Vsr 10 3d print

Vsr 10 best STL files for 3D printer・Cults

Airsoft Vsr-10 full cylinder guide sleeve

€1

Barrel Stabiliser MB05 n DB VSR-10 Gel Blaster

€1.94

Barrel Adaptor/Stabiliser VSR-10 and MB05 Gel Blaster

€1.94

VSR 10 Stock

€4.03

hop up vsr support

€1.25

piston guide vsr

€0.50

barrel spacer vsr

€1

bolt cover vsr10

€0.50

SCOPE BASE

€1.03

Scope Base 85mm

Free

Airsoft M870 parts set

€6

Silverback SRS-VSR Magazine Adapter

€10

VSR-10 magazine handstopper

Free

low profile TDC for SSG10 or VSR 10

€2

airsoft VSR 10

€3. 36

VSR10 / MB03 hop up chamber lever (FOR TDC)

Free

Airsoft scope knob tuning

€2.04

Airsoft Lee Enfield No4 - VSR 10 ! - R3D

€17.17

Whiskey 3 VSR10 chassis (M4 Magazine)

€4.90

High scope rail for VSR10

Free

TDC 2.0 PRO UPGRADE

€5.08

VSR 10 Airsoft Skeleton Conversion Kit

€10

VSR10 barrel cap adapter

Free

VSR-10 G-Spec Tiger tank muzzle brake

€5

VSR-10 G-Spec 14mm thread endcap

€1

BAR-10 bolt cover

Free

Barrel spacer VSR - MB44xx

Free

11 mm VSR 10 silencer

Free

vsr extended rail big

€6

vsr extended rail small

€6

VSR-10 Stock - modular

€7. 58

58

VSR-10 G-Spec stock LEFT HAND VERSION

€10

VSR HC1 stock

€6.45

VSR LTS1 body kit

€6.43

VSR LT1 stock

€6.43

VSR S1 stock

€6.43

VSR L1 stock

€6.43

VSR-10 G-Spec stock. Right hand version

€10

VSR-10 Scope picatinny

€3

VSR-10 G-spec silencer

€5

AS Val Warzone

€3.75

Novritsch SSG10 Glide Ring Tube

Free

VSR10-BAR10 MAGAZINE WALL MOUNT

€2

VSR 10 Bulpup Stock

€10

VSR 10 HPA Bulpup Stock

€15

VSR-10

€5

3d printing

have a 3d file you would like to have printed? send me an email or message with the file and what color you would like ill get back to you with a price and print options

Sort By: DefaultName (A - Z)Name (Z - A)Price (Low > High)Price (High > Low)Rating (Highest)Rating (Lowest)Model (A - Z)Model (Z - A)

Show: 25305075100

MP5k to M4 stock adapter (3D printed)

3d printed on my own printer. with high strength PETG plastic should fit most standard mp5's so..

with high strength PETG plastic should fit most standard mp5's so..

$15.00

3D Printed VSR-10 Magazine Puller

Glue one of these onto your VSR-10 magazine, and behold. It's now much easier to remove!..

$1.00

3D Printed Scorpion EVO Odin Adapter

You bought yourself a really nice gun, why not enjoy a really nice magazine loading experience?Allow..

$15.00

3D Printed Riser w/ Battery Compartment

3D printed optic riser that also functions as a battery compartment. Perfect for front-wired guns wi..

$20.00

3D Printed Rail Mount Shotgun Shell Rack

3D printed on my own printer with high strength PETG plastic.Mounts to standard Picatinny rail. Hold..

$15.00

3D Printed PEQ Battery Box

3D printed battery box for your thicc energy needs, which attaches to Picatinny rail. Great for fron..

Great for fron..

$20.00

3D Printed Odin Sidewinder Adapter (MP5)

3D printed adapter for loading MP5 magazines with an Odin Innovations M12 Sidewinder.Makes for an ea..

$10.00

3D Printed Magwell Spacer for LCT AK

Load your mags more easily with this 3D printed spacer. Just insert in your magwell and you're ready..

$10.00

3d printed c9a2 rail

3d printed on my own printer. with high strength carbon fiber PETG plastic..

$20.00

3D Printed Ares MSR to 14mm CCW Adapter

3D printed on my own printer with high strength PETG plastic.Allows Ares MSR series to be used with ..

