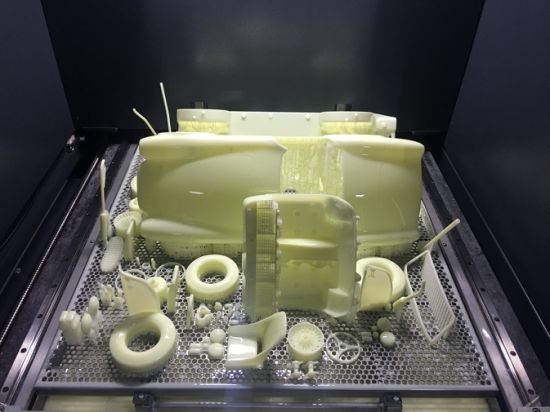

Ucf 3d printer

Manufacturing Lab - UCF College of Engineering and Computer Science

Days/Hours: Tuesday, Wednesday, and Thursday, 8 a.m. – 5 p.m.

Upon entering the Manufacturing Lab, please sign in on the clipboard and speak with the lab manager, Clarence Bess, before using the lab equipment to further discuss and develop your project. Don’t forget to sign out when leaving.

The Manufacturing Lab is also home to Limbitless Solutions.

Services

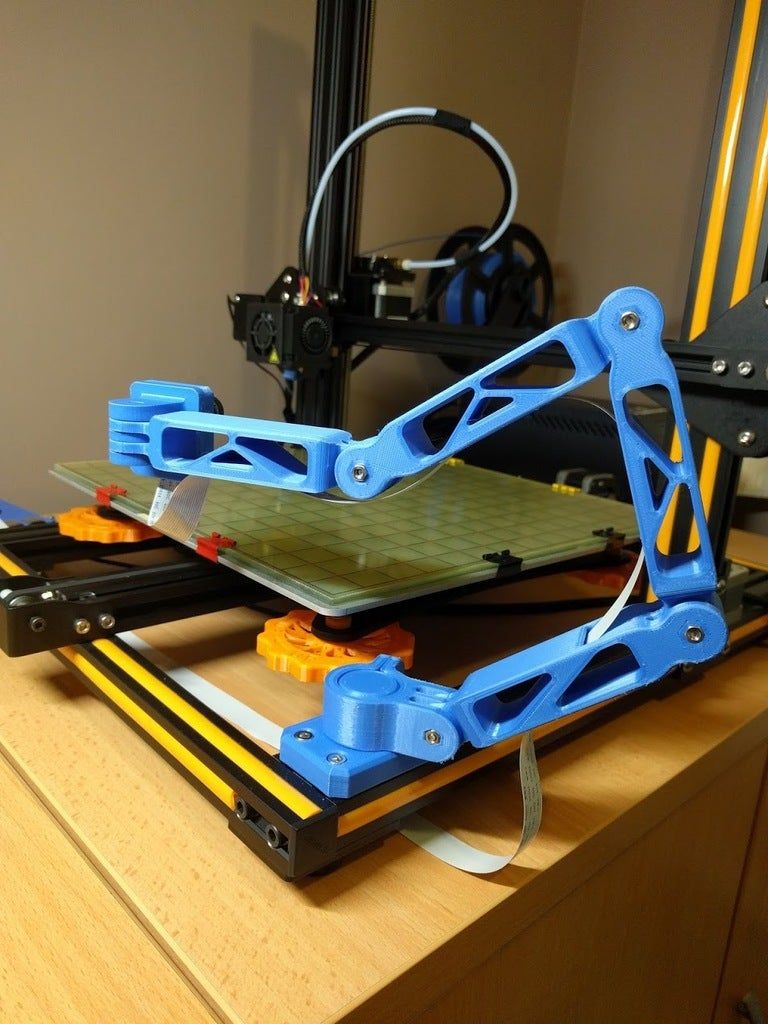

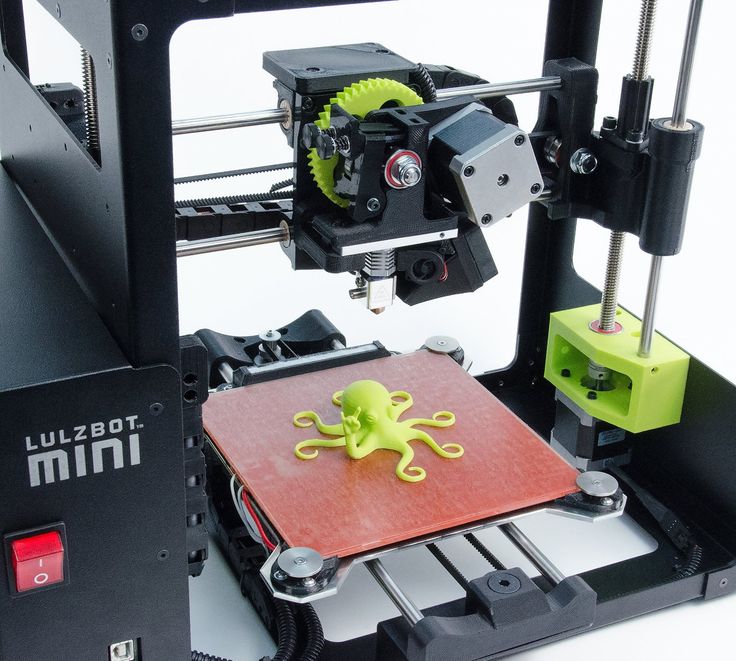

- 3D Printer (located in office) Please send over designs in a STL file. See below for information on how to make a request to use the printer.

- 3 Manual Milling Machines with digital read outs.

- Hurco

- Tri Onics

- Sharp

- Small Computer Numerical Control Milling Machine (Can be programmed to cut to cut aluminum, steel, copper, brass, wood, plastic. Does not cut concrete.)

- Haas VF-2, Milling Machining Center (holds 20 different tools and changes cutters/drills)

- Fadal Machining Center (folds 20 different tools and changes cutters/drills)

- Haas ST-10 Lathe

- Time Master Manual Lathe with digital readout and 5-foot bed.

- MasterCam Lab

- Run a program here before we go to the machine to see how it works. Includes simulator.

- Small supply of stock including wood, aluminum, steel, acrylic and copper.

- WellSaw Horizontal band saw

- DoAll Horizontal band saw

- DeWault cut-off saw (for cutting materials that are heat treated)

- Vertical cut-off saw

