Vulcan 3d print

Technology – ICON

Vulcan Construction System

Meet Vulcan

Our Home-Sized

3D Printer

Designed and engineered from the ground up for volume 3D printing of homes with precision and speed.

The Vulcan Construction SystemDesigned and engineered from the ground up for volume 3D printing of homes with precision and speed.

| Total Width | 46.5 feet |

| Total Height | 15.5 feet |

| Weight | 9500 lbs |

| Voltage | 230/240 V single phase |

| Print Height | 10.5 feet |

| Print Width | 36.5 feet |

| Print Length | Infinite |

| Print Speed | 5-10" /sec |

| Software | BuildOS |

| Material Mixing & Pumping | Magma System |

| Required Concrete | Lavacrete |

Vulcan Construction System

Meet Vulcan

Our Home-Sized

3D Printer

Designed and engineered from the ground up for volume 3D printing of homes with precision and speed.

Vulcan Construction System

Print SuiteRobotics + Software + Materials

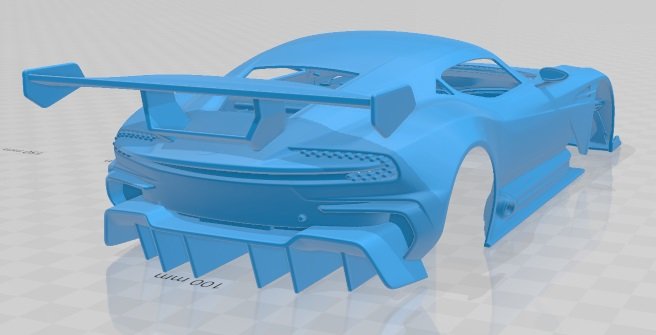

The Vulcan construction system is a combination of hardware, materials, and software to construct homes and large-scale structures. Every part of the system has been designed, engineered, and built from the ground up at ICON to build the highest quality homes possible.

The Vulcan construction system is comprised of the Vulcan printer and the Magma portable cement mixing unit that prepares ICON’s special cement building material, Lavacrete, for printing. All of this hardware is driven by our BuildOS software suite. BuildOS generates and prepares architecture for printing, then controls the robotic hardware on-site to turn digital plans into physical homes.

Vulcan is a large-scale, construction 3D-printer that prints entire homes on location. The printer is designed to be rapidly transported to build sites, then moved quickly from site to site. Vulcan prints directly on the ground or a poured slab.

A portable cement factory that feeds a Vulcan printer on location. Magma ingests dry Lavacrete, hydrates, and then adjusts the formula in real time based on the conditions at the build site itself. Once material is mixed, Magma pumps the Lavacrete to Vulcan for printing.

Lavacrete is a special cement created by ICON’s material science team to be both highly printable and incredibly strong. Lavacrete has gone through rigorous testing and development yeilding an extremely durable building material.

A collection of software products, BuildOS creates digital architecture and then helps control the robots that turn those designs into physical buildings. BuildOS software spans multiple device interfaces to accelerate construction through high-precision, parametric architecture for ICON’s construction operations.

Vulcan

Robotic ConstructionThe Vulcan is our third generation, large-scale 3D-printer system for additive construction. The current Vulcan system is 1.5x larger, 2x faster than our previous generation and capable of printing homes and structures up to 3,000 square feet without relocation. The Vulcan can produce resilient, single-story homes faster than conventional methods and with less waste and more design freedom.

The current Vulcan system is 1.5x larger, 2x faster than our previous generation and capable of printing homes and structures up to 3,000 square feet without relocation. The Vulcan can produce resilient, single-story homes faster than conventional methods and with less waste and more design freedom.

- Vulclan Size 15' x 46'-6"

-

Bead Volume 12' x 38' x 150'

Magma

Mix MasterMagma is a smart, portable cement factory that feeds a Vulcan printer with material to print a home. Intelligent and working in perfect sync with a Vulcan printer on-site, Magma takes the guesswork out of complex, high-performance cementitious material.

