Smartech 3d printing

About Us | Smartech Markets Publishing

Our coverage provides insight for those companies offering 3D printing services, materials and software sectors, as well as those that make the 3D printers themselves

SmarTech is the leading provider of market research and industry analysis in the 3D printing/additive manufacturing sector. We have published reports on most of the important revenue opportunities in the 3D printing sector including personal printers, low-volume manufacturing, 3D printing materials, medical/dental markets and other promising 3D market segments. Our client roster includes some of the largest 3D printer firms, materials firms and investors in the world. And you can follow SmarTech on Twitter where we discuss technology trends, company announcements and the industry’s on-going progress.

SmarTech Coverage Areas

Industry reports are our core deliverable, but we also carry out custom consulting when clients need more detailed assessments of companies and markets than can be included in an off-the-shelf report. In addition, SmarTech offers due diligence services to the financial community.

Equipment And Software

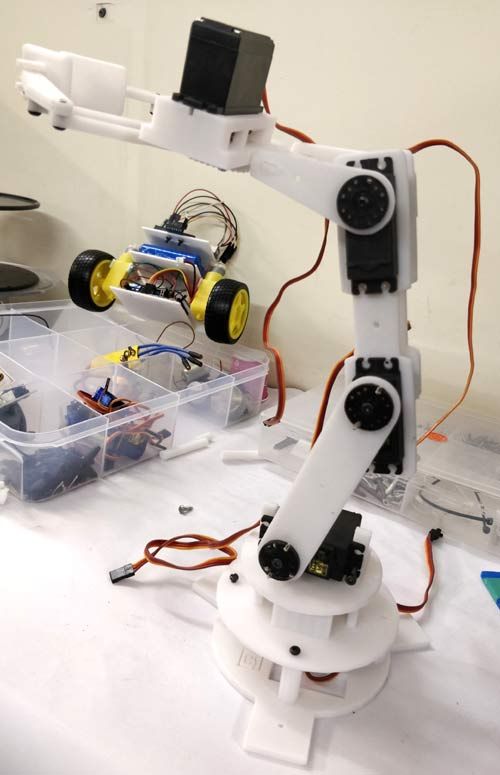

- 3D Printers

