3D printing of humans

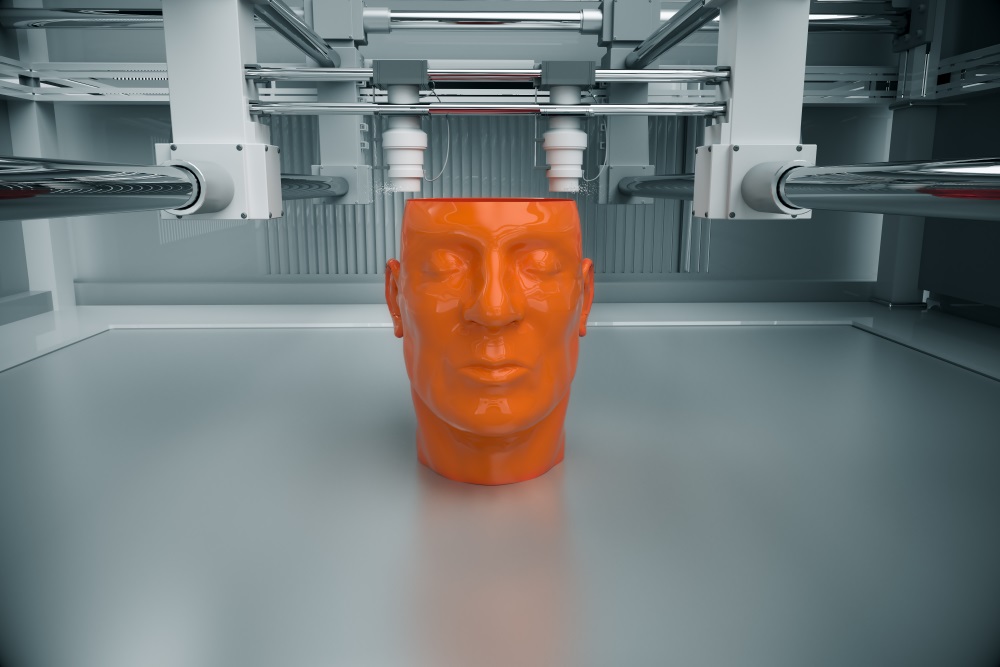

On the Road to 3-D Printed Organs

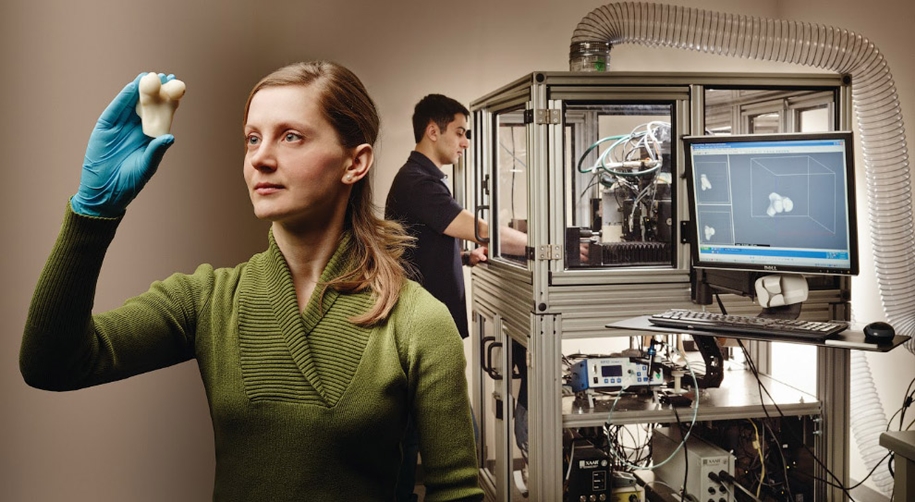

For years, scientists have predicted that 3-D printing—which has been used it to make toys, homes, scientific tools and even a plastic bunny that contained a DNA code for its own replication—could one day be harnessed to print live, human body parts to mitigate a shortage of donor organs. So far, researchers also used 3-D printing in medicine and dentistry to create dental implants, prosthetics, and models for surgeons to practice on before they make cuts on a patient. But many researchers have moved beyond printing with plastics and metals—printing with cells that then form living human tissues.

No one has printed fully functional, transplantable human organs just yet, but scientists are getting closer, making pieces of tissue that can be used to test drugs and designing methods to overcome the challenges of recreating the body’s complex biology.

First steps

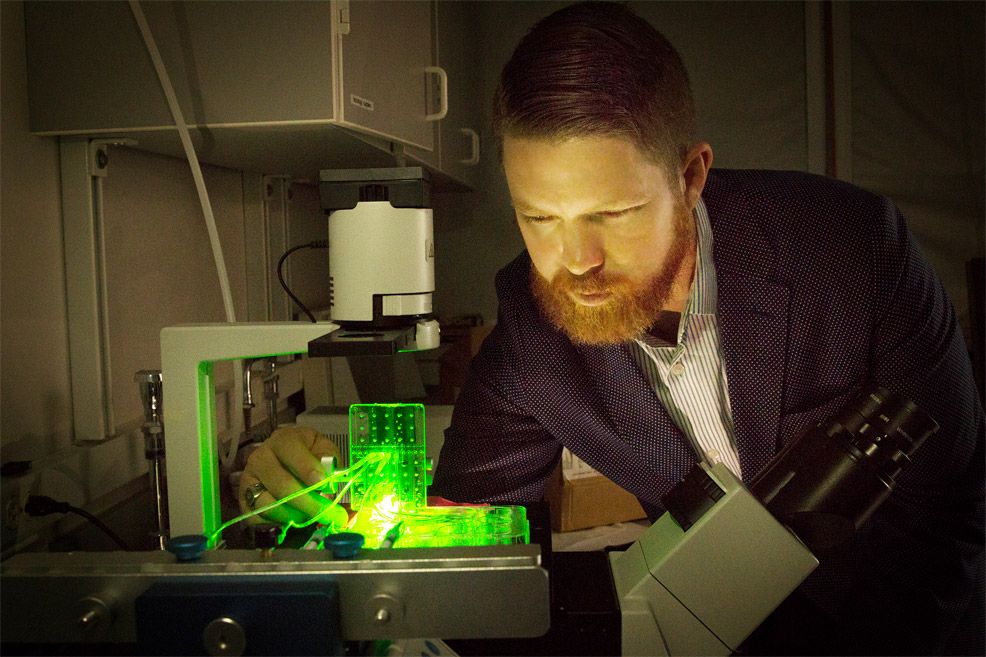

A confocal microscopy image showing 3-D–printed stem cells differentiating into bone cells

LEWIS LAB, WYSS INSTITUTE AT HARVARD UNIVERSITY

The first 3-D printer was developed in the late 1980s. It could print small objects designed using computer-aided design (CAD) software. A design would be virtually sliced into layers only three-thousandths of a millimeter thick. Then, the printer would piece that design into the complete product.

