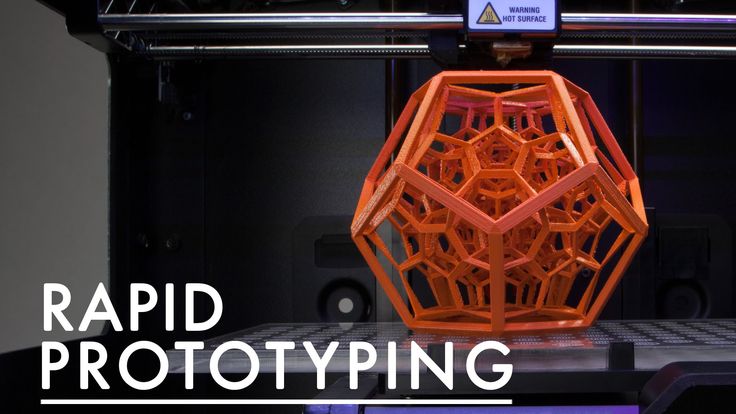

What is 3d printing rapid prototyping

What is Rapid Prototyping? - Definition, Methods and Advantages

What is Rapid Prototyping?

Rapid prototyping is the fast fabrication of a physical part, model or assembly using 3D computer aided design (CAD). The creation of the part, model or assembly is usually completed using additive manufacturing, or more commonly known as 3D printing.

Where the design closely matches the proposed finished product it is said to be a high fidelity prototype, as opposed to a low fidelity prototype, where there is a marked difference between the prototype and the final product.

How Does Rapid Prototyping Work?

Rapid prototyping (RP) includes a variety of manufacturing technologies, although most utilise layered additive manufacturing. However, other technologies used for RP include high-speed machining, casting, moulding and extruding.

While additive manufacturing is the most common rapid prototyping process, other more conventional processes can also be used to create prototypes.

These processes include:

- Subtractive - whereby a block of material is carved to produce the desired shape using milling, grinding or turning.

- Compressive - whereby a semi-solid or liquid material is forced into the desired shape before being solidified, such as with casting, compressive sintering or moulding.

TWI

TWI offers a range of welding support to our Industrial Members, including welding consultancy services and welding technology assistance.

TWI is an Industrial Membership based organisation. TWI's experts can provide your company with an extension to your own resources as well as engineering consultancy services. Our experts are dedicated to helping industry improve safety, quality, efficiency and profitability in all aspects of materials joining technology. Industrial Membership of TWI currently extends to over 600 companies worldwide, embracing all industrial sectors.

You can find out more by contacting us, below:

What are the Different Types of Rapid Prototyping?

Stereolithography (SLA) or Vat Photopolymerization

This fast and affordable technique was the first successful method of commercial 3D printing. It uses a bath of photosensitive liquid which is solidified layer-by-layer using a computer-controlled ultra violet (UV) light.

Selective Laser Sintering (SLS)

Used for both metal and plastic prototyping, SLS uses a powder bed to build a prototype one layer at a time using a laser to heat and sinter the powdered material. However, the strength of the parts is not as good as with SLA, while the surface of the finished product is usually rough and may require secondary work to finish it.

