Ways 3d printing is being used

10 Surprising Ways 3D Printing Is Being Used Now

Mars Ice House: a prize-winning design for the 3D Printed Habitat Challenge for Mars.Wikimedia Commons

1. A new generation of prosthetics“Turning disabilities into superpowers” is the defining vision of UK-based Open Bionics. Their mission is to create “affordable, assistive devices that enhance the human body.”

RELATED: 7 INDUSTRIES IN 2019 THAT ARE CURRENTLY BEING DISRUPTED BY 3D PRINTING

Their first product was the Hero Arm, which they describe as “the world's first medically certified 3D-printed bionic arm, with multi-grip functionality and empowering aesthetics.” It is “a lightweight and affordable myoelectric prosthesis.”

The company now offers a selection of themed covers for the Hero Arm, including Star Wars BB-8, Marvel Iron Man, Disney Frozen and Deus Ex. They are “custom-made using innovative 3D-printing and 3D-scanning techniques.”

Dedication to helping children by providing them with 3D printed hands is also the driving passion behind a group of volunteers who formed e-NABLE. Its members now number in the thousands, and they have made it possible for thousands of children around the world to regain hand function. See the video below:

2. Printing skin for the faceThis 3D Skin Printer Helps Heal Wounds and Burns explained how 3D printing can be used to bioprint replacement skin for wound and burn victims as you can see in the video below.

But that was demonstrated on an arm, but now the researchers at Wake Forest Institute for Regenerative Medicine (WFIRM) are developing a way to create a bioengineered BioMask that could be applied to people’s faces.

New solutions are necessary for the skin on the face because existing techniques for grafting skin “can often lead to scarring, infection or graft failure,” explains the press release. The BioMask delivers better results, as shown in the proof-of-concept study

“The mask was created by using 3-D bioprinting customized with a face CT image. Then, wound dressing material and cell-laden hydrogels were precisely dispensed by the printer and placed in a layer by layer fashion to create the skin constructs into the mask shape.”

Once the technique is adopted, it can prove life-changing for people who would otherwise have had to remain scarred forever.

3. Quick and economical home constructionAnother way 3D printing is being used to make the world a better place is by reducing the cost of home construction enough to make new houses accessible to those whose income puts adequate shelter beyond their reach.

One company that has made this its mission is ICON. Its tagline is “We’re changing the way people live.” It set out to apply 3D printing to houses and envisions whole communities set up that way in a kind of 21st-century version of Levitton.

Its tagline is “We’re changing the way people live.” It set out to apply 3D printing to houses and envisions whole communities set up that way in a kind of 21st-century version of Levitton.

Most Popular

Last year ICON built the Chicon house, described as “the first permitted 3D-printed home built in the United States” in Austin, Texas in 2018. It took a few weeks to print “and sparked the imagination of customers, investors, press, and the SXSW conference community.”

Now it has advanced the technology to the point where it can get a house up in just a day and at a cost of just $4000 as you can see in this video:

ICON believes that its 3D printing applied to concrete is the solution to low-income housing, both in the USA and abroad. To that end, it has partnered with a charity called New Story that has provided funding for homes in Mexico, Haiti, El Salvador, and Bolivia and for needy households.

“By partnering with ICON in select regions, New Story will be able to see out their vision more efficiently and deliver the promise of a life beyond survival to thousands more,” it reports.

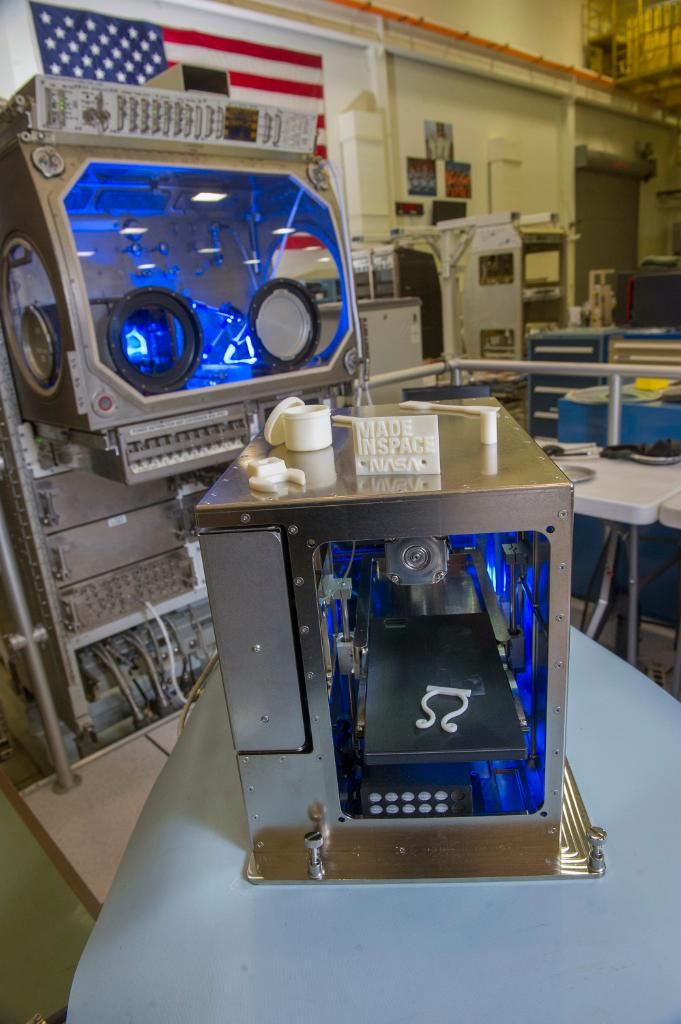

4. Homes on MarsApplying 3D printing to home construction also has ramifications for the space program. In planning a mission to Mars, NASA has to deal with the challenge of setting up shelter for the people who will be living on the red planet. To that end, it launched the 3D-Printed Habitat Challenge

See the video below:

5. Plane partsAirbus adopted 3D printing technology for plane parts a few years ago. In 2016 it began using titanium for engine components, as you can see in this video:

Since then it has extended its use of 3D printing to finish off its plane interiors with parts made in partnership with a 3D printing company based in Belgium called Materialise.

“Not only are 3D-printed parts as strong as those made with traditional molding methods,” Airbus explained, but their reduced weight offers an advantage for efficiency, and now they are able to produce the parts with a look that can be “seamlessly integrated” into the decor of the interior of the plane.

6.

Making musicIn 2014 a complete band of 3D-printed instruments, including a drum, keyboard, and guitars, played together live at Lund University in Sweden. Lund University professor Olaf Diegel printed the instrument that were played by students at Lund University’s Malmö Academy of Music.

Here’s the video of that event:

7. Exquisite metal jewelry designsIt was possible to 3D print jewelry over a decade ago, though those were limited to what could be fashioned out of plastic. Now, thanks to advanced additive manufacturing techniques in metal, it is possible to design and execute delicate, metal necklaces, earrings, bracelets, rings, etc. , as you can see in the video below:

, as you can see in the video below:

8. 3D printed eyeglasses

While you can 3D print individual glasses frames, as you see in the video above, that is not the most efficient use for the product. As in other areas of manufacturing the 3D printing is used for rapid prototyping.

“The ability to have our 3D printed concept prototypes mimic the exact same color and texture as the finished product has significantly accelerated the development of new eyeglass frames,” explained Daniel Tomasin, the Product Sample Coordinator at Safilo states.

As it eliminates the need to paint, they are able to create a prototype in ⅕ the time. As he said, “we can quickly respond to market trends and reduce our prototyping cycle from 15 hours to just 3 hours. ”

”

Luca Bordin, a 3D Modeling Specialist at Safilo added, “This arms us to not only dramatically reduce our turnaround time, but helps improve communication with the designers, enabling us to achieve the best product possible.”

9. Vegan meat

Whether the interest stems from concern for health, animal welfare, the environment, or just developing more economical food choices, lately there’s been increasing interest in developing vegan alternatives to meat. And 3D printing is playing a central role in that.

Giuseppe Scionti, the Italian founder and CEO of Barcelona-based Nova Meat has developed a technique to 3D print meat that can duplicate the texture of beef or poultry using vegetable proteins. Unlike some other vegan meat substitutes, it does not have to be reduced to hamburger.

In an interview with Business Insider, Scopto pointed out that he selects his ingredients with sustainability in mind: "I used raw materials that don't have a negative impact on the environment," skipping the things that would have to be imported and so contribute to a “detrimental impact on the environment. "

"

You can see how the process works in the video below:

10. This takes the cake

Dinara Kasko is a young pastry chef from Ukraine. She holds a degree from the University of Architecture and Design and has experience as an architect-designer and a 3D visualizer. She combined that expertise with her passion for cakes, and that’s how here business with specially shaped cakes made out of her specially designed molds was born.

For You

science

Will the future of humanity in space involve rotating habitats or planetary settlements?

Matthew S. Williams | 10/2/2022

scienceRevolutionizing treatment of neurodegenerative diseases - One patient at a time

Ameya Paleja| 8/16/2022

cultureAn AI-based party vows to win Denmark's general election in 2023. Can it succeed?

Can it succeed?

Paul Ratner| 8/23/2022

More Stories

science

A nuclear war simulation shows the devastation we could face if one country pulls the trigger

Chris Young| 10/20/2022

innovation

FIFA World Cup in Qatar: AC stadiums show how technology is shaping sports

Baba Tamim| 10/21/2022

culture

US Air Force to unveil first new stealth bomber in 34 years, the B-21 Raider

Ameya Paleja| 10/21/2022

Eight ways 3D printing is being used today

After years of hype, 3D printing technology has come into its own – and is now being used to quickly design and manufacture equipment in the face of the current COVID-19 pandemic.

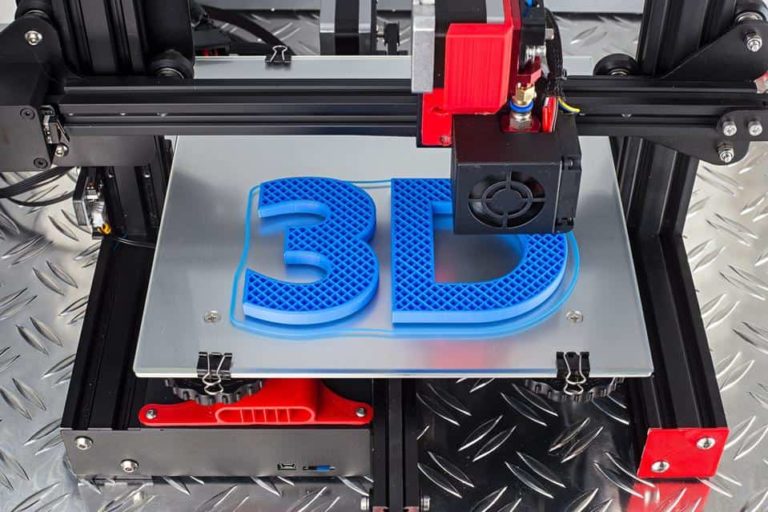

3D printing typically refers to the process of converting digital blueprints into three-dimensional solid objects by layering additive materials on top of one another. Organisations may use it during the planning stage for small-scale prototypes, others may use it to develop tools or architect features, and some may opt to run the whole end-to-end design process through 3D printing.

