Delta 3d printer vs prusa

Will Josef Prusa Release a Delta Printer under His Own Brand? / Habr

Prusa Research with Josef Prusa in charge bought 80% of shares of Czech manufacturer Trilab, as well as got full control over the company. Trilab is known for its delta 3D printers. Does this merging mean that there will be a delta-kinematics 3D printer under the Original Prusa brand?

If you are aware of Betteridge’s law of headlines, then you already know the answer: no, there will not be a delta printer any time soon and his team doesn’t even work on one, or at least not yet. Nevertheless, the merger is worth the attention, since it shows that Josef can be an aggressive market player.

Let’s get one thing straight: not only did Prusa manage to stay afloat without going bankrupt or disappearing but also started an active expansion in the environment of the current additive manufacturing market. This is worth respecting. Josef’s last name is mainly associated with the open-source 3D printers kinematics, although recently the company released the Prusa XL printer with the CoreXY kinematics. Original Prusa solutions were copied by many and the market is full of affordable offerings. Josef Prusa continues to do his job: selling relatively expensive devices and not conceding its market position.

Let’s compare Prusa with two other legendary brands that were involved with the early days of the RepRap project— MakerBot and Printrbot,founded by Bre Pettis and Brook Drumm respectively. These companies had a harder time competing with Chinese solutions. Makerbot had to stop using an open design and open-source software solutions, close their plant in Brooklyn and start manufacturing in Asia. After that they became owned by Stratasys and left the hobbyists market, now mostly focusing on the professional FDM solution. Pettis himself left the company and started doing other things. Printrbot had it even worse: the company was closed due to falling sales in 2018 .

But Prusa doesn’t have any problems. Their original printers with no enclosures are still popular and Josef isn’t looking to merge with larger companies like Makerbot did, but he’s actually growing his own ‘empire’. His own production is sold under the Original Prusa brand but the name is not the only reason for its popularity: Prusa constantly works on improving the equipment and making its own ecosystem. Cheap clones can’t be a powerful competition if Prusa offers a premium version with high-quality parts, multi-material printing system and high-quality Prusament materials. There is also its own slicing solution called PrusaSlicer that is a version of the Slic3r program.

His own production is sold under the Original Prusa brand but the name is not the only reason for its popularity: Prusa constantly works on improving the equipment and making its own ecosystem. Cheap clones can’t be a powerful competition if Prusa offers a premium version with high-quality parts, multi-material printing system and high-quality Prusament materials. There is also its own slicing solution called PrusaSlicer that is a version of the Slic3r program.

But if you want to survive long-term, you should do more: and Josef Prusa, being an ambitious entrepreneur, doesn’t spend all of his money on fun things, he pours it back into his business. And that’s where the story with Trilab comes into play: it’s not Prusa’s first merging and likely not the last.

Prusa Research bought another 3D printer manufacturer back in 2018. It was the Futur3D company that is focused on SLA devices. Their solutions and developments became the base for a new resin 3D printer Original Prusa SL1. The machines were popular and Prusa managed to keep a good pace: once the shift from the RGB to monochrome curing screens became apparent, they upgraded the device that was now called Original Prusa SL1 Speed. Moreover, they offered an upgrade for the owners of the original version and offered a modernized wash and cure stations CW1S (the predecessor was called CW1), and recently they launched their own line of 3D printing resins.

The machines were popular and Prusa managed to keep a good pace: once the shift from the RGB to monochrome curing screens became apparent, they upgraded the device that was now called Original Prusa SL1 Speed. Moreover, they offered an upgrade for the owners of the original version and offered a modernized wash and cure stations CW1S (the predecessor was called CW1), and recently they launched their own line of 3D printing resins.

And now Trilab became a part of Prusa Research. It’s also a Czech company and it has its own brand recognition: not only among hobbyists. Since 2016, they’ve been developing professional additive manufacturing solutions. For example, in the summer 2021 they released a new line of delta 3D printers named AzteQ with the build volume of Ø400 x 600 mm, thermostatic chambers, high-temp extruders and full integration of the Palette system for 4-to-8 filament splicing. Their distribution strategy is similar to the expansion strategy of DeltaWASP, the manufacturer of such well-known delta 3D printers such as Delta WASP 2040 Clay. And this is the answer why we shouldn’t expect delta printers from Original Prusa in the near future.

And this is the answer why we shouldn’t expect delta printers from Original Prusa in the near future.

The reason is the different markets. Original Prusa mainly targets enthusiasts, while the Trilab solutions are focused on the professional segment. Josef Prusa doesn’t want to cause confusion among the buyers and there’s no reason to restructure an already successful firm.

