Fast 3d print

7 Fastest 3D Printers 2022 In Every Price Range

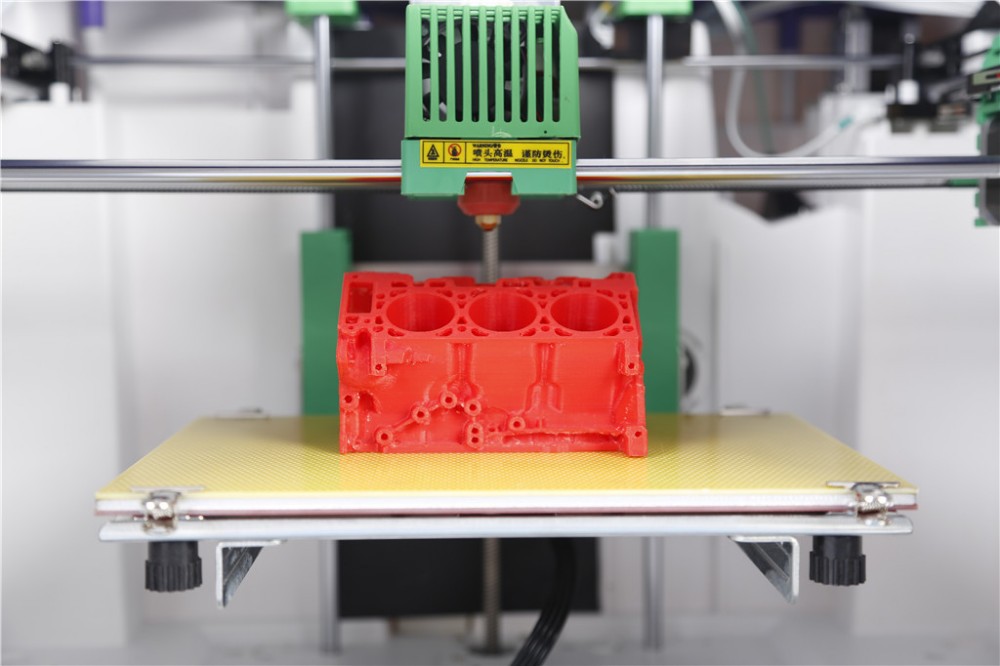

One of the major gripes with 3D printing is many consider it to be slow. However, over time both the speeds of FDM and resin printers have crept up — and there are now some super-fast options for both technologies.

For industrial printing, there are printers now reaching speeds competitive with traditional manufacturing, aiming to displace injection molding.

But what are the other fastest 3D printers in the world?

We have listed the world’s fastest 3D printers in every price range below, for both FDM and resin printers – but first, let’s explain the factors that affect the speed of 3D printing.

Do Bigger 3D Printers Print Faster?

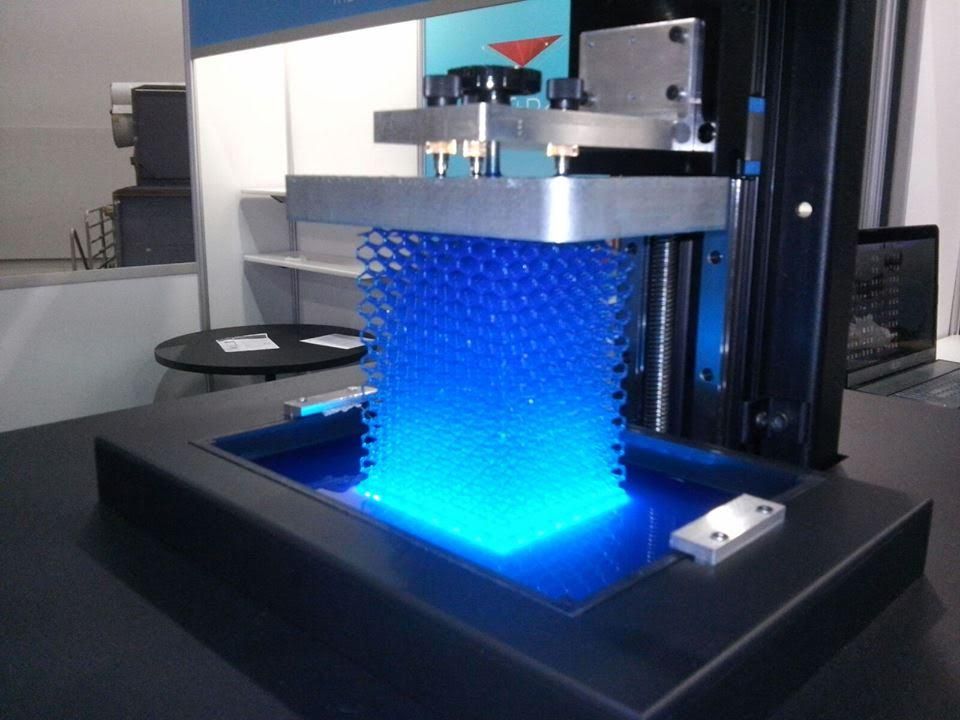

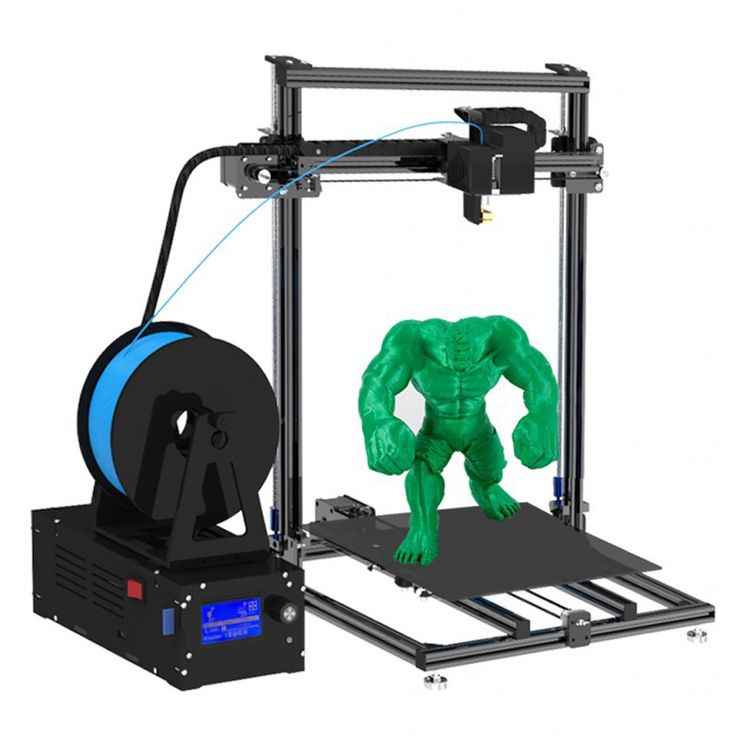

A bigger resin 3D printer does indeed print faster, but this is more in the sense of being more productive. A resin printer cures an entire layer on the XY axes, regardless of size, in one go. This means that the larger the printer, the more productive the printer is.

However, this isn’t the case for FDM printers, which need to deposit filament across the entire layer before moving on to the next.

FAST FDM PICK

Flsun Super Racer200mm/s makes it one of the fastest FDM printers around

Comes 95% pre-assembled

Available at Amazon here

FAST RESIN PICK

Anycubic Photon M3 PlusSuper-fast 100mm/h speed

Larger resin build area for scalable minis prints or larger resin models

Available at Anycubic here Amazon here

SUPER-FAST PICK

Phrozen Sonic Mega 8KExtremely high-res 8K LCD screen

Enormous build area and 70mm/h speed

Available At Phrozen here Amazon here

How Fast is a 3D Printer?