There were two main strategies a printer might use to lay down the pattern: it could extrude a paste through a very fine tip, printing the design starting with the bottom layer and working upward with each layer being supported by the previous layers. Alternatively, it could start with a container filled with resin and use a pointed laser to solidify portions of that resin to create a solid object from the top down, which would be lifted and removed from the surrounding resin.

When it comes to printing cells and biomaterials to make replicas of body parts and organs, these same two strategies apply, but the ability to work with biological materials in this way has required input from cell biologists, engineers, developmental biologists, materials scientists, and others.

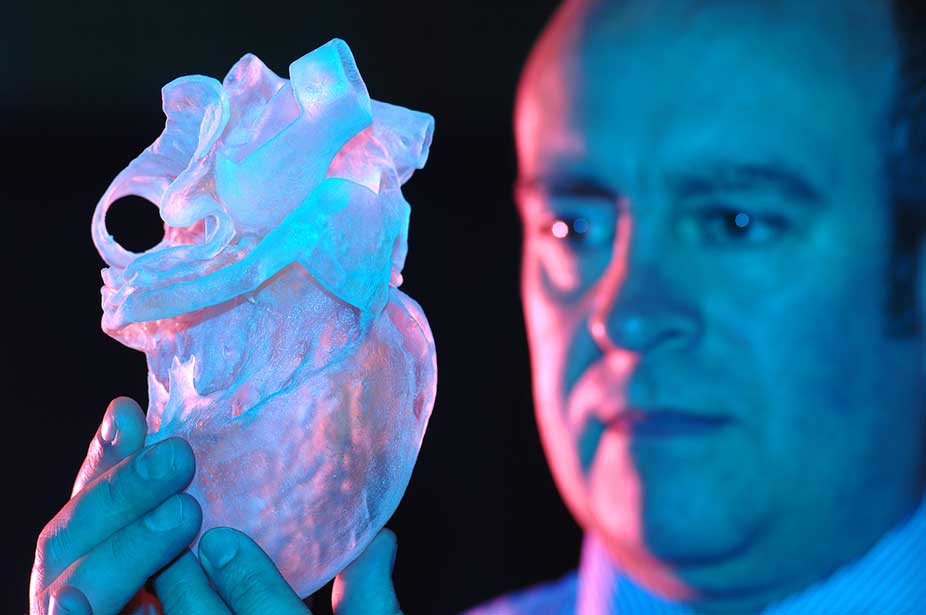

So far, scientists have printed mini organoids and microfluidics models of tissues, also known as organs on chips. Both have yielded practical and theoretical insights into the function of the human body. Some of these models are used by pharmaceutical companies to test drugs before moving on to animal studies and eventually clinical trials. One group, for example, printed cardiac cells on a chip and connected it to a bioreactor before using it to test the cardiac toxicity of a well-known cancer drug, doxorubicin. The team showed that the cells beating rate decreased dramatically after exposure to the drug.

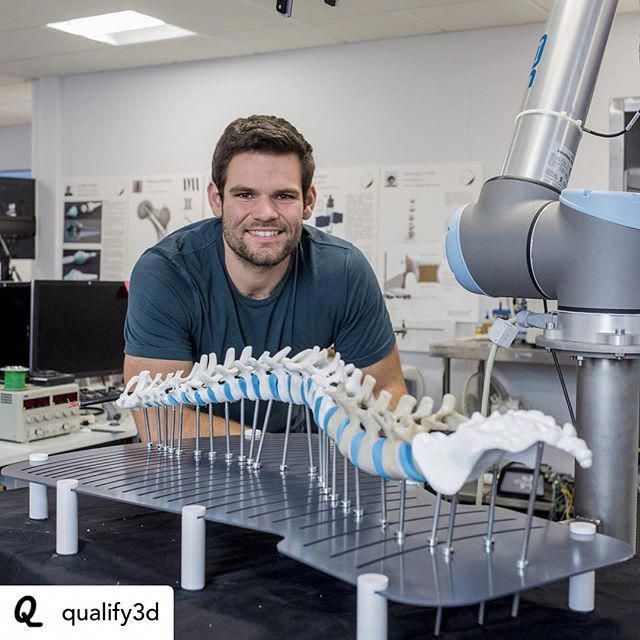

However, scientists have yet to construct organs that truly replicate the myriad structural characteristics and functions of human tissues. “There are a number of companies who are attempting to do things like 3-D print ears,” and researchers have already reported transplanting 3-D printed ears onto children who had birth defects that left their ears underdeveloped, notes Robby Bowles, a bioengineer at the University of Utah. The ear transplants are, he says, “kind of the first proof of concept of 3-D printing for medicine.”

The ear transplants are, he says, “kind of the first proof of concept of 3-D printing for medicine.”

Researchers have been using 3D-printing techniques in hopes of developing tissues that can be transplanted into humans. Some printed tissues, such as skin and bone, are already being tested in humans, while many others are early in development.

See full caption

THE SCIENTIST STAFF

Bowles adds that researchers are still “a ways away” from printing more-complex tissues and organs that can be transplanted into living organisms. But, for many scientists, that’s precisely the goal. As of February 2020, more than 112,000 people in the US are waiting for an organ transplant, according to the United Network for Organ Sharing. About 20 of them die each day.

