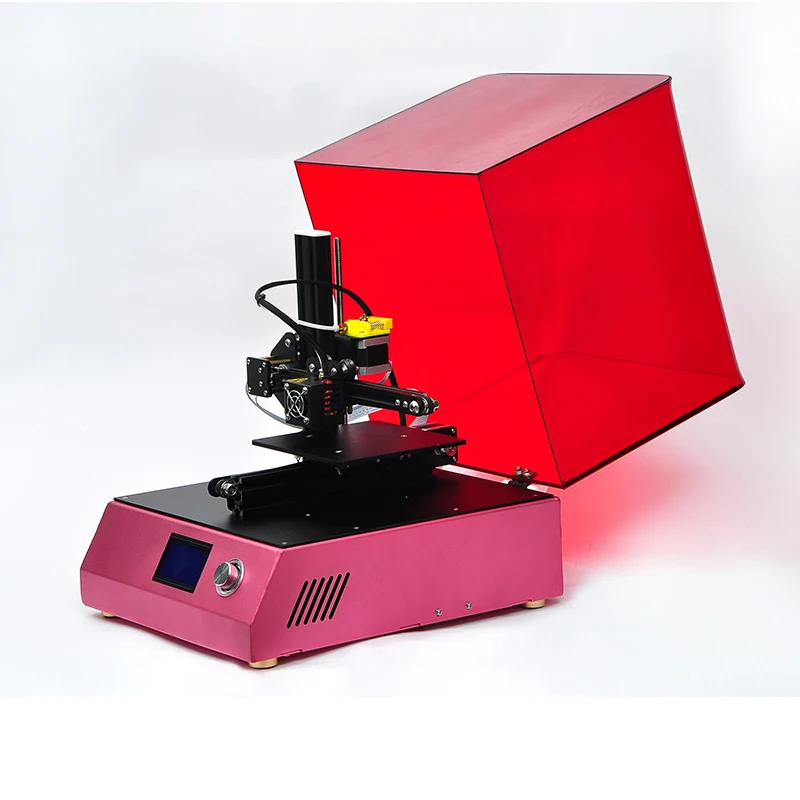

Maker farm 3d printer

Makerfarm Pegasus 12'' 3D Printer In-Depth Review

ADVERTISEMENT

8Expert Score

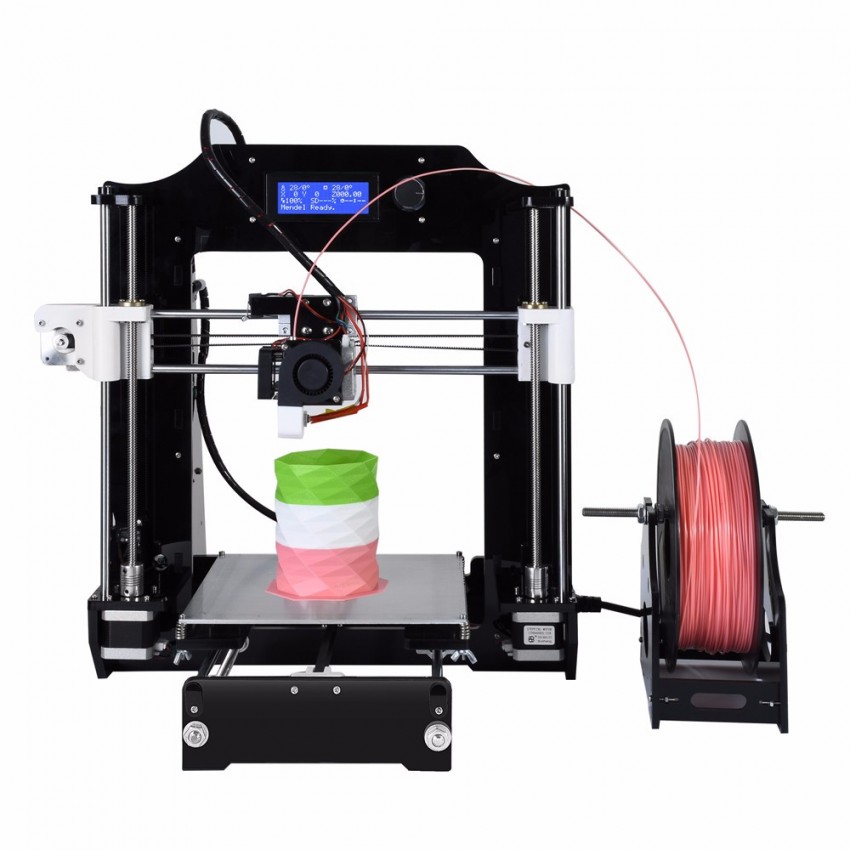

Makerfarm Pegasus 12'' 3D printer

Belonging to the class of affordable 3D printers, Makerfarm Pegasus 12 has a high print quality that is considered to be an anomaly. So if you are yet to experience the market, you can definitely look forward to adding this to your list.

Affordability

9

Quality

7

Speed

8

Capability

8

Practicality

7

User Expectations

9

PROS

- Rigid Frame.

- Lower layer height.

- Aluminum heat bed.

- LCD interface.

CONS

- No mention of customer support via phone, or video call, openly on the websites.

- Absence of pictures of parts or functional prototypes printed using this printer.

A huge build volume present in Makerfarm Pegasus 12 lets you print large parts in one go. The printer's heated bed avails printing with 3D printer ...

Add to wishlistAdded to wishlistRemoved from wishlist 0

Add to compare

|

Table of Contents

Available in three different sizes, Makerfarm Pegasus is manufactured by an America based company.

The 12 inches model offers the largest build volume for building parts and functional prototypes.

Though differentiating between build volumes of various models, Makerfarm has kept uniformity when it comes to frame and hot end options.

The former being made of Aluminum, whereas the latter is the part that’s from the company which is very renowned for making hot ends.

Makerfarm Pegasus offers a print bed that is one of the largest you can get while buying a printer under the budget of $800.

Apart from offering huge build volume, the heated bed, hot end options, and open filament system are also some features that are pretty impressive.

Belonging to the class of affordable 3D printers, Makerfarm Pegasus 12’s high print quality is an anomaly.

Although not being too user-friendly as other expensive printers, Makerfarm Pegasus works fine with an experienced hand.

It is to be noted how this printer belongs to those printers that have sprung out from the technological innovation in the field of 3D printing.