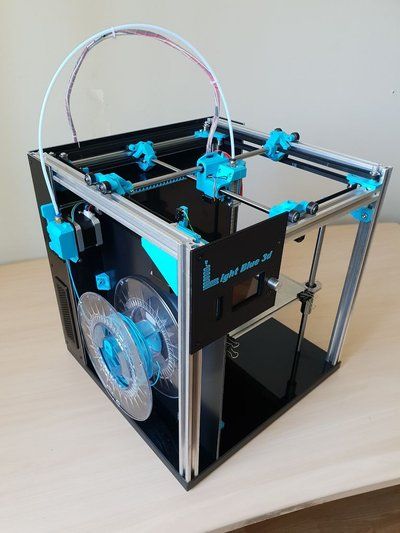

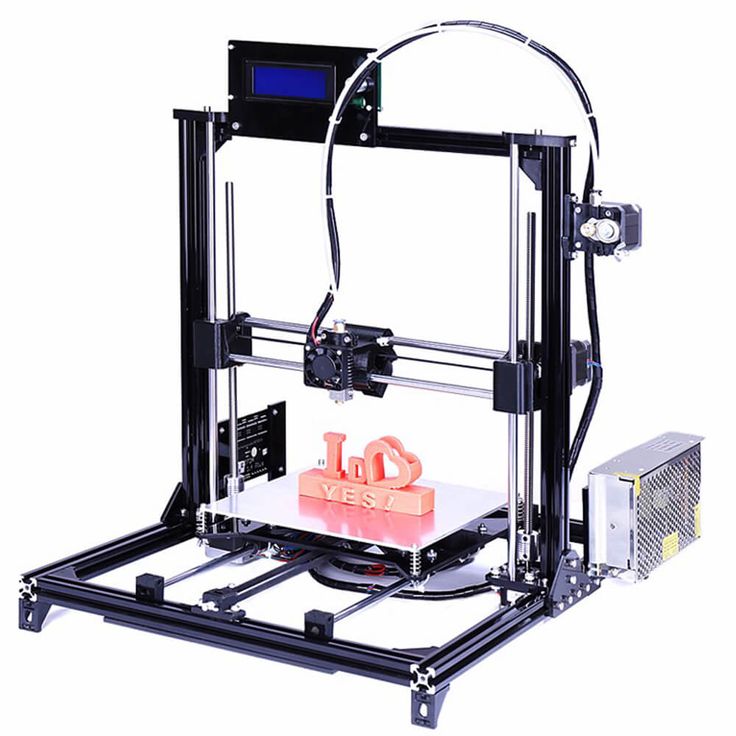

Fused Deposition Modelling (FDM) or Material Jetting

This inexpensive, easy-to-use process can be found in most non-industrial desktop 3D printers. It uses a spool of thermoplastic filament which is melted inside a printing nozzle barrel before the resulting liquid plastic is laid down layer-by-layer according to a computer deposition program. While the early results generally had poor resolution and were weak, this process is improving rapidly and is fast and cheap, making it ideal for product development.

While the early results generally had poor resolution and were weak, this process is improving rapidly and is fast and cheap, making it ideal for product development.

Selective Laser Melting (SLM) or Powder Bed Fusion

Often known as powder bed fusion, this process is favoured for making high-strength, complex parts. Selective Laser Melting is frequently used by the aerospace, automotive, defence and medical industries. This powder bed based fusion process uses a fine metal powder which is melted in a layer by layer manner to build either prototype or production parts using a high-powered laser or electron beam. Common SLM materials used in RP include titanium, aluminium, stainless steel and cobalt chrome alloys.

Laminated Object Manufacturing (LOM) or Sheet Lamination

This inexpensive process is less sophisticated than SLM or SLS, but it does not require specially controlled conditions. LOM builds up a series of thin laminates that have been accurately cut with laser beams or another cutting device to create the CAD pattern design. Each layer is delivered and bonded on top of the previous one until the part is complete.

Each layer is delivered and bonded on top of the previous one until the part is complete.

Digital Light Processing (DLP)

Similar to SLA, this technique also uses the polymerisation of resins which are cured using a more conventional light source than with SLA. While faster and cheaper than SLA, DLP often requires the use of support structures and post-build curing.

An alternative version of this is Continuous Liquid Interface Production (CLIP), whereby the part is continuously pulled from a vat, without the use of layers. As the part is pulled from the vat it crosses a light barrier that alters its configuration to create the desired cross-sectional pattern on the plastic.

Binder Jetting

This technique allows for one or many parts to be printed at one time, although the parts produced are not as strong as those created using SLS. Binder Jetting uses a powder bed onto which nozzles spray micro-fine droplets of a liquid to bond the powder particles together to form a layer of the part.

Each layer may then compacted by a roller before the next layer of powder is laid down and the process begins again. When complete the part may be cured in an oven to burn off the binding agent and fuse the powder into a coherent part.

Applications

Product designers use this process for rapid manufacturing of representative prototype parts. This can aid visualisation, design and development of the manufacturing process ahead of mass production.

Originally, rapid prototyping was used to create parts and scale models for the automotive industry although it has since been taken up by a wide range of applications, across multiple industries such as medical and aerospace.

Rapid tooling is another application of RP, whereby a part, such as an injection mould plug or ultrasound sensor wedge, is made and used as a tool in another process.

What are the Advantages?

There are a number of rapid prototyping advantages, such as being able to gain a more complete picture of how a product will look or perform in the early stage of the design and manufacturing cycle, allowing changes or improvements to be implemented earlier in the process. The time this takes can vary from a few days to a number of months, depending on the methods used.

The time this takes can vary from a few days to a number of months, depending on the methods used.

RP is a very cost effective way to prototype products as it is an automated process, requiring less staff to operate. This process is also extremely precise, being able to use computer aided design (CAD) to help reduce the amount of material wastage and does not require special tools for prototyping each new product. Being able to act quickly and solve ay problems also reduces the risk of costly errors during the manufacturing stage.