For many years, biological engineers have tried to build 3-D scaffolds that they could seed with stem cells that would eventually differentiate and grow into the shapes of organs, but “to a large extent those techniques don’t allow you to introduce kind of the organization of gradients and the patterning that is in the tissue,” says Bowles. “There is no control over where the cells go in that tissue.” By contrast, 3-D printing enables researchers with to very precisely direct the placement of cells—a feat that could lead to better control over organ development.

“There is no control over where the cells go in that tissue.” By contrast, 3-D printing enables researchers with to very precisely direct the placement of cells—a feat that could lead to better control over organ development.

Differentiation

Ideally, 3-D printed organs would be built from cells that a patient’s immune system could recognize as its own, to avoid immune rejection and the need for patients to take immunosuppressive drugs. Such organs could potentially be built from patient-specific induced pluripotent stem cells, but one challenge is getting the cells to differentiate into the subtype of mature cell that’s needed to build a particular organ. “The difficulty is kind of coming together and producing complex patternings of cells and biomaterials together to produce different functions of the different tissues and organs,” says Bowles.

To imitate the patterns seen in vivo, scientists print cells into hydrogels or other environments with molecular signals and gradients designed to coax the cells into organizing themselves into lifelike organs. Scientists can use 3-D printing to build these hydrogels as well. With other techniques, “the patterns achieved have typically been two-dimensional,” Eben Alsberg, a bioengineer at the University of Illinois, tells The Scientist in an email. “Three-dimensional bioprinting permits much more control over signal presentation in 3D.”

Scientists can use 3-D printing to build these hydrogels as well. With other techniques, “the patterns achieved have typically been two-dimensional,” Eben Alsberg, a bioengineer at the University of Illinois, tells The Scientist in an email. “Three-dimensional bioprinting permits much more control over signal presentation in 3D.”

So far, researchers have created patches of tissue that mimic portions of certain organs but haven’t managed to replicate the complexity or cell density of a full organ. But it’s possible that in some patients, even a patch would be an effective treatment. At the end of 2016, a company called Organovo announced the start of a program to develop 3-D printed liver tissue for human transplants after a study showed that transplanted patches of 3-D printed liver cells successfully engrafted in a mouse model of a genetic liver disease and boosted several biomarkers that suggested an improvement in liver function.

Vasculature

Only in the past few years have researchers started to make headway with one of the biggest challenges in printing 3-D organs: creating vasculature. After the patches were engrafted into the mouse’s liver in the Organovo study, blood was delivered to it by the surrounding liver tissue, but an entire organ would need to come prepared for blood flow.

After the patches were engrafted into the mouse’s liver in the Organovo study, blood was delivered to it by the surrounding liver tissue, but an entire organ would need to come prepared for blood flow.

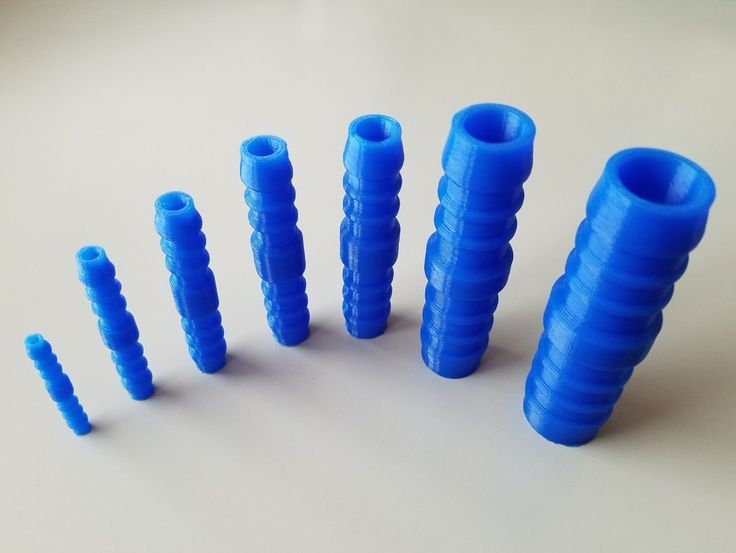

“For any cells to stay alive, [the organ] needs that blood supply, so it can’t just be this huge chunk of tissue,” says Courtney Gegg, a senior director of tissue engineering at Prellis Biologics, which makes and sells scaffolds to support 3-D printed tissue. “That’s been recognized as one of the key issues.”

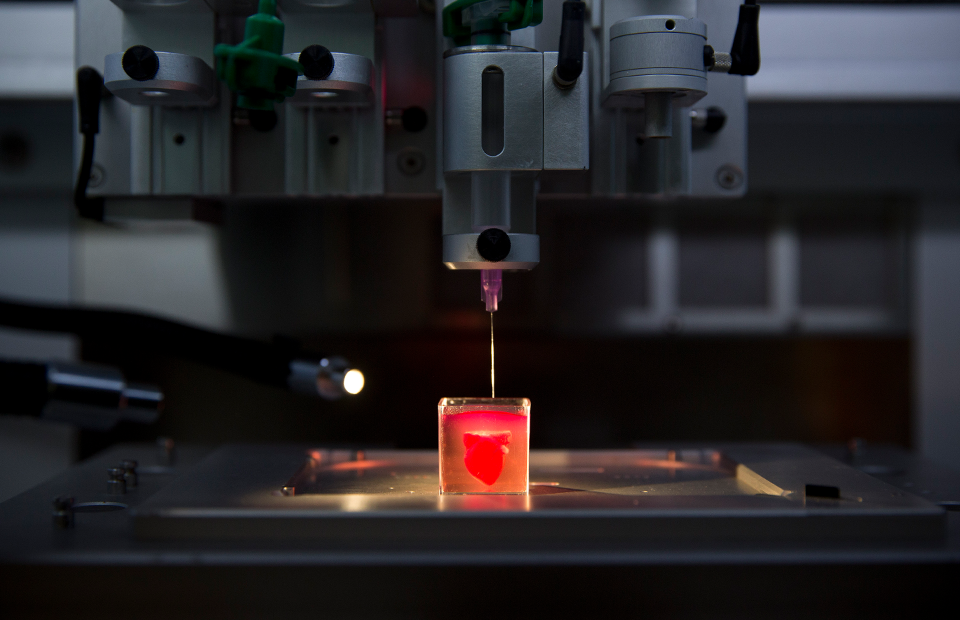

Mark Skylar-Scott, a bioengineer at the Wyss Institute, says that the problem has “held back tissue engineering for decades.” But in 2018, Sébastian Uzel, Skylar-Scott, and a team at the Wyss Institute managed to 3-D print a tiny, beating heart ventricle complete with blood vessels. A few days after printing the tissue, Uzel says he came into the lab to find a piece of twitching tissue, which was both “very terrifying and exciting.”