The innovation that aimed at bringing awareness about this technology to people, at the same time, enabling people who are already aware of the technology to buy and use it at a cheaper cost.

Having stated so, let’s start to explore the bits and pieces of this printer. From features to specifications, we will lead you on a journey that will give you an insight into how Makerfarm Pegasus 12 is when viewed in terms of parts and not as a whole.

ADVERTISEMENT

Features

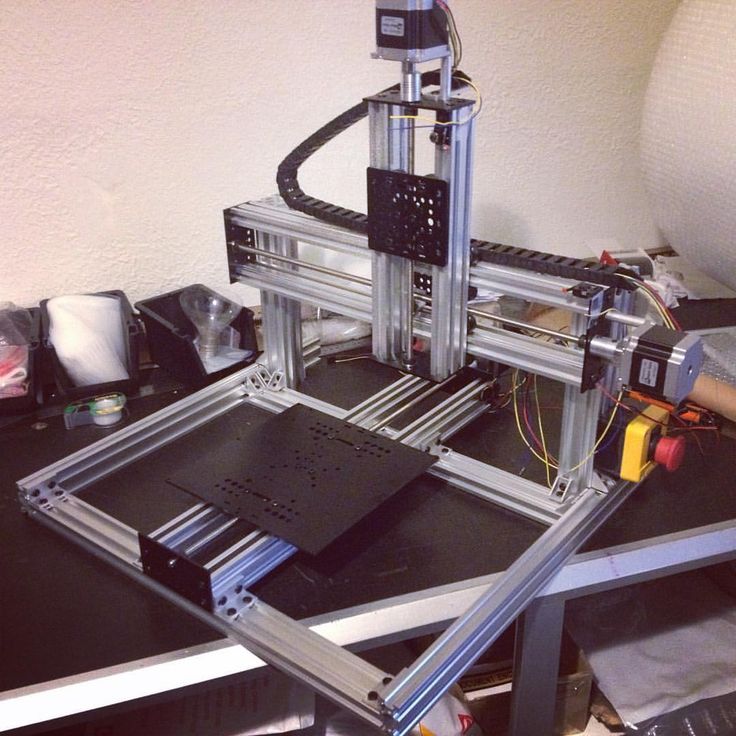

The extremely rigid 20*40 Aluminum frame assures you that the printer would not vibrate even while printing a larger part at a higher speed.

A build envelope of 11.5 inches * 12 inches * 13.5 inches along X, Y and Z-axis would surprise you while you would be out there looking in the market for buying affordable 3D printers offering huge build volume.

And make you want to check the price of the printer again and again.

The RAMPS Electronics Standard board would save your work progress and start from there itself even in case of electricity failure.

Based on standard FDM 3D printing technology, Makerfarm Pegasus 12 offers 50-micron layer height in every part and functional prototype that’s being printed on it.

For making the user interaction and monitoring interesting, the printer is equipped with a graphical LCD Interface. Meaning that you can even print without using a PC if you wish to.

Aluminum Frame

Aluminum is a material that is believed to be rigid and hence if the frame is made out of it, it has been extremely rigid.

But in case you do not know why the frame should be rigid, what benefit it does to 3D printing of parts or functional prototype, here’s an explanation for you.

The complete frame supports the rail system in the printer. The rail system of the printer is attached to the nozzle system of the printer.

And the nozzle system of the printer moves up again and again after a layer is printed.

So, there are chances of the printer to vibrate or move on to the desk where it is located in the frame is not rigid.

ADVERTISEMENT

Standard Electronics and LCD interface

First things first, electricity is the fuel that you are doing to need to run this 3D printer for printing 3D parts or functional prototypes.

The manufacturer of this printer claims how they have used standard electronics of RAMPS Company for ensuring parts move in the way and at the time they are meant to.

The complete precise 3D printing requires the print head to move exactly when the layer is printed, in order to print the other layer.

Stating about the LCD interface, the printer has it located at the top right corner of the frame.

With this LCD interface the company is making an important point and that being, you can print without the inclusion of any computer in the printing process because you have the LCD interface.

This LCD would give you the ability you need for monitoring the printing process, operating various parts of the printer, and starting, pausing, or stopping the printing process in case there is a need for so.

Good build envelope and layer height

The building envelope of Makerfarm Pegasus is 11.5 inches on the X-axis, 12 inches on the Y-axis, and 13.5 inches on the Z-axis.

Which is very good when you compare this to the printers that are available at the same price as this printer is.

This feature would let you print parts or functional prototypes of large size which are used in the aerospace defense industry, healthcare, or automotive.

A lot of the print quality is based on the layer height of parts or functional prototypes manufactured by a printer.

So, if you were to judge the print quality of any printer, you can do that by comparing layer heights.

As per the general conception, the lesser the layer height, the better the parts look.

And, the layer height of parts printed using Makerfarm Pegasus is 50 microns. This talks a lot about the precision this machine could offer.