The Magma system feeds Vulcan printers with ICON’s advanced cement-based material, Lavacrete. Using any of ICON’s proprietary Lavacrete blends, the Magma system mixes Lavacrete, additives, and water automatically, depending on current site weather conditions, then supplies the ready-to-print Lavacrete to the Vulcan. Think of Magma as an extremely smart print cartridge, super-sized for home construction.

Weather and environmentally aware, a Magma unit adjusts & mixes ICON’s Lavacrete material in real time for the best possible material.

Build OS

Digital NativeICON’s tablet-based operating system controls every aspect of print operations via an intuitive, simple, and beautiful user interface.

The BuildOS system translates floor plans into print jobs and then directs both Vulcan and Magma, using real-time data down to the millisecond to produce the highest quality printed structures in the world.

From its powerful CAD and print planning to enable machine learning and predictive analytics for Vulcan robots, this advanced software brings construction into the 21st century.

ICON’s tablet-based operating system controls every aspect of print operations via an intuitive, simple, and beautiful user interface.

The BuildOS system translates floor plans into print jobs and then directs both Vulcan and Magma, using real-time data down to the millisecond to produce the highest quality printed structures in the world.

From its powerful CAD and print planning to enable machine learning and predictive analytics for Vulcan robots, this advanced software brings construction into the 21st century.

Materials

Rock SolidScience

Materials

Rock SolidScience

ICON’s proprietary Lavacrete can be printed at high speeds while retaining form, enabling homes to be built faster while keeping construction projects on schedule and on budget. As a high-strength concrete boasting a compressive strength of 2,000 - 3,500 psi, Lavacrete can withstand extreme weather and greatly reduce the impact of natural disasters while providing maximum efficiency.

As a high-strength concrete boasting a compressive strength of 2,000 - 3,500 psi, Lavacrete can withstand extreme weather and greatly reduce the impact of natural disasters while providing maximum efficiency.

ICON’s proprietary Lavacrete can be printed at high speeds while retaining form, enabling homes to be built faster while keeping construction projects on schedule and on budget. As a high-strength concrete boasting a compressive strength of 2,000 - 3,500 psi, Lavacrete can withstand extreme weather and greatly reduce the impact of natural disasters while providing maximum efficiency.

ICON presents bigger, faster Vulcan 3D printer » 3dpbm

Stay up to date with everything that is happening in the wonderful world of AM via our LinkedIn community.

Texas-based construction 3D printing company ICON has once again upgraded its Vulcan system. The next-gen 3D printer was announced in parallel to a new 3D printed home initiative—the Exploration Series—which ICON is working on in collaboration with various world-class architects. We’ve got our first glimpse of the inaugural build of the series, House Zero, which is designed by Texas firm Lake|Flato Architects.

We’ve got our first glimpse of the inaugural build of the series, House Zero, which is designed by Texas firm Lake|Flato Architects.