For any cells to stay alive, [the organ] needs that blood supply, so it can’t just be this huge chunk of tissue.

—Courtney Gegg, Prellis Biologics

Instead of printing the veins in layers, the team used embedded printing—a technique in which, instead of building from the bottom of a slide upwards, material is extruded directly into a bath, or matrix. This strategy, which allows the researchers to print “free form in 3-D,” says Skylar-Scott, rather having to print each layer one on top of the other to support the structure, is a more efficient way to print a vascular tree. The matrix in this case was the cellular material that made up the heart ventricle. A gelatin-like ink pushed these cells gently out of the way to create a network of channels. Once printing was finished, the combination was warmed up. This heat caused the cellular matrix to solidify, but the gelatin to liquify so it could then be rinsed out, leaving space for blood to flow through.

But that doesn’t mean the problem is completely solved. The Wyss Institute team’s ventricle had blood vessels, but not nearly as many as a full-sized heart. Gegg points out that to truly imitate human biology, “an individual cell will have to be within 200 microns of your nearest blood supply. . . . Everything has to be very, very close.” That’s far more intricate than what researchers have printed so far.

Gegg points out that to truly imitate human biology, “an individual cell will have to be within 200 microns of your nearest blood supply. . . . Everything has to be very, very close.” That’s far more intricate than what researchers have printed so far.

Due to hurdles with adding vasculature and many other challenges that still face 3-D–printed tissues, laboratory-built organs won’t be available for transplant anytime soon. In the meantime, 3-D printing portions of tissue is helping accelerate both basic and clinical research about the human body.

Emma Yasinski is a Florida-based freelance reporter. Follow her on Twitter @EmmaYas24.

Why astronauts are printing organs in space

Loading

Health

Why astronauts are printing organs in space

(Image credit: Nasa)

By Josh Sims2nd June 2021

With a global shortage of organs suitable for transplant into critically ill patients, some researchers are looking at 3D printing of living tissue as a solution – but to do it they might need to go into orbit.

A

Andrew Morgan has seen some of the worst things that can happen to the human body. As a battlefield doctor with the US Army, he's treated young soldiers whose bodies had been torn and broken in explosions. "I've seen the loss of limbs and some devastating injuries as the result of blasts," he says. Witnessing the slow healing and recovery process first-hand got Morgan thinking – what if new tissue or even entire organs could be simply printed off to replace injured body parts?

"The ability to transplant tissues made from the injured person's own cells would be hugely beneficial," he says.

That's why Morgan conducted a series of unusual experiments over several months last year – in outer space. You see, Morgan is also a Nasa astronaut. In April 2020 he returned from a 272-day stay on the International Space Station (ISS). While he orbited 248 miles (400km) above the Earth's surface, Morgan created living tissue, cell by cell, using a 3D printer and something called bio-ink.

"It's not unlike changing a printer cartridge at home," says Morgan of the equipment he used. "You put in the ink cartridge, allow the culture to develop and then remove the tissue cassette for analysis."

So far, so simple. But there is a reason why Morgan and his fellow astronaut Christina Koch were doing these experiments while in orbit.

"When you're 3D-printing a tissue culture on the ground, there's a tendency for them to collapse in the presence of gravity," he says. "The tissues require some sort of [temporary, organic] scaffold to hold everything in place, especially with cavities like the chambers of a heart. But you don't have those effects in a micro-gravity environment, which is why these experiments have been so valuable."

Experiments conducted on the International Space Station by Andrew Morgan showed organs could be printed a low gravity environment (Credit: Nasa)

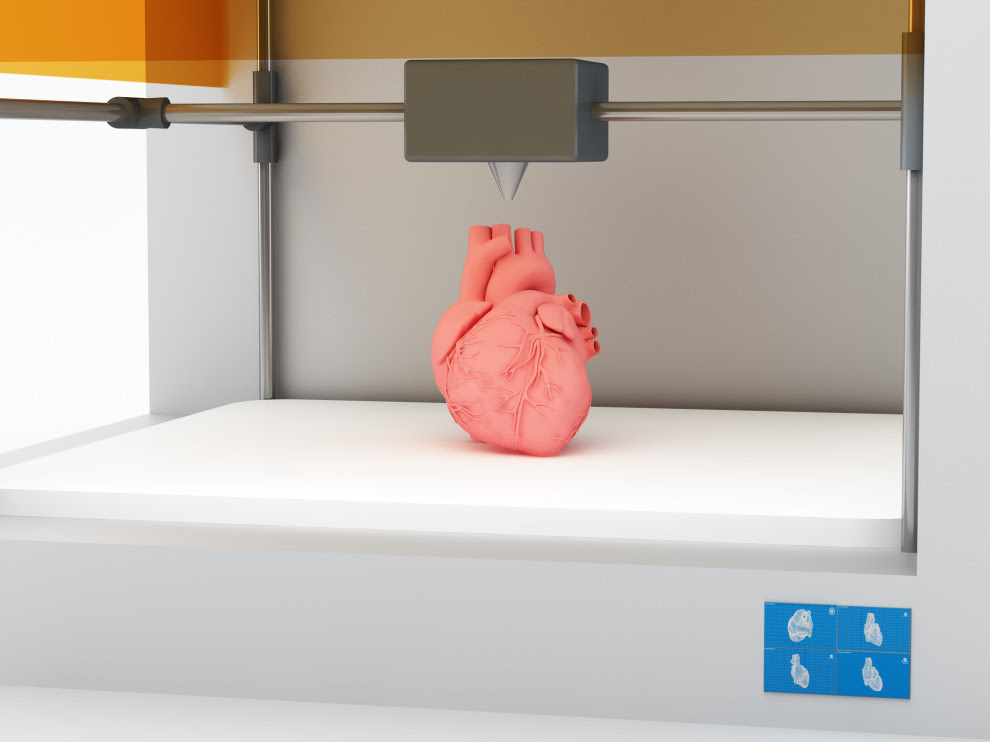

The micro-gravity environment of the ISS was ideal for testing the Bio Fabrication Facility, which was launched into orbit in 2019 and is due for an upgrade in 2021. Developed by US companies Techshot and NScrypt, it is designed to print human cells into organ-shaped tissues. Initially Morgan was using it to test prints of cardiac-like tissue of increasing thicknesses. Ultimately, however, the team behind the technology hopes to refine the equipment so they can print entire human organs in space, which can be used in transplants.

