3D printer toronto

Downsview : Toronto Public Library

| Year | Details |

|---|---|

| 1956 | North York Public Library Board appoints Paul Meschino as the architect for the proposed Downsview Branch, 18 April. On 4 May, it passes a bylaw to expropriate "certain lands at the corner of Keele Street and Paxtonia Boulevard for public library purposes, said lands being part of Block B, Plan 4571, North York owned by Goodburn Construction Ltd." On 23 May, it approves "a price of $30,000.00 with the understanding that a donation of $2000.00 will be made to the Board." (North York Public Library Board minutes). |

| 1960 | North York Public Library Board plans Downsview Branch as its first regional library for the west end of the municipality. |

| 1961 | Sod-turning ceremony, 9 May. |

| 1962 | Opened to the public, 6 March. Paul Meschino Architect. |

| 1963 | Officially opened on 26 May, with the cornerstone (dated 1961) laid by Vivian Thomas Graff, the widow of William L. Graff, North York’s chief librarian since 1955, who had died in office on 15 October 1962. |

| 1965 | Enlarged to regional/area size. Officially opened, 15 April. Paul Meschino Architect. |

| 1995 | Closed for renovations and expansion, 26 June. |

| 1996 | Reopened, 6 May. Makrimichalos Cugini Architects. |

| 1997 | Included on an inventory of North York's Modernist Architecture, prepared by the City of North York Planning Department, Urban Design Division. |

| 2011 | Renovation that included addition of Express Checkout, new shelving and display cases and reconfiguration of the service desk. |

