3D printer water soluble filament

Water Soluble Filament: Properties, How to Use, and Best Brands

3D Insider is ad supported and earns money from clicks, commissions from sales, and other ways.

Anyone who has ever been interested in 3D printing knows about ABS and PLA. After all, they are the stars of the show, so to speak. However, as in any movie or TV show, there are also some supporting characters who are less famous but are no less vital to the bigger picture. Water-soluble filaments fulfill this role in 3D printing. In this article, we go over what water-soluble filaments are, how they work, how to use them, and which brands you should buy.

What are water-soluble filaments?

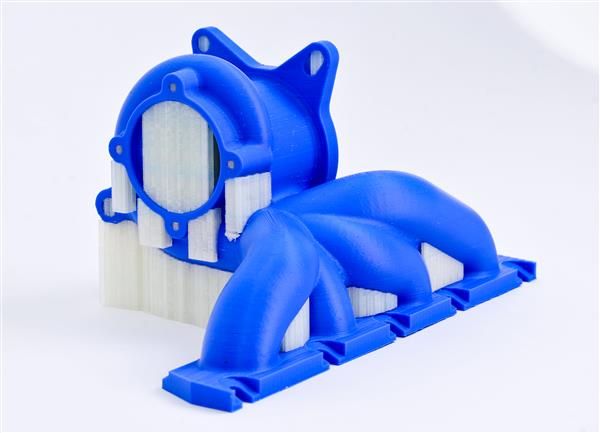

As the name implies, water-soluble filaments produce prints that dissolve when soaked or submerged in water. If you have never used them before, you might ask – what will a print that degrades so easily be good for? Water-soluble filaments are primarily used to create support structures. You may be eyeing a design that has several overhanging features or have parts that are more complex than usual. If you do not want your print to fall apart before you are even done printing, then it would be a good idea to incorporate support structures into your design.

The most common compound used for water-soluble filaments is polyvinyl alcohol, or PVA. Being a polar compound, PVA completely dissolves in water, although the process may take a couple of hours. It is non-toxic and biodegradable, making it the material of choice for many industrial applications, such as textile glazing, paper coating, and contact lens solutions.

The best part about using PVA is that it breaks down into harmless and non-toxic alcohols after it dissolves in water. This means that you can safely dispose of the dissolved solution down your drain after using, although we still recommend flushing it down with liberal amounts of water to remove the alcohol-saturated solution from your drain pipes.

How do they work?

Prints with support structures made with PVA only need to be soaked in water to dissolve the support material. It can take up to 24 hours for PVA to fully dissolve. This process can be accelerated by using warm water, or by agitating the solution every now and then. You can even use a sonicator to really quicken up the dissolving process.

It can take up to 24 hours for PVA to fully dissolve. This process can be accelerated by using warm water, or by agitating the solution every now and then. You can even use a sonicator to really quicken up the dissolving process.

It is essential to use sufficient water to allow for the complete dissolution of PVA. PVA tends to become water-starved quickly and will form solid and viscous clumps under these conditions. Should this happen, mixing the solution or manually removing the support material using pliers are easy remedies. You might have to experiment a little to get the perfect ratio of water to PVA material.

How do you use water-soluble filaments?

PVA in particular works really well as a support material in tandem with PLA since they print at practically the same temperature range. If you are printing with PLA and will need to provide support structures, then PVA is by far your best choice. It is also possible to use PVA in tandem with other filaments, such as Nylon or TPU, but this may not be as easily done as with PLA. In such cases, you may want to consider other materials for support structures such as HIPS.

In such cases, you may want to consider other materials for support structures such as HIPS.

Since PVA will be printed simultaneously with PLA, you will need to use a printer that is capable of dual extrusion. If this is something that you do not have right now, then we recommend that you get an upgrade. Dual extrusion printers not only allow you to print designs with support structures, but you can also make prints using two filaments with different colors. The upgrade will definitely be worth it as it opens up a whole new dimension of 3D printing.

A temperature of 185 °C to 200 °C works best when printing PVA in tandem with PLA. PVA tends to break down rapidly at too high temperatures, so make sure that you do not go over 200 °C. At extremely high temperatures, PVA undergoes pyrolysis, the products of which cannot be removed by high temperature treatment. Removing burned PVA may require some heavy drilling, or you might have to replace your extruder altogether, so you will have to be extra careful.

A heated bed is not necessary when printing with PVA, but it will help in ensuring better adhesion for both PVA and PLA. We recommend using a heated bed at a temperature of 45 °C to 60 °C. If you are not using a glass heated bed, then a layer of blue painters’ tape or glue stick applied to the surface should significantly aid adhesion. To reduce warping, you may set the bed temperature a little on the high side during the first few layers and gradually decrease as the print progresses.