Rapid Prototyping helps designers present new concepts to board members, clients or investors so that they can understand and approve a development or product. This visualisation can also allows designers to gain ready feedback from customers and clients based on an actual physical product rather than a concept.

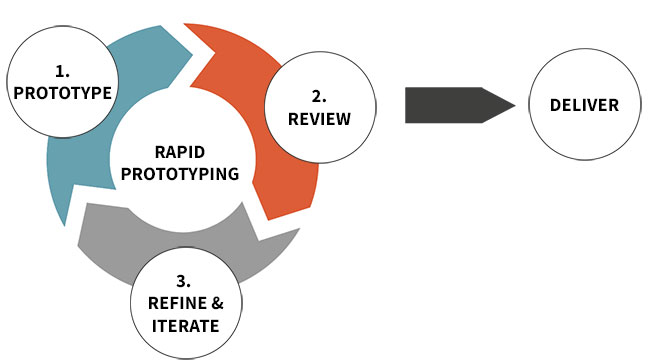

As rapid prototyping is an iterative process it allows customer requirements to be incorporated into designs cost-effectively. The process cuts out the need for customised products to be designed from scratch while providing greater choice and flexibility for customers.

How Much Does it Cost?

The cost depends on a number of factors, including volume or size of the part or parts being created, the surface finish, the materials used and how much post manufacture processing is required.

Rapid Prototyping Services

TWI has world leading experience and expertise in 3D printing technologies / additive manufacturing processes. We can also assist with rapid prototyping technology and manufacturing process development.

Additive Manufacturing

TWI provides companies with support covering every aspect of metal additive manufacturing (AM).

Selective Laser Melting

We can work with you to design and manufacture components that outperform parts made using conventional methods.

What is Rapid Prototyping & 3D Printing? Benefits & How to

Rapid prototyping sounds great, but where can it be used in the engineering process? The answer may not be wholly surprising at this point: from initial proof-of-concept to final-look-and-feel prototype, rapid prototyping can come into play across the entire process.

Concept Prototypes

The earliest prototypes are often conceptual. Proof-of-concept prototypes serve as physical validation of the ideas that may have emerged as a sketch on a napkin. Taking an idea into the three-dimensional real world is the best way to prove viability. Getting hands-on with a concept model can help your engineering team understand their next steps at the same time as it may encourage management to simply move forward with a project.

These early prototypes are often the roughest, as they are the lowest-risk representations made in the rapid prototyping cycle. These prototypes are made quickly and generally in different materials and colors than later-stage prototypes, much less final designs.

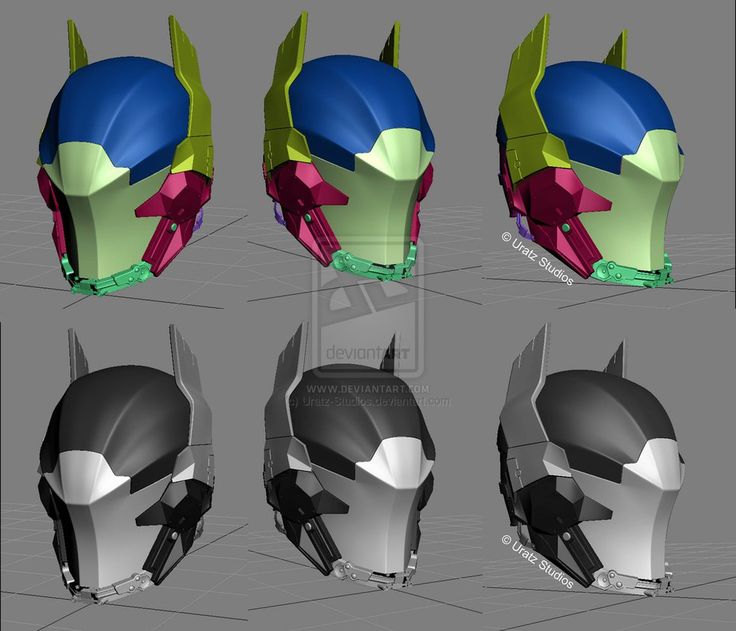

Aesthetic or Industrial Design Prototypes

Once a design is validated in its roughest form, it moves next into an aesthetic or industrial design step. These next prototypes begin to hone in on how the design should look and feel, with the thought process beginning to turn toward usability and functionality -- without necessarily being fully functional quite yet. To ensure a new part will fit into a greater whole, or a new product will fit with your brand’s existing aesthetic or functional line, these prototypes more accurately look like something that is moving toward a final design. These prototypes also enable engineers to consider how exactly to best manufacture the eventual final design.