$8.00

3D Printed AAP-01 Short Stroke Kit

Four buffers for the AAP-01's guide rod. Add as many as you see fit and enjoy the snappier action!..

Add as many as you see fit and enjoy the snappier action!..

$10.00

3D Printed Hi-Capa Stand

3D printed stand for your Hi-Capa so you can display your fly race pistol...

$20.00

3D Printed Potato Grip

Comrade, potato is not just for making of vodka. Potato is ultimate ergonomic form envisioned by cre..

$12.00

pistol stand

3d printed strong and durable single stack and double stack sizes 28x20x70 32x13x70..

$15.00

Showing 1 to 27 of 27 (1 Pages)

STL file Stock VSR 10・3D printing design for download・Cults

Airsoft electronic speed loader

2.02 €

Upper tank Airsoft M4

0,50 €

Model LMG UPPER M4 Airsoft

1. 34 €

34 €

Upper tank Airsoft M4

0,50 €

TOP M4 AIRSOFT

0,50 €

holster for airsoft 1911

1.08 €

Holster for Airsoft Glock 17

1,08 €

airsoft speed loader controlled by drill

1.34 €

Best 3D Printer Files in the Miscellaneous Category

Mystery Machine

6.81 €

Customizable Top Bar Hive internal jar feeder

Free

EDC Flashlights Holder for Glasses

Free

FrameCorp Face Palm

0,60 €

Vic Pied Piper

Free

Storage box (Polymaker boxes)

Free

Lithophane SPIDERMAN

Free

Covid-19 Decatlon / TheNice / Other mask 3M 5N11 Particulate Filter N95 Adapter

Free

Bestsellers in Miscellaneous category

ItsLitho "Pure" personalized lithophane Christmas ball

1,90 €

Wolf - Flexi Articulated Animal (printed in place, without supports)

2 €

RS-X-Bow "Government - 1911" style

6. 25 €

25 €

Eeveelution articulated mega pack

10 €

Halloween pumpkin lantern ItsLitho

1,90 €

T-800 Terminator Moving Skull

15€ -25% 11.25 €

Adderini - 3D Printed Repeating Slingbow / Crossbow Pistol

6.25€

Articulated pretty spider

2.49 €

Ghost Boom x10

1.99 €

Ciberpunk 2077 Gun Rebecca "Guts"

4 €

Polestar 2 center console accessories

7.09 €

flexible volute

2 €

Charmander - pokemon with flexible articulation (seal in place, without supports)

1,50 €

Articulated Raykuaza Flexible Dragon Pokémon

1 €

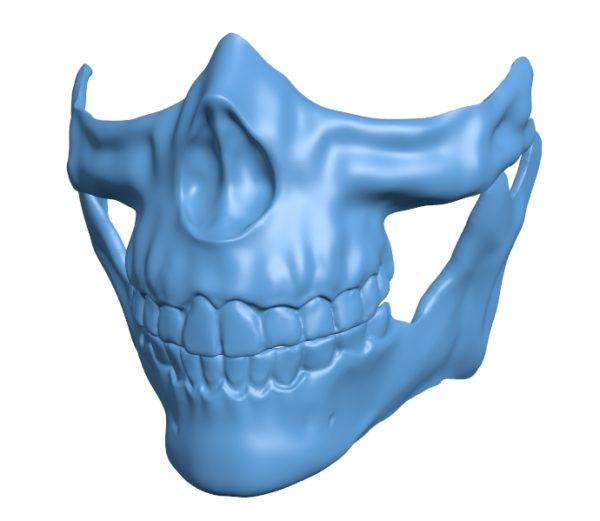

Black Phone Movie Invader 2 Piece Mask 3 Style Frowning Smile Without Mouth STL

10. 25€

25€

Predator-inspired movable mask

€6.20 -ten% 5.58 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

-

AD: Disable the AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

3D printing — Worldskills Russia national team

“

3D printing technology was invented back in the 80s of the last century, but became popular not so long ago. With this printing method, the material is layered on top of each other, forming a finished product, and not just a two-dimensional image. Thanks to this, the possibilities of 3D printing are almost limitless: you can produce both a small high-precision part and an entire structure! In this tutorial, we'll walk through the entire 3D printing process from start to finish.

With this printing method, the material is layered on top of each other, forming a finished product, and not just a two-dimensional image. Thanks to this, the possibilities of 3D printing are almost limitless: you can produce both a small high-precision part and an entire structure! In this tutorial, we'll walk through the entire 3D printing process from start to finish.

