3D print tattoo machine

Designer Creates Fully Functional 3D Printed Tattoo Machine - 3DPrint.com

One of the best things about the maker community at large is that it’s full of intensely creative individuals, and creativity likes to stand out. One way that this often happens is in presentation; some makers you can tell from their pallor from hours spent in workshops and garages rather than in the sunshine, some from their scars (hey, there’s a learning curve when working with machinery!), and some simply have it written all over themselves.

If, for example, you were to meet me, you’d know a few things pretty quickly–not least among them that I’m a pretty big geek. Literally (I’m really tall) and descriptively: I wear my geek on my sleeve. That is, I have a half-sleeve tattoo covering my preferred geekdoms, from Doctor Who to fine art (van Gogh’s ‘Starry Night’) to Shakespeare to Lord of the Rings, Sherlock, and Harry Potter, my fantastic tattoo artist provided me a one-of-a-kind creation (and work-in-perpetual progress) to help me outwardly celebrate my love for these arts and writings. All of my other tattoos came from different shops, but I went to one particular artist for this piece, and from my first sitting I was impressed by his top-of-the-line tattooing equipment (you can barely hear the machine at all, which is crazy for a famously-buzzing piece of machinery).

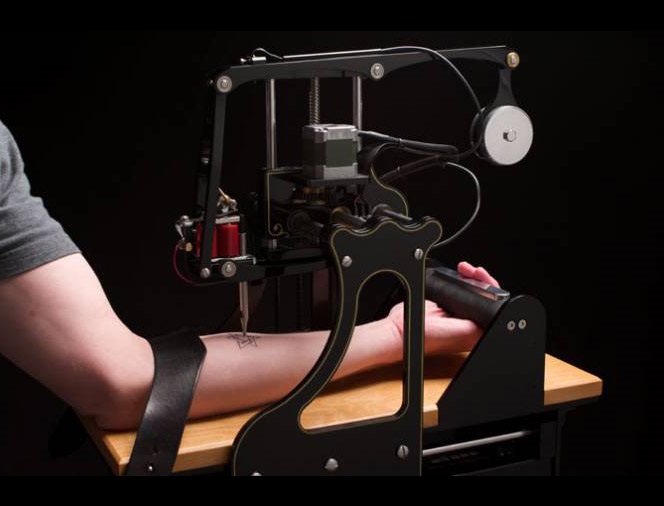

Tattoo machines don’t, though, have to be high-end from renowned companies to be impressive. Take Austrian designer Marc Schuran, for instance. This innovative maker has designed, created, and successfully tested a 3D printed tattoo machine, showcased in his Behance portfolio.

“I tried to build classic tattoo printing machines,” he told 3DPrint.com. “They worked very well, so I decided to create this 3d printed model.”

Schuran created the piece as his term project last year, based on “research about different archetypes and their evolution through the years.” Designed using Rhinoceros 5 and coming off a Stratasys uPrint SE printer in two pieces (grip and frame) following about three hours of print time, the design doesn’t just look like an authentic tattooing machine–it is one.

“The device works pretty good,” Schuran told us. “I tattooed about 10 people with this machine, no problems. A few details need to be revised for a better comfort during the working progress.”

