Diamond 3d printer

Sandvik creates first 3D printed diamond composite — Sandvik Group

- Innovation

Sandvik Additive Manufacturing has created the first ever 3D printed diamond composite. While this diamond does not sparkle, it is perfect for a wide range of industrial uses. The new process means that this super-hard material can now be 3D printed in highly complex shapes and can thereby revolutionise the way industry uses the hardest natural material on the planet.

Diamond is harder than anything else in nature. It is a key component in a large range of wear resistant tools in industry, from mining and drilling to machining and also medical implants. Since 1953 it has been possible to produce synthetic diamond, but since it’s so hard and complicated to machine, it is almost impossible to form complex shapes.

Until now, production of super hard diamond materials only has allowed for a few simple geometric configurations to be formed. By using additive manufacturing and a tailor-made, proprietary post-processing method, Sandvik has managed to 3D-print diamond composites which can be formed into almost any shape.

Historically, 3D printing in diamond was something that none of us imagined was achievable

The difference between Sandvik’s diamond and natural or synthetic diamond is that Sandvik’s is a composite material. Most of the material is diamond, but to make it printable and dense it needs to be cemented in a very hard matrix material, keeping the most important physical properties of pure diamond.

The opportunities are enormous

Due to Sandvik’s use of additive manufacturing, diamond components can now be created application ready, in very complex shapes, without the need for further machining. This will open up the possibility of using it in applications that were previously considered impossible.

“Historically, 3D printing in diamond was something that none of us imagined was achievable,” explained Anders Ohlsson, Delivery Manager at Sandvik Additive Manufacturing. “Even now we are just starting to grasp the possibilities and applications that this breakthrough could have.

“On seeing its potential, we began to wonder what else would be possible from 3D-printing complex shapes in a material that is three times stiffer than steel, with heat conductivity higher than copper, the thermal expansion close to Invar – and with a density close to aluminium. These benefits make us believe that you will see this diamond composite in new advanced industrial applications ranging from wear parts to space programs, in just a few years from now.”

The 3D printing process

“The additive manufacturing process used is highly advanced,” explained Mikael Schuisky, Head of R&D and Operations at Sandvik Additive Manufacturing. “We are printing in a slurry consisting of diamond powder and polymer using a method called stereolithography, where complex parts are produced, layer by layer, using ultraviolet light.

Sandvik’s 3D printed diamond composite is a true innovation. It means that we can begin to use diamond in applications and shapes never conceived possible before

“This step was extremely complicated. However, after extensive R&D efforts and several trials we managed to take control over the process and made the first 3D printed diamond composite.”

However, after extensive R&D efforts and several trials we managed to take control over the process and made the first 3D printed diamond composite.”

“It was incredible to see what we can achieve when we combine Sandvik’s leading expertise in materials technology with our strong capabilities in additive manufacturing and post processing,” commented Mikael Schuisky. “We have some of the world’s leading experts in both materials and additive manufacturing, which in a case like this can benefit many industries around the globe making it possible to use diamond in applications and shapes never conceived possible before.”

“Rather than looking to actually develop completely new materials, today the big push within the industry involves the often-radical restructuring of existing materials,” said Annika Borgenstam, Professor at the Department of Materials Science and Engineering at Stockholm’s KTH Royal Institute of Technology.”

Annika Borgenstam, Professor at the Department of Materials Science and Engineering, KTH Royal Institute of Technology.

“Using revolutionary new processes such as additive manufacturing will open up completely new ways of using the same types of materials that we have today, by building in the properties that we need.”

“Sandvik’s 3D printed diamond composite is a true innovation. It means that we can begin to use diamond in applications and shapes never conceived possible before,” said Susanne Norgren, Adjunct Professor in Applied Materials Science at Uppsala University. “Just imagine what it could do to industries, when it is possible to print anything, in any shape – in diamond.”

Just imagine what it could do to industries, when it is possible to print anything, in any shape – in diamond

Susanne Norgren, Adjunct Professor in Applied Materials Science, Uppsala University

Sustainable with superior properties

Another key advantage of additive manufacturing is that it allows engineers to minimize material waste, making the technology more sustainable. The diamond powder in Sandvik’s process can be extracted from the polymer in the slurry after the printing, and then be recycled and reused in another print-job.