PVA is quite soft and fragile at high temperatures, so we recommend printing at low speeds. You may start at a very low setting of 30 mm/sec and try to work your way up. To quicken up the cooling of the print, you may use a cooling fan at 50% setting.

What are the best brands of water-soluble filaments?

Being fairly common, there are currently a lot of choice of water-soluble filaments in the market. We highlight the best ones in terms of price and performance below so you will not need to spend unnecessary time choosing.

The PVA filament from the reliable GizmoDorks brands is a good place to start. Coming from a well-known filament manufacturer, this PVA filament will likely have good quality and consistency. The GizmoDorks PVA filament is available in standard 1.75mm and 2.85mm diameters, and are sold in 0.5kg spools.

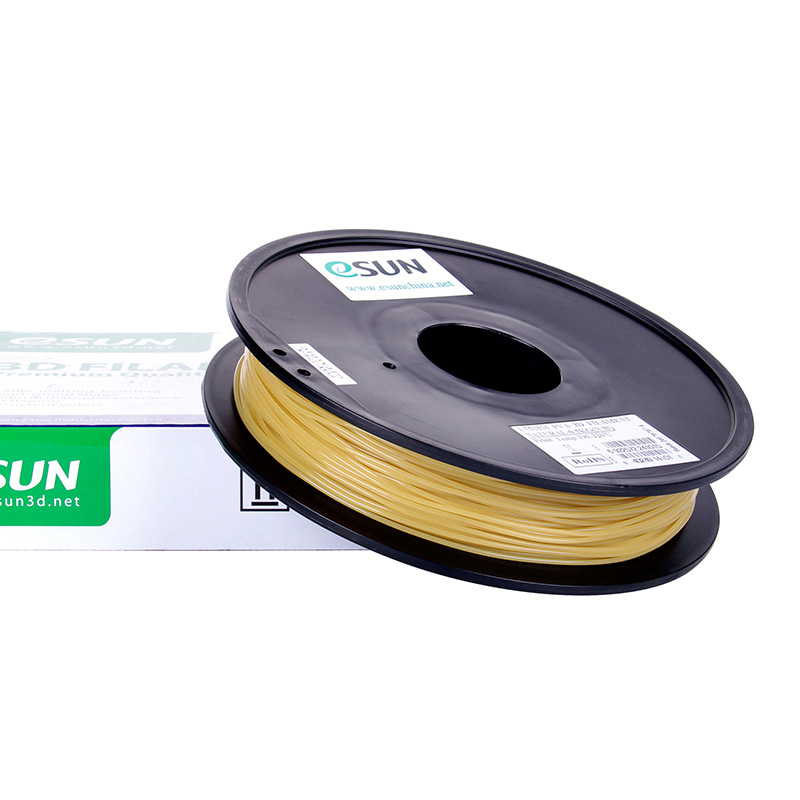

The PVA filament from eSun is also another popular choice amongst 3D printers. The filament is pretty much within the price range of other brands, and many users have reported great performance and ease of use with it. It is available in 1.75mm diameter and in 0.5kg spools.

SainSmart also sells its own version of a no-frills PVA filament. It has all the usual benefits of PVA as a support material and has good compatibility with a wide range of standard 3D printers. Users of this filament have said that it detaches very easily from the PLA, making it easier and quicker to do post-processing dissolution. The SainSmart PVA filament is available in 1. 75mm diameter and in 0.5kg spools.

75mm diameter and in 0.5kg spools.

Finally, the Hydrofill Water Soluble Filament from AirWolf 3D is probably the fanciest entry in this selection. This filament was designed to withstand higher temperatures, so it may be used in tandem with either ABS or PLA. It still readily dissolves in water, so you will not need to buy any other solvent (unlike HIPS). Given its wide printing temperature range, we imagine that you can even use this filament to make support material for other filaments, such as Nylon. It is a little more expensive than the standard PVA filaments, but it opens up a world of possibilities in terms of material compatibility.

The final word

Water-soluble filaments may not be the star of the show, but there is no doubt that they are an essential ingredient when printing highly complicated 3D designs. We consider them specialist filaments, in that they only serve one purpose but perform its objective really well. If you are planning to print complicated designs or designs with long overhangs, then you might have to start learning how to use water-soluble filaments.

It might take some tweaking and some experimentation before you get the hang of working with water-soluble filaments, but they are well worth the effort given the number of designs that you will suddenly be able to make. To top it all off, using water-soluble filaments makes the task of removing support material practically effort-free, on top of being environment friendly. If your goal is to up your 3D printing game, then we suggest buying your first spool of water-soluble filaments and going to town with it.

