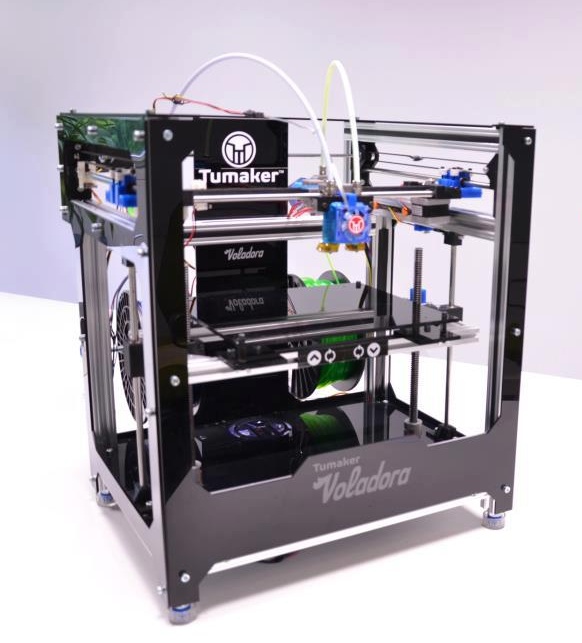

Voladd 3d printer

Tumaker Voladd 3D Printer White

Simple, productive and connected. Voladd is perfect for technical offices, professional environments and industry 4.0, who need to develop small parts or high quality assemblies and work in a network.

It´s connected. It´s 4.0:

- Voladd is a 3D printer for the 4.0 industry because it is connected in capital letters. In fact, the first thing you will do is connect it to the Voladd platform to enjoy your private area, wherever you are and whenever you want. With NFC technology, Voladd will manage consumables for you, transparently. And you can go even further with the MQTTT protocol so you can do amazing things by communicating with other robots or IOT devices.

Organize your designs in one place, to have it everywhere:

- Organize everything in a private Cloud Library as a list that you can share with colleagues, departments, team members, and even customers. Everything well organized so you can have your designs, your manufacturing, everywhere.

Advanced features for professionals:

- Behind every Voladd PRO 3D printer is the power of the Voladd Cloud. The Cloud Operating System that allows you to do impossible things until recently. In addition, the integrated Voladd platform offers advanced options for professionals that seamlessly integrate with the Voladd PRO 3D printer as well as other Tumaker products. That´s why it´s the easiest way to create and share digital objects ever created.

Easier. More productive:

- Voladd includes Voladd Cartridge, a new generation of cartridges that allows you to achieve better results and make you more productive. Stop wasting time with tedious filament charging processes. It is to install it and be operational in seconds. No fuss, you´ll be more productive.

Multiple 3D printers in one:

- Voladd is the world´s first 3D printer with cartridges that include a variable diameter printhead. An ingenious and innovative system, which allows to create objects with different definition and layer height. With Voladd you have definition control at another level. It works just like the thicknesses of a marker. When you want to have a quality object, quickly, and without definition being essential, we will use a normal point cartridge. If we want an object that requires more detail and definition, we will use HD or fine point cartridge. This way, you will be able to face different printing strategies for an infinite number of solutions.

With Voladd you have definition control at another level. It works just like the thicknesses of a marker. When you want to have a quality object, quickly, and without definition being essential, we will use a normal point cartridge. If we want an object that requires more detail and definition, we will use HD or fine point cartridge. This way, you will be able to face different printing strategies for an infinite number of solutions.

The World´s Best Leveraged Professional 3D Printer:

- Voladd occupies approximately what a 15´´ laptop with the screen open. The total size ratio with printing area is spectacular, providing a printing capacity of 3281cm3. In short, Voladd uses print space more efficiently than any other 3D printer on the planet.

Specifications:

Size:

- (x) 29cm (y) 40cm • (z) 29cm

Print area:

- 175mm (x) 12Smm (y)150mm (z).

- Total: 3281 cm3.