ADVERTISEMENT

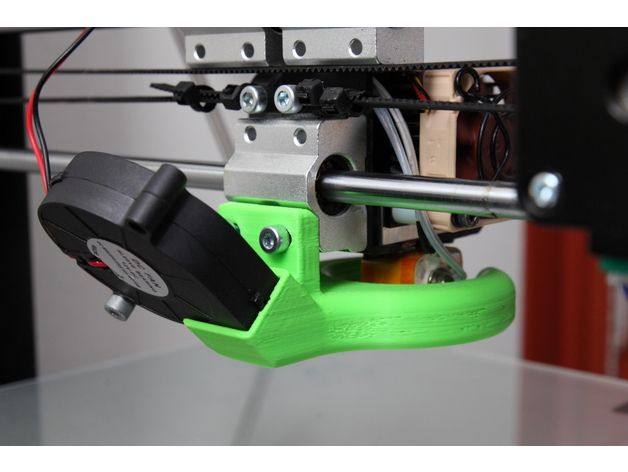

V Slot Extrusion and 66 oz-in motors for all axis

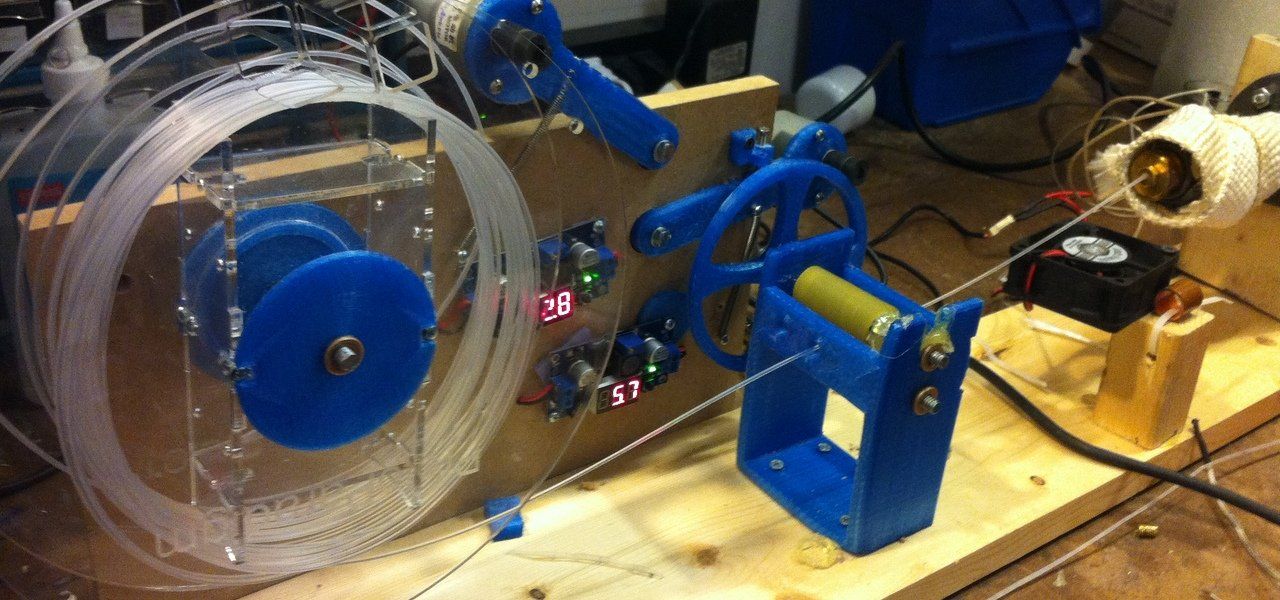

The extruder is the place where the raw material for 3D printing is kept and heated to be brought on to the level wherein it melts on the printing bed of the printer.

This printer has such an extruder which is V in shape. And it is believed that the printer that has such an extruder can print with higher speed and give smoother operation to the printer during the printing process.

The motors are to be used in the entire axis for the regular movement of the print head from the print as soon as one layer is printed, so it is necessary for the motors to function in a fixed and equal manner for ensuring equal printing of layer on each axis as per the design.

Specifications

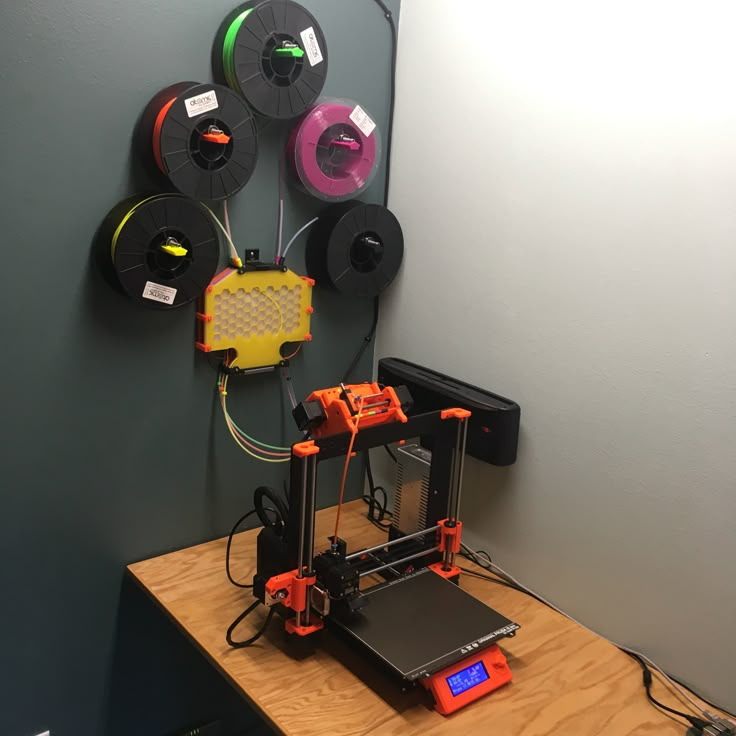

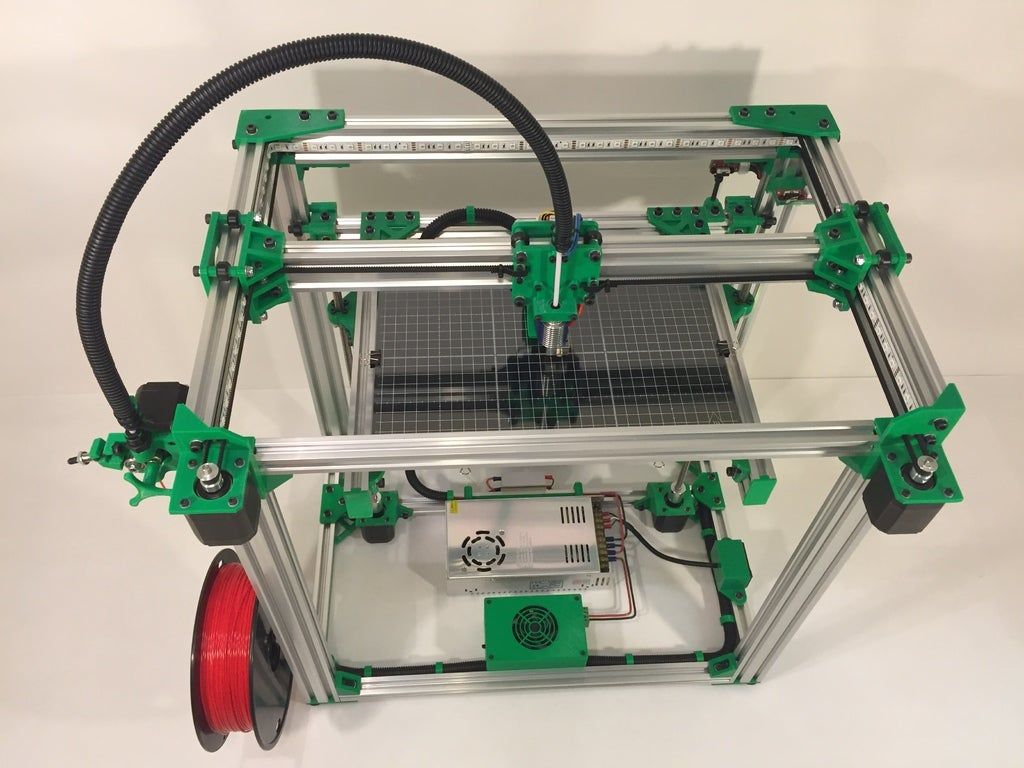

Credit: thingiverse.comThe printer’s dimensions when it is completely assembled, without the spool are 21.25 inches * 23 inches * 23.5 inches. It has an aluminum heat bed mount.

