3D printer with camera

Anker's New 3D Printer Has a Smart Camera to Spot Failed Prints

By

Andrew Liszewski

Comments (17)Alerts

Image: Anker

On the consumer end, there’s one feature that no 3D filament printer currently offers: 100% reliability. Prints can fail for a variety of reasons that are usually impossible to predict, and while Anker’s first 3D printer makes no promises of perfect reliability, it at least saves users from hours of wasted print time with a built-in AI-powered camera designed to spot problems and failures early in the process.

Anker is currently a brand best known for its affordable charging products, including everything from durable cables, to high-powered wall warts, to batteries that keep your devices powered on the go. But it’s also a brand that has been experimenting in many other consumer electronics categories, like wireless earbuds and compact projectors. Its latest non-power product is the AnkerMake M5 and it looks like it’s trying to finally make 3D printers consumer-friendly—or at least consumer-friendlier.

The AnkerMake M5's most appealing feature is that Anker promises it’s easy to assemble and can go from unboxing to ready to print in roughly 15 minutes. A 49-point auto-leveling system is also used for the print bed which should make a process that’s absolutely critical for successful prints much easier for those with no experience in battling finicky 3D printers.

But a print bed that’s not perfectly level is just one problem in a long list of things that can potentially go wrong during a 3D print. Depending on what’s being printed, these machines can take countless hours to do their thing, and unless a part is mission-critical for another project, no one has the time or patience to babysit a 3D printer until it’s done. There’s nothing more frustrating than leaving a 3D printer to run overnight only to find out the next morning that five minutes after you walked away things went completely awry.

Image: Anker

Anker can’t guarantee that will never happen with the AnkerMake M5, but out of the box it features an integrated webcam that not only allows timelapse recording of prints to be captured and shared on social media, it also allows the user to sporadically monitor the printer’s progress remotely through a smartphone. The AnkerMake M5 also goes one step further by upgrading its camera with AI smarts that can automatically detect issues with a print, and send alerts to the user that they’ll need to intervene, potentially allowing a failed print to be saved before it becomes a giant mess of extruded plastic.

Image: Anker

Anker’s boldest claim about its new 3D printer is its speed. Out of the box and post-assembly Anker claims the AnkerMake M5 can print at 250 mm/s at its default speed for those wanting to create a high-fidelity model with a relatively smooth finish. That’s already much faster than the highest print speed on other popular 3D printers available today, but for those who don’t need as much detail and are simply looking to quickly churn out rough iterative prototypes, the AnkerMake M5 also offers an accelerated mode that boosts print speeds up to 2,500 mm/s², reducing print times by up to 70 percent.

These are some lofty claims by Anker because the old saying, ‘haste makes waste’ especially applies to 3D printing where taking a slower approach can often greatly improve the chances of a successful print. Unfortunately, it will be some time before the AnkerMake M5's capabilities can be tested because Anker is bringing it to market through a Kickstarter crowdfunding campaign launching sometime today.

The earliest backers can pre-order the printer for $429 which is much less than the eventual retail pricing which is expected to be well north of $750, Anker told The Verge. Delivery is expected as soon as September, but you’ll want to take that with a grain of salt. Anker is obviously a company that’s successfully brought countless consumer electronics devices to market, but it’s facing the same supply chain issues as every other company on Earth. There’s little doubt the AnkerMake M5's crowdfunding campaign will be a success, but as with 3D printers, a heaping helping of patience is recommended if you choose to back this one.

Top 5 Best Cameras For 3D Printers 2022 (In All Price Ranges)

Ever wondered at what point it all went wrong? No, we’re not just being philosophical about our lives — we mean in the unrecognizable mess that was supposed to be your latest 3D printing project. Without watching every second, it can be difficult to diagnose the problem.

