Artists using 3d printing

9 Artists Who Are Killing It With Custom 3D Printing

Wait! Don’t trash that egg sandwich. There’s an artist who can use it in her next contemporary fresco. And if you’re not going to reuse that screw. . .hand it over. Andrew Meyers might want it for his portrait of Princess Di. Artists are known for pushing boundaries and for disrupting our eyeballs by using unconventional materials. But no disruption can compare with the increasing number of artists using custom 3D printing to bring their creations to life. The growing popularity of this medium has lead to a question that is bothering some within the industry: Is it even considered art?

It’s a question that’s much older than 3D printing itself. Artists have continually employed new and unusual vehicles for their creations. In the case of 3D printing, embedded within the philosophical debate about what defines art, is another question, “Does 3D printing make art too easy?” After looking at the ingenious and tedious efforts of the following nine artists, you can decide the answers to both questions.

Don’t Tell These Nine Their Work Ain’t Art

These artists are thinking outside the proverbial and overused “box.” Their work not only employs 3D printing technology, which is original in its own right, but they use the technology in innovative ways or to break through the limitations of traditional processes.

1. Tomoko Nagao

Tomoko Nagao is a Japanese artist who reinterprets Renaissance masterpieces. In 2017, she strayed from her traditional oil and stencils on walls and canvases and traveled further back in time to create two micro-pop sculptures with a large 3D printer. Her Salome exhibit, 3D printed by Sisma Italia, put a funny spin on a biblical story and bridged an ancient event with modern technology.

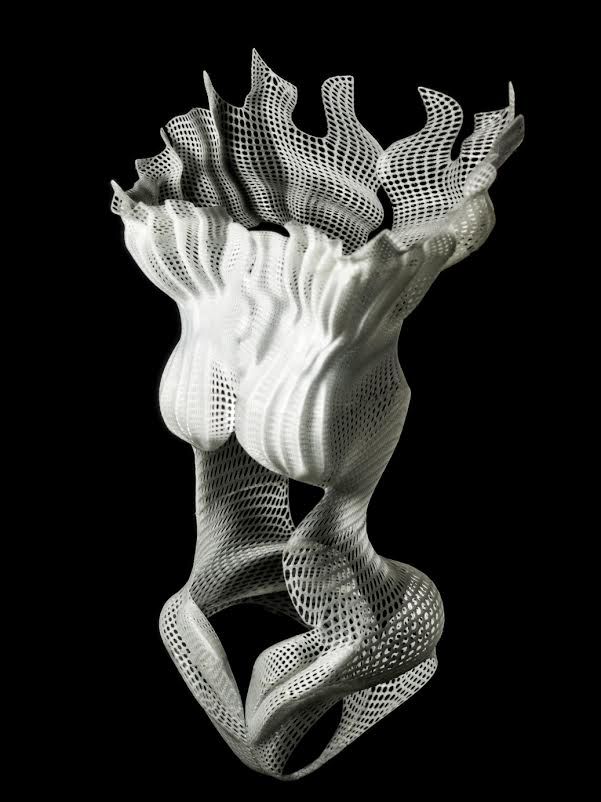

2. Neri Oxman

Neri Oxman is an architect, designer, internationally recognized artist, and professor at the MIT Media Lab. This PhD aims to push the limits of additive manufacturing using new materials like concrete and glass, and in fact even develops the machines to print them. Besides fashion wear and architecture, Neri uses 3D printing to create art.

Besides fashion wear and architecture, Neri uses 3D printing to create art.

3. Rob and Nick Carter

Rob and Nick Carter went back in time, too, but not to biblical times. They took a 400 year-old painting and recreated the scene outdoors. They used 3D printing to duplicate tree trunks. Nine of them. Then they bronzed each and placed them in a field. This real-life work is titled Bronze Oak Grove.

3D printing makes duplication easy and fast, but there are other reasons artists are turning to this technology.