Developed by US companies Techshot and NScrypt, it is designed to print human cells into organ-shaped tissues. Initially Morgan was using it to test prints of cardiac-like tissue of increasing thicknesses. Ultimately, however, the team behind the technology hopes to refine the equipment so they can print entire human organs in space, which can be used in transplants.

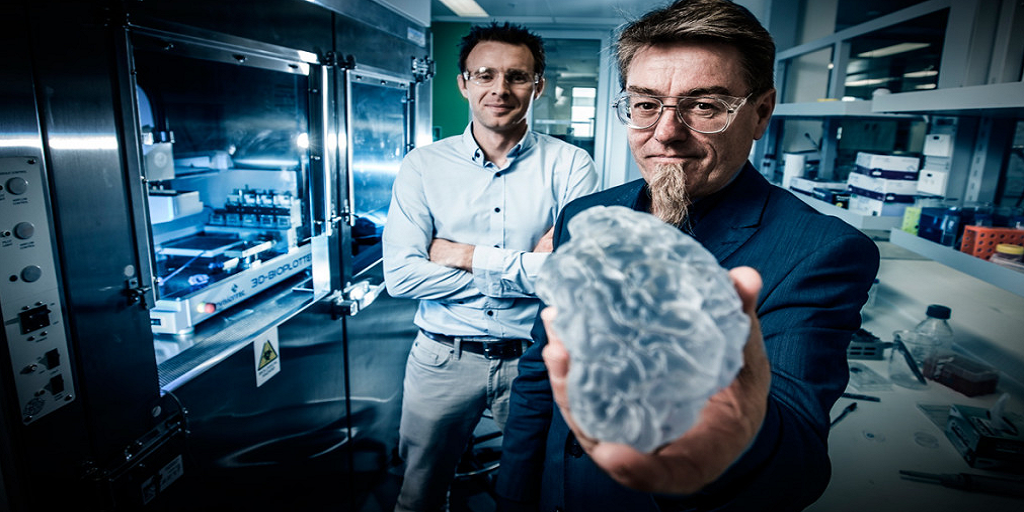

Printing human organs is not quite as science fiction as it sounds. A number of bio-technology companies are working on different approaches, which aim to use a patient's own cells make new tissue. In most cases they re-programme the cells by following a Nobel Prize-winning process developed a decade ago to turn them into stem cells, which are then theoretically capable of developing into any part of the human anatomy. Given the right nutrients and encouragement, these can then be induced into the cell type of choice. By suspending stem cells in a hydrogel that can be built into a scaffold to stop the growing structure collapsing in on itself, the desired cell type can then be printed layer by layer into living, functioning tissue.

"We've already produced tissue that has successfully been transplanted back onto animals – skin transplants, for example," explains Itedale Redwan, the scientific officer for Cellink, the first company to commercialise bio-ink. "Recently we've worked on laser-assisted printing to allow printing at the very small level of capillaries, or blood and waste transplant vessels. Being able to print at this level will be essential, but the big step will be putting such tissue into humans."

Redwan estimates it could be 10-15 years before fully functioning tissues and organs printed in this way will be transplanted into humans. Scientists have already shown it is possible to print basic tissues and even mini-organs. In 2018, a team at the University of Newcastle printed the first human corneas, while a group at Tel Aviv University produced a miniature heart by printing with human tissue from a cardiac patient and believe it could be used to engineer cardiac patches to repair heart defects. Scientists at Michigan State University have since taken that a step further by printing a mini human heart using a stem cell framework that imitates the environment in which a foetus develops, allowing for the creation of all the cell types and intricate structures necessary for a functioning heart.

Scientists at Michigan State University have since taken that a step further by printing a mini human heart using a stem cell framework that imitates the environment in which a foetus develops, allowing for the creation of all the cell types and intricate structures necessary for a functioning heart.

But the heart is a relatively simple pump consisting of a series of chambers surrounded by muscle tissue. Some researchers have already made headway towards building more complex organ and tissue structures. One group at Wake Forest Institute for Regenerative Medicine in Winston-Salem, North Carolina, have integrated nerve cells into printed muscles, a key step towards restoring muscle control and function in future transplants.

Building full scale, complex organs like the liver and kidney, however, is a far bigger challenge. These organs are mixtures of many cell types, infused with networks of blood vessels and nerves.

You might also like:

- Can we fight the ageing process?

- The woman with a 100-year-old liver

- What happens if you wake up during surgery

Jennifer Lewis, a professor of biologically inspired engineering at Harvard University who has experimented with tissue printing, takes a cautious view on the hurdles still to overcome. Recreating the full function of an organ – the synchronicity of the heart's action, for example, or the filtration function of a kidney – is no easy thing. An important step will be replicating the process of organogenesis – where the multi-cellular architecture of human tissue and organs form in the embryo to develop different functions, she says.

Recreating the full function of an organ – the synchronicity of the heart's action, for example, or the filtration function of a kidney – is no easy thing. An important step will be replicating the process of organogenesis – where the multi-cellular architecture of human tissue and organs form in the embryo to develop different functions, she says.

"We're finding, for example, that often the function of tissue is not as mature when created in the lab as opposed to in vivo," says Lewis. "They might do this kind of thing on Westworld easily enough, but that's the dream. Yet you can see the pathways to how that might become a reality within a couple of decades."

Stem cells can be used to print tissues layer by layer, but producing complex fully functioning organs is still a challenge (Credit: BSIP/Getty Images)

One company, BioLife4D, which develops and manufactures bio-printing technology, is focusing on printing biological components for use in repairing the human heart as stepping stones towards producing an entire printed transplantable heart. It believes there's a multi-million dollar market for the various components, such as heart valves, that it will need to learn how to print along the way.