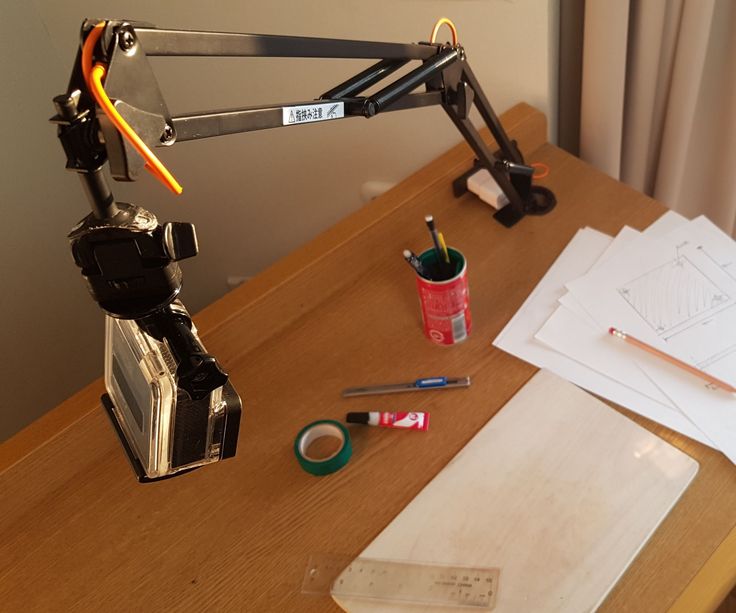

Most 3D prints take hours, so monitoring them from start to finish is a huge time commitment, and your time is too valuable to spend it camped over your printer’s extruder. The best substitute is to use a camera that is compatible with your 3D printer. That way, you can step away for as long as you like, and still keep an eye on your latest creation.

3D printing should be exciting, but wasting filament on bad prints is frustrating. Using a camera to capture the process helps you make amendments where necessary, whilst adding to the fun. Not only do they record the whole process to help with monitoring any issues, but you can also create cool time-lapses to upload so your friends can watch the magic unfold. You can even use cameras for your 3D printer for remote monitoring from potentially the other side of the globe!

You can even use cameras for your 3D printer for remote monitoring from potentially the other side of the globe!

Therefore, for this guide, we have taken our pick of the best cameras for 3D printers.

3D printer cameras are not to be confused with 3D cameras, which record 3D footage. We also have a ranking of the best 3D cameras.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Best Cameras For Monitoring a 3D Printer

Logitech HD Pro C920 – Best Time Lapse Camera For 3D Printing

- Price: Check price on Amazon here

The clarity of the HD Pro C920 makes it a popular camera in the 3D printing world. There are many 1080p cameras around, but many come out with laggier footage due to low frame rates. Thankfully, this camera offers 1080p resolution and shoots consistently 30 fps in full HD. It also boasts plenty of features that more expensive brands don’t always provide, such as still quality images via its 15MP camera.

A common downside to cameras for 3D printing is that they can be difficult to mount. A camera that falls on its side, or is lopsided and misses the action, is no good, but mounting is one of this Logitech camera’s strengths. It features a built-in tripod screw, which makes it perfect for mounting on different printers, and it is also compatible with other mounting options.

The HD Pro C920 is one of the best cameras for time-lapse videos of your 3D prints, and with its 778-degree field view, you can be sure everything is in shot.

Being a lightweight camera with motion detection technology allows it to start when the print gets going. No one wants to have to skip forward when watching the footage back, so it is great that it can be left on standby.

Wyze Cam – Best Affordable Camera for 3D Printing

- Price: Check price on Amazon here

Some of your most ambitious and thrilling 3D printing projects will take all night. When this is the case, you want a camera that can pick up every tiny detail, and still provide crystal clear images.

For any night filming in the dark, the Wyze Cam offers night vision technology. It shoots at 1080p at 30 fps to show every detail of that 3D print in progress.

Being able to operate a camera for 3D printing via voice command is great when you have your hands full. The Wyze Cam is compatible with Alexa and Google Assistant which will make it easy to find out how much longer it is going to take before the print is finished.

The included app makes remote 3D print monitoring a breeze: if over-extrusion is causing problems early on, you can stop the print to save time and money whilst preventing a drooping mess from forming. The app can even be shared with family and friends if there is a project that you need someone else to keep an eye on.

Getting close up to the footage while keeping the camera at a safe distance from the hot filament is easier thanks to its 8x digital zoom. Long printing videos can take up a lot of memory, so it is great that the Wyze Cam can record to the cloud, as well as be used with an SD card.

Instead of wasting precious seconds of footage, it can be set to start recording when it senses motion. An excellent and affordable option, the Wyze Cam 3D printer camera is a great option for any budget.

Microsoft Lifecam HD-3000 – Best 3D Printer Camera For Beginners

- Price: Check price on Amazon here

At first, the 3D printing world can be intimidating, so it is good to find an easy-to-use and budget-friendly 3D printer camera.

For a camera that is so compact, the HD-3000 records great quality, smooth video. The 720p resolution might not be as impressive as some of the other options, but this is a camera known for being reliable.

Its wide-angle record will help to capture every part of the build area, even monitoring large build volumes that go right to your print bed’s edges. This, and 4x zoom, make it ideal for cinematic style recording.

Dull images are fine if you’re recording the printing of a cube, but hopefully your creations will be more exciting. Microsoft has included TrueColor technology to enhance the brightness. This makes it capable of keeping vibrant picture quality in different lighting.

Microsoft has included TrueColor technology to enhance the brightness. This makes it capable of keeping vibrant picture quality in different lighting.

Part of what makes 3D printing so fun is the social element. The HD-3000 features built-in social media sharing, so your time-lapses can be shared instantly with the click of a button. It’s easy to use, makes sharing your printing successes as easy as ever, and it’s easy on the wallet — what’s not to love?