Warning; 3D printers should never be left unattended. They can pose a firesafety hazard.

PVA Water Soluble Support 3D Printing Filament

$48.00 – $72.00

4 interest-free payments with Learn More

AquaTek™ PVA [Polyvinyl Alcohol] is a water-soluble support filament based on a new generation of PVA. This filament is ideal for printing complex parts using PLA, PVB, Nylon, and TPU.

[yith_wcwl_add_to_wishlist]

SKU: Select options above Brand: AquaTek™ Categories: Water Soluble Support, Support Filaments

- Description

- Reviews

- Questions & Support

This is a water-soluble support filament based on a new generation of PVA (polyvinyl alcohol, PVOH). AquaTek™ PVA Water Soluble Support is tap water-soluble and is easily removed from the printed part with room-temp water.

AquaTek™ PVA Water Soluble Support is tap water-soluble and is easily removed from the printed part with room-temp water.

Extruder Temp

190-220°C

Bed Temp

23-70°C

Heated Chamber

Not required

Nozzle Specs

No special concerns

Bed Adhesion

Magigoo Bed Prep

Layer Height

No special concerns

Drying Specs

65°C for 4 hours

Supports

PVA is water soluble

Benefits of AquaTek™ PVA:

- Superior to traditional PVA filament

- Easily soluble in warm water

- Eco-friendly, biodegradable, and safe to dispose in house or office drains

- Ideal support material for the most popular desktop printing materials

Compatible Materials:

- AquaTek™ PVA is an industry favorite water soluble support material, it works excellent with all the following, and is very popular among makers and the desktop 3D printing community.

9 ohm surface resistivity on 3DP sample using concentric ring test method.

9 ohm surface resistivity on 3DP sample using concentric ring test method. - Note: Internal studies have indicated that increased extruder temperatures can achieve higher levels of conductivity. Likewise, lower extruder temperatures have resulted in lower levels of conductivity. Each printer is set up differently, as well as varied printed part geometries. Therefore, expect some trial time to understand how this filament works with your specific printer and in the context of your specific application.

Recommended Support Removal Techniques:

Break away excess support material that’s easily accessible. This reduces dissolution time (more support material = a longer time to dissolve).

Submerge the part in warm water. Hot tap water is typically 38-49°C, which is more than adequate for dissolving AquaTek™ PVA. Please be safe with hot water!

Agitating and stirring the water reduces dissolution time further, either with mechanical agitation or a sonic cleaning bath system. Re-heat or replace the warm water as it cools off for as long as you still see support material un-dissolved.

Re-heat or replace the warm water as it cools off for as long as you still see support material un-dissolved.

Residue is ecologically safe and can be disposed of down a home or office drain. Rinse thoroughly with fresh, warm water.

Filament Specifications:

1.75mm and 2.85mm +/- 0.05mm in diameter

Recommended Print Settings:

- Extruder: 190-220°C

- Bed Temp: 23-70°C

- Bed Prep: Magigoo Bed Prep gives us the best results.

- Heated Chamber: Not required

- Other: AquaTek™ PVA will absorb moisture from ambient humidity like crazy, therefore best practice is to dry and store filament in a sealed container while not in use.

- Drying Instructions: 65°C for 4 hours

Questions?

Send us a message and we'll reach out as soon as we can!

Please enable JavaScript in your browser to complete this form.Name *

Business / Organization

Email *

Phone

What can we help you with? *

Newsletter Signup

- Sign me up for the 3DXTECH newsletter

Using Dissolvable Filament to Create Supports

Using Dissolvable 3D Printing Filament is an easy and effective way to create support structures for your 3D printed part. In this article, we'll take a look at the different types of dissolvable filaments on offer, the benefits of using them over insoluble filaments, and tips and tricks for the smoothest possible printing process.

In this article, we'll take a look at the different types of dissolvable filaments on offer, the benefits of using them over insoluble filaments, and tips and tricks for the smoothest possible printing process.

