3D printed terrain models

Terrain Models Custom 3D Fabrication Services

Tradition + Technology

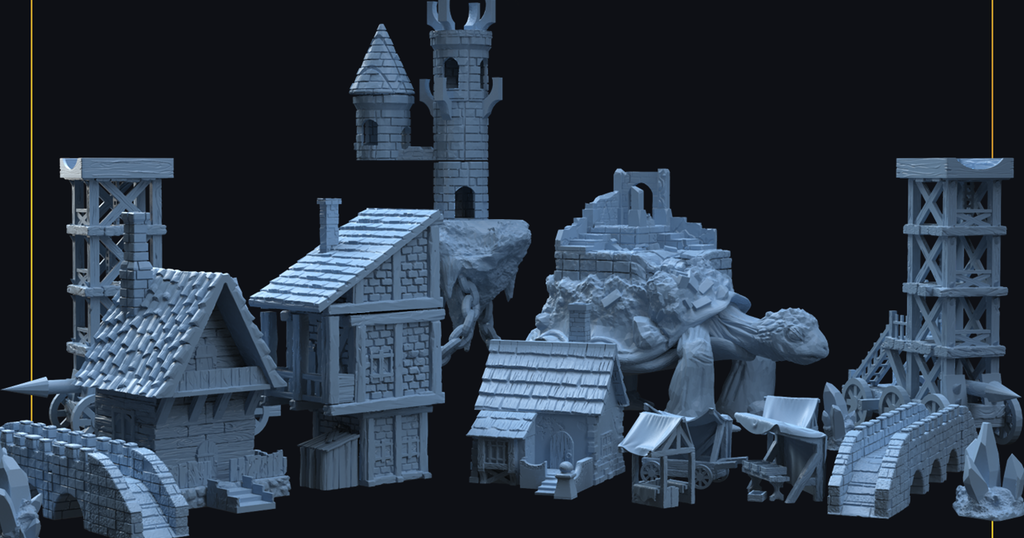

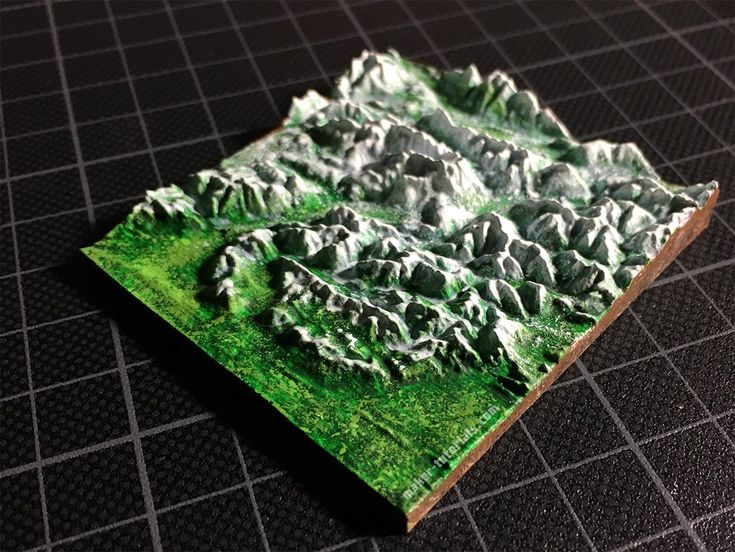

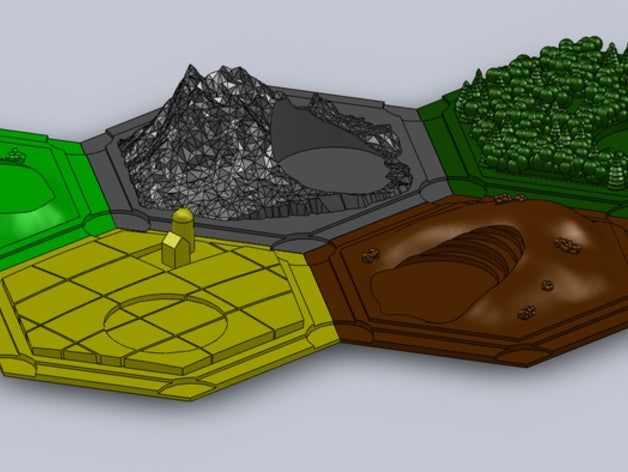

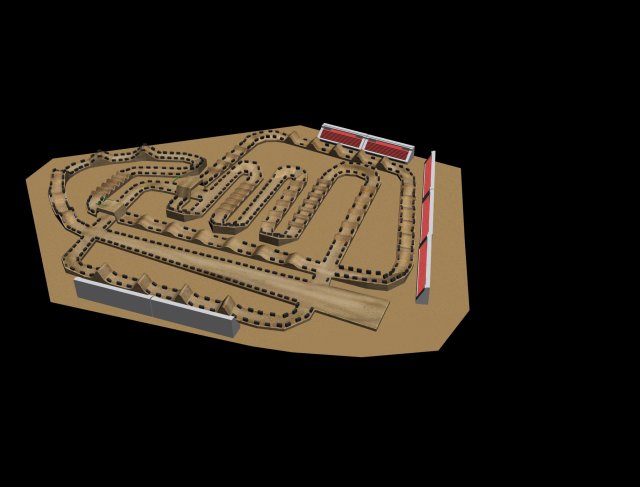

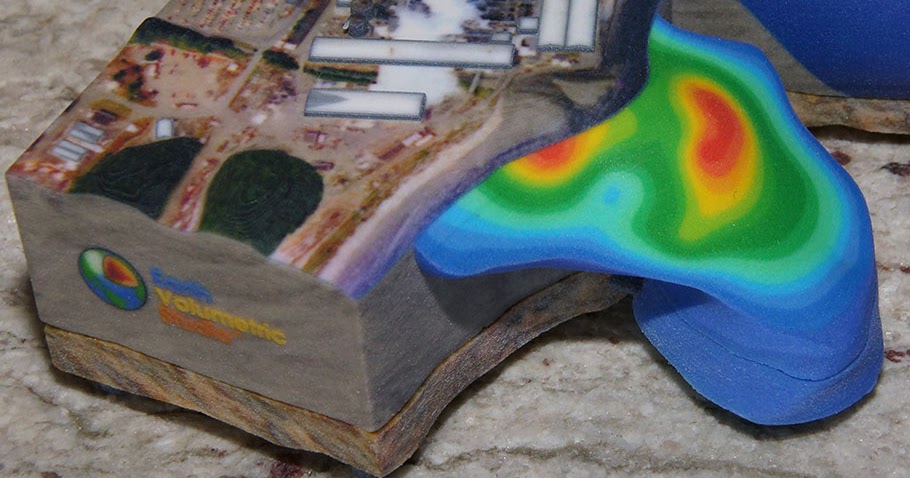

3D printing technologies are helping humans venture into new frontiers. 3D printers can accurately create realistic 3D views of planet surfaces, ocean floors, drone captured terrains and underground geology formations, and even the surface of the moon. Terrain models can benefit developers, mining companies, outdoor sports industries, and educational organizations.