Printer size-printing area ratio:

- >7%

Internal computer:

- BeagleBone Black low consumption mini computer

- Processor: AMggsx IGHz cortex. A8

A8

Operati ng System:

- GNU Linux Debian RTos

Connmunication:

- Wi-Fi´ 80211 b/g,´n

- NFC

- Ethernet

- MQTT

Software:

- No software. From Web browser.

- App: Android & IOS

Printing plate:

- Removable. Neodymium magnet assembly.

- Adjustable with three high tactile precision

- Surface treatment improve grip.

- Semi-directed plate to remove objects easily.

- Optional glass platform.

Fans:

- Magnetic levitation piece coolers with activation deactivation depending on the direction of mcwement to reduce consumption.

- Noise attenuation to improve comfort-

- Main fan with automatic

Buttons & Leds:

- Multifunction button with color indicators.

- On/Off button.

- Switch dial for Voladd Cartridge assembly.

- Connectivity Led indicator 0K.

- Voladd General Status Led 0K.

- Server Interaction Led.

- Head Heating Led indicator

Safety:

- Temperature Incidence Prevention Algorithm

- Head Indicator

- 256 bit AES data encryption with TLS/SSL

- Safe insertion and blocking system for the head.

- Hiccup Overcharge Protection.

- 3096 margin for overtension.

- Protection for supply overheating with Shutdown automatic start after recovering optimal condition.

Other:

- CE, EAC Certification

- Automatic Firmware updates

Electrical and operating requirements:

- Line voltage: I OOV to 240V AC

- Frequency: SOHz to 60Hz

- Operating temperature: 230 to 350 C (730 to 950 F)

- Storage temperature: •2S to 45 (-130 to 1150 F)

- Relative humidity: to 9096 noncondensing

Contents of the box:

- Voladd 3D printer

- Voladd Cartridge 420 gr. White.

- Printing base

Weight:

- Without packaging: 4,5Kg

- With packaging: 6,9Kg

Do you want more electronics and computers products from the brand Tumaker? At techinn, your online electronics and computers store, you have at your disposal a large number of electronics and computers products related to Tumaker Voladd 3D Printer. At this moment Tumaker Voladd 3D Printer is in stock. Our customer´s needs come first to us and we select each item of electronics and computers equipment with great attention to detail.

Voladd 3d Printer – Ednology Marketplace

Purchase this Product and Earn 961 Reward Points ($48.00)

Roll over image to zoom in

Click to open expanded view

Earn 961 Reward Points

$961.27

3D printer with an integrated online platform including thousands of available objects and accessible from any device from every part of the world

Add to wishlist

Request a quote

Compare

SKU: 00294890 Category: 3D Printers

Report Abuse

- Description

- Documents

- Videos

- Awards

- Discussion (0)

Specifications

- 3D printer with an integrated online platform including thousands of available objects and accessible from any device from every part of the world

- Very easy to use: Explore, select and print instantly

- Includes NFC technology to manage consumables in real-time

- Electronics with minicomputer BeagleBone Black and operating system Linux Debian with Kerner Real time included

- Dynamic airflow system that varies depending on the print direction

Product details

- Product Dimensions: 40 x 29 x 29 cm ; 4.

5 Kg

5 Kg - Boxed-product Weight: 4.5 Kg

- Manufacturer reference: VOLADD-1

- ASIN: B0799L7XTG

No videos added!

No awards added!

Share your thoughts!

Let us know what you think...

Leave a Review Ask a Question Post a Video Post a Photo

Only logged in customers who have purchased this product may leave a review. Log in now

Ask a Question

Attach a photo or videoPhoto Video

Enter a URL (optional)

Choose a file

Post a Video

Title (optional)

Enter a URL *

Post a Photo

You must be logged in to join the discussion.

