Wasp 3d printer house

Tecla house 3D-printed from locally sourced clay

James Parkes | Leave a comment

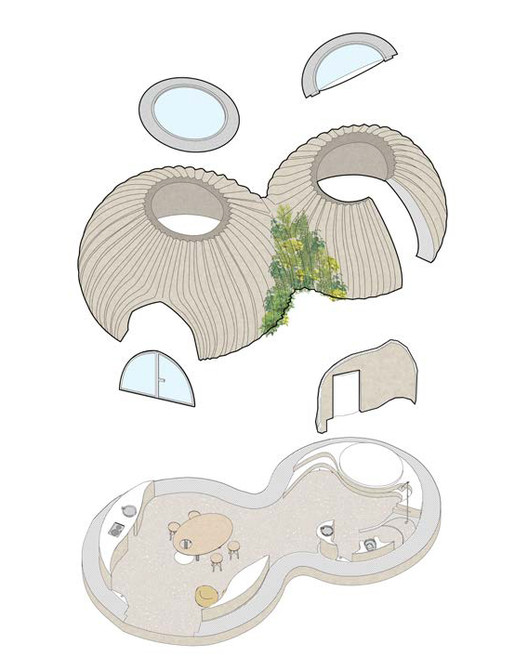

Bologna-based architecture studio Mario Cucinella Architects and 3D printing specialists WASP have collaborated to create a low-carbon housing prototype that is 3D printed using clay.

Named Tecla, a combination of the words technology and clay, the home was designed by Mario Cucinella Architects and was constructed and engineered by Wasp using clay sourced from a nearby riverbed.

Top: Tecla was made by Mario Cucinella Architects and Wasp. Above: the prototype was printed using 350 layers of clayPrinted in Massa Lombarda, Italy, the home is formed of two connected dome-shaped volumes with a ribbed outer wall that is made up of 350 stacked layers of 3D-printed clay.

The clay is arranged in undulating layers that not only provide structural stability but also to act as a thermal barrier.

The prototype was constructed using a multilevelled, modular 3D printer that uses two synchronised arms, each with a 50-square metre printing area that can print modules simultaneously.

Mighty Buildings plans neighbourhood of 3D-printed homes for California

By using this technology, housing modules can be built within 200 hours while consuming an average of six kilowatts of energy and reducing typical construction waste almost entirely said the construction team.

The prototype has a ribbed exteriorAccording to the studio, the housing prototype combines ancient building techniques with modern technology to form recyclable, low-carbon, climate-adaptable housing.

"TECLA responds to the increasingly serious climate emergency, to the need for sustainable homes and to the great global issue of the housing emergency that will have to be faced," said Mario Cucinella Architects.

"Particularly in the context of urgent crises generated, for example, by large migrations or natural disasters. "

"

The 60-square-metre structure is 4.2 metres in height and comprises a living space, kitchen and sleeping area and is fitted with services and a circular skylight on its roof.

Although mainly windowless, its entrance is marked by a glazed door within a large lancet arch.

A large lancet arch marks the entrance to the housing prototypeOn its roof, large circular skylights were fitted within its narrowest point allowing light to enter the space throughout the day.

Its interior has a similar organic aesthetic as the walls were left bare with a lancet archconnecting the different zones.

Furnishings were also partly printed using locally sourced earth to unite the space and were designed to be reused or recycled to align with the circular values of the prototype.

The prototype was developed as a response to climate emergency. Photograph is by ItaldronThe geometry of its envelope can be adapted and modified to work with different types of raw earth and respond to a variety of different climatic conditions.

"The aesthetics of this house are the result of a technical and material effort," said Cucinella. "It was not an aesthetic approach only. It is an honest form, a sincere form."

The prototypes can be constructed in 200 hours. Photograph is by ItaldronTecla was developed as part of an eco-sustainability research study that looked to bioclimatic principles and vernacular architecture and construction to produce low-carbon homes.

"TECLA shows that a beautiful, healthy, and sustainable home can be built by a machine, giving the essential information to the local raw material," said Wasp founder, Massimo Moretti.