- 12-inch Compound Miter Saw (usually for cutting wood)

- Small Lathe, Jet Lathe with a 3-foot bed

- Hardware (screws, nuts, bolts)

- Basic tools

General Rules and Procedures

- Food and drinks are not allowed in the Manufacturing Lab.

- Please sign in and speak with Clarence Bess, lab manager, before entering the lab and working.

- No loose-fitted clothing or jewelry is permitted in the lab.

- Close-toed shoes only.

- Cell phones are permitted in the workspace.

- Clean up after yourself.

- To request a work order and receive a quote for a project, visit machinelab.

cecs.ucf.edu and click on request a quote > e2-113-mlserver > orders > add new item. Please allow up to 72 hours for a response.

cecs.ucf.edu and click on request a quote > e2-113-mlserver > orders > add new item. Please allow up to 72 hours for a response. - Don’t forget to attach your design (preferably in Solidworks) for machining. If the job is to be made on the 3D Printer, save your design as STL Files and then attach.

- Capacity: If no machines running – 20 people. If machines are in use – five people per one instructor. Eye protection needed.

Cost

- Any work completed by the lab manager is $40 an hour. Please see the General Rules and Procedures section, above, for more information on requesting a quote.

- The first half hour of work is free, but you must be present to watch and learn from the lab manager.

- For 3D Printer, the cost is $7/cubic inch for print jobs.

Contact: Clarence Bess, lab manager

[email protected]

(407) 823-1604

Please contact Clarence Bess to schedule tours and events.