| 2012 | 50th celebration of Downsview Branch. |

| 2016 | Digital Innovation Hub created on the main floor level. |

| 2018 | Youth Hub opens September, 2018. |

OBJEX UNLIMITED | ABOUT US

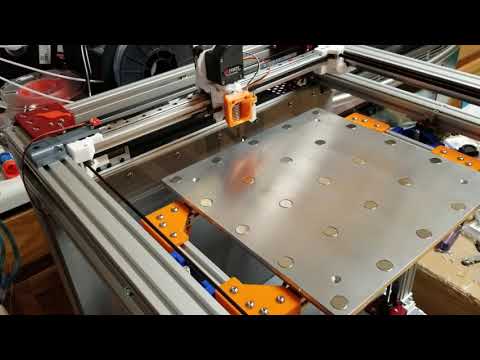

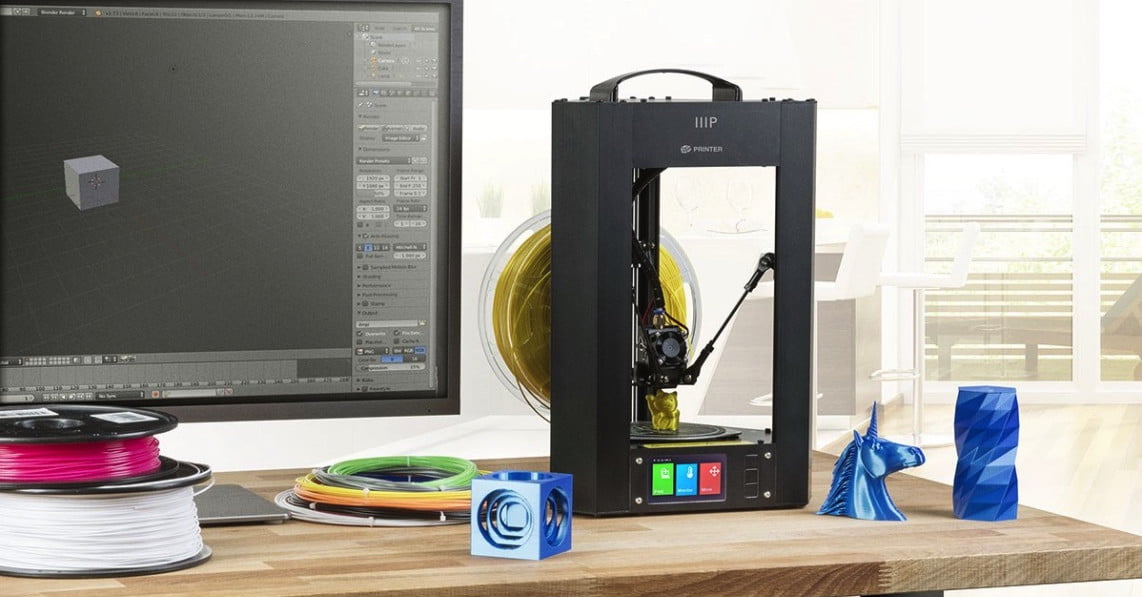

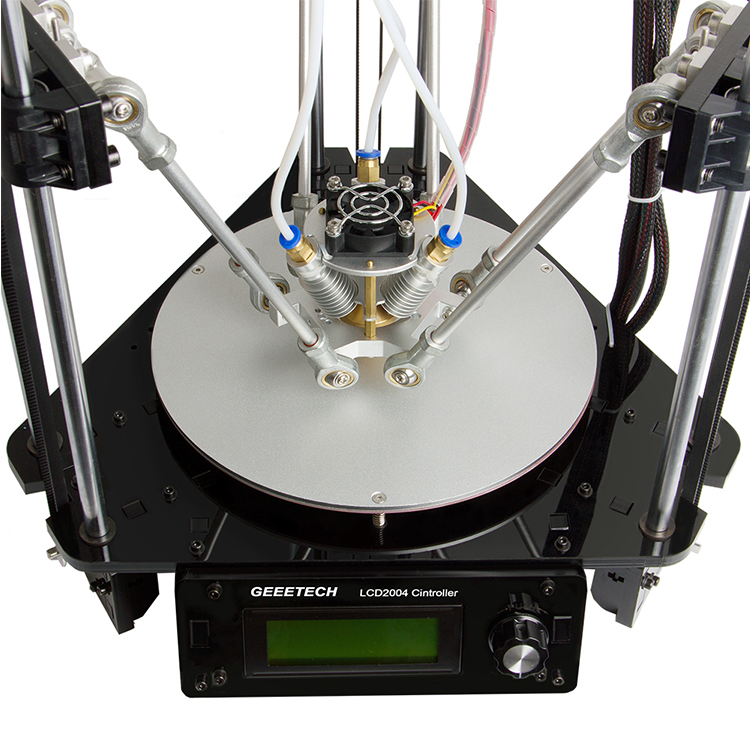

We are at the forefront of the 3D printing revolution and push the boundaries of traditional manufacturing.

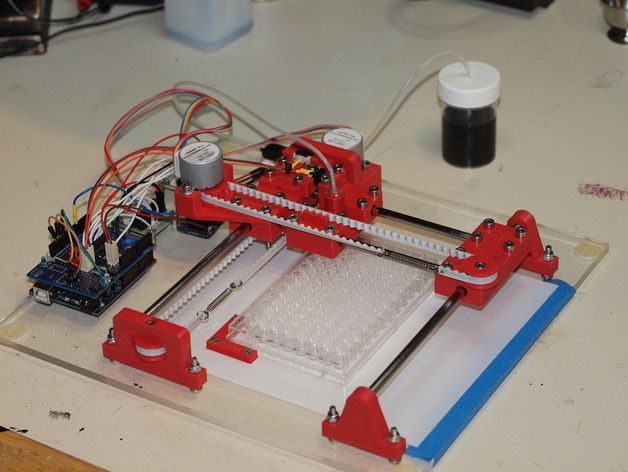

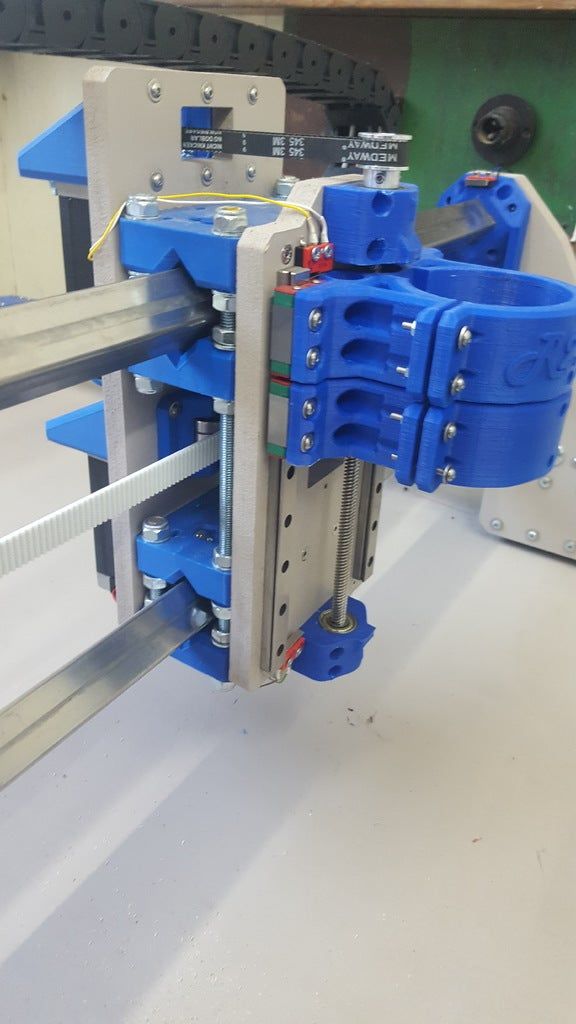

Objex Unlimited is your one stop shop for everything 3D. We offer a full in house service bureau and catering our products and services to an array of industries for various application.