The diamond powder in Sandvik’s process can be extracted from the polymer in the slurry after the printing, and then be recycled and reused in another print-job.

The diamond composite has been tested and found to have extremely high hardness, exceptional heat conductivity, while also possessing low density, very good thermal expansion and fantastic corrosion resistance.

“We now have the ability to create strong diamond composites in very complex shapes through additive manufacturing, which fundamentally will change the way industries will be able to use this material. As of now, the only limit to how this super-hard material can be shaped and used is down to the designer’s imagination,” Mikael Schuisky concluded.

Go to our website for additive manufacturing

A Guinness World Record Diamond Ring Made With 3D Printing

Published on January 11, 2021 by Madeleine P.

Imaginarium, a 3D printing service based in India, broke a surprising record last year when it contributed to the creation of the ring with the most diamonds in the world: 7,801 to be exact. This record was entered in the Guinness World Records last September and was made possible thanks to additive manufacturing. Named The Divine – 7801 Brahma Vajra Kamalam, the ring was modeled using computer-aided design (CAD) and its mold was 3D printed using direct castable resin before being cast in gold. A long-term job that started in September 2018.

This record was entered in the Guinness World Records last September and was made possible thanks to additive manufacturing. Named The Divine – 7801 Brahma Vajra Kamalam, the ring was modeled using computer-aided design (CAD) and its mold was 3D printed using direct castable resin before being cast in gold. A long-term job that started in September 2018.

In the jewelry sector, more and more players are turning to 3D printing to create more complex custom molds. The goal is to 3D print the model of the jewelry with wax. It is then wrapped in a refractory material, thus making it possible to obtain a mold. The wax inside is then heated to create a vacuum inside the mold, which will be filled with molten metal – gold, silver, bronze. The mold is then broken to obtain the final product. Thanks to additive manufacturing, jewelers can imagine and create more original models, which would be impossible to obtain via conventional manufacturing processes.

The Divine in its final form (photo credit: Imaginarium)

This is surely what motivated Kotti Srikanth, manager of Diamond Store by Chandubhai, to use the Imaginarium printing service. His goal was to design a ring with as many diamonds as possible, which involved knowing exactly where each would be placed. After imagining several iterations, the designers of the ring explain that they ultimately opted for a flower shape, more specifically a Himalayan camellia flower. This would offer a perfect balance between traditional and more modern forms.

His goal was to design a ring with as many diamonds as possible, which involved knowing exactly where each would be placed. After imagining several iterations, the designers of the ring explain that they ultimately opted for a flower shape, more specifically a Himalayan camellia flower. This would offer a perfect balance between traditional and more modern forms.

CAD modeling made it possible to see how many diamonds it was possible to place into the design and once the file was ready, the collaboration with Imaginarium could begin. The 3D printing service explains that it divided the ring into seven sections namely six flowers and the ring. Each flower has a different size allowing them to be stacked on top of each other. A RapidShape resin machine was used to 3D print the model of the ring: the material would be directly castable making it easy to create the gold piece.

The different sections of the ring in castable resin (Photo Credits: Imaginarium and Guinness World Records

Kotti Srikanth adds, “Imaginarium were able to manufacture the petals and the ring in the shape we imagined using high-quality materials. We received the castings very quickly and Imaginarium even helped us ascertain the number of diamonds once we had set them in the ring.”

We received the castings very quickly and Imaginarium even helped us ascertain the number of diamonds once we had set them in the ring.”

Though the record was beaten last November with a ring containing 12,638 diamonds, Srikanth’s ring is significant because of the role that 3D printing played in its creation. You can find out more about Imaginarium HERE.

What do you think about the role of 3D printing in jewelry? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

Lockheed Martin patents 3D diamond printing / Habr

Products of any shape! The author wanted to insert a diamond tyrannosaurus rex, but Google did not find a suitable picture. Photo Source: Crystal Fox

Lockheed Martin, one of the world's largest aerospace manufacturers, filed for a patent on April 4 for a new 3D printing technology, artificial diamond 3D printing.

