Carbon m1 super fast 3d printer price

The Carbon M1 3D Printer - Start 3D Printing at Full Scale

The Carbon DLS™ process at an entry-level price

Nicht in Europa erhältlich!

Contact an Expert

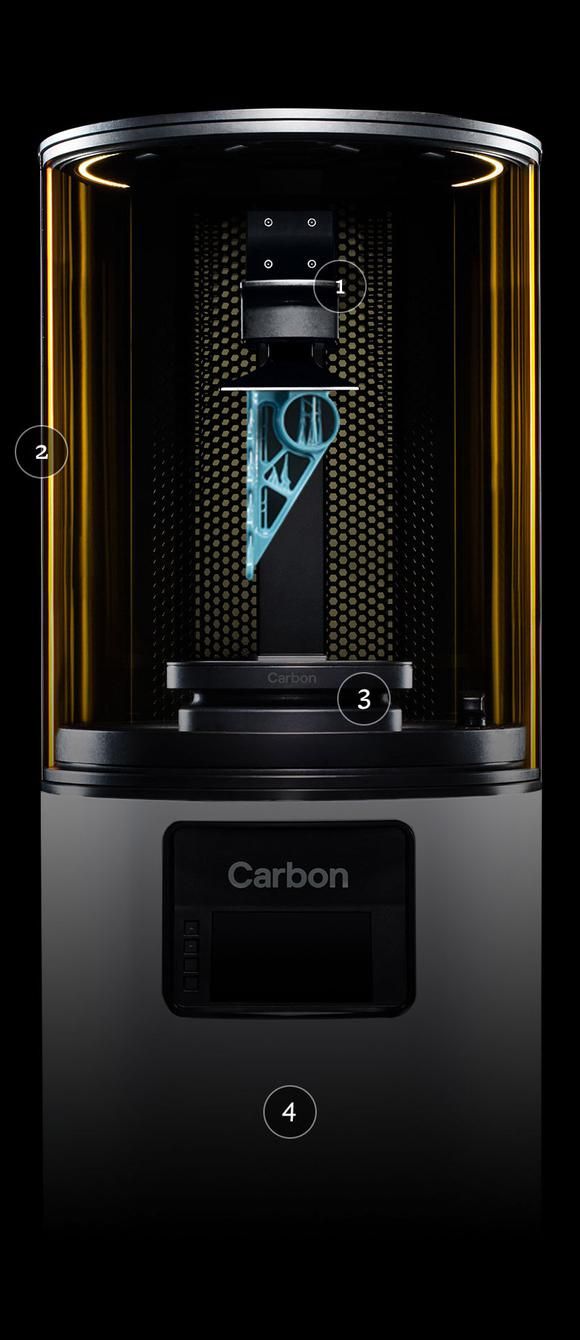

The M1 Printer

Prototyping and production at small volumes

Offering the same speed, accuracy, and reliability as the larger M2 printer, the M1 enables any company to unlock the benefits of producing parts using the groundbreaking Carbon Digital Light Synthesis™ (Carbon DLS™) process at an affordable price. The M1 printer is compatible with all one-part resins, third-party resins, and dual-cure resins that do not require heating during the print.

Get Started with the DLS Process

Get the great accuracy, consistency, reliability, and material performance of Carbon DLS technology at a low price point.

Accelerate Prototyping and Production

Small batch sizes and fast print times are perfect for printing a high mix of low-volume applications throughout the day, such as functional prototypes in multiple dual-cure resins, or multiple dental applications.

Contact an Expert

DLS Process

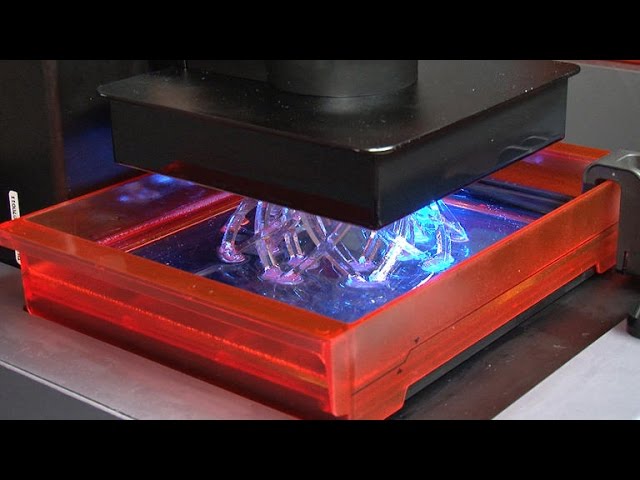

Carbon Digital Light Synthesis technology uses light projection in combination with oxygen-permeable optics to produce isotropic parts with exceptional surface finish.

Learn More

Materials

Carbon offers the widest range of real, functional materials and industry-proven third-party dental resins.

Learn More

The DLS Advantage

We offer unique capabilities and industry-leading service and support. See why Carbon is more than a printer.