Although the technical capabilities of 3D printing have become more affordable and widespread in recent years, the 3D printing process goes back as far as the 1980s, when the first additive manufacturing equipment was developed.

Here are a few of the most creative 3D printing uses so far.

Read next: Can 3D printing live up to the hype?

Healthcare

Healthcare is being transformed with 3D printing, and there are applications being adopted across the UK as to rapidly respond to the challenges surrounding the COVID-19 outbreak.

Ricoh 3D, a Telford-based company, announced last week that it will be providing NHS staff with 40,000 3D-printed face shields a week in order to stay protected against COVID-19.

According to the company, the 3D-printed shields will offer a re-usable solution that also cut long-term costs.

“We were seeing reports of nurses faces being cut and bruised by their existing protective equipment,” Mark Dickin, additive manufacturing and moulding specialist at Ricoh 3D, said. “Our frontline workers are battling enough already, without having to tend to sore and swollen faces at the end of a 12-hour shift.”

“Our frontline workers are battling enough already, without having to tend to sore and swollen faces at the end of a 12-hour shift.”

Other 3D-printing companies supporting public health organisations include startups such as Edumaker and Tocabot, who set out to redress the lack of Personal Protective Equipment (PPE) for health service workers.

On the other end of the scale, enterprise giant IBM announced an employee-driven project to create 3D-printed face visors for health service staff. In the early stages, 20 visors were sent to staff at University Hospital Southampton, and subsequently, over 300 visors have been developed and distributed.

The visors are made from three components: a 3D-printed frame, an acetate sheet, and an elastic strap to secure the frame. Initially, IBM staff were using their own supplies for development but they have since requested crowdfunding on GoFundMe for mass production.

Pre-pandemic, the NHS began trialing 3D-printed bionic hands for children in partnership with a Bristol-based startup, Open Bionics in 2017.

The use of 3D printing for prosthetics means more lightweight designs as well as lowering costs from what is normally priced at up to £60,000 down to £5,000 using a 3D printer.

3D printing has also been used as a way to help surgeons when planning to carry out a transplant as a 3D model can be used in the pre-planning phase of complex surgery. Guy’s and St Thomas’ NHS Foundation Trust were the first to carry this out using Stratasys multi-material 3D printing technology.

Read more: Can Axial3D transform surgery with 3D-printed anatomical models?

Aerospace

UK startup, SYS Systems, has been providing its 3D printing solutions across a number of industries starting with Aerospace.

Using a technology known as Fused Deposition Modelling (FDM), it creates strong and durable thermoplastic 3D models with fire retardant properties needed for Aerospace safety.

According to SYS Systems, the FDM technology produces temperature, UV, chemical and environmental resistant thermoplastic which doesn’t absorb moisture.

Aviation

3D printing has delivered a lot of opportunities in the aviation and manufacturing industries, with many big names using the technology to their advantage.

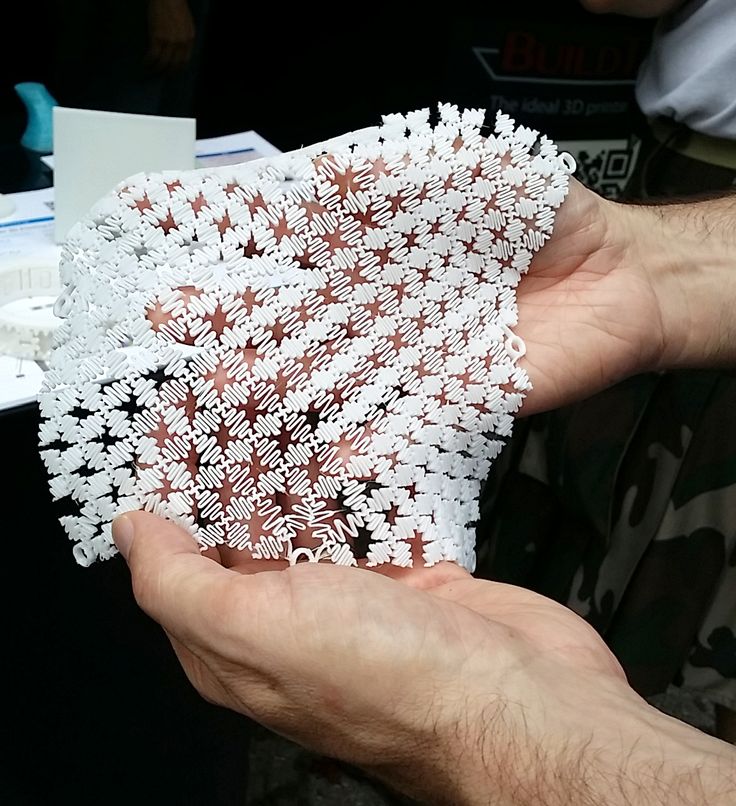

The technology has found a niche in aircraft manufacturing – for example, Finnair has used 3D printing for small-batch manufacturing in its Airbus A320 aircraft.

The airline has integrated 3D printed spacer panel parts into its cabins to fill in overhead storage gaps, with the addition of lattices inside the panels.

German industrial manufacturing company, Siemens revealed that it will invest £27 million to open the UK’s biggest 3D printing factory in Worcester in partnership with Material Solutions. The factory, which will explore 3D printing in aviation, should bring in more than 50 jobs as Siemens plans to embrace the growth of additive manufacturing.

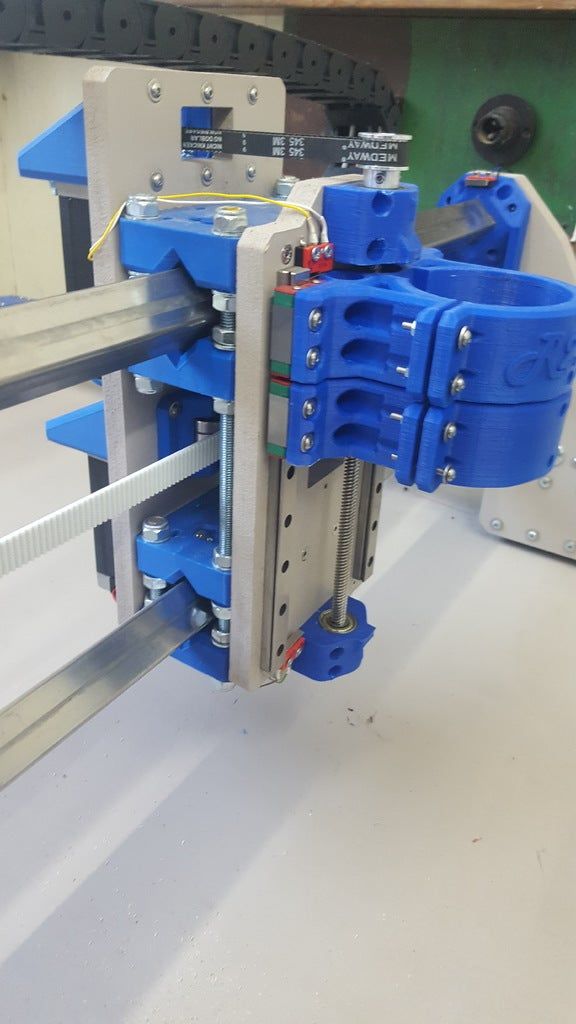

Engineering

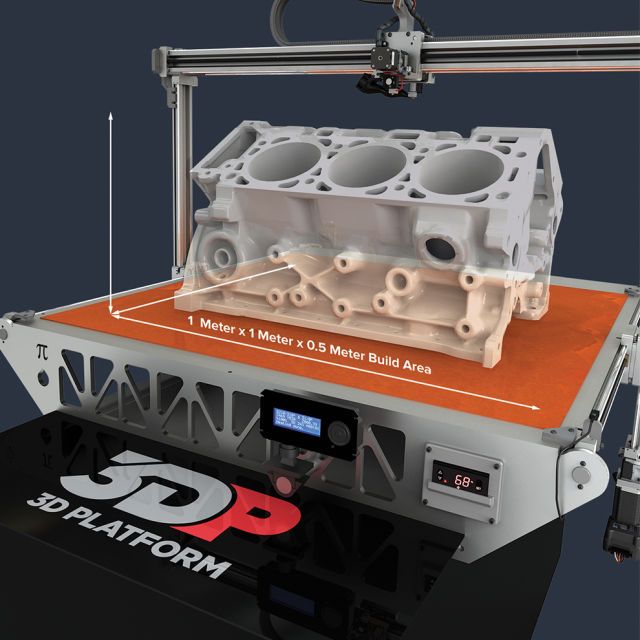

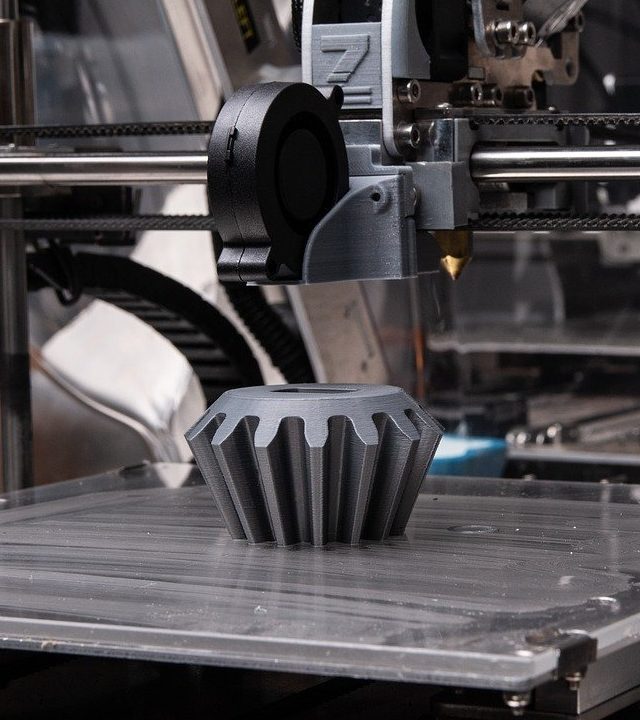

3D printing has made a huge impact on the engineering industry in a number of ways.