Creating 3D raised maps used to be extremely laborious even with the best equipment. 3D printers can create models faster than ever before, make them more precise, and are lower-priced (considering man hours). 3D terrain models can be created using a wide variety of technologies to create as accurate as possible models. Models can be printed using thousands of colors and texturized elements, and traditional handwork for landscape can be added.

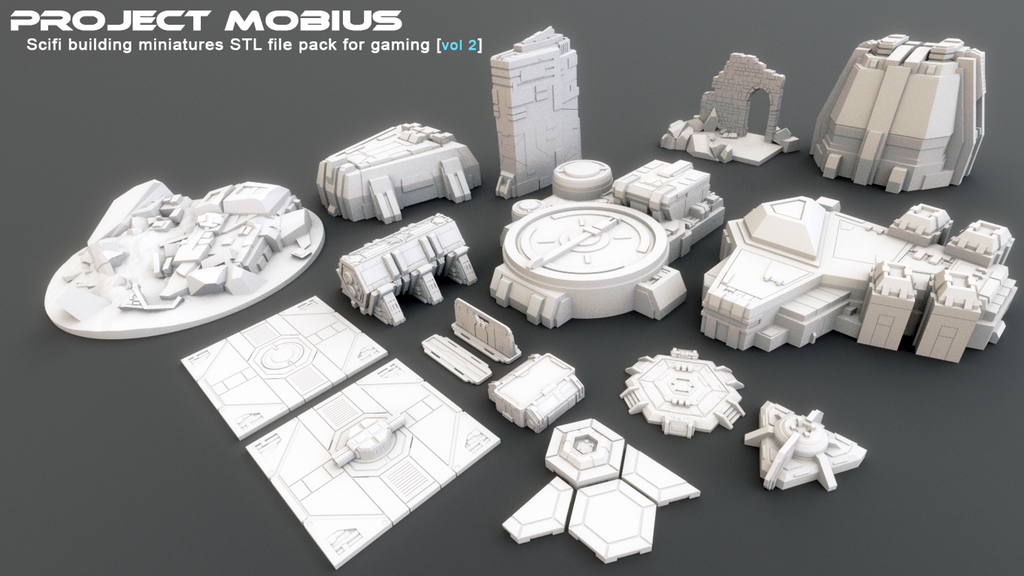

WhiteClouds is a full-service company and can also provide customized, handcrafted bases to hold your terrain models and offers 3D cutting services if requested. It is simple to submit design ideas and start a conversation with WhiteClouds. There are no limitations to what can be created or what technologies can be used to make the terrain models.