It believes there's a multi-million dollar market for the various components, such as heart valves, that it will need to learn how to print along the way.

"But if you're able to print a liver, you have nothing until you print the next entire liver," says the company's chief executive Steve Morris. "From a scientific standpoint you could also bio-engineer a heart with a specific defect to allow for the testing of treatment."

Redwan stresses that, in the short term, printed organs will make it possible to more effectively model diseases in the laboratory and aid drug development. That, in turn, should help to decrease levels of animal testing. In the medium term, when full-sized organs are printable, the challenge may then become meeting demand. Currently there are huge shortages of donor organs to meet demand for those who need a transplant.

"There are, for example, around one million people around the world waiting for a kidney transplant," says Lewis. The World Health Organization estimates around 130,000 organ transplants take place each year, but this meets just 10% of the transplant need. In the US alone there are 107,000 patients on transplant waiting lists. "Just to be able to offer those people organs would be of huge impact in and of itself," says Lewis.

In the US alone there are 107,000 patients on transplant waiting lists. "Just to be able to offer those people organs would be of huge impact in and of itself," says Lewis.

Those lucky enough to receive a donor transplant also have to spend the rest of their lives on immunosuppressant drugs to stop their bodies rejecting these "foreign" organs. But if a new organ can be printed using their own cells, it should greatly reduce the risk of rejection.

Faced with such need and potential benefit, it makes the great lengths needed to grow organs in space seem more worthwhile. But printing in space doesn't come cheap. The Bio Fabrication Facility on the ISS cost $7m (£5m), and add to that the cost of firing the cells and other raw materials into orbit before bringing the organs back safely. Large production runs are also going to be difficult. It has led some to investigate whether the low-gravity environment found in orbit can be replicated back here on Earth to grow complex, delicate organs. Russian medical company 3D Bioprinting Solutions, for example, has produced a system that uses a magnetic field to levitate tissue as it forms the desired structure.

Russian medical company 3D Bioprinting Solutions, for example, has produced a system that uses a magnetic field to levitate tissue as it forms the desired structure.

Scientists also have to work out how to get a printed organ's vasculature and nerve endings to work. But in the meantime it's expected that the Bio Fabrication Facility might be able to take on work for industrial and institutional customers looking to explore its potential for printing tissue further. Some such as Techshot's chief scientist Gene Boland imagine a time – in the 2030s or 2040s perhaps – when bio-print facilities are established in low Earth orbit, taking advantage of the micro-gravity environment to print ever more complex human tissues to, perhaps, ever more advanced specifications.

For others trying to develop this revolution in transplant technology, the quest is deeply personal.

"My daughter was born with only one lung," says Ken Church, chief executive of NScrypt, the company that helped to develop the bio-printer used by Andrew Morgan on the ISS. "She's 27 and fine now but still only has one lung. But that got me looking into subject of tissue engineering – back when bio-printing wasn't a thing – and I became fascinated by the idea of it."

"She's 27 and fine now but still only has one lung. But that got me looking into subject of tissue engineering – back when bio-printing wasn't a thing – and I became fascinated by the idea of it."

NScrypt is now developing the next generation bio-printer, a bio-reactor, which, rather than benefitting from a low-gravity environment to prevent necrosis at the centre of any printed tissue, does so with other approaches, such as spinning it, shaking it, or infusing it with oxygen as it grows.

"If I can grow a lung for my daughter in her lifetime, that excites me," says Church.

But while it is easy to get caught up in the excitement of printing organs on demand, there are also some other, bigger implications that require thought. The prospect of being able to print human organs is, after all, likely to have a profound impact on society, not least in the boost to average longevity that it entails. If cardiovascular disease is the leading cause of death for most people in the West – an estimated one in three people die from it – replacing the heart with a younger, healthier one, could potentially add decades to lifespans. Not everyone, it seems, is happy with that idea.

Not everyone, it seems, is happy with that idea.

One approach that is being tried is to levitate tissue in a magnetic field as it grows (Credit: Yuri Kadobnov/Getty Images)

"We've had complaints, with one email calling us 'evil incarnate'," says BioLife4D's Morris. "They argued that the ability to print organs and so extend life wasn't right given the scarcity of resources already leading to so much suffering and that extending lives would only extend that suffering."

There are other potential ethical tightropes to be walked too.

"What if some parent requests that their 12-year-old's heart is replaced with a bigger one so that it pumps harder, with greater efficiency, and so he becomes the star athlete at school," he suggests. "If we can print a heart with two valves, why not print one with an extra two valves built in? Personally, I have doubts here – if evolution hasn't already given us a heart with extra valves we probably shouldn't go there. But if you had to replace an organ anyway, I wouldn't have aversions to replacing it with one that's in some way improved. "

"

Faced with the high cost of printing organs – particularly if they are grown in orbit – delivering hearts or lungs that have been enhanced in some way could be a way of attracting people who are willing to pay for these techniques.

"This is going to be a very divisive question," says Ravi Birla, a tissue engineer with BioLife4D. "If you change everything in a person, organ by organ, arguably what's left isn't the human that was born, but some other creature."

He says while at the moment the focus is on using organs for life-saving surgery, there will inevitably be some comparisons with cosmetic surgery too. "The question now is how one draws the boundaries between the two," he says. "And it's easy to see how one might see the option for enhanced organs as akin to the use of performance-enhancing drugs in sport – most people may be against them, but they're still used, still they're commercialised."

But perhaps the most dramatic uses of organ printing will not be here on Earth at all. As humans start delving deeper into space by first returning to the Moon and then beyond to Mars, bio-printing could be an essential, life-sustaining tool. Millions of miles from Earth, organ donors will be in short supply, but so too will something else – food.

As humans start delving deeper into space by first returning to the Moon and then beyond to Mars, bio-printing could be an essential, life-sustaining tool. Millions of miles from Earth, organ donors will be in short supply, but so too will something else – food.

"This is the tip of the spear as to the possibilities of printing organs," says Boland. Techshot, which part-funded the installation of the bio printer on the ISS and oversaw some of the remote operating experiments, assisted by astronaut Andrew Morgan. The company has now signed an agreement with space station company Axiom Space to install the first commercial bio-printer on the ISS too.