-

Orlando Sentinel Oct. 8, 2022

What Florida learned from Hurricane IanProf. Thomas Wahl featured

-

Science Magazine Sept. 22, 2022

AI-based screening method could boost speed of new drug discoveryAsst. Prof. Ozlem Garibay featured

-

News 6 WKMG Aug. 7, 2022

In this Florida city, when drivers go the wrong way, most don’t crash. Here’s why.Prof. Haitham al-Deek featured

-

Phys.org July 14, 2022

High-tide floods surge as climate changes and sea level risesAssoc. Prof. Thomas Wahl featured

-

Spectrum News 13 April 28, 2022

Engineering students advance smart car technology as UCF tests driverless shuttlesAssoc. Prof. Yaser Fallah featured

- Read More

View Calendar

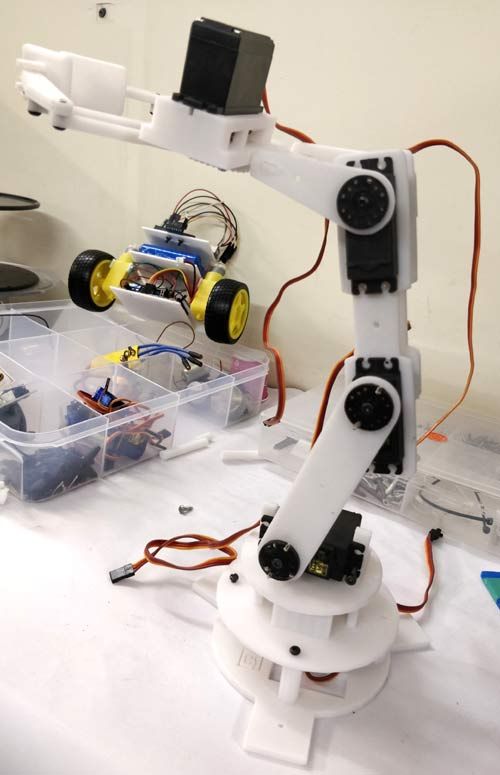

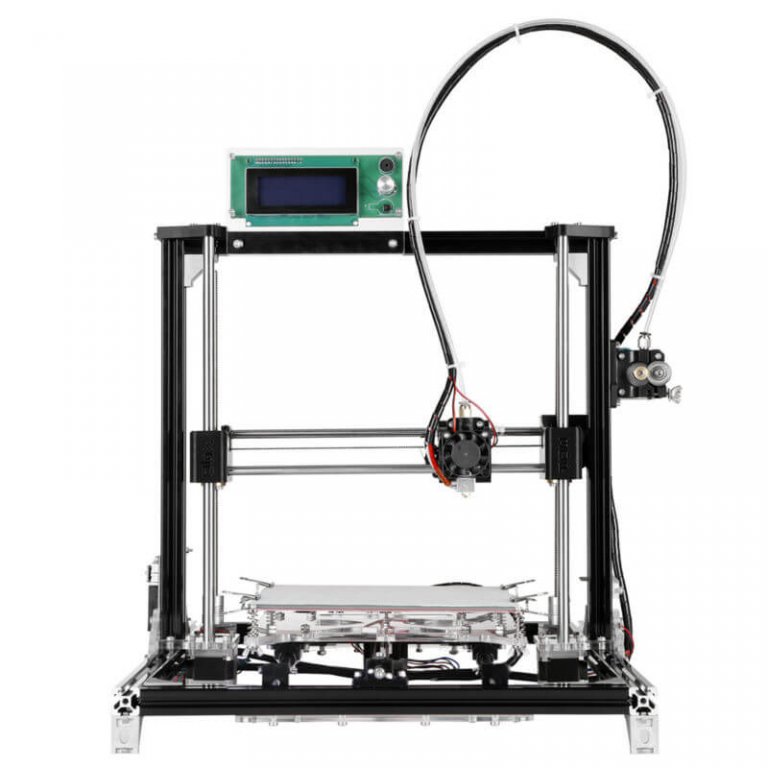

Army lab, UCF optimize 3D printing process | Article

ABERDEEN PROVING GROUND, Md. - Army researchers collaborated with academic partners from the University of Central Florida to improve additive manufacturing. This partnership may help deliver extreme lightweight components to future Soldiers.

