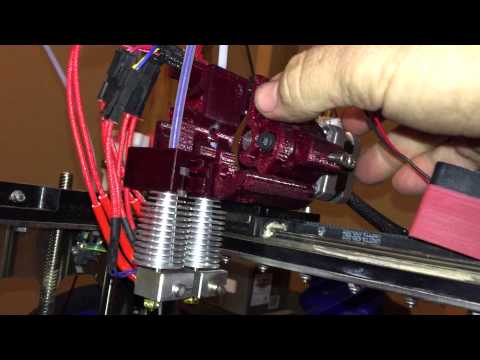

Viking 3d printer

V-King CoreXY – Viking 3D Printers

All that is special to the V-King CoreXY 3d Printer

You find your juction deviation number from using this formula: You can read more about it here: Calculating Juction Deviation

By Roy Berntsen, ago

There is a Google Spreadsheet with all parts for the V-king. If you wish to use it to keep track of what parts you have printed, you have to make a copy of the spreadsheet. Click here to have a look at the spreadsheet.

By Thomas Edvardsen, ago

Calibrate your printer This article will try to show you the best ways to calibrate your printer, and how to fine-tune your slicer settings for your chosen filament. Calibrate extruder steps/mmShould be done into the air with no nozzle pressure. Teaching Tech has described how to do this here. Level Read more…

By Thomas Edvardsen, ago

The community has created several components for the V-King printer. Below is an unverified list: Here is also a github community repository https://github.com/RoyBerntsenDesign/Vking-Community-Files V-King Enclosure Panels https://www.thingiverse.com/thing:3623752 V-King WyzeCam V2 Cover https://www.thingiverse.com/thing:3623734 V-King Panel Due 7i Enclosure https://www.thingiverse.com/thing:3583124 V-King Conduit https://www.thingiverse.com/thing:3583098 V-King Top Corner Cover https://www.thingiverse.com/thing:3510808 V-King Bottom Corner Cover Read more…

By kelly stephenson, ago

App for tuning: I use this app for tuning the belts: https://play. google.com/store/apps/details?id=com.stonekick.tuner For XY! Try using the note A1to B1 as a start and tension from there. Remember that too tens belts are worse than loose Try to get both sides same note but it is more important that the Read more…

google.com/store/apps/details?id=com.stonekick.tuner For XY! Try using the note A1to B1 as a start and tension from there. Remember that too tens belts are worse than loose Try to get both sides same note but it is more important that the Read more…

By Roy Berntsen, ago

How to place the idlers on a CoreXY 3d Printer? So since we are dealing with smooth and toothed idlers it is important to place them correctly inside the X-Idler brackets on the X axis Here is how it looks like seen from the motor side of the printer – Read more…

By Roy Berntsen, ago

Explaining X0, Y0 I drew up this to explain what is where on a CoreXY 3d printer It has no X or Y motor as they both work together and there is no front, left, right or rear on this printer as you choose this yourself X0, Y0 is always Read more…

By Roy Berntsen, ago

YouTube Playlists: The Complete Animation Playlist Live Build Video Playlist A360 3D Viewing Links: V-King Top Assembly The X-Carrier

By Roy Berntsen, ago

Optical Endstop Setup The same should apply to other type of 3 wire endstop like mechanical ones Make sure V from end-stop goes to 5V on board, G to GND and S to Dx (x is a number on the pinout) Endstop and Flag Placement