GoPro Hero 8 – Best Picture Quality

- Price: Check price on Amazon here

Ok, GoPro cameras don’t need any introduction, but they are ideal cameras for 3D printing. The Hero 8 shoots 4K video at 60 fps, making it one of the best cameras for 3D printing if you’re looking for resolution and picture quality.

Even when shooting at the highest setting of 60 fps, it uses HyperSmooth technology to keep the image stable.

It can be difficult to get the whole image in a shot when setting a camera up and close to the 3D printer. Thankfully, the wide-angle lens that is synonymous with GoPro makes it perfect for close-ups. Capturing every detail seems to be the name of their game.

Thankfully, the wide-angle lens that is synonymous with GoPro makes it perfect for close-ups. Capturing every detail seems to be the name of their game.

Being able to monitor your print from afar is a huge plus point, as standing around for hours at the mercy of a recording takes something away from the fun. The live HD streaming of the Hero 8 makes it a great option for anyone who wants clear images from their smartphone or tablet, and fancies live streaming their print to any interested fans or friends.

Raspberry Pi Camera Module V2

- Price: Check price on Amazon here

The Raspberry Pi 3D printing camera is astonishingly compact — it weighs just 3 grams! It is about the size of a credit card at 25 x 24 x 9mm, making it perfect for mounting into the printer’s bed.

The V2 offers the same quality pictures and video as many standalone cameras, with 1080p quality at 30 fps. This is all in full HD which makes its popularity within the 3D printing community unsurprising.

Because it is widely used to monitor 3D printing, there is plenty of online support for using the Raspberry Pi Camera Module V2. An active community helps to take a lot of the guesswork away so you can get the most out of the camera, and if you run into any issues, you can get help from others who have been in your position.

It connects via a ribbon cable which is usually included and has a fixed focus for clear pictures. If you want to just take stills, the camera packs 8 megapixels for high-quality photos.

Everyone wants to create cool videos that can move with the print bed as it works its magic. The V2 allows you to keep the print central to the image, capturing every moment without anything falling out of the shot, and it’s so light that it won’t affect your printer’s stability.

There are two main ways of monitoring a 3D print; using a camera, or 3D printing software like OctoPrint. Here is how we separate the best from the ones worth avoiding:

Software Compatibility

Raspberry Pi is one of the best hardware solutions since it makes it easy to control a 3D printer. A Raspberry Pi 3D printer camera will make it easier to use software like OctoPrint where you can control the printer remotely.

A Raspberry Pi 3D printer camera will make it easier to use software like OctoPrint where you can control the printer remotely.

Resolution

Sure, you’re not going to be shooting the next Hollywood blockbuster on a 3D printer camera, but you still want quality images if recording a time-lapse. Look for 1080P or even 4K resolution if possible.

Community Support

Many of the best cameras for 3D printing are not specifically designed to be used in this way. Purchasing a camera that is popular within the 3D printing community will help when it comes to troubleshooting any issues with setup.

How to choose a 3D printer, or why you need a heating table and a closed chamber / Sudo Null IT News In this article I will talk about the different categories of printers for this very important parameter. After all, the range of materials that the printer can print also depends on the heating of the table. I will also touch on the question of why a closed chamber is needed.