One of our most recent terrain projects was of the Great Smoky Mountains National Park and some surrounding area.

Gallery of Selected Terrain and Topography Projects

Features & Benefits

- Time saving. 3D print technologies can produce accurate terrain maps quicker than any previous technology used.

- Precision. Maps can be as exact as the information given to create the maps.

- To scale. They can be built to scale within any parameters needed.

- High tech. WhiteClouds utilizes all types of technologies including simple drawings, Google Earth, drone images, and LIDAR data to create terrain maps.

- Affordability. 3D printing is becoming reasonably priced, making it advantageous enough for many industries to use.

- Enthusiasm.

3D maps communicate across languages to excite interest in your project regardless of people’s background or language.

3D maps communicate across languages to excite interest in your project regardless of people’s background or language. - Details. Prints can depict the tiniest of details as well as thousands of colors.

- Portability. Maps can be created using lighter materials than what was available in the past, making them easier to transport

Technology and Materials

- With 3D printing technology, you aren’t limited to straight lines and boxes. A 3D printer can easily print jagged edges, curved walls, and rounded rooflines.

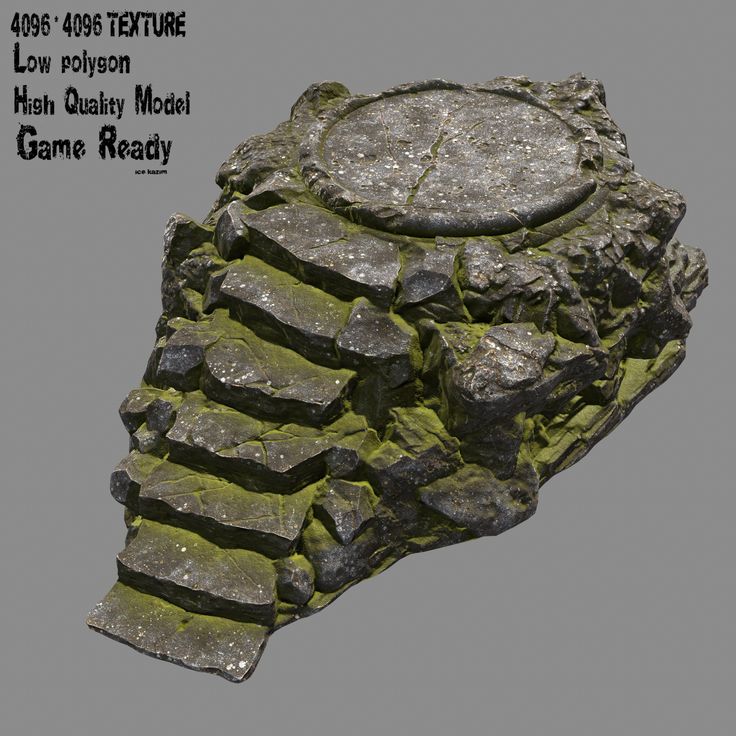

- We can 3D print models in different materials including UV-cured resin. The type of model determines which material will produce the best results. We can help you choose the material that is best for your project.

- We use foam fabrication technologies such as CNC Cutting, Hot Wires, Laser Cutting, Hot Knifing, and Sculpting.

- 3D Printed Terrain models, architectural models, and topographical models show incredible detail.

The resolution of our printers is finer than a human hair.

The resolution of our printers is finer than a human hair. - Terrain models can be 3D printed in full-color (over 750,000 variations of color) for awe-inspiring presentations and displays. No painting required!

- Our in-house spray booth gives us flexibility in different types and grades of paint and finishing capabilities.

Pricing

The cost of terrain 3D models is based on the volume of material (size of the model), the time it takes to create the 3D printable file or CNC file, and other elements of the model. Each model is bid individually and the best way to determine cost is to email us, call us at 385-206-8700, or fill out the form below and let us bid on your project.

Get a Free Price Estimate for Custom Terrain Models

Workflow

Common Questions & Answers

-

What file type is required to 3D print a model?

We work with all architectural CAD programs including AutoCAD, Revit, Chief Architect, ArchiCAD, and Sketchup, just to name a few. If you desing in 3D, we will start with your 3D files. If you have 2D blueprints and elevations, artist’s sketches (or even napkin drawings), we can build a model from these as well.