Learn More

Discover the right Carbon 3D printer for your production needs and budget

M1 | M2 | M3 | ||

| Build Volume (X x Y x Z) | 141 x 79 x 326 mm 5.  6 x 3.1 x 12.8 in 6 x 3.1 x 12.8 in | 189 x 118 x 326 mm 7.4 x 4.6 x 12.8 in | 189 x 118 x 326 mm 7.4 x 4.6 x 12.8 in | |

|---|---|---|---|---|

| XY; Z Resolution* | 75 µm; 25, 50 or 100 µm | 75 µm; 25, 50 or 100 µm | 75 µm; 25, 50 or 100 µm | |

| General Accuracy** | Up to ±70 μm + 1 μm per mm dimension size Up to ±0.003 in + 0.001 in per in dimension size | Up to ±70 μm + 1 μm per mm dimension size Up to ±0.003 in + 0.001 in per in dimension size | Up to ±65 µm+ 1 µm per mm dimension size Up to ±0.0026 in + 0.001 in per in dimension size | |

| Production Repeatability Accuracy** | Up to ±40 μm Up to ±0.002 in | Up to ±40 μm Up to ±0.002 in | Up to ±37 μm Up to ±0.  002 in 002 in | |

| Printer Software | Included in your subscription with regular OTA software updates about every eight weeks. | |||

| Service & Support | Integrated service package with real-time customer support and preventative maintenance for optimized machine uptime. | |||

| Pricing | Carbon 3D printers start at $25k per year and come with a variety of packages suited to your needs. Contact us for printer-specific pricing details. | |||

* Z resolution is adjustable from single digit microns to multiple hundred microns, and can be optimized through working with Carbon on your target application.

** For more information about accuracy, please refer to Carbon DLS accuracy guidelines for engineering materials and dental materials.

See the full lineup of Carbon printers

Get a Quote

Contact an Expert

Smart Part Washer

Reduce labor costs and increase throughput

Simple, Mess-Free Washing

A game-changer in cleaning parts. Simply place the build platform from an M2 printer into the Smart Part Washer and let it run.

Simply place the build platform from an M2 printer into the Smart Part Washer and let it run.

Maximize Part Quality

Get a consistent, predictable, and thorough clean of your prints by moving from a manual process to a smart, automated process.

70% Labor Savings Per Wash

With optimized wash protocols, labor time per print is minimal. Spend that time more productively—making new parts.

| Size | 35 in. x 24 in. x 49 in |

| Weight | 350 lb |

| Washer Volume | 1x build platform |

Cutting-Edge Design Powered by Advanced Software

Use Familiar Tools

Carbon 3D printers support STL files. Use standard CAD tools to generate your design, then upload your STL into Carbon’s print planning tool.

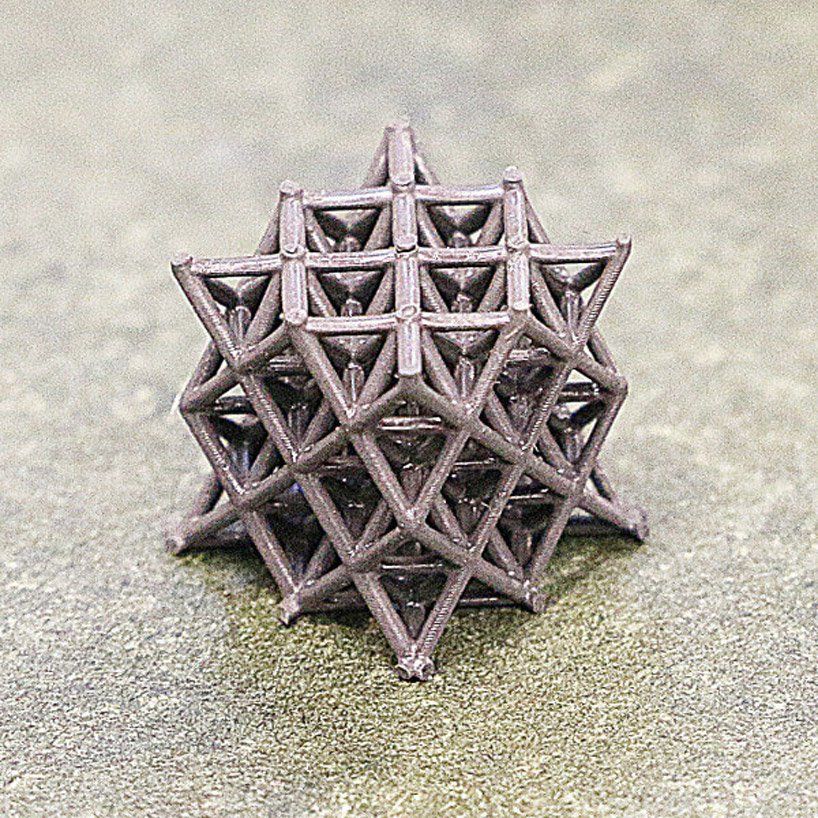

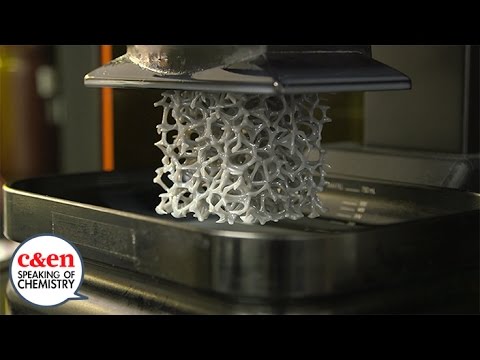

Lattice DesignCarbon’s Design Engine software helps customers generate the perfect lattice to fit desired form, mechanical response, and durability requirements.