The build envelope of the printer as mentioned above is 11.5 inches * 12 inches * 13.5 inches.

The layer height in the parts or functional prototypes produced by the printer is 50 microns. The printer uses GT2 pulleys and belts.

It has a Genuine e3d .40mm Hot End Nozzle for 1. 75mm Filament and an Optional e3d-Lite6 or e3d-v6 for 3mm Filament.

75mm Filament and an Optional e3d-Lite6 or e3d-v6 for 3mm Filament.

There are 66oz-in Motors for all axis’ pre-wired with the printer and the bed leveling that is done is by Firmware Bed leveling.

There is a micro Adjustable Z End stop inside the printer.

ADVERTISEMENT

Price

The price of Makerfarm Pegasus is $645.

First Impressions

There is a filament holder is connected with the nozzle system which is capable of moving up and down with the help of the rails on the frame of the printer.

A rectangular in shape LCD interface is located at the top right of the printer frame i.e. exactly on the top right vertice of the cubical cage or frame of the printer.

Setup

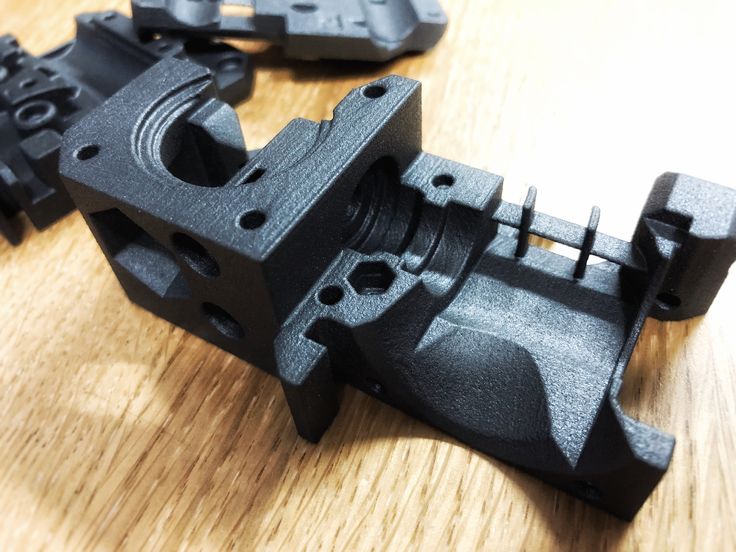

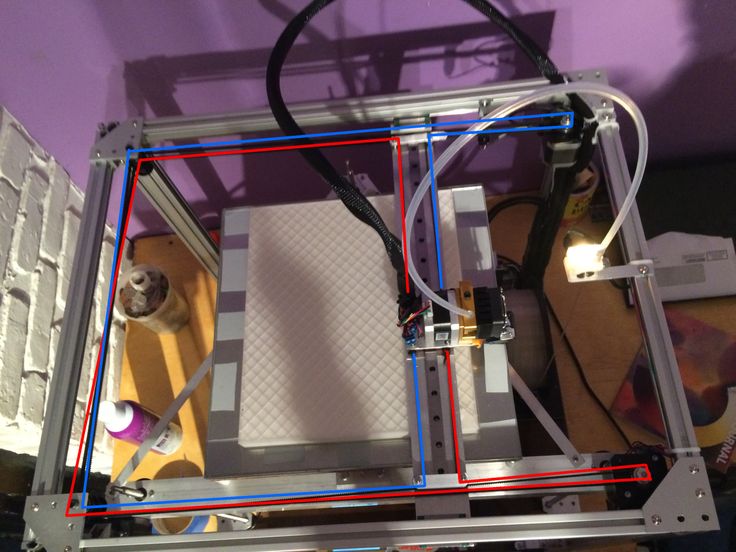

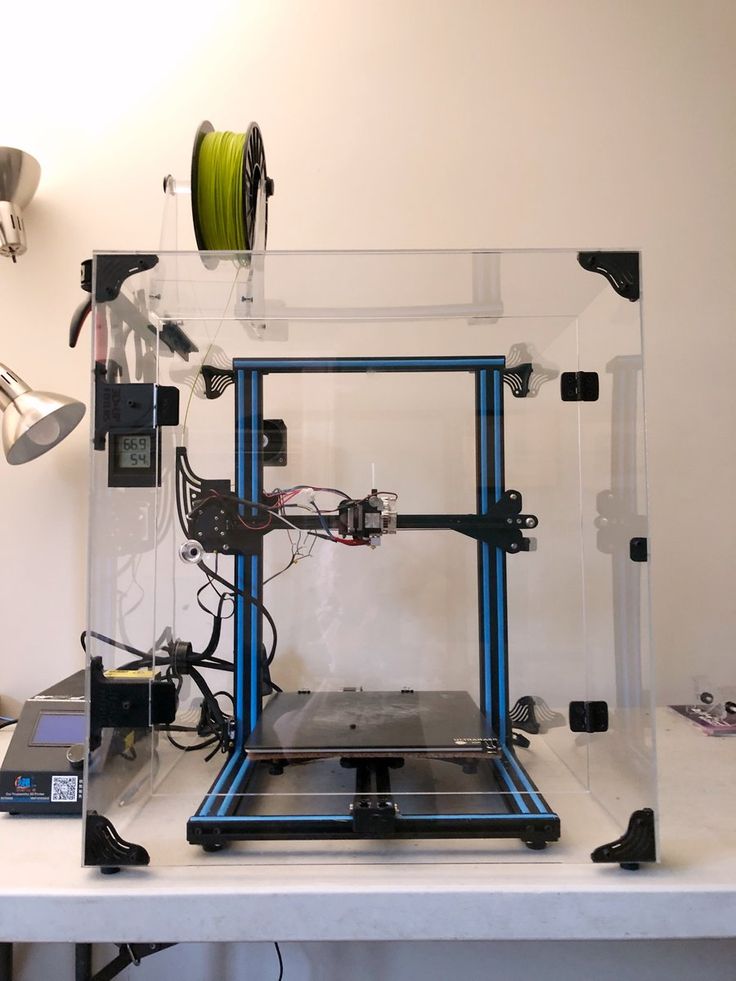

The printer is available in a DIY kit that requires you to assemble everything including the gantry frame, as well as the X-Y-Z axis motor mounts, belts, printer hot-ends, and extruders.