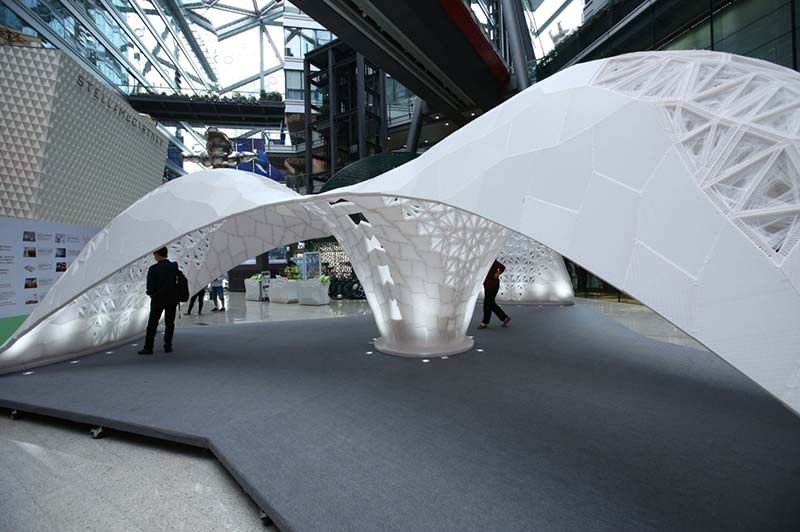

The goal of ICON’s newly launched Exploration Series is to work with architects to create new design languages and architectural vernaculars informed by the possibilities of construction 3D printing. In other words, to make the most out of the design freedom that 3D printing affords.

House Zero (Image: Lake|Flato Architects)The first house in the series, House Zero was specifically designed for 3D printing and integrates many unique features, including an energy efficient design and elevated structure. The house, which is now under construction in East Austin, will comprise a 2,000+ square foot 3 bedroom/2.5 bathroom dwelling, along with a 350 sq-ft 1 bedroom/1 bath unit—or guest house. The house’s design draws from regional styles, specifically modernist ranch house aesthetics, with the added technological flair of 3D printing.

“This is the moment when people around the world will see more of the architectural design freedom and benefits of a 3D printed house and believe that they too would want to live in a 3D printed house,” said Jason Ballard, co-founder and CEO of ICON. “If people fall in love with what we’re doing here, it turns out the Vulcan is the only construction system in the world capable of delivering this home and others like it. We are hopeful this catalyzes widespread enthusiasm and excitement for the future of construction and architecture. We’re getting ready to stand up manufacturing in our new facilities and begin larger scale projects in anticipation of such a response.”

“If people fall in love with what we’re doing here, it turns out the Vulcan is the only construction system in the world capable of delivering this home and others like it. We are hopeful this catalyzes widespread enthusiasm and excitement for the future of construction and architecture. We’re getting ready to stand up manufacturing in our new facilities and begin larger scale projects in anticipation of such a response.”

Ashley Heeren, Associate at Lake|Flato, added: “House Zero has allowed Lake|Flato to develop our ethos of human and nature-centric design with an entirely new framework. It’s been a thrill for our team to design this home of the future and explore new ways to create high-performance shelter that celebrates craftsmanship, seeks increased efficiency and eliminates steps in the construction process. This welcoming, practical home design expands the performance capabilities of 3D printing technology and is unlike any other home we’ve designed to date. ”

”

The new build is enabled by ICON’s proprietary Vulcan 3D printer, the latest generation of which is 1.5 times larger and 2x faster than the company’s previous systems. The robotic 3D printer, which weights 9,500 lbs and integrates an automated control system, has the capability to 3D print homes spanning up to 3,000 square feet. ICON has developed its Vulcan technology for the purpose of producing single-story homes more efficiently and economically.

ICON has had a prolific few years: it raised $9 million in seed funding in 2018, another $35 million in 2020, and has produced two dozen 3D printed homes and structures for the American and Mexican markets. Notably, it put its first 3D printed homes on the mainstream housing market in early 2021 in collaboration with developer 3Strands. One of the company’s main goals, however, is to use its technology to offer social housing as well as housing for disaster stricken regions. Like many others in the construction AM space, ICON also has ambitious to go beyond Earth, and is continually exploring the possibility of producing habitats on the Moon and Mars in cooperation with NASA.

Related Articles

Back to top button

Best STL Files for 3D Printing Vulkan・Cults

Kaina - My singing monsters

3.49 €

Volcano mini golf

Free

Vulcan nozzle box

Free

Volcano 23

25 €

Bondtech BMG Volcano Dual Drive Tool Head for Taz 5 etc.