By Roy Berntsen, ago

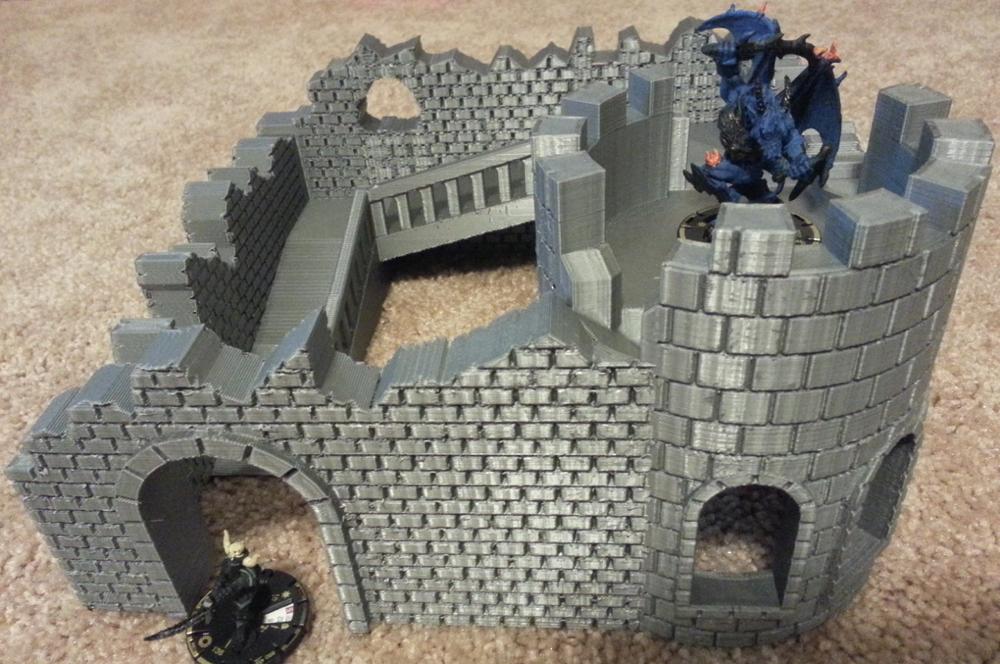

Viking best 3D printing models・Cults

Skip to contentviking axe 2

Free

viking axe 1

€5

Cauldron, wicca bowl, planter pot, Halloween

€0. 79

79

Genma Airship 5

€13.77

Viking Sword

€2.25

Viking Helmet

€2.32

Warrior Axe

Free

hand axe

Free

Goddess holder, sacrificial bowl, wicca, pagan

€0.75

PENDANT OF GLORY TO SVAROG 3D model

€8

Dice Box - Jörmungandr | Mythic Roll

€7.90

Dice Tower - The Gate of Valhalla | Mythic Roll

€9.90

Relief map Fjordland Norway 2022

€2

Viking Old Warrior Miniature (28mm) (test)

Free

Medieval Table collection for wargaming (28mm|1:56)

Free

Viking|Scandinavian House for wargaming (28mm|1:56) (openable door)

Free

Shield Maidens

€6. 65

65

Shield Maidens (Idle poses)

€2.56

WITCHES' KNOTS NECKLACE / COLLAR NUDO DE BRUJA

€1.42

Wet palette XXL

Free

viking silverware v1

Free

vikings Litho Ragnar

Free

Viking Litho

Free

viking helmet logo

Free

viking pattern

Free

viking patterns

Free

2 designs of ravens

Free

Wet palette big

Free

Viking bear hunter ring 3d print

€10.18

Wooden watchtower with guardhouse (11) - Alkemy Lord of the Rings War of the Rose Warcrow Saga

€1.90

Scandinavian wooden house with large fireplace (10) - Alkemy Lord of the Rings War of the Rose Warcrow Saga

€1. 90

90

Scandinavian house with large canopy and ornaments (9) - Alkemy Lord of the Rings War of the Rose Warcrow Saga

€1.90

Viking building with large thatched roof and roof window (8) - Alkemy Lord of the Rings War of the Rose Warcrow Saga

€1.90

Viking building in thatch and wood with ornaments (7) - Alkemy Lord of the Rings War of the Rose Warcrow Saga

€1.90

Viking building with bevelled roof and wooden column (6) - Alkemy Lord of the Rings War of the Rose Warcrow Saga

€1.90

Large Viking building with double entrance and railings (5) - Alkemy Lord of the Rings War of the Rose Warcrow Saga

€2.90

Viking building with sloping roof (4) - Alkemy Lord of the Rings War of the Rose Warcrow Saga

€1.90

Large Viking building with floor and large door (3) - Alkemy Lord of the Rings War of the Rose Warcrow Saga

€2. 90

90

Viking house with wooden door and roof decorated with horns (2) - Alkemy Lord of the Rings War of the Rose Warcrow Saga

€1.90

Viking house with high roof and big chimney (1) - Alkemy Lord of the Rings War of the Rose Warcrow Saga

€1.90

Scandinavian outdoor and camping accessories (set of 6 items) - Alkemy Lord of the Rings War of the Rose Warcrow Saga

€1.50

runes bowl

€0.50

Hercules Greek Vase/amphora

€8.92

Viking sword of Ragnar Lothbrok

Free

Viking Helmet - Viking Helmet

€1.28

Thor god

€2

trinity knot shelf

€0.99

Mate Viking helmet

€4.68

3D Printer Sharebot VIKING | Machine World

3D Printers & Scanners / 3D Printers / Resin Printers / 3D Printer Sharebot VIKING

Service

Taiwanese equipment is highly reliable, well-proven components are used in its production.