“Trilab manufactures high-end 3D printers for the commercial segment, their brand is quite well known. But our devices are focused on hobbyist and enthusiast makers, and they also feature an open-source design which can cause problems in the commercial and industrial markets. So we will perfectly complement each other. We have a perfect B2C system without the intermediaries, we can sell 3D printers and the materials right from our Prague headquarters. Trilab has business partners not only in the EU but in Japan, Israel, Canada and Australia. Their business experience is different from ours”, explained Josef Prusa.

“In the beginning of 2021 we found ourselves in the need for a strategic partner to help us with further development and extending the market share. After months of negotiations we suddenly realized that the best thing we could do is to partner with another Czech company — Prusa Research, commented Michal Boháč, the CEO of Trilab.

So in the end, Prusa Research won’t interfere with Trilab’s workflow and brand but the companies will help each other and exchange technologies. Original Prusa certainly has plans for the commercial segment as it seems looking at their 3D printing farm shown at the Dubai Expo 2020.

The price of the Trilab acquisition is not mentioned but the companies confirmed the merger at the Formnext 2021 exhibition in Frankfurt am Main. Trilab’s staff is to remain the same including the company founders: Vojtěch Tambor and Michal Boháč. But the company will be called ‘Trilab — A Prusa Research Company’ from now on.

How to Choose Between Cartesian and Delta 3D Printers – Fargo 3D Printing

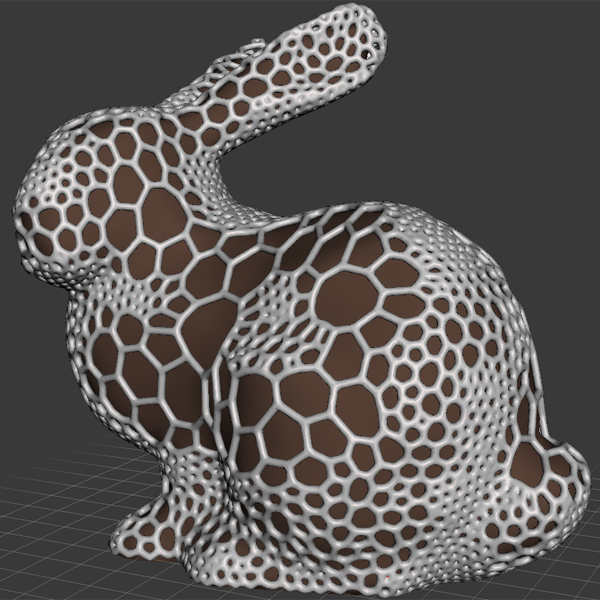

In 3D printing, there are several different styles of printers. The two most common desktop 3D printer styles are Cartesian and Delta. These printers both use Fused Deposition Modeling (FDM) technology but have different ways to navigate the print head through the 3D print space.

The two most common desktop 3D printer styles are Cartesian and Delta. These printers both use Fused Deposition Modeling (FDM) technology but have different ways to navigate the print head through the 3D print space.