As for the technologies and 3D printers we have now, simply stating the fastest possible 3D printing speeds is difficult.

That’s because – and I know it’s frustrating to read this – it depends on several factors:

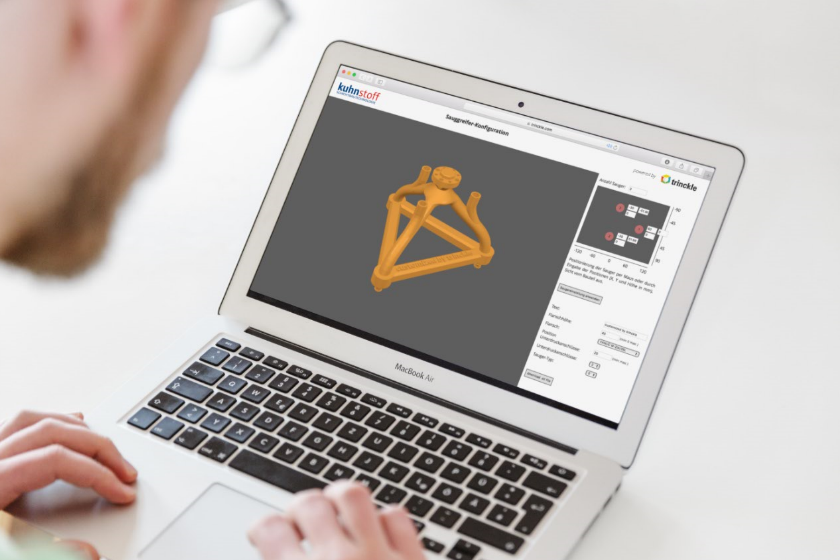

Resolution of the 3D printed part: before you start printing, you need to slice your model into layers on a 3D slicer. The more layers, and the thinner each layer, the longer the part will take to print at the same speed. A part printed with 50-micron layers will have twice as many layers as the same part printed with 100-micron layers, and take twice as long at the same speed.

- We also have a guide to high resolution 3D printers.

Quality of print: theoretically you could run a budget 3D printer at an extremely high speed, and it would still print. But the results wouldn’t be anything like how it looked on your slicer. It would be a mess of filament hairs and blobs, because the speed settings were set too fast. Some 3D printers can handle high-speed 3D printing, some cannot.

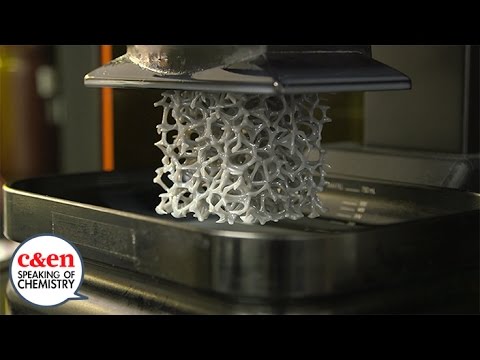

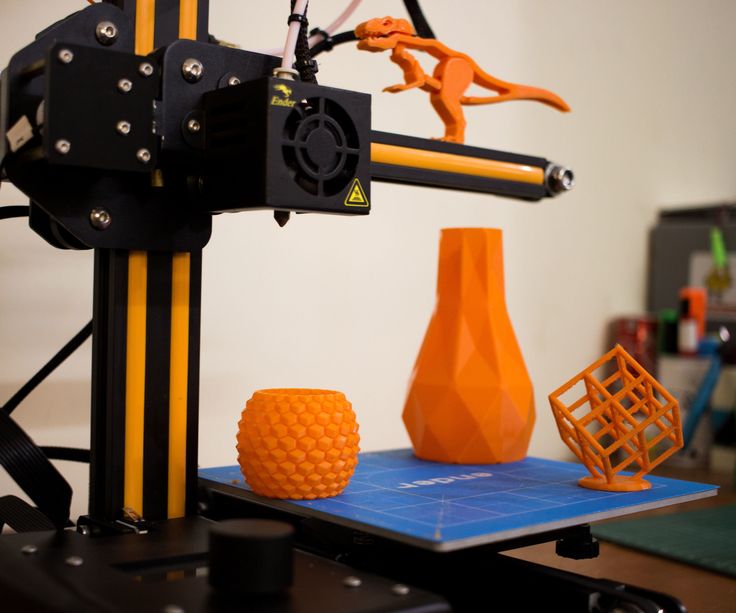

3D printing technology: how fast a 3D printer prints depends on the technology. Resin 3D printers are significantly faster than FDM 3D printers as they can cure entire layers at once, rather than depositing filament over each part of the layer. The fastest 3D printing technologies include Multi Jet Fusion and resin 3D printing technologies like MSLA.Resin 3D printing technologies are known for being faster than FDM.

Resin 3D printers are significantly faster than FDM 3D printers as they can cure entire layers at once, rather than depositing filament over each part of the layer. The fastest 3D printing technologies include Multi Jet Fusion and resin 3D printing technologies like MSLA.Resin 3D printing technologies are known for being faster than FDM.

Material: some materials are easier to print than others, putting less demand on the printer and leading to a slightly faster print.

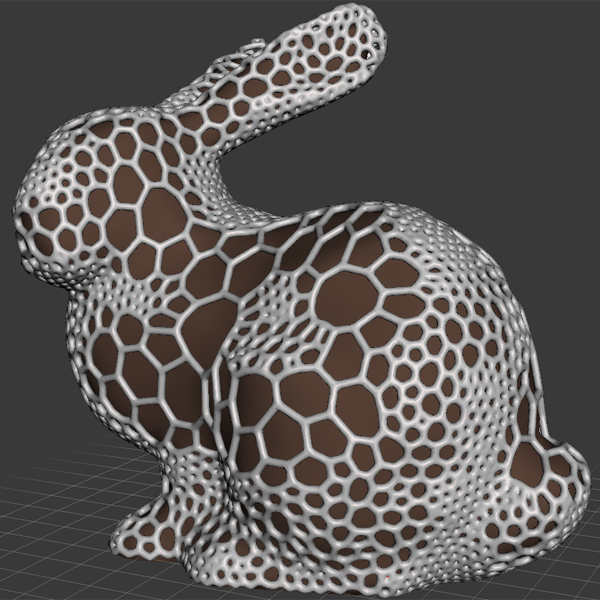

Complexity of the model: You will be able to print a cube block far quicker than an intricate 3D printed jewelry piece. This is because you can print larger layers and at a faster print speed without a notable loss of quality, since the cube is a very simple shape with no details.

Size of print: fairly obvious, but a larger print will take far longer than a small one. A full-size vase will take around 12 hours to print in normal detail on most FDM 3D printers, but a small statue may take under an hour.

Nozzle size: for FDM 3D printing, smaller nozzles mean more intricate details can be printed more accurately, but larger nozzles can potentially print faster.

Will 3D printers get faster?