The warranty period for equipment is 1 year from the date of signing the acceptance certificate. In the event of a warranty case, spare parts and repairs are absolutely free for the customer. Troubleshooting is carried out by the own service department World of the Machine Tool. The main spare parts are in our warehouse, repairs take a short time.

Leasing

We have extensive experience in supplying equipment to Leasing. Contact us for details.

Warranty

The warranty period for the equipment is 1 year from the date of signing the acceptance certificate. In the event of a warranty case, spare parts and repairs are absolutely free for the customer.

Tools and accessories

Our technologists and programmers will work out the technology for free and write control programs for the manufacture of your parts. Including we can supply equipment with technology and production of a batch of parts. You pay for equipment, tooling and tools. The Machine Tool World is an official dealer of the leading tool manufacturers, so we can offer competitive prices and delivery times.

You pay for equipment, tooling and tools. The Machine Tool World is an official dealer of the leading tool manufacturers, so we can offer competitive prices and delivery times.

Writing control programs

Our software engineers will write control programs for your details. He has experience in implementing complex projects in the defense and aviation industries. When you purchase a tool from us, the service is free.

Commissioning

Commissioning of the equipment takes place in several stages: equipment installation, accuracy check and signing of the accuracy check certificate, manufacturing of parts and signing of the equipment acceptance certificate. Training of your employees takes place simultaneously with commissioning and launch of parts.

Delivery

Delivery time for most items is 10-12 calendar days. Warehouse items are delivered within 1-2 working days from the date of payment of the invoice. When invoicing, our process engineer without fail checks the availability of items in the warehouse and informs you. Delivery is carried out by courier service at our expense.

When invoicing, our process engineer without fail checks the availability of items in the warehouse and informs you. Delivery is carried out by courier service at our expense.

Writing control programs

Our software engineers will write control programs for your details. He has experience in implementing complex projects in the defense and aviation industries. When you purchase a tool from us, the service is free.

Warranty

We guarantee the correct selection of tools and accessories, corresponding to your tasks. Free replacement in case of error.

Price on request

Op. Zone-190x120x200 mm

Technology-LCD

Type-Professional

Material-Photopolymer

Service

0068

Product Description

Sharebot Viking is a photopolymer 3D printer with a large build chamber and resin series available for any application.

It is used both for making jewelry and for creating any other models, from mechanics to prototyping. A wide range of resins makes it possible to obtain finished models with a variety of structural characteristics, suitable for any sector of use and production.

Sharebot Viking is very easy to use and comes with Pyramis, a 3D printing management software that provides optimal model support.

Specifications

| Technology | LCD |

| Platform dimensions | 190 x 120 x 200 mm |

| Z resolution | 50 – 100 µm |

| XY plane accuracy | 75 µm |

| Approval | 37. 5 µm 5 µm |

| Print speed | Max. 15 mm/h (depending on photopolymer) |

| Firmware | Pyramis |

| Wave length | 405 mm |

| Connection | USB - WIFI - Ethernet |

| Display | 3. 5” touch screen 5” touch screen |

| Dimensions | 390 x 270 x 470 mm |

| Weight | 21 kg |

Tasks

Direct production of end product and tooling

Production of functional prototypes and visual models

Research work and educational tasks

Foundry processes

industries

Medicine

Jewelry

Education

Consumables

S-TUGH 9000 G-Model 9000 G-STRONG 9000 S -HARD

S-CLEAR

S-WAX

Media

Photopolymer

Accessories

Sharebot DUC 9 ultrasonic cleaner0007 Sharebot UCB curing chamber

Warranty

1 year

Brochure with tech.

Features

Features Yes

Scroll Up

bring your wildest ideas to life

Recently, a new manufacturer has appeared in our catalog - Discovery 3D Printer, and now - a new addition! We are proud to present Sharebot, an Italian company dedicated to the development of high-precision, reliable and easy-to-use professional 3D printers. The goal of the company, which has been developing dynamically since 2013, is to provide small and medium-sized businesses, as well as scientific and educational institutions with the ideal tools to optimize the production process and bring the most daring and ambitious ideas to life.