Glossary

In order to successfully master the material, we recommend that you study the following concepts:

Apparatus that works on the principle of additive manufacturing. The finished product is, as it were, "grown" from a certain material

The principle of production, in which the finished product is formed by gradually adding material to the base

Programs that allow you to cut STL models into layers and, based on this, generate a G-code in which commands are written for 3D printer

Video lecture

Synopsis

Additive manufacturing technologies

There is a huge variety of 3D printing technologies in the world today, from the oldest and simplest FDM technology to the emerging 3D bioprinting technology.

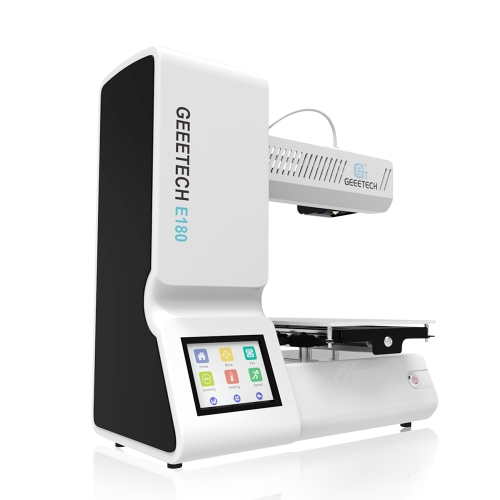

SLA (stereolithography)

Technology for the production of models from liquid photopolymer resins. The polymerization of the resin occurs due to irradiation with an ultraviolet laser at the points of contact of the material with the beam. Upon completion of the contour construction, the working platform is immersed in a tank with liquid resin for a distance equal to the thickness of one layer. After leveling the surface of the liquid material, the process of building the next layer begins. The cycle is repeated until the complete model is built.

The main advantage of stereolithography is its high printing precision. The minimum layer height can be as low as 25 microns.

Among the shortcomings, it is worth noting the high cost of manufactured models due to the high price of consumables.

Here is an example of a printed part with mechanical supports.

SLS (Selective Laser Sintering)

In this manufacturing process, a laser selectively sinters polymer powder particles, fusing them together to create layer after layer.

This technology provides high precision, detail and allows the production of parts with good and stable mechanical properties, unlike FDM and SLA. And printing in the volume of consumables allows you to print parts of even the most complex shape without mechanical supports.

Here is an example of a part printed using this technique.

MJP (Multi Inkjet 3D Printing)

This technology is based on layering an object from a wax-based photopolymer to build supports and a resin with properties selected for the part itself.

MJP is somewhat similar to SLA technology: both use photopolymer resins and UV lasers. But MJP is distinguished by more detailed printing and the presence of wax supports, which, in turn, allows you to completely get rid of the post-processing of the model.

This is what a part made using this technology looks like.

CJP (colour inkjet)

The principle of printing is to apply powdered materials layer by layer, after which a binder polymer is applied. The peculiarity of the technology is that polymers of different colors can be used, which makes it possible to create multi-colored and textured parts.

The peculiarity of the technology is that polymers of different colors can be used, which makes it possible to create multi-colored and textured parts.

This technology is used to create realistic prototypes of buildings, clothes and shoes, human organs in medicine, and to make scanned human figures.