×

- Log in

- Register

Log In Your Account

Register An Account

I am a customer I am a vendor

[bws_google_captcha]

Continue as a Guest

Email address *

Already have an account? Log In

Don't have an account? Sign Up

Continue as a Guest

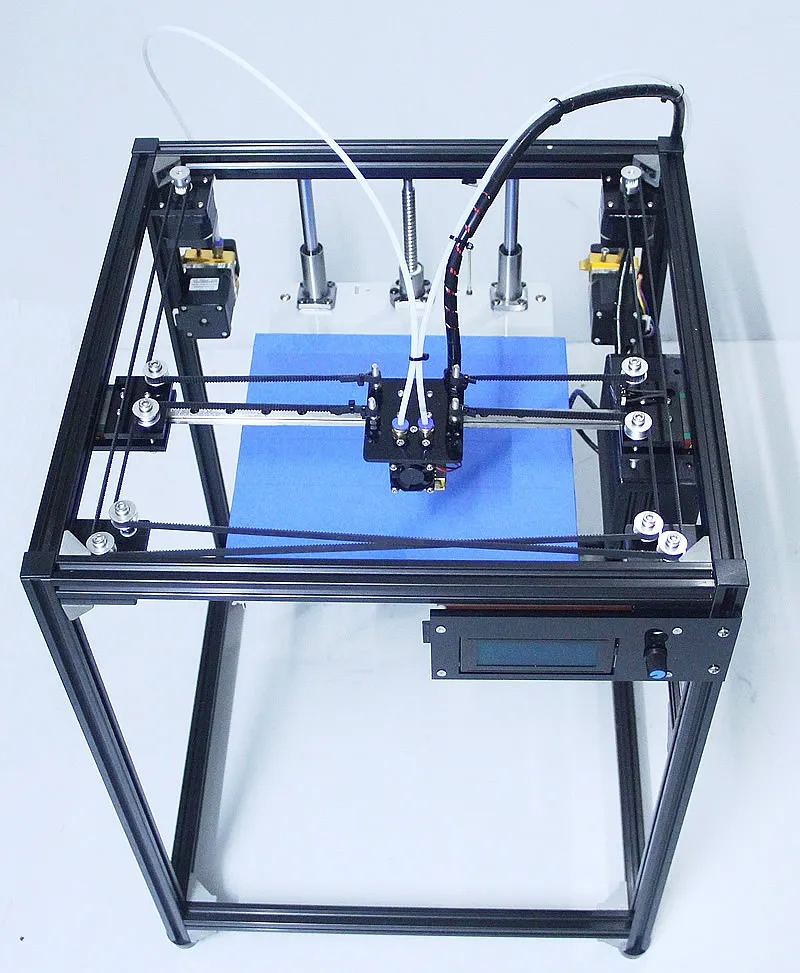

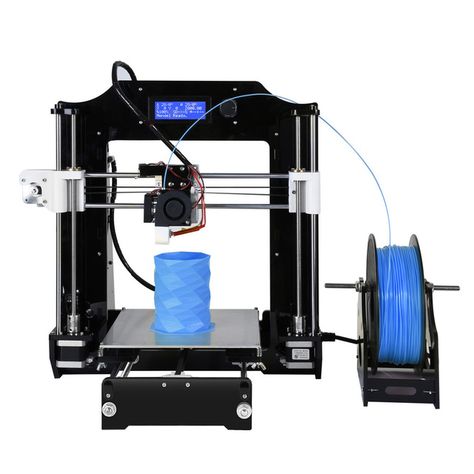

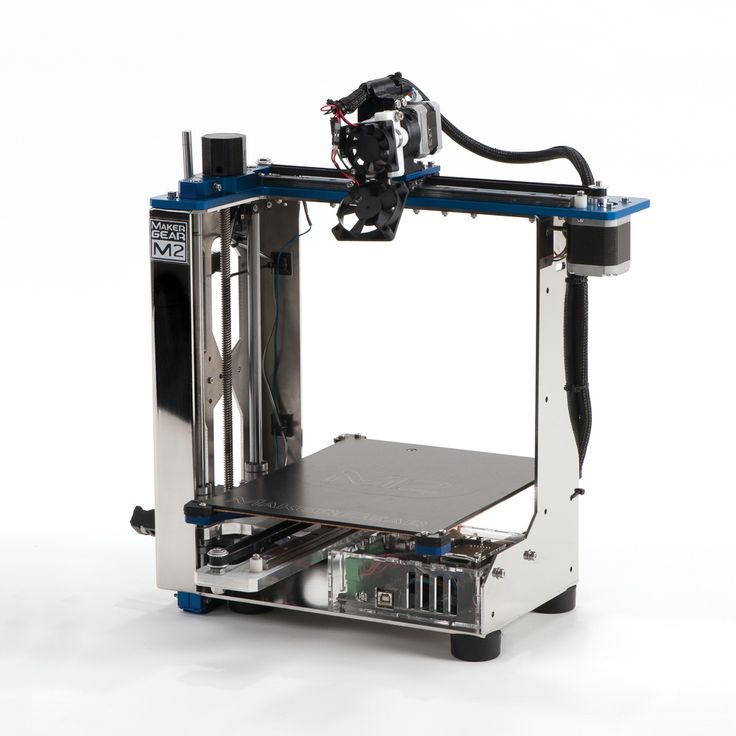

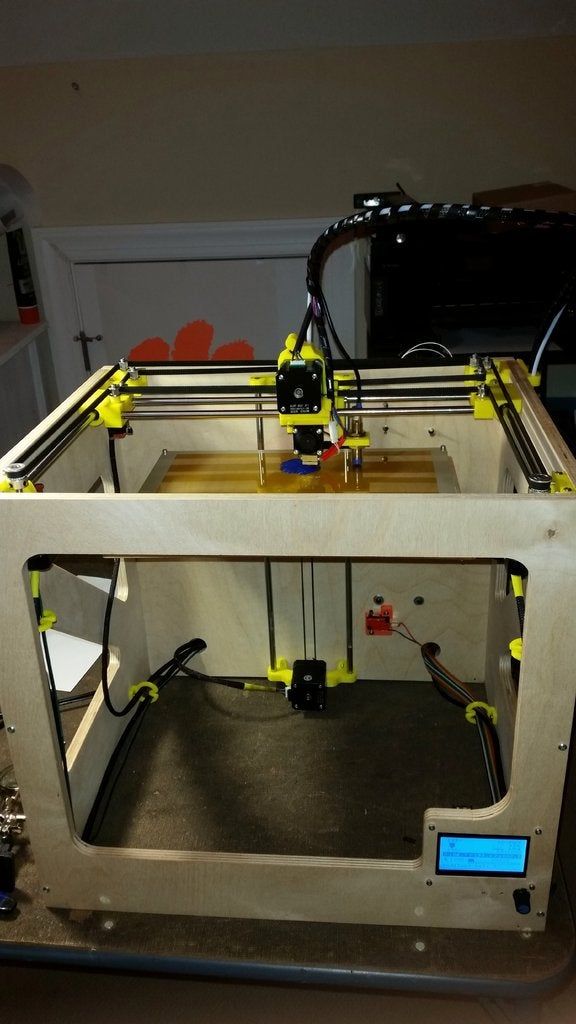

3D MC2 printer - Construction kit

3D MC2 printer - Construction kit - MC2 3D printer buy at Master Kit. Driver, programs, diagram, reviews, instructions, DIY, DIY

Driver, programs, diagram, reviews, instructions, DIY, DIY

3D MC2 printer - Constructor - MC2 3D printer buy at Master Kit. Driver, programs, diagram, reviews, instructions, do-it-yourself, DIY

You can buy Master Kit 3D MC2 printer from us - Designer - MC2 3D printer: price, photo, DIY, do-it-yourself, specifications and equipment, reviews, review , instruction, driver, programs, scheme

Master Kit, 3D MC2 printer, Constructor - MC2 3D printer, price, description, photo, buy, DIY, DIY, reviews, review, instruction, delivery, driver, programs, scheme

https://masterkit.ru /shop/1920960

Master Kit MC2 is designed to assemble a 3D printer with your own hands and is equipped with Mastertronics electronics for REPRAP 3D printers (electronics connection diagram and assembly instructions are attached).