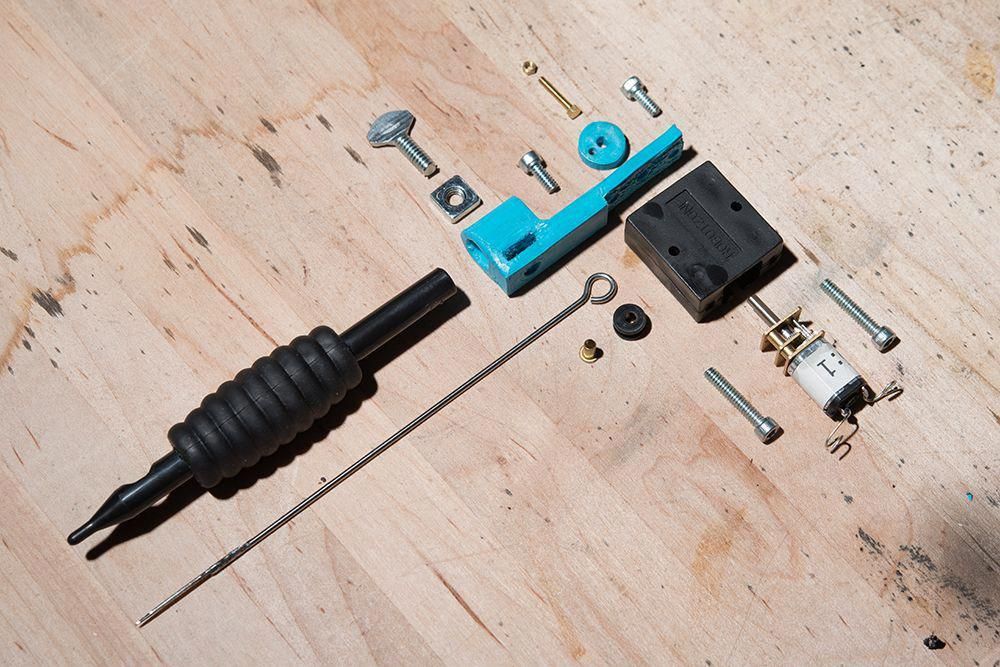

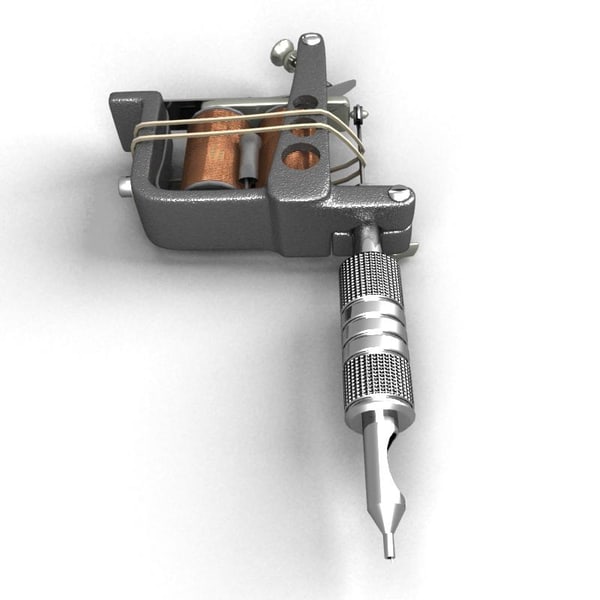

The two main components of the machine were 3D printed, but not everything could be, as it’s still a machine that has to function. Among the non-3D printed pieces were what Schuran calls the “classic tattoo machine parts,” such as the contact screw, tip, tube, coils, and needles.

While the tattoos shown on his portfolio consist of straight, black lines that make for fairly simplistic designs, this is clearly a step up from other DIY-type tattoo machines that often consist of simple components like (shudder) a ballpoint pen or a safety pin. Schuran is still at work on refining the design, noting that he is now working on “a revised version of this machine.”

Would you trust this machine to add some ink to your skin? Let us know in the 3D Printed Tattoo Machine forum thread on 3DPB. com.

com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3D printed tattoo machine • Austria • behance • diy • tattoo

Please enable JavaScript to view the comments powered by Disqus.

T³: 3D Printing a Rotary Tattoo Machine - News

Don't try this at home!

Favorited Favorite 1

Today on Tech Talk Tuesday, we're gonna talk about tattoo machines! If you've seen me on the site before, you've probably noticed that I have a few tattoos and I'm not the only one. In fact, almost half of all adults between 26 and 40 have at least one tattoo. Turns out they're not just for sailors anymore! That being said, most people aren't aware that the modern tattoo machine was essentially invented by our old friend (or nemesis?) Thomas Edison.

You see, in 1876, Edison patented a device which he called a Stencil-Pen. While the first iteration of this device used a rotary drive, a patent filed the following year would almost pass for a modern tattoo machine and it was intended for making stencils. A pair of coils would drive a needle up and down at a rate of up to 50 cycles per second and the user would write or draw with the needle in order to punch a series of tiny holes in heavy paper. The perforated paper could then be used to roll ink through and make several duplicates of the image. This technology never really caught on; However, in 1891, a fellow named Samuel O'Reilly had the bright idea to modify the original rotary Stencil-Pen for making tattoos. Sam even received a patent for his addition of an ink tube to act as a reservoir. Just a few weeks after Mr. O'Reilly built his tattoo machine based on the rotary action of the original Stencil-Pen, a Mr. Thomas Riley adapted the coil-driven design for tattooing.