Learn More

Surface TexturesThere’s no need for a complicated pipeline of third-party tools. Add branded, aesthetic, or functional textures to your parts, all from within Carbon software.

Save Time and Improve Quality with Automated Print Preparation

Auto Layout

Save time when preparing builds with multiple parts by using Carbon’s auto layout feature.

Advanced Auto Supports

Advanced auto supports save time and ensure high-quality results by offering a reliable, FEA-backed strategy for supporting parts during printing.

Boost Efficiency with Print Analytics

Manufacture at Scale

Because every machine is connected, Carbon’s entire workflow can be logged, monitored, and reviewed through tools and dashboards to offer deep insights into fleet performance and utilization.

Fleet Management Dashboard

Review production data and manage a fleet of devices in real-time from one dashboard. Queue new projects seamlessly.

Queue new projects seamlessly.

Part Traceability

Preserve a part’s entire history—from CAD file, to design, to print—in one digital record. Streamline quality assurance with embedded unique part identifiers to quickly review a part’s history.

Better Operations with Connected Hardware

Over-the-Air Software Updates

Carbon’s 3D printers constantly get better, even after they’re installed. Regular software updates improve every aspect of the Carbon DLS™ process, offering improved user experience, faster and more accurate prints, and more sophisticated process management.

View Software Release History

Real-time Status and Control

Monitor and manage printer and parts at every stage of the printing process wherever you are, regardless of whether you have one or hundreds of Carbon 3D printers.

Accelerated Customer Support

Carbon’s customer support team can identify and troubleshoot printer issues remotely without interrupting business operations. Data-backed predictive maintenance through real-time alerts inform customers about issues that might impact production.

Data-backed predictive maintenance through real-time alerts inform customers about issues that might impact production.

Carbon 3D Printer Pricing - Carbon

Carbon 3D printer pricing starts at $25k per year. Contact a Carbon expert to help you select the right printer and tailor pricing based on your needs.

Get a Quote Now

Carbon product offerings and pricing vary by country and region. Please contact a Carbon expert for a quote.

Discover the right Carbon 3D printer for your production needs and budget

Carbon printers come in a variety of models with build volumes and price points to suit your specific needs.

M1 | M2 | M3 | M3 Max | L1 | ||

| Build Volume (X x Y x Z) | 141 x 79 x 326 mm 5.  6 x 3.1 x 12.8 in 6 x 3.1 x 12.8 in | 189 x 118 x 326 mm 7.4 x 4.6 x 12.8 in | 189 x 118 x 326 mm 7.4 x 4.6 x 12.8 in | 307 x 163 x 326 mm 12.1 x 6.4 x 12.8 in | 400 x 250 x 460 mm 15.7 x 9.8 x 18.1 in | |

|---|---|---|---|---|---|---|

| XY; Z Resolution* | 75 µm; 25, 50 or 100 µm | 75 µm; 25, 50 or 100 µm | 75 µm; 25, 50 or 100 µm | 75 µm; 25, 50 or 100 µm | 160 µm; 25, 50, or 100 µm | |

| General Accuracy** | Up to ±70 μm + 1 μm per mm dimension size Up to ±0.003 in + 0.001 in per in dimension size | Up to ±70 μm + 1 μm per mm dimension size Up to ±0.003 in + 0.001 in per in dimension size | Up to ±65 µm+ 1 µm per mm dimension size Up to ±0.  0026 in + 0.001 in per in dimension size 0026 in + 0.001 in per in dimension size | Coming Soon | Up to ±70 μm + 1 μm per mm dimension size Up to ±0.003 in + 0.001 in per in dimension size | |

| Production Repeatability Accuracy** | Up to ±40 μm Up to ±0.002 in | Up to ±40 μm Up to ±0.002 in | Up to ±37 μm Up to ±0.002 in | Coming Soon | Up to ±40 μm Up to ±0.002 in | |

| Explore M1 | Explore M2 | Explore M3 | Explore M3 Max | Explore L1 | ||

* Z resolution is adjustable from single digit microns to multiple hundred microns, and can be optimized through working with Carbon on your target application.

** For more information about accuracy, please refer to Carbon DLS accuracy guidelines for engineering materials and dental materials.

Need Pricing for Your Part?

Not in the market for a printer but want to understand pricing for your part? Get a quote from a certified Carbon production partner. These manufacturers are certified experts in the Carbon DLS 3D printing process––from design to production.

Get Part Pricing

Carbon 3D Printer Pricing FAQs

How much does a Carbon 3D printer cost?

Carbon 3D printer pricing starts at $25k per year. Contact a Carbon expert now to help you select the right printer and tailor pricing based on your needs.

Contact a Carbon Expert

“The subscription model is beneficial as we are able to make payments over time versus one large capital investment. This enables us to keep costs down and allows for the flexibility to add more printers as the division grows.” Nick Windlow Smile Shapers, Director of Business Development

Why are Carbon 3D printers offered as a subscription?

We focus on helping you succeed in delivering better products in less time–not on selling you equipment. We build an ongoing relationship with you starting the day your printer is installed, and consistently and reliably deliver technology updates, expertise, and support to help you every step of the way. We have proven this approach with a broad range of customers, from major global brands to family-owned businesses, helping them deliver exceptional products efficiently.