Cartesian

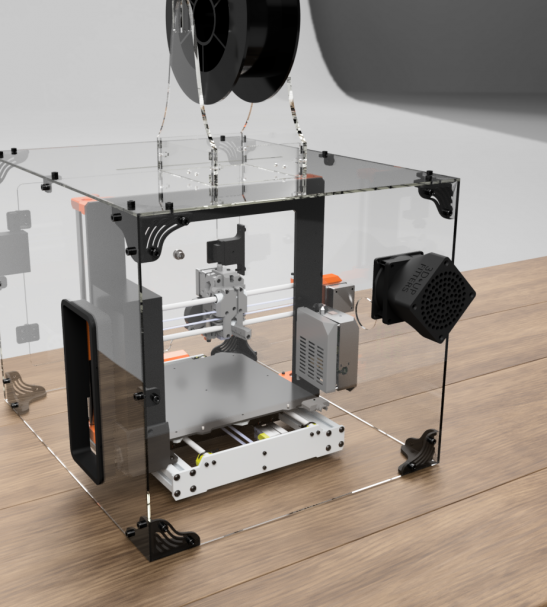

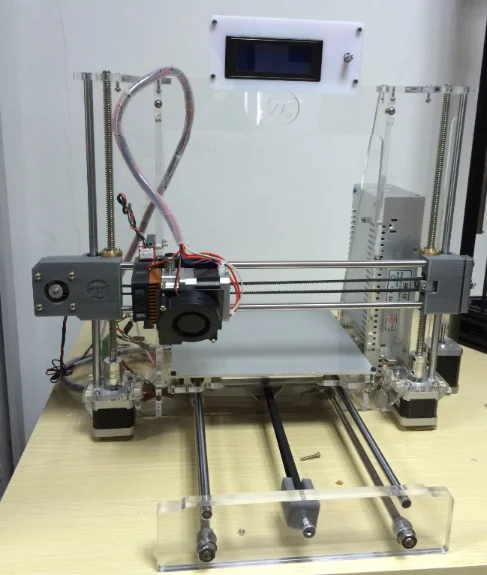

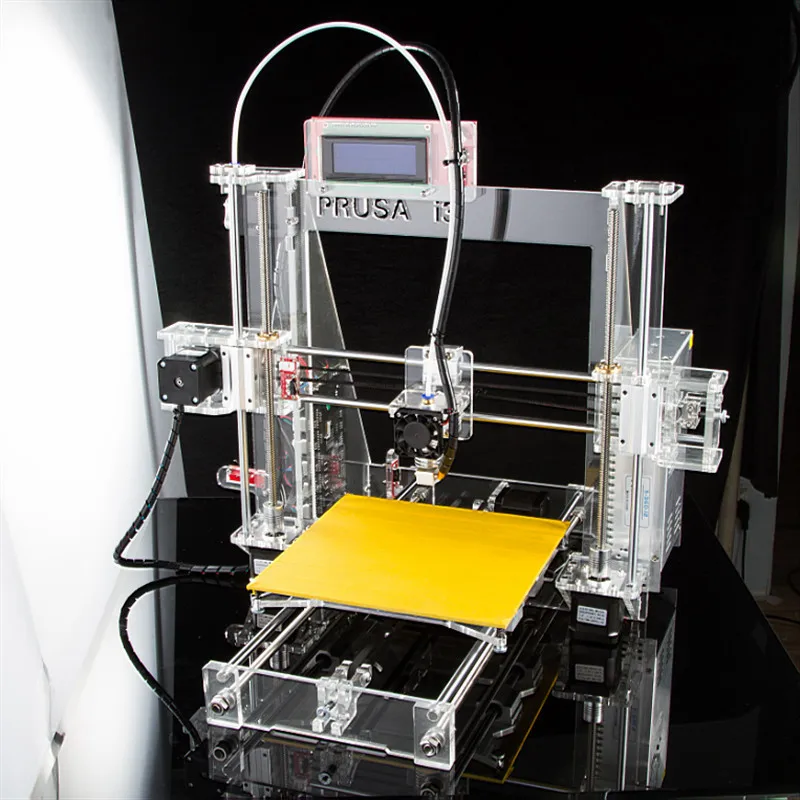

A Cartesian Printer.

From: All3DP

Cartesian printers are named after the Cartesian coordinate system that uses X, Y, and Z coordinates to plot points. This system of coordinates is used to determine the location of the print head and the extruder. Cartesian printers do this through a system of rails which are used to move the print head and the print bed to position the extruder anywhere in the 3D space.

Pros

One of the greatest advantages of Cartesian printers is their popularity. Since Cartesian printers are the most widely used type of printer, there is far more support for users of these printers than for users of Delta printers. It is easier to find parts and to repair Cartesian printers because of this solid market.

In addition, prints from a Cartesian printer tend to have a better surface finish than prints from a Delta printer. This is because Cartesian printers have more rigid axes, which allow less room for error when the print head moves within the 3D space.

This is because Cartesian printers have more rigid axes, which allow less room for error when the print head moves within the 3D space.

Cons

There are no overall problems with Cartesian printers. Most issues that arise are specific to different brands. As such, any disadvantages of Cartesian style printers depend on the manufacturer. Check out our troubleshooting and guide pages to see common issues with various 3D printer brands and models.