"Eventually bio-printing is going to be important for deep space exploration too – for the printing of animal cells for food, or of tissues in the case of medical emergencies.

"In the meantime these experiments on the ISS are going to unlock some of the secrets of bio-printing to make it work here on Earth first. This is the real leapfrog moment. "

"

--

Join one million Future fans by liking us on Facebook, or follow us on Twitter or Instagram.

If you liked this story, sign up for the weekly bbc.com features newsletter, called "The Essential List". A handpicked selection of stories from BBC Future, Culture, Worklife, and Travel, delivered to your inbox every Friday.

3d printing of a person - 3d printing of figures of people on a 3d printer in Moscow

Masterpieces of fine art always amaze with filigree and liveliness of human images. It would seem that copying the human image will forever remain beyond the capabilities of ordinary people. But, nevertheless, time moves inexorably forward, sweeping away restrictions and providing opportunities.

Possibilities and advantages of the masterpiece technology

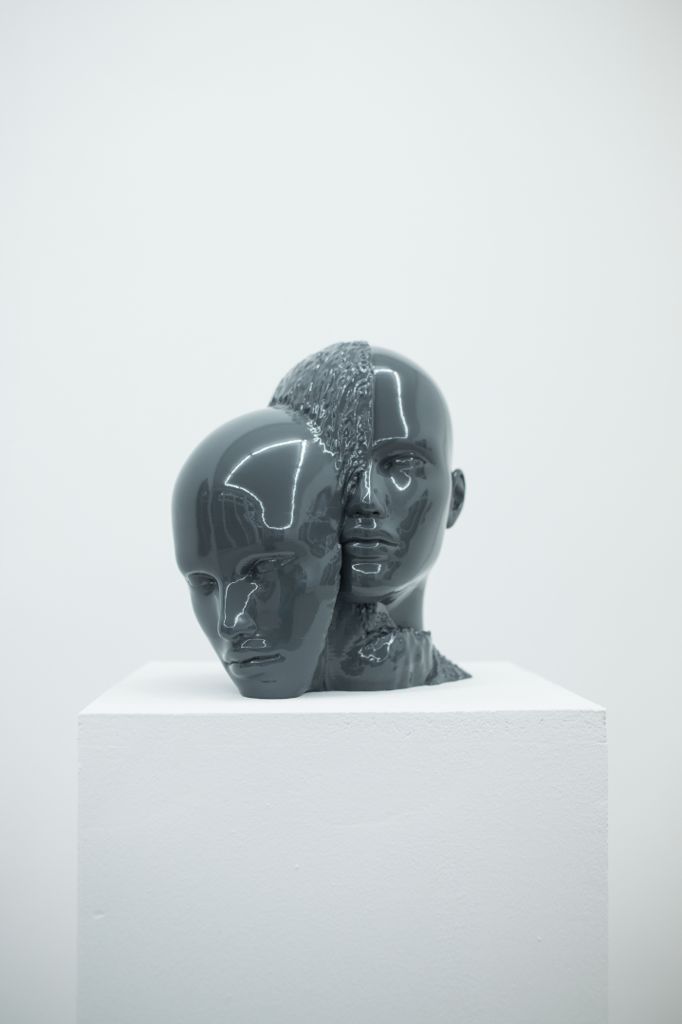

Every person on the planet is unique, therefore, any copy of a person, whether it be a statuette, a model or a portrait on paper, will also have a uniqueness. 3D printing of people is a technology that allows you to reduce the centuries-old most complex mystery of sculpture, painting, modeling of human images to a few simple manipulations with modern digital equipment.

3D printing of people is a technology that allows you to reduce the centuries-old most complex mystery of sculpture, painting, modeling of human images to a few simple manipulations with modern digital equipment.

And, let it sound a little cynical, but 3D printing of a person opens up incredible opportunities in various areas of our lives. Just imagine, the creation of sculptural copies of a person takes months, and sometimes years. The cost of such a sculpture is often simply beyond the reach of an ordinary person. And the chances of becoming a model of a talented sculptor are negligible.

On the other hand, getting your own exact copy a few centimeters in size is now not at all difficult and not expensive. Moreover, a real boom in the popularity of 3D printing is brewing in the world, which will soon create a significant alternative to photo printing and video chronicles. And it's not just about private ambitions and fun!

Spheres of demand for 3D printing technology of people

3D printing of figurines is already widespread today in:

● advertising;

● decoration of wedding celebrations;

● souvenir industry;

● prototyping of industrial and commercial facilities;

● design;

● medicine.

The noble mission of innovative technology

Moreover, the circle of people professionally interested in the service in order to develop their business is constantly growing. In addition to the persistent interest in technology, its profitability and spectacularity, 3D printing of people also serves noble purposes, for example:

● allows blind people to tactilely get acquainted with the external images of their relatives and friends, communication with which is limited to virtual space;

● allows future parents to admire their baby in the womb, not only with the help of ultrasound pictures. 3D printing of a baby figurine built thanks to innovations will allow you to get to know him visually even before he is born;

● Printing figurines on a 3D printer helps people with mental trauma and disorders to adapt to a certain social environment;

● in psychology and educational disciplines, three-dimensional models of people are involved in methods of working with children.

Steps for creating 3D copies of a person

High-quality and high-quality 3D printing of people actually requires several preparatory steps.

● In the first, a full-length 3D scan of a person is performed

● In the second, a copy of the 3D model is carefully processed

● In the third, the figure is scaled down and printed.

The technology also includes a number of post-press processing steps. Figures may require surface grinding, painting or tinting, freeing them from auxiliary elements - clamps, additional details, coating with protective varnishes, finishing agents.

Consumables and features of technological processes

Various materials are used for 3D printing of human figures and

even different equipment, technically and technologically different from each other. So, the result can be presented in plastic, gypsum, polymer mixtures. It can be single color or multicolor. Realistic or only in general terms reminiscent of the original.

Human 3D printing technologies are also different. The most popular and frequently used are two:

● layer-by-layer reconstruction of the model on an inkjet 3D printer;

● laser baking, stereolithography on a laser printer.