As reported on reliable 3D printing websites, the complete setup of this printer can take about three to four hours.

Reading all this might make you want to compare this printer with a printer that comes completely assembled.

But, there is an advantage of assembling printer parts on your own. And that is, you get to see which part is in coordination with which one.

So, when the time comes to make some smaller changes or something isn’t working how it should, you know which area to look out for in the printer.

Having stated so, there are sixteen steps involved in the assembly of this printer.

The nuts and bolts which come with the printer for its assembly are of metric sizes M3, M4, and M5 ranging from one to three centimeters long.

Coming to the motors, the Y and Z motor brackets need to be precisely located at specific places along with their respective frame supports.

Also, there are no pre-drilled holes for suiting the brackets so you’d have to use your ruler.

Although this is not a problem requiring much care, it does add another factor to be taken into consideration for ensuring dimensional accuracy in parts and functional prototypes printed by the printer.

The drive belts of this printer are also not pre-cut to length, so during your assembly, you’d have to measure and cut accordingly.

After the cutting is done properly, secure it by zip-tying them through the drive mechanisms.

ADVERTISEMENT

Printing Type/Cost

The printer is based on FDM 3D printing technology wherein you would need spools of materials that you wish to 3D print with.

You would have to heat them up and then the melted form of that material is something that would be spread on the print head layer after the other.

FDM is an abbreviation for Fused Deposition Melting. It is the most preferred 3D printing technology, based on which the majority of 3D printers in the field function.

The complete process of FDM 3D printing depends on three major steps:

- Steady heating of the printing material till its glass transition temperature.

- Laying down the first layer on the print bed of the printer, precisely according to the geometry of the intended part or functional prototype.

- Uniform cooling of the printer layer.

And once that will cool down, the final part will be 3D printed.

The cost of 3D printing a part in this way is mostly lower than that of printing a part or functional prototype using any other technology that utilizes a laser.

But the printing cost has many variables that need to be considered before calculating the printing cost.

And, it may differ for the same models as well when the filament choice or any other responsible variable differ.

ADVERTISEMENT

Print Quality

Credit: thingiverse.comIn the price range that Makerfarm Pegasus 12 falls, there are not enough printers that offer 50 microns layer resolution for parts and functional prototypes.

The print quality is consistent whether your part size is smaller or bigger.

Makerfarm Pegasus 12 is also able to manage high quality while printing continuously for hours. Making this printer suitable for a number of applications.

Customer Support

You can make your Account on the Makerfarm store online. Doing so would avail you options to connect with the makers of the printer.

Parameters Influencing Buying Decision

Factors that are mentioned in the brief below should be taken into account while purchasing this printer.

3D Printer cost: Affordable.

3D Print quality: Layer height of 50 microns would mean that they are hard to see.

3D Print speed: Faster because of the V slot extruder.

3D Printer capability: The printer prints with all the popular materials.

3D Printer Practicality: It has all the features that you would wish to have in a printer to make you familiar with the 3D printing technology.

3D Printer User expectations: If you are a beginner in the field, your expectations in terms of cost, would be extremely satisfied.

The Verdict

There are highs and lows of the printer, just like every other.

But if you are yet to experience the market, you can definitely look forward to adding this to your list.

Comparing it with the printers under a similar price range would offer you a better insight of what this machine is worth.

The Maker Farm Prusa i3 3D Printer Review: Does it Live Up to the Hype?

- About

- Latest Posts

Total 3D Printing Team

3D Printing Experts at Total 3D Printing

We're the Total 3D Printing team and we love to help others learn more about 3D printing. Whether this is your first time checking out 3D printers or you've got multiple 3D printers and want to add more, we're here to help show you the ropes and to give you the information you need to succeed.

Latest posts by Total 3D Printing Team (see all)

Maker Farm is based in Massachusetts and is somewhat of a unique company. They offer a range of products that mostly consists of parts and components for 3D printers but they offer several 3D printer kits as well, including a kit to build your very own Prusa i3 3D Printer.

They supply MakerBot and several other major manufacturers with parts and supplies for their 3D printer products but part of their mission to bring affordable 3D printing to the average consumer.

The company prides itself on providing excellent customer service and because its main business is manufacturing parts they have the technical experience to offer excellent support.

If you experience any issues or problems while trying to build your Prusa i3, you can have confidence they will be resolved without much trouble by utilizing Maker Farm’s various support systems, available via their website, email or phone.

With the few questions we did have while assembling our unit emails were returned very promptly and Maker Form never left us wondering if they would respond. Overall a very good customer service experience and that can make all the difference, especially when working with a kit-based unit.

The Prusa i3 KitKits are available for sale through Maker Farm’s website and they offer multiple different styles and models in addition to the Prusa i3. Shipping time ranges anywhere from 5-10 days depending on where you live and they offer to ship to almost anywhere on the globe. Almost all of their kits are under $800 and they offer some units as low as $375.

Shipping time ranges anywhere from 5-10 days depending on where you live and they offer to ship to almost anywhere on the globe. Almost all of their kits are under $800 and they offer some units as low as $375.