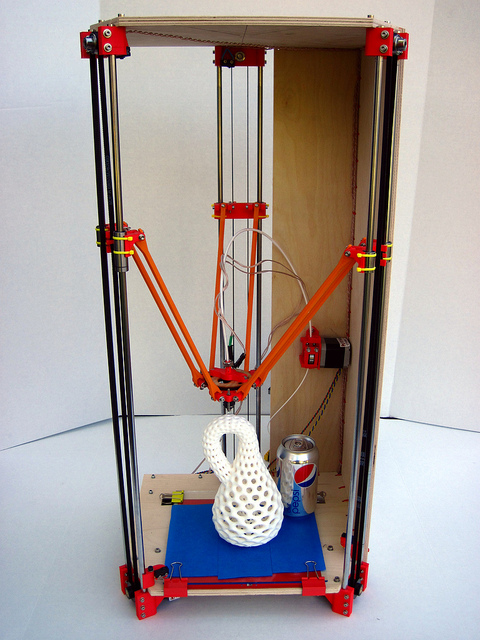

Delta

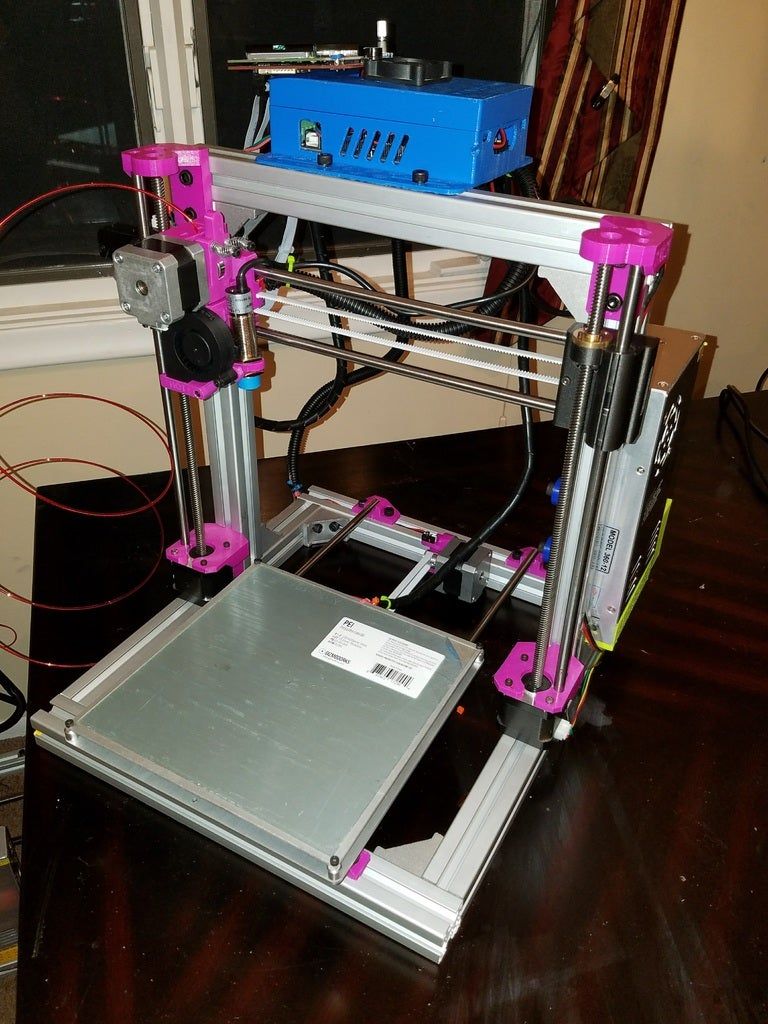

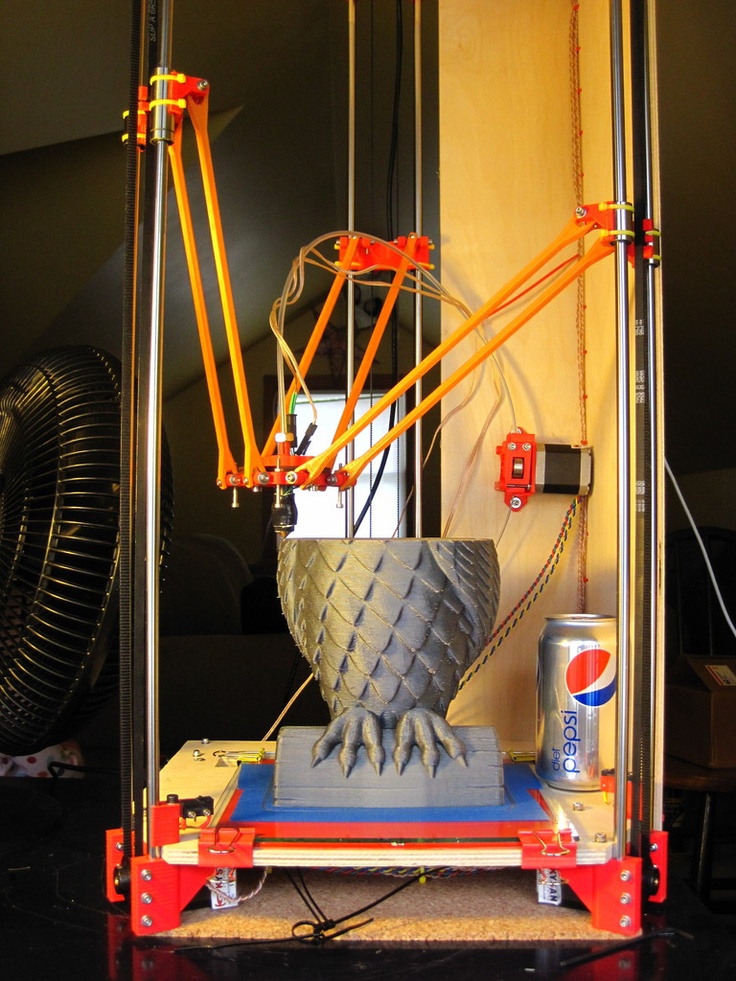

A Delta Printer.