If you desing in 3D, we will start with your 3D files. If you have 2D blueprints and elevations, artist’s sketches (or even napkin drawings), we can build a model from these as well. -

Do the printers print in color?

Yes. Most of our terrain models are printed in a material that prints in full color (up to 750,000 different colors). Anything printed in UV-cured resin materials are a single color but can be painted. -

What is the material used?

We match the correct material and fabrication process to your requirements in terms of presentation, size, and transportability. We fabricate in our model shop using different types of foam, wood, metal, resins, and acrylics. We can also 3D print in uv-cured resin, plastic, rubber-like acrylic, and nylon. -

What is the largest model you can 3D print?

There is no limit to the size for a terrain model. If we are using 3D printing technologies for building the terrain, our 3D print envelope on our larger printers is 9″ x 15″ x 20″. This is the largest model we can print in a single piece. We can 3D print larger models in multiple pieces. We have built many terrain models that are finished anywhere from 2’x2′ to 10’x14′ (including base). If we are using a foam type structure, it is very easy to build out very large models.

This is the largest model we can print in a single piece. We can 3D print larger models in multiple pieces. We have built many terrain models that are finished anywhere from 2’x2′ to 10’x14′ (including base). If we are using a foam type structure, it is very easy to build out very large models. -

What is the turnaround time for a 3D-printed terrain model?

We usually ask for four to six weeks from the time we take the order to when you will receive the model. We understand that sometimes deadlines are tight and we can accommodate rush orders in as little as one week. -

Can you 3D print homes, buildings, swimming pools, arbors, hardscaping features, etc.?

Yes. We 3D print many of these items in our terrain models.

Do you have a question we didn’t answer? Don’t hesitate to contact us at 1-385-206-8700 or [email protected].

Worldwide Delivery

WhiteClouds has delivered models around the world.

History of Terrain Models

Terrain maps have been used since the simplest of flat maps existed. Raised terrain maps show landscape details that can be understood without the use of language or modern mathematics. Some historians speculate that simple terrain maps existed since the 15th century. Other may argue they existed before spoken language to show through simple soil drawing the location of food sources or the path of herd migrations.

In recorded history, some of the most notable terrain maps include Emperor Maximillian the First’s commissioned terrain models of the eastern Alps during the 1500s. During this time, terrain maps were mostly used for military operations or siege plans. More modern terrain maps emerged from Switzerland in the 19th century using more reliable map contour lines.

Long before 3D printers, countries such as Germany, Italy, France, and the USA used a pantograph to guild a milling cutter to create raised maps and terrain models. This method was refined during World War II. Again, mostly used for military operations. Nowadays, 3D maps are used for more than just military uses. They can be used to depict a variety of terrains including the surface of other planets, ocean floors, prospective mining locations, watershed flows, and new development areas.

This method was refined during World War II. Again, mostly used for military operations. Nowadays, 3D maps are used for more than just military uses. They can be used to depict a variety of terrains including the surface of other planets, ocean floors, prospective mining locations, watershed flows, and new development areas.

3d Printed Terrain - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

3D printing: the possibilities of additive technologies

Additive technologies or 3D printing is the process of creating an object that exactly corresponds to a three-dimensional model by applying material layer by layer. This innovation has become a global trend. The main advantage of the technology is resource saving. Losses of useful substance tend to zero.

This innovation has become a global trend. The main advantage of the technology is resource saving. Losses of useful substance tend to zero.

Application

3D printers have not yet penetrated into every home, but they are already present in all key areas of human life. 3D printing is in demand in the automotive industry, energy, medicine, food industry, construction/design, fashion industry.

In resource- and labour-intensive industries, the development of a product prototype costs a lot of money. With traditional casting or machining technologies, this takes weeks, months. Using the possibilities of volumetric printing, the work is done many times, and sometimes dozens of times, more quickly. At the same time, the quality does not suffer at all and the parameters of the product remain extremely accurate. By the way, the strength of the prototype is more than 20% higher than that of the classic production.

In medicine, the possibilities of 3D printing are used to design dentures, skeletons, and even internal organs. Additive technologies make it possible to create a medical instrument with certain parameters for specific patients with pathologies and anatomical features. This allows you to take a huge step forward in training and preparation for operations.

Additive technologies make it possible to create a medical instrument with certain parameters for specific patients with pathologies and anatomical features. This allows you to take a huge step forward in training and preparation for operations.

In 2011, a kidney was “drawn” on a 3D printer. Scientists have created an exoskeleton to support atrophied muscles. There are even special “pens” that “draw” living cells on injured skin areas.