The design is as simplified as the laws of kinematics, construction materials, modern components and electronics of the Master Kit allow.

Only 22 plastic parts! The entire assembly process was filmed!

2 types of equipment: with and without power supply.

Comparison 3D Printers Master Kit DIY

No

21 400

On admission to the warehouse

Designer Master KIT MC2 is designed to assemble a 3D printer and is equipped with MasterTronic electronics for 3D REPRAP printers (electronics connection diagram and assembly instructions included).

The design is as simplified as the laws of kinematics, construction materials, modern components and electronics of the Master Kit allow.

Only 22 plastic parts! The entire assembly process was filmed!

2 types of equipment: with and without power supply.

Master Kit DIY 3D Printer Comparison

Specifications

| Assembly Time0024 | 2-3 hours | |

| Press size (working field dimensions XYZ) | 140 x 140 x 110 | |

| Material | plastic + Metal | PLA plastic |

| Filament diameter | 1. 75 mm 75 mm | |

| Number of print heads | 1 9005||

| Supported formats | STL, GCode | |

| layer thickness | - 0.4 mm | |

| Operating temperature | 200 - 240 ° C | |

| Step table heating | no (optional yes) | |

Dimensions (XYZ)0062 | 250 x 290 x 220 mm | | |

| Power | 12 V, 5 A | |

| The speed of movement along the axes X, Y | 45 mm/s (120 mm/s maximum) | |

| Z-axis travel speed | 100 mm/min | |

| Tool type | Huxley (2 mm). Optional J-head (2 mm) Optional J-head (2 mm) | |

| Recommended power supply | 100 - 240 V, 50 - 60 HZ, 60 W | |

| Platform material | Glass 200 x 150 mm | |

| Auto -overlief - the function of the print head of the print head | 9006Minimum layer thickness | 0.1 mm |

| Weight with packaging, G | 2270 |

What are the specifications of this printer?

What are the specifications of this printer?  I have prepared a list of existing 3D printed buildings for 2020.

I have prepared a list of existing 3D printed buildings for 2020.  To strengthen the structure, it is reinforced, which can be both vertical and horizontal. The laying of the horizontal armored belt is carried out between the layers, the vertical reinforcement is installed after the composition has hardened, and then it is poured with concrete.

To strengthen the structure, it is reinforced, which can be both vertical and horizontal. The laying of the horizontal armored belt is carried out between the layers, the vertical reinforcement is installed after the composition has hardened, and then it is poured with concrete.

The main part of the castle, measuring 3m x 5m and 3.5m high, was printed as a single unit, and the towers were then printed separately.

The main part of the castle, measuring 3m x 5m and 3.5m high, was printed as a single unit, and the towers were then printed separately.  m.

m.  For its construction, the engineers used a large manipulator, at the end of which an extruder for polyurethane foam is fixed. While working, he applied the foam in accordance with the 3D model of the building loaded into it. After applying the foam, the builders periodically filled the erected part with concrete, and also inserted the frames of doors and windows.

For its construction, the engineers used a large manipulator, at the end of which an extruder for polyurethane foam is fixed. While working, he applied the foam in accordance with the 3D model of the building loaded into it. After applying the foam, the builders periodically filled the erected part with concrete, and also inserted the frames of doors and windows.  Print speed 2.5 meters / min. Each layer is 50-70 mm. The print material is concrete made largely from recycled tiles and sand.

Print speed 2.5 meters / min. Each layer is 50-70 mm. The print material is concrete made largely from recycled tiles and sand.  The walls are made up of 27 printed blocks, and the parapets needed another 21 blocks to make.

The walls are made up of 27 printed blocks, and the parapets needed another 21 blocks to make.