Undulating curved layers provide structural stability. Photograph is courtesy of Wasp"We like to think that TECLA is the beginning of a new story," added Mario Cucinella Architects founder and creative director, Mario Cucinella.

"It would be truly extraordinary to shape the future by transforming this ancient material with the technologies we have available today. "

"

In 2019, WASP used its Crane Wasp 3D printer to create a small home constructed using soil and agricultural waste.

Elsewhere, 3Strands and ICON collaborated to build four 3D-printed homes using disaster-proof concrete.

Photography is by Iago Corazza unless stated otherwise.

Subscribe to our newsletters

Your email addressDezeen Debate

Our most popular newsletter, formerly known as Dezeen Weekly. Sent every Thursday and featuring a selection of the best reader comments and most talked-about stories. Plus occasional updates on Dezeen’s services and breaking news.

New! Dezeen AgendaSent every Tuesday and containing a selection of the most important news highlights. Plus occasional updates on Dezeen’s services and breaking news.

Dezeen DailyA daily newsletter containing the latest stories from Dezeen.

Dezeen JobsDaily updates on the latest design and architecture vacancies advertised on Dezeen Jobs. Plus occasional news.

Plus occasional news.

News about our Dezeen Awards programme, including entry deadlines and announcements. Plus occasional updates.

Dezeen Events GuideNews from Dezeen Events Guide, a listings guide covering the leading design-related events taking place around the world. Plus occasional updates.

We will only use your email address to send you the newsletters you have requested. We will never give your details to anyone else without your consent. You can unsubscribe at any time by clicking on the unsubscribe link at the bottom of every email, or by emailing us at [email protected].

For more details, please see our privacy notice.

Thank you!

You will shortly receive a welcome email so please check your inbox.

You can unsubscribe at any time by clicking the link at the bottom of every newsletter.

WASP and Azure Printed Homes take strides in sustainable 3D printed homes

0Shares

Construction 3D printing announcements have regularly made the headlines in recent months, from the commercialization of 3D printed housing developments to novel sustainable building methods using recycled materials.

The latest construction announcements combining both commercialization and sustainability come from construction 3D printing firms Azure Printed Homes and WASP. The former has secured a contract to develop what it claims will be the first housing development to be 3D printed from recycled plastic, while the latter has continued its work to create sustainable 3D printed architectures using natural materials.

A render of one of Azure’s 3D printed ADUs. Image via Azure Printed Homes.Azure’s recycled housing community

Hot off the heels of opening its new 15,000 square foot factory in California, Azure has been chosen by Oasis Development to create 14 3D printed prefabricated homes in Ridgecrest, California, made entirely from 3D printed plastic.

Azure Printed Homes was founded in 2019 with the goal of developing homes faster, more economically, and with less of an environmental impact. The company already manufactures and sells 3D printed backyard studios and accessory dwelling units to homeowners, and is reportedly the first construction firm to repurpose plastic waste as a primary home building material.

Now and in line with its original mission statement, Azure is scaling up its capabilities to build 3D printed houses for Oasis Development’s new housing community.

“Azure is excited to prove the concept of this technology, and to become a partner of choice for home builders,” said Ross Maguire, Azure’s CEO. “It’s great to partner with Oasis Development in Ridgecrest, on a genuinely innovative project aiming to demonstrate the benefits of 3D printing using recycled materials.”

A render of Azure’s 3D printed backyard office. Image via Azure Printed Homes.With its 3D printing technology, the firm says it can build structures 70 percent faster and with 30 percent fewer costs than traditional home construction techniques. The company hopes to reduce homeowners’ energy bills entirely through a combination of building airtightness and the use of low-carbon technologies like heat pumps and solar panels.

Azure will begin 3D printing the 14 homes in August this year, and plans to have completed the entire build by the following month. The homes will form the first community of durable homes 3D printed entirely using waste plastic material intended for landfills, incineration, or that would have ended up in our oceans.

The homes will form the first community of durable homes 3D printed entirely using waste plastic material intended for landfills, incineration, or that would have ended up in our oceans.