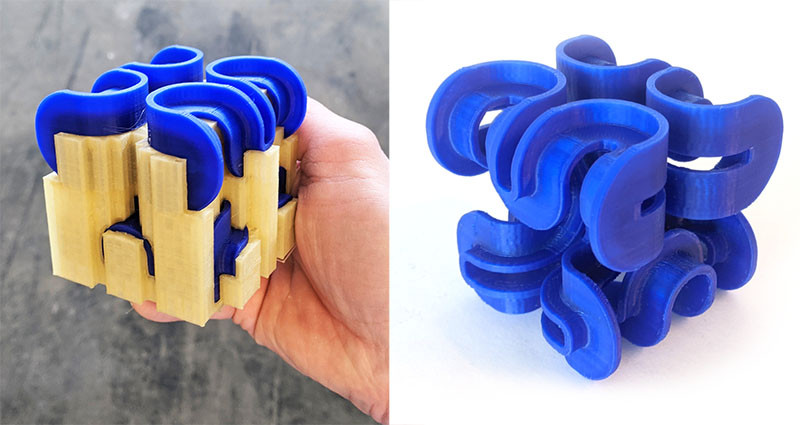

FDM 3D printing is a manufacturing technology that allows you to create parts with complex geometries that are usually impossible to obtain using traditional methods. However, when using this technology, each layer of the part requires supports, either on the structure of the part itself or on an additional support structure.

With a single extruder 3D printer, you are limited to using the base material of the printed part to create the support structure. Things are different with dual-extruder printers, since dissolvable filaments can be used to create support structures.

Soluble 3D Printing Filament Types

Water Soluble 3D Printing Filaments

Such materials are known for their solubility in ordinary water without any aggregates. This makes them an excellent option, as their dissolution does not pose any danger, and also does not cause any reaction to the base material of the product.

This makes them an excellent option, as their dissolution does not pose any danger, and also does not cause any reaction to the base material of the product.

One of these materials is PVA, which is the most commonly used support material in 3D printing. BVOH is another widely used material with better material compatibility than PVA as well as faster dissolution time.

Water Soluble Chemical 3D Printer Filaments

Some industrial grade materials are not compatible with filaments such as PVA or BVO due to their chemical properties and/or heat resistance. For this reason, materials like BVOH or PVA have been designed with additional properties to make them compatible with high temperature materials such as PEEK, PEKK, PPSU, PP and others.

In order to dissolve these supports, the pH of the water must be acidic in order to break down the sugar that this type of material normally contains, as this is less dangerous than the use of solvents.

Soluble 3D Printer Filaments with Organic Solvents

These are the least used materials due to the difficulty of using organic solvents with polymers most used in 3D printing as the solvent can react with the print material and damage it.

The advantage of using these materials is their high compatibility with the construction material. The most common example is HIPS as a support material for ABS.

Insoluble and dissolvable filaments for 3D printers

Soluble filaments for support structures have advantages and disadvantages compared to using insoluble filaments:

- Easy to remove supports

- Since the supports are soluble, simply dip the model in the appropriate solvent and wait until the supports are gone. This is very useful for parts with a very complex structure.

- Improved contact surface quality

- This advantage is related to the first point; since the material is easily removed, a strong base can be created in the area where supports are required, resulting in a smooth surface without filament residue.

- Less need for post-processing of the model

- The ability to print complex 3D models with high surface quality using dissolvable filaments also reduces the need for post-processing tasks such as polishing, sanding, gluing, etc.

- Longer print times in increasing the time of 3D printing, since materials need to be changed in the process. However, there are techniques for optimizing the support structure to reduce this problem.

Tips for creating support structures with dissolvable filaments

By changing some settings in your slicer, you can get solid supports to improve the quality of your 3D model.

Strengthening the Supports

It is quite common to create thin supports for very thin parts of a model, however they are not strong and tend to break during the printing process. To increase their durability, you can adjust the following support configuration options:

Horizontal Support Extension: Increases the overall thickness of the support, allowing the tower to be thicker and stronger.

Avoid breakage of supports during printing

The thickness of supports is equal to the diameter of the hot end, so they are usually quite fragile and can break during printing. By changing the pattern and other parameters, the strength can be increased:

By changing the pattern and other parameters, the strength can be increased:

- Support pattern: Patterns such as grid and triangle are quite resistant to tearing during printing. It is recommended to print such patterns only on soluble material, as they are quite difficult to remove.

- Supports printing speed: If the supports are printed too fast, there is a risk of breaking the structure. Reducing the speed avoids vibration or damage to the structure as the head passes.

Improving the quality of the surface of the model

The quality of the contact surface depends on the distance Z from the support pattern, the direction of the upper and lower perimeter lines and the amount of material holding the base of the model. Changing these parameters can improve the quality of the surface, but will complicate the process of extracting supports.

- Density of supports: The higher the density, the better the model will hold and therefore the surface finish will improve.

- Top/Bottom Line Direction: Changing the direction of the perimeter pattern helps hold the bottom layer of the model, as it allows the support and the perimeter pattern to intersect better.