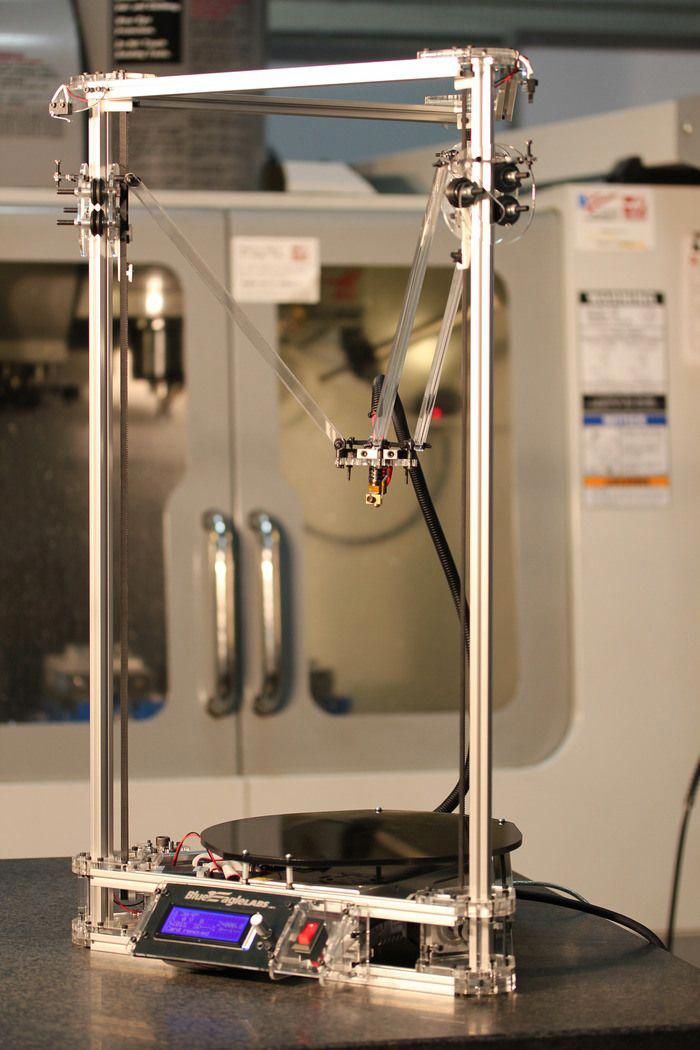

Almost certainly. We’ve already seen a number of major innovations that make 3D printers faster in the last decade. In 2012, the first delta 3D printers started to appear, which print significantly faster than previous Cartesian 3D printers.

Then, new resin 3D printer innovations such as Carbon 3D’s CLIP, and Uniz’s UDP technologies made SLA and DLP faster. Other significant speed innovations include HP’s Multi Jet Fusion technology, and also the huge advances being made in many metal 3D printers such as those by Desktop Metal and Markforged.

The Fastest 3D printers 2022 in Every Price Range

| Name and brand | Build volume (mm) | Max speed | Price | Where to buy |

|---|---|---|---|---|

| Flsun Super Racer | 260 x 260 x 330 | 200mm/s | $499 | Amazon here |

| Anycubic Photon M3 Plus | 197 x 122 x 245 | 100mm/h | $699 | Anycubic here |

| Anycubic Photon M3 Max | 298 x 164 x 300 | 60mm/h | $1099 | Anycubic here |

| Phrozen Sonic Mega 8K | 330 x 185 x 400 | 70mm/h | $2199 | Phrozen here |

| Uniz Slash UDP | 293 x 122 x 200 | 600mm/h | $1,999 | Matterhackers here |

| WASP 2040 Pro Turbo | 200 x 200 x 400 | 500mm/s | $3,400 | Amazon here |

| HP Jet Fusion 5200 | 380 x 284 x 380 | 4115cm3/h | Quote |

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

When you buy through links on our site, we may earn an affiliate commission. Learn more

Flsun Super Racer – Fastest FDM 3D Printer Under $500

- Price — Check latest price at Amazon here

- Technology: FDM Delta

- Max Print Speed: 200 mm/h

- Build Volume: 260 x 260 x 330 mm

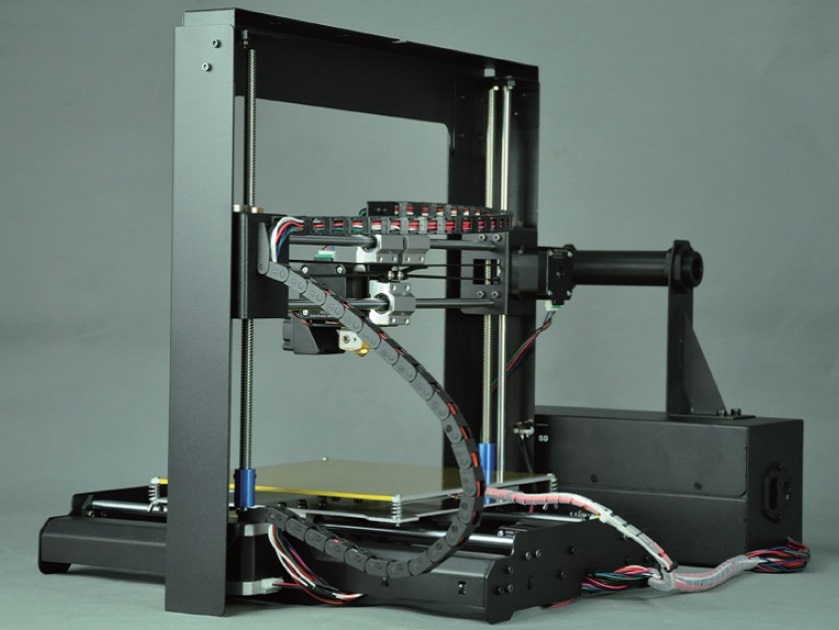

True to its speedy name, the Flsun Super Racer is a Delta FDM printer that absolutely gallops with a top print speed of 200 mm/h. It’s an upgraded version of Flsun’s QQ-S, which after some one-on-one time we found to be a competent, worthwhile printer for large projects.

Delta printers are known for offering higher speeds than their Cartesian brothers, but Flsun is pushing the boat out to new extremes with the Super Racer. Most standard FDM printers perform best at a comfortable 50-60 mm/h, while the Super Racer delivers solid quality prints at four times that.

With a decently-sized 260 x 260 x 330 mm build volume, the Super Racer is also big on vertical print capacity, ideal for those towering prints that exceed the dimensions of budget FDM printers. Throw in a thoughtful design, quality components, automatic bed leveling, breezy 20-minute assembly, a responsive, easy-to-navigate detachable touch screen, and the Super Racer comes awfully close to a speed freak’s dream 3D printer.

Throw in a thoughtful design, quality components, automatic bed leveling, breezy 20-minute assembly, a responsive, easy-to-navigate detachable touch screen, and the Super Racer comes awfully close to a speed freak’s dream 3D printer.

Now, all this speed does come with a trade-off. Delta printers, the Flsun Super Racer included, lack the accuracy and consistent print quality offered by Cartesian 3D printers. The difference is relatively negligible, but it’s a point to consider before buying for makers that favor quality over speed.

On the filament front, the Flsun Super Racer’s Bowden extruder setup works great for PLA but coughs up the usual Bowden-related jamming and clogging issues with flexibles. For example, if you’re working with TPU, you’re better off sticking to a classic Cartesian printer – ideally with a direct drive extruder.

Anycubic Photon M3 Plus/Max – Fastest Resin 3D Printers Under $1,000

- Price: $699 / $1,099 — M3 Plus Available here / M3 Max Available here

- Technology: MSLA Resin

- Max Print Speed: 100 mm/h / 60 mm/h

- Build Volume: 197 x 122 x 245 mm / 298 x 164 x 300 mm

More than simply an update to the long-running Photon series, the Anycubic Photon M3 machines are turning more than a few heads as the fastest resin 3D printer range around.