We build an ongoing relationship with you starting the day your printer is installed, and consistently and reliably deliver technology updates, expertise, and support to help you every step of the way. We have proven this approach with a broad range of customers, from major global brands to family-owned businesses, helping them deliver exceptional products efficiently.

Advantages of the Carbon subscription

-

A partner committed to your long-term success instead of a one-time printer sale.

Paying upfront for a printer puts all the performance risk on you as the customer for your success. We believe in our technology and approach enough to share the risk to ensure you are successful. Instead of paying us upfront for equipment, you pay us as you use it. If we don’t deliver exceptional value, you won’t renew your subscription.

-

Flexibility in your capital equipment investments.

Carbon subscriptions can vary in length depending on your needs.

Shorter subscriptions allow our customers to try out different printers without having to buy them outright. You have the option to renew your subscription, return your 3D printer, or upgrade your 3D printer.

Shorter subscriptions allow our customers to try out different printers without having to buy them outright. You have the option to renew your subscription, return your 3D printer, or upgrade your 3D printer. -

Updates, maintenance, and support are included.

Owning a printer means you own maintenance and upkeep. With Carbon, we handle maintenance and we routinely upgrade printers with new software to improve your printers’ performance. Carbon printers have a track record of consistent, reliable and accurate production over time. We maintain them and ensure excellent uptime so that you can focus on developing and producing great products.

The value of a subscription model for connected 3D printers

| Traditional Ownership of Non-Connected 3D Printer | Subscription Model for Connected 3D Printer | |||||||

|---|---|---|---|---|---|---|---|---|

| Continual platform improvement | Gradually becomes obsolete after date of purchase | Improves over time with over the air updates every few weeks | ||||||

| Immediate support for new materials | Purchase separately or available on new version | Included* | ||||||

| Integrated technical support | Purchase service package separately | Included | ||||||

| Minimal unplanned downtime | Not connected, resulting in slower response time | Real-time customer support | ||||||

| Predictive maintenance to optimize machine uptime | Lagged service response time halts production efforts | Preemptive troubleshooting by Carbon keeps machines running | ||||||

* Exceptions include additional hardware costs for specific materials, e. g., RPU 130 and EPU 41 Black. g., RPU 130 and EPU 41 Black.Learn more about our subscription pricing model. | ||||||||

What happens after my subscription term is finished?

Once your subscription has finished, you have the option to renew your subscription, return your 3D printer, or upgrade your 3D printer.

Can I upgrade my printer during my subscription term?

Yes, you can upgrade your 3D printer during your Carbon subscription term.

What types of platform improvements can be expected?

Gain access to the latest software tools and support for new materials

Improvements to the Carbon platform add new features and capabilities in design and automation, fleet and factory management, and printing and post-processing. These updates can instantaneously deliver improved print outcomes, better workflow management, new design capabilities, and seamless support for new resins. See our recent platform improvements here.

What makes Carbon technical support so great?

Real-time customer support with predictive maintenance

Our connected 3D printers offer streamlined, remote troubleshooting and accelerated customer support. By monitoring customer operational metadata, we can precisely predict and prevent issues before they impact production. With a customer’s permission, our services team is able to view important contextual data and replicate issues quickly, cutting downtime.

By monitoring customer operational metadata, we can precisely predict and prevent issues before they impact production. With a customer’s permission, our services team is able to view important contextual data and replicate issues quickly, cutting downtime.

Ready to Get Started?

Speak with an expert to learn more about how Carbon can support your product development process at every step, from concept to mass production.

Contact a Carbon Expert

Get a Free Sample Part

There’s no substitute for holding a 3D printed part in your hand. Experience the quality of Carbon DLS-printed parts by requesting a free sample part below.

Request a Free Sample Part

Get Your Parts Made

Not in the market for a printer but still want Carbon DLS-printed parts? Find a certified Carbon production partner to get your parts made. These manufacturers are certified experts in the Carbon DLS 3D printing process—from design to production.

Find a Carbon Production Partner

Find a Carbon Dental Outsource Partner

Carbon 3D Printers

The L and M Series printers and Smart Part Washer offer versatility and enable scalable manufacturing.

Learn More

Materials

Find the right material for your project, from consumer product elastomers to high-temperature automotive materials.

Learn More

Carbon Design Engine

Design high-performance conformal lattices to improve product performance and speed up print time.

Learn More

Carbon M2 3D printers and robots: high-speed 3D printing / Sudo Null IT News CLIP, washing stations and a robotic arm to service the entire system. The system is designed for high-speed printing of finished parts in production, but can also print prototypes. We tell and show. nine0003

Video

Carbon Speedcell

- Print Technology: CLIP DLS (Proprietary Type of Photopolymer Stereolithography)

- Construction area, mm: 189 x 118 x 326

- Accuracy (pixel size), µm: 75

- Purpose: production

- Interface: Wi-Fi, USB, Ethernet

- Print speed: dependent on media/settings; up to 25-100 times higher than other printing technologies

Application

The SpeedCell system is highly scalable and can be used for both prototyping and series production.

Device

At the heart of the SpeedCell system are Carbon M2 3D printers using Continuous Liquid Interface Production technology, or CLIP for short. The method of continuous printing in a liquid medium was patented in 2014 and today it is the fastest method of photopolymer printing, surpassing SLA and DLP in tens of times

Carbon M2, the company's second generation of printers, was introduced last year. Its displacement is twice the parameters of the debut model M1, while maintaining all other key characteristics.