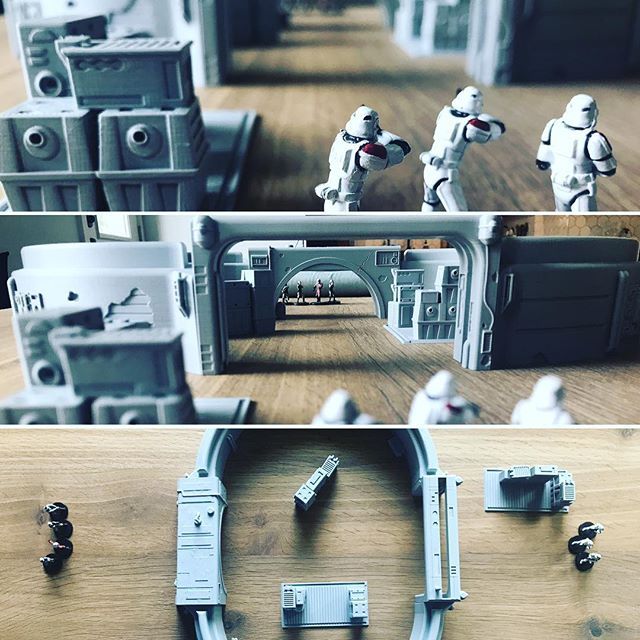

On 3D printers, models of premises are created with a visual study of interiors, buildings and entire residential areas with details of houses, utilities, and infrastructure facilities.

In the field of science and education, the benefits of 3D printing are expressed in the creation of visual aids with which the learning process becomes easier and more efficient.

3D printing is in demand in the fashion world. On the printer, you can create shoes, clothes, perfume bottles. While this process is expensive, therefore, it is not used in mass production. However, piece products made on 3D printers are already presented on the catwalks.

However, piece products made on 3D printers are already presented on the catwalks.

Creative 3D Printed Sandals

The advantage of introducing AF technologies into the light industry is the ability to create products for a specific physique/foot shape. This is especially true for athletes, people with deviations of the anatomical structure. For example, designer Ross Berber introduced the world to shoes printed on a 3D machine. His collection includes 5 pairs.

3D printing allows for a breakthrough in innovation. Before a product can be mass-produced, a prototype must be tested and repeatedly tested. This is done on 3D models. You can create them in minutes.

Three-dimensional technologies are used in jewelry, when creating maps of the area, making souvenirs, customizing finished products (applying a pattern, logo).

How does a 3D printer work?

A classic 3D printer is a 3D printing device that works on the principle of FDM (Fusion Deposition Modeling). On three-dimensional equipment, you can create an object of almost any shape, with curves, a relief surface. The product "increases" simultaneously in the horizontal and vertical direction.

On three-dimensional equipment, you can create an object of almost any shape, with curves, a relief surface. The product "increases" simultaneously in the horizontal and vertical direction.

Printers work with various materials: plastic, metal, and so on. With their help, you can create parts that can withstand a significant load. In order for the printer to print three-dimensional figures, it is equipped with:

- extruder - for heating and forcing plastic through the printheads;

- motors (usually linear) - set in motion the mechanisms;

- work surfaces - the platforms on which everything happens;

- sensors for fixing moving parts;

- Cartesian robots - devices moving along three axes.

Printers work differently, but the classic sequence of actions can be described by a single algorithm. First, a 3D image is created. This requires specialized software. After that, the model is “cut” into horizontal layers. A special program (G-code generator) is also provided for this. The computer converts the codes into information that the 3D printer can recognize. The next step is to recreate the model.

A special program (G-code generator) is also provided for this. The computer converts the codes into information that the 3D printer can recognize. The next step is to recreate the model.

Smartprint HB-8 3D printer

3D printing technologies

There is monochrome and color 3D printing - more than a dozen technologies (plus their modifications). Among the most common:

- SLA - stereolithographic laser printing. The technology provides the creation of models with high detail. Its essence is the layer-by-layer application of a photopolymer material. It hardens under the influence of a laser. Then the working platform is lowered. A translucent composition is used as a photopolymer: it is easy to process, paint, glue.

- SLS - the technology is suitable for working with plastics and metals. The reagent is sintered under the laser beam. The products are very durable.

- HPM - printers work with thermoplastic, auxiliary soluble materials.

The latter are used to create complex multilevel models with cavities and functional holes. Finished products may have a different shape. They are durable, resistant to stress, mechanical and chemical stress.