To ensure a new part will fit into a greater whole, or a new product will fit with your brand’s existing aesthetic or functional line, these prototypes more accurately look like something that is moving toward a final design. These prototypes also enable engineers to consider how exactly to best manufacture the eventual final design.

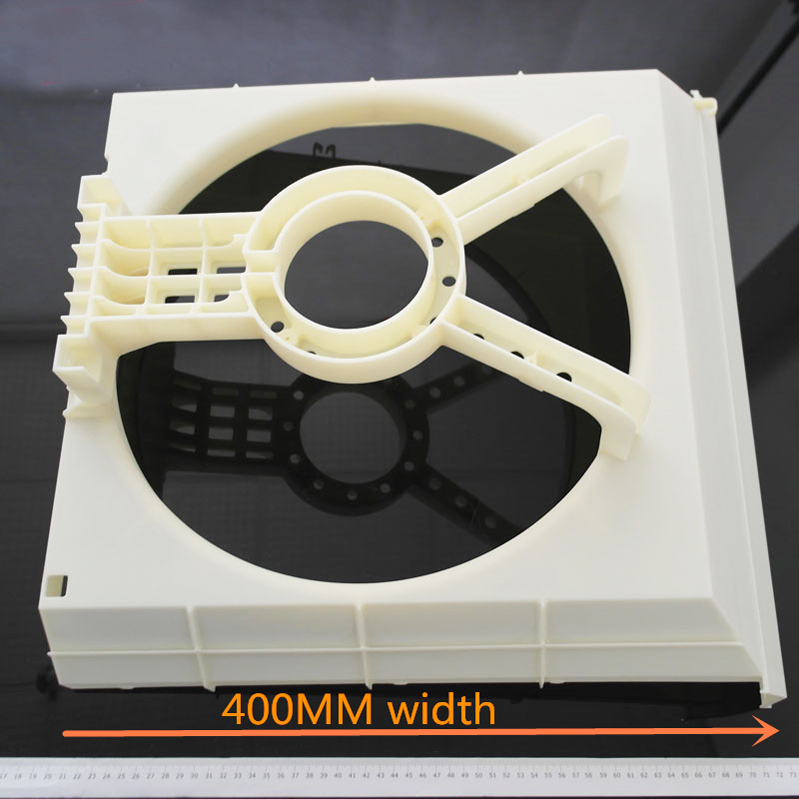

Especially when working with life-sized, larger designs like furniture, having life-sized prototypes to fit to spaces and users becomes ever more important as designs move through the prototyping cycle. Large-scale 3D printing can bring these large-scale designs to life, allowing for a full iteration to be made and tested in less than the time it would take for a traditional tool to be made. Furniture maker Steelcase experienced this benefit first-hand as they use their large-format BigRep 3D printer to create new furniture designs:

Functional Prototypes

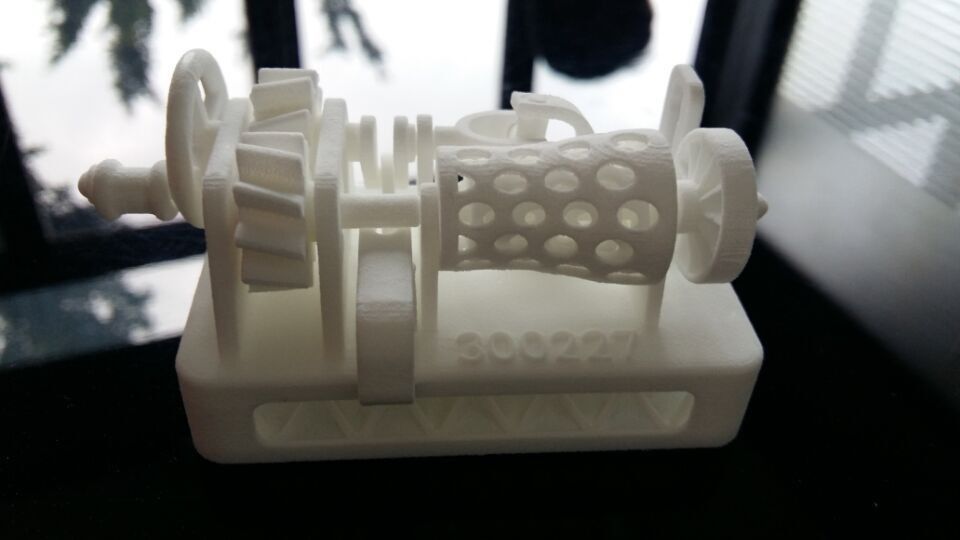

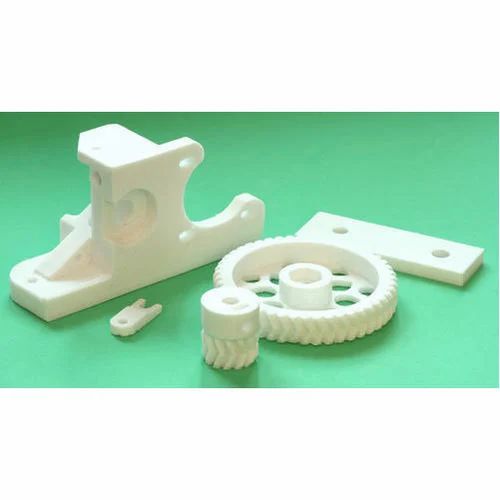

A functional prototype does just that: it functions. These later-stage prototypes are often made of materials similar to what will be used in a final product, to validate that everything will work as intended. Engineers at this stage pay attention to performance: does it fit, does it function, do load-bearing parts bear loads?

Engineers at this stage pay attention to performance: does it fit, does it function, do load-bearing parts bear loads?

Attention must be paid to detail, to how the final part will be manufactured (especially if this will be done in a different process than the prototype; for example, 3D printing a prototype for a part that will ultimately be injection molded) as well as how the final part will be post-processed/finished.

Test Serial Production

Many products bound for the mass market are bound for mass production, and this may mean in a different manufacturing process. While 3D printing may be the right technology for both rapid prototyping and serial production of the final part - consider, for example, cases of mass customization - this will not always be the case.

Prototyping must take into account the eventual manufacturing process to be used, and later-stage prototypes should use the same materials and fit into the appropriate manufacturing parameters as the final parts will be. Consideration for traditional production processes comes more into play here, for example for tooling, jigs and fixtures, or any other necessary implements. Design for additive manufacturing (DfAM) may move toward traditional design for manufacturing (DFM) thinking.

Consideration for traditional production processes comes more into play here, for example for tooling, jigs and fixtures, or any other necessary implements. Design for additive manufacturing (DfAM) may move toward traditional design for manufacturing (DFM) thinking.

Demonstration or Presentation Model Prototypes

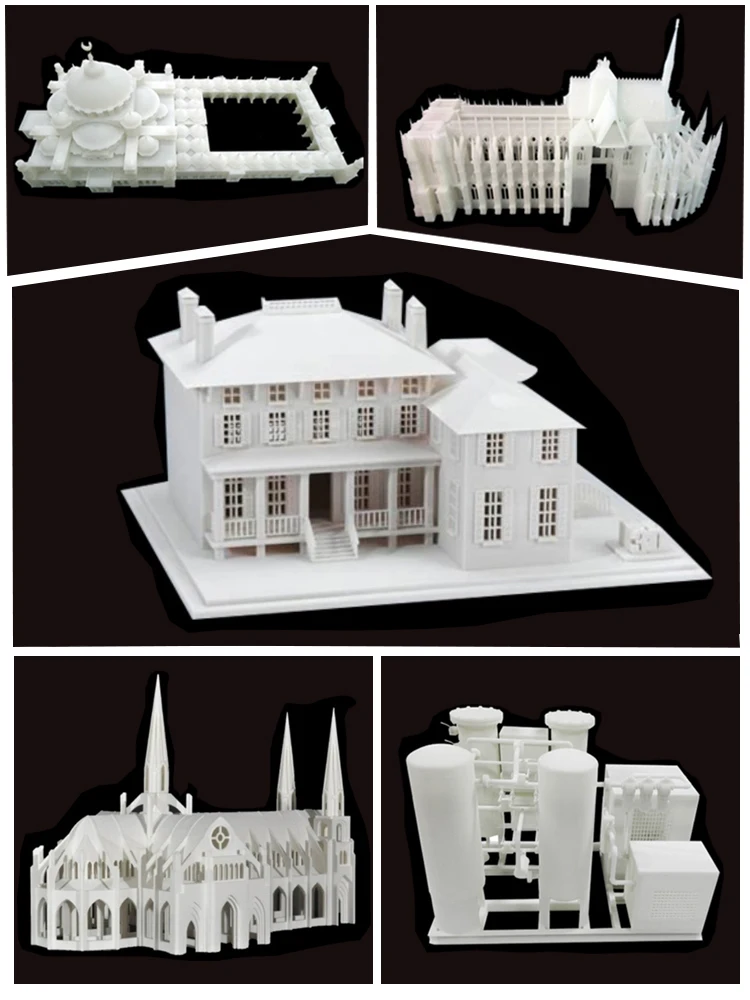

The final look is the final stage in prototyping, the last step before full production begins. At this stage, a prototype should not only feel and operate like the final product, but needs to look like it, too. This prototype can be used for marketing materials while production ramps up, for convincing investors of final viability and feasibility, for final field testing, or for any other demonstration or presentation needs. The goal of rapid prototyping is to reach this stage faster than ever before using conventional prototyping workflows.