Robots

To speed up the work of such an "additive cell", Carbon suggests using a manipulator. Upon completion of printing on one of the 3D printers, the robotic arm removes the platform with the finished object, moves it to the washing station, and then installs a clean platform on the 3D printer. nine0005

Ultra-fast printing machines and systems are becoming more accessible to manufacturing companies that want to move away from traditional methods of manufacturing parts or supplement them with additive technologies.![]()

Materials

In addition to SpeedCell, Carbon also presented at IMTS an updated range of consumables for its printer line, which includes both standard photopolymers and specialty resins. nine0005

A complete list of materials now includes several rigid, flexible and elastic polyurethanes, the latest resins based on cyan esters, epoxy components and urethane methacrylate.

The Carbon range also includes a dental material, silicone photopolymer and biocompatible polyurethane for medical applications, which has already been approved by the US Food and Drug Administration.

Carbon's CLIP-enabled 3D printers hold the record for high-speed resin 3D printing and are the only supplier of such equipment in the industrial segment. nine0005

XYZprinting produces a reduced-sized desktop analogue using its own similar technology: these are xPF series printers, in particular, the MfgPro 180 xPF and MfgPro 220 xPF. You can learn more about them here.

To select and purchase production 3D printers, please contact Top 3D Shop.

Want more exciting news from the world of 3D technology?

Follow us on social. networks:

History of 3D printing

In this section, we wanted to trace the history of 3D printing from its inception to the present day, as well as give a forecast regarding the future development of technology.

The first 3d printer was invented by the American Charles Hull, he worked on the technology of stereolithography (SLA), a patent for the technology was issued in 1986. The printer was a fairly large industrial installation. The installation "grew" a three-dimensional model by applying a photopolymerizable material to a moving platform. The basis was a digital model pre-modeled on a computer (3D model). This 3d printer created three-dimensional objects, rising by 0.1-0.2 mm - the height of the layer. Despite the fact that the first device had many disadvantages, the technology has received its application. Charles Hull is also the co-founder of 3dsystems, one of the world's leading manufacturers of industrial 3D printers. nine0005

Charles Hull is also the co-founder of 3dsystems, one of the world's leading manufacturers of industrial 3D printers. nine0005

Charles Hull was not the only one to experiment with 3D printing technology, as in 1986 Carl Deckard invented Selective Laser Sintering (SLS). You can learn more about the method in another article, briefly: a laser beam sinters a powder (plastic, metal, etc.), while the mass of the powder is heated in the working chamber to a temperature close to the melting point. The basis is also a digital model pre-modeled on a computer (3D model). After the laser passes through the horizontal layer, the chamber is lowered to the layer height (usually 0.1-0.2 mm), the powder mass is leveled with a special device and a new layer is applied. nine0005