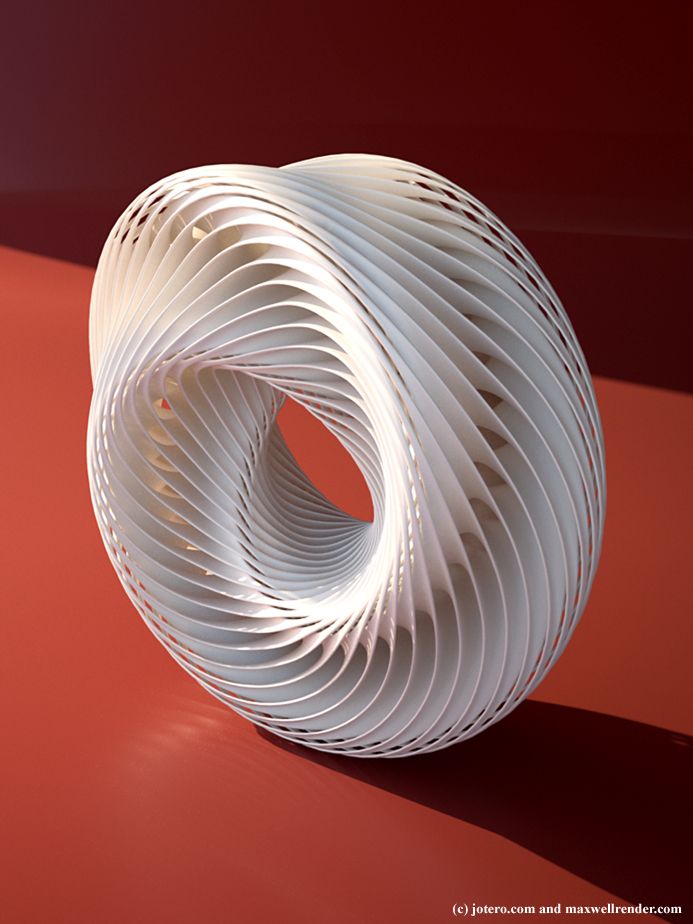

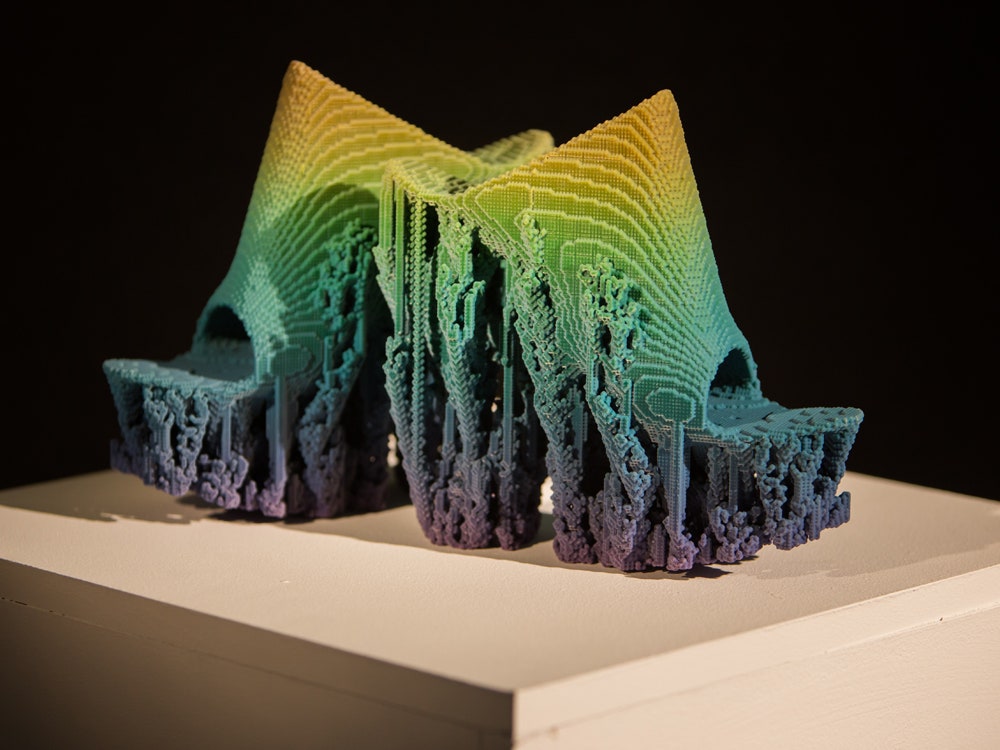

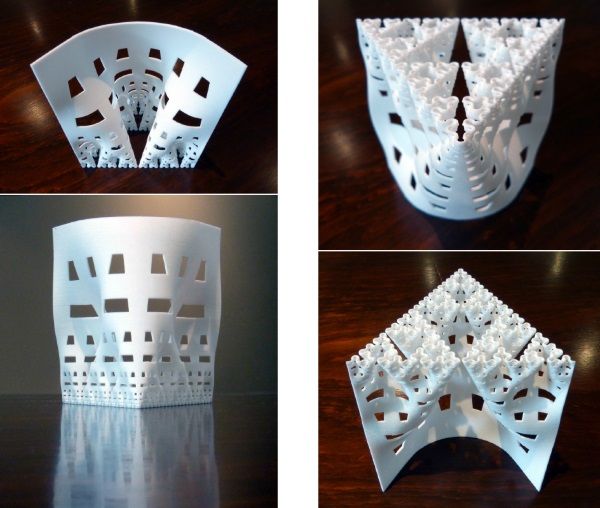

4. Batsheba Grossman

Batsheba Grossman uses her mathematics background to create cool works of metal art. 3D printing allows her to produce the shapes she envisions, a feat impossible to achieve without the technology. Batsheba said, “If you show these to somebody who works in metal, they fall on the floor.”

Additive manufacturing, the more technical title for custom 3D printing, builds layer upon layer, allowing artists to create difficult curves, bends, and hollow points without the fear of damaging their work. What professional would not want to decrease risk in their work? What about being granted the the opportunity to create a greater range of designs?

What professional would not want to decrease risk in their work? What about being granted the the opportunity to create a greater range of designs?

5. Julian Voss-Andreae

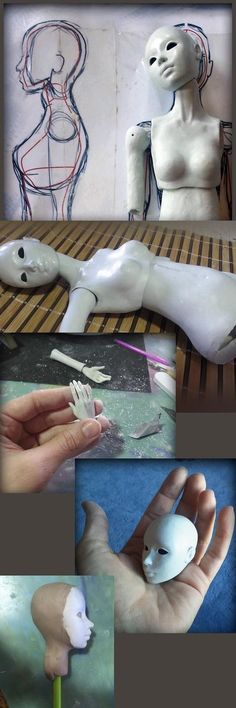

Julian Voss-Andreae lives in Portland, Oregon, and creates larger-than-life outdoor monuments. 3D printing technology frees him to create arbitrary designs. Often, they are large format human figures, sometimes becoming invisible at different angles.