“Oasis is pleased to announce our partnership with Azure to deliver 3D printed modular homes to Ridgecrest,” said Ken Bagga, CEO of Oasis Development. “We have been actively researching several potential prefab manufacturers for this particular project for several years. We finalized our current plans for this development with Azure’s input. This expertise has accelerated our learning around their innovative products and processes.

The LDM WASP Extruder XXL. Photo via WASP.“Now that our agreement is signed, we look forward to seeing these new modern homes being manufactured by Azure Printed Homes and installed in our Ridgecrest development.”

WASP strengthens IAAC partnership for sustainable architectures

WASP has long been a pioneer within sustainable 3D printed architectures, having previously deployed its Crane WASP 3D printer to build its Gaia small eco house for its sustainable Shamballa village project in Italy, and later to fabricate its TECLA eco-friendly housing model printed entirely from local earth.

The company has worked with the Institute for Advanced Architecture of Catalonia, Barcelona (IAAC) for the best part of four years to advance the field of additive manufacturing for sustainable architecture. The partners have worked together as part of IAAC’s postgraduate education program in 3D Printing Architecture (3DPA) which gives students the chance to engage with different areas of research within robotic manufacturing, material research, and performance-based design.

For their latest project, WASP and the IAAC will inaugurate the first housing prototype 3D printed with the firm’s Crane WASP 3D printer at Valldaura Labs, a campus created by the IAAC focused on research and education on self-sufficient habitats. The sustainable habitat will be printed with the firm’s new LDM WASP Extruder XXL, with those interested invited to watch the live broadcast of the build on February 28th, 2022.

According to WASP, the build is an example of the firm’s openness to engaging with universities and research centers around the world to advance sustainable building methods for the future using additive manufacturing.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows a render of one of Azure’s 3D printed ADUs. Image via Azure Printed Homes.

Tags 3D Printing Architecture Azure Printed Homes Crane WASP Gaia IAAC Ken Bagga LDM WASP Extruder XXL Oasis Development Ross Maguire Shamballa project TECLA Valldaura Labs wasp

Hayley Everett

Hayley is a Technology Journalist for 3DPI and has a background in B2B publications spanning manufacturing, tools and cycling. Writing news and features, she holds a keen interest in emerging technologies which are impacting the world we live in.

Writing news and features, she holds a keen interest in emerging technologies which are impacting the world we live in.

build an eco-house like a potter's wasp

3D print: build an eco-house like a potter's wasp

It looks like a sea urchin shell. But in fact, another animal provided the template for Tecla, an eco-house that can be built with 3D printing: its design is centered on the nest of a pottery wasp that places its eggs in a globular clay house, which they place on branches or walls erected .

Pottery wasp nest.

Tecla, Visualization

Prefabricated buildings from a bird's eye view.

Tecla under construction

The outer and inner domes were built at the same time.

The project is a collaboration between Italian 3D printing company Wasp and Mario Cucinella Architects.

As for the tiny wasps, 3D printing at home also uses fabric from its immediate environment: the earth. As such, according to its creators, it is "composed entirely of reusable and recyclable materials". They were carbon neutral, adapted to any climate and any location setting. In addition, the house is designed in such a way that it can stand on its own or be combined into larger formations depending on the needs.

They were carbon neutral, adapted to any climate and any location setting. In addition, the house is designed in such a way that it can stand on its own or be combined into larger formations depending on the needs.

One construction site, several 3D printers

Currently located in Massa Lombarda, near Ravenna, Tecla prototype is realized. 3D printing work has recently been completed. They built a small house with several 3D printers that worked simultaneously. Since the structure consists of an outer and an inner dome, the load-bearing structure, roof and shell can be implemented in parallel.

According to a joint media announcement between the company and the architects, Wasp 3D printers can move over an area of 50 meters. Therefore, it was possible to print structures in any form within a few days.

If everything goes according to plan, the cottage will be completed this spring3D printing: build an eco-house like a potter's wasp

It looks like a sea urchin shell. But in fact, another animal provided the template for Tecla, an eco-house that can be built with 3D printing: its design is centered on the nest of a pottery wasp that places its eggs in a globular clay house, which they place on branches or walls erected .