Sharebot consistently builds experience and competencies by creating more and more advanced and innovative products using various technologies. Starting with the development of desktop 3D printers, the manufacturer moved on to more complex professional systems. One of the latest achievements of the company is the release in 2019 of a unique compact metal printing machine MetalOne. In just a few years, Sharebot has taken its rightful place in the 3D printing market, building a wide distribution network and more than 3,500 customers worldwide.

In just a few years, Sharebot has taken its rightful place in the 3D printing market, building a wide distribution network and more than 3,500 customers worldwide.

Sharebot Viking Resin

3D Printing Process They are:

- FDM/FFF - plastic filament fusing modeling;

-

LCD/LSL is one of the printing methods based on photopolymerization; unlike stereolithography (SLA technology), the photopolymer resin is illuminated not by a laser, but by an LED ultraviolet matrix through an LCD screen mask;

-

SLS - selective laser sintering;

-

SLM - selective laser melting.

What can I print on Sharebot?

- Prototypes and functional products made of plastics of small, medium and large dimensions.

- Prototypes, master models and functional products made of photopolymers.

- Small test and functional products made of polyamide and metal powders.

Prototypes and mechanical parts made with Sharebot professional 3D printers

What industries are in demand Sharebot?

- Engineering

- Instrumentation

- Automotive

- Architecture

- Medicine (including biomedicine and dentistry)

- Jewelery

- R&D

- Education

8 Unique Benefits

-

A wide range of 3D printers with build chambers of various sizes.

-

4 3D printing technologies.

-

A large selection of innovative materials of our own production and the possibility of using third-party materials.

-

Create products with the most complex geometries thanks to the use of two independent extruders in one machine (Sharebot 43 and Q Dual models).

-

Build platform auto-calibration system.

-

Printer remote control system and filament feed control using a special sensor.

-

Simple and intuitive software (Simplify 3D, Slic3r).

-

Experience and partnerships with leading companies in the European market.

Quality, performance, customization: success stories

Startup Medere develops innovative projects in the field of medicine using advanced technologies, including 3D printing. One such project was creating custom insoles using the Sharebot Q 3D printer, which helped achieve great results with difficult-to-use flexible elastomers. The printer also contributes to the fight against coronavirus: for the Tor Vergata hospital in Rome, Sharebot has been used to model and print elastic band holders on surgical masks, which provide medical staff with greater convenience, especially when working in multiple shifts.

Renowned Italian race bike manufacturer Aprilia uses the Sharebot 42 compact FDM printer to create prototypes to improve aerodynamics and rider comfort. Aprilla Racing, the division responsible for the MotoGP World Championship, has printed a trial run of PLA footrest mounts to find the best fit for each of the team's riders. Then the final products were made on a CNC milling machine.

Aprilla Racing, the division responsible for the MotoGP World Championship, has printed a trial run of PLA footrest mounts to find the best fit for each of the team's riders. Then the final products were made on a CNC milling machine.

Sharebot's R&D department completed the Aircraft 3D project, which consisted of building a large-scale aircraft model on a Q XXL rig. The large build chamber size (700 x 400 x 300 mm) and the special 0.8 mm diameter extruder are ideal for printing large and durable prototypes in industries such as automotive, engineering and aviation. Parts of the model (body, wings and tail) were printed with a layer thickness of 0.6 mm. Thus, it was possible to increase the speed of production without sacrificing quality and resolution. The printing process took only 206 hours, while with a standard 0.4mm extruder it would take almost twice as long. Then the parts of the aircraft were glued together, polished and painted.

Now let's go directly to the Sharebot line of equipment. A detailed description and technical characteristics of each model are available via the links to the catalog of the iqb.ru website.

A detailed description and technical characteristics of each model are available via the links to the catalog of the iqb.ru website.

Sharebot

Sharebot 43 3D Printer Review: Halve production times with two extruders

Compact FDM printer with 300 x 250 x 200 mm build chamber.

Production of functional prototypes and visual models in the research and educational fields.

Two independent extruders with a working temperature of up to 300°C allow you to print objects with complex geometry using soluble supports. This makes it possible to print two identical objects at the same time, thereby cutting the production process in half.

Sharebot XXL Plus: high performance and precise machine with unique chamber volume

-

Professional 3D printer based on FDM technology for creating prototypes and large models up to 705 x 250 x 200 mm.

-

New X and Y axis calibration system to print more accurate and high quality products and Z axis alignment system for more stable printing process.