- Additive Manufacturing Software

Materials

- Metals

- Plastics

- Composites

- Ceramics

- Bio-Materials

End User Markets

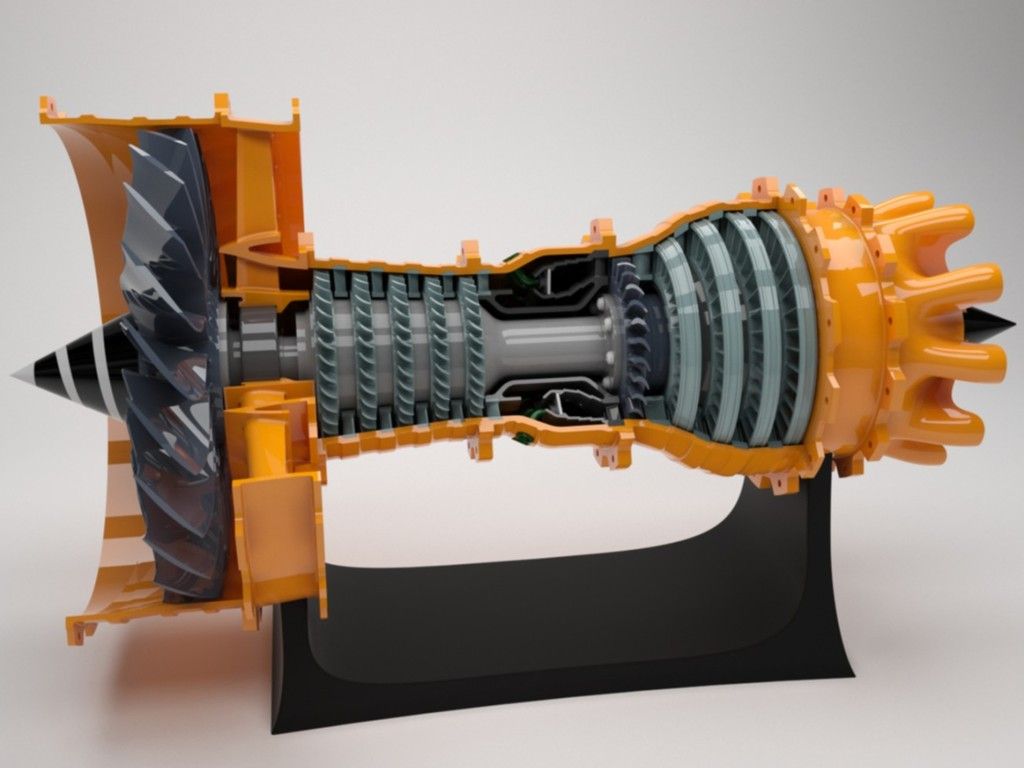

- Aerospace

- Automotive

- Oil and Gas

- Medical

- Dental

- Bio-Printing

- Consumer

- Industrial

- Service Bureaus

- Emerging

Why SmarTech?

When a company purchases a report from SmarTech Analysis or engages us for custom consulting, it receives comprehensive analysis that reflects today’s 3D printing market realities and tomorrow’s possibilities.

Detailed forecasts that are both believable and provide our clients with an edge over the competition. Actionable recommendations identifying where money will be made and where it will be lost. Candid market assessments based on today’s best strategic thinking, not just data dumps from the Internet. SmarTech offerings complement internal product planning and technology roadmapping and provide low-cost knowledge enhancement for firms in the 3D printing industry.

Clients

Smart Tech 3d Printing! 3d printing prototypes,Seattle,Tacoma,Evert ,Kirkland,

Materials and More

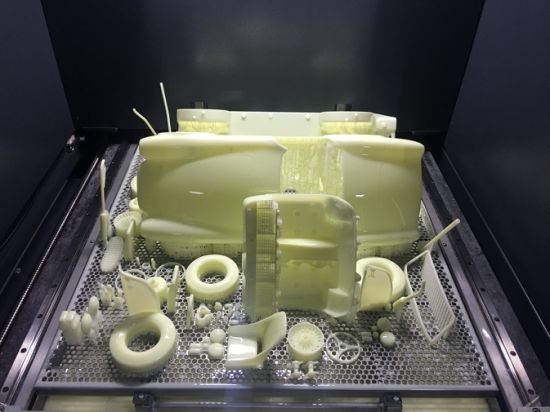

Our printers can utilize a variety of thermoplastics, including ABS, PLA, nylon, PETG, and more.