British Formula One motor racing company Williams F1 uses 3D printing to create some of the parts in its racing cars, as well as creating parts for models for testing in wind tunnels. The technology shortens the timescale of parts development, with the ability to give a quicker response on how well features work.

The technology shortens the timescale of parts development, with the ability to give a quicker response on how well features work.

“We use our polymer 3D printers for production as well as prototyping, so the majority of our work is for testing in the wind tunnel, so we’re actually making parts that get bolted on to our 60% model and they go to the wind tunnel to see if they’re functional.

“Other parts we’ll do as fit and form for the engineers to see if the part they’ve designed is what they envisaged on their CAD system,” Richard Brady, Team leader ADM at Williams F1 told Techworld.

BT also began trialing 3D printing in 2017, as a way to turn engineering ideas into reality quickly. The telco has seen a reduction of costs in prototyping tools such as a cable threading needle for making it easier to add new circuits in a roadside cabinet, and a vibrating bullet for delivering fibre into homes.

Architecture

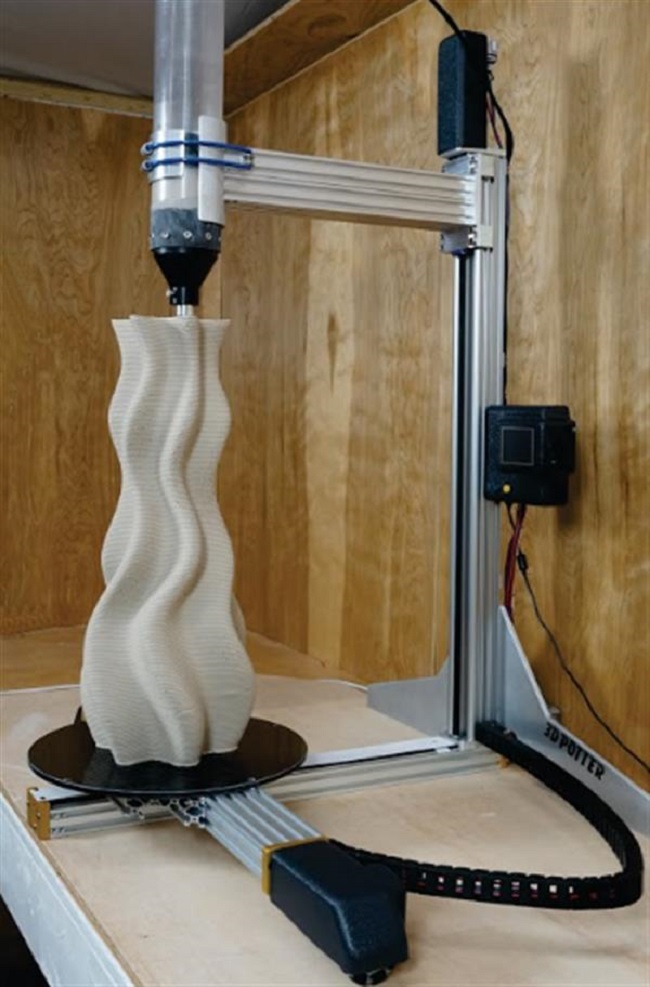

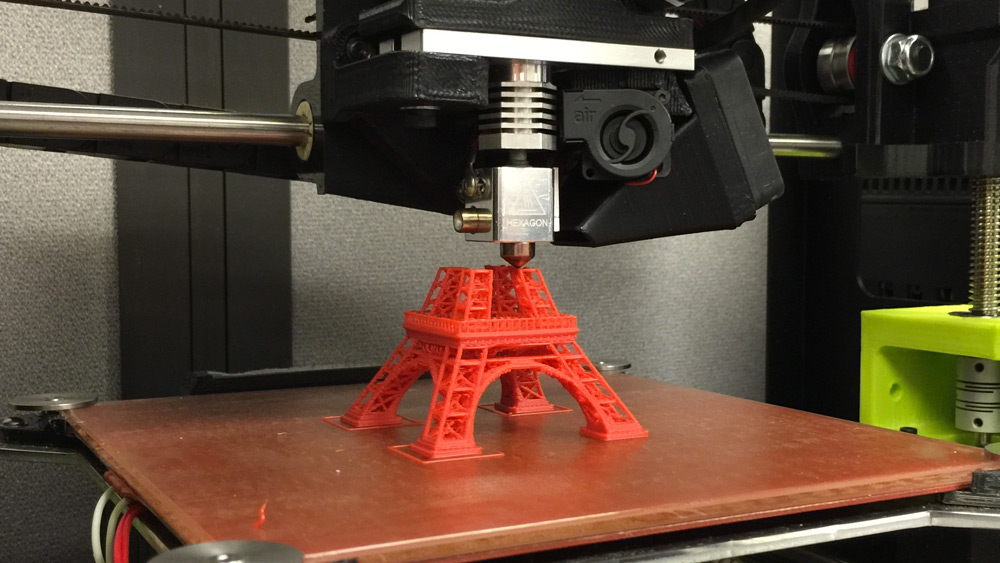

3D printing has revolutionised architecture. We may even see 3D printed houses become mainstream soon. In Amsterdam, architecture firm Dus Architects developed a ‘3D print canal house’ as part of a three year research and design project.

We may even see 3D printed houses become mainstream soon. In Amsterdam, architecture firm Dus Architects developed a ‘3D print canal house’ as part of a three year research and design project.

The canal house has each room printed separately before being assembled and stacked to create the house. The KamerMaker, a 20-foot 3D printer, is the product used to develop the house.

Automotive

In the automotive industry, 3D printing has been deployed to revolutionise the creation of vehicles.

One example is ‘Strati’, an electric car developed by Local Motors that’s been described as the ‘world’s first 3D-printed electric car’.

It took just 44 hours to print during the 2014 International manufacturing technology show in Chicago, and the car was manufactured using a large-scale 3D printer.

In 2018, car manufacturer MINI launched a 3D printing customisation service for customers to create their own car parts such as door handles or parts of the side plates.

The parts are customised and printed using professional services in partnership with Carbon, EOS and HP.

Automotive maker Divergent has also developed a new approach to auto manufacturing that incorporates 3D-printed joints. This approach, named ‘Node’, involves 3D printed aluminium nodes which are then combined with 3D-printed carbon fibres.

The manufacturer has developed its ‘Blade’ supercar and ‘Dagger’ motorcycle using this technique.

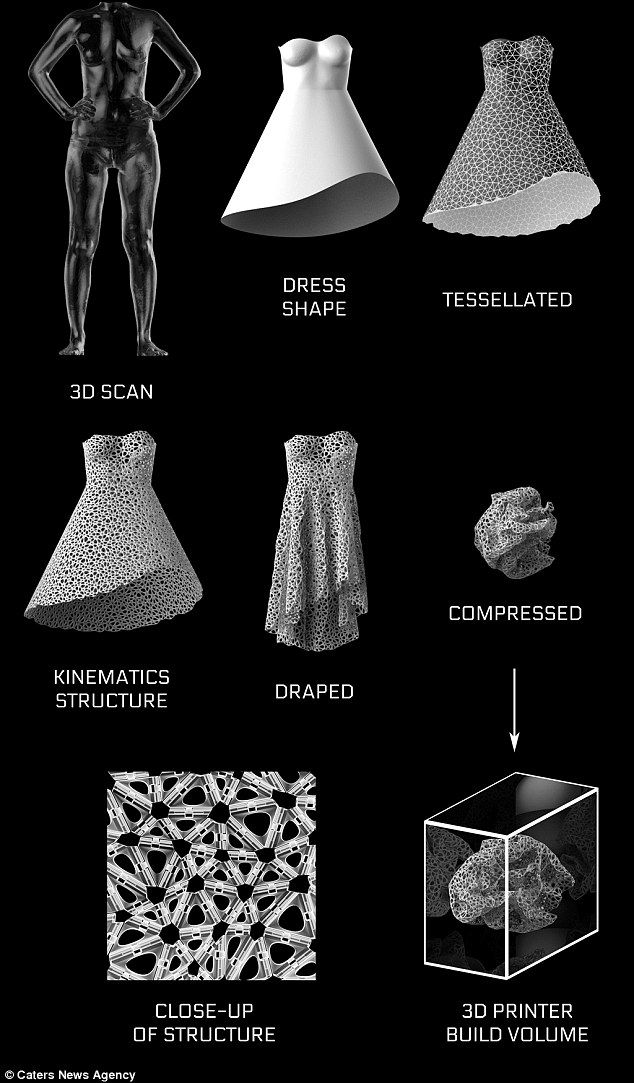

Fashion

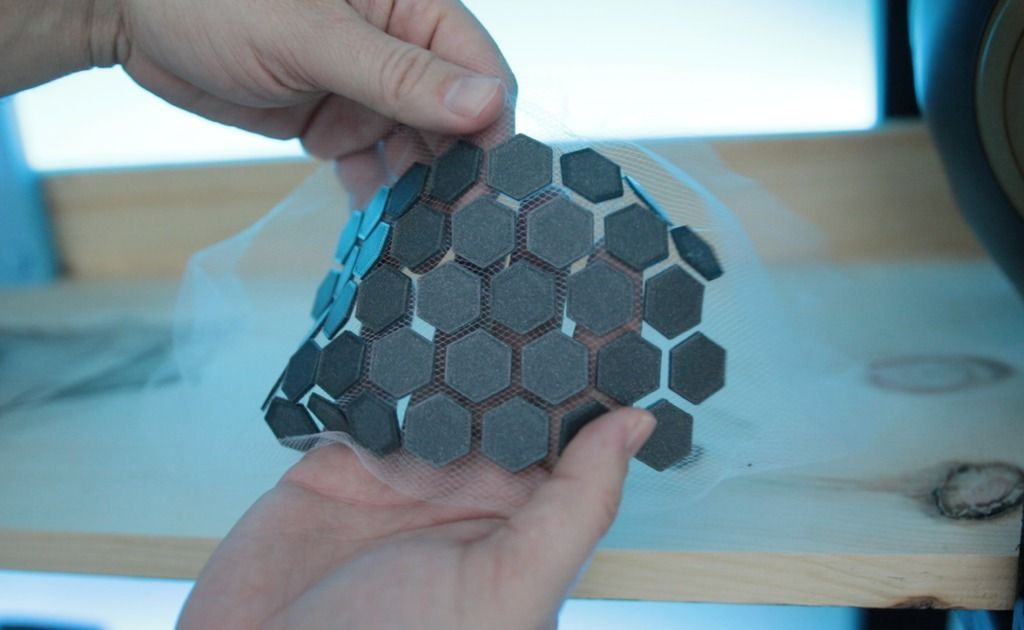

The fashion industry has also turned to 3D printing. In April 2017, Adidas partnered with Silicon Valley startup Carbon to launch a trainer with a 3D-printed sole.