Objex Unlimited is a leading service provider as well as authorized equipment reseller for multiple suppliers, and give our customers access to more than just one piece of equipment. Our well rounded facility offers a vast majority of industry leading tools and technology.

Objex Unlimited uses the product and services we sell and are honest about their capabilities. On a daily basis we experience the pros and cons to every element we cater. Come by our studio any time and we will show you in person- our facility and capabilities.

Objex Unlimited has invested in the learning curve so our customers don’t have to. For over a decade Objex Unlimited has grown and employed some of the brightest minds in the 3D realm. Our team is experienced in the products we offer and the services we provide. We employee a multidisciplinary team of engineers, designers, technicians, artists, sculptors, and mathematicians… and have a trained team that understands a broad range of industries, application, and technologies. Our team has an unmatched range of skills, from concept to design to production to finishing, industrial and organic, engineering and artistic.

We build lasting relationships with our customers; by going that extra mile and pushing the boundaries of 3D printing and 3D scanning to find the right tech and solutions to our customer’s toughest challenges. We share our experience and expertise to focus on providing solutions that work best for our customers’ needs and requirements to help them get better faster.

Toronto’s 3D Printing Studio and Scanning Service Experts

Objex Unlimited is a 3D solutions provider and Canadian equipment reseller, specializing in 3D Printing, 3D Scanning, and 3D Design Services. Our full in-house service bureau offers customers a one-stop shop for everything 3D; delivering products and services that span an array of industries for various applications.

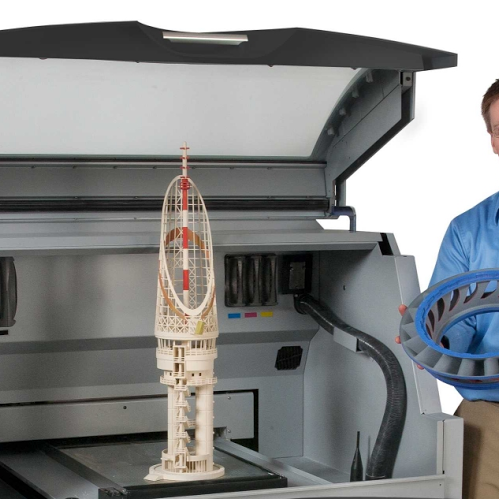

Combining cutting edge technology, art and engineering, Objex Unlimited designs and produces highly detailed physical models, Rapid Prototypes, Concept Models, end us production part and outstanding unique personalized products. We can bring your CAD designs to life by creating real parts you can use and models that can be held in your hand.

Don’t let prototype production hold up your design cycle. When we say rapid, we mean rapid. Our commitment to you is to deliver within days. Whether we 3D print your CAD designs, or work with you through the concept development stage, we offer a high level of quality, service and integrity.

Canada’s 3D Equipment Supplier

As Canada’s Authorized distributor and resellers of 3D Systems, Artec 3D, Mimaki 3D, INTAMSYS, 3DXTech and XYZ 3D Printing products we provide our clients many of the highest quality and most effective 3D solutions on the market; working with industries such as: Jewellery Design and Casting, Geospatial Prototyping, Medical Modelling, Architectural Models, Archaeological Modelling, Full Colour 3D Printing, Geometric Parts, Mechanical Modelling, Organic Art, Toy Development & Unique Art, to name a few.

Every member of our team is working hard to build relationships with proactive insight, responsiveness and a genuine desire to help you succeed.

TELL US ABOUT YOUR NEXT PROJECT.