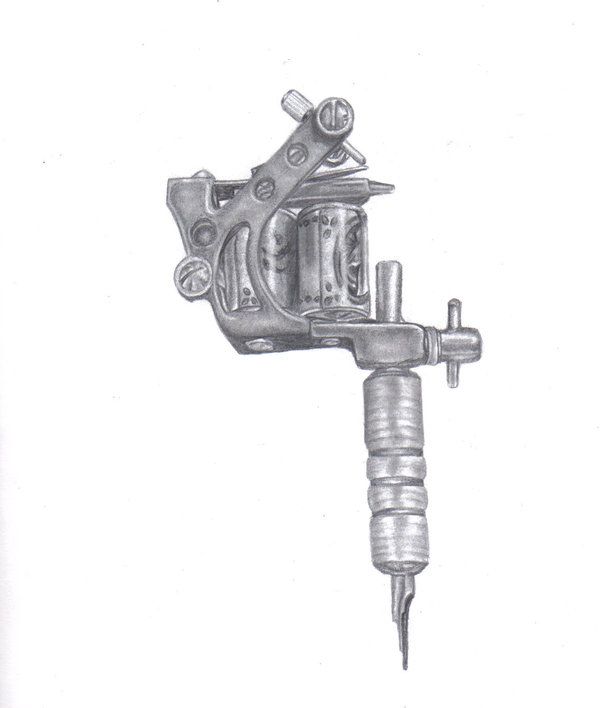

The coil-driven tattoo machine saw several incremental improvements over the years and it's still the preferred "iron" for most artists. If you've ever been in a tattoo parlor, you've heard the buzzing of a coil machine. It's easy to adjust the speed, depth and throw of a coil-based machine, and they're easy to repair. That doesn't mean, however, that the rotary machine disappeared entirely. Manfred-Kohrs improved on O'Reilly's rotary design in 1978 and used it to tattoo several notable musicians, artists and celebrities. Today, companies such as Welker, Bishop and Sabre still produce and sell rotary tattoo machines. Because of the ubiquity of small electric motors, rotary machines are also the DIY tattoo machine of choice.

So, if a tattoo machine is so simple, why can't we just 3D-print one? Well, as it turns out, we can. And I did! It's bare-bones simple, but it qualifies as a working iron as you'll see in the video below:

As I mentioned in the video, the electronics for this project are pretty simple. I'm using a SparkFun Pro Micro to feed PWM signals to our TB6612FNG Breakout Board based on inputs from a Rotary Potentiometer and a Foot Switch. The motor is one of our Micro Gearmotors in an Actobotics Enclosure and it seemed perfectly happy chugging along through the entire tattoo session. Here's a diagram to better illustrate the variable speed driver circuit:

I'm using a SparkFun Pro Micro to feed PWM signals to our TB6612FNG Breakout Board based on inputs from a Rotary Potentiometer and a Foot Switch. The motor is one of our Micro Gearmotors in an Actobotics Enclosure and it seemed perfectly happy chugging along through the entire tattoo session. Here's a diagram to better illustrate the variable speed driver circuit:

The 3D printing itself wasn't all that exciting for this project. The print, including the enclosure for the power supply, takes just over an hour on my Taz 5 and isn't a complex shape. The only really clever bit of design was making a slot for a square nut to fit into in order to mount the thumbscrew for the needle tube. The working machines were printed from PLA, because that's what I had on the printer at the time, but ABS might work even better. I printed one from ABS for the video above so I'll probably test the ABS construction soon. I'm also excited to have Shapeways print one for me in gold-plated metal!

Okay, I want to take a moment to re-iterate: Tattoos are PERMANENT! If you try this, you can screw up and wear that mistake for life (or until you have cash for laser removal) And do not EVER tattoo others unless you are a trained professional! There's a reason people study and train for a long time to become respected tattoo artists. This is not a good way to "save a buck" on a tattoo; I only did this because I have an enduring fascination with body modification and some experience that helped me along.