For the best and most accurate reproduction of the image of a person, it is advisable to use the method of layer-by-layer gluing of a cellulose-starch mixture.

The use of 3D printed human figures in the advertising industry

Of course, the advertising industry has traditionally been at the forefront of bringing innovation to its service. 3D printing of human figures has become the basis of several high-profile advertising campaigns in Spain, Germany, and the UK, during which passers-by on the streets and visitors to shopping centers were asked to quickly create their own miniature on a 3D printer.

But the scope of advertising use of this technology is much wider:

● Figures of real employees of the company in company uniforms can make up a static installation.

● May be part of a believable animated advertisement.

● Given as a souvenir, they will be a powerful motivation for a common cause and common success.

● 3D printing of human figures in addition to the presentation of 3D models of industrial, construction, social facilities can bring liveliness and dynamics to the presentation of projects.

● Using a 3D printer, you can create not only mini copies of real people, but also transform familiar replicated images of famous sculptures. For example, dress the Venus de Milo in the costume of a stewardess of the advertised airline, and use a mini copy of Rodin's sculpture in an advertisement for ladies' accessories.

The position of 3D copies of a person in souvenir production

A treasure trove of invaluable prospects 3D printer and human printing will bring to souvenir production. With the help of technology, you can make:

● popular interior figurines;

● intricate paperweights;

● gift personalized figurines;

● wedding souvenirs of the bride and groom;

● commemorative figurines of anniversaries and heroes of the occasion.

Variants of representation of the image in a three-dimensional miniature

When creating souvenir miniatures of people, you can most often find three directions for recreating the image:

● realistic or ordinary, the one that can be found in an amateur photo or in life;

● staged, when models are presented in fantasy, stylized images, for example, superheroes or characters from famous fairy tales, movies, literary works, comics;

● wedding, couple real or fictional image.

Bride and groom figurines - this is just the beginning!

The industry of wedding paraphernalia, in addition to commemorative figurines of the newlyweds, can use 3D printing of figurines to create original decorations for invitations, decorating a wedding cake, a festive table, use mini-copies as props for an original wedding photo shoot and video shooting of a romantic love-story.

Online services and their features

It is worth saying a few words about online 3D scanning services. This first step of 3D printing a figurine takes the least time and is the least labor intensive. The presence of many specialized applications on the network that help you scan the image yourself makes the task even easier.

This first step of 3D printing a figurine takes the least time and is the least labor intensive. The presence of many specialized applications on the network that help you scan the image yourself makes the task even easier.

Actually, the results of scanning and allow you to remotely provide services of three-dimensional modeling of a person. The more diligently the scan is made, the more similarity will be between the model and the figurine. By the way, the service of 3D printing of people can be provided not only on the basis of a scan of a real person, but also on the basis of photographs taken from different angles.

How to obtain the necessary sources for 3D printing

To recreate the image in a 3D model, try to get pictures from eight angles in a circle, where the angle step will be 45 degrees. This information will be useful to those who plan to organize a surprise related to the secret production of a mini-copy of a person on a 3D printer. And even if a spontaneous photo session provides less information about the image than a scan, the result will still be recognizable.

Our company is ready to offer all interested people 3D human printing services, as well as business cooperation in this area. Our technical equipment allows us to implement not only our own, but also third-party projects, providing a successful launching pad for your business to take off. We will be glad to assist you in creating a three-dimensional human copy and mutually beneficial cooperation.

3D human figurines • Custom made from photo

3D human figurine • Custom made from photo.

Studio of design and 3D print 3DSOL Creates exclusive

3D figures of people according to the photos sent photos for an unexpected

gift to a person to a person

to order a 3D figure on photo

9000 2 TIN 15040704444080 2 MIRS and 3D printing

3D figures of people from photo

We ran out of ideas and you don't know what to give

to a loved one? Send us a photo, according to them we will make a mini-copy of it, a 3d figurine with a portrait resemblance, which will be an unexpected surprise for a relative, friend.

Telegram Instagram icon-Phot icon-mail WhatsApp

Ask a question

Portfolio

Partettes

9000 3dSolIn several photographs we will make paired statuets of two loving each other, and you will give close emotion to the nearby unpretentious. .

More

Celebrity figurines

3DSOL

Order 3d celebrity figurines for your collection. Choose a photo where you like the emotion and pose of your idol.

More details

Athletes figurines

3DSOL

a gift to someone close to you.

More details

Character figurines

3DSOL

Order a 3D figurine of your favorite character for your collection. Give your loved one a mini-copy of their favorite character.

More

Sculptural compositions

3DSOL

Order exclusive figurines, full-length 3D figures for landscaping parks, recreation areas, decoration of festive events.

More details

Hobby figurines

3DSOL

Give your loved one a 3d figurine — his mini-copy, which will remind him of his favorite pastime.

Read more

Caricature figurines

3DSOL

Caricature 3d figurine is an excellent gift solution for a loved one. This is a gift that will definitely never be forgotten and will delight every time

More details

Single figurines Pair figurines Famous people figurines Athletes figurines Character figurines Sculptural compositions Hobby figurines Caricature figurines

Photopolymer figurines

Large selection of photopolymer 3D technologies print 3D growth figures made of foam and plastic have found their application in a variety of areas: outdoor advertising, decorating cafes and restaurants, decorating shopping centers and offices, photo studios and children's entertainment centers, conducting promotions and advertising campaigns, landscape gardening and decor. »

»

© Sprint3d

Order a 3D growth figure

Materials for 3D printing

Reviews

The best gift is an unexpected surprise. But often the problem arises that the holiday is near, and you have run out of all the ideas and you don’t know what to give.

Design and 3d printing studio 3dSol offers an excellent option: to make exact mini copies - 3d figures of people you love based on the photos you sent.

The figurine will remain with a person for life, it will give a good mood, remind you of you and a memorable day.

We will help in its manufacture, surprise you with an acceptable price and good quality. You can order both a figure of one person and a composition of a group of people.

3d figurine from the photo is a good gift for parents on their wedding anniversary, friend, team leader.

It is better to give a single figurine to a loved one for any holiday. It will be done in an original way every year, and fix changes in a person's appearance.