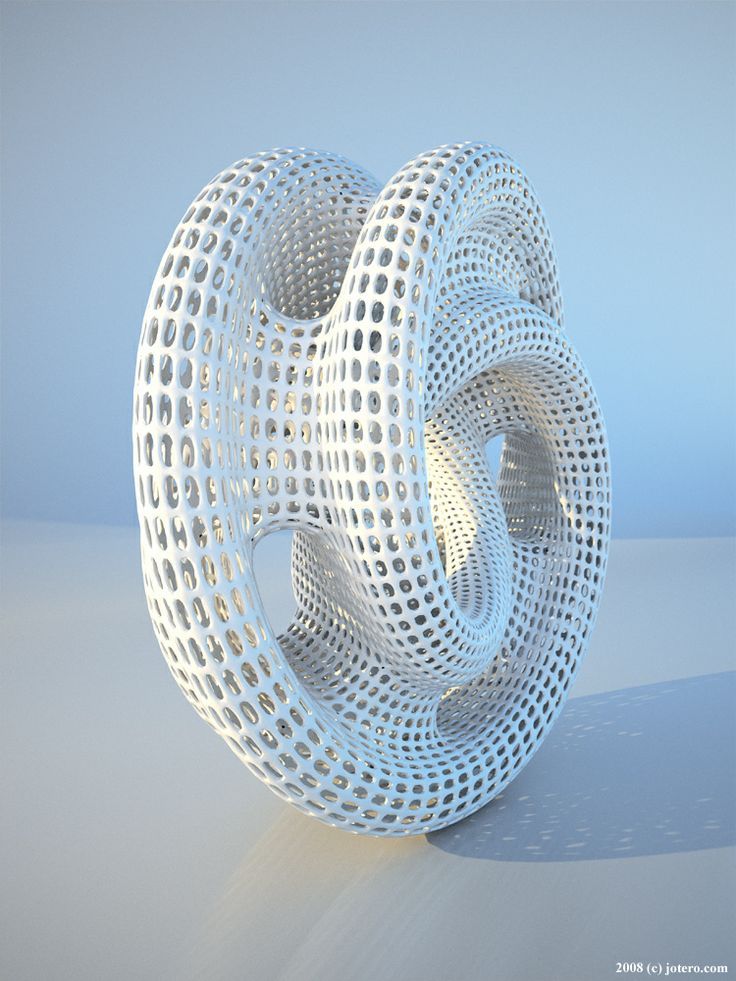

6. Dario Santacroce

Dario Santacroce is an Italian sculptor determined to create perfect forms. Traditional sculpting methods did not deliver the perfection he envisioned. The solution Dario sought lie in the preciseness of custom 3D design and printing. First, he created prototypes on his own MakerBot. Then, for the final work, he searched and found a printing company in Germany. Dario’s Spherical Creations interlock three spheres around an invisible triangle. And they’re perfect, thanks to 3D printing technology (and Dario’s determination).

And they’re perfect, thanks to 3D printing technology (and Dario’s determination).

7. Gilles Azzaro

Do you remember President Barack Obama’s speech hailing 3D printing? You missed it? Well here it is. Gilles Azzaro captured that segment of the President’s State of the Union address and turned the digital voiceprint into a work of art. Showing the peaks and valleys of Obama’s voice, and guided by a line of light in sync with the President’s voice, Azzaro’s Next Industrial Revolution creatively combines multiple senses.

8. Ona Sadkowsky

Contemporary urban artist, Ona Sadkowsky, likes to be creative in a more “naughty” way. Putting her pastel paints to the side, Ona sketched a provocative 3-dimensional piece for an annual art fair. She sent the sketch to Dekom 3D Plus in her hometown of Zurich where the Dekom team turned her sketch into a computer-generated 3-dimensional model. Then they printed it on their Massivit 1800 3D printer. The final product was an eye-catching character that was popular at the fair, drawing lots of attendees to take photos with it.

Then they printed it on their Massivit 1800 3D printer. The final product was an eye-catching character that was popular at the fair, drawing lots of attendees to take photos with it.

9. Nick Ervinck

Nick Ervinck is known for adding color to his complex 3D-printed works of art. He uses CAD software to design his art and then sends it out for printing.

Bonus #10. Eyal Gever

Eyal Gever employed large format 3D printing to create a miniature model of the castle he was commissioned to decorate with a digital light show. The 4-meter long replica, seen above his desk, saved the artist from flying to the location to test and perfect his work before the actual show.

Growth in 3D Printed Art

3D printing technology is spreading, not only across more and more industries but within the art industry itself. With this growth, comes an increasing number of options for printing your work. There are desktop 3D printers, 3D printing hubs, and large format 3D printers available for your giant creations. With that in mind, to all the artists out there we say, Ask not what you can create with 3D printing, but Where will you have your next work printed?

With this growth, comes an increasing number of options for printing your work. There are desktop 3D printers, 3D printing hubs, and large format 3D printers available for your giant creations. With that in mind, to all the artists out there we say, Ask not what you can create with 3D printing, but Where will you have your next work printed?

Tell us about your experiences creating 3D art in the comments below.

Top 10 Applications of 3D Printing in Art

Published on October 7, 2021 by Jamie D.

3D printing gives a completely new meaning to the saying “art knows no boundaries,” proving that new technologies and creativity are in fact very compatible, contrary to popular belief. Because the use of additive manufacturing allows artists to go one step further in their creative process. Keyword design freedom: working with additive manufacturing processes enables the realization of highly complex geometries with a high level of detail. Advantages that can be used to create replicas for museums, for example. But the application of 3D printing in the art sector is by no means limited to this purpose. More and more, the focus is on the additively manufactured object itself. The technology is increasingly being adapted by artists as a tool with which the realization of an idea knows hardly any limitations – except gravity. In our selection, we would like to present some current examples that we feel illustrate the importance of 3D printing for art.

Advantages that can be used to create replicas for museums, for example. But the application of 3D printing in the art sector is by no means limited to this purpose. More and more, the focus is on the additively manufactured object itself. The technology is increasingly being adapted by artists as a tool with which the realization of an idea knows hardly any limitations – except gravity. In our selection, we would like to present some current examples that we feel illustrate the importance of 3D printing for art.