Free

Salamander Hammer Symbols SM Vehicle

0.81 €

Fire salamander helmets

2 €

Universal straight extruder - BMG, V6, Volcano

Free of charge

Salamander hammer set (modsymbol)

1,86 €

Bl touch titan aero volcano fan support

Free

Ender 5 Plus Direct Drive X Carriage Project

Free

Tevo Black Widow Titan Extruder/Volcano Hotend/BLTouch Mount Assembly

Free

Ojos del Salado

2. 48 €

48 €

Black Volcano

Free

Drummer - My singing monsters

1.16 €

Firearm hammer

Free

Manta MK2 Vulkan Fan Spacer

Free

Creality Ender 5-5+ Hemera Conversion

1.94 €

Volcano Vaporizer Balloon Wall Clip - by Storz and Bickel

0.86 €

Volcano Vaporizer Smart Funnel - by Storz and Bickel

0.86 €

Mount St. Helens

Free

Mount Adams

Free

Vesuvius

Free

Seabed Hawaiian Islands

Free

BLTouch & Tronxy AutoLevel Mount for V6 and Volcano

Free

Volcano Nimble Fan Bracket

Free

SV01 Double-sided fandu for bmg, 40mm hotendfan and 50mm blowerfan

Free

Vulcan cookie cutter - Vulcan cookie cutter

0. 96 €

96 €

Mount Etna

Free

Anycubic Chiron Volcano Hot End Upgrade Kit

Free

Titan E3Dv6 and Volcano Fan Mounts

Free

Titan with E3Dv6 Volcano

Free

Convert Anycubic Chiron BMG Bowden Extruder to Direct Drive Extruder

Free

DRAGON MARINE SHIELD

5 €

SEA DRAGON SHOULDER

4,50 €

E3D V6 Dual Fan

Free

E3D 40mm dual fan for V6 and Volcano

Free

E3D V6 Volcano 4010 Fan Holder and Carriage for H-Bot

Free

SEAL DRAGON SKINS

1,50 €

SEA DRAGON HELMET

4 €

Complete collection - 17 3D models - THE MOST BEAUTIFUL MOUNTAINS IN THE USA

9. 91 €

91 €

Mount Susitna - Alaska - USA - THE MOST BEAUTIFUL MOUNTAINS IN THE USA

2.48 €

Mount Sneffels - Colorado - USA - THE MOST BEAUTIFUL MOUNTAINS IN THE USA

2.48 €

Mount Shuksan - Washington - USA - THE MOST BEAUTIFUL MOUNTAINS IN THE USA

2.48 €

Mount Shasta - California - USA - THE MOST BEAUTIFUL MOUNTAINS IN THE USA

2.48 €

Mount Ranier - Washington - USA - THE MOST BEAUTIFUL MOUNTAINS IN THE USA

2.48 €

Mount Hunter - Alaska - USA - THE MOST BEAUTIFUL MOUNTAINS IN THE USA

2.48 €

Mount Hood - Oregon - USA - THE MOST BEAUTIFUL MOUNTAINS IN THE USA

2. 48 €

48 €

Some parts of the Vulcan rocket will be 3D printed / Sudo Null IT News0001

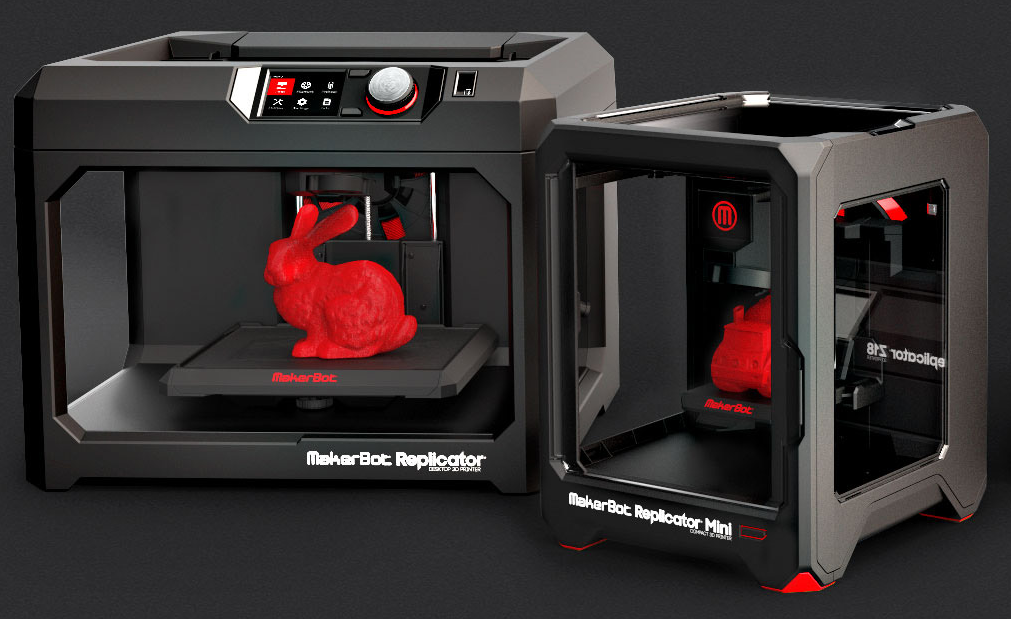

atomlib 3D printers production and simplify the development process through rapid prototyping. By printing parts made of plastic and metal, it is expected to reduce costs by a million dollars a year. For an existing Atlas V rocket, 3D printing reduced the cost of the air conditioning system by 57%.