But in fact, another animal provided the template for Tecla, an eco-house that can be built with 3D printing: its design is centered on the nest of a pottery wasp that places its eggs in a globular clay house, which they place on branches or walls erected .

Pottery wasp nest.

Tecla, Rendering

Bird's eye view of completed buildings.

Tecla under construction

The outer and inner domes were built at the same time.

The project is a collaboration between Italian 3D printing company Wasp and Mario Cucinella Architects.

As for the tiny wasps, 3D printing at home also uses fabric from its immediate environment: the earth. As such, according to its creators, it is "composed entirely of reusable and recyclable materials". They were carbon neutral, adapted to any climate and any location setting. In addition, the house is designed in such a way that it can stand on its own or be combined into larger formations depending on the needs.

One construction site, several 3D printers

Currently located in Massa Lombarda, near Ravenna, Tecla prototype is realized. 3D printing work has recently been completed. They built a small house with several 3D printers that worked simultaneously. Since the structure consists of an outer and an inner dome, the load-bearing structure, roof and shell can be implemented in parallel.

3D printing work has recently been completed. They built a small house with several 3D printers that worked simultaneously. Since the structure consists of an outer and an inner dome, the load-bearing structure, roof and shell can be implemented in parallel.

According to a joint media announcement between the company and the architects, Wasp 3D printers can move over an area of 50 meters. Therefore, it was possible to print structures in any form within a few days.

If everything goes according to plan, the cottage will be completed this spring

3D printing: build an eco-house like a potter's wasp

It looks like a sea urchin shell. But in fact, another animal provided the template for Tecla, an eco-house that can be built with 3D printing: its design is centered on the nest of a pottery wasp that places its eggs in a globular clay house, which they place on branches or walls erected .

Pottery wasp nest.

Tecla, Rendering

Bird's eye view of completed buildings.

Tecla under construction

The outer and inner domes were built at the same time.

The project is a collaboration between Italian 3D printing company Wasp and Mario Cucinella Architects.

As for the tiny wasps, 3D printing at home also uses fabric from its immediate environment: the earth. As such, according to its creators, it is "composed entirely of reusable and recyclable materials". They were carbon neutral, adapted to any climate and any location setting. In addition, the house is designed in such a way that it can stand on its own or be combined into larger formations depending on the needs.

One construction site, several 3D printers

Currently located in Massa Lombarda, near Ravenna, Tecla prototype is realized. 3D printing work has recently been completed. They built a small house with several 3D printers that worked simultaneously. Since the structure consists of an outer and an inner dome, the load-bearing structure, roof and shell can be implemented in parallel.

According to a joint media announcement between the company and the architects, Wasp 3D printers can move over an area of 50 meters. Therefore, it was possible to print structures in any form within a few days.

If everything goes according to plan, the cottage will be completed this spring3D printing: build an eco-house like a potter's wasp

Teaserbild-Quelle: Mario Cucinell Architects / WASP

It looks like a sea urchin shell. But in fact, another animal provided the template for Tecla, an eco-house that can be built with 3D printing: its design is centered on the nest of a pottery wasp that places its eggs in a globular clay house, which they place on branches or walls erected .

Pottery wasp nest.

Tecla, Rendering

Bird's eye view of completed buildings.

Tecla under construction

The outer and inner domes were built at the same time.

The project is a collaboration between Italian 3D printing company Wasp and Mario Cucinella Architects.

As for the tiny wasps, 3D printing at home also uses fabric from its immediate environment: the earth. As such, according to its creators, it is "composed entirely of reusable and recyclable materials". They were carbon neutral, adapted to any climate and any location setting. In addition, the house is designed in such a way that it can stand on its own or be combined into larger formations depending on the needs.

One construction site, several 3D printers

Currently located in Massa Lombarda, near Ravenna, Tecla prototype is realized. 3D printing work has recently been completed. They built a small house with several 3D printers that worked simultaneously. Since the structure consists of an outer and an inner dome, the load-bearing structure, roof and shell can be implemented in parallel.

According to a joint media announcement between the company and the architects, Wasp 3D printers can move over an area of 50 meters. Therefore, it was possible to print structures in any form within a few days.