Hypnerotomachia Naturae

The sculpture “hypnerotomachia naturae”, which was realized by Stefan Maier and Giacomo Pala under the supervision of Bart Lootsma at the Institute for Architectural Theory at the University of Innsbruck, is at first glance reminiscent of a construction kit. And deliberately so: because the modular construction is meant to remind us of the connection and contradictions of man’s relationship with nature and technology. Hypnerotomachia was realized in concrete in collaboration with concr3de and exhibited last year as part of the exhibition ‘beauty before wisdom. the knowledge of art and the art of science’ at the Tiroler Landesmuseum in Innsbruck. On display is a multitude of individual parts that are connected with each other to form a large whole. The individual objects are intended to remind the viewer thematically of the diversity of utopias, myths and cultures.

the knowledge of art and the art of science’ at the Tiroler Landesmuseum in Innsbruck. On display is a multitude of individual parts that are connected with each other to form a large whole. The individual objects are intended to remind the viewer thematically of the diversity of utopias, myths and cultures.

Mat Collishaw’s Equinox at the Dubai Expo 2020

For the World Expo 2020 in Dubai, which due to the pandemic actually just started recently on October 1st, 2021, the artist Mat Collishaw has come up with something special with the work “Equinox”. In an optical illusion, a gigantic lotus flower in the center of the Terra Pavilion truly comes to life. The blossoms spin, insects circle and flutter around the flower, pollinating it. For this ecological dance to succeed, the five-meter high and three-meter wide zoetrope opens and closes with the help of hydraulics. opened and closed. The petals were all 3D printed. It is not known which process the artist used for the realization, but we do know that Collishaw has in the past created a zoetrope for the Galleria Borghese in Rome in collaboration with the Spanish company Sicnova 3D.

A 3D printed replica of Michelangelo’s David

Created specially for the World Expo 2020 in Dubai, the Italian pavilion has produced a replica of Michelangelo’s David using 3D technology. The engineering department of the University of Florence and the Swedish hexagonal industrial group are behind the project. The 3D printed statue, which represents the biblical hero David as he approaches his battle with the giant Goliath, is the same size as the original, over 5 meters high. And in order to fully digitize the work, thousands of scans were required. As for the printing, the organizers of the project decided to divide the work into 14 printable pieces. They were printed from acrylic resin, and then assembled by art restorers using glue and marble dust.

The Silent Orchestra

Developed by Peter Lang and acoustics experts from the University of Applied Sciences in Rosenheim, Silent Orchestra is a 3D printed sculpture. Inspired by the nests of wasps and hornets, the work acts as an acoustic absorber. Composed of tubes of different sizes, Silent Orchestra was 3D printed using the FDM process. To do this, Peter Lang first hand-drew the outline of the object in each layer on 3 x 6 meter sheets of fleece before scanning them. Then, in collaboration with Additive Tectonics, the sound absorber was 3D printed from Tecnaro’s Arboblend biopolymer, which is 100% bio-based. A unique and sustainable work of art, capable of absorbing sound, that combines the best of craftsmanship and new technologies.

Inspired by the nests of wasps and hornets, the work acts as an acoustic absorber. Composed of tubes of different sizes, Silent Orchestra was 3D printed using the FDM process. To do this, Peter Lang first hand-drew the outline of the object in each layer on 3 x 6 meter sheets of fleece before scanning them. Then, in collaboration with Additive Tectonics, the sound absorber was 3D printed from Tecnaro’s Arboblend biopolymer, which is 100% bio-based. A unique and sustainable work of art, capable of absorbing sound, that combines the best of craftsmanship and new technologies.

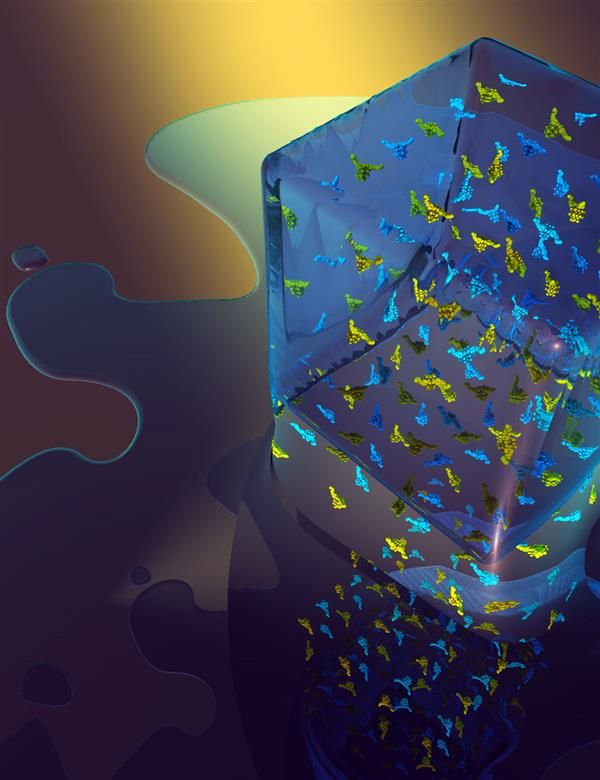

Claude Monet’s Famous Water Lillies, But 3D Printed

Joseph Coddington, a student at Victoria University of Wellington, has carried out an interesting project that combines 3D printing technologies with works of art. Specifically, he has analyzed how voxel additive manufacturing can be used to replicate a panel from artist Claude Monet’s “Water Lilies” collection, a series of paintings created between 1914-26. To do this, Coddington replicated the painting digitally and then used the Stratasys J750 3D printer to produce the prints. This method allowed him to define a color for each individual dot, called voxels, throughout the volume of a final model. He further states that his goal was to showcase the new applications and artistic qualities that voxel 3D printing can offer in art.