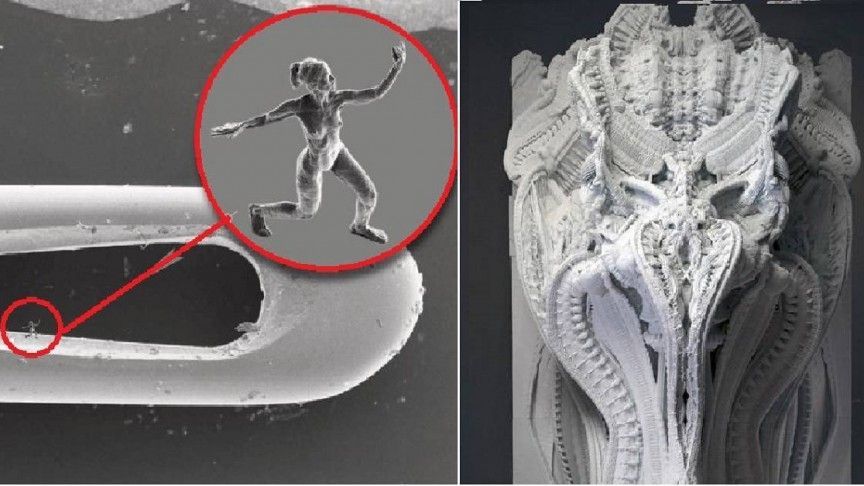

High Resolution, High Detail

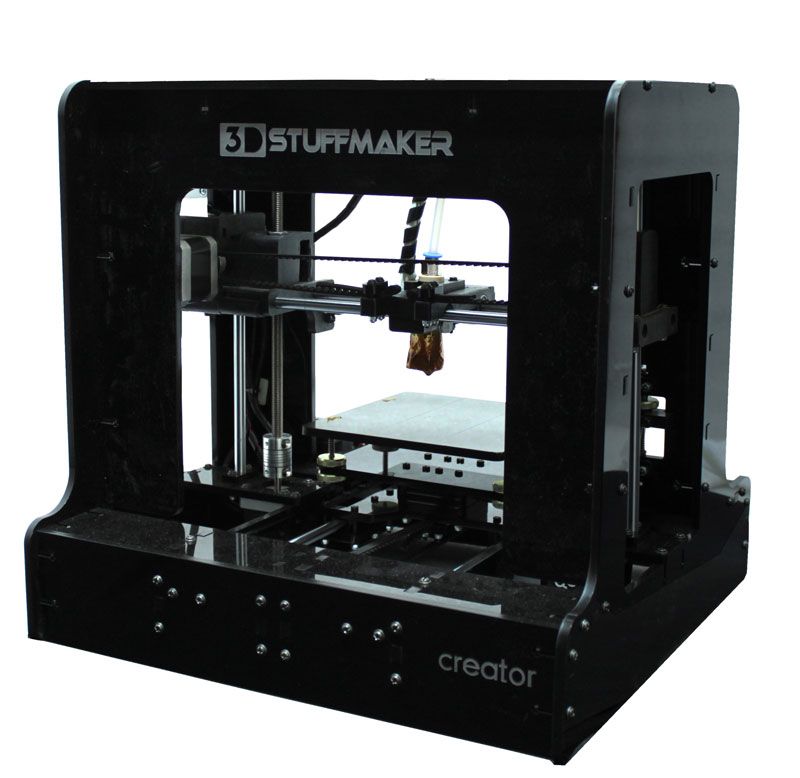

From our 100 micron FDM printers to our 16 micron Polyjet machine, our prints preserve the detail and accuracy of your models.

Truly Rapid Prototyping

We specialize in time-sensitive projects that need a quick turnaround time, whether you need hundreds of prints or just one.

3D PRINTING

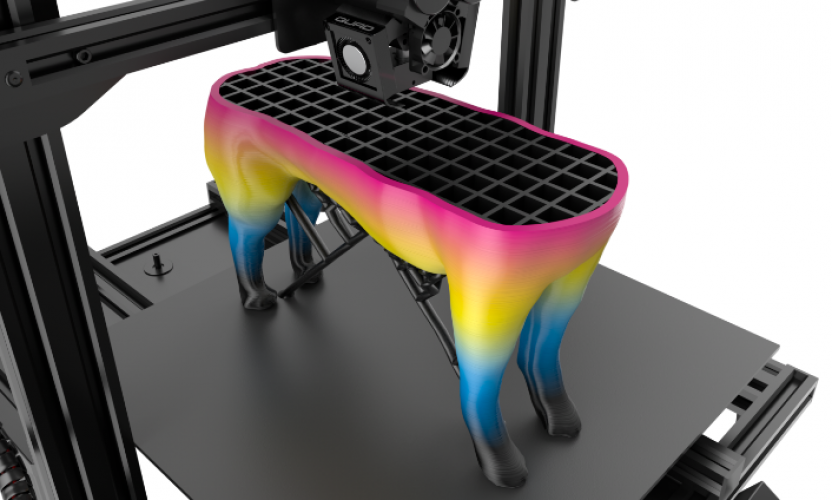

Our fleet of 3D printers can produce high resolution, professional quality prints in a variety of materials. Smart Tech 3D Printing allows startups to create fast, affordable prototypes to attract investors and set ideas in motion. And due to the highly-customizable nature of 3D printed objects, this new manufacturing process is revolutionizing the way that businesses interact with their customers.