-

Simple, intuitive and user-friendly interface provides complete control of the process with the ability to configure all print settings.

-

An updated filament presence sensor streamlines workflow, and a detector allows you to pause printing when the filament runs out.

-

Ability to print objects from a variety of innovative materials such as the exclusive ABSolute® and Sharebot WOOD.

Sharebot Q: Precision FDM remote control printer

-

A3 (400 x 300 x 300 mm) print area for professional FDM prototypes and final products with high quality and precision.

- The

3D printer allows you to fully manage the printing process remotely, streamlining your workflow, as well as manage multiple operations simultaneously from the same platform (even on different 3D printers) with a single click.

-

Platform Auto Calibration System

-

The web interface allows you to control the printing process thanks to the built-in webcam.

-

Built-in spool case system, compatible with 750g spools and special 2.2kg PLA-S filament.

-

Double drag filament system with motors both on the extruder and next to the spool (Bowden system) that improves extrusion and simplifies the printing process.

-

Incandescent sensor controls the operation, avoiding any failures.

Sharebot Q XXL: A modern tool for large format 3D printing

-

The machine combines the main features of the previous Q model (platform auto-calibration system, Sharebox3D interface and remote control) with the largest build chamber (700 x 350 x 300 mm).

-

Professional 3D printing solution with two extruders operating at temperatures up to 450°C.

Sharebot Q Dual: Dual extruder printer for the highest quality products

-

Designed for high quality parts and prototypes with the most complex geometries.

-

If both extruders are activated, the print volume is 700 x 250 x 300 mm; with one extruder - 700 x 270 x 300 mm.

-

Due to the autonomous control of each of the extruders, many different configurations can be used.

-

Standard profile supports 0.4mm PET extruder and 0.8mm PLA extruder for support. This configuration allows you to reduce print time by quickly creating and removing supports.

Sharebot BIG: the ideal solution for 3D printing large resin parts

-

Robust 3D printer designed for large format printing with photopolymers (LSL technology).

-

Ideal for the production of small batches of large models (building chamber size - 470 x 240 x 340 mm) in mechanical engineering, instrumentation, medicine.

-

Prints durable objects, great for post-processing.

-

The printer is equipped with a wash tank and a special programmable CURE UV oven, which allows you to complete the curing process.

-

Easy to operate and economical.

Sharebot VIKING: universal photopolymer 3D printer

-

Printing of small prototypes, master models and functional products from photopolymers using LCD technology (building chamber size - 470 x 240 x 340 mm).

-

The widest choice of materials, which allows you to get ready-made models with a variety of properties and find a unique solution in any industry - from the jewelry industry to mechanical engineering.

-

Supplied with Pyramis software which ensures optimal support creation.

-

Easy to operate.

Sharebot SnowWhite: professional 3D printing of small polyamide parts

-

Professional 3D printer based on polyamide powder laser sintering (SLS) technology.

-

Excellent solution for printing small test and functional items (up to 100 x 100 x 90 mm) during research work.

-

Allows you to create objects of any shape without the use of supports from a wide range of professional thermoplastic powders such as PA 12, PA 11 and TPU.

-

After profiling the material, the printing process is fully automated and the results are completely repeatable. Compared to other SLS printers, the time from powder loading to the first layer is only 10 minutes.

-

Economical (power consumption - less than 1.5 W / h) and high productivity (print speed - up to 25 mm / h).

-

The printer requires only 300 g of powder, and the remaining powder can be reused.

Sharebot MetalOne: Compact printer for metal powders and product properties

-

Ideal for testing new materials.

-

With a build chamber of 65 x 65 x 100 mm and DMLS/SLM printing technology, you can create objects from a small amount of metal powder (only 800 g).

-

Equipped with a 250W fiber laser.

-

The ability to use both nitrogen and argon, which makes it possible to study almost any powder.

Results: briefly

Sharebot professional 3D printers (Italy) are affordable advanced solutions for rapid prototyping and manufacturing of functional products from plastics, photopolymers, polyamide and metal. The company offers a wide range of additive machines and consumables that will allow you to get finished models of various sizes, with the most complex geometry and the required properties, significantly reducing production time and costs.

High quality products, reliability and productivity are ensured by solutions such as printing with two independent extruders, an auto-calibration platform system and remote printer management. Sharebot is the best choice for small and medium-sized industries, laboratories, research centers and universities. For your enterprise, this is a real opportunity to increase your competitiveness and take a step towards Industry 4.