In particular, the Anycubic Photon M3 Plus proposes a top print speed of 100 mm/h. The beauty of resin printers is that they cure in layers, regardless of how much space on the build plate that layer takes. Those 100 mm/h apply whether you’re printing a single small miniature or a batch of twelve, which makes the Anycubic Photon M3 Plus exponentially more productive.

The Anycubic Photon M3 Max is no slouch either, offering a respectable 60 mm/h, but does this across a massive 298 x 164 x 300 mm. That’s the largest of any Anycubic resin printer and among the highest capacities found on consumer-grade printers, rubbing shoulders with the hulking Elegoo Jupiter and Phrozen Sonic Mega 8K.

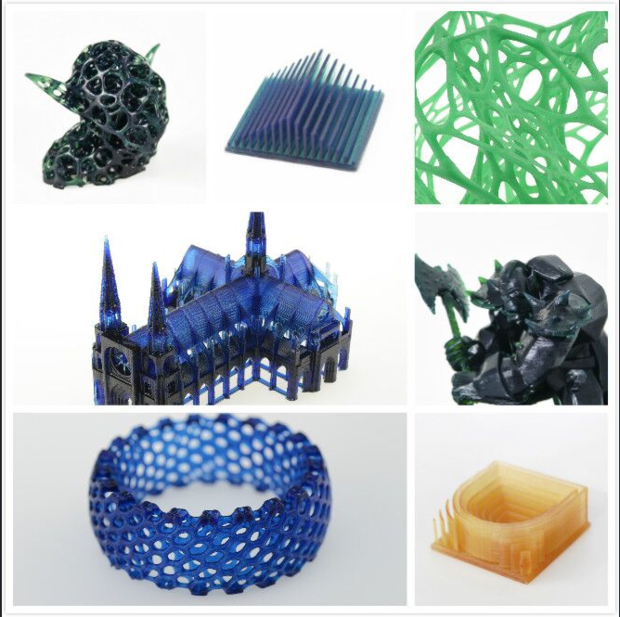

Elsewhere, the Photon M3 duo stands out for offering excellent detail with 34 microns XY resolution on the Plus and 46 microns on the Max. The Max has a 7K LCD, one of the highest pixel counts on the market, while the Plus pushes a 6K LCD – higher than the standard 4K found on comparable printers. Both machines also ship with Anycubic excellent textured checkerboard build plate, which offers superb print adhesion.

Both machines also ship with Anycubic excellent textured checkerboard build plate, which offers superb print adhesion.

Read the full comparison: Anycubic Photon M3 vs M3 Plus vs M3 Max

Phrozen Sonic Mega 8K – Fastest High-Quality Resin 3D Printer

- Price: $2,199 — Available at Phrozen official here

- Technology: MSLA Resin

- Max Print Speed: 70 mm/h

- Build Volume: 330 x 185 x 400 mm

With the Phrozen Sonic Mega 8K, size and speed combine into arguably one of the most impressive mid-range professional resin printers on the market.

The 330 x 185 x 400 mm build volume is the largest available in this price range, and the Sonic Mega 8K darts across this printing expanse at a nippy 70 mm/h. No other printers manage to weave in such a large build volume with such high speeds; it’s always been one or the other.

The Phrozen Sonic Mega 8K allows makers to hone in on all the fine features and intricacies of even the most detailed models and minis thanks to a 43-micron resolution, propped up by a pixel-rich 15’’ 8K LCD. It’s a level of quality that simply isn’t currently available on any other printer in the same printer segment.

It’s a level of quality that simply isn’t currently available on any other printer in the same printer segment.

The build plate comes pre-calibrated, allowing you to print without delay once the Mega 8K lands on your doorstep. A clever dual linear rail design ensures the printer behaves and delivers those sharp details even high up into the upper reaches of the build area.

If you need a mammoth-format printer at a reasonable price to power a small business where time is of the essence, there’s little else out there that comes close to the Phrozen Sonic Mega 8K. If the build volume exceeds what you’ll conceivably ever need, a lower-cost resin printer such as the Anycubic Photon M3 Plus or even the standard M3 is likely a better use of your money. The Phrozen Sonic Mega 8K is a jumbo printer and will be far too much for most amateur makers.

Uniz Slash Plus UDP — Fastest desktop 3D printer

- Max print volume: 293 x 122 x 200 mm

- Price: $1,999 — Available on Matterhackers here

- Fastest 3D printer speed: 600mm/hour in UDP mode

Uniz have made a big impact since their original Kickstarter campaign that raised over $500,000 to produce super-fast resin 3D printers at consumer prices. This quick 3D printer uses Uniz’s Uni-Directional Peel (UDP) technology to print far faster than its competitors, at up to 600mm/hour when in UDP mode.

This quick 3D printer uses Uniz’s Uni-Directional Peel (UDP) technology to print far faster than its competitors, at up to 600mm/hour when in UDP mode.

When not in UDP mode the maximum 3D printer speed is 200mm/hour, but this is still super fast. This is because not all parts are compatible, for example, any parts with cross sections, or fully enclosed parts cannot be printed in UDP mode; and no parts with solid infill can be printed either. You are also restricted as very tall prints cannot be printed in UDP mode, but if your part qualifies then you can print extremely quickly!

Not only is it an extremely fast 3D printer, but it’s also accurate. This SLA 3D printer has an XY resolution of 75 microns, and a minimum layer of thickness of just 10 microns. As a result, parts have very good surface finish and look almost like they have no layers at all. The printer can also calibrate itself, can be operated via your phone or table on the mobile app, and weighs just 12kg. It’s certainly one of the best speedy 3D printers for the price.

WASP 2040 PRO Turbo — Fastest 3D printer in the world

- Price: $3,400 — Available on Amazon here

- Max print volume: 200 x 200 x 400 mm

- Fastest 3D printer speed: 500mm/s recommend (some say it can print even faster!)

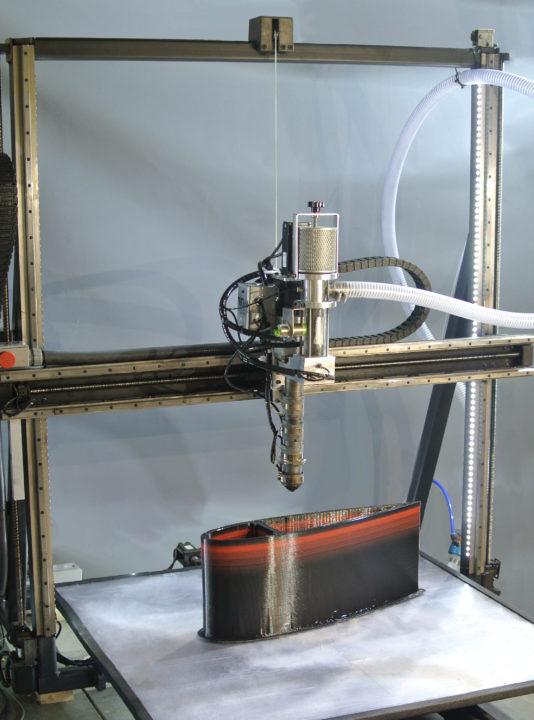

Delta 3D printers are known for their speed, and are the fastest FDM 3D printers in the world. The WASP 2040 PRO Turbo is a delta printer that is not only incredibly fast – at up to a recommend 500mm/s – but is also extremely accurate for an FDM printer. The resolution of up to 50 microns means very accurate and low cost prototypes and parts can be produced, and in record time. WASP claim they make the fastest 3D printers in the world for FDM.