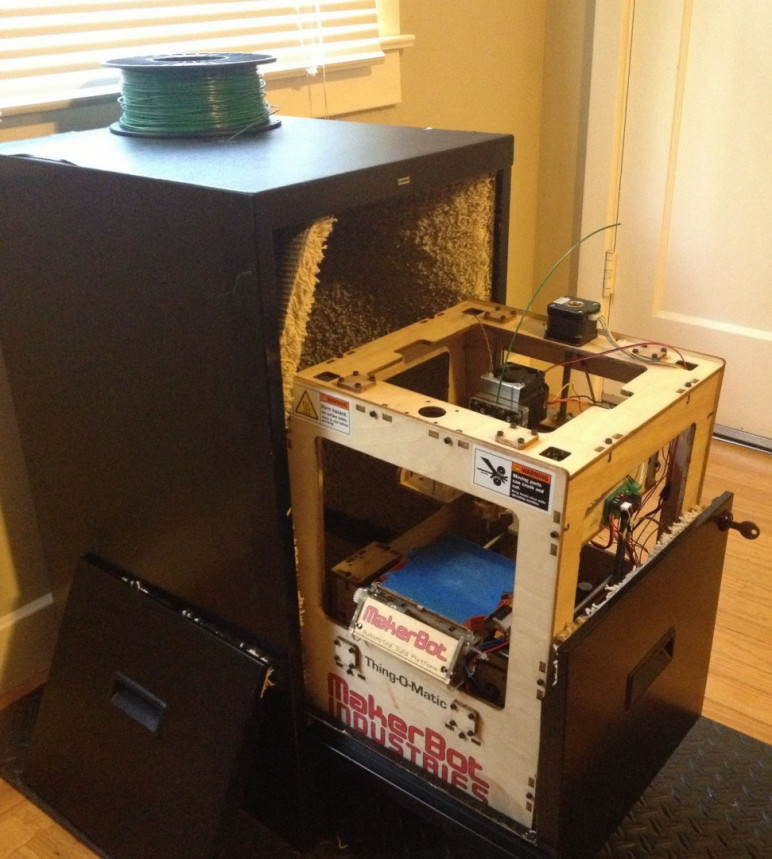

FDM (Fusion Deposition Modeling)

This technology is printed by fusing the material layer by layer.

Although FDM technology is the oldest printing technology, it has become widespread relatively recently. It includes ease of study and use, availability on the market of additive technologies and an excellent ratio between price and quality of finished products.

FDM technology allows you to use different types of media for printing. Each material differs in its properties and printing parameters. These can be:

- simple plastics: ABS, PLA;

- engineering plastics: PetG, ePeek;

- special materials: PVA, Hips, Flex.

Making a part on a 3D printer

Safety precautions

- While the 3D printer is in operation, do not reach into the working area where the printing is being done.

- Protective goggles and gloves must be worn when handling photopolymer printers that use photopolymer resin.

- Wear respiratory and eye protection when using printers that use powder media.

What We Need

3D Printer

3D Printing Plastic

Computer with Slicer 0285

USB stick

Special adhesive for 3D printing

Napkins

Making settings for printing

1.

2. We arrange the model so as to minimize the number of supports.

3. Set the print options. Set the height of the layer. It should not exceed the diameter of the nozzle installed on the printer. The higher the layer height, the faster the print, but the surface quality of the model suffers.

It should not exceed the diameter of the nozzle installed on the printer. The higher the layer height, the faster the print, but the surface quality of the model suffers.

4. Set the fill percentage. They affect the occupancy rate of the model: the higher the percentage, the stronger the model. But at the same time, material consumption and printing time increase.

5. Perform support settings. The main ones are the gaps between the model and the support body during printing. When setting supports, you must take into account the height of the layer.

6. Perform adhesion settings. They allow you to create "skirts" around the models, which increase the contact area of the model with the table. The smaller the contact area, the wider the "skirt" should be.

7. After setting all parameters, press Slicing.

8. Save the job and send it to the printer.

Preparing the printer

1. Loading material into the printer.

Loading material into the printer.

2. In the program, go to the "Plastics" section, select the "Plastic Loading" item and set the type of plastic you want to load.

3. Calibrating the printer. To do this, go to the "Service" section, select the "Desk settings" item and follow the instructions on the screen.

4. The job can be run in one of the print speed profiles: Draft, Standard, or Quality. Each profile is labeled with an estimated print time. Select the desired profile.

5. Apply the 3D printing adhesive to the napkin and spread it evenly on the table.

6. We start the job and wait for the part to be printed.

Finished product measurement and post-processing

1. Printing completed. Let the model cool down and remove it from the table.

Important

Do not remove the finished model from the table immediately, as this can ruin the model itself or even damage the table

2. We are reviewing the finished product. We take the dimensions of the physical model and compare them with the dimensions of the three-dimensional model.

We are reviewing the finished product. We take the dimensions of the physical model and compare them with the dimensions of the three-dimensional model.

3. We evaluate the surfaces of the model. Very slight roughness is the norm for FDM printing. To achieve ideal surfaces, the model needs further post-processing.

“

In this lesson, we went through the entire path of a 3D printer operator and figured out the steps that go into it. And now consolidate your knowledge by completing a small task.

Interactive task

To reinforce your knowledge, take the test

| Let's start! |

| Next |

| Check | 0409

Sorry, you answered all questions incorrectly

Read the lecture and watch the video again

| Go again |