To do this, Coddington replicated the painting digitally and then used the Stratasys J750 3D printer to produce the prints. This method allowed him to define a color for each individual dot, called voxels, throughout the volume of a final model. He further states that his goal was to showcase the new applications and artistic qualities that voxel 3D printing can offer in art.

The Yinyun art installation

The so-called Yinyun is an art installation composed of 85 3D printed ceramic pieces. It is located in the Taipower D/S ONE showroom in Taipei, Taiwan. In order to successfully develop the project, those responsible used a generative design algorithm to extract the electrical data and visualize it on each unit, creating a gradient effect. Later, additive manufacturing technologies came into play to create each of the parts using ceramics, specifically based on a mixture of recycled material. At the same time, they managed to create an original detailed surface relief thanks to this technique. The main feature of the Yinyun installation is that the complex shapes of the pieces mean that none of the units is the same as any other.

The main feature of the Yinyun installation is that the complex shapes of the pieces mean that none of the units is the same as any other.

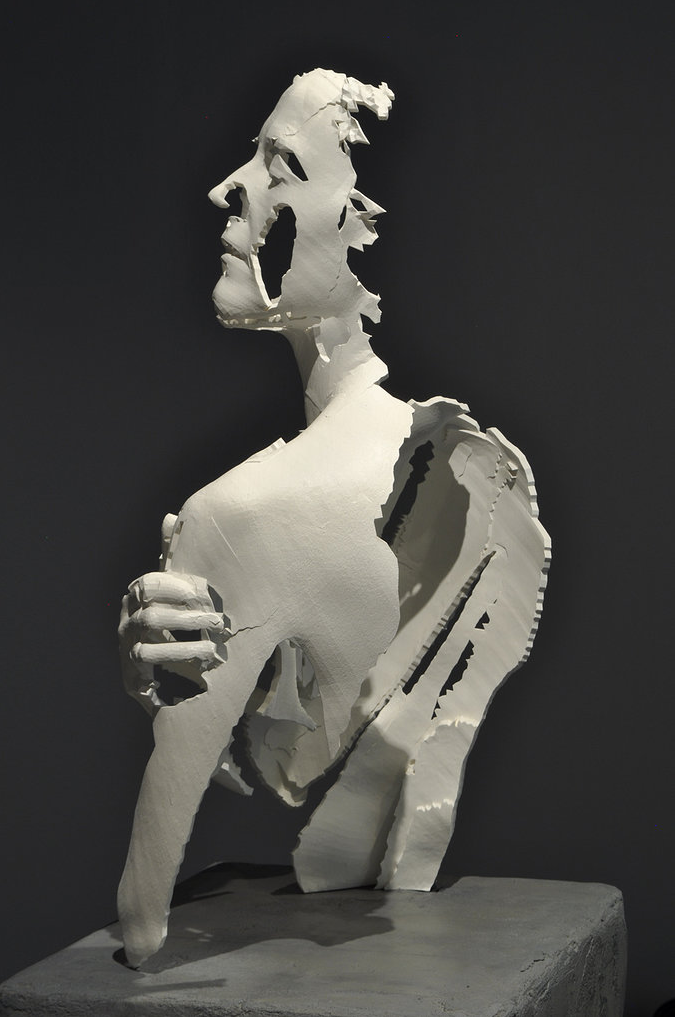

Sebastian Errazuriz and his 3D printed sculptures

New York-based designer Sebastian Errazuriz has developed a collection of statues for New York’s Elizabeth Collective gallery in May 2019. While the project is not brand new, the characters represented are familiar to all. The artist has taken some major personalities like Steve Jobs, Trump, Elon Musk and Jeff Bezos and turned them into 3D printed statues reminiscent of Roman mythology. The collection has been named “The Beginning of the End” and seeks to show all the technological changes that will change humanity. It uses technology as a way to denounce the impact of technology. Thus, we can see the bust of the founder of Facebook, called “The New Opium”, with this idea that we have become addicted to the social network. The team first retrieved hundreds of images of these personalities to reconstruct them in 3D, a time-consuming task that took several months. We don’t know what printing technology was used but the details are there! The video below goes over the whole project:

We don’t know what printing technology was used but the details are there! The video below goes over the whole project:

Mellifera, the 3D printed beehives

For the London Design Festival held last September, French architect Arthur Mamou-Mani imagined Mellifera: The Dancing Bee Hives, a set of 3D printed structures reminiscent of beehives. 3D printed from PLA, they were installed in the center of the spiral staircase of the famous Fortnum & Mason store in Piccadilly. The aim of the architect is to remind the importance of bees in our society and the need to rehabilitate our urban spaces to allow them to survive. He chose 3D printing and more specifically PLA for its lower environmental impact. Arthur Mamou-Mani stated in an interview that PLA has a carbon footprint up to 80% lower than its petroleum equivalents.

MAD Architects 3D-Printed Furniture at Milan Design Week

During Milan Design Week, MAD Architects, headquartered in Beijing, debuted their 3D-printed furniture design project. For the project, the studio reinterpreted Christian Dior’s iconic piece of furniture, the Medallion Chair. Using 3D printing technology the design studio was able to depict the set of chairs being in motion. According to the designers, the 3D-printed polyurethane chairs, entitled “Meteor”, serve as a reflection on time and space.