From: All3DP

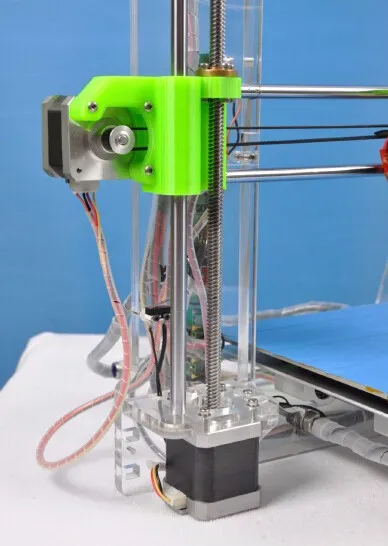

Delta printers, like Cartesian printers, also work within the Cartesian plane. However, they use a different system to navigate and locate the print head within the 3D space.

A delta printer consists of three arms on rails that move up and down independently to move the print head. Delta printers use trigonometric functions based on the angles that these arms create to determine the precise location of the print head within the 3D print space.

Pros

Delta printers have circular print beds which gives them a more efficient use of the printing space, especially when printing circular prints. Additionally, many of the print beds are non-moving, which can be an advantage for some prints. Due to their design, Delta printers can also print taller objects than most Cartesian printers.

Additionally, many of the print beds are non-moving, which can be an advantage for some prints. Due to their design, Delta printers can also print taller objects than most Cartesian printers.

One of the main advantages of a Delta printer is its speed. These printers were designed for quick printing. Delta print heads are built to be as light as possible, which results in a quicker printing process.

Cons

However, this design’s focus on speed results in several disadvantages for the printer. One is the precision of the printer. As the speed of the printer increases, its precision decreases. Because of this, Delta printers tend to print with less detail and a rougher surface finish than Cartesian printers.

Another main disadvantage is the Bowden style extrusion. To reduce the weight of the print head, the stepping motor is removed and placed on the body of the printer. The filament is then fed to the print head using a Bowden tube. This style of extrusion limits the number of filaments that can be used and can cause binding within the tube itself. This is a problem that is currently being addressed by Zesty Technology and their new Nimble extruder drive, which is lighter than a standard extruder drive or stepping motor. Learn more about Bowden extrusion here.

This is a problem that is currently being addressed by Zesty Technology and their new Nimble extruder drive, which is lighter than a standard extruder drive or stepping motor. Learn more about Bowden extrusion here.

Which One Should You Choose?

Diagram of a Cartesian Printer (left) and a Delta Printer (right).

From: Printspace3D

When choosing between them, you should consider what you want from the printer. Cartesian printers often come preassembled and work right out of the box. In addition, as they are more popular, there is more customer support for Cartesian printers. Delta printers often come in kits and need to be assembled before use. They are also very advantageous when making tall objects.

Get updates, deals, and more great posts by joining our community of over 6,000!

[sexy_author_bio]

Will Josef Pruscha release a delta printer under his own brand?

Prusa Research, under the leadership of you-know-who, bought out 80% of the shares and took control of the Czech manufacturer of delta-kinematic 3D printers Trilab. Does this mean that in the near future the range under the Original Prusa brand will also be replenished with delta printers? We understand.

Does this mean that in the near future the range under the Original Prusa brand will also be replenished with delta printers? We understand.

If you are familiar with Betteridge's Law, then you already know the answer - no, nothing like that Josef and his team are going to do, at least not yet. Nevertheless, the deal is worthy of attention, because it clearly demonstrates the aggressive market policy of Josef and his team.

Let's face it: the fact that Prusha's company not only managed to survive, but also actively develops in the modern additive market inspires respect. Josef's name is associated primarily with open-source "drygostok", christened his name, although the company has just rolled out a Prusa XL 3D printer with CoreXY kinematics. The original "prushes" were not copied by anyone, and the market is littered with cheap offers from Chinese manufacturers. Prusha, on the other hand, continues to do its job, offering quite expensive products, but not giving up an inch of the market.

For comparison, let's take a couple more legendary brands that stood at the origins of the RepRap movement - MakerBot and Printrbot, founded by the equally legendary Bree Pettis and Brook Drumm. These companies had a tough time competing with the Uncle Liao Gang, so much so that MakerBot was forced to abandon its open hardware and software architecture, close its own Brooklyn plant and move production to Asia, move under the umbrella of Stratasys Corporation and, by and large, exit the amateur sector and focus on the development of professional FDM 3D printers. Personally, Pettis left the company altogether, deciding to do other things. Printrbot got even worse: Brook complained more than once about unfair competition from the Chinese, and in 2018 the company closed amid falling sales.