If everything goes according to plan, the cottage will be completed this spring

3D printer for building a house

Today, 3D printers can print both residential and non-residential buildings. We are talking not only about miniature summer houses, but also about multi-storey structures suitable for year-round use. They are made on the basis of concrete, therefore, in terms of their technical characteristics, they are almost identical to standard housing. With the help of 3D, you can create buildings of unusual shape and configuration, bring to life the most avant-garde design solutions. It is much easier and cheaper than trying to implement the same idea using traditional building technology.

The main prospects for 3D printing in construction are twofold. The first is the economically rational creation of unique buildings according to author's projects. The second is to provide the poor with durable, environmentally friendly, comfortable housing with minimal financial investment. Unfortunately, the development of both of these areas today is hindered by the lack of a legislative framework for 3D construction. In the absence of uniform standards and regulations for the entire industry, this technology cannot become truly mass-produced. This article will give an overview of already implemented 3D construction projects, describe the nuances of building mixtures and printers, and list the objective pros and cons of this technology.

Unfortunately, the development of both of these areas today is hindered by the lack of a legislative framework for 3D construction. In the absence of uniform standards and regulations for the entire industry, this technology cannot become truly mass-produced. This article will give an overview of already implemented 3D construction projects, describe the nuances of building mixtures and printers, and list the objective pros and cons of this technology.

Construction 3D printer technologies

Construction 3D printers are equipped with extruders, from which concrete is extruded and laid in layers, forming the outer and inner walls of the future building. The drawing of the building is preliminarily developed as a three-dimensional model in a CAD computer program. To give concrete the necessary liquid consistency, it is mixed with water and additives. The resulting mixture is fed under pressure into a hose connected to the printer head. From the head, the material flows to the previous printed layers or directly to the construction site.

When compared with ordinary building concrete, the material for 3D construction will most closely resemble the M50 grade in terms of its characteristics. To give it additional strength, the walls of the building are reinforced. For this purpose, fiber is added to the solution or fiberglass reinforcement is laid in the walls.

WARNING : Finished building walls will not be perfectly smooth. Living builders will have to level them, plaster, and perform cladding.

3D printing is not very suitable for creating long structures. In the absence of legislation that would regulate its use for continuous development, this technology will be used primarily to create:

- gazebos;

- landscape buildings;

- flowerbeds and benches;

- small bridges;

- country houses;

- children's towns;

- garages;

- buildings for economic purposes.

This level of medium and small 3D businesses, but not large urban developers.

CAUTION : The 3D building site must be perfectly level. This is required both for laying the guide rails and for ensuring their subsequent parallelism.

Types of construction 3D printers

XYZ printers

Such devices are also known as portal devices. These are frames in which the print head moves along the XY axes. To hang the head from the frame, portals are used (usually there are three of them). High-precision stepper motors are used to move portals.

Use XYZ printers in three ways:

- If the building is compact, it can be printed entirely.

- If the building is large, the printer will be placed in the workshop and will print the components of the building individually.

- If you place the printer inside a building you are building, it will be able to print the interior walls for it.

Delta

Delta printers can create more sophisticated objects than XYZ devices. They are not tied to 3D guides. Their printheads hang on thin arms attached to vertical rails.

They are not tied to 3D guides. Their printheads hang on thin arms attached to vertical rails.

Robots

Printers of this variety are industrial type robotic arms. They are equipped with extruders, controlled by a computer.

D-Shape

D-Shape devices are separated into a separate category for an objective reason: their filament is not a solution, but a dry powder material. The filament is laid in layers with the desired thickness and compacted, then it is impregnated with a binder substance from the printer nozzle. Then, excess raw materials are removed from the finished element.

Building mixtures

3D printing in construction is based on concrete. Difficulties can arise when the material passes through the extruder, so the consistency of the concrete must be such that it does not spread and lays down in uniform layers. The material must set quickly in order to retain its shape - however, if the process is carried out at too high a speed, the superimposed layers will lose their chemical activity and will not form a single structure at the point of contact. Also, if the concrete sets too quickly, it will clog the nozzle and damage the printer. The strength of concrete is increased by adding plasticizers. Thanks to them, the mixture becomes more mobile, the water-cement ratio decreases.