Polyjet

SLA

Stereolithography Apparatus

Description

- A Stereolithography Apparatus uses a laser to draw each layer of the print onto a vat of liquid resin, layer by layer.

Advantages

- Smooth surface finish

- Extremely high resolution

- Rigid, flexible, or clear parts are possible

Limitations

- Prints tend to be brittle

-

Parts are vulnerable to UV light, such as from the sun

- Limited material options compared to FDM

Gallery

Get a free quote today.

425-614-6451

Sprayed liquid photopolymer

Statistics

✓ Max single part size:

20" x 20" x 20"

0.016 mm vertically

✓ Potential materials:

Opaque or clear resins, variety of colors

Minimum 0.5mm wall thickness

✓ Cost per square inch:

Please call for a quote.

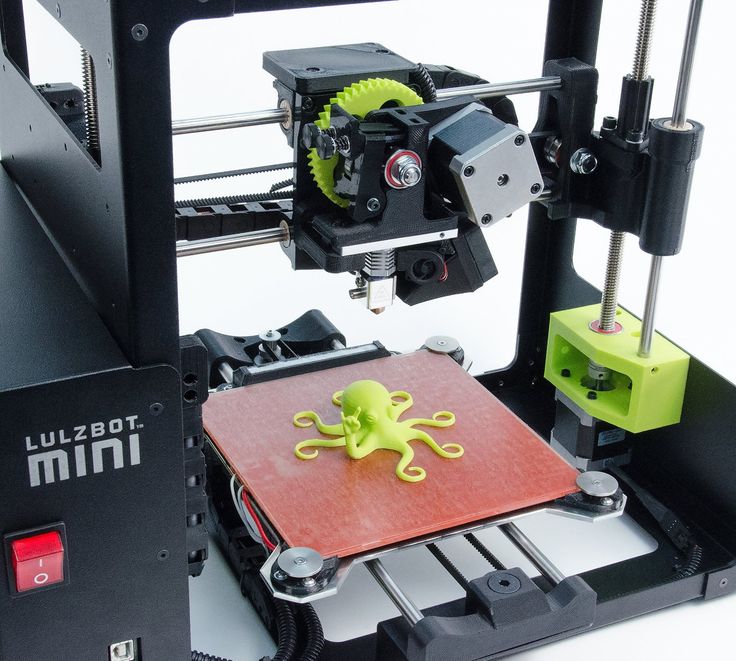

FDM

Fused Deposition Modeling

Description

- Fused Deposition Modeling builds up a model by extruding very thin layers of thermoplastic onto the build plate. FDM processes can use a wide range of materials.

Advantages

- Cost effective and efficient

- Resolution up to 0.1 mm

- Easily post-processed for a smooth finish

- Functionally unlimited build size via plastic welding

- Diverse selection of materials in a huge variety of colors and effects

Limitations

- Prints will have fine ridges on the vertical axis, known as layer lines.

- Postprocessing is necessary to remove these artifacts.

- Lesser resolution than other processes.

Statistics

✓ Max single part size:

48" x 48" x 40" (unlimited size w/ welding)

0.05 mm vertically

✓ Potential materials:

ABS, PLA, PETG, nylon, flexible materials, etc.

Minimum 0.5mm wall thickness

✓ Cost per square inch:

Please call for a quote.

Description

- Polyjet 3D printing utilizes a nozzle that sprays very fine droplets of photopolymer layer by layer.

Advantages

- Smooth surface finish

- Extremely high resolution of up to 0.016 mm

- Both rigid and flexible parts are possible

Limitations

- Less cost effective

- Maximum print size of 12" x 20"

- Limited selection of materials

Statistics

✓ Max single part size:

12" x 20"

0.016 mm vertically

✓ Design considerations:

Minimum 0.2mm wall thickness

Please call for a quote.