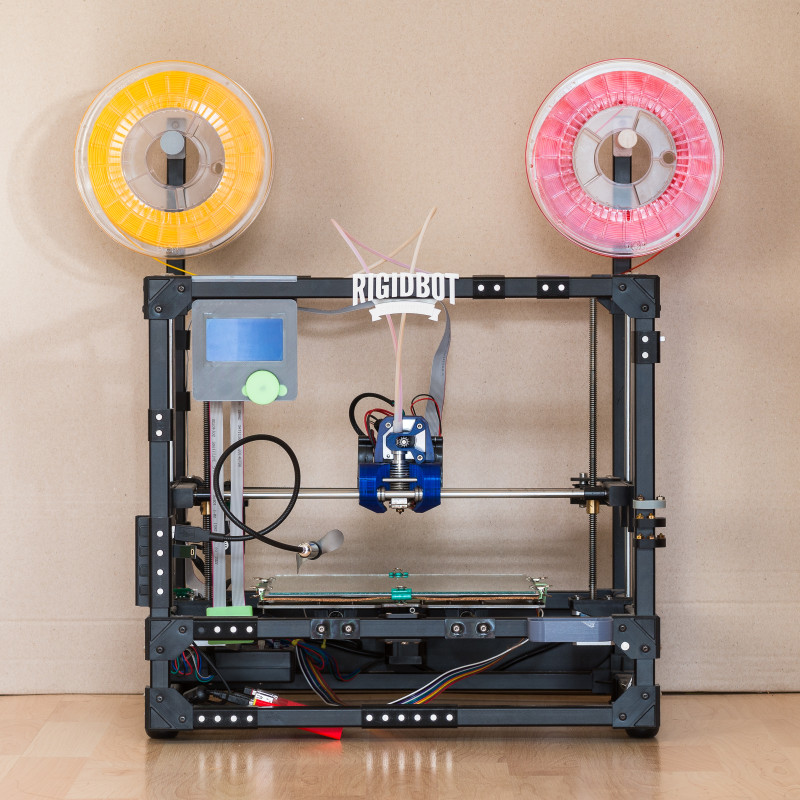

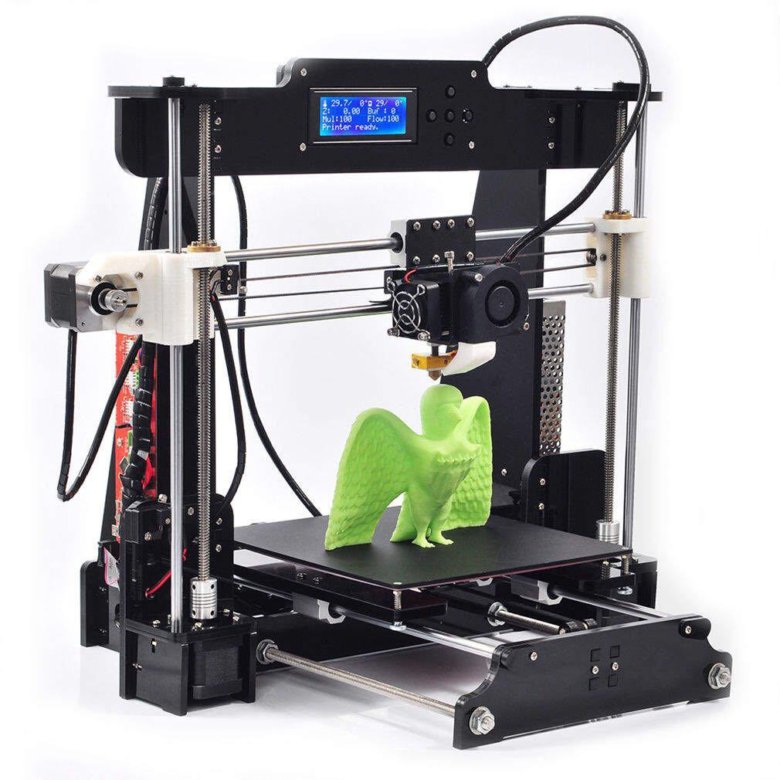

Printers without underbed heating

They are able to print only one type of plastic - PLA. This material is suitable for prototypes, souvenirs, and when heated to 60 ° C, it becomes soft and the product loses its shape. With great effort on such printers, you can try to print with other materials, but the result will not please you. Usually these are Prusa-type printers with a movable table, but there are also "cubes".

Problems occur due to shrinkage (reduction in size) of the plastic product after cooling. If the plastic shrinks (and this is almost all plastics, except for PLA), then the edges of the product begin to tear off the table on which the print is being made, the geometry of the product is irreparably damaged or it completely peels off from the table, risking damage to the print head, which continues to move.

The plus (or minus?) of such printers is that manufacturers save not only on the table heater, but on everything else. Therefore, these are cheap printers.

Therefore, these are cheap printers.

At the same time, in the description of such printers, the absence of table heating may not be indicated in any way (be careful!), but sometimes the possibility of printing with other plastics, except for PLA, is indicated, which misleads the buyer. And you will encounter printing problems after purchasing such a printer.