This is not a good way to "save a buck" on a tattoo; I only did this because I have an enduring fascination with body modification and some experience that helped me along.

That being said, if you want to build one for yourself, you can find everything on the GitHub repository. I had fun doing this project and I've since gotten a lot of compliments on my tattoo. It's not professional-grade, but I know that I made it myself and that feels pretty good. Anyway, here are some pictures of the completed machines:

If you have any interest in coil machines, let me know in the comments! I may decide to build a coil-based machine and make a video about that process and how modern coil machines work. Thanks for watching my video and for reading today's Tech Talk Tuesday!

3D printer - tattoo machine! A new page in the history of 3D technologies.

An original 3D printer-tattoo machine has been created

The relative novelty of 3D printing technology leads to its many unique applications in various fields. Obviously, too little time has passed for a complete transformation of the methodology, since society has not had time to fully master the existing methods of additive manufacturing. However, the bright minds of mankind are constantly working on the development and improvement of 3D printing technology. And sometimes this leads to very unexpected results. In each case, the technique itself is directly involved, or rather, special equipment for it. But what happens if we discard all unnecessary and leave only the principle of operation of a 3D printer? We have a great example: a 3D printer - a tattoo machine.

Obviously, too little time has passed for a complete transformation of the methodology, since society has not had time to fully master the existing methods of additive manufacturing. However, the bright minds of mankind are constantly working on the development and improvement of 3D printing technology. And sometimes this leads to very unexpected results. In each case, the technique itself is directly involved, or rather, special equipment for it. But what happens if we discard all unnecessary and leave only the principle of operation of a 3D printer? We have a great example: a 3D printer - a tattoo machine.

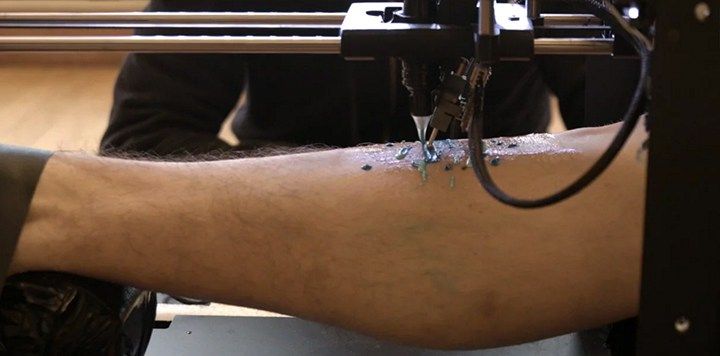

Back in 2014, a group of enthusiasts from France set an extravagant goal: to combine a 3D printer with a tattoo machine and actively began to implement their idea. Thus was born an unusual invention that fully performs its functions with some limitations. In 2015, the developers presented their creation to the world, which by that time was able to draw a picture on a human hand well fixed in the case. From such a blank, a 3D printer developed - a tattoo machine.

From such a blank, a 3D printer developed - a tattoo machine.

Of course, the French did not stop there and boldly continued experiments on an amazing device. One of the main intentions of the developers was to adapt the mechanism for applying a tattoo to any part of the body, and now, after some time, they found an original way to solve this problem.

3D printer - tattoo machine: features of

But before we get to it, we will tell you a little about the process of creating the first sample. To make a 3D tattoo machine, the developers removed the extruder from the MakerBot 3D printer and replaced it with a tattoo needle. The next step was to equip the device with special sensors that scan the surface of the user's skin, on the basis of which the device adapts to the size and structure of the skin of the limb, which significantly increases the accuracy of drawing the pattern.

In the course of work, the creators had to face a number of difficulties, since a 3D printer in the traditional sense is not adapted to perform its functions on such an atypical surface. The need to follow the curves of the human body led the French to delve into robotics, which led them to another interesting idea.

The need to follow the curves of the human body led the French to delve into robotics, which led them to another interesting idea.

With the help of an industrial robot and 3D scanning technology, they could get the information needed to program a mechanical arm to tattoo a human body. Since the task turned out to be entirely feasible, the developers immediately took up its implementation, in which they were greatly facilitated by the conclusion of cooperation with the notorious company Autodesk.