WASP 3D printers are known for their reliability, with the Italian company ensuring the printers operate with workhorse-like consistency. It can print 3D printer filaments including ABS, PLA, PETG and Nylon, so if you want to print stronger parts from one of the tougher plastics you still can, and you can use third party filaments if you prefer – the WASP allows for these. and you can choose to buy the WASP 2040 as either a single or dual extruder 3D printer.

and you can choose to buy the WASP 2040 as either a single or dual extruder 3D printer.

Unlike most RepRap 3D printer deltas, the WASP 2040 Turbo comes fully assembled, so those who aren’t masters of DIY do not need to worry. You can also choose to order it either as a single or dual extruder 3D printer based on your printing needs.

It’s the world’s fastest 3D printer for FDM, and also accurate and reliable – what more could you want for under $5,000!

- It also has a variation designed specifically as a clay 3D printer.

HP 3D Jet Fusion 5200 — Fastest Industrial 3D printer

- Price: Requires a quote

- Max print volume: 380 x 284 x 380 mm

- Fastest 3D printer speed: 4115cm3/hour

HP have only been actively involved in the 3D printing industry for the last few years, but have brought such technological advantages in that short space of time. The Jet Fusion 5200 epitomizes this, marking uncharted territory for 3D printing where it is now considered viable for mid-range production.

Multi Jet Fusion has always been known for its fast 3D printing speed, but the Jet Fusion is even faster than its predecessors. With speeds up to 4115cm3/hour, it’s faster than the Jet Fusion 4200 (4000cm3) and the 3200 (2800cm3) – and these were already some of the fastest 3D printers in the world. The high-quality 1200dpi print head resolution allows for extremely accurate parts with smooth surface finishes and crisp, sharp edges.

The Jet Fusion 5200 combines this astonishing speed with low part cost and scalability. Whole layers can be printed at once, rather than tracing each layer as with Selective Laser Sintering, meaning multiple parts can be printed at once without a drop off in productivity. Multi Jet Fusion isn’t known for its versatility of materials, but PA12, PA11 Nylons and TPU are strong materials with good properties for a variety of industries. It’s extremely fast, extraordinarily accurate, and a rare example of 3D printers being competitive in mid-volume part production – very exciting.

Do you really need a fast 3D printer?

Speed is always useful; nobody chooses to wait in a queue longer than they need to. However, with the quickest 3D printers, there are some cases where you can’t take advantage of this speed.

For FDM 3D printers, some materials become volatile and print with imperfections if you don’t slow right down, like PEEK, PC, and others. Printing at 150mm/s+ would just ruin your prints, so the speed is useless here.

Also, if you are printing a very simple object like a cube, speed becomes less useful as you can just use very large layer heights and print quickly anyway.

However, if your business depends on quick production, then absolutely go for a printer that can either print objects very quickly, or multiple objects simultaneously. The ability to rapidly prototype new designs and innovate quicker is invaluable, and other industries like 3D printed jewelry production or hearing aids need to be able to print custom designs at the highest speeds possible.

So, it depends. For hobbyists, speed is great for quality of life and printing all the cool things and useful 3D prints you can. For industry it can be more necessary, and businesses often opt for an industrial 3D printer than can meet their production speed requirements.

How Fast Can PLA Be 3D Printed?

The fastest FDM printers, such as the Flsun Super Racer, can print PLA up to 200 mm/h. However, the most common 3D printers, such as the Ender 3, can print PLA at around 50 to 80 mm/h without sacrificing print quality.

Related articles:

- Best large resin 3D printers (bigger = faster!)

- Best delta FDM 3D printers

- Best FDM 3D printers

How to 3D print faster

Arun Chapman22 July 2022

Guide

When 3D printing, there may be times that you want to speed up your printing experience. Maybe you need to save time, increase productivity – or just don’t want to wait any longer than necessary for a print to finish.

Luckily, there are a number of hardware and software adjustments you can make that will reduce your print time without risking print success. In this blog, we’ll take a look at some of them.

Choosing the fastest nozzle for 3D printing

To start 3D printing faster, it helps to have a look at the nozzle on your 3D printer. The larger the nozzle, the lower the print time, as more material can be extruded through it at once. Smaller nozzles, meanwhile, can print with higher degrees of precision. This means that a 0.8mm nozzle, for example, will be capable of higher print speeds than 0.25mm nozzles.

Striking a balance between precision and speed is the 0.4mm nozzle, which is often seen as the 3D printing “standard.” Different prints, however, have different needs, so you’ll need to ensure that you pick the nozzle that best meets your requirements before starting your project.

Slicer settings that speed up your 3D printing

There are several software settings within your slicer that you can fine-tune to increase your printing speed. The following settings can be adjusted in most types of slicing software, including Ultimaker Cura:

The following settings can be adjusted in most types of slicing software, including Ultimaker Cura:

Print speed

Print speed defines the speed (in mm/s) at which the print head moves while printing. Adjusting the print speed in your slicer software’s settings will enable you to print faster, although increasing your print speed without making other adjustments will likely result in a worse quality print, depending on the part you are creating. How high you can push this setting will depend on your printer, and how much time you are able to spend tweaking other settings for optimal results.

Acceleration and jerk

Acceleration and jerk settings refer to the speed at which your print head moves from a still position – as well as how much it will slow down before changing direction. A higher jerk value will result in faster print speeds but are also harder on your hardware, which can result in lower print quality. Increasing your acceleration setting too high will often result in ringing in your final print.

Layer height

Layer height is one of the easiest and most impactful settings to change. Thinner layer heights result in prints with higher levels of detail and overall quality, as well as smoother surfaces. If you’re looking for faster print speeds, however, you should print with higher layer heights, which means thicker layers and substantially reduced overall print time. At the cost of reduced detail.

How to print less to print faster

Adjusting your 3D printer so that it uses less material during a print has two major benefits. For one, you’ll save 3D printing filament. Second, you’ll print faster. Here are a few ways to do so:

Choose the right infill pattern

In Ultimaker Cura, you can adjust the infill pattern of your print. The infill pattern refers to the pattern of the interior of a 3D print. Different patterns will provide prints with different qualities, such as prints that are stronger. They also affect print speed. The Lines infill pattern in Ultimaker Cura, for example, prints with less overall material and is designed to print faster. Additionally, the Lightning infill pattern, introduced in Ultimaker Cura 4.2, generates an internal structure that is specifically formed to support the parts of the object that are harder to print. Little or no support is given in areas where a successful print can be completed without it. The result is faster prints that use much less material.

Additionally, the Lightning infill pattern, introduced in Ultimaker Cura 4.2, generates an internal structure that is specifically formed to support the parts of the object that are harder to print. Little or no support is given in areas where a successful print can be completed without it. The result is faster prints that use much less material.

Adjust infill density

As well as infill type, you can also adjust the fill density. This defines the density of the infill pattern, which, as a result, increases or decreases the amount of plastic inside your print. An infill density of around 20% is often sufficient for visual models that don’t need much functional strength. It is possible to go lower but the chance of a failed print is much higher below 10-15%. Higher densities are typically only needed for end-use parts. Whatever your needs, remember that the lower the infill density, the less material is used – and the faster the print.

Print less support

For certain prints, such as those with complex geometries, you will need to print with support material. However, this will increase print times, as more material will need to be extruded. Using, or creating, designs that use less support material will result in faster print times. Tree supports are one way you can accomplish this.