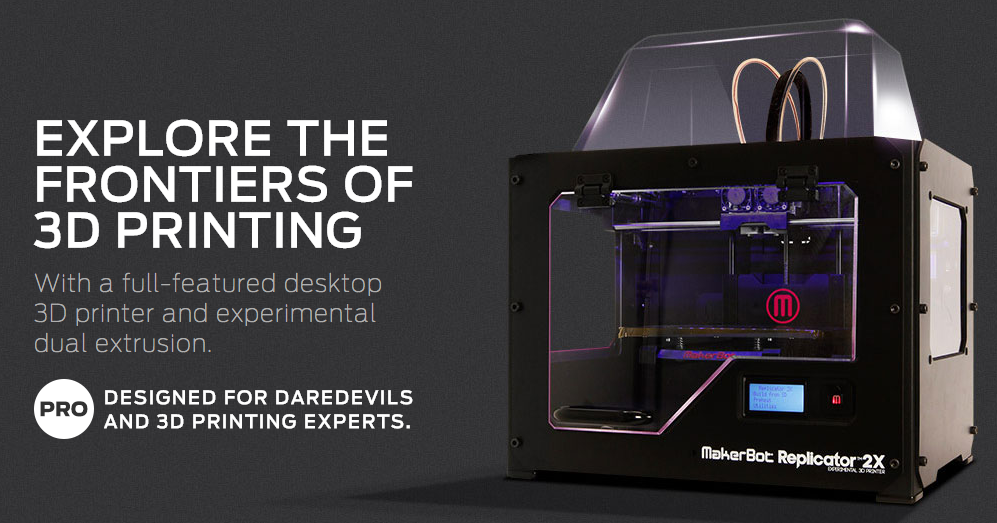

The best known non-heated printer is the Makerbot Replicator 2

From Chinese models - TEVO Michelangelo

Next, the story will focus on more interesting printers with a heated table from 100 ° C to 170 ° C, which are designed for printing with plastics with shrinkage - from classic ABS to Polycarbonate. The higher the maximum temperature of the table, the more plastics you can print, because. heating of the table prevents damage to the part due to shrinkage during printing. At the same time, the higher the melting temperature of the plastic, the stronger the table should be heated.

Printers with heated table up to 100°C

Suitable for printing with many plastics, except for technical ones. At the same time, printing large products with popular ABS plastic at such a low temperature will be problematic. In reality, ABS requires from 110°C to 130°C on the table, especially for cheap brands with high shrinkage, which are very widely represented on the market. Printing with more interesting technical plastics - nylon, polypropylene, polycarbonate, on such printers will not work at all.

At the same time, printing large products with popular ABS plastic at such a low temperature will be problematic. In reality, ABS requires from 110°C to 130°C on the table, especially for cheap brands with high shrinkage, which are very widely represented on the market. Printing with more interesting technical plastics - nylon, polypropylene, polycarbonate, on such printers will not work at all.

Chinese printers include Anycubic, various Flashforge models.