Rivals Nike and New Balance have also experimented with 3D printing but have only developed prototypes using the technique.

Dr Scholl is another footwear brand using 3D printing, for the mass customisation of shoe insoles.

In partnership with Wiivv, a 3D-printing company, Dr Scholl provides a customisation app which creates scan of the customers feet to then assist in customising the insoles using scanning and mapping technology.

Education

Creativity and problem solving in schools has been boosted by 3D printing.

In subjects such as engineering 3D printing can be used by design students to print out prototypes; demonstrations of this have already been deployed across some institutions around the world.

Back in 2013, the UK government announced a 3D printer programme to boost the teaching of STEM subjects. Following the announcement, the programme was trialled in 21 schools.

Since then, 3D printing has been deployed across secondary and primary schools to give students the opportunity to design and test their own objects in real life.

The ‘CREATE’ education project was set up in the UK in 2014 to help schools integrate 3D printing into the curriculum by providing teachers with resources, lesson plans and presentations.

Capabilities and Applications of 3D Printing

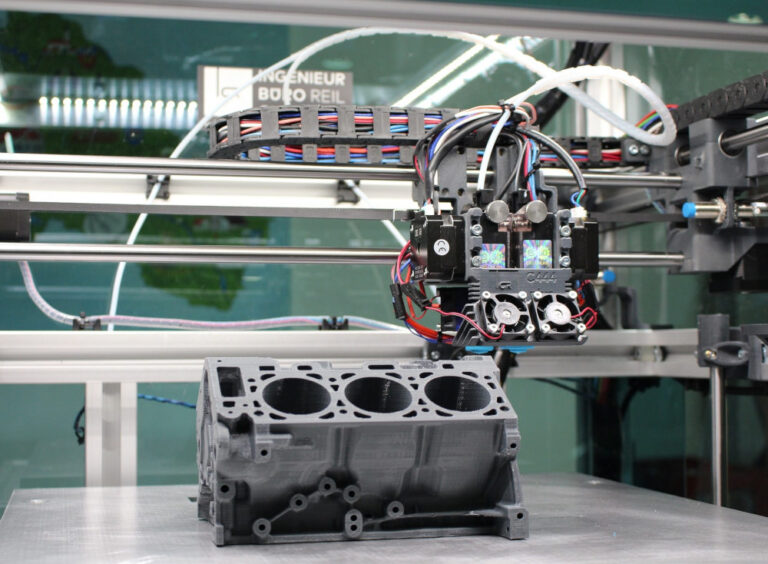

Whereas massive industrial equipment in special workshops used to produce parts, today 3D printing helps. Using this technology, it is possible to print parts of different complexity, which are not inferior in quality and characteristics to those produced by traditional methods.

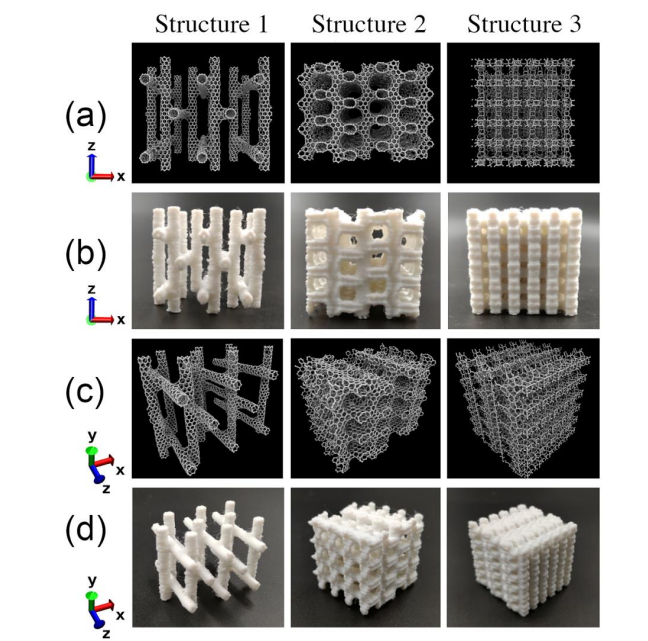

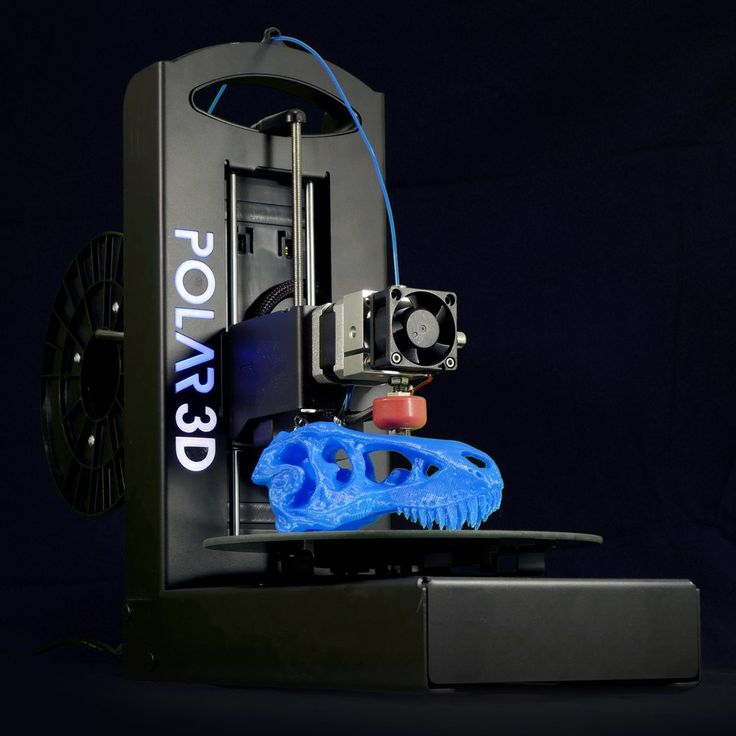

3D printing technology

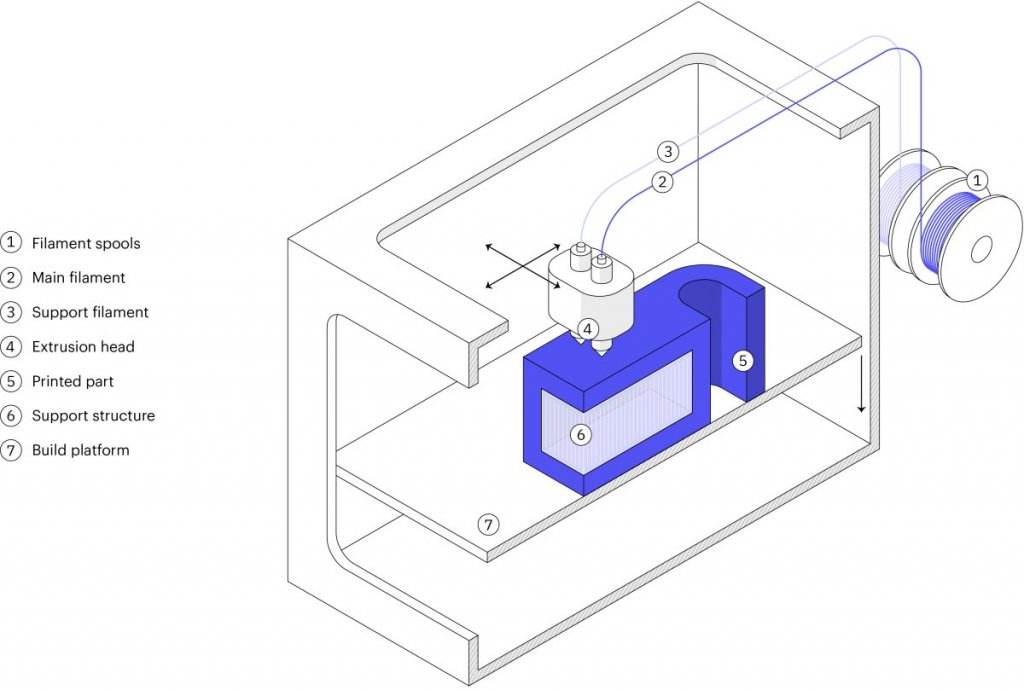

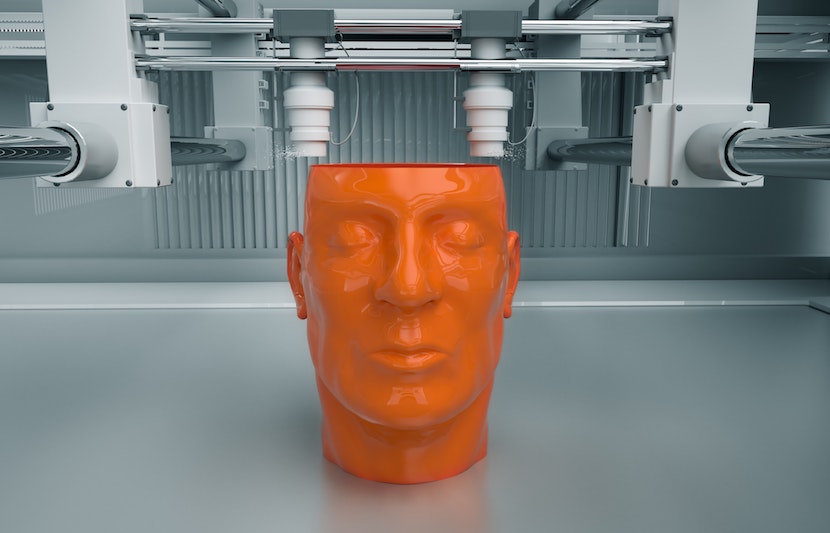

Printing on a 3D printer consists in the layer-by-layer formation of the structure of the future part from its graphic representation compiled on a computer in the form of files with three-dimensional graphic structures. They are created manually using specialized software, or obtained by scanning a real prototype.

Printers capable of recreating parts from sheet, liquid or powder material. The possibilities of a 3D printer in terms of the use of material for printing are very wide - it can be:

- plastic;

- nylon;

- glass powder;

- metallic powder;

- building mixtures;

- other materials.

The future details are obtained by fusing layer upon layer in such a way that their shape corresponds to her digital prototype.