Also, if the concrete sets too quickly, it will clog the nozzle and damage the printer. The strength of concrete is increased by adding plasticizers. Thanks to them, the mixture becomes more mobile, the water-cement ratio decreases.

WARNING : The concrete used for 3D printing is not the same as for traditional construction. In 3D, fine-grained mixtures are needed, which each company produces according to its own recipe. When compiling the recipe, the specifics of the target objects are taken into account, as well as the nuances of the design of the printer and its nozzle.

Examples of houses printed on a 3D construction printer

Houses printed using 3D technology have already been built in many countries of the world: Russia, China, USA, UAE. Here are some of the most striking examples of this.

AMT "Spetsavia"

This Yaroslavl enterprise first specialized in the production of CNC machines, and now has shifted to the development of construction 3D printers. The hallmark of this company was the building for the guards of the Yekaterinburg cement plant, stylized as the Winterfell castle from the Game of Thrones. The first property with an area of 165 sq. m AMT was printed in 2015: part of the structure was created on the site, and part was delivered from the factory in a disassembled state.

The hallmark of this company was the building for the guards of the Yekaterinburg cement plant, stylized as the Winterfell castle from the Game of Thrones. The first property with an area of 165 sq. m AMT was printed in 2015: part of the structure was created on the site, and part was delivered from the factory in a disassembled state.

Apis Cor

Irkutsk company Apis Cor uses a curious technology: the print head is placed on a telescopic rod, which is adjustable in height and placed on a turntable. Such an installation prints walls around itself from a gypsum mixture. Once completed, the printer can easily be transported to a new construction site using a conventional crane. In 2019, the company built a 640 sq. m, which required 500 hours of printer operation. In Stupino, a similar building was erected for demonstration purposes, not for living.

Winsun

Winsun has been on the market since 2003 and has registered 225 national patents. Its pragmatic goal is to provide affordable housing for the poor, cut construction costs in half, and use sustainable materials to ensure that Chinese cities do not have a haze of smog.

Its pragmatic goal is to provide affordable housing for the poor, cut construction costs in half, and use sustainable materials to ensure that Chinese cities do not have a haze of smog.

In 2014, Winsun made an ambitious announcement that they were ready to print 10 residential buildings in 10 days. As a result, they really built 10 houses with an area of 200 square meters. m and costing only $4,800 each. The configuration of the houses was the most primitive, but they could be inhabited.

In 2015, Winsun Suzhou Industrial Park realized more complex 3D projects: a cozy mansion with an area of 1,100 square meters. m and a five-story residential building. The dimensions of the printer used for these works were 6 × 10 × 40 m. The blocks were printed separately and then assembled into a single structure. For the production of the building mixture, construction and industrial waste, fiberglass, sand, cement and a specialized hardener were used. Both building materials and time were required 3 times less than for the construction of buildings using traditional technology, and the composition of the construction team decreased by 5 times.

CyBe Construction

In 2019, this Dutch company was approached by clients from the UAE. They would like 25% of all new buildings in Dubai to be 3D by 2025. The world's first 3D office building is located in Dubai. CyBe Construction was invited to showcase its capabilities at SRTI Park, a research center specializing in water technology, renewable energy, environmental technology, digitalization, industrial design 4.0, mobility and smart cities. The CyBe Construction 3D Printer runs at speeds up to 600mm/s and creates all the supporting structures for a building in less than an hour. It can perform formwork, walls, sewer pits, floors.

D-Shape

As mentioned above, D-Shape printing technology is somewhat different from the rest. It uses the stereolithography method, and sand with an inorganic binder composition acts as a filament. In its appearance, such a material resembles marble, and in terms of strength and durability it surpasses both reinforced concrete and masonry. It only takes 24 hours for the mixture to dry completely. Already in 2012, the company announced its readiness to print two-story buildings with interior walls, stairs, pipelines, vaulted roofs, columns and other elements. The development priority of D-Shape is the creation of custom-shaped houses that are not afraid of hurricanes, earthquakes and other natural disasters.