Angela Merkel Equestrian Statue

Though unconfirmed whether the former German head of state was an equestrian during her lifetime, a Bavarian artist took creative license, depicting Angela Merkel riding horseback in a 3D-printed concrete statue. The life-size statue, sitting 2.70 meters high, is to commemorate the years of service from the first female chancellor of Germany. The artist, Wilhelm Koch, 3D-printed the statue using recycled concrete, which can be interpreted as a nod to Merkel’s political work towards climate change policy.

‘RGB Scone, Hold Your Nose’ by Alan Phelan

‘Hold Your Nose’ by Alan Phelan is a 3D printed, 5.5-meter-high sculpture made out of eco-plastic and paper that is on display in Dublin, Ireland as part of an initiative from the Dublin City Council to commission six public sculptures for parks and public spaces throughout the city. ‘RGB Scone, Hold Your Nose’ was the first to be commissioned. The sculpture was designed to be put on a historical plinth that has been empty in Dublin since the original statue was removed in 1860s. The ‘exuberant’ sculpture was made first as a readymade, small-scale model which was then 3D scanned and printed to scale before assembly. The artist was inspired by different forms of emancipation from the area including Irish independence, EU Presidencies, tribunals of inquiry, and important civic events related to marriage equality and reproductive choice.

The sculpture after printing and papering and before installation (photo credits: Alan Phelan)

Magic Queen

One application for art in AM that might be a little out of the box is a project that was presented at the 2021 Venice Architecture Biennale, Magic Queen. Magic Queen is a 3D printed biodegradable structure made out of local soil that has been designed to be a landscape for different plants and mushrooms. It is tended to by a robotic gardener that both waters the landscape and senses for changes in surface texture and growth of the flora on the structure in order to maintain the landscape. The project was created by MAEIN, a practice led by Daniela Mitterberger and Tiziano Derme, and was designed as a way to show the fusion between organic materials and machines, proving the possibility of empathy and co-existence of the two. 3D printing with soil allowed the designers to create a unique structure perfectly suited to sustain life. You can find out more in the video below.

Magic Queen is a 3D printed biodegradable structure made out of local soil that has been designed to be a landscape for different plants and mushrooms. It is tended to by a robotic gardener that both waters the landscape and senses for changes in surface texture and growth of the flora on the structure in order to maintain the landscape. The project was created by MAEIN, a practice led by Daniela Mitterberger and Tiziano Derme, and was designed as a way to show the fusion between organic materials and machines, proving the possibility of empathy and co-existence of the two. 3D printing with soil allowed the designers to create a unique structure perfectly suited to sustain life. You can find out more in the video below.

What do you think of our choices for 3D printing in the art sector? Did you already know some of these projects? Let us know in a comment below or on our Facebook and Twitter pages. Don’t forget to sign up for our free weekly newsletter, with all the latest news in 3D printing delivered straight to your inbox!

Don’t forget to sign up for our free weekly newsletter, with all the latest news in 3D printing delivered straight to your inbox!

What is 3D printing in 2021

3D printing technology has changed the manufacturing process of everything that surrounds us. From children's toys and clothes to prostheses, implants, etc.

The 3D printing process is also known as additive manufacturing. In simple terms, a computer program tells the printer where to lay thin layers of material that gradually turn into a solid object.

Types and processes of 3D printing technologies

The first mention of 3D printing technology appeared in the late 1980s. They were called rapid prototyping technologies. The name refers to a process that was conceived as a faster and more cost-effective method of prototyping in product development. The very first patent application for this technology was filed by Dr. Hideo Kodama in May 1980. But, unfortunately for the inventor, the full patent specification was not submitted until one year after the application was filed. Kodama used ultraviolet light to cure plastic and create an AM object.

But, unfortunately for the inventor, the full patent specification was not submitted until one year after the application was filed. Kodama used ultraviolet light to cure plastic and create an AM object.

Years later, the American Scott Crumb developed the most common type of 3D printing today - FDM (Fused deposition modeling). This technology stands for deposition modeling. This type is characterized by the fact that the thermoplastic material is heated to a liquid state and extruded through the nozzle layer by layer.

Charles Hull, co-founder of 3D Systems, was one of the inventors of the 3D printing technology known as stereolithography. The technology is based on photochemical processes.

But Kodama, Crump, and Hull weren't the only ones to develop 3D printing techniques.

WINBO 3D printer at Art-Up Design Studio

Here are some other types of 3D printing in use today:

- FDM (Fused Deposition Modeling) is by far the most common method for producing thermoplastic parts and prototypes today.

Based on the melting of the filament in the nozzle with its subsequent laying in layers. It is also the most economical way of 3D printing due to the availability of a wide range of thermoplastic materials with different technical characteristics, which allow generating both functional parts of mechanism prototypes and volumetric cases, as well as any free spatial decorative forms.

Based on the melting of the filament in the nozzle with its subsequent laying in layers. It is also the most economical way of 3D printing due to the availability of a wide range of thermoplastic materials with different technical characteristics, which allow generating both functional parts of mechanism prototypes and volumetric cases, as well as any free spatial decorative forms. - SLA (Stereo Lithography Apparatus) is based on the layer-by-layer curing of a liquid photopolymer material under the influence of UV study. Can print objects in multiple colors and materials with different physical properties, including rubber-like parts. The high printing accuracy of this method makes it more expensive and not optimal for simple plastic structures.

- DLP (Digital Light Processing) cures polymers using a light projector rather than an ultraviolet laser. This allows you to create a whole layer in one exposure, thus increasing the speed of production.

Metals too have their own 3D printing techniques. The type of technology is selected depending on the features of the object.

The type of technology is selected depending on the features of the object.

- SLS (Selective Laser Sintering) is based on layer-by-layer sintering of polymer powder particles using laser radiation. The nylon powder melts into a strong, hard plastic. Due to the peculiarity of the technology, the surface of the part is not ideal, but very functional for use in prototypes with hinges and latches.