Smart Build is building a two-story 3D printed house in Stavropol

News

The project is being implemented on the territory of the Stavropol regional industrial park "Master".

“There is another company in Russia that prints at home, but they don’t have this level of industrial printer. We came up with it ourselves and brought the idea to life. Today, for the company, house printing is like an additional service, plus other areas that we are developing in the construction industry. The near future, I have no doubt, is a large-scale one for this technology. People will very soon be convinced of the benefits of building buildings using a 3D printer,” said Ilya Medvedev, co-founder of Smart Build.

The project is of a demonstration nature, two weeks are allocated for implementation. The building will house a microelectronics assembler shop: the interior layout includes a workshop and storage rooms, the management will be located on the second floor.

“An important advantage of this technology is that we give architects a free hand. A 3D printer allows you to create such forms of a house or building that are not available with standard construction technologies. It makes no difference to the printer whether to print round houses or diamond-shaped ones,” said Ilya Medvedev.

It makes no difference to the printer whether to print round houses or diamond-shaped ones,” said Ilya Medvedev.

Soon the company intends to build two houses on Berezovaya Street - one of standard brick construction, the other of concrete using a 3D printer. The foundation has already been laid, and in the near future the company will begin 3D printing of fixed formwork outdoors.

“Our production will help stop labor migration. Today it is a two-story building, in the near future it is possible to build buildings up to five floors high,” said Ilya Medvedev.

Report from Svoe TV channel:

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at news@3Dtoday. ru.

ru.

construction Stavropol Smart Build

Follow author

Follow

Don't want

13

More interesting articles

ten

Subscribe to the author

Subscribe

Don't want

On October 21, the solemn opening of the production site for the production of so-called...

Read more

5

Subscribe to the author

Subscribe

Don’t want

Rostec State Corporation presented at the Weldex-2022 exhibition a vacuum cathode-beam...

Read more

82

Subscribe to the author

Subscribe

Don't want

Collaboration 3D

We are pleased to present you our joint development with Speci. ..

..

Read more

3D printing: the possibilities of additive technologies

Additive technologies or 3D printing is the process of creating an object that exactly corresponds to a three-dimensional model by applying material layer by layer. This innovation has become a global trend. The main advantage of the technology is resource saving. Losses of useful substance tend to zero.

Area of application

3D printers have not yet penetrated into every home, but they are already present in all key areas of human life. 3D printing is in demand in the automotive industry, energy, medicine, food industry, construction/design, fashion industry.

In resource- and labour-intensive industries, the development of a product prototype costs a lot of money. With traditional casting or machining technologies, this takes weeks, months. Using the possibilities of volumetric printing, the work is done many times, and sometimes dozens of times, more quickly. At the same time, the quality does not suffer at all and the parameters of the product remain extremely accurate. By the way, the strength of the prototype is more than 20% higher than that of the classic production.

At the same time, the quality does not suffer at all and the parameters of the product remain extremely accurate. By the way, the strength of the prototype is more than 20% higher than that of the classic production.

In medicine, the possibilities of 3D printing are used to design dentures, skeletons, and even internal organs. Additive technologies make it possible to create a medical instrument with certain parameters for specific patients with pathologies and anatomical features. This allows you to take a huge step forward in training and preparation for operations.

In 2011, a kidney was “drawn” on a 3D printer. Scientists have created an exoskeleton to support atrophied muscles. There are even special “pens” that “draw” living cells on injured skin areas.

On 3D printers, models of premises are created with a visual study of interiors, buildings and entire residential areas with details of houses, utilities, and infrastructure facilities.

In the field of science and education, the benefits of 3D printing are expressed in the creation of visual aids with which the learning process becomes easier and more efficient.

3D printing is in demand in the fashion world. On the printer, you can create shoes, clothes, perfume bottles. While this process is expensive, therefore, it is not used in mass production. However, piece products made on 3D printers are already presented on the catwalks.