Techniques Used

3D printing can be done using a variety of techniques.

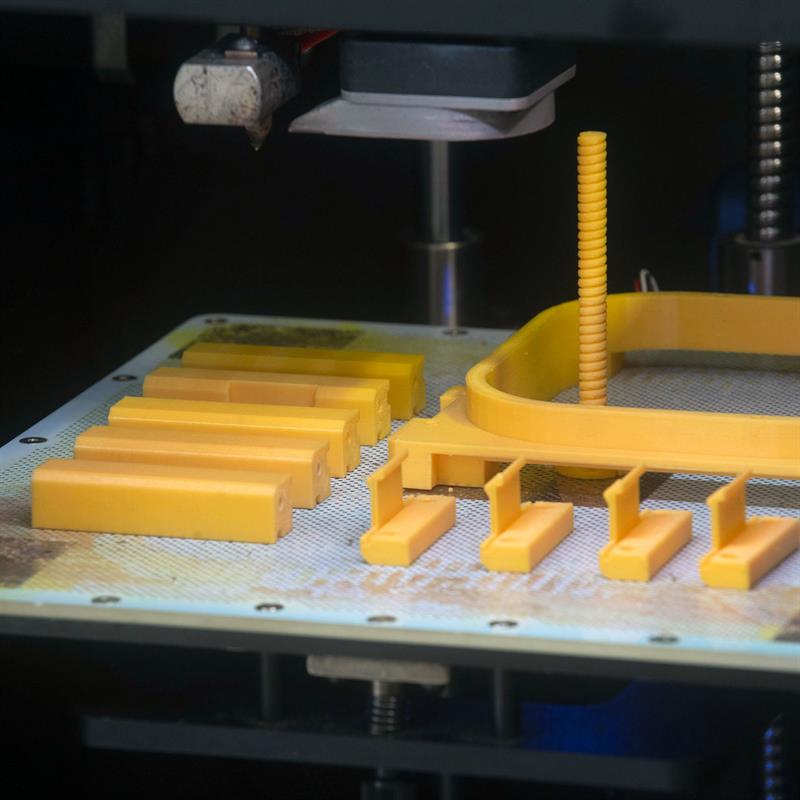

- Extrusion printing consists in heating the base material to the melting temperature and extruding it through the extruder nozzle, forming fragments of the future part.

Various polymeric compounds act as the starting material;

Various polymeric compounds act as the starting material; - The powder technique involves inkjet printing, in which binders are applied to a thin powder layer, followed by impregnation with wax or a polymer composition. Next, sintering of adjacent powder layers is performed. For this, direct or selective fusion with a laser or cathode ray tube is used;

- Laminating opens up wide possibilities for 3D printing. Using this method, you can significantly reduce the cost of manufactured spare parts. This technology involves the use of paper, sheets of thin plastic and metal as the base raw material.

Applications

Because a 3D printer can create parts of a wide variety of shapes, 3D printing has become used in various industries. Most commonly used in:

- industry;

- medicine;

- construction;

- automotive industry;

- aviation.

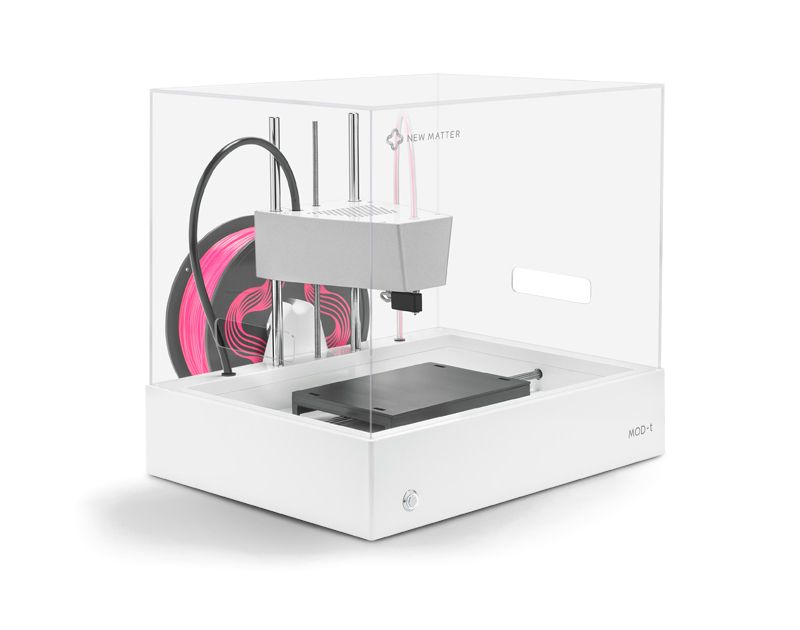

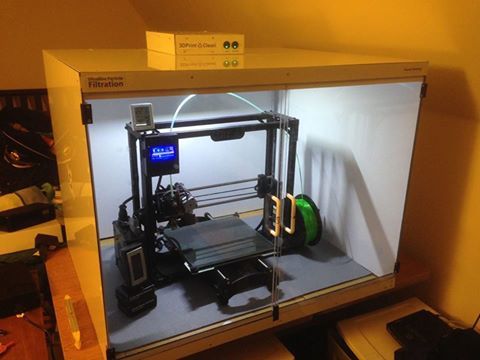

Advances in technology and declining prices for 3D printers are driving their widespread adoption at the consumer level. Anyone who is at least a little versed in technology and has free financial resources can start home production of the necessary things and parts.

Anyone who is at least a little versed in technology and has free financial resources can start home production of the necessary things and parts.

3D printing at home

If earlier everyone wanted to have a regular printer for printing documents, photos, presentations at home, today desires have switched to a 3D printer. Why might it be needed at home? Given the almost unlimited possibilities of 3D printing, a printer at home will become not just another high-tech toy for technology lovers, but an essential tool for the home. With it, it will be possible to print-produce:

- elements of furniture fittings;

- Christmas tree decorations;

- stands for office supplies;

- clothespins;

- Kids toys;

- chessmen;

- original protective cases for tablets and phones.

Having a 3D printer at home will eliminate unnecessary waste of time looking in stores and the market for some small detail that you can now make yourself.

Medicine

An important point in the development of 3D printing technologies is that they can be used in medicine. The most common use of 3D printers is in dentistry. They help to quickly make jaw implants and temporary crowns, which are necessary for a full life of the patient. The manufacture of jaw implants on a printer greatly simplifies the work of a dental surgeon.

In addition to jaw implants, other complex elements necessary for the restoration of the human skeleton can be made. For example, a modeled and then printed human skull implant made it possible to restore its integrity after a serious injury.

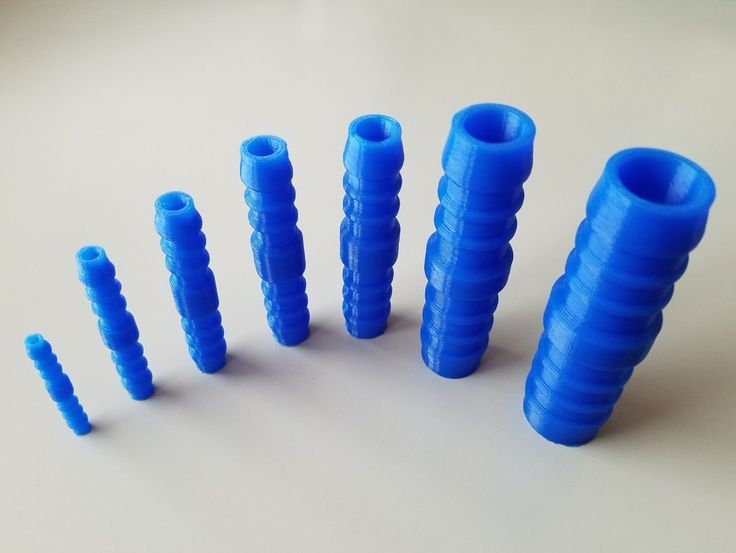

3D printing in medicine is actively used in prosthetics. Thanks to this technology, it is possible to produce prostheses that take into account the individual characteristics of the physical structure of the patient's body. By forming special microcavities in the prosthetic element, the possibilities of normal functioning of healthy tissue cells in contact with the material of the prosthesis are opened. This speeds up the process of human adaptation to the prosthesis.

This speeds up the process of human adaptation to the prosthesis.

Another successful example of 3D printing in medicine is the fact that scientists were able to grow a fragment of liver tissue using healthy liver cells. These samples are used to test and validate drugs on them. It is too early to talk about their transplantation to a person, but this is only for now.

Construction

In addition to printing parts used in the construction process, scientists are trying to create a printer that could be used to construct various buildings. Already today, the first construction 3D printers are being produced that can print-build houses with a total volume of 100-145m3. So far, it has not been possible to find the optimal solution that would satisfy civil engineers, but work on the introduction of 3D printing into the construction of houses is very active. Basically, they are aimed at creating a universal technique that can work with different building materials.

3D printing in construction will reduce human labor costs and injuries of builders, reduce the cost of building materials, and reduce the time required to build houses. At the exit, it is planned to receive a house ready for laying engineering communications, installing plumbing, electrical wiring, etc.

Industry

The purpose of 3D printing in industry is the manufacture of spare parts that are needed to restore the integrity or performance of components and mechanisms. The use of reverse engineering technology will allow you to restore the part in the presence of its whole or damaged prototype. Using 3D modeling, you can reconstruct the structure of a part and then print it on a printer.

If you need to change the functionality of the product, it is easy to make adjustments to its structure. To do this, you need to make the appropriate changes in the 3D model and then print the improved part. Thanks to different printing technologies and a wide choice of base materials, it is possible to produce parts with the required parameters. You can change their elasticity, strength, surface texture, color, etc.

You can change their elasticity, strength, surface texture, color, etc.

Industrial 3D printing allows you to create prototypes of future parts, print one-offs or start small-scale production.

Engineering Solutions has long introduced 3D printing technology and is ready to print products of any complexity.

The future of 3D printing

The prospects for the development and implementation of 3D printing technologies in various industries are very huge. If today 3D printers are used in several industries, then tomorrow it will be dozens of different industries. The most anticipated emergence of 3D printing in the following industries:

- electronics - in the near future it is expected that with the help of a printer it will be possible to print not just a separate part, but finished digital devices and devices;

- Pharmaceuticals - already now there are several drugs manufactured using 3D printers, in the future, almost a large part of the pharmaceutical industry will be able to be served by 3D printing equipment;

- food industry - no matter how strange it sounds, the printer can also print food; this technology is still at the development stage, but it also has a future, so soon it will be possible to order a dessert that will be prepared by a 3D printer.