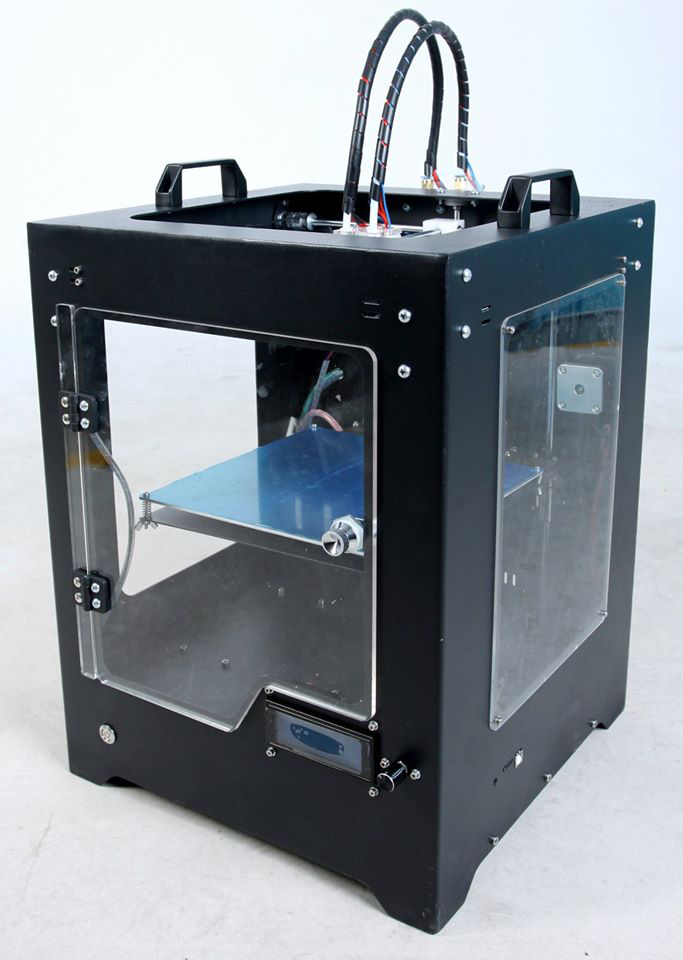

Printers with heated table up to 120°C

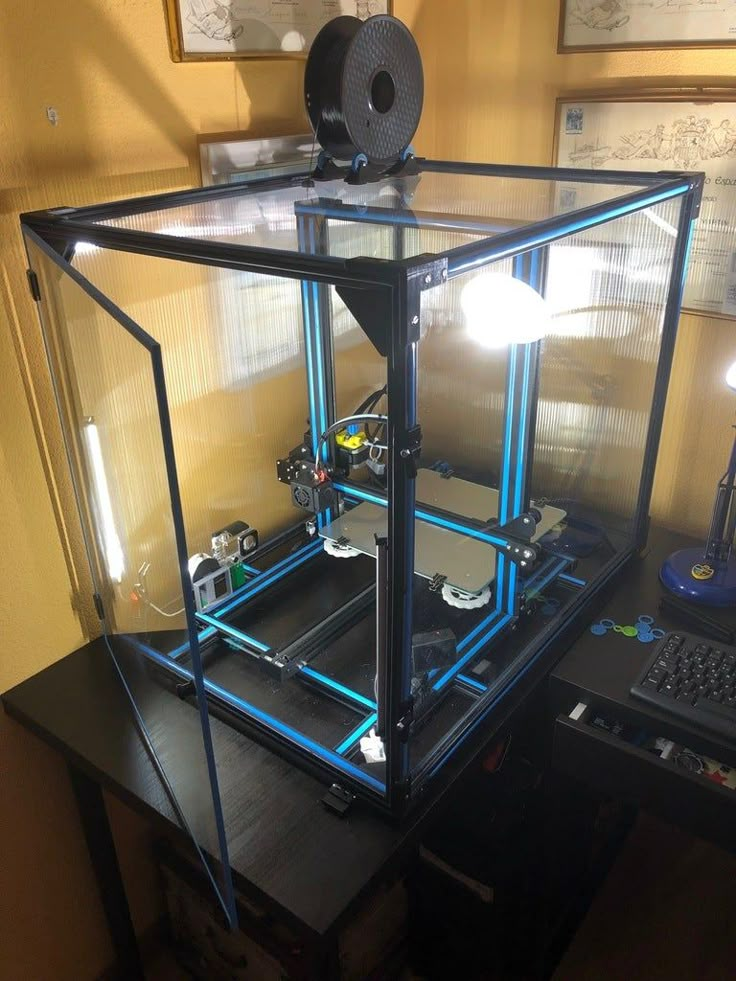

Perfect for ABS printing. But, if you need to print large ABS products, then such a printer also needs a closed print chamber. It is needed to maintain a high air temperature around the printed product, which reduces shrinkage during printing along the entire height of the product. The higher the chamber temperature is kept, the better for printing!

And this is where things get interesting. Those manufacturers who have conventional models with an "open chamber" cover them with a plastic transparent "aquarium" on top, and sellers offer them under the guise of printers with a closed chamber! Of course, such a solution is cheap, but the larger the volume of the chamber, the more difficult it is to maintain a high temperature in it, and in this case the volume increases significantly. This means that in such printers, the temperature in the chamber will be lower than necessary for high-quality printing.

This means that in such printers, the temperature in the chamber will be lower than necessary for high-quality printing.

Even more interesting is the situation when the printer is closed on the sides, but completely open on top and does not have any cover at all. At the same time, sellers pass them off as printers with a closed camera (be careful!).

The question is, why not cover any printer from above completely, without increasing the volume with an "aquarium"? Yes, because all simple models are designed so that a bundle of wires rises vertically from the extruder (print head), as well as a tube through which a thread with plastic is fed (look carefully at the photos of the printer from all sides when choosing). All this sticks out from the top of the printer and does not allow it to close normally. This is especially true for printers with remote Bowden plastic feed, where the motor pushing the plastic thread is placed on the printer body.

It would seem, so what? Well, turn the wires to the side of the extruder so that they do not stick up and do not interfere . .. However, for this you need to apply design solutions with a horizontal arrangement of wires and tubes suitable for the extruder, and design the printer initially taking into account the closed chamber.

.. However, for this you need to apply design solutions with a horizontal arrangement of wires and tubes suitable for the extruder, and design the printer initially taking into account the closed chamber.

Interestingly, even some expensive closed imported printers have a large height and an increased clearance inside the chamber between the extruder and the top cover, because. in them, the designers could not (did not want to) turn the plastic supply tube horizontally. So, in them the volume of the chamber is larger than necessary.

Most of both imported and domestic printers fall into this category.

Printers with heated table from 130°C to 150°C

These printers are already quite well developed by designers. Most of these printers do have a well-heated closed chamber with side wires and extruder tubes. They can print both large products made of ABS plastic, and small products made of technical plastics - nylon, polypropylene, polycarbonate.

Of the domestic printers in this category, we note Picaso3D and PrintBox3D.

Printers with heated table up to 170°C

Here we come to closed printers with a very high table temperature. These printers have been engineered to take into account the trend in 3D printing to increase operating temperatures, which means the ability to print with increasingly durable, heat-resistant plastics. There are few such printers, they are expensive, with rare exceptions.

Why heat the table so much? The fact is that the higher the melting temperature of the plastic, the more the table and the surrounding air in the chamber must be heated, otherwise the product will peel off the table during printing and printing will be interrupted. So, for polycarbonate, the extruder print temperature can reach 310 ° C. If small details can be printed at a table temperature of 130°C, then medium ones are already from 150°C, and large ones can be kept on the table only at 170°C.