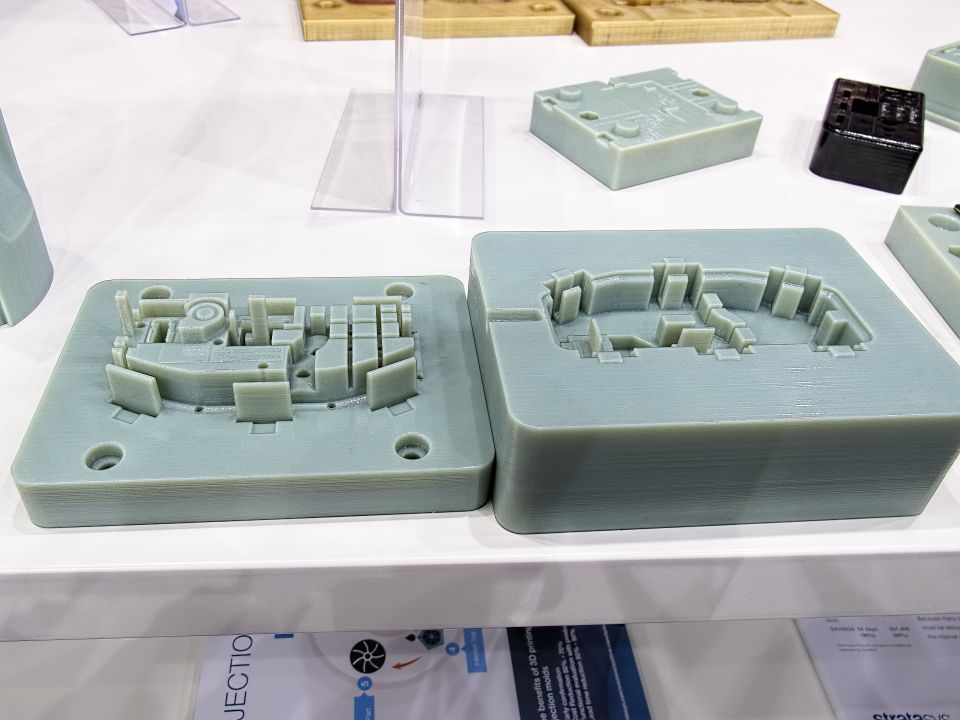

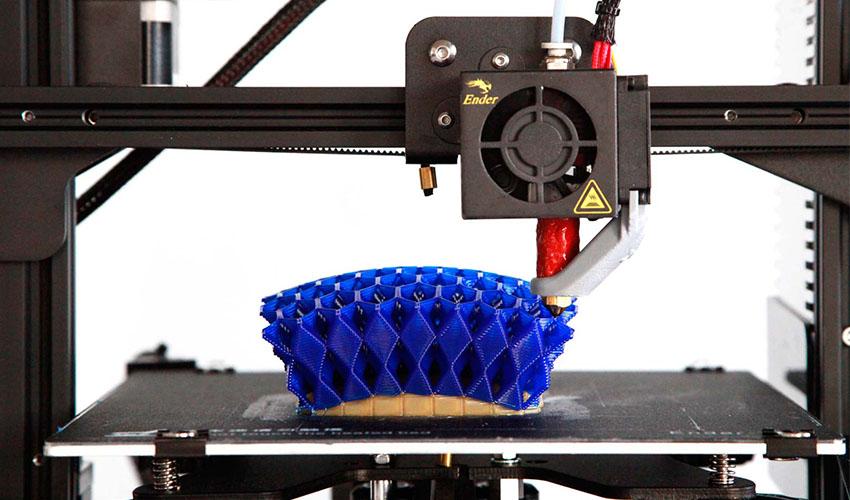

However, the most famous and widespread 3D printing method today is layer-by-layer direction (FDM). The idea of technology belongs to Scott Crump (Scott Crump), the patent dates back to 1988. You can learn more about the method in another article, in short: material (usually plastic) is fed from the heated nozzle of the print head using a stepper motor, the print head moves on linear guides along 1 or two axes, and the platform moves along 1 or 2 axes . The basis of the movement is also a 3D model. The molten plastic is laid on the platform along the established contour, after which the head or platform is moved and a new layer is applied on top of the old one. Scott Crump is one of the founders of Stratasys, which is also one of the leaders in the production of industrial 3D printers. nine0005

The basis of the movement is also a 3D model. The molten plastic is laid on the platform along the established contour, after which the head or platform is moved and a new layer is applied on top of the old one. Scott Crump is one of the founders of Stratasys, which is also one of the leaders in the production of industrial 3D printers. nine0005

All the devices described above belonged to the class of industrial devices and were quite expensive, so one of the first 3d Dimension printers from Stratasys in 1991 cost from 50 to 220 thousand US dollars (depending on the model and configuration). Printers based on the technologies described above cost even more and until very recently, only a narrow circle of interested specialists knew about these devices.

Everything began to change since 2006, when the RepRap project (from the English Replicating Rapid Prototyper - a self-replicating mechanism for rapid prototyping) was founded, with the goal of creating a self-copying device, which was a 3D printer working on technology FDM (layer by layer deposition). Only, unlike expensive industrial devices, it looked like a clumsy invention made from improvised means. Metal shafts serve as a frame, they also serve as guides for the print head. driven by simple stepper motors. The software is open source. Almost all connecting parts are printed from plastic on the 3D printer itself. This idea originated among English scientists and aimed at spreading available additive technologies so that users can download 3D models on the Internet and create the necessary products, thus minimizing the production chain. nine0005

Only, unlike expensive industrial devices, it looked like a clumsy invention made from improvised means. Metal shafts serve as a frame, they also serve as guides for the print head. driven by simple stepper motors. The software is open source. Almost all connecting parts are printed from plastic on the 3D printer itself. This idea originated among English scientists and aimed at spreading available additive technologies so that users can download 3D models on the Internet and create the necessary products, thus minimizing the production chain. nine0005

Leaving aside the ideological component, the community (which exists and develops to this day) managed to create a 3d printer accessible to the "ordinary person". So a set of unprinted parts can cost around a couple of hundred US dollars and a finished device from $500. And even though these devices looked unsightly and were significantly inferior in quality to their industrial counterparts, all this was an incredible impetus for the development of 3D printing technology.

As the RepRap project developed, 3D printers began to appear, taking as a basis the base laid down by the movement in technical and, sometimes, ideological terms (for example, commitment to the concept of open source - OpenSource). The companies that made printers tried to make them better both in terms of performance, design and user experience. The first RepRap printers cannot be called a commercial product, since it is not so easy to manage (and even more so to assemble) and it is not always possible to achieve stable work results. Nevertheless, companies tried to close the more than significant gap in quality, leaving a significant gap in cost whenever possible. nine0005

First of all, it is worth mentioning the MakerBot company, which started as a startup, took the ideas of RepRap as a basis and gradually turned them into a product of a new quality.

Their flagship product (and in our opinion the best to this day) remains the MakerBot Replicator 2 3D printer. The model was released in 2012 and later discontinued, but remains one of the most popular 3D printer models to this day " personal" segment (according to 3dhubs). The word "personal" is in brackets because this printer, which cost $2,200 at the time of release, was (and is) primarily used for business purposes, but falls into the personal segment due to its cost. This model differs from its progenitors (RepRap), being, in fact, a finished commercial product. Manufacturers abandoned the concept of OpenSource, closing all sources and software codes. nine0005

The model was released in 2012 and later discontinued, but remains one of the most popular 3D printer models to this day " personal" segment (according to 3dhubs). The word "personal" is in brackets because this printer, which cost $2,200 at the time of release, was (and is) primarily used for business purposes, but falls into the personal segment due to its cost. This model differs from its progenitors (RepRap), being, in fact, a finished commercial product. Manufacturers abandoned the concept of OpenSource, closing all sources and software codes. nine0005