The future of 3D printing in industries where it is already used is less fantastical. Existing 3D printers are expected to become more:

- reliable;

- durable;

- high-speed;

- available.

Also expected to expand the range of base materials that can be used for printing.

Source

Tags:

3D printing applications, 3D printer, 3D printing technology, 3D printing in the home, 3D technologies in medicine, implant, 3D printing in prosthetics, construction 3D printers, 3D modeling, reverse engineering technologies, food 3D printer

3D printing for dummies or "what is a 3D printer?"

- 1 3D printing term

- 2 3D printing methods

- 2.1 Extrusion printing

- 2.2 Melting, sintering or gluing

- 2.3 Stereolithography

- 2.4 Lamination

- 3 Fused Deposition Printing (FDM)

- 3.

1 Consumables

1 Consumables - 3.2 Extruder

- 3.3 Working platform

- 3.4 Positioners

- 3.5 Control

- 3.6 Types of FDM printers

- 4 Laser stereolithography (SLA)

- 4.1 Lasers and projectors

- 4.2 Cuvette and resin

- 4.3 Varieties of Stereolithography Printers

3D printing term

The term 3D printing has several synonyms, one of which quite briefly and accurately characterizes the essence of the process - "additive manufacturing", that is, production by adding material. The term was not coined by chance, because this is the main difference between multiple 3D printing technologies and the usual methods of industrial production, which in turn received the name "subtractive technologies", that is, "subtractive". If during milling, grinding, cutting and other similar procedures, excess material is removed from the workpiece, then in the case of additive manufacturing, material is gradually added until a solid model is obtained.

Soon 3D printing will even be tested on the International Space Station

Strictly speaking, many traditional methods could be classified as "additive" in the broad sense of the word - for example, casting or riveting. However, it should be borne in mind that in these cases, either the consumption of materials is required for the manufacture of specific tools used in the production of specific parts (as in the case of casting), or the whole process is reduced to joining ready-made parts (welding, riveting, etc.). In order for the technology to be classified as “3D printing”, the final product must be built from raw materials, not blanks, and the formation of objects must be arbitrary - that is, without the use of forms. The latter means that additive manufacturing requires a software component. Roughly speaking, additive manufacturing requires computer control so that the shape of final products can be determined by building digital models. It was this factor that delayed the widespread adoption of 3D printing until the moment when numerical control and 3D design became widely available and highly productive.

3D printing techniques

There are many 3D printing technologies, and even more names for them due to patent restrictions. However, you can try to divide technologies into main areas:

Extrusion printing

This includes methods such as deposition fusion (FDM) and multi-jet printing (MJM). This method is based on the extrusion (extrusion) of consumables with the sequential formation of the finished product. As a rule, consumables consist of thermoplastics or composite materials based on them.

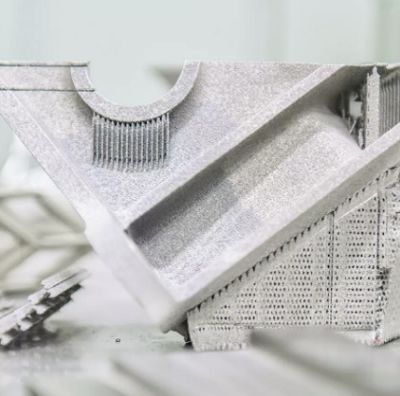

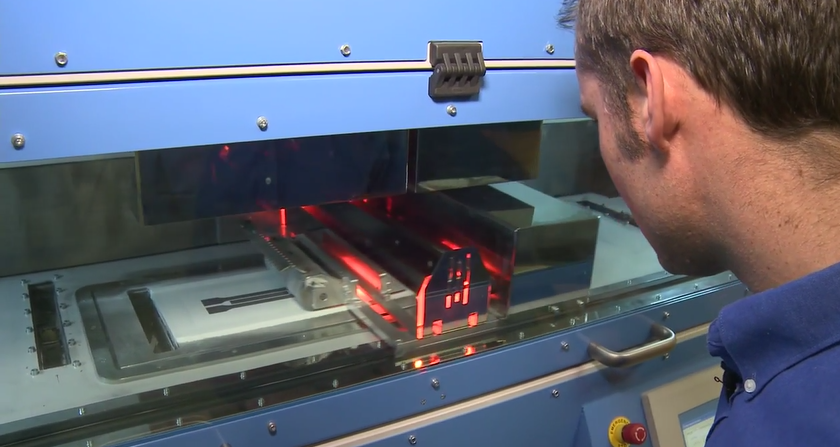

Melting, sintering or bonding

This approach is based on bonding powdered material together. Formation is done in different ways. The simplest is gluing, as is the case with 3D inkjet printing (3DP). Such printers deposit thin layers of powder onto the build platform, which are then selectively bonded with a binder. Powders can be made up of virtually any material that can be ground to a powder—plastic, wood, metal.

This model of James Bond's Aston Martin was successfully printed on a Voxeljet SLS printer and blown up just as successfully during the filming of Skyfall instead of the expensive original

sintering (SLS and DMLS) and smelting (SLM), which allow you to create all-metal parts. As with 3D inkjet printing, these devices apply thin layers of powder, but the material is not glued together, but sintered or melted using a laser. Laser sintering (SLS) is used to work with both plastic and metal powders, although metal pellets usually have a more fusible shell, and after printing they are additionally sintered in special ovens. DMLS is a variant of SLS installations with more powerful lasers that allow sintering metal powders directly without additives. SLM printers provide not just sintering of particles, but their complete melting, which allows you to create monolithic models that do not suffer from the relative fragility caused by the porosity of the structure.![]() As a rule, printers for working with metal powders are equipped with vacuum working chambers, or they replace air with inert gases. Such a complication of the design is caused by the need to work with metals and alloys subject to oxidation - for example, with titanium.

As a rule, printers for working with metal powders are equipped with vacuum working chambers, or they replace air with inert gases. Such a complication of the design is caused by the need to work with metals and alloys subject to oxidation - for example, with titanium.

Stereolithography

How an SLA printer works

Stereolithography printers use special liquid materials called "photopolymer resins". The term "photopolymerization" refers to the ability of a material to harden when exposed to light. As a rule, such materials react to ultraviolet irradiation.

Resin is poured into a special container with a movable platform, which is installed in a position near the surface of the liquid. The layer of resin covering the platform corresponds to one layer of the digital model. Then a thin layer of resin is processed by a laser beam, hardening at the points of contact. At the end of illumination, the platform together with the finished layer is immersed to the thickness of the next layer, and illumination is performed again.

Lamination

Laminating (LOM) 3D printers workflow

Some 3D printers build models using sheet materials - paper, foil, plastic film.

Layers of material are glued on top of each other and cut along the contours of the digital model using a laser or a blade.

These machines are well suited for prototyping and can use very cheap consumables, including regular office paper. However, the complexity and noise of these printers, coupled with the limitations of the models they produce, limit their popularity.

Fused deposition modeling (FDM) and laser stereolithography (SLA) have become the most popular 3D printing methods used in the home and office.

Let's take a closer look at these technologies.

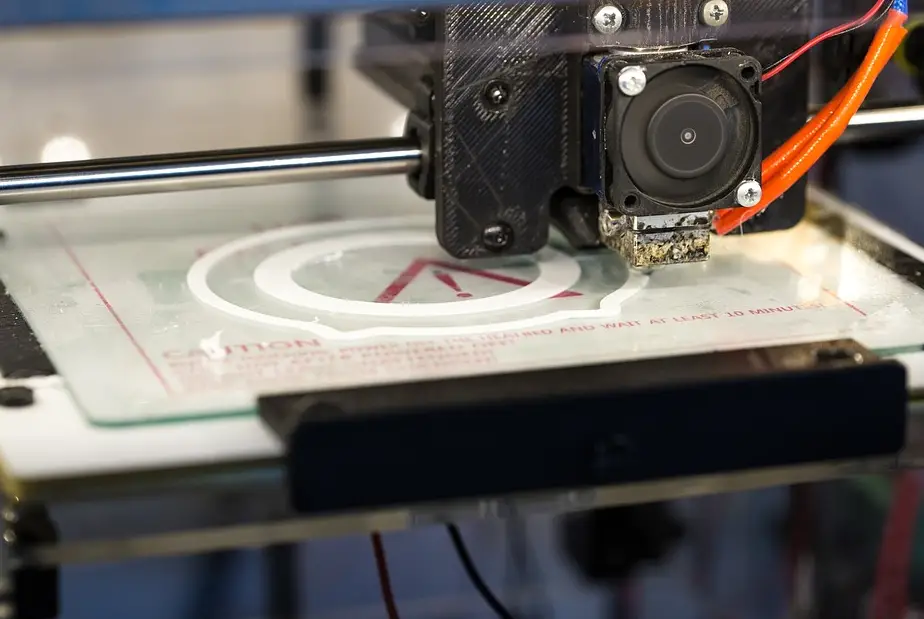

Fused Deposition Printing (FDM)

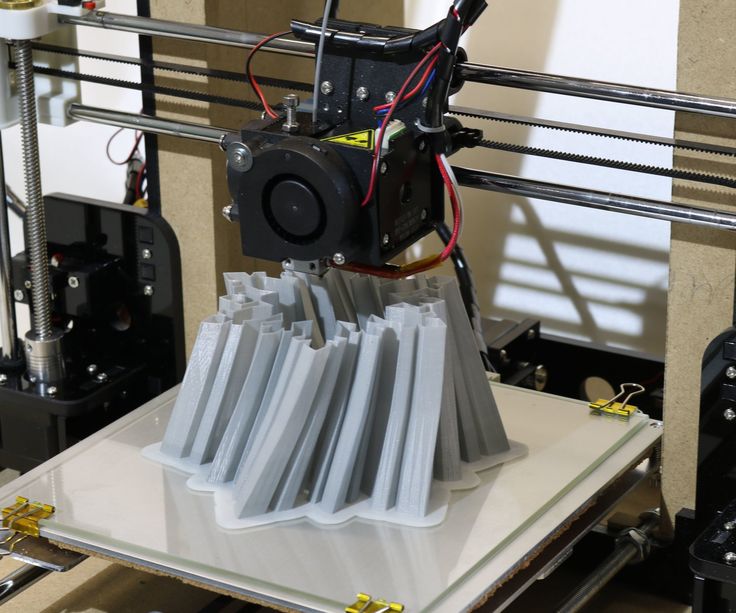

FDM is perhaps the simplest and most affordable 3D construction method, which makes it very popular.

High demand for FDM printers is driving device and consumable prices down rapidly, as technology advances towards ease of use and improved reliability.