- Army researchers collaborated with academic partners from the University of Central Florida to improve additive manufacturing. This partnership may help deliver extreme lightweight components to future Soldiers.

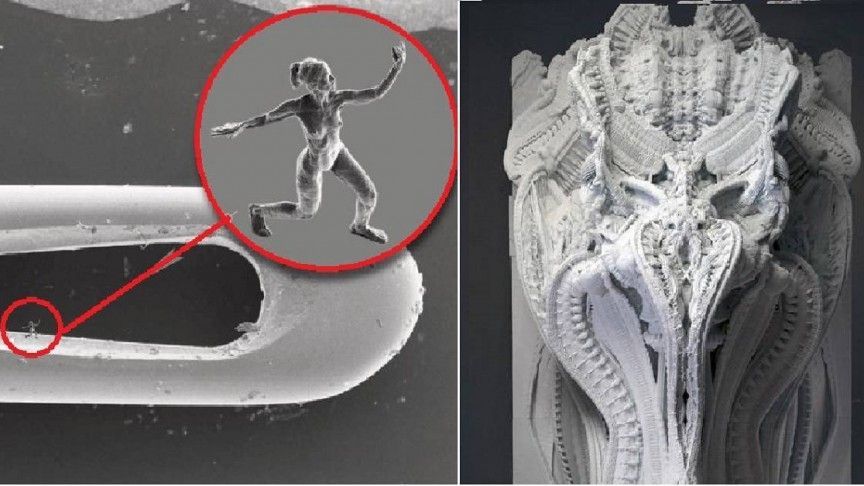

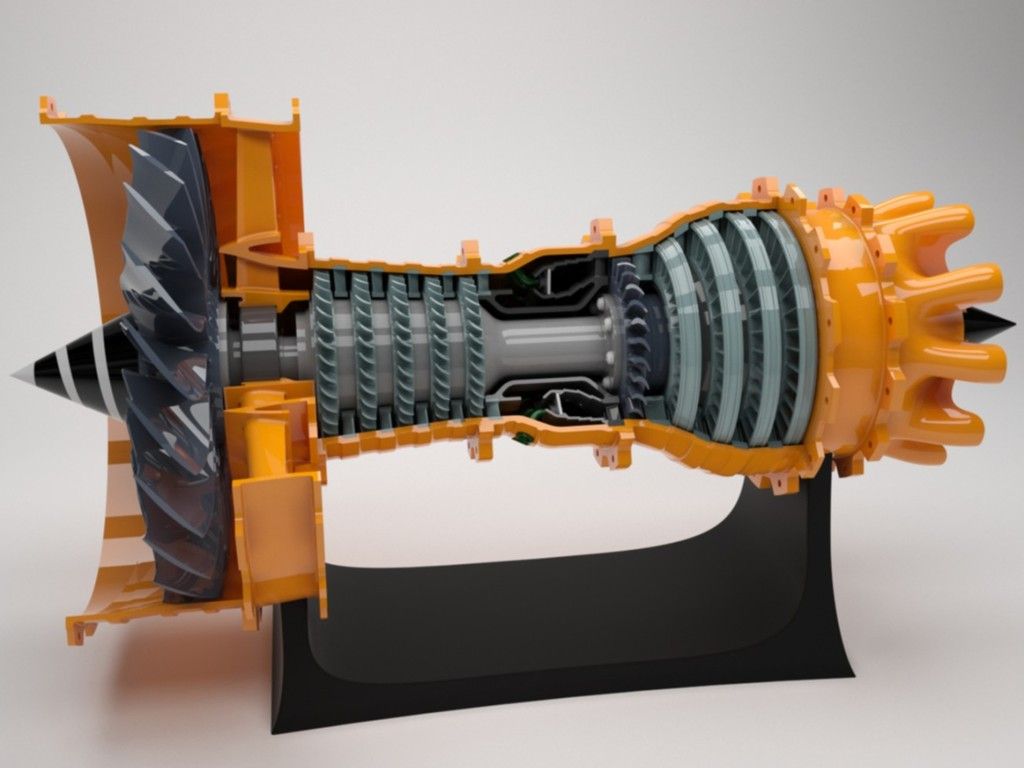

By optimizing the printing process for the additive manufacturing of a high-strength magnesium alloy and fabricating 24 micro-lattice structures, researchers characterized the compressive strength and failure modes, which will enable much lighter Army components.