The latter are used to create complex multilevel models with cavities and functional holes. Finished products may have a different shape. They are durable, resistant to stress, mechanical and chemical stress. - DLP is a relatively new 3D modeling technology. The printers that support it print with photopolymer resin. The material hardens when exposed to light.

The most progressive technologies are EBM and SLM. The first involves the impact on the material with an electron beam, and not with a laser, the second works with metals.

Equipment for 3D printing is produced by companies from the USA, Europe, and Asia. Among the famous ones are Photocentric, 3D systems, Makerbot, Azuma Engineering Machinery Inc. and others.

3D model of the ship strikes with realism

Advantages of additive technologies

The advantages of 3D printing include:

- Resource efficiency.

Products are "grown" from scratch, that is, the production is completely waste-free. For comparison: when creating a blank using traditional methods, material losses sometimes reach up to 85%.

Products are "grown" from scratch, that is, the production is completely waste-free. For comparison: when creating a blank using traditional methods, material losses sometimes reach up to 85%. - Efficiency. The time from the development of the layout to the receipt of the product can be reduced several times, or even tens of times, without compromising quality.

- Mobility. The equipment is compact, layouts can be transferred online.

- Precision. Layered synthesis ensures absolute compliance with specified technical parameters.

- Strength. The indicator is 25–30% higher than that of products obtained by traditional methods (forging, casting).

- Weight. This is an important advantage for industry, aircraft and mechanical engineering. The mass of individual products is reduced by 40–50% without loss of strength.

Souvenirs and toys are successfully printed in Russia using 3D printing technology

3D printing is also used in advertising printing. For example, for the production of souvenirs. Advertising agencies involved in cross-marketing willingly order a range of services, which includes both traditional production of business cards or flyers, as well as innovative solutions.

For example, for the production of souvenirs. Advertising agencies involved in cross-marketing willingly order a range of services, which includes both traditional production of business cards or flyers, as well as innovative solutions.

An overview of 5 modern 3D printers that appeared on the market in 2017, see the video:

Results

- 3D printing is in demand in almost all areas (industry, medicine, education, energy).

- In some industries, additive technologies are already actively used, in others they are just being introduced.

- Technology contributes to business development, gives competitive advantages - a layout is made in a matter of minutes, resource consumption is optimized.

- Manufacturers are constantly improving equipment for three-dimensional printing, developing new technologies.

3D printer for architect and designer, pros and cons, examples of use

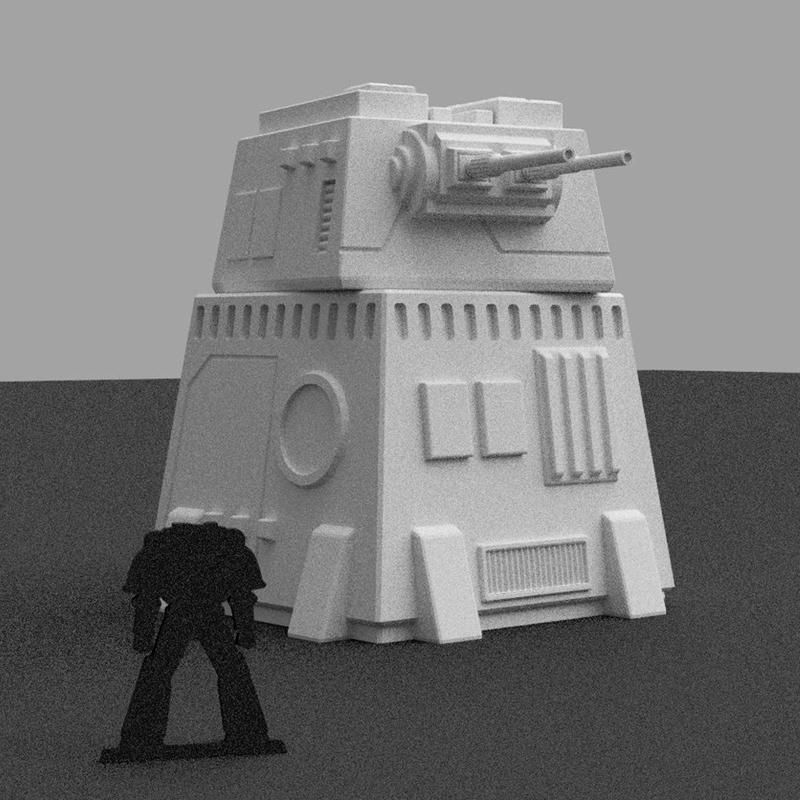

3D technologies are becoming good helpers in various fields. In architecture and design, 3D printers are successfully used mainly to create architectural models.

In architecture and design, 3D printers are successfully used mainly to create architectural models.