Consumables

ABS filament spool and finished model

FDM printers are designed to print with thermoplastics, which are usually supplied as thin filaments wound on spools. The range of "clean" plastics is very wide. One of the most popular materials is polylactide or "PLA plastic". This material is made from corn or sugar cane, which makes it non-toxic and environmentally friendly, but makes it relatively short-lived. ABS plastic, on the other hand, is very durable and wear-resistant, although it is susceptible to direct sunlight and can release small amounts of harmful fumes when heated. Many plastic items that we use on a daily basis are made from this material: housings for household appliances, plumbing fixtures, plastic cards, toys, etc.

In addition to PLA and ABS, printing is possible with nylon, polycarbonate, polyethylene and many other thermoplastics that are widely used in modern industry. More exotic materials are also possible, such as polyvinyl alcohol, known as "PVA plastic". This material dissolves in water, which makes it very useful for printing complex geometric patterns. But more on that below.

More exotic materials are also possible, such as polyvinyl alcohol, known as "PVA plastic". This material dissolves in water, which makes it very useful for printing complex geometric patterns. But more on that below.

Model made from Laywoo-D3. Changing the extrusion temperature allows you to achieve different shades and simulate annual rings

It is not necessary to print with homogeneous plastics. It is also possible to use composite materials imitating wood, metals, stone. Such materials use all the same thermoplastics, but with impurities of non-plastic materials.

So, Laywoo-D3 consists partly of natural wood dust, which allows you to print "wooden" products, including furniture.

The material called BronzeFill is filled with real bronze, and models made from it can be ground and polished, achieving a high similarity to products made from pure bronze.

One has only to remember that thermoplastics serve as a binding element in composite materials - they determine the thresholds of strength, thermal stability and other physical and chemical properties of finished models.

Extruder

Extruder - FDM print head. Strictly speaking, this is not entirely true, because the head consists of several parts, of which only the feed mechanism is directly "extruder". However, by tradition, the term "extruder" is commonly used as a synonym for the entire print assembly.

FDM extruder general design

The extruder is designed for melting and applying thermoplastic thread. The first component is the thread feed mechanism, which consists of rollers and gears driven by an electric motor. The mechanism feeds the thread into a special heated metal tube with a small diameter nozzle, called a "hot end" or simply a "nozzle". The same mechanism is used to remove the thread if a change of material is needed.

The hot end is used to heat and melt the thread fed by the puller. As a rule, nozzles are made from brass or aluminum, although more heat-resistant, but also more expensive materials can be used. For printing with the most popular plastics, a brass nozzle is quite enough. The “nozzle” itself is attached to the end of the tube with a threaded connection and can be replaced with a new one in case of wear or if a change in diameter is necessary. The nozzle diameter determines the thickness of the molten filament and, as a result, affects the print resolution. The heating of the hot end is controlled by a thermistor. Temperature control is very important, because when the material is overheated, pyrolysis can occur, that is, the decomposition of plastic, which contributes both to the loss of the properties of the material itself and to clogging of the nozzle.

For printing with the most popular plastics, a brass nozzle is quite enough. The “nozzle” itself is attached to the end of the tube with a threaded connection and can be replaced with a new one in case of wear or if a change in diameter is necessary. The nozzle diameter determines the thickness of the molten filament and, as a result, affects the print resolution. The heating of the hot end is controlled by a thermistor. Temperature control is very important, because when the material is overheated, pyrolysis can occur, that is, the decomposition of plastic, which contributes both to the loss of the properties of the material itself and to clogging of the nozzle.

PrintBox3D One FDM Printer Extruder

To prevent the filament from melting too early, the top of the hot end is cooled by heatsinks and fans. This point is of great importance, since thermoplastics that pass the glass transition temperature significantly expand in volume and increase the friction of the material with the walls of the hot end. If the length of such a section is too long, the pulling mechanism may not have enough strength to push the thread.

If the length of such a section is too long, the pulling mechanism may not have enough strength to push the thread.

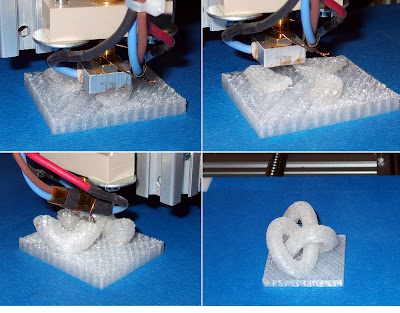

The number of extruders may vary depending on the purpose of the 3D printer. The simplest options use a single print head. The dual extruder greatly expands the capabilities of the device, allowing you to print one model in two different colors, as well as using different materials. The last point is important when building complex models with overhanging structural elements: FDM printers cannot print “over the air”, since the applied layers require support. In the case of hinged elements, temporary support structures have to be printed, which are removed after printing is completed. The removal process is fraught with damage to the model itself and requires accuracy. In addition, if the model has a complex structure with internal cavities that are difficult to access, building conventional supports may not be practical due to the difficulty in removing excess material.

Finished model with PVA supports (white) before and after washing

In such cases, the very water-soluble polyvinyl alcohol (PVA) comes in handy. Using a dual extruder, you can build a model from waterproof thermoplastic using PVA to create supports.

After printing, PVA can simply be dissolved in water and a complex product of perfect quality can be obtained.

Some FDM printers can use three or even four extruders.

Work platform

Heated platform covered with a removable glass work table

Models are built on a special platform, often equipped with heating elements. Preheating is required for a wide range of plastics, including the popular ABS, which are subject to a high degree of shrinkage when cooled. The rapid loss of volume by cold coats compared to freshly applied material can lead to model distortion or delamination. The heating of the platform makes it possible to significantly equalize the temperature gradient between the upper and lower layers.

Heating is not recommended for some materials. A typical example is PLA plastic, which requires a fairly long time to harden. Heating PLA can lead to deformation of the lower layers under the weight of the upper ones. When working with PLA, measures are usually taken not to heat up, but to cool the model. Such printers have characteristic open cases and additional fans blowing fresh layers of the model.

Calibration screw for work platform covered with blue masking tape

The platform needs to be calibrated before printing to ensure that the nozzle does not hit the applied layers and move too far causing air-to-air printing resulting in plastic vermicelli. The calibration process can be either manual or automatic. In manual mode, calibration is performed by positioning the nozzle at different points on the platform and adjusting the platform inclination using the support screws to achieve the optimal distance between the surface and the nozzle.

As a rule, platforms are equipped with an additional element - a removable table. This design simplifies the cleaning of the working surface and facilitates the removal of the finished model. Stages are made from various materials, including aluminum, acrylic, glass, etc. The choice of material for the manufacture of the stage depends on the presence of heating and consumables for which the printer is optimized.

For a better adhesion of the first layer of the model to the surface of the table, additional tools are often used, including polyimide film, glue and even hairspray! But the most popular tool is inexpensive, but effective masking tape. Some manufacturers make perforated tables that hold the model well but are difficult to clean. In general, the expediency of applying additional funds to the table depends on the consumable material and the material of the table itself.

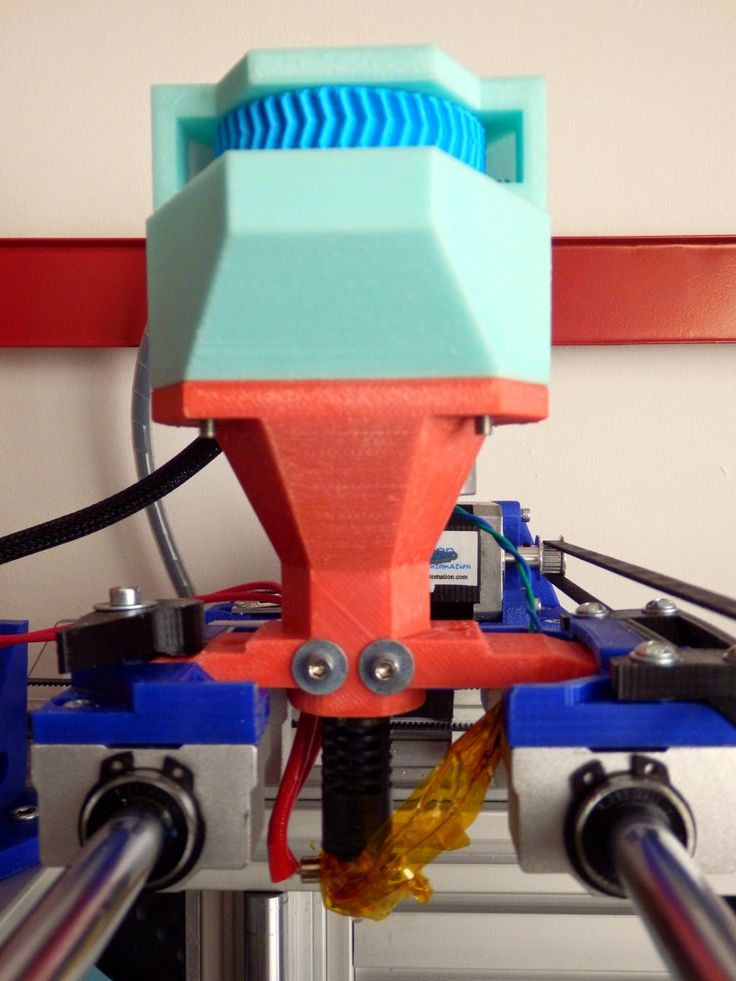

Positioning mechanisms

Scheme of operation of positioning mechanisms

Of course, the print head must move relative to the working platform, and unlike conventional office printers, positioning must be carried out not in two, but in three planes, including height adjustment.

Positioning pattern may vary. The simplest and most common option involves mounting the print head on perpendicular guides driven by stepper motors and providing positioning along the X and Y axes.

Vertical positioning is carried out by moving the working platform.

On the other hand, it is possible to move the extruder in one plane and the platforms in two.

SeemeCNC ORION Delta Printer

One option that is gaining popularity is the delta coordinate system.

Such devices are called "delta robots" in the industry.

In delta printers, the print head is suspended on three manipulators, each of which moves along a vertical rail.

The synchronous symmetrical movement of the manipulators allows you to change the height of the extruder above the platform, and the asymmetric movement causes the head to move in the horizontal plane.

A variant of this system is the reverse delta design, where the extruder is fixed to the ceiling of the working chamber, and the platform moves on three support arms.

Delta printers have a cylindrical build area, and their design makes it easy to increase the height of the working area with minimal design changes by lengthening the rails.

In the end, everything depends on the decision of the designers, but the fundamental principle does not change.