However, this will increase print times, as more material will need to be extruded. Using, or creating, designs that use less support material will result in faster print times. Tree supports are one way you can accomplish this.

Tree supports, which are an option available in Ultimaker Cura, are generated around a print to help support areas that would be unsuccessful without them. Tree supports wrap around a print, rather than directly below areas that need to be supported, and are thicker near the bottom and thinner as they rise. They also branch off at an angle with only a thin tip of each branch touching the areas that need support. The result resembles the branches of a tree – hence, “tree support – and, in addition to being easier to remove and leaving less scarring, they use less material, meaning your print will be finished more quickly.

It’s also worth mentioning that you can reduce how many supports are needed by orienting your model optimally inside the slicer. In Ultimaker Cura, you can use the preview mode after slicing to see how much support material will be printed. Try changing the orientation of your print to see how it affects the amount of supports used.

Try changing the orientation of your print to see how it affects the amount of supports used.

How to design for faster printing

When creating your own 3D prints, you can take certain steps to make designs that enable your 3D printer to print faster.

Orientation

In 3D printing, orientation refers to how your model is positioned in relation to the build plate. 3D printers print faster on the X and Y axes. This means that keeping the Z-axis height to a minimum will enable your 3D printer to print much faster.

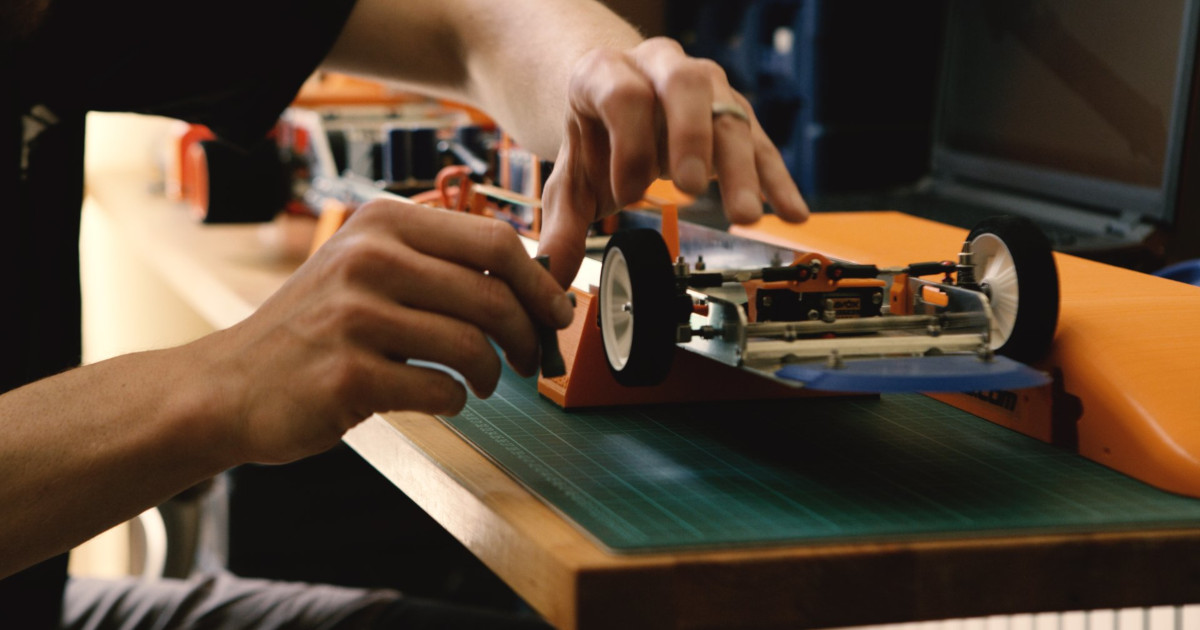

Sub-assemblies

Parts with complex geometries often require supports in order to be printed successfully. Printing supports can add a lot to your overall print time. One way to avoid this is to cut the 3D model for your print into multiple parts which can be printed flat on the build plate in such a way that supports are no longer necessary. Doing this can reduce your print times significantly but it will add extra time post-print as you will have to assemble the resulting pieces together again after printing.

Teardrop holes

Creating parts with “teardrop holes” can help you print horizontal holes without the need for support material. Teardrop holes refer to holes that are teardrop-shaped, rather than round, avoiding large overhangs and considerably decreasing your print speed.

We hope you found the above tips helpful. Are you ready to start printing parts at super speed? Download the latest version of Ultimaker Cura for free. With it, you can enjoy all the features described in this blog, and more!

Download now

Is it possible to print 10 times faster on a 3D printer? Tips for increasing the speed of your 3D printer

3DPrintStory 3D printing process Is it possible to print 10 times faster on a 3D printer? Tips for Increasing 3D Printer Speed

From time to time, all 3D printing enthusiasts think about increasing the speed of a 3D printer and creating figures and models in a matter of hours, not days. Wouldn't it be great if you could 3D print 10 times faster than you can now? This article provides tips on how to increase the speed of your 3D printer without losing quality.

Wouldn't it be great if you could 3D print 10 times faster than you can now? This article provides tips on how to increase the speed of your 3D printer without losing quality.

Before we take a closer look at the secrets that will help you print faster and share ideas for fast 3D printing, it's worth a little imagination about the incredible future. Maybe one day you will buy an affordable and fast device that turns STL files into detailed figures and models from your favorite video games and movies in just a couple of hours or even faster... And this one will really happen. But! Now let's put aside the fantasies and return to the current reality. The reality is that the following tips will actually help you speed up your 3D printing, so let's get started.