Illuminated layout

Architectural layouts can be divided into several types:

Layouts can be used for a variety of purposes:

-

Visualization for buyers or to coordinate the project with the client. Many customers find it much more difficult to perceive a digital layout of a building or interior. 3D printing allows you to quickly and inexpensively produce, for example, a miniature apartment model with a furniture model. The client himself will be able to visually see a variety of interior options and choose the one he likes the most.

-

Project presentation. A presentation with a beautiful layout looks much more colorful and effective, for example, a building or an entire microdistrict. But making an architectural model in the classical way is a long and painstaking, often manual, work.

What if you need multiple layouts? A 3D printer can significantly speed up and reduce the cost of production of a layout.

What if you need multiple layouts? A 3D printer can significantly speed up and reduce the cost of production of a layout.

The cost of the layout depends on several factors - this is the complexity of manufacturing and artistic value. The use of a 3D printer allows you to speed up and significantly simplify the production of complex and simple layouts. For example, making a layout of modern buildings with non-linear geometry becomes a real headache for layout designers. 3D printing allows you to quickly and accurately reproduce an exact copy of any building, regardless of its geometry.

Building layout with non-linear geometry

FDM printers for architecture and design

FDM is a technology for layer-by-layer deposition of plastic to obtain a physical model. As a consumable material, a plastic thread is used - a filament.

FDM printers are very popular due to their large working area, printing speed and inexpensive consumables.

The choice of printer model depends on what needs to be produced. Some devices are poorly designed to work with some engineering plastics.

Pros and cons

pros

Models of 3D printers appeared with an “infinite” printable area along one of the axes. These printers use a conveyor belt instead of a printtable. Such printers are suitable for mass production.

For the manufacture of simple layouts, you can give preference to models with a single extruder. But if a 3D printer is required to solve a variety of tasks, then models with two extruders and a closed chamber should be preferred. Such devices are universal and can print on almost any material.

Minuses

Application and printing examples

Model of the city of Astana. Production took 1 month.

Building kit

Prefabricated house model

Layout San Francisco

Furniture and interior elements made on a 3D printer

Layout of the floor of the building for arranging furniture

Printer Rating

CreatBot D600 Pro

CreatBot D600 Pro

Features:

Print technology: FDM/FFF

Workspace size: 600x600x600

Number of extruders: 2

Max. extruder temperature: 420 degrees

extruder temperature: 420 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, PEEK, Decorative plastics, others

CreatBot D600 Pro is a professional device that has many options that will be useful not only for a beginner, but also for an experienced user. Two extruders with a high heating temperature and a closed chamber allow you to print on all available types of plastics. And automatic table calibration using the BL-Touch sensor eliminates the need to level the table plane.

Raise3D E2

Raise3D E2

Features:

Print technology: FDM/FFF

Working area size: 330 * 240 * 240 mm - when printing with the 1st extruder

295x240x240 mm - when printing with 2 extruders

Number of extruders: 2

Max. extruder temperature: 300 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, Decorative plastics, others

Raise3D E2 is a small device with unusual kinematics. Raise3D E2 has two independent extruders that allow the printer to work in several modes:

Raise3D E2 has two independent extruders that allow the printer to work in several modes:

In addition, Raise3D E2 is equipped with a convenient touch screen, automatic table calibration, an assistant for calibrating the height of extruders relative to each other and other nice features that do not affect the final print, but make working with the printer easier and more comfortable.

Raise3D Pro2 and Pro2 Plus

Raise3D Pro2 left and Pro2 Plus right

Features:

Print technology: FDM/FFF

Stage size: Raise3D Pro2

305x305x300 mm - when printing with the 1st extruder;

280x305x300 mm - when printing with 2 extruders

Raise3D Pro2 Plus 305x305x605 mm - when printing with the 1st extruder;

280x305x605 mm - when printing with 2 extruders

Number of extruders: 2

Max. extruder temperature: 300 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, Decorative plastics, others

As you can see from the specifications, the only difference between Raise3D Pro2 and Pro2 Plus is the size of the workspace in height. Pro2 Plus has twice as much.

Pro2 Plus has twice as much.

The Raise3D Pro2 series has proven itself in various fields. These are reliable workhorses with a set of all the necessary options for high-quality printing, and the presence of two extruders allows you to make models of any complexity.

PICASO 3D Designer XL Pro

PICASO 3D Designer XL Pro

Characteristics:

Print technology: FDM/FFF

Working area size: 360 x 360 x 610 mm

Number of extruders: 2

Max. extruder temperature: 410 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, PEEK, PC, Decorative plastics, others

PICASO 3D Designer XL Pro is a Russian-made professional printer with an enlarged working area. Designer XL Pro is equipped with automatic table calibration, plastic feed control sensor and other nice features.