Highlights of the 3D Printer - Tattoo Machine

As David Thomasson, an engineer at the latter's research lab, points out, “Our research is really focused on a closer interaction between man and machine, which will most certainly be achieved in the near future. With this project, we are moving almost to the limit. In fact, all developed devices imply complete separation from humans. It's completely new territory."

Finally, after much experimentation and countless 3D scan data, the device was completed. The 3D printer-tattoo machine has been successfully tested and is fully ready for its intended use. It looks like this is really a completely new page in the history of 3D technology.

The 3D printer-tattoo machine has been successfully tested and is fully ready for its intended use. It looks like this is really a completely new page in the history of 3D technology.

https://vimeo.com/175491863

Return to the main

3D printer will leave tattoos without work

Archive

Subscribe to

Subscribe

Justice, where they made a computerized tattoo machine out of a 3D printer?

- It seems that it was not in "Justice"?

- Well, it doesn't matter, did you see it? Those French turned the MakerBot Replicator 2 into a tattoo machine!

The idea came from a workshop called Public Domain Remix, sponsored by the French Ministry of Culture at ENSCI les Ateliers, the famous Parisian school of design. The event attendees were tasked with remixing public domain images, sounds and videos. One group calling themselves Appropriate Audiences decided to remake a 3D printer to create tattoos of public domain images. With the help of French Le FabShop hackspaces, the team took a desktop 3D printer they found at school, replaced the extruder with a pen, and created their own prototype in their allotted 8 hours in the workshop. The resulting machine drew pictures in front of all participants in the program. This was also observed by the Minister of Culture of France himself.

With the help of French Le FabShop hackspaces, the team took a desktop 3D printer they found at school, replaced the extruder with a pen, and created their own prototype in their allotted 8 hours in the workshop. The resulting machine drew pictures in front of all participants in the program. This was also observed by the Minister of Culture of France himself.

Tattoo Supplies

After the event was over, the design team decided to move on and swap out the pen for a real tattoo machine borrowed from an aspiring tattoo artist. To demonstrate the quality of the tattoo, they chose the simplest design - it became a regular circle, and first they tested the machine on silicone leatherette. Then they had to find a volunteer who would be willing to get their first robotic tattoo. It turned out to be easier than they thought, since there were quite a few volunteers who liked the idea of spoiling their skin in this new 21st century way.

"Feather trials" on leatherette

The process of calibrating the printer and getting ready to make a quality tattoo turned out to be a bit tedious. The design team had to first create an adapter on a 3D printer that would fix the tattoo machine in such a way that it would not vibrate. In the printer software, the print wall thickness was set to 0.2mm, with no fill, as they hadn't figured out how to fill the tattoos with color yet.

The design team had to first create an adapter on a 3D printer that would fix the tattoo machine in such a way that it would not vibrate. In the printer software, the print wall thickness was set to 0.2mm, with no fill, as they hadn't figured out how to fill the tattoos with color yet.

Measuring the distance between the upper arm and the print platform

The team then had to measure the distance between the volunteer's upper arm and the printer's print platform; This distance was set in the print Gcode to compensate for the difference between the hand surface and the print platform. The team also had to consider a travel stop, which is used to calibrate the printhead before printing/tattooing, because the length of the needle is different from the length of the extruder. Because leather is more elastic than silicone, the team had to use a piece of rubber to stretch the volunteer's skin.

Second round of tattoo printing

Finally everything was ready for printing. After sterilizing the equipment and filling the needle with ink, they sent the drawing to print. After the machine turned on and was ready to start printing, they paused the printer and placed a volunteer's hand in the assembly chamber. The next step, as described on the project page on the Instructables website, was "start the engine, cross your fingers at random, and... GO!"

After sterilizing the equipment and filling the needle with ink, they sent the drawing to print. After the machine turned on and was ready to start printing, they paused the printer and placed a volunteer's hand in the assembly chamber. The next step, as described on the project page on the Instructables website, was "start the engine, cross your fingers at random, and... GO!"

While in some ways it may seem like the guys at Appropriate Audiences have taken 3D printing technology a step back by turning it into a 2D inking device, they might be the ones that will spark new ideas in the world of tattoo art and contour printing. on a surface. Perhaps this experiment could end up putting talented tattoo artists out of work, but in the future, if you get a robotic tattoo, you'll have no one to blame for a bad drawing but yourself!

Article prepared for 3DToday.