Prusha doesn’t even blow in the mustache. The original “drygotables” continue to be in demand, and Josef not only does not seek patronage from large corporations, as MakerBot did, but, on the contrary, is building his own empire. To make it clear to everyone, he sells his products under the Original Prusa brand, but it is popular not so much because of the name, but thanks to the tireless work to improve the equipment offered and create its own ecosystem. Are the Chinese copying “drygosts” and selling them cheap? And we will make a premium version with quality components and throw on top the multi-material printing system, the “best filaments” Prusament, and even our own version of the Slic3r slicer, now known as the PrusaSlicer.

To make it clear to everyone, he sells his products under the Original Prusa brand, but it is popular not so much because of the name, but thanks to the tireless work to improve the equipment offered and create its own ecosystem. Are the Chinese copying “drygosts” and selling them cheap? And we will make a premium version with quality components and throw on top the multi-material printing system, the “best filaments” Prusament, and even our own version of the Slic3r slicer, now known as the PrusaSlicer.

But this is not enough to survive, and Prusha is doing what any ambitious entrepreneur should do - not to spend income on yachts and mansions (at least not all of them), but to invest money back into the business. And here we are back to the Trilab story. The fact is that this is not the first acquisition, and probably not the last.

In 2018, Prusa Research acquired another Czech developer of 3D printers, Futur3D, a company specializing in stereolithography systems. The developments of this company formed the basis of a new photopolymer 3D printer, but now under Josef's own brand - Original Prusa SL1. New 3D printers quickly found buyers, and Prusa Research did not hesitate, and as soon as the massive transition from RGB to monochrome matrices began, they rolled out an upgraded version called Original Prusa SL1 Speed, offered owners of first-generation systems an upgrade to a new level, upgraded washing stations and re-illumination of CW1 to the CW1S variant (to be honest, we liked the original name CurWa more), and in October of this year she also launched her own line of photopolymer resins.

The developments of this company formed the basis of a new photopolymer 3D printer, but now under Josef's own brand - Original Prusa SL1. New 3D printers quickly found buyers, and Prusa Research did not hesitate, and as soon as the massive transition from RGB to monochrome matrices began, they rolled out an upgraded version called Original Prusa SL1 Speed, offered owners of first-generation systems an upgrade to a new level, upgraded washing stations and re-illumination of CW1 to the CW1S variant (to be honest, we liked the original name CurWa more), and in October of this year she also launched her own line of photopolymer resins.

And now Prusa Research has taken over Trilab, also a Czech company, and quite well-known, but not on the amateur market. This company has been operating since 2016, developing professional additive systems. For example, this summer Trilab rolled out a new line of AzteQ delta printers with a build area up to Ø400x600 mm, temperature-controlled working chambers, high-temperature extruders and the ability to integrate Palette systems for splicing from four to eight filaments. And this is where the answer to the question lies, why delta printers under the Original Prusa brand should not be expected in the near future.

And this is where the answer to the question lies, why delta printers under the Original Prusa brand should not be expected in the near future.

The nuance lies in the different sales markets. While Original Prusa's equipment and supplies are primarily for enthusiasts, Trilab's 3D printers are designed for the professional sector. Josef does not want to confuse buyers, is afraid of the very unfair competition and prefers to consolidate resources instead of unnecessary restructuring of an already successful enterprise.

“Trilab makes high quality 3D printers for the corporate sector and their brand is well recognized in this area. Our machines, on the other hand, are aimed more at amateurs, and besides, they are open source, and this can create obstacles when working in the corporate and industrial sectors. We complement each other perfectly. We have an excellent B2C system without intermediaries, we can sell 3D printers and consumables worldwide directly from the headquarters in Prague. Trilab has business partners not only in the European Union, but also in Japan, Israel, Canada and Australia. Their business experience is completely different from ours,” Pruscha explains.

Trilab has business partners not only in the European Union, but also in Japan, Israel, Canada and Australia. Their business experience is completely different from ours,” Pruscha explains.

“At the beginning of 2021, we realized that we needed a strategic partner to further develop and expand our market. After many months of negotiations with many foreign companies, we came to the rather unexpected conclusion that the best option is to join forces with another Czech company, Prusa Research,” commented Michal Bohacs, CEO of Trilab.

So in the end, Prusa Research will not interfere with Trilab's work under the already established scheme and under its own name, but at the same time, enterprises will be able to support each other and share best practices. For the corporate sector, Original Prusa has plans of its own, judging by the 3D printer farm showcased at Dubai Expo 2020.

The value of the deal with Trilab was not disclosed, but the parties confirmed the fact of the merger at the Formnext 2021 trade show taking place these days in Frankfurt am Main. The Trilab staff will retain their full positions, including company founders Vojtěch Tambor and Michal Bohács. Is that the company itself will now officially be called Trilab - A Prusa Research Company. To make everything clear to everyone.