- SLM (Selective Laser Melting) is based on layer-by-layer sintering of metal powder under the action of a laser beam. Used in the manufacture of decorative items. Therefore, it is useful for applications in medicine and lightweight structures. Often this method is used in conjunction with traditional metal casting technology to create prototypes or final products.

- EBM (Electron Beam Melting) is based on layer-by-layer melting using an electron beam. The printing uses electromagnetic coils to superheat the metal powder in a vacuum.

How 3D printing works

3D printing is the process of layering one on top of another. Every 3D printed object starts life as a 3D model in a computer program.

Every 3D printed object starts life as a 3D model in a computer program.

You can create your own design in programs such as Maya, Blender, ZBrush, CATIA, Solidworks. In addition, ready-made 3D models of parts can be downloaded from sites such as Thingiverse or CGTrader.

When you have a 3D model obtained in one way or another, you “run” it through the “slicer” program (from the English word “to slice”), which converts the original 3D model in STL format into print layers. The information received is eventually converted into a special data format called G-code for further printing on a 3D printer.

Such programs usually come with the 3D printer, or they can be freely downloaded, such as the Cura program. What these softwares have in common is that they create thousands of lines of code for layers. This code tells the printer how to print.

Next, you need to set up your 3D printer, select the print quality and the correct material settings. To start printing, you load your "sliced" part into the printer via a USB stick, SD card, or send directly from your computer. And the printer starts a slow additive layering process.

And the printer starts a slow additive layering process.

Photograph of Christian Rail from Pixabay

Materials used in 3D printing

The materials available for 3D printing have come a long way. Currently, there is a wide range of materials that differ both in properties, types, and in the states supplied (powder, threads, granules, resins, etc.).

Some materials are developed for specific applications to perform special tasks. For example, the medical sector, where special photopolymer resins (SLA 3D printing technology) are used, the properties of which make it possible to print implants, casts, and so on.

Some of the most commonly used materials:

- Plastics. Sintering (SLS) typically uses polyamides or nylon supplied in powder form. It is a strong, flexible and durable material. It is white in color, so it needs to be tinted before or after printing. The most common 3D printing technology today is FDM, which uses ABS or PLA plastic filaments.

These plastics are available in a wide range of colors. Compared to PLA, ABS plastic has higher strength characteristics. But PLA is biodegradable, so it's as widespread as ABS.

These plastics are available in a wide range of colors. Compared to PLA, ABS plastic has higher strength characteristics. But PLA is biodegradable, so it's as widespread as ABS. - Metals. More and more metals and metal composites are finding their way into industrial 3D printing. The most common of them are derivatives of aluminum and cobalt. Due to its strength characteristics, stainless steel is often used in powder form in 3D printing technologies such as sintering, melting, EBM. In the last couple of years, silver and gold have been added to the list of metals suitable for printing. This made it possible to significantly expand the possibilities of jewelry production.

- Ceramics. A relatively new group of materials used in 3D printing. The peculiarity of printing with these materials is that the printed ceramic parts must go through the same processes as ceramic products made by traditional methods - firing and glazing.

- Biomaterials. Currently, a large number of studies are being conducted aimed at exploring the possibility of 3D printing from biomaterials for the needs of medicine.

This includes the printing of human organs for transplantation, external tissues for replacement of body parts. To do this, leading institutions research living tissues.

This includes the printing of human organs for transplantation, external tissues for replacement of body parts. To do this, leading institutions research living tissues. - Food. Over the past few years, there has been an increase in experimentation with food 3D printing extruders. Chocolate printing is the most widely used. There are 3D printers that use sugar, pasta, meat, dough.

Photo of mebner1 from Pixabay

What 3D printing is used for

If you can think of an item, then most likely you can print it. Children's toys, jewelry, phone cases and much more are already being printed by enthusiasts on 3D printers. Some use 3D printing for fun. Fun projects already exist: a printed guitar, a loom, and an intricate sculpture created from a combination of laser-fused glass and nylon. 3D printing has already moved beyond its origins in plastic printing and has moved into the use of metal, rubber, wood, synthetic fabrics, and ceramic resins. Functional 3D-printed human organs have not yet been created, but scientists say that this is a matter of the near future.

Functional 3D-printed human organs have not yet been created, but scientists say that this is a matter of the near future.

Because additive manufacturing of complex objects is faster and cheaper than traditional molding and casting methods, it has found its way into industry and the arts. The possibilities of this technology are almost limitless, but 3D printers are not perfect machines. In addition to all the advantages, there are also reasons for concern.

Ethical issues in 3D printers

3D printers consume a lot of energy and emit ultra-light plastic particles into the air, which are then inhaled by humans. These harmful emissions can be compared to a cigarette lit indoors.

While humanity is trying to reduce the use and consumption of plastic, 3D printers are another technology heavily dependent on it. This presents a problem for all ecosystems, in particular for the already suffering oceans with their floating islands of plastic.

A few years ago, the news of the first 3D printed firearm caused a media frenzy. The creation of untraceable weapons by a private individual remains a modern security problem.

From a legal point of view, there is no clear answer to the question of who is liable in the event of harm to health caused by a printed object. Indeed, in most cases, the developer of a 3D model, the manufacturer of a 3D printer, and the one who printed it are different people or organizations. Determining liability for potential injury and death is a new challenge.

At the same time, the use of 3D printing technology in the medical field to print tissue raises a number of ethical and moral issues. These issues are similar to the talk of stem cell research and gene editing that has been going on for decades.

On the other hand, we have a powerful tool in our hands that is changing the way we create and produce things. We still don't fully understand what this means for our future.