Join Our Newsletter

Objex Unlimited

36 Fieldway Road,

Toronto, Ontario M8Z 3L2

Email: [email protected]

Phone: 416-233-7165

Mon – Fri

9am – 5pm EST

©2016 Copyright • Objex Unlimited • 36 Fieldway Road, Toronto, ON M8Z 3L2 • 416-233-7165 • Objex Unlimited 3D Printing Studio • Toronto’s 3D Printing and 3D Service Experts • Objex Unlimited is your resource for everything 3D. We take great pride in the services we provide, and will find the best 3D printing solution for you. We will work with you to complete your project and reach your goals ahead of schedule. We offer a variety of 3D printers, 3D scanners, 3D Design, Additive Manufacturing, Rapid Prototyping and 3D software, and will work with you to find the best solution for your needs. We are an authorized reseller of 3D Systems, Artec Group, LMI Technologies, Geomagic and Agisoft 3D products. Our talented and diverse staff deliver high-quality, industry-leading results. Our commitment is to fulfil your project needs within budget and on-time. Servicing: Canada, Ontario, Toronto, Montreal, Quebec, Edmonton, Calgary, Vancouver, Markham, Mississsauga, Oshawa, Richmond Hill, Concord, Durham, Ottawa, Waterloo, Kitchener, Windsor, Guelph, Vaughn.

We take great pride in the services we provide, and will find the best 3D printing solution for you. We will work with you to complete your project and reach your goals ahead of schedule. We offer a variety of 3D printers, 3D scanners, 3D Design, Additive Manufacturing, Rapid Prototyping and 3D software, and will work with you to find the best solution for your needs. We are an authorized reseller of 3D Systems, Artec Group, LMI Technologies, Geomagic and Agisoft 3D products. Our talented and diverse staff deliver high-quality, industry-leading results. Our commitment is to fulfil your project needs within budget and on-time. Servicing: Canada, Ontario, Toronto, Montreal, Quebec, Edmonton, Calgary, Vancouver, Markham, Mississsauga, Oshawa, Richmond Hill, Concord, Durham, Ottawa, Waterloo, Kitchener, Windsor, Guelph, Vaughn.

| 3DNews Technologies and IT market. Interesting news from the world of high-tech The University of Toronto has created a portable ... The most interesting in the reviews 05/07/2018 [23:00], Dmitry Prikhodko 3D printing is rightfully considered a simple and effective solution for simplifying the manufacturing process in the manufacture of components used in a wide variety of industries. The versatility of modern 3D printers allows them to build houses, create superior components for cars and other vehicles, and find applications in heavy industry. Such systems are no less in demand in medicine. Suffice it to recall ergonomic prostheses and those made taking into account the individual physiological characteristics of the patient and the complexity of his fracture of a splint made of polymeric materials. This time, scientists from the University of Toronto intend to make an improvised tool for healing deep wounds from a 3D printer. A portable 3D printer weighing less than 1 kg, resembling a marking label gun in appearance and operation, will cope with the task in about two minutes. The exact time of the operation will depend on the size of the damage to the skin. The device does not require a sample of the patient's epidermis, since Canadian specialists use the so-called "bio-ink" to form tissue layers. This material enters the skin in the form of strips similar to adhesive plaster, but differing from it in viscosity due to the presence of alginic acid in the composition. At this stage, the hand-held 3D printer has been successfully tested on animals, first rats and then pigs. The next step is clinical trials involving humans. Source: If you notice an error, select it with the mouse and press CTRL+ENTER. Related materials Permanent URL: https://3dnews.ru/969351 Categories: News Hardware, interesting things from the world of hi-tech, on the cutting edge of science, 3D technologies, Tags: 3d printer, medical ← В past To the future → |

McDonald's donated liters of oil for a scientific 3D printer

Repost

Lab student at the University of Toronto Scarborough

© Don Campbell / utoronto.ca

Author RBC Style

February 20, 2020

Professor Andre Simpson from the University of Toronto at Scarborough faced a problem - expensive and non-environmental ink for a 3D printer. It turned out that they can be replaced with vegetable oil, which McDonald's willingly provided to the laboratory.

It turned out that they can be replaced with vegetable oil, which McDonald's willingly provided to the laboratory.

Simpson runs the University's Center for NMR Spectroscopy, where he studies changes in the environment at the micro level, examining objects using nuclear magnetic resonance. This is similar to diagnosing diseases through magnetic resonance imaging, clarifies CNN.

“We take NMR spectroscopy and use it to look at tiny living organisms to understand their biochemical response to environmental change. The goal is to close the gap between medical research and the study of natural conditions, ”Andre Simpson explained to the correspondent.

Advertising on RBC www.adv.rbc.ru

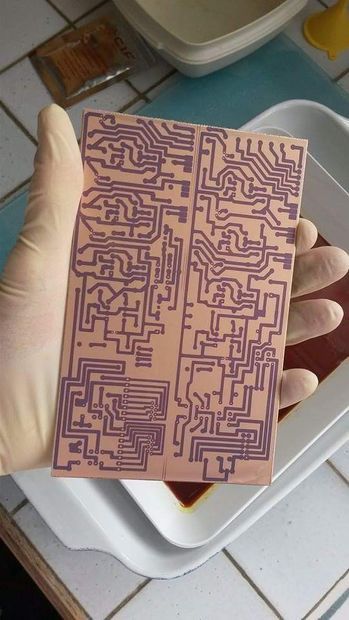

In 2017, the professor bought a 3D printer especially for his laboratory in order to create structures on site that would help organisms survive inside the NMR spectrometer during the experiment. However, plastic photopolymer for printing turned out to be not only not environmentally friendly, but also too expensive - $500 per 1 liter.