In parallel with the release of equipment, the company actively developed the Thingiverse resource, which contains many models for 3d printing, available for download for free. During the development of the first printer and beyond, the community has helped the company a lot, testing the product and offering various upgrades. After the release of the Replicator 2 (and the closure of development), the situation has changed. You can learn more about the history of MakerBot and other companies and people associated with 3d printing by watching the film Print the legend. nine0005

You can learn more about the history of MakerBot and other companies and people associated with 3d printing by watching the film Print the legend. nine0005

This film also highlights the history of Formlabs, one of the first companies to launch an affordable 3D printer based on SLA (Strereolithography) technology. The company raised funds for the first FORM 1 model through crowdfunding, encountered production difficulties, but eventually released an affordable and productive 3D printer, closing the quality gap described above.

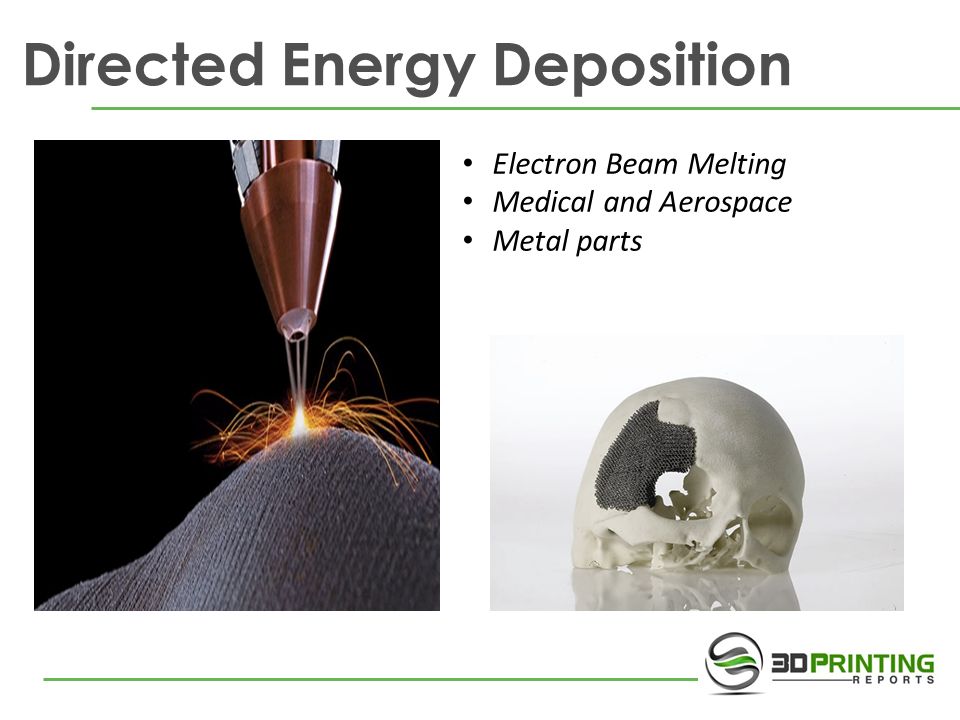

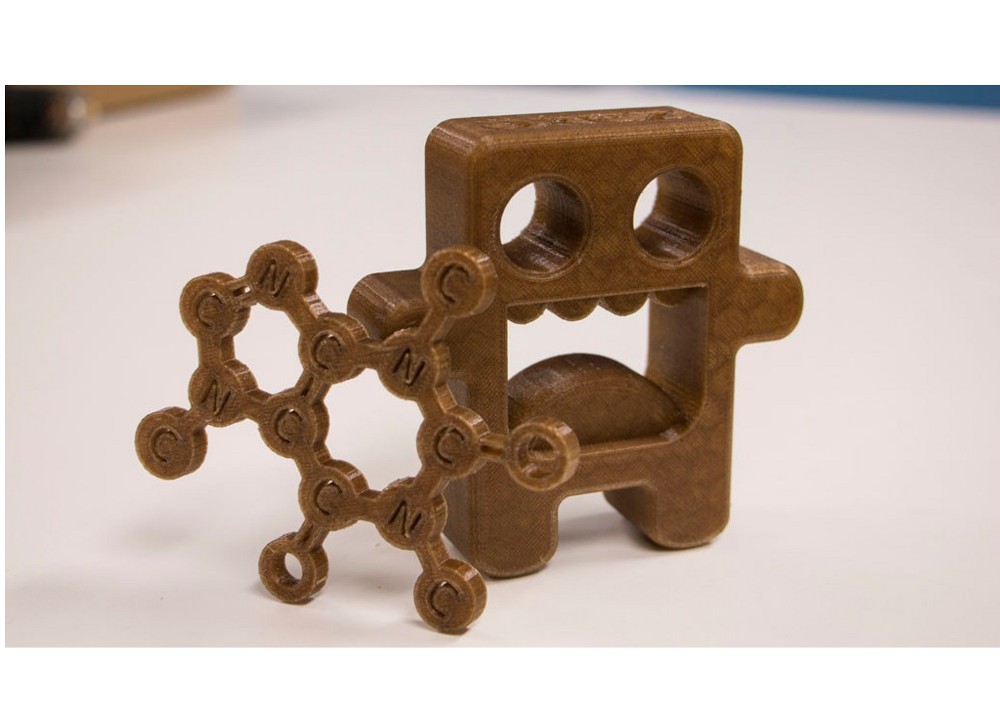

And although the 3D printers described above were far from perfect, they laid the foundation for the development of affordable 3D printing technology, which continues to this day. At the moment, the quality of FDM and SLA printers is increasing, but there is no significant price reduction, rather, on the contrary, it is growing slightly. Along with FDM and SLA, many companies are developing in the field of powder sintering (SLS), as well as metal printing. Despite the fact that such printers cannot be called affordable, their price is much lower in comparison with analogues from the professional segment. It is also worth noting the development of the line of materials, in addition to the standard ABS and PLA plastics, today many different materials are used, including nylon, carbon fiber and other durable and refractory materials. nine0005

Despite the fact that such printers cannot be called affordable, their price is much lower in comparison with analogues from the professional segment. It is also worth noting the development of the line of materials, in addition to the standard ABS and PLA plastics, today many different materials are used, including nylon, carbon fiber and other durable and refractory materials. nine0005

Personal 3d printers of today are very close to professional devices, the development of which also does not stop. In addition to the "founders" of the technology (Stratasys, 3dsystems), many small companies specializing in industrial 3D printing technologies (metal in particular) have emerged. 3D printing is also attracting the attention of large corporations, which, with varying degrees of success, are striving to take their place in a growing market. Here it is worth highlighting HP, which recently released the HP Jet Fusion 3D 4200 model, which has gained popularity among 3d printing professionals (as of 2018, it is at the top of the ranking of professional 3D printers in the quarterly reports of the 3dhubs portal). nine0005

nine0005

However, 3D printing technologies are developing not only in breadth, but also in depth. One of the main disadvantages of 3D printing, compared to other production methods, is the low speed of creating models. A significant advance in terms of accelerating 3D printing was the invention of CLIP technology by CARBON, printers operating on this technology can produce models 100 times faster than classic SLA technology.

There is also a constant expansion of the range, properties and quality of materials and post-processing of products. All this accelerates the transition to the use of 3d printers in production, and not just as prototyping devices. Today, many large and not only companies and organizations are closely using a 3D printer in their production chain: from consumer goods manufacturers NIKE and PUMA to BOEING and SPACE X (the latter prints engine parts for its rockets that could not be made in any other way) . nine0005