In addition, these printers have the potential to print other refractory plastics. For example, at an extruder temperature of 400°C, PEEK (polyether ether ketone) can be printed. This refractory and durable plastic is used in aviation and space technology.

In this high-temperature category, we note the Chinese Intamsys FUNMAT HT printer with an extruder temperature of up to 450°C, a bed temperature of up to 160°C.

Of the domestic ones, we cannot fail to mention the Faberant Cube

3D printer with extruder temperature up to 340°C, bed temperature up to 170°C.

Terminals

If you want to print with different plastics, and not just one PLA, then the 3D printer must have a heated bed. If you intend to print large ABS products, then you need a real closed chamber, without an "aquarium" on top. The higher the maximum table temperature, the greater the range of materials you can use in your printer. For printers with a heated bed up to 170°C, this range is very large, up to polycarbonate and PEEK, if the heating of the extruder allows.

For printers with a heated bed up to 170°C, this range is very large, up to polycarbonate and PEEK, if the heating of the extruder allows.

In the following articles, the story will go into more detail about the maximum temperature of the extruder, kinematics and other things.

PEEK 3D printer overview

Contents:

- Introduction

- Material Features PEEK

- Professional and industrial 3D printers

- Apium P220

- TOTAL Z Anyform 500-PRO HOT+

- Creatbot PEEK-300

- AON3D M2 2020

- IEMAI Magic HT Pro

- TSAR 3D TS547-PEEK

- Tractus T850P

- Stratasys F900 Pro

- Conclusion

Introduction

PEEK is widely used in traditional manufacturing, but it is also used in some 3D printers. The thermoplastic polymer offers impressive mechanical properties including high temperature performance, mechanical strength and excellent chemical resistance. These properties make it popular in additive manufacturing, especially for metal replacement.

These properties make it popular in additive manufacturing, especially for metal replacement.

It would be a crime to ignore such a versatile polymer, and 3D printer manufacturers have not ignored it. With the development of additive technologies, 3D printers that print, among other things, with PEEK material, are becoming more accessible not only for large-scale industries with large budgets, but also for medium and small businesses and even for private clients. From PEEK it is convenient to print prototypes of future metal products and even final products that will immediately go to work. The market for printing with engineering materials is constantly expanding, which invariably causes two consequences: a decrease in the cost of the installation itself and an increase in its build chamber.

PEEK material features

To print PEEK, the printer must have 3 important features:

- High temperature extruder

The melting point of PEEK is 343° C. This means that the extruder must be heated to at least this temperature, and in fact to a higher temperature. The hot end of the extruder must also be all-metal and resistant to abrasives.

This means that the extruder must be heated to at least this temperature, and in fact to a higher temperature. The hot end of the extruder must also be all-metal and resistant to abrasives. - Heated print platform

For printing high performance resins, a heated bed is required, which must be heated to at least 120° C. This ensures the correct adhesion of the first layers and the overall quality of the 3D print. - Closed heated chamber

PEEK is very prone to shrinkage and warpage. Ideally (and this is especially important for large parts), the printer should have a closed chamber and maintain the temperature in it at 143 ° C, i.e. glass transition temperature of PEEK. Otherwise, the product will delaminate after printing.

It is extremely important to control these temperatures and keep them constant, as fluctuations can ruin the print.

Using their experience, our company's engineers have compiled a list of modern 3D printers capable of printing with PEEK and other refractory plastics. If you are planning to get acquainted with printing with engineering plastics or start production using 3D printing, we offer our TOP printers in 2020.

If you are planning to get acquainted with printing with engineering plastics or start production using 3D printing, we offer our TOP printers in 2020.

Professional and industrial 3D printers

Apium P220

I would like to start with the Apium P220 printer. Apium is one of the first printers to print with PEEK, the benchmark in print quality in the industry. The manufacturer deliberately does not increase the print chamber, as is fashionable with other manufacturers, in favor of the quality of the resulting products. The

P220 is classified as a professional printer only because of its small size and low noise level, in fact, in terms of print quality and technologies used in the installation, this printer can be safely called industrial. The printer produces all the required temperatures: the extruder is heated up to 540° C, the table - up to 160° C, and the temperature in the chamber can be stably maintained at 180° C. Build area 205x155x150mm

In addition, the printer has a unique technology for maintaining the temperature in the print area, thus allowing the lower layers already printed to cool down a little. This approach as a result increases the accuracy of printing, adhesion between layers and improves the controllability and predictability of the entire process. Even the smallest details are printed perfectly.

This approach as a result increases the accuracy of printing, adhesion between layers and improves the controllability and predictability of the entire process. Even the smallest details are printed perfectly.