3D prototyping, development of prototypes in the company Foliplast on favorable terms

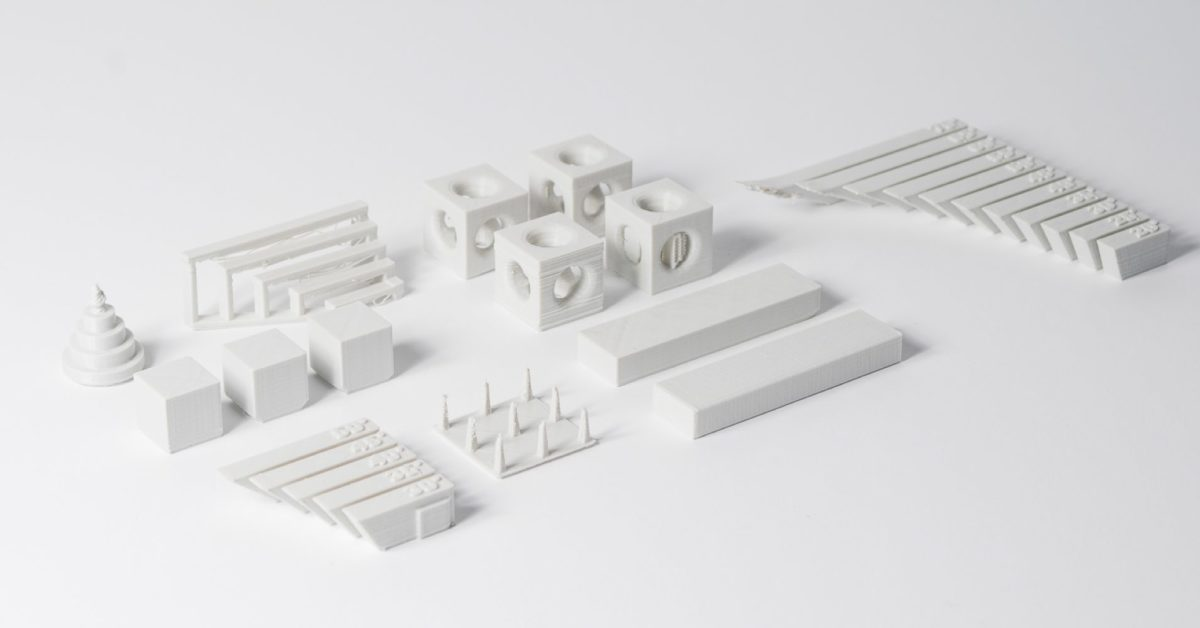

In a short time we get accurate samples of various parts and functional models of products.

Rapid prototyping includes a number of technologies that allow you to quickly get an accurate layout of various parts, products or a prototype to demonstrate the useful properties of an object. Prototyping allows you to conduct marketing research of products at the stage of its development, evaluate the appearance and ergonomics of the product, check the assembly of all structural elements, identify design errors and make the necessary changes before starting production.

Today, not a single new development can do without rapid prototyping technologies. Prototyping is used in mechanical engineering, printing, electrical and electronic industries, but is not limited to these areas.

Most often, prototypes are made as the first step in the production of pilot or serial batches of plastic parts. Here, these samples act as master models for subsequent vacuum casting into silicone molds or using RIM technology. And it is precisely at the stage of making master models that the foundation for the quality of a future batch of products is laid. The key role here is played by the accuracy of the manufactured prototype and the quality of finishing of its surfaces. Thus, how carefully the prototype was fine-tuned in accordance with the requirements of the customer, such an appearance of the product will be obtained. The labor intensity here is in direct proportion to the required quality. If you want parts like from an injection molding machine, then it will take time, care and experience of modelers.

The key role here is played by the accuracy of the manufactured prototype and the quality of finishing of its surfaces. Thus, how carefully the prototype was fine-tuned in accordance with the requirements of the customer, such an appearance of the product will be obtained. The labor intensity here is in direct proportion to the required quality. If you want parts like from an injection molding machine, then it will take time, care and experience of modelers.