Creative 3D Printed Sandals

The advantage of introducing AF technologies into the light industry is the ability to create products for a specific physique/foot shape. This is especially true for athletes, people with deviations of the anatomical structure. For example, designer Ross Berber introduced the world to shoes printed on a 3D machine. His collection includes 5 pairs.

3D printing allows for a breakthrough in innovation. Before a product can be mass-produced, the prototype must be tested and repeatedly tested. This is done on 3D models. You can create them in minutes.

This is done on 3D models. You can create them in minutes.

Three-dimensional technologies are used in jewelry, when creating maps of the area, making souvenirs, customizing finished products (applying a pattern, logo).

How does a 3D printer work?

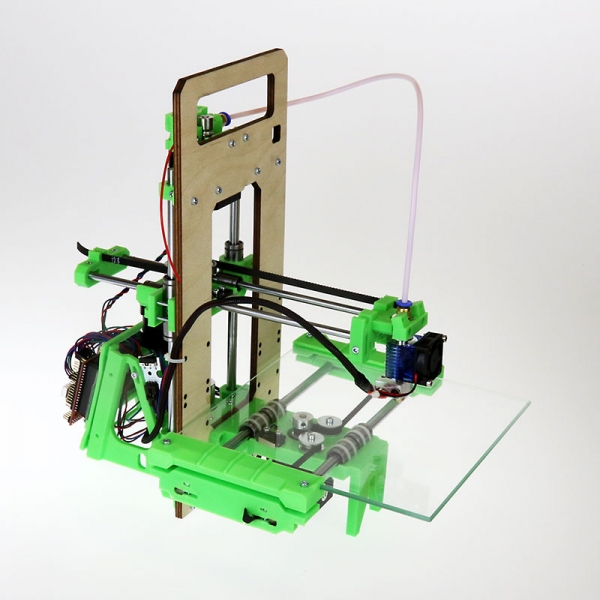

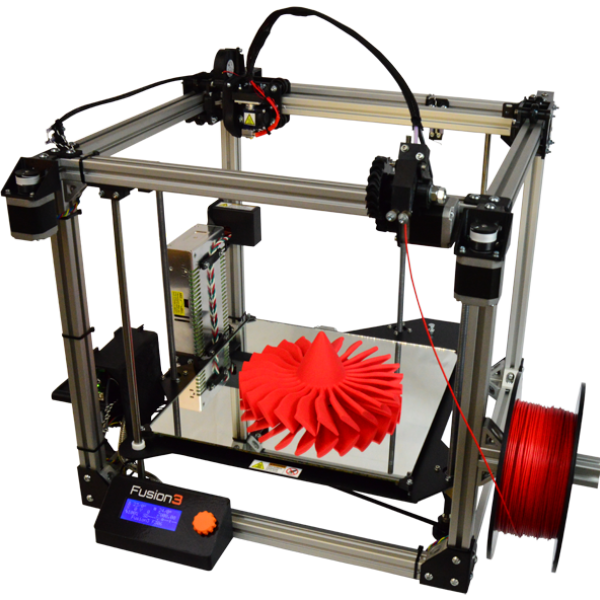

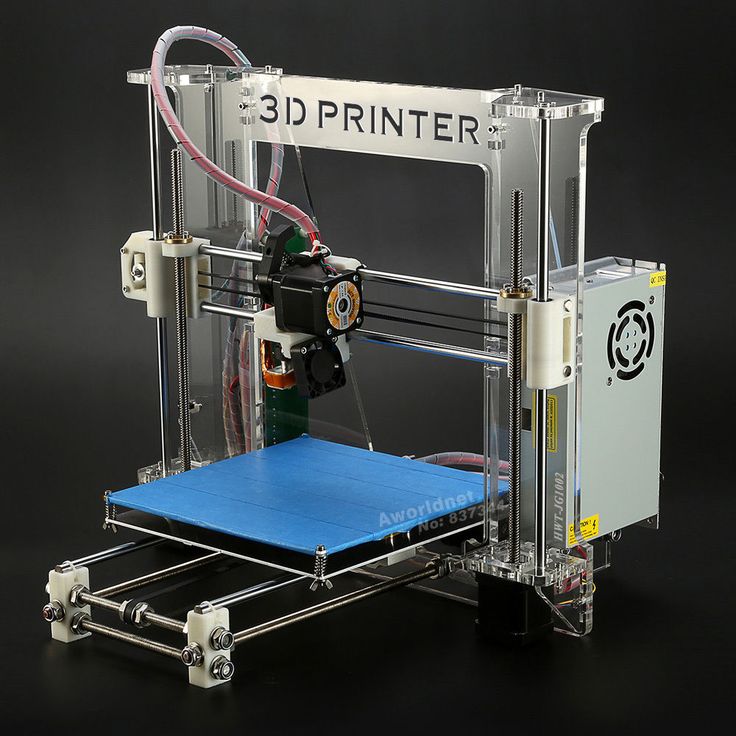

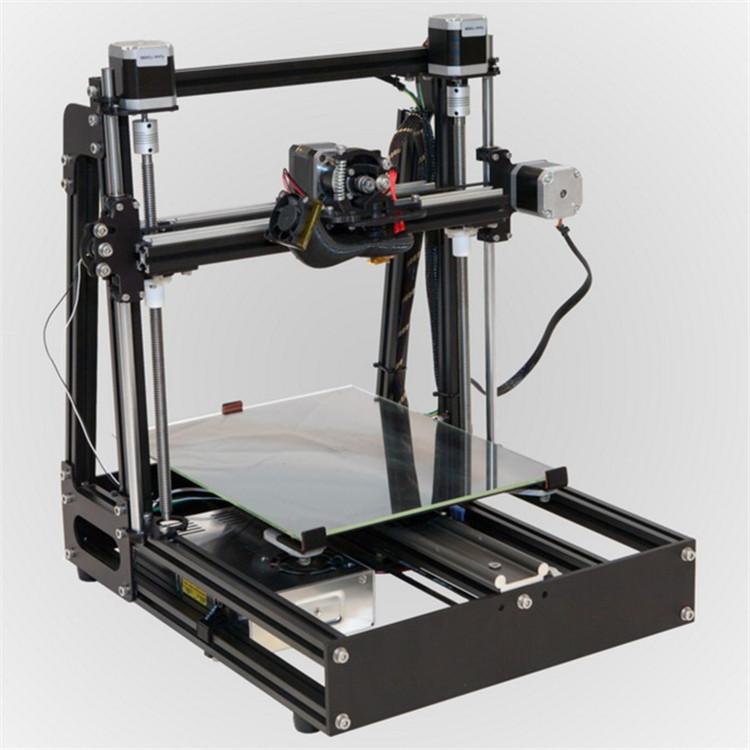

A classic 3D printer is a 3D printing device that works on the principle of FDM (Fusion Deposition Modeling). On three-dimensional equipment, you can create an object of almost any shape, with curves, a relief surface. The product "increases" simultaneously in the horizontal and vertical direction.