In addition to the "classic" scope of 3D printing, today you can increasingly see news about how a house or some organ (or rather, a small part of it) was printed on a 3D printer from bio-material. And this is true, several companies around the world are testing or already partially using 3D printing in the construction of buildings and structures. This mainly concerns the contour pouring of walls (similar to the FDM method) with a special composite concrete mixture. And in Amsterdam there is a 3D printed bridge project and this list will only expand over time, since the use of 3D printing in construction can significantly reduce costs and increase the speed of work at certain stages. nine0003 With regards to medicine, here 3D printing also finds application, but at the moment it is not printing organs, but rather the use of technology in prosthetics (of various kinds) and bone replacement. Also, 3D printing technology is widely used in dentistry (SLA technology). Regarding the printing of organs, this is still far in the future, at the moment bio-3D printers are experimental facilities in the early stages, the success of which is limited to printing a few limited-viable cells. nine0005

And this is true, several companies around the world are testing or already partially using 3D printing in the construction of buildings and structures. This mainly concerns the contour pouring of walls (similar to the FDM method) with a special composite concrete mixture. And in Amsterdam there is a 3D printed bridge project and this list will only expand over time, since the use of 3D printing in construction can significantly reduce costs and increase the speed of work at certain stages. nine0003 With regards to medicine, here 3D printing also finds application, but at the moment it is not printing organs, but rather the use of technology in prosthetics (of various kinds) and bone replacement. Also, 3D printing technology is widely used in dentistry (SLA technology). Regarding the printing of organs, this is still far in the future, at the moment bio-3D printers are experimental facilities in the early stages, the success of which is limited to printing a few limited-viable cells. nine0005

Looking to the future, it is safe to say that 3D printing technology will expand both in breadth and depth, improving technology, speeding up processes, improving quality and improving material properties. 3D printers will increasingly replace old methods in production chains of various scales, and world production, due to this, will move towards the “on demand” scheme of work, increasing the degree of product customization. Perhaps someday, 3D printers will be widely used at the household level for the production of necessary things (the dream and goal of the RepRap movement), but this requires not only the development of technology, but also a paradigm shift in social thinking, as well as the development of a powerful design ecosystem ( 3d modeling) products (which is often forgotten). nine0005

3D printers will increasingly replace old methods in production chains of various scales, and world production, due to this, will move towards the “on demand” scheme of work, increasing the degree of product customization. Perhaps someday, 3D printers will be widely used at the household level for the production of necessary things (the dream and goal of the RepRap movement), but this requires not only the development of technology, but also a paradigm shift in social thinking, as well as the development of a powerful design ecosystem ( 3d modeling) products (which is often forgotten). nine0005

3d printing of houses (and other structures) will no doubt also develop, reducing costs and production time, which, together with the development of new approaches in architecture and urban planning (such as modular construction and the prefabricated method), will give a tangible impetus to development the industry as a whole.

Biological 3D printers will be an important tool in scientific research.