Material from 3dprintingindustry.com translated for you Top 3D Shop .

In a patent application, inventor David G. Findlay describes a new 3D printing process that uses a ceramic-bonding polymer and nanoparticle filler to create synthetic diamond objects in almost any shape imaginable.

About technology

David G. Findley:

“The method consists in layering layers of ceramic powder and bonding them with pre-dissolved polymer.

After layering is completed, the object is heated to at least the polymer decomposition temperature, which is lower than the powder sintering temperature.”

Image: U.S. Patent and Trademark Office, Lockheed Martin

While the printer is likely to be used primarily for making drills, cutters and perhaps even light armor, it could be great news for jewelers who can create diamonds of almost any shape.

About Lockheed Martin

Quiet supersonic vehicle for NASA. Source: Lockheed Martin

Headquartered in Bethesda, Maryland, USA, Lockheed Martin is a global security and aerospace company with approximately 98,000 employees worldwide. The company is engaged in research, design, development, production, integration and support of modern technological systems, products and services.

US Air Force F-35 fighter. Source: nationalinterest.org

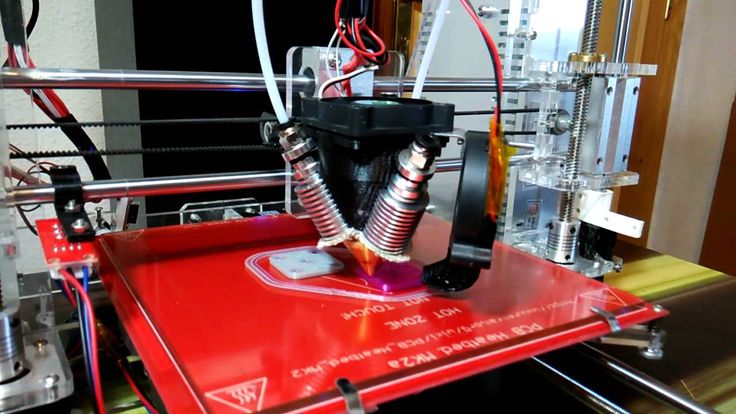

What else do 3D printing and diamonds have in common? to increase the production of parts for diamond industry equipment.

The company used to cover its 3D printing needs with third parties, but the addition of two machines means round-the-clock production at its diamond research center in Maidenhead, UK.

3D printers are being used to create automated methods for checking and sorting diamonds, and to prototype parts for new equipment.

De Beers Technologies Senior Mechanical Engineer Andrew Portsmouth:

“Whenever I have an idea, my first thought is 'will it work'? Now we can print a prototype overnight, test it the next day, find out the features and flaws, make changes and print the corrected one by the next morning to repeat all the tests. It's impossible to put into words how much 3D printing speeds up development."

Optical measuring cell housing. Image: tctmagazine.com

One of the pieces of equipment, the body of the optical measurement cell (pictured above), cannot be created without 3D printing.

“The design features of this case give it many advantages in application, but these same features mean that it is not possible to manufacture it in ways other than 3D printing,” explained Andrew.

"Manufacturing this part on the Fortus 360mc resulted in a 3-4 times reduction in cost compared to the previous method, simply because it is a much cheaper process. "

"

What do you think Lockheed Martin will print with artificial diamond?

What other applications, besides instrumental and jewelry, can be found for this technology? Share your opinion in the comments.

US Synthetic Offers Diamond Nozzles for FDM 3D Printers

News

respectively, durability.

These nozzles are designed by US Synthetic, a ChampionX Corporation manufacturing equipment and chemicals for the oil and gas industry. Specifically, US Synthetic specializes in cutting tools using synthetic diamonds, and now, apparently, has decided to take on components for 3D printers.