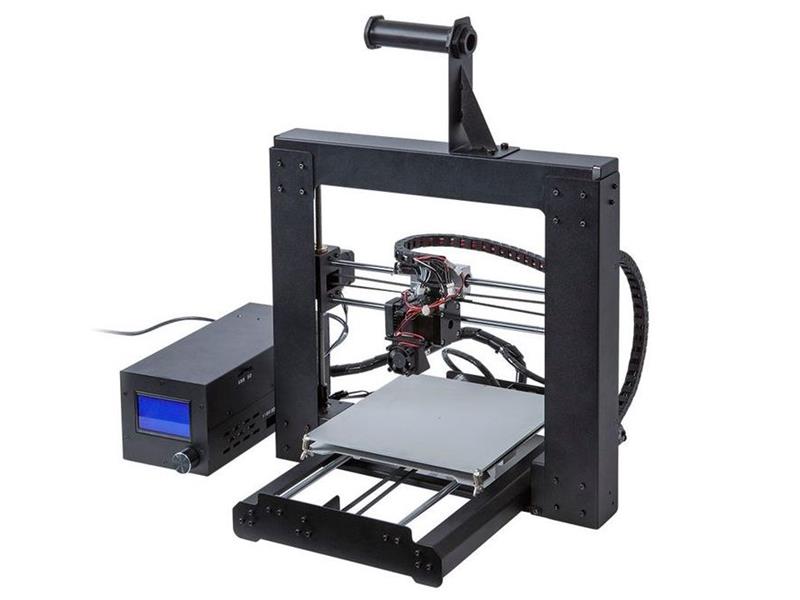

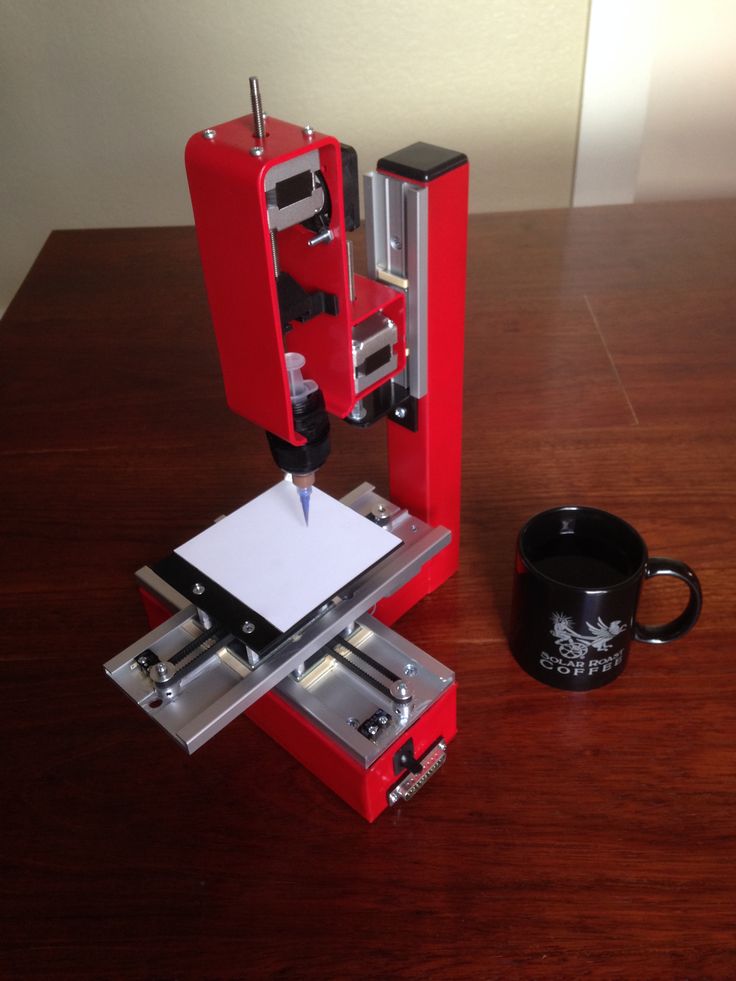

The i3 comes as a kit which requires you to assemble most of the components that come in the kit to produce a fully functional and affordable 3D printer.

Almost everything needed comes included with the kit but users will need to use their own piece of 8 x 8 glass print bed cover and a twelve-volt power cord.

Getting StartedThe kit comes efficiently packaged in a single box with sensitive parts susceptible to damage during shipping stored in plastic containers with hard plastic covers, keeping the parts all in proper working order. The rest of the printer’s parts and accessories are separately packed in plastic bags or similar containers making it easy to identify all the different components involved.

The only negative comment we have about the arrival of our unit is no contents list was provided for all the parts that are supposed to be included, which would have been nice. However, if you spend a few minutes reviewing the provided information you can begin to find out relatively quickly if anything is missing. In our case, everything was provided as promised.

However, if you spend a few minutes reviewing the provided information you can begin to find out relatively quickly if anything is missing. In our case, everything was provided as promised.

It doesn’t take long to understand why many major manufacturers use Maker Farm as a supplier for some of the 3D printer components as all of the parts provided looked to be solid and well made. If you have any experience with hardware and working with mechanical machines then you will know right away the included parts down to even the screws and bolts were all high-quality.

Sometimes a cheap screw here or there may not make a big difference overall but it is always nice to know a company isn’t trying to get by with providing less than ideal quality.

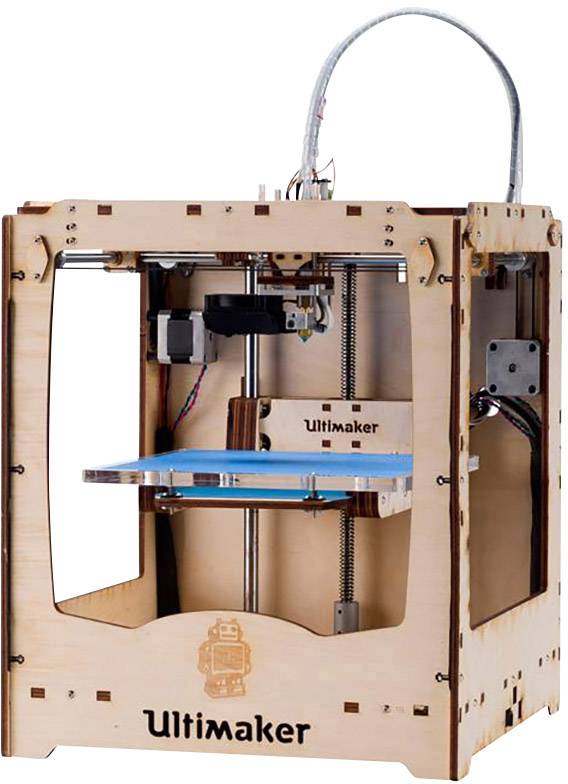

Assembling the i3The parts for the frame of the i3 are laser cut plywood which means they may have marks on one side or the other. This can detract a bit from the overall appearance of the unit so some users may want to paint these parts before they begin to assemble the entire unit. According to the specs, Maker Farm states you can assemble the total kit and have a working 3D printer in less than three hours.