TOTAL Z Anyform 500-PRO HOT+

Undoubtedly the best domestic industrial printer that prints with engineering plastics. There is a large insulated build chamber measuring 500x500x500mm and the ability to maintain a temperature of 300°C, which is even redundant for PEEK printing. The basic printer is equipped with one extruder with a working temperature of 500 ° C, optionally you can install another one of the same.

The printer fits through a 900mm doorway, which in turn means it will fit in almost any lab or office.

Creatbot PEEK-300

PEEK 300 is a 3D printer from the Chinese manufacturer Creatbot. It offers a lot of features that are usually found only in more advanced industrial-grade 3D printers. Thanks to the high temperature extruder and closed chamber, this machine can print consistently good results on both PEEK and PEI. The extruder is heated up to 500°C, and the platform - up to 200°C, constantly maintained temperature in the chamber - up to 120°C.

The extruder is heated up to 500°C, and the platform - up to 200°C, constantly maintained temperature in the chamber - up to 120°C.

It also has a low filament sensor to alert the user when the filament is about to run out. In addition, it is equipped with the function of baking the product directly in the build chamber. The printer has an impressive build area of 300x300x400 mm.

AON3D M2 2020

Aon-M2 2020 is one of the largest printers, the build area has dimensions of 454x454x640 mm and allows you to print complex tooling, cases and many other large format products.

Aon-M2 2020 is designed for printing on high performance thermoplastics such as PEEK, PEKK, ULTEM. It is compatible with many material brands including Solvay, Sabic, DSM, Infinite Material Solutions and more and comes with proven print profiles for them. This printer has two independent extruders, one for printing polyetheretherketone (PEEK) parts directly, the other for printing supports.

Despite its size, the printer is up and running in less than 15 minutes.

IEMAI Magic HT Pro

Another Chinese-made printer. The unit has all the necessary kit for printing PEEK plastic and fits easily on the desktop. The printer is also the most budget-friendly in the line of high-temperature printers. The size of the construction area is 310x310x480 mm, with a maximum temperature in the chamber up to 120° C.

The unit is perfect for the production of product prototypes.

TSAR 3D TS547-PEEK

Another domestic printer, which, according to the manufacturer, allows you to print PEEK plastic. The printer has an impressive build area and supports the ability to print with any plastic available on the market.

The printer stands out with a patented extruder change mechanism that allows you to change the extruder in less than a minute. You can even add a pellet extruder to the printer.

Tractus T850P

The Dutch company Tractus 3D specializes in the development of Delta printers. In fact, the T850P is the only delta printer on the market that prints with engineering plastics. This FDM printer has a build area of 550x476x1140mm and is great for the office. It can process materials such as PLA, PEEK and ULTEM. The T850 extruder heats up to 450°C and the platform heats up to 175°C. According to the manufacturer, the extruder requires less than 90 seconds to warm up to operating temperature. The T850P can print at speeds up to 450 mm per second with a resolution of 10 microns.

In fact, the T850P is the only delta printer on the market that prints with engineering plastics. This FDM printer has a build area of 550x476x1140mm and is great for the office. It can process materials such as PLA, PEEK and ULTEM. The T850 extruder heats up to 450°C and the platform heats up to 175°C. According to the manufacturer, the extruder requires less than 90 seconds to warm up to operating temperature. The T850P can print at speeds up to 450 mm per second with a resolution of 10 microns.

The printer is equipped with a filament dryer, which is also unique to delta printers.

Stratasys F900 Pro

The F900 is an industrial 3D printer manufactured by FDM patent holder Stratasys. Currently the largest PEEK printer. The printer works only with Stratsys materials, but it gives the user guaranteed print quality right out of the box, there is no need to test and configure the printer for each new spool.

The printer software provides a preview of the model. The printer has a built-in video camera with which you can monitor printing in real time. The build chamber size is 914x609x914 mm.

The printer has a built-in video camera with which you can monitor printing in real time. The build chamber size is 914x609x914 mm.

Conclusion

In conclusion, I would like to say that despite the apparent similarity, each printer has its own unique set of functions and purpose. This once again proves that the printer must be selected based primarily on the planned tasks.

If you have any questions about printing PEEK plastic, we will be happy to answer them.

Buying a PEEK printer in our company you get 20% discount on filament. You can choose a printer at the link: https://topstanok.ru/oborudovanie_dlya_3d_pechati/professionalnye_3d_printery/f/materialpechati-2098/

At TopStanok you can order not only equipment for printing with engineering plastics PEEK and ULTEM, but also printing products from engineering plastics to order. Turning to our company, you get an engineering study, assistance in the selection and operation, as well as an official manufacturer's warranty!

Read our other articles about engineering plastics and PEEK printing:

- Printing features of PEEK plastic

- Printing with PEEK and ULTEM (PEI) engineering plastics

For all questions, our specialists will be happy to advise you, you can contact them in any convenient way:

- By e-mail: Stanok@topstanok.

Learn more