Control

Typical Arduino-based controller with add-on modules

FDM printer operation, including nozzle and platform temperature, filament feed rate, and stepper motors for positioning the extruder, is controlled by fairly simple electronic controllers. Most controllers are based on the Arduino platform, which has an open architecture.

The programming language used by printers is called G-code (G-Code) and consists of a list of commands executed in turn by the 3D printer systems. G-code is compiled by programs called "slicers" - standard 3D printer software that combines some of the features of graphics editors with the ability to set print options through a graphical interface. The choice of slicer depends on the printer model. RepRap printers use open source slicers such as Skeinforge, Replicator G and Repetier-Host. Some companies make printers that require proprietary software.

The choice of slicer depends on the printer model. RepRap printers use open source slicers such as Skeinforge, Replicator G and Repetier-Host. Some companies make printers that require proprietary software.

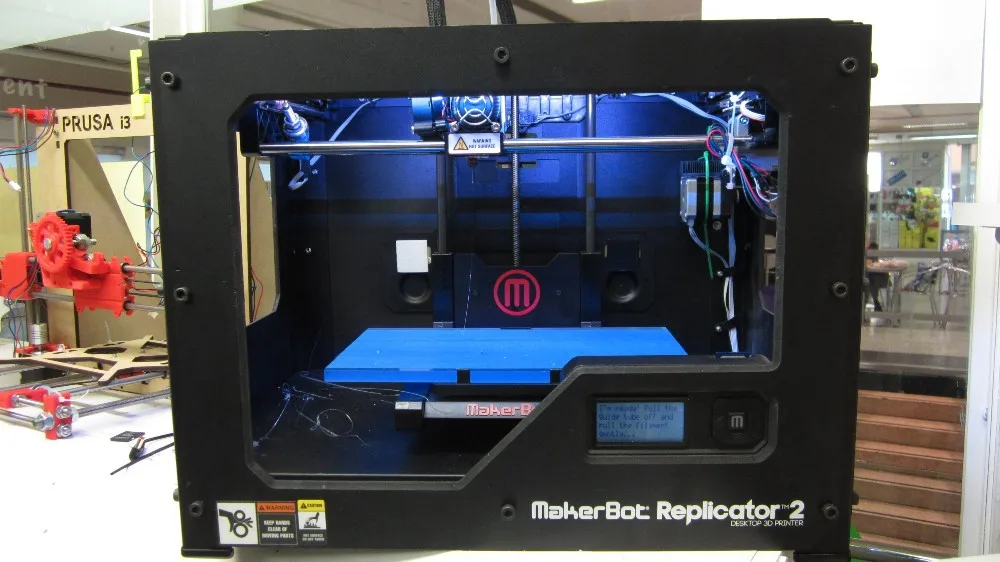

The code for printing is generated using slicers

As an example, we can mention the Cube printers from 3D Systems. There are companies that offer proprietary software but allow third-party software, as is the case with the latest generation of MakerBot 3D printers.

Slicers are not designed for 3D design per se. This task is done with CAD editors and requires some 3D design skills. Although beginners should not despair: digital models of a wide variety of designs are offered on many sites, often even for free. Finally, some companies and individuals offer 3D design services for custom printing.

Finally, 3D printers can be used in conjunction with 3D scanners to automate the process of digitizing objects. Many of these devices are designed specifically to work with 3D printers. Notable examples include the 3D Systems Sense handheld scanner and the MakerBot Digitizer handheld desktop scanner.

Notable examples include the 3D Systems Sense handheld scanner and the MakerBot Digitizer handheld desktop scanner.

MakerBot Replicator 5th Generation FDM Printer with built-in control module on the top of the frame

The user interface of a 3D printer can consist of a simple USB port for connecting to a personal computer. In such cases, the device is actually controlled by the slicer.

The disadvantage of this simplification is a rather high probability of printing failure when the computer freezes or slows down.

A more advanced option includes an internal memory or memory card interface to make the process standalone.

These models are equipped with control modules that allow you to adjust many print parameters (such as print speed or extrusion temperature). The module may include a small LCD display or even a mini-tablet.

Varieties of FDM printers

Professional Stratasys Fortus 360mc FDM printer that allows printing with nylon

FDM printers are very, very diverse, ranging from the simplest home-made RepRap printers to industrial installations capable of printing large-sized objects.

Stratasys, founded by FDM inventor Scott Crump, is a leader in industrial plant manufacturing.

You can build the simplest FDM printers yourself. Such devices are called RepRap, where "Rep" indicates the possibility of "replication", that is, self-reproduction.

RepRap printers can be used to print custom built plastic parts.

Controller, rails, belts, motors and other components can be easily purchased separately.

Of course, assembling such a device on your own requires serious technical and even engineering skills.

Some manufacturers make it easy by selling DIY kits, but these kits still require a good understanding of the technology. RepRap Printers

And, despite their "homemade nature", RepRap printers are quite capable of producing models with quality at the level of expensive branded counterparts.

Ordinary users who do not want to delve into the intricacies of the process, but require only a convenient device for household use, can purchase a ready-made FDM printer.

Many companies are focusing on the development of the consumer market segment, offering 3D printers for sale that are ready to print “straight out of the box” and do not require serious computer skills.

3D Systems Cube consumer 3D printer

The most famous example of a consumer 3D printer is the 3D Systems Cube.

While it doesn't boast a huge build area, ultra-fast print speed, or superb model build quality, it's easy to use, affordable, and safe: This printer has received the necessary certification to be used even by children.

Mankati FDM printer demonstration: http://youtu.be/51rypJIK4y0

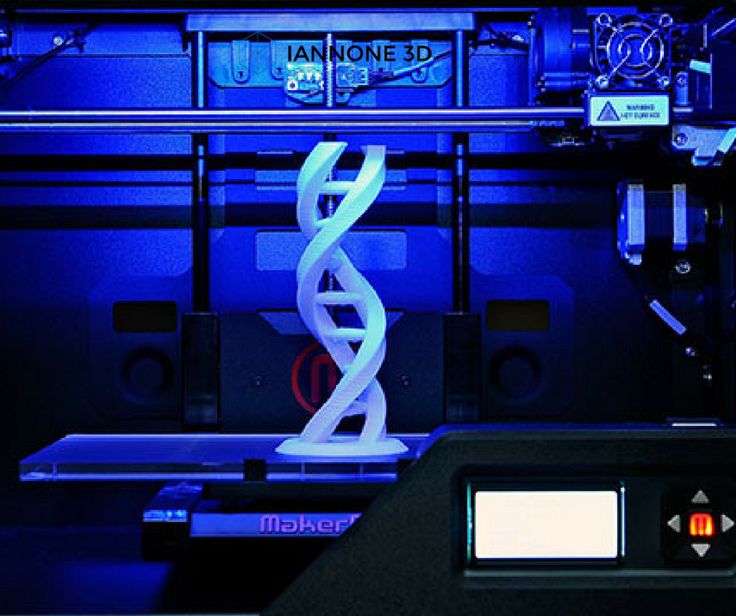

Laser Stereolithography (SLA)

Stereolithographic 3D printers are widely used in dental prosthetics

Stereolithographic printers are the second most popular and widespread after FDM printers.

These units deliver exceptional print quality.

The resolution of some SLA printers is measured in a matter of microns - it is not surprising that these devices quickly won the love of jewelers and dentists.

The software side of laser stereolithography is almost identical to FDM printing, so we will not repeat ourselves and will only touch on the distinctive features of the technology.

Lasers and projectors

Projector illumination of a photopolymer model using Kudo3D Titan DLP printer as an example

The cost of stereolithography printers is rapidly declining, due to growing competition due to high demand and the use of new technologies that reduce the cost of construction.

Although the technology is collectively referred to as "laser" stereolithography, most recent developments use UV LED projectors for the most part.

Projectors are cheaper and more reliable than lasers, do not require the use of delicate mirrors to deflect the laser beam, and have higher performance. The latter is explained by the fact that the contour of the whole layer is illuminated as a whole, and not sequentially, point by point, as is the case with laser options. This variant of the technology is called projection stereolithography, "DLP-SLA" or simply "DLP". However, both options are currently common - both laser and projector versions.

This variant of the technology is called projection stereolithography, "DLP-SLA" or simply "DLP". However, both options are currently common - both laser and projector versions.

Cuvette and resin

Photopolymer resin is poured into a cuvette

A photopolymer resin that looks like epoxy is used as consumables for stereolithographic printers. Resins can have a variety of characteristics, but they all share one key feature for 3D printing applications: these materials harden when exposed to ultraviolet light. Hence, in fact, the name "photopolymer".

When polymerized, resins can have a wide variety of physical characteristics. Some resins are like rubber, others are hard plastics like ABS. You can choose different colors and degrees of transparency. The main disadvantage of resins and SLA printing in general is the cost of consumables, which significantly exceeds the cost of thermoplastics.

On the other hand, stereolithographic printers are mainly used by jewelers and dentists who do not need to build large parts but appreciate the savings from fast and accurate prototyping. Thus, SLA printers and consumables pay for themselves very quickly.

Thus, SLA printers and consumables pay for themselves very quickly.

An example of a model printed on a laser stereolithographic 3D printer

Resin is poured into a cuvette, which can be equipped with a lowering platform. In this case, the printer uses a leveling device to flatten the thin layer of resin covering the platform just prior to irradiation. As the model is being made, the platform, together with the finished layers, is “embedded” in the resin. Upon completion of printing, the model is removed from the cuvette, treated with a special solution to remove liquid resin residues and placed in an ultraviolet oven, where the final illumination of the model is performed.

Some SLA and DLP printers work in an "inverted" scheme: the model is not immersed in the consumable, but "pulled" out of it, while the laser or projector is placed under the cuvette, and not above it. This approach eliminates the need to level the surface after each exposure, but requires the use of a cuvette made of a material transparent to ultraviolet light, such as quartz glass.

The accuracy of stereolithographic printers is extremely high. For comparison, the standard for vertical resolution for FDM printers is considered to be 100 microns, and some variants of SLA printers allow you to apply layers as thin as 15 microns. But this is not the limit. The problem, rather, is not so much in the accuracy of lasers, but in the speed of the process: the higher the resolution, the lower the print speed. The use of digital projectors allows you to significantly speed up the process, because each layer is illuminated entirely. As a result, some DLP printer manufacturers claim to be able to print with a vertical resolution of one micron!

Video from CES 2013 showing Formlabs Form1 stereolithography 3D printer in action: http://youtu.be/IjaUasw64VE

Stereolithography Printer Options

Formlabs Form1 Desktop Stereolithography Printer

As with FDM printers, SLA printers come in a wide range in terms of size, features and cost.