The Trilab staff will retain their full positions, including company founders Vojtěch Tambor and Michal Bohács. Is that the company itself will now officially be called Trilab - A Prusa Research Company. To make everything clear to everyone.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

Top 3D printers in the first half of 2018

3DPrintStory Reviews The best 3D printers of the first half of 2018

Want to find the best 3D printer within your budget? Want to know where to start and what to buy? In this article we will try to help. There is already a huge range of 3D printers on the market and it is difficult for a beginner to make a good informed choice. Well, searching for the best 3D printer in a certain category only complicates the choice.

Well, searching for the best 3D printer in a certain category only complicates the choice.

After countless hours of printing and mastering a huge variety of desktop printers, the team at ALL3DP, the renowned American resource, has unveiled their top 3D printers you can buy in the first half of 2018.

The selection below represents the top in various conditional categories that will help you choose your own desktop 3D printer depending on the priority criterion.

So, the top 3D printers of the first half of 2018:

PRUSA I3 MK3 - the best 3D printer

for someone. If you want the best FDM printing results, Prusa i3 MK3 is the 3D printer for you.

Why should you buy it. Because he's fun to work with. If you buy a kit, assembly will be a joy. And if you choose one of the pre-assembled ones, this versatile FDM/FFF 3D printer will deliver superior printing right out of the box.

How much will you pay. $90,210,999 (excluding VAT).

Why we chose the Prusa i3 MK3 as the best 3D printer. Can a Maker machine be the best overall 3D printer? Yes, that's exactly what we think. For starters, the Prusa i3 MK3 offers unbeatable value for money. In terms of print quality, it will easily outperform 3D printers three times more expensive.

This is a quiet, fast 3D printer that is a pleasure to use.

You won't have to worry about material selection. It prints almost everything on the market.

Thanks to its open source philosophy, the Prusa i3 MK3 has many upgrades, making it the perfect machine for experimentation and fine tuning. The Prusa Control slicer has several useful features and is constantly updated.

At the time of writing this review, there was a very strong temptation to give this 3D printer a 10 out of 10. The only problem we had was that the material amount control sensor did not work correctly with translucent thread, but this problem will be fixed in future versions.

The alternative to the best 3D printer

The Ultimaker is known to be the "Rolls-Royce of the 3D printing world": it's expensive, but you get unsurpassed comfort, ease of use and quality. The flagship model of the Ultimaker empire is stuffed with a maximum of advanced technologies. It has a dual extruder, replaceable cores for quick nozzle changes, wireless connectivity, a print chamber and more. Thanks to the Cura Connect software, you can start building a printer farm with it. This is a professional machine for professional FDM 3D printing. The price also corresponds to the professional level :).