Photopolymer printing in architecture and design

The principle of operation of a photopolymer printer is based on the illumination of a special resin using directional UV radiation. Photopolymer printers can work on one of three technologies:

Photopolymer printers can work on one of three technologies:

Photopolymer printers allow you to get a product with an ideal surface. It is not for nothing that LCD, DLP and SLA devices are actively used in the jewelry and dental industries, where accuracy and the ideal surface of the finished model are important.

Currently, LCD technology has gained particular popularity due to its availability and inexpensive printers.

Pluses and minuses

pros

Minuses

-

After printing, it is necessary to rinse and dry the product in a UV chamber. After printing, it is necessary to wash off excess polymer from the surface of the finished print. For this, isopropyl alcohol is usually used, although resins have now appeared that can be washed with plain water. In order for the photopolymer to gain the declared strength, it must be additionally illuminated under an ultraviolet lamp or in a special box.

Application and printing examples

Miniature model of building

Model of the Cathedral of the Intercession of the Most Holy Theotokos on the Moat (St. Basil's Cathedral)

Basil's Cathedral)

City map

Miniature "extras" for the model

Printer rating

Prismlab RP400

Prismlab RP400

Features:

Print Technology: DLP/LCD/SLA

Material: Photopolymer resin

Construction area size: 384x216x384 mm

XY positioning accuracy: 100/67/50 microns

Z-axis positioning accuracy: 100/50 microns

Prismlab RP400 is a professional photopolymer machine with a large printable area. Humidity and temperature sensors in the build chamber allow Prismlab to adjust print settings for the best print quality, while open source software allows the use of third-party photopolymer resins.

Peopoly Phenom XXL

Peopoly Phenom XXL

Characteristics:

Print Technology: DLP/LCD/SLA

LCD display resolution: 3840x2160 (23. 8", 16:9, UHD 4K)

8", 16:9, UHD 4K)

Material: Photopolymer resin

Construction area size: 527x296x550 mm

XY positioning accuracy: 137 µm

The Peopoly Phenom XXL is a large format photopolymer printer with a huge printable area. The improved monochrome LCD matrix allows you to quickly and accurately produce large models or small batches of small products.

Phrozen Sonic MEGA 8K

Phrozen Sonic MEGA 8K

Features:

Print Technology: DLP/LCD/SLA

LCD resolution: 15" 8K Mono LCD

Material: Photopolymer resin

Build area size: 330 x 185 x 400 mm

XY Positioning Accuracy: 43 µm

Sonic Mega 8K is the first LCD printer with a matrix resolution of 8k, but the accuracy of printing depends on the resolution of the matrix. Sonic Mega 8K allows you to produce large models with amazing clarity, without “blurring” or smoothing small elements.

Construction printers

Construction printers are just groping for their niche for application, and the technology itself is still far from ideal. But the projects already implemented allow us to imagine a possible future where it will be possible to print entire houses.

But the projects already implemented allow us to imagine a possible future where it will be possible to print entire houses.

Application and printing examples

Bridge in Shanghai.

In Shanghai, using a construction 3D printer, a whole bridge was printed and installed over a pond in the Baoshan area. The new bridge is 26.3 meters long and 3.6 meters wide.

Shanghai Bridge

Before making a concrete, full-size model, a reduced copy of the bridge 1: 4 was printed for testing the strength and safety of the structure. 3D printing took 450 hours. A load and deformation monitoring system was installed in the finished bridge. This allows you to explore the properties of printed concrete elements in real time.

Up close, you can see the concrete layers that appeared due to the peculiarities of printing

Bridge in Amsterdam

In Amsterdam, a printed steel bridge was installed. It connects the embankments of the Oudesijds Achterburgwal canal. The length of the finished bridge is 12.2 m, the width is 6.3 m, and the weight is 6000 kg.

It connects the embankments of the Oudesijds Achterburgwal canal. The length of the finished bridge is 12.2 m, the width is 6.3 m, and the weight is 6000 kg.

Bridge in Amsterdam

Sensors were installed in the bridge to track the deformation of the structure and count the number of people passing through it. For the manufacture of a modern "crossing" 4 robots for 6 months layer-by-layer made a construction of stainless wire.

Bridge manufacturing process

Printed house in Germany

In Germany, builders built an entire house using a 3D construction printer. The house is designed for 5 families, the total area is 380 sq.m.

Almost finished house

In the model of the house, cavities are initially laid for all communications, which the builders will later install. Thus, while the printer is building walls, the workers are solving other tasks.