4.7). There is no auto level, manual adjustment with screws.

X and Y axis - on MGN12H Chinese rails. The two Y-axis rails are attached directly to the printer frame with T nuts that are driven into the profile from the end. The X-axis rail is mounted on a massive 2040 profile aluminum beam, which is attached to the printed parts, which in turn are attached to the rail carriage. The original printed parts had wheels on the side of the rail opposite the carriage, presumably to stabilize the heavy X-axis beam, but "strange logic" decided to modify the parts by removing the wheels from them to reduce movement resistance. nine0003

The X and Y axes use conventional mechanical mouse buttons.

The Z axis is supported by two T8 screws driven by two motors. 12 wheels provide a stable position, 3 for each corner of the Z gantry.

The Z-axis end is optical, which gives greater parking repeatability.

Extruder: titan aero from triangles. It is aero that allows you to save a lot of space in Z, as well as reduce nozzle deviations due to the inertia of the heavy X axis. The extruder mount has also been modified with “strange logic”. The wheels were removed similarly to the Y axis, the mount itself was reduced in size, which was supposed to reduce the resistance to movement and made it possible to reduce the dead zone along the X axis. In addition, the mount itself became monolithic, which was supposed to remove backlash from fastening several parts to each other. nine0003

When moving in the X and Y axes, a massive beam with an extruder transfers a powerful momentum of inertia to the entire structure during printing, which makes everything seem to vibrate even at minimum speeds. To minimize vibration, no springs are used when attaching the printer table. The table is mounted rigidly on M3 screws with a bunch of locknuts.

To minimize vibration, no springs are used when attaching the printer table. The table is mounted rigidly on M3 screws with a bunch of locknuts.

To reinforce the frame of the printer, an aluminum corner is used, which acts as the diagonals of the frame and side walls made of sheets of some kind of plastic. Also, to reinforce the structure, a sheet of plywood is used as a bottom, with a minimal curve, which we managed to find in a couple of hardware stores in the city. Additionally, M5 studs and metal corners are used to reinforce the structure. All this together makes the design almost non-separable. Of course, you can disassemble, but the return collection will take an absolutely inadequate amount of time. nine0003

RuRamps4d+Arduino DUE is used to control the printer. This option was chosen because it seemed easy to modify, maintainable and visually reliable. The XY axis motors and the extruder are equipped with quiet TMC2208. XY axis motors are additionally equipped with protection scarves to protect drivers from those who like to move the beam with the extruder by hand. The Z-axis motors are connected in series and driven by one A4988.

The Z-axis motors are connected in series and driven by one A4988.

In general, I am satisfied with the sandwich control board, the elements in the power circuit are reliable there. I did not use specialized boards on ARM and there is nothing to compare in terms of convenience and printing at high speeds. nine0003

User interaction is through screen 2004 and encoder. STL for printing are taken from the SD card.

The is powered by a 500W ATX power supply that promises 22A on two 12V lines.

Initially, the printer was planned to be a desktop printer, but it turned out to be a desktop one. From the advantages of this design, it turned out that if you roll the printer under the table and close the only open edge, you get a large thermal chamber. Of the minuses, unfortunately, increased fire hazard. nine0003

Print speed: At 80mm/s I printed and it worked fine. To achieve higher speeds, I think that a 12V heating element and a conventional heating cube is not enough.

A few examples of printing:

I don't do commercial printing and printing of vases and useless models from the Internet, so, examples of printing will be on what was found.

"Restoration" of a steam engine model. Small parts and wheels were missing. nine0003

Car park model. 3d printing + printing on paper + coloring.

A new handle for the refrigerator, instead of crumbling.

Development of cheap automatic long roller blind. From scraps of bubbling plastic.

As they said - not a vase

Sot -organizer in a cupboard for small things

We will summarize:

I wanted a large printer for the "large" press, but 220*220 turned out to be sufficient , and the increased size led to problems with weight. The structure on an aluminum profile seemed to be easily modified, but to compensate for vibration problems, the entire structure was riddled with corners and studs, which left no living space on the profile.