Anticipating ruin, Simpson decided to study the composition of the photopolymer and realized that some of its molecules are identical to those present in ordinary vegetable oil. “The thought came: what if we make a photopolymer for a 3D printer from vegetable oil?” the professor said.

Then another task arose before him and 10 laboratory assistants - to get the required volumes of used oil. The researchers applied to fast food restaurants near the university and were flatly refused everywhere. Almost everywhere: McDonald's unexpectedly agreed to a scientific adventure, giving out 10 liters of oil to the petitioners.

Butterfly printed with vegetable oil

© Don Campbell / utoronto.ca

The product was filtered and cleaned of food debris, then synthesized in small volumes over the course of a year in an attempt to convert them into material for 3D printing. The graduate student responsible for the process, Rajshri Ghosh Biswas, printed openwork butterflies from each synthesized and processed batch.

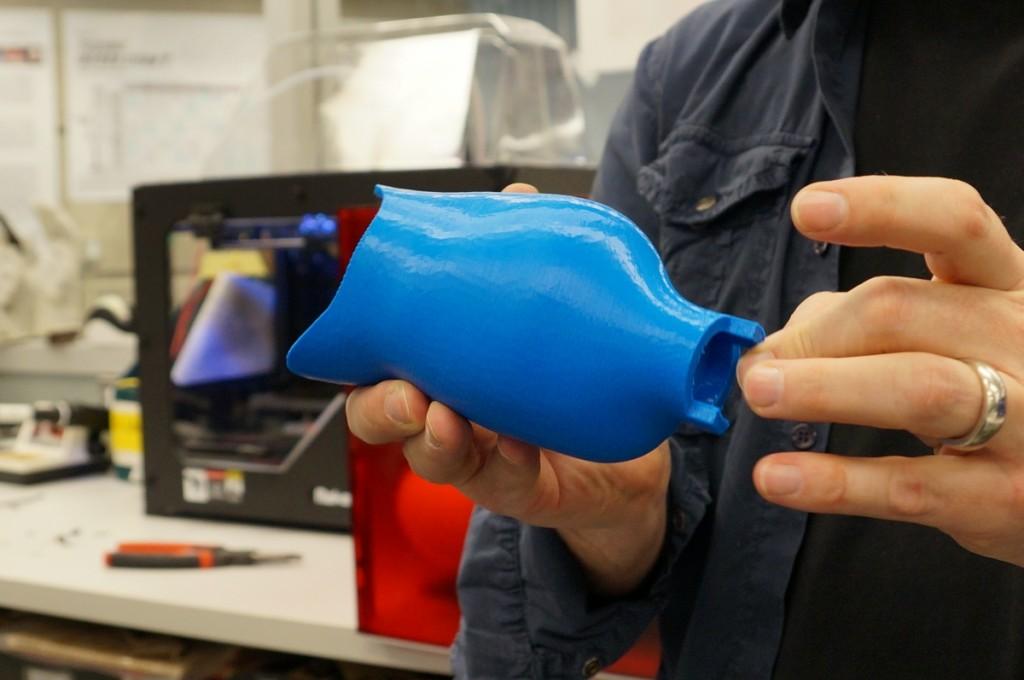

The skin graft device they showed in 2014, which is a kind of printer for printing the skin, has been significantly modified and acquired the form of a portable device. It is intended for a system for the rapid restoration of damaged areas of the skin by applying artificial cover to the affected areas. The device will allow you to independently treat wounds in the form of cuts or burns with damage up to the hypodermis (subcutaneous base), without resorting to the services of qualified medical personnel.

The skin graft device they showed in 2014, which is a kind of printer for printing the skin, has been significantly modified and acquired the form of a portable device. It is intended for a system for the rapid restoration of damaged areas of the skin by applying artificial cover to the affected areas. The device will allow you to independently treat wounds in the form of cuts or burns with damage up to the hypodermis (subcutaneous base), without resorting to the services of qualified medical personnel.  Artificial skin is based on living cells in combination with collagen and fibrin.

Artificial skin is based on living cells in combination with collagen and fibrin.