Industrial prototyping is one of the main activities of Foliplast. In our work, we focus on the wishes of our customers and rely on proven methods. There are more than 20 types of Rapid Prototyping, including those for metals, wax, plastics and other materials. Over many years of practice, we can select from this variety of technologies the most suitable for specific tasks. So, if you need an accurate and high-quality prototype, you need to use SLA 3D printing technology. For simple design testing, assembly checks, you can use more budgetary FDM or SLS technologies. Of course, such a gradation is rather arbitrary, since there are times when more than one technology is applicable.

Of course, such a gradation is rather arbitrary, since there are times when more than one technology is applicable.

Each specialist of our company has extensive experience and excellent qualifications, which allows us to provide services of consistently high quality and quickly. 3D prototyping is based on the use of high technologies. We use advanced modern equipment, innovative techniques. The accumulated experience, combined with efficient production, ensures the fulfillment of orders at a high professional level.

We offer not only rapid prototyping of products and parts of any complexity using 3D printing technologies, but also small-scale production of plastic products.

How is product prototyping carried out?

The most modern method of creating a prototype is printing on a 3D printer. In fact, the prototyping of products by 3D printing is a layer-by-layer construction of a physical structure based on the developed mathematical model. Among the advantages of the technology: visibility, reduction of production preparation time, as well as a reduction in the cost of construction and design. Note that if you already have a part sample, then our specialists can use it as a master model in the production of silicone tooling for the vacuum casting method, which is effective for obtaining small batches of parts due to the speed and relative ease of manufacturing silicone molds.

Note that if you already have a part sample, then our specialists can use it as a master model in the production of silicone tooling for the vacuum casting method, which is effective for obtaining small batches of parts due to the speed and relative ease of manufacturing silicone molds.

Product prototyping steps

Rapid Prototyping includes the following stages:

- computer modeling, which consists in the development of a virtual three-dimensional model in stl format;

- then follows the development of the adopted technology;

- actual production of a 3D model;

- final refinement of the required texture of view surfaces.

1. Mathematical model of the part 2. SLA 9 prototype0003

By fully complying with the norms at the indicated stages of 3d prototyping using any chosen method, our company guarantees the efficiency and high quality of the final product.

Applied 3d printing technologies

Often, instead of the more correct and accurate term Rapid Prototyping (Rapid Prototyping), the concept of 3d printing is used. To date, there are a large number of volumetric printing technologies, but all of them have the same principle of layer-by-layer build-up. Below are descriptions of the main 3D printing technologies that have received the widest distribution.

SLA - Stereo Lithography Apparatus

SLA is laser prototyping. The technology involves the use of a special photopolymer, a light-sensitive resin, as a model material. The working tool in this process is an ultraviolet laser, which sequentially transfers the cross sections of the model to the surface of the container with photosensitive resin. Liquid plastic hardens only in the place where the laser beam has passed. Then a new liquid layer floats on the hardened layer, and a new contour is drawn with a laser. The process is repeated until the completion of the model building.

Stereolithography is the most common RP technology. It covers almost all branches of material production from medicine to heavy engineering. SLA technology allows you to quickly and accurately build a product model of almost any size. The quality of the surfaces depends on the construction step. Modern machines provide a construction step of 0.1 ... 0.025 mm. Stereolithography gives the best result when creating master models for the subsequent production of silicone molds and casting polymer resins into them, as well as jewelry master models.

SLS - Selective Laser Sintering

Laser prototyping is not limited to liquid foundations. The SLS method allows you to create copies based on powdered components. According to this process, models are created through a sintering effect using the energy of a laser beam. In this case, unlike the SLA process, the laser beam is not a light source, but a heat source. Getting on a thin layer of powder, the laser beam sinters its particles and forms a solid mass, in accordance with the geometry of the part. Polyamide, polystyrene, sand and some metal powders are used as materials. A significant advantage of the SLS process is the absence of so-called supports when building a model. During the SLA process, when building overhanging elements of a part, special supports are used to protect the freshly built thin layers of the created model from collapse.

Polyamide, polystyrene, sand and some metal powders are used as materials. A significant advantage of the SLS process is the absence of so-called supports when building a model. During the SLA process, when building overhanging elements of a part, special supports are used to protect the freshly built thin layers of the created model from collapse.