- Support Pattern and Top/Bottom Pattern: The support and perimeter patterns affect how the support model attaches, ideally the patterns should overlap as often as possible to better secure the first layer.

Always remember that it is important to keep filaments in a dry environment, as soluble materials readily absorb moisture and can cause printing problems. Materials such as PVA and BVOH can be dissolved in plain water. This water can also be heated to shorten the removal time of supports.

We hope you follow our advice and recommendations to improve the surface quality of your 3D printed parts and make the process faster and more efficient.

We will keep you updated with the latest news!

Your iGo3D Russia team

Our social media groups:

VKontakte

Telegram

YouTube

3D printing support | ESUN PVA

Skip to navigationSkip to content

Cart

Envelope Telegram Vk whatsapp Youtube

Product search

0₽ Cart

- +7 (495) 143-28-00

- info@multismol.

ru

ru - Mon - Fri: 9:00 - 18:00

0₽ Cart

Plastic

Accessories

ESUN PVA - Water Soluble Support for 3D Printing

3 450₽ Add to cart

3 450₽

Product Quantity ESUN PVA - Water Soluble Support for 3D Printing

Article: PVA-ESU-05-NAT-175 Categories: Buy ESUN plastics and photopolymers in Multismol, Materials for engineers, Plastics for 3d printing Tags: 1.75mm, FDM, Water-soluble, Eco-friendly Brand: Esun

ESUN PVA is a water-soluble plastic support for 3D printing.

- Soluble in water

- Support printing only

- Delivery: 2-5 days

- Colour: natural

- Diameter: 1.75

- Smell: not strong

- Manufacturer: eSun, China

- Net weight: 0.5 kg

ESUN PVA is a water soluble material for 3D printing support structures. The applied 3d printing technology is FDM.

- Description

- Details

- Payment

- Guarantees

- Delivery

- Return

- Reviews 0

ESUN PVA - Water soluble support for 3D printing.

ESUN PVA is a highly specialized water soluble 3d plastic. This material is used exclusively for printing support structures. Support from this material is removed by dissolving in water at room temperature. Meanwhile, warm water can be used to speed up the dissolution process.

ESUN PVA filament is highly hygroscopic and not suitable for product printing.

The main disadvantages of the material:

Firstly, the high price (compared to PLA and HIPS). Secondly, the material is hygroscopic. Thirdly, ESUN PVA is fragile. As a result, the material is not suitable for printing products, parts or models. Scope - printing support structures only.

Secondly, the material is hygroscopic. Thirdly, ESUN PVA is fragile. As a result, the material is not suitable for printing products, parts or models. Scope - printing support structures only.

ESUN PVA Water Soluble 3D Printing Support Properties:

- biodegradable;

- dissolves in room temperature water;

- is non-toxic, no effect on the skin;

- can be printed with most other materials due to high adhesion;

- after cooling is easily separated from the base material;

- plasticity between plastic and rubber;

- heating the water to 60 °C will greatly accelerate the dissolution;

Print options:

- Print temperature range: 190-210°C;

- Table temperature: 60-80 °C

Parts

| Weight | 0.99kg |

|---|

Payment

The Multismol online store provides cash and non-cash payment. Cash payment is possible only upon delivery of the order by an employee of a courier company in Moscow, Moscow region, St. Petersburg and the region. In all other cases, we accept non-cash payments through the secure Internet acquiring of PJSC Sberbank. We accept cards of payment systems VISA, Mastercard, MIR, JSB. You can also use SberPay to pay. If you want to purchase goods for business, let us know about it and we will issue you an invoice for payment from the current account of a legal entity or individual entrepreneur. You can get more detailed information about payment in the section - Payment. |

Guarantees

| The Multismol shop carries out its activities within the framework of the legislation of the Russian Federation. We guarantee that all goods are purchased legally from manufacturers, we do not distribute illegal goods or fakes. We guarantee a refund if the product is out of stock or not delivered. We use the official Internet acquiring of Sberbank PJSC for payment, which guarantees secure payment. |

Delivery

| We deliver orders in Moscow and the region, in St. Petersburg, in Russia, in countries near and far abroad. The general conditions for the delivery of orders, as well as specific information on each delivery method, are set out in the Delivery section of the Multismol online store. |

Return

| Return of goods is carried out in accordance with the Civil Code of the Russian Federation, the Law of the Russian Federation "On Protection of Consumer Rights", regulations governing online trading in the Russian Federation. To facilitate the return procedure, we ask you to record packaging violations, the absence of goods in the package or the presence of other goods in the package upon receipt of the goods. |

And also, in case of delivery of low-quality goods.

And also, in case of delivery of low-quality goods.