This can detract a bit from the overall appearance of the unit so some users may want to paint these parts before they begin to assemble the entire unit. According to the specs, Maker Farm states you can assemble the total kit and have a working 3D printer in less than three hours.

However, if you are not very experienced, then plan on spending considerably longer than three hours. In fact, even if you are experienced with projects of this type, it is a good idea to spend extra time and ensure all components properly fit together and things are done right.

While Maker Farm does provide kit assembly instructions on their website, they mostly help with organizing all of the various components and ensuring you have everything needed. You will need to visit YouTube in order to find the complete instructions that walk you through how to assemble all of the parts together and end up with a working unit.

It is important to note, you should make sure you watch the appropriate instructional video for the exact kit you ordered. The kits come in 6, 8 and 10-inch varieties so there can be some important differenced while building the unit and how it should be done.

The kits come in 6, 8 and 10-inch varieties so there can be some important differenced while building the unit and how it should be done.

All components of our machine fit together nicely and we did not experience any issues with parts that seemed awkward or did not fit well together. This can be a major problem with some 3D printer kits, especially kits that are in the affordable category.

It is always a huge hassle to receive bad parts and then have to wait to assemble your printer until you receive new parts. It was refreshing to have everything fit and work well right from the start.

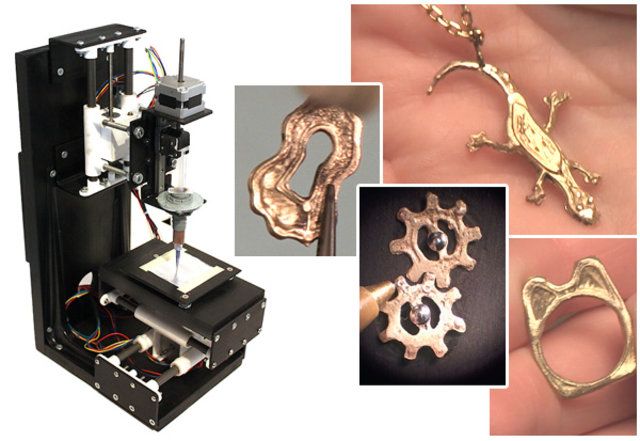

Printing with the Maker Form Prusa i3All of the electronic components that came with the kit are fully flashed so you will need to download the required Arduino software that is primarily for the drivers. These drivers need to be installed on whatever computer you plan to use with your i3 as the main controller of the 3D printing functions in order for everything to work properly.

The download process is easy and can be accomplished in just a few minutes. Once installed, everything should be ready to go once you power on the unit and connect it to your laptop or desktop.

Depending on how you order you i3 it is capable of printing with ABS, PLA, PVA, HIPS, and many other materials that require higher temperatures. The type of nozzle you order will determine what type of materials you can use.

Some nozzle choices are available at no additional cost, a few cost extra and one choice even reduces the price of the kit by a few dollars. You will also have a choice of a wood bed or aluminum bed as well as the type of extruder that you want.

There are various options for different upgrade packages and adjustments that you can make to your i3 3D Printers such as adding another extruder and other options.

These upgrade packages vary quite a bit in cost so it all depends on exactly what type of performance you need and how you will be using your unit. Be sure when ordering your Prusa i3 Kit to review all of the options available and think about what you want today and what you might want a year from now after a bit more experience.

Be sure when ordering your Prusa i3 Kit to review all of the options available and think about what you want today and what you might want a year from now after a bit more experience.

Half the fun of buying an i3 kit is actually going through the building process and then customizing your unit the way you want. Some may find it frustrating if they are not prepared for the entire process or have little experience with completing this type of project.

However, if you enjoy the process of building and customizing your own unit, then the Maker Form Prusa i3 Kit can be a great choice. It provides a lot of customization options and above average 3D printing capability without spending a lot of money.

Additionally, if you are looking for a budget unit that is inexpensive that you can add to over time improving the performance, then this kit is a perfect fit for your requirements.

Maker Farm Prusa i3

499.00Print Speed

5. 0/10

0/10Build Area

7.5/10Precision

8.0/10Value

9.0/10Ease of Use

8.5/10Pros

- Customizable

- Value

Cons

- Quality of Components

Check Price

Complete 3D Printing Solution - 3D Farms

Home

Complete solution for 3D printing - 3D farms

What is a 3D farm

A 3D farm is a set of 3D printers, usually of the same type and performing standard tasks, within one enterprise.

A well-managed 3D printing farm can be a strong addition to an existing business or stand alone. Creating a cell from several 3D printers will increase production capacity, allow simultaneous production in several materials and offer 3D printing to customers as a paid service. nine0003

The use of 3D printing in production allows you to shorten the production cycle, reduce overhead costs and reduce the time needed to translate projects into a finished product.

3D printer farms are the best solution for starting or expanding your business. Their advantages:

- Easy scalability – from small workshop to factory

- Quick install and start nine0034 Ideal for fast turnaround times

Why you need a 3D farm

For a large team

A 3D farm increases the efficiency of a team of engineers or designers - having several 3D printers will allow you to print models at the same time, without taking up a queue for printing and without waiting for several hours or days.

By dedicating one specialist to maintain the farm, you free the rest from the need to fill printers with material and control printing, which allows them to focus on their work. nine0003

For more productivity

Regardless of the field of activity, the production cell of several 3D printers allows you to increase production volumes.

The Formlabs farm, for example, which includes fifty Form 2 printers, produces about 650 models per week in different types of polymer, and only seven people work there. When printers are bundled together, there is no need for an operator for each device. nine0003

Multi-material

Most 3D printers print one material at a time. There are models of FDM printers with two or even three extruders, but such printers are also limited in the number of plastics used at the same time. This forces you to wait for the end of printing to create the next model from a different material, which stretches the process for many hours. With the help of a 3D farm, you can print parts from any number of materials at the same time, limited only by the number of printers in your farm. nine0003

With the help of a 3D farm, you can print parts from any number of materials at the same time, limited only by the number of printers in your farm. nine0003

Custom print

3D print shop websites and 3D hubs accept 3D printing orders over the Internet, converting printer life into profit. Users who print too little to buy a 3D printer send them their models in .STL or .OBJ format and receive finished prints. This industry is growing, the service is gaining popularity. If you are interested in getting into this field and capturing your piece of the market, then it's time to get a small 3D farm, which can then be easily scaled up by adding new printers. nine0003

For Guaranteed Success

Even with the most reliable 3D printer, there is always the possibility of a breakdown, operator error or disruption due to unforeseen circumstances. If you have only one 3D printer, this situation can slow down the entire organization while it is being repaired, causing production delays and customer dissatisfaction. Having a farm of 3D printers, you are protected from suddenly being left without a 3D printing tool, and especially important orders can be duplicated by printing at the same time to ensure that force majeure is avoided. nine0003

Having a farm of 3D printers, you are protected from suddenly being left without a 3D printing tool, and especially important orders can be duplicated by printing at the same time to ensure that force majeure is avoided. nine0003

Options for execution

Fermlabs

FORMLABS FORM 2 Farm 2 is equipped with high-precision stereolithographic 3D printers that have proved to be well-produced by the quality standards in table stereolite.