Potential effect on the global economy

If 3D printing continues to develop at the same pace as it is now, then its use could potentially affect the global economy. The transition of production and distribution from the current model to localized custom manufacturing can reduce the imbalance between exporting and importing countries.

3D printing is creating new industries and new professions. Professions related to the production of 3D printers or, for example, a vacancy for a rapid prototyping technician at the Cartier jewelry house. New professional services are emerging, such as supply of materials, printer operator, legal services in dispute resolution and intellectual property issues. With the development of 3D printing technology, the issue of "piracy" becomes an urgent problem.

The impact of 3D printing on developing countries is a double-edged sword. The positive effect for such countries is the reduction in the cost of production through the use of recycled and other local materials. But the loss of manufacturing jobs could hit these economies hard, and it will take time to find a balance.

But the loss of manufacturing jobs could hit these economies hard, and it will take time to find a balance.

Where can I use a 3D printer

Owning a 3D printer with the necessary software and materials can still be expensive for individual needs, so public 3D printers are becoming more common.

There are places like labs and 3D printing shops. You can send your design and pick up the finished part in a couple of days. Some companies, such as ART AP Design Studio, also do 3D printing.

If you are a student or student, 3D printing services may be available at your school.

Printed products in Art-Up Design Studio

Where can I learn how to use a 3D printer

For those who already have the specialty of an engineer, there are advanced training programs (Additional education) from the Russian Academy of Crafts, designed for 36 or 72 academic hours.

The training course in an accessible lecture form reveals the theoretical and practical foundations of design, three-dimensional modeling, design of plastic products. It provides for the performance of work and tests within the framework of the design tasks of the course and the final exam.

As a result of mastering the program, the trainee receives a certificate "Specialist in Additive Technologies". Profession Code 15.02.09

If you are just starting out, you can find vocational training programs with 144 academic hours.

It is important to understand that the basic knowledge is obtained in practical exercises on real equipment. For example, you can get up-to-date skills using modern equipment at the SKOLKOVO Technopark at the production base of the CUC OOO Design Studio ART AP, which is the anchor partner of this educational program.

As a result of training, the student of the course "Specialist in additive technologies" independently solves the following professional tasks:

- modeling and design of plastic parts,

- fundamentals of aesthetics in the design of industrial products,

- features and types of 3D printing equipment,

- preparation of the model for 3D printing,

- setting up and launching a 3D printer,

- features of printing from various materials,

- post-processing of 3D printing results,

- Product assembly.

Investing in yourself is the most profitable and rewarding investment.

Nikita Pelevin, Alexey Kutyaev for the Russian Academy of Crafts

On the cover of the article ZMorph4D photo from Pixabay

| 3DNews Technologies and IT market. Interesting news from the world of high-tech The world's first 3D printer for... The most interesting in the reviews 03/31/2014 [09:46], Dmitry Prikhodko There are printers that work with sugar and food coloring, using these components as consumables to create edible confectionery masterpieces. 3D printers have also been created that use both various types of plastic and metal powder to be sintered and layered to give the final shape. However, until recently, ceramics was not available as a material for 3D printing devices. The process of making porcelain products is accompanied by long processing and drying in special installations under the influence of high temperatures. The creation of even simple samples of porcelain utensils or dishes requires the attention of several technologists and goes through certain basic stages. Students from the University of Bristol decided to correct this misunderstanding and, under the guidance of Professor Stephen Hoskins, created a 3D printer that works with clay. This printer is able to create a full-fledged blank for heat treatment, which will later become a familiar ceramic cup, plate or original figurine. The presented samples of products on the video look very worthy: One thing to be clear: in fact, ideas for clay printers have been around before. The same company 3D Systems demonstrated at the beginning of this year the CeraJet device, whose functions include the manufacture of ceramic dishes. As for 3D Systems CeraJet, although this printer model is capable of printing dishes, it still formally appeared later than the project of Mr. Hoskins and his wards. About a year ago, the first working sample of a 3D printer was already demonstrated, so the professor, his colleagues and students deservedly received the title of pioneers in this field. www.hwdio.com Of course, the key steps in the process itself have not changed significantly. The printer takes over the main task - giving the clay product the necessary initial shape in order to proceed to the subsequent glazing and firing of its parts. The composition of the base material with which the presented apparatus "prints" was created and patented by the same professor Stephen Hoskins. The main one is clay powder, which, connecting layer by layer, turns into a solid figure. The device, according to its authors, should attract the attention of designers and artists, as well as major manufacturers of various ceramic products. The invention is not only purely scientific in nature, but is also intended to bring dividends to its creators in the form of income from sales of the device. Over time, the authors of the project plan to register their own company and open an online store. The printer itself will be further upgraded and subjected to the necessary improvements. |

There were other prototypes of 3D printers, but they all had one thing in common: due to the type and structure of the consumables used, the products did not have sufficient reliability and quality. Simply put, it was not possible to create durable cups that would not differ in any way from dishes made by the classical manufacturing method.

There were other prototypes of 3D printers, but they all had one thing in common: due to the type and structure of the consumables used, the products did not have sufficient reliability and quality. Simply put, it was not possible to create durable cups that would not differ in any way from dishes made by the classical manufacturing method.  Transferring a virtual model to a full-fledged clay blank requires a lot of time, but now the production of porcelain items will become available even at home. True, with an amendment, but the fact that the buyer has a large apartment, because the overall size of a 3D printer for ceramics is comparable to a washing machine.

Transferring a virtual model to a full-fledged clay blank requires a lot of time, but now the production of porcelain items will become available even at home. True, with an amendment, but the fact that the buyer has a large apartment, because the overall size of a 3D printer for ceramics is comparable to a washing machine.