“We used a magnesium alloy known as WE43, which has only been successfully 3D printed by a handful of researchers,” said Dr. Brandon McWilliams, the lead researcher for 3D printing metals at the U.S. Army Combat Capabilities Development Command, known as DEVCOM, Army Research Laboratory. “In this work, we optimized the process to achieve higher density than previously reported and used that to produce and characterize lattice structures made up of WE43.”

Magnesium Elektron WE43 is a high strength casting alloy. It can be used in temperatures of up to 300°C (572°F), according to AZoM, an online publication for the materials science community. “This alloy has good mechanical properties coupled with excellent corrosion resistance.”

It can be used in temperatures of up to 300°C (572°F), according to AZoM, an online publication for the materials science community. “This alloy has good mechanical properties coupled with excellent corrosion resistance.”

Advanced additive manufacturing has the potential to deliver critical parts at the point of need, reducing the need for lengthy logistic chains. Also, the U.S. Army’s modernization strategy calls for lightening the load to help support future Soldiers.

The research team published their findings in the peer-reviewed journal Materialia.

McWilliams said he believes joining advanced lightweight alloys with novel multi-scale structures through additive manufacturing will be a key aspect of modernizing Army weapon systems. There are many lightweight structural applications in the automotive, aerospace and biomedical industries.

“Current systems are too heavy, which increases burden to the Soldier, reduces fuel efficiency and degrades mission effectiveness,” he said. “It is my goal as an Army researcher to conduct research, which has the maximum chance of success of transition from basic and applied research stage to practical application in order to enable transformational overmatch.”

“It is my goal as an Army researcher to conduct research, which has the maximum chance of success of transition from basic and applied research stage to practical application in order to enable transformational overmatch.”

Partnering with academia and industry has been a priority with the laboratory since it introduced its Open Campus initiative.

“This was an exciting and rewarding collaboration that produced the technological accomplishment founded on fundamental understanding of materials and additive manufacturing,” said Prof. Yongho Sohn, lead researcher at University of Central Florida. “Technological vision with clear scientific objectives defined by Dr. McWilliams and his team was the key to our contribution.”

Army researchers will now evaluate the high strain rate and ballistic properties of these 3D-printed materials and look for demonstration applications, such as ultra-lightweight unmanned aircraft system and robotic vehicle components, he said.

Visit the laboratory's Media Center to discover more Army science and technology storiesDEVCOM Army Research Laboratory is an element of the U. S. Army Combat Capabilities Development Command. As the Army’s corporate research laboratory, ARL is operationalizing science to achieve transformational overmatch. Through collaboration across the command’s core technical competencies, DEVCOM leads in the discovery, development and delivery of the technology-based capabilities required to make Soldiers more successful at winning the nation’s wars and come home safely. DEVCOM is a major subordinate command of the Army Futures Command.

S. Army Combat Capabilities Development Command. As the Army’s corporate research laboratory, ARL is operationalizing science to achieve transformational overmatch. Through collaboration across the command’s core technical competencies, DEVCOM leads in the discovery, development and delivery of the technology-based capabilities required to make Soldiers more successful at winning the nation’s wars and come home safely. DEVCOM is a major subordinate command of the Army Futures Command.

New 3D-printed lunar regolith bricks can withstand 250 million atmospheres of pressure

Scientists are constantly coming up with new methods for building habitats on the Moon and beyond

As part of their Artemis lunar program, NASA has asked scientists to develop new building methods moon bases capable of withstanding the harsh conditions of our satellite.

Thanks to experiments conducted by the University of Central Florida, future lunar astronauts will be able to use bricks from lunar regolith and salt water to build bases. This was reported in a statement by the press service of the university.

This was reported in a statement by the press service of the university.