United Launch Alliance is a joint venture between Lockheed Martin and Boeing, which makes about 12 launches a year. On April 13, at a presentation in Colorado, ULA head Tory Bruno presented a new Vulcan rocket with all-American engines. The first launch is scheduled for 2019, the cost is from $165 million. It is assumed that the engines of the first stage will be reused, for this they are going to shoot, parachute and catch by helicopter. The new missile, its engines and bold plans for reuse are a response to ULA's current partial reliance on Russian RD-180 supplies. It is noticeable that even the failed success of the landing program of the first stage of the Falcon 9 rocketSpaceX inspires fear among the leadership of the ULA.

It is noticeable that even the failed success of the landing program of the first stage of the Falcon 9 rocketSpaceX inspires fear among the leadership of the ULA.

Parts of Atlas and Delta rockets will also be printed, but it is important for ULA to introduce 3D printing at the earliest stages of Vulcan's development. The parts to be printed are now being selected. There are more than 100 plastic ones and about 50 metal ones on the lists of candidates. It is planned that 3D printing will save about a million dollars a year.

5m Volcano, ULA

Missile part is expensive, and if ordered from a third party company, it takes time to provide specifications and find a common language. If something is wrong with the part, then it will have to be sent back for revision. Time is spent not only on this, sometimes contractors do not have time to complete their work on time. In-house 3D printing makes it easy to control the production process. Printing will also be used in its traditional role for rapid prototyping. It allows you to immediately produce the desired part so that the engineer can feel it, evaluate the functionality before placing an order for its manufacture.

It allows you to immediately produce the desired part so that the engineer can feel it, evaluate the functionality before placing an order for its manufacture.

Two Fortus 900mc printers from Stratasys were purchased to fulfill these plans. First of all, these machines will be used to create a new air conditioning system for the Atlas V rocket. The system is designed for the pre-flight delivery of liquid nitrogen to the electronic components of the rocket booster to cool them. The launch with the updated SLE is scheduled for 2016. Previously, the air conditioning system contained 140 parts, which were produced by independent suppliers. With 3D printing and deposition modeling technology, this number dropped to 16, which also reduced costs by 57%. The assembly time of the device has also dropped.

Manufactured using Stratasys ULTEM 9085 thermoplastic, which has a wide operating temperature range from cryogenic to very hot. The two new Fortus 900mcs cannot print with metal, 3D printers for this purpose are still being selected.