It only takes 24 hours for the mixture to dry completely. Already in 2012, the company announced its readiness to print two-story buildings with interior walls, stairs, pipelines, vaulted roofs, columns and other elements. The development priority of D-Shape is the creation of custom-shaped houses that are not afraid of hurricanes, earthquakes and other natural disasters.

BatiPrint

At the 2017 Design Week in Nantes, France, BatiPrint printed a residential building called Yhnova House. This social project was developed by scientists from the University of Nantes. First, it was opened for viewing and visits, and then people settled in the house. The area of Yhnova House is 95 sq. m, it has 5 rooms. The building is energy efficient, so the bills for housing and communal services for its inhabitants are lower than for residents of ordinary houses. BatiPrint used a laser-guided robot arm to print. The construction process did not depend on the vagaries of the weather, for the construction it was not necessary to erect scaffolding. The creators of the project especially focused on the fact that there was much less waste and environmental damage from it than with traditional construction.

The creators of the project especially focused on the fact that there was much less waste and environmental damage from it than with traditional construction.

WASP

The Italians WASP, in collaboration with the architects Mario Cucinella Architects, have built unusual residential buildings in Bologna with an easily recognizable rounded shape. This project was named Tecla. For the construction of houses, they used recycled materials and an XYZ printer called Crane. Previously, the company printed a GAIA house, literally created from damp earth. Builders are guided by the principle of "zero kilometer" - it is important for them that building materials are of local origin, and they would not have to be transported from other regions or countries.

The very name of the WASP brand is translated as "wasp". His team draws inspiration from nature and strives primarily for sustainability and energy efficiency. The company sets as its task the construction of not individual buildings, but ecovillages designed to solve the problem of overpopulation of the planet and the shortage of traditional resources. The layout of such settlements is based on honeycombs. Despite the fact that the buildings from WASP look like summer houses, they are designed for year-round operation.

The layout of such settlements is based on honeycombs. Despite the fact that the buildings from WASP look like summer houses, they are designed for year-round operation.

Contour Crafting

The American company Contour Crafting holds over 100 patents and considers construction speed a top priority. She plans to spend less than a week building one house, and people can move in 2-5 days after construction is completed. The 3D printer from Contour Crafting weighs only 360kg and has a standard reach of 12m and is expandable. According to company representatives, their technology is more promising than that used in Winsun. The Chinese combine 3D technologies with a traditional approach, and Contour Crafting seeks to fully automate the process, thereby speeding up and reducing the cost as much as possible. The house does not have to be assembled in parts: the printer will build it in layers from cement right on the construction site.

Pros and cons

The pace of development of 3D technologies suggests that the shortcomings that builders have to put up with so far will be overcome in the very near future.

Pros

- Building with an original design is much easier and cheaper to print in 3D than to build using traditional technologies.

- 3D printing makes it possible to realize almost any fantasy of architects and designers.

- The printing process is fast and accurate. The printer unmistakably transfers all the details of the project into material reality. If something went wrong, it means that there was an error in the project or a low-quality filament was caught.

- The need for human labor is practically eliminated.

- Less debris and waste from construction. All components are printed exactly in the right quantity for a specific project. If some components for unforeseen reasons remain unused, they can be disposed of (that is, a new filament can be made from them).

- The construction process poses significantly fewer risks and threats to both people and the environment.

Cons

- Living builders, manufacturers of traditional building materials, construction equipment rental companies are out of work.

- Those living workers who will nevertheless be involved in the process will have to urgently acquire new skills and improve their qualifications.

- Many printers today can only print on one type of filament.

- The choice of building filaments is limited.

- Printers can be difficult to store and transport from one job site to another.

- The development of models for printing buildings can only be trusted by experts, who are still very few. Lack of knowledge or experience can lead to the collapse of the structure and other unpleasant consequences.

- Assembly of prefabricated components on site can in some cases be as time consuming as conventional construction.

- Modern legislation is not perfect enough to put 3D construction on stream.

3D technologies already make it possible to build comfortable residential buildings for year-round use. These can be both compact houses with a minimum area and cost, as well as spacious mansions and five-story apartment buildings.