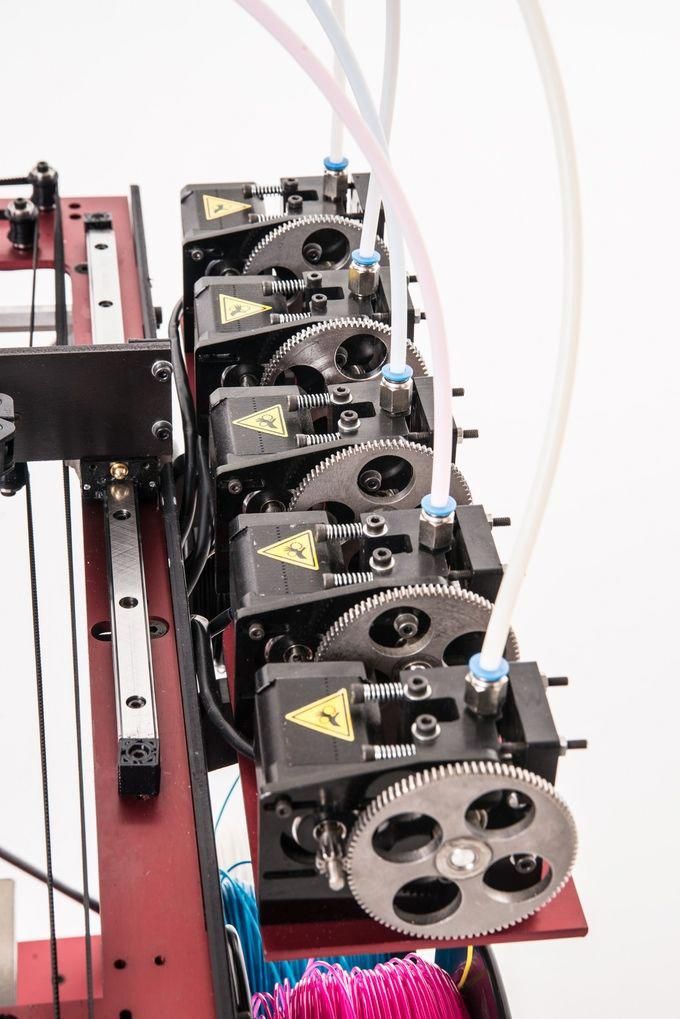

Printers work with various materials: plastic, metal, and so on. With their help, you can create parts that can withstand a significant load. In order for the printer to print three-dimensional figures, it is equipped with:

- extruder - for heating and forcing plastic through the printheads;

- motors (usually linear) - set in motion the mechanisms;

- work surfaces - the platforms on which everything happens;

- sensors for fixing moving parts;

- Cartesian robots - devices moving along three axes.

Printers work differently, but the classic sequence of actions can be described by a single algorithm. First, a 3D image is created. This requires specialized software. After that, the model is “cut” into horizontal layers. A special program (G-code generator) is also provided for this. The computer converts the codes into information that the 3D printer can recognize. The next step is to recreate the model.

Smartprint HB-8 3D printer

3D Printing Technologies

There is monochrome and color 3D printing - more than a dozen technologies (plus their modifications). Among the most common:

- SLA - stereolithographic laser printing. The technology provides the creation of models with high detail. Its essence is the layer-by-layer application of a photopolymer material. It hardens under the influence of a laser. Then the working platform is lowered. A translucent composition is used as a photopolymer: it is easy to process, paint, glue.

- SLS - the technology is suitable for working with plastics and metals. The reagent is sintered under the laser beam. The products are very durable.

- HPM - printers work with thermoplastic, auxiliary soluble materials. The latter are used to create complex multilevel models with cavities and functional holes. Finished products may have a different shape. They are durable, resistant to stress, mechanical and chemical stress.

- DLP is a relatively new 3D modeling technology. The printers that support it print with photopolymer resin. The material hardens when exposed to light.

The most progressive technologies are EBM and SLM. The first involves the impact on the material with an electron beam, and not with a laser, the second works with metals.

Equipment for 3D printing is produced by companies from the USA, Europe, and Asia. Among the famous ones are Photocentric, 3D systems, Makerbot, Azuma Engineering Machinery Inc. and others.

and others.

3D model of the ship strikes with realism

Advantages of additive technologies

The advantages of 3D printing include:

- Resource efficiency. Products are "grown" from scratch, that is, the production is completely waste-free. For comparison: when creating a blank using traditional methods, material losses sometimes reach up to 85%.

- Efficiency. The time from the development of the layout to the receipt of the product can be reduced several times, or even tens of times, without compromising quality.

- Mobility. The equipment is compact, layouts can be transferred online.

- Precision. Layered synthesis ensures absolute compliance with specified technical parameters.

- Strength. The indicator is 25–30% higher than that of products obtained by traditional methods (forging, casting).

- Weight. This is an important advantage for industry, aircraft and mechanical