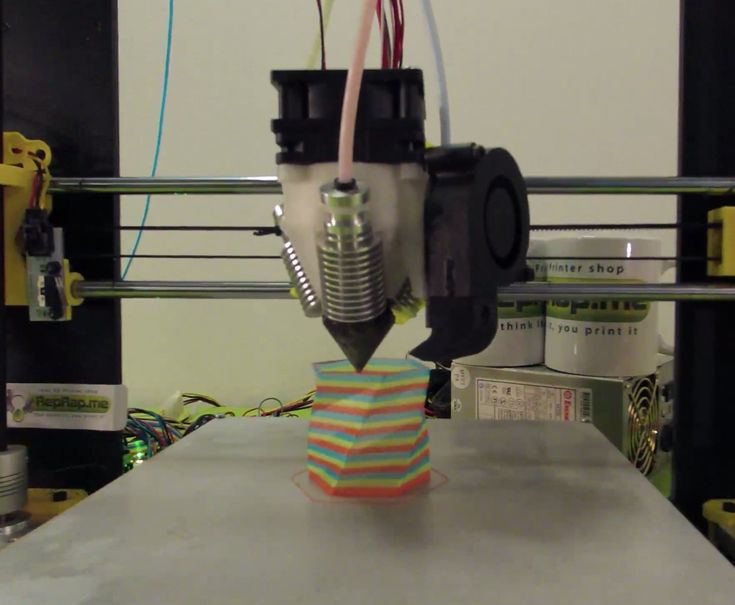

There is nothing fundamentally new here: back in 2016, the well-known Swedish engineer Anders Olsson (the author of the so-called “Olsson blocks”) designed nozzles with ruby tips specifically for 3D printing with highly abrasive materials. AliExpress is already inundated with clones of such dies, and the originals (pictured above) are still offered by 3DVerkstan and used in CC Red modular hotends for Ultimaker third generation 3D printers. Following the ruby nozzles, sapphire ones appeared, for example, from the Russian company Technology 21st Century (in the illustration below). The appearance of diamond options was only a matter of time.

Following the ruby nozzles, sapphire ones appeared, for example, from the Russian company Technology 21st Century (in the illustration below). The appearance of diamond options was only a matter of time.

The authors emphasize that DiamondBack nozzles do not use coatings, but polycrystalline diamond inserts. The developers promise a full bouquet of benefits: the ability to print with any filament, increased interlayer adhesion and quality, ease of cleaning and reduced risk of plugging, high wear resistance, the ability to 3D print at lower extrusion temperatures and increase its efficiency. Yes, diamond has a very high thermal conductivity, but only practice will show how much diamond tips affect all of the above. The metal part, by the way, is made of brass. In any case, the mention of increased wear resistance is understandable, because for the sake of it, such nozzles are created in the first place.

What we have in the end: nozzles capable of printing both conventional polymers like PLA or ABS, and all kinds of highly abrasive materials, such as composites with carbon and glass fiber fillers or polymer-metal filaments. In terms of survivability, the developers point to their own experience in creating cutting tools, where diamond coatings last 2-8 times longer than tungsten carbide counterparts. And yes, tungsten carbide nozzles also exist. It is not recommended to operate diamond nozzles at temperatures above 300°C, but in the future it is planned to offer higher temperature options - ruby competitors already hold up to 500°C. DiamondBack nozzles are designed to work with filaments with a diameter of 1.75 mm, fit hot ends with M6x1 threads and are available in diameters of 0.4, 0.6 and 0.8 mm.

In terms of survivability, the developers point to their own experience in creating cutting tools, where diamond coatings last 2-8 times longer than tungsten carbide counterparts. And yes, tungsten carbide nozzles also exist. It is not recommended to operate diamond nozzles at temperatures above 300°C, but in the future it is planned to offer higher temperature options - ruby competitors already hold up to 500°C. DiamondBack nozzles are designed to work with filaments with a diameter of 1.75 mm, fit hot ends with M6x1 threads and are available in diameters of 0.4, 0.6 and 0.8 mm.

Single nozzles available for $76 without shipping. In parallel, there is a choice of different pair combinations and triple sets: for example, a complete set of three nozzles of different diameters will cost early customers $199. The start of deliveries is scheduled for November this year. Additional information is available on the Kickstarter crowdfunding site at this link.