In the SLS process, there is no need for such supports, since the construction is carried out in a homogeneous mass. Once built, the model is extracted from the powder array and cleaned up. Models made of polystyrene are designed to produce castings using the "burned-out models" method. The most popular model material is powdered polyamide. This material is used to create layouts, scale copies, functional models, i.e. models capable of performing their function as a part of a machine or device. For example, car interior trim parts or decorative body elements. 9FDM - Fused Deposition Modeling head with a controlled temperature, heating up in it to a semi-liquid state. The extrusion head applies the material with high precision and very thin layers on a fixed base. Subsequent layers also lie on the previous ones, solidify (harden), connecting with each other. The main disadvantage of the method is the insufficiently smooth surface of the created part. In addition, when applying the molten material, some melting of the previous layer occurs. Here, the accuracy of matching with the original model suffers. Therefore, this method has a limitation on the minimum size of gaps in the created product.

The extrusion head applies the material with high precision and very thin layers on a fixed base. Subsequent layers also lie on the previous ones, solidify (harden), connecting with each other. The main disadvantage of the method is the insufficiently smooth surface of the created part. In addition, when applying the molten material, some melting of the previous layer occurs. Here, the accuracy of matching with the original model suffers. Therefore, this method has a limitation on the minimum size of gaps in the created product.

You can order rapid prototyping services in our company with delivery of products to Moscow, St. Petersburg, Kazan, Samara, Novosibirsk and other cities of Russia.

Make a request by phone 8 (800) 302-13-41.

T You can also leave a request in any feedback form on the site, and you will be contacted as soon as possible.

The exact prices for prototypes, as well as the terms of delivery and payment, will be provided by Foliplast employees.

3D prototyping of models, parts - additive technologies from DDM.Lab

Modern technologies allow you to create a really worthwhile product without spending a lot of development resources. 3D prototyping is the ability to produce an object according to a drawing or mathematical model in full size or scale, without losing the main functions of the final product. When using metals, thermoplastics, polymer blends and composites, high quality and functionality can be achieved without resorting to classical production.

Prototyping 3D models eliminates the risk of inaccurate design and engineering calculations and, consequently, unnecessary costs.

3D printing a model from a simplified (non-final) material or mass production material is the optimal solution for product development. You will be able to test a sample, check its functional properties and assembly compliance, make a presentation, and correct shortcomings even before the start of mass production.

Work stepsPrototyping typesTechnologiesPrices for 3D prototyping

Work steps

3D prototyping allows you to quickly start production in several main steps: Testing the finished product, adjusting the digital model if necessary

With a prototype, you can evaluate its appearance, ergonomics, and even experience its functionality. If the object meets the requirements of the company, it can be used as a master model or tooling for the first batch of goods - in DDM.Lab you can order the production of products by molding into silicone (from 10 to 1000 pieces) or single- or reusable production tooling.

Prototypes are most often ordered by large machine-building and instrument-making companies, developers of innovative products and designers interested in the speedy release of plastic and metal products. Leave a request, and our experts will select for you the best way to introduce additive technologies into production!

Types of prototypes

Conventionally, prototypes can be divided into several types:

- Industrial - created for large manufacturing enterprises (assemblies, housings, parts and spare parts)

- Transport - such prototypes are used in mechanical engineering, aviation, shipbuilding (from development to individual parts or assemblies of land, water and air transport)

- Product prototypes allow you to work out the format of the future product and its packaging

- Presentation models, for example, a model of an apartment, a building or an entire city, make it possible to convey the project with its architectural features and interior design as clearly as possible.

for solving the problems of orthopedics, endoprosthesis, orthodontics.

for solving the problems of orthopedics, endoprosthesis, orthodontics.

Technologies

- FDM thermoplastic deposition modeling allows you to quickly and inexpensively produce fully functional samples of products and production tooling from a wide range of materials

- Inkjet printing with PolyJet photopolymers allows printing highly realistic color and multi-material products and tooling

- Selective laser fusion of metals LBM / SLM is often used for high-precision production of end products with complex geometry from metal-powder compositions of small fractions

- Gas-powder jet deposition using directed energy exposure DED/LMD is used for quick repair of worn surfaces of products, as well as for the manufacture of products from "scratch" from metal powder compositions

- 3DMP Arc Welding/Arc Wire Deposition - the most affordable and productive solution for the rapid production of high-stress end metal parts

- BJ inkjet printing by applying material powder and bonding it with a binder to create molds from sand-polymer compositions

- Selective SLS laser sintering for the rapid production of full-featured parts, production tooling from a wide range of polyamide and composite (polyamide-based) powders, and polystyrene powders for creating burnable master patterns for foundries

- SEAM screw extrusion hybrid additive manufacturing for rapid production of large-sized products using granular thermoplastics, including those filled with carbon fibers binder.

Learn more