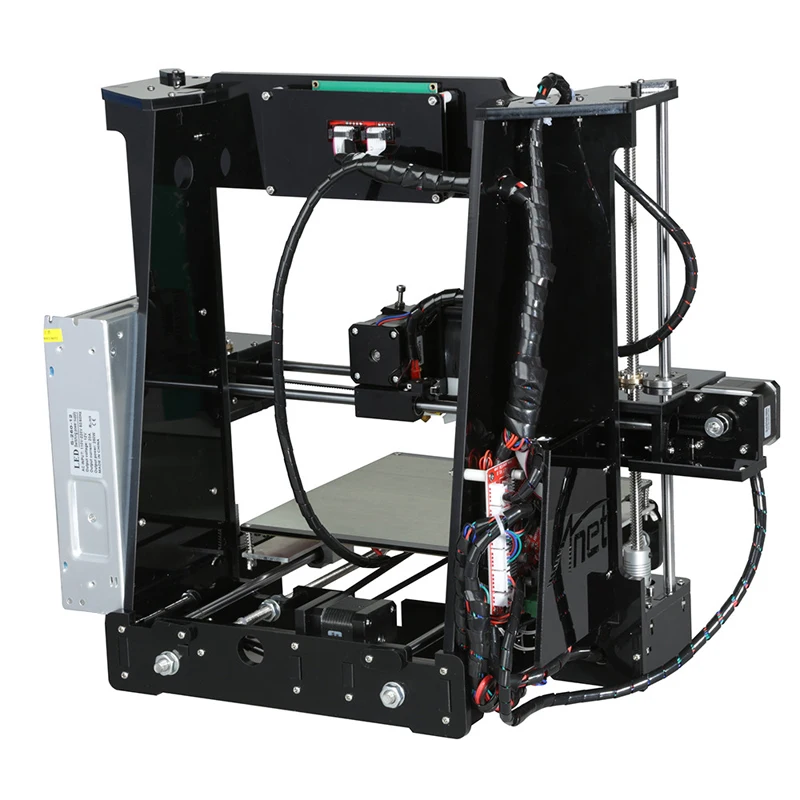

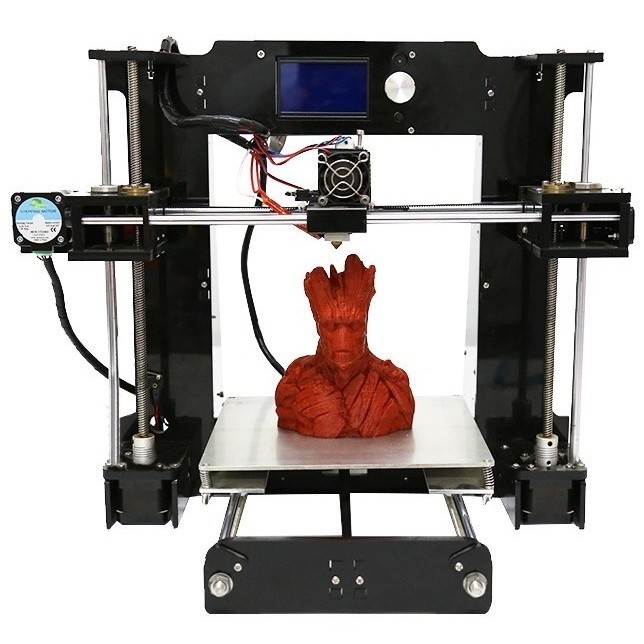

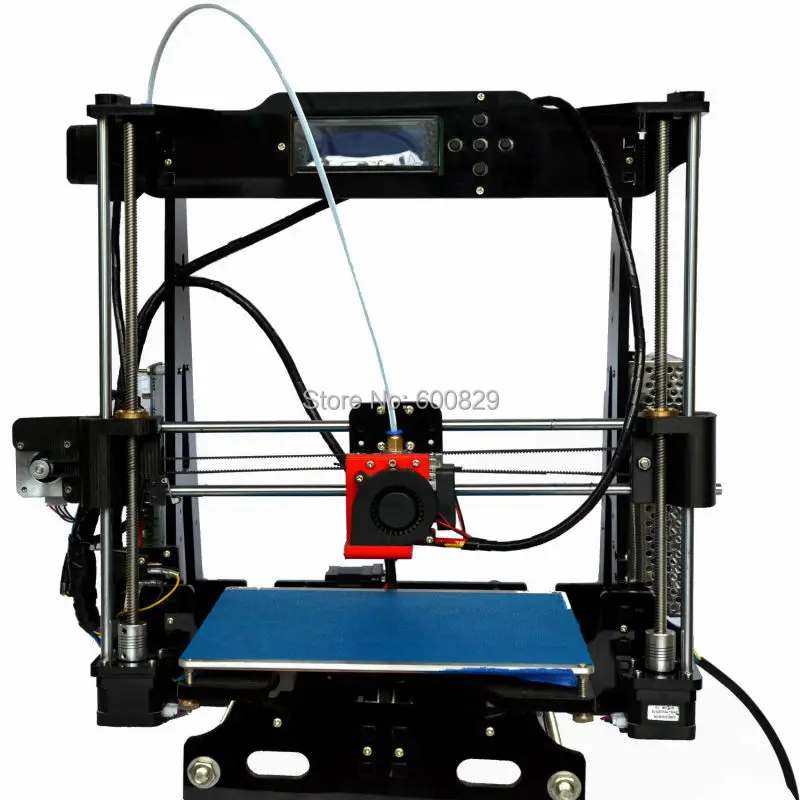

Anet A8 - the most popular 3D printer

For whom. 3D printing enthusiasts and hobbyists who already have some knowledge of 3D printing.

Why should you buy it. Because you can hack it. First of all, consider the Anet A8 as the starting point for your 3D modding adventure.

How much will you pay. The market price is about $200.

The market price is about $200.

Why did you choose Anet A8 as the most popular 3D printer. In search of the most popular 3D printers, we analyzed the frequency of search queries.

Since its release in February 2016, Anet A8 has steadily risen to the top of the 3D printer search results. In February 2018 alone, over 74,000 people worldwide used the term "Anet A8".

What makes the Anet A8 so popular? We think it's a low price, a huge number of modifications and compatibility with many materials. In addition, a large, lively and helpful community has appeared on Facebook, because in general the Anet A8 is more than a printer - it is a hobby.

But beware: we don't think the Anet A8 is a good option for beginners and not a kid's 3D printer at all. Careful assembly will be required, and you will run into a lot of problems during print setup. Problems are solved, but it takes time and desire If you already have some experience in 3D printing, then Anet A8 can really be a great choice.