Moon outpost colony. 300ad/iStock

Ranajay Ghosh, professor at the Department of Mechanical and Aerospace Engineering, UCF, and colleagues have found that 3D-printed bricks from lunar regolith - dust and loose rock from the moon's surface - can withstand the moon's extreme conditions. The results of the study were detailed in a recent issue of Ceramics International.

The team combined 3D printing and Binder Jetting, an additive manufacturing process in which a liquid binder is placed on top of a layer of solid particles. "The Binder Jetting technique is ideal for refractory materials that are difficult to laser melt," says Ghose. "Therefore, this technology has a high potential for the sustainable production of regolith-based parts, components and building structures."

In their Binder Jetting experiment, the researchers used salt water as a binder, with powder acting as lunar regolith.

Ranajay Ghose and Peter Warren demonstrate space bricks

Regolith and human blood could form the basis for future space habitats

First, scientists printed raw blanks, which were then fired in a kiln at temperatures up to 1200 °C. This made it possible to manufacture products that can withstand pressures 250 million times higher than Earth's atmospheric pressure.

The team's work paves the way for future BJT crewed flights in space, Ghosh said. In addition, the results of the study show that bricks can be made in space from readily available materials. This is an extremely important discovery, given the fact that transporting a huge amount of building materials to the moon would be prohibitively expensive.

"The results of this experiment are an important argument in the ongoing debate about finding a balance between using extraterrestrial resources in situ and transporting materials from Earth," says Ghose. "The longer we improve technologies that use regolith, the more opportunities we will have to build and deploy outports on the Moon, Mars and other planets in the solar system. "

"

Last year, scientists at the University of Manchester proposed using the blood and urine of astronauts as a binder for future habitation on Mars. According to the authors, this approach will significantly reduce the cost and increase the speed of building future extraterrestrial colonies.

recommendations

Sources: University of Central Florida, Jouranl Interesting Engineering, Materials Today Bio

1. (https://www.sciencedirect.com/science/article/pii/S25

421000442)

2. (https://interestingengineering.com/science/3d-printed-bricks-withstand-pressures)

3. (https://www.ucf.edu/news/ucf-researchers-create-lunar- regolith-bricks-that-could-be-used-to-construct-artemis-base-camp/)

This content has been written by a website visitor and has been rewarded.

Scientific articles in the field of 3D printing

Monofilament is not the only form of consumable available for FDM 3D printing. A separate variety is a consumable in the form of a granule. A granule is the initial form of any plastic product. The monothread itself is also made from granules.

A granule is the initial form of any plastic product. The monothread itself is also made from granules.

Read more→

FDM and SLA 3D printing technologies have many differences: the printing process, the type of consumables and their cost, and most importantly, the quality of printed products, namely their resolution and smoothness. An SLA printer will not replace your FDM printer, since these are different tools that are good at different things.

Read more→

Our team is actively developing the production of composite materials for 3D printing, and recently, a new composite material has appeared on sale - PLA-CCF - this is PLA filled with crushed carbon fibers.

Read more→

Very often we receive requests about whether we do not accept waste that appears in the 3D printing process? (supports, monofilament pieces, unsuccessful printing, etc. ) In this publication, we will answer this question in detail and tell you where to dispose of 3D printing waste

) In this publication, we will answer this question in detail and tell you where to dispose of 3D printing waste

Read more→

Monofilament has a range of Elastan in various hardnesses: D70, D100, D160. Elastan D100 has the largest range of colors: white, beige, yellow, red, blue, green, metallic, black, while D70 and D160 are available in white and black. The problem with a unique color can be solved by ordering the desired individual color in quantities from 3 kg.

Read more→

In the 3D printing process, good adhesion of the printed product to the 3D printer platform is an important factor. If the first layer of the printed product does not adhere to the platform, then there is a high probability that the 3D printing will not be successful.

Read more→

ASA - acrylonitrile styrene acrylate - one of the worthy alternatives to ABS plastic, ideal for outdoor use. In this regard, the main areas of its use are the automotive industry, elements of landscape design, technical products for outdoor use, and advertising.

In this regard, the main areas of its use are the automotive industry, elements of landscape design, technical products for outdoor use, and advertising.