Buy Formlabs Form 2

- High definition and quality

- Reliable printing process - ultra low reject rate

- An assortment of advanced photopolymers designed specifically for this printer, for any purpose

- Ideal for jewelry and dental applications

Ultimaker Farm

Ultimaker builds some of the most accurate and high quality FDM printers in the world. This solution is perfect for prototyping or custom 3D printing. The farm is equipped with Ultimaker 3 Extended 3D printers, which print simultaneously with two filaments in a working area of 215 x 215 x 305 mm. nine0003

Buy Ultimaker 3 Extended

- High quality printing from a renowned manufacturer

- Possibility of remote control via WEB

- Inexpensive and proven, familiar materials - Nylon, ABS, PLA, CPE

- Ideal for prototyping, small batch production of finished products

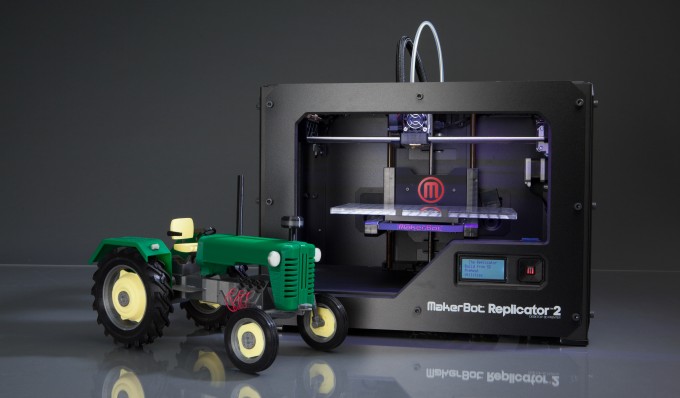

Makerbot Farm

MakerBot Farm is a centralized, scalable 3D printing center consisting of MakerBot Replicator + 3D printers.

The solution includes 3D printers and installation, custom printer manufacturer software, job training, technical support, and filament supplies.

Buy Makerbot Replicator +

- All settings standardized - high level of simplicity and reliability

- Optimized for PLA Makerbot

- All Inclusive - printers, installation, software, training, supplies and maintenance

Farm Custom

We will select 3D printers according to your requirements and create a project of the farm, taking into account the field of activity, the size and layout of the room, customer preferences, ergonomics and increasing efficiency. nine0003

To create an individual 3D farm project, please contact our staff.

To calculate the cost of and the timing of your order, send your request through the form or by mail:

stl@top3dshop. ru

ru

{simple_form}

3D Printing Farm

nine0259 3dunitprint2021-07-22T15:07:51+03:003dunitprint Knowledge base 3d farm, 3d farm Comments Off on 3D Printing Farm

Most likely, you have already heard about 3d printing farms: this is a kind of agglomeration of printers connected in a single information field and performing related or duplicating tasks for printing products. This additive manufacturing technology is designed to speed up the process of printing large-format objects or to print a large number of identical products. nine0015 Benefits

Ever since 3D printing was introduced in the 1980s, it has always been criticized for its slow and expensive manufacturing process. Well, that's not the case anymore thanks to print farms. Let's say you want to make a thousand parts on a printer, and it takes one hour to make each part. On one 3D printer, the production of these parts would take 1000 hours.

However, with a farm of 1,000 machines, the same production cycle would theoretically only take one hour. This reduces both lead time and costs. And that's the whole point of a 3D printing farm: efficient on-demand production. Print farms bridge the gap between prototyping and manufacturing. There are no tooling costs, which means products are brought to market much faster. nine0015 Another aspect of 3d printed farms worth mentioning is the ability to produce personalized goods. Since only a digital drawing of the part is required to make it, 3D printer agglomeration is capable of producing many personalized products.

The same principle applies to printing large format objects. Due to the fact that the area of additive manufacturing is limited, for prototyping a large object, whether it be a tall figure or an art object, it is necessary to divide the 3D model into many components and print each of these elements separately. Using the standard 3D printing method, it is necessary to manually divide the digital model into segments and then sequentially print it. This process is quite laborious, entails a lot of associated costs, which negatively affect the cost and timing of manufacturing large-sized products. Until recently, this situation led to the fact that “giants” began to appear on the 3d technology market - large-format printers such as Massivit, Colossus and others. The practice of using these printers with our partners has shown that in fact only the printing time and payroll (costs for personnel servicing the printer) are reduced. The cost of printing itself (equipment depreciation + material) is much higher than that of simple devices. nine0015 Also, the vast majority of large-format products are made of foam plastic, by milling it and subsequent processing with fiberglass. However, this technology also has a number of negative factors: the fragility of the foam, low detailing of objects.

This process is quite laborious, entails a lot of associated costs, which negatively affect the cost and timing of manufacturing large-sized products. Until recently, this situation led to the fact that “giants” began to appear on the 3d technology market - large-format printers such as Massivit, Colossus and others. The practice of using these printers with our partners has shown that in fact only the printing time and payroll (costs for personnel servicing the printer) are reduced. The cost of printing itself (equipment depreciation + material) is much higher than that of simple devices. nine0015 Also, the vast majority of large-format products are made of foam plastic, by milling it and subsequent processing with fiberglass. However, this technology also has a number of negative factors: the fragility of the foam, low detailing of objects.

Our company is one of the first in Russia to introduce and start using printing through 3D farms.

Due to the fact that all 3d printers are interconnected by a single information interface, when printing a large-format object, the digital model is automatically divided into segments and then sent to devices for printing in parallel.

75 mm0.07 in

75 mm0.07 in