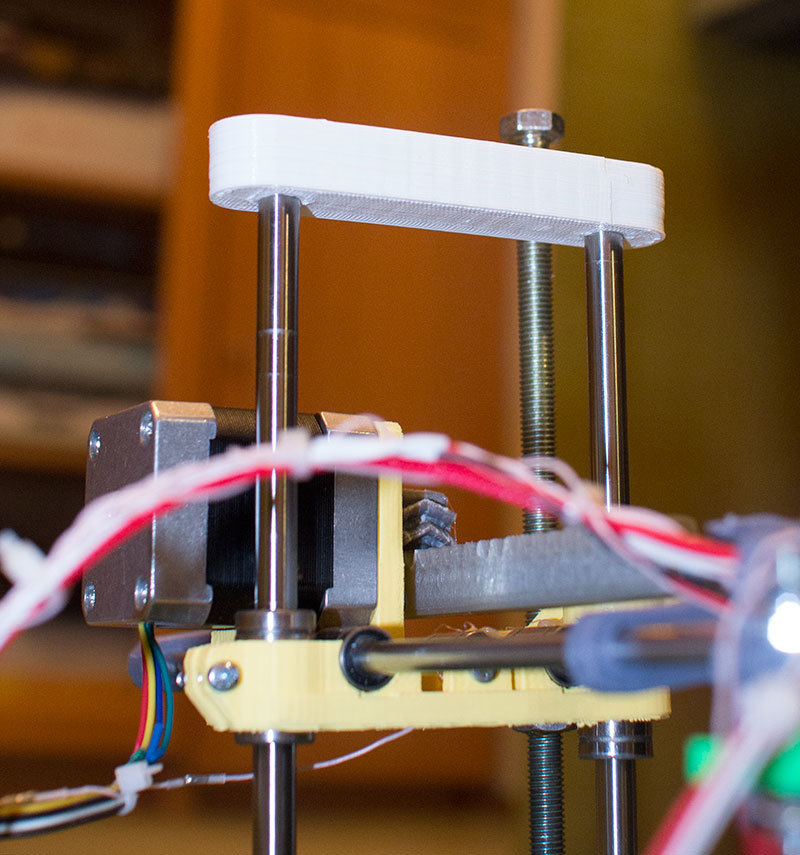

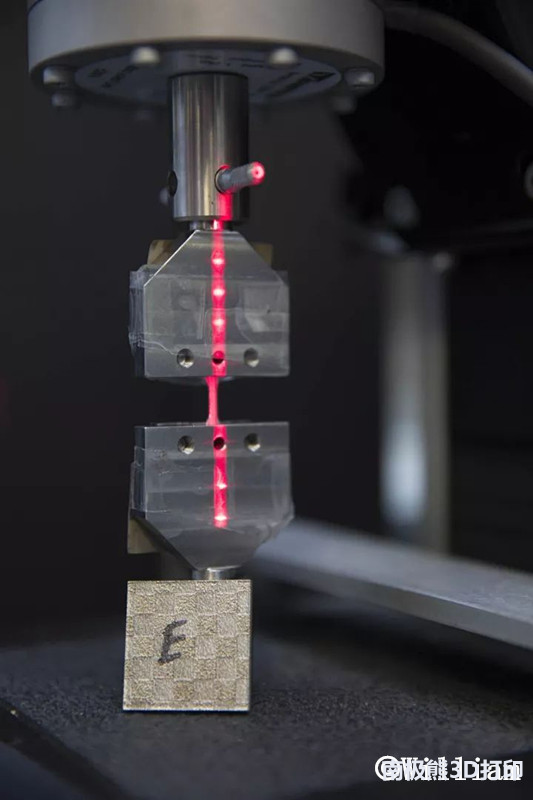

There are great guys - John Hart and Jamison Goh from MIT - the real geniuses of modernizing technology. According to MIT news, these two professors, along with their colleagues, have been working to increase the speed of a 3D printer and have developed an innovative model called Fast FFF.

The name Fast FFF stands for "Production of Fast Fibers". This model is capable of stacking material 10 times faster than any existing desktop 3D printer. In addition, the print head with fantastic 3D printing speed can work with renewable materials.

As the engineers noted, in order to increase the speed of 3D printing, three main factors had to be taken into account:

- The force applied by the print head when pushing the 3D printing material through the nozzle;

- The time required to heat up the material so that it melts and can flow through the nozzle;

- Print head movement speed.

All these things have been improved in the Fast FFF prototype. As a result, it was possible to 3D print two simple eyeglass frames in less than 4 minutes and a complex bevel gear in about 10 minutes. These models were printed with a 0.2mm layer and proved to be strong and durable.

Fast FFF prototype 3D printer cost about $15,000. This is a good price compared to expensive commercial 3D printers that cost over $100,000 and are about three times slower. But if you compare the price with an affordable home 3D printer under $300 or $500, the Fast FFF is clearly too expensive, even though it can 3D print 10 times faster than a regular FDM 3D printer. And it's currently unclear if an affordable ultra-fast 3D printer for home use will hit the market...

This is a good price compared to expensive commercial 3D printers that cost over $100,000 and are about three times slower. But if you compare the price with an affordable home 3D printer under $300 or $500, the Fast FFF is clearly too expensive, even though it can 3D print 10 times faster than a regular FDM 3D printer. And it's currently unclear if an affordable ultra-fast 3D printer for home use will hit the market...

While you can't get your home 3D printer to 3D print 10 times faster than it is now, or beat the innovative Fast FFF machine, there are secrets :).

Most of the tips that can help improve your 3D printing speed can also affect the quality of your figurine or model. However, sometimes it's worth it.

Adjust 3D print speed

Settings is the first thing you can try if you want to increase your 3D print speed. Every hobbyist likes to work with certain slicing software. It is worth exploring all the possibilities and changing the settings to suit your needs.

The ability to control the speed of the print head is amazing. Sometimes this does not negatively affect the quality of a complex 3D printed model. And when you do something simple, you can significantly increase the speed without losing quality.

Replace nozzle

Sometimes you don't care about 3D printing accuracy. In this case, a larger nozzle may suffice. For example, you can change the nozzle on your 3D printer from 0.4mm to 0.8mm. Or you can choose even 1.0mm print head.

Much depends on your current nozzle size. Standard printheads are 0.2mm and 0.4mm. But choosing a larger size can save time and speed up 3D printing.

Increase layer height

If you increase the speed of the 3D printer by changing the nozzle to a larger diameter, you will also have to increase the layer height of the 3D print. The maximum height you can select is approximately 75% of the current nozzle diameter.

So if you change the nozzle from 0. 4 mm to 0.8 mm, you can increase the layer height to 0.6 mm. These settings will affect the quality of your 3D model and cause you to lose a lot of impressive detail because the layers will be thinner and the speed will be much faster. Keep this in mind when experimenting with nozzle size and layer height.

4 mm to 0.8 mm, you can increase the layer height to 0.6 mm. These settings will affect the quality of your 3D model and cause you to lose a lot of impressive detail because the layers will be thinner and the speed will be much faster. Keep this in mind when experimenting with nozzle size and layer height.

Reduce wall thickness of 3D models

100% infill models and figurines take longer to print, but are durable when finished. You've probably guessed how to make 3D print faster by playing with wall thickness and reducing infill. But in this case, you need to be careful, because the thin walls of the 3D model and less infill can lead to poor quality 3D printing.

If you have a resin based 3D printer, you can save resin and increase 3D printing speed by working with the appropriate DLP/SLA Eco version of STL files offered by Gambody - Premium 3D Printing. The Eco version ensures that your walls are thick enough to make your 3D model strong, detailed and of the highest quality.

Print two 3D models at the same time

Another way to speed up your 3D printer without sacrificing product quality is to work on two projects at the same time. This is only possible if both models or figurines are small and can fit on the same 3D printer table without interfering with each other.

This option can be set in the slicing software. Select centering and place both models for 3D printing on the work surface. The main disadvantage of this method is that both models will be printed from the same material, but the final print speed will be significantly increased.

Do not use supports

When a large amount of support material is needed to 3D print a complex model, printing time will increase. This way, whether you choose to do projects with fewer supports or learn how to 3D print without supports, you can speed up and print the prototypes and figures you need faster.

Change the infill pattern of a 3D model

If you don't want to adjust the infill density, but still want to improve 3D printing speed, try adjusting the infill pattern in the slicer settings. People work with different patterns, but the most popular version for speed optimization is "lines" or "straight lines".

People work with different patterns, but the most popular version for speed optimization is "lines" or "straight lines".

Filling in a line pattern is very simple. Your 3D printer will make fewer moves when creating a straight infill figurine and can reduce print time by up to 20%-25%. But the models will not be as durable as those with a triangular or mesh pattern.

Adjust the jerk and acceleration settings

After making changes to the slicing software in the hope of increasing the speed of 3D printing, you can also try changing the jerk settings. They are responsible for how fast the print head can move. Of course, the print head must move smoothly, because increasing the speed can negatively affect the quality of the 3D print and even lead to problems with the mechanical part of the 3D printer.

There are also acceleration settings that need to be adjusted. They control the speed at which the print head reaches its maximum speed. It's worth playing around with these settings to find a balance between the jerk and acceleration settings to slightly increase print speed without affecting the quality of the 3D model or 3D printer.

For example, if you work with the jerk setting at 10 (low) and select a speed of 60mm/sec, you won't save much time in 3D printing, but the print quality will be ok. Increasing speed to 120mm/s and jerk to 40 will cut 3D printing time by 25%! However, the quality of the printed 3D model will also be greatly reduced.

Replace 3D Printer

If you are not satisfied with your current 3D print speed capabilities, you can always look for another 3D printer with higher speed. However, such a device can be expensive. Most printers designed for home use are not as fast as industrial 3D printers.

For example, the cheapest FDM printers can cost as little as $300 or even $200, and they typically print at 60mm/sec. They will never reach the speed of industrial equipment such as the Massivit 1800 which can reach speeds of 1000mm/s.

Select objects for 3D printing quickly

Another way to increase the speed of 3D printing is to search for new ideas for 3D printing as quickly as possible. It is ideal for beginners who want to learn on the go and improve their skills as they progress from simple models to more complex figures.

It is ideal for beginners who want to learn on the go and improve their skills as they progress from simple models to more complex figures.

How fast do FDM 3D printers print

What resolution do 3D printers print

Threaded connection of printed parts

6 Safe Ways to 3D Print

3D printing at home gives us the ability to produce custom objects at a very low cost. However, the time it takes to turn a 3D model into a physical object is not as short as one might think. The size and quality of the print has a decisive influence on the speed of printing, and it can take many hours to get the final result. In fact, various tests show that printer speed has a much smaller effect on print time than size and quality settings.

Desktop printers

3D print speed settings

In general, there are currently three sets of speed settings supported by 3D printers. The first block includes speeds from about 40 to 50 mm / s, the second - 80-100 mm / s, the fastest printing is carried out at about 150 mm / s. Some printers can even print at speeds over 150mm/s.

Some printers can even print at speeds over 150mm/s.

Usually, however, faster 3D printing means lower quality. At speeds above 150 mm/s, the quality drops significantly, and problems can arise, since the filament is prone to slip at such speeds.

How to set the print speed

Typically, the 3D print speed is set in the slicer software used to prepare the 3D model for printing. In Cura, for example, you just need to enter the desired print speed in the Print speed field in the Basic tab (in previous versions, you first had to switch to the Advanced mode and open the Speed tab).

Cura calculates the duration of the print process based on print speed and quality settings.

As soon as the print speed ( Print speed ) or other setting is changed, Cura recalculates the print time and displays it (see arrow). Cura's calculations turn out to be very close to real-time printing.

How long does 3D printing take in practice?

To find out how fast 3D printers actually print, two popular desktop printers, the Ultimaker 2 and the Wanhao Duplicator 6, were tested on two more or less complex objects.

These two models were printed:

3DBenchy. This 3D model is designed to test and measure the speed of 3D printers; it is quite complex and requires attention. The boat is 6 cm long, 4.8 cm high and 3.1 cm wide. Here you can get the 3DBenchy STL file for testing for free.

3DBenchy's 3D printing speed is relatively slow, the model is quite difficult to print (Photo: 3DBenchy.com).

Universal tablet stand (up to 1.2 cm thick). The stand is 14 cm long, 4.2 cm high and 9.8 cm wide. The STL file is available for free on Thingiverse.

The stand is quite large and difficult to print (Photo: Thingiverse).

These objects were printed at two speeds, 100 mm/s and 50 mm/s, at similar settings. Here are the results:

Here are the results:

Printer

Model

50 mm/sec

100 mm/sec

Ultimaker 2

9000 3dbenchy2 h 09 min.0005

1 h 55 min

Wanhao Duplicator 6

3DBENCHY

2 h 13 min

1 h 51 min

Ultimaker 2

Stand

9000 6 h 23 min 9000 4 h 36 min 9000 2 minWanhao duplicator 6

Stand

6hrs 27mins

4hrs 45mins

- For the smaller models, the difference between slow and fast print is not that noticeable: almost 2.25 hours versus less than 2 hours. Unless you're insanely short on time, choose a slower speed for better print quality.

- For large models, the print speed differs more significantly: 6.5 hours versus 4.75 hours.

Cunning. If you don't have your own 3D printer, download the free Cura software from the Ultimaker website. Cura has profiles for most desktop printers (FDM), so you can check how long it takes to print a specific 3D model on a particular device - just import the STL file and play with Cura settings. To try another 3D printer, select Machine > Add new machine.

To try another 3D printer, select Machine > Add new machine.

Does high-speed sintering promise the fastest 3D printing?

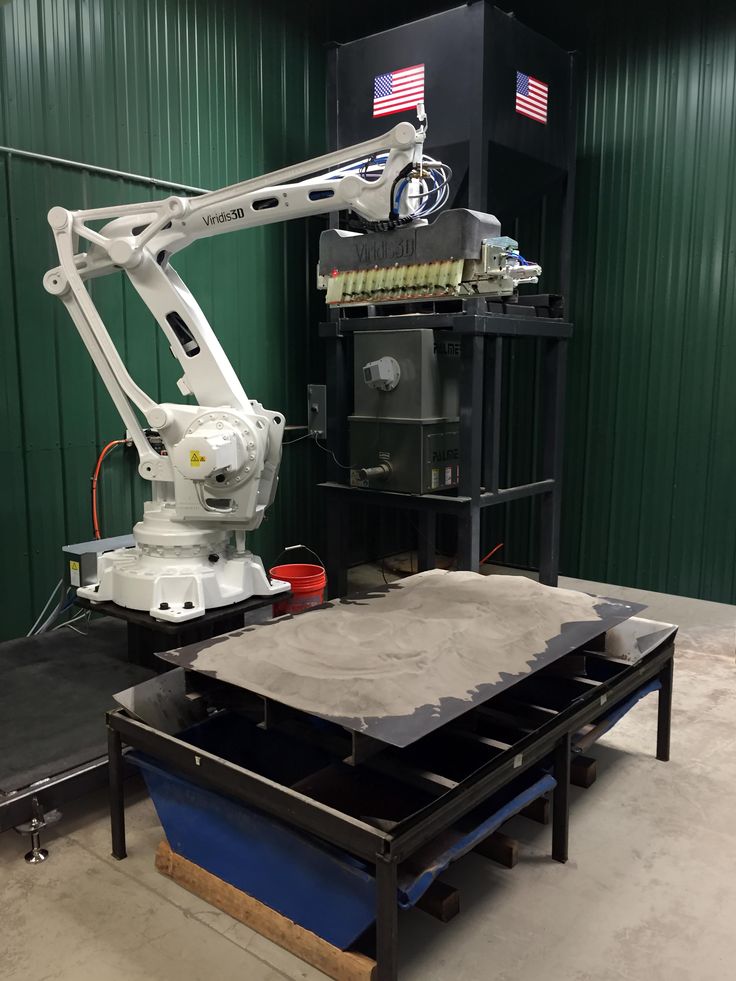

On an industrial scale, even more impressive prospects dawn on the horizon. The University of Sheffield has announced that its scientists have built a £1m-funded 3D printer that can produce plastic parts as quickly as traditional mass-production methods such as injection molding.

The process is called high-speed sintering (HSS), which melts the polymer layer by layer (similar to the additive printing process), but instead of using lasers, HSS prints on a powder substrate with infrared-absorbing inks. After the layer is printed, it is exposed to infrared radiation, the ink-coated powder is heated, resulting in melting, while the non-irradiated powder remains cold.

A team led by Prof. Neil Hopkinson claims that their machine is capable of producing parts up to 1 m³, i.