In addition to high hardness, rigidity and relative ease of 3D printing, ASA has good chemical resistance, temperature resistance and, most importantly, shape and color stability under the influence of various environmental factors. ABS products tend to yellow over time (to erode), especially when used outdoors. In the case of ASA, there are no such problems.

Read more→

ABS pro is a new improved plastic based on ABS, which eliminates the main disadvantages of ABS, such as: delamination and deformation during FDM 3D printing of bulk products, fragility of printed products during operation, low resistance to UV radiation.

In addition to the complete absence of delamination and deformation phenomena during FDM 3D printing of bulk products, ABS pro has increased strength to various types of deformation and resistance to UV radiation.

Read more→

While PLA and ABS are the top choice for FDM 3D printing materials, coPET is quickly gaining ground. The reason lies in the fact that coPET material is more durable, resistant to many solvents and does not lose its properties as quickly when exposed to environmental conditions compared to ABS and PLA. Another of perhaps the most important advantage of coPET over standard FDM 3D printing materials is the ease of FDM 3D printing, similar to PLA.

Read more→

Often, for the accomplishment of technical tasks, a material is needed, which is a bi-volod in a high quality, showing a sufficiently large amount of attention, especially in the case of details in working mechanisms. In this review, 4 plastics of structural designation are presented with a description of their features and directly zastosuvannya, which allow rationally choosing plastic for specific purposes and could.

Read more→

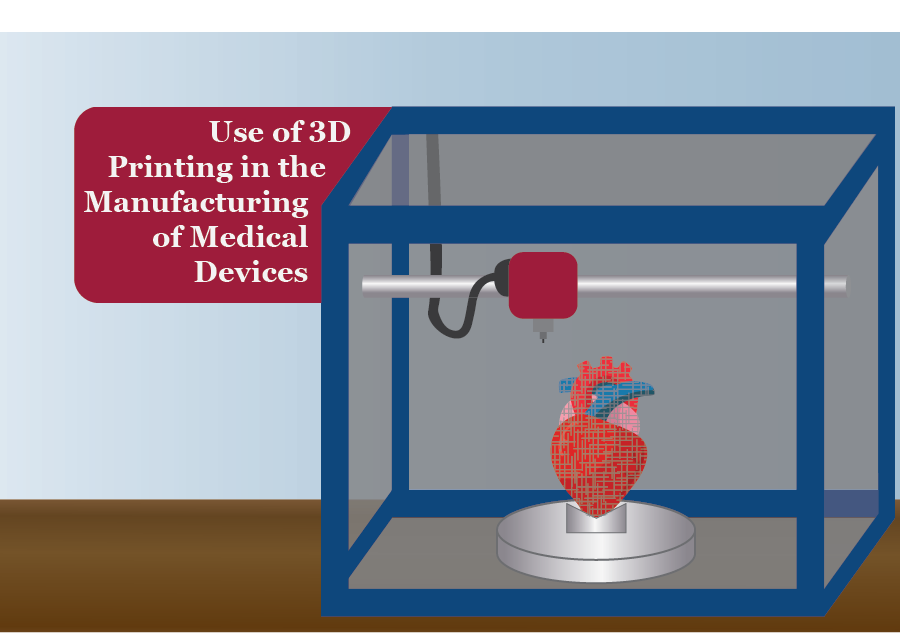

Currently, there is a growing interest in the production of biocompatible plastics for the creation of long-acting implants using additive technologies. Implant sizes are always different for different human vessels or bones and require a custom design. It is difficult for traditional processing methods such as injection molding or injection molding to compete with additive technologies due to their long production cycles and the high cost of molding tooling for product development.

Read more→

Clarity of products obtained with monofilaments with up to 97% light transmission using FDM 3D printing, is significantly reduced due to the imposition of layers on top of each other, which causes the light rays to scatter. best effect light transmission of the printed product, as it was noted, it is possible reach after post-processing SAN plastic.

Read more→

ABS, PLA, coPET? These plastics are thermoplastics (materials that become soft when heated and harden again when cooled, a process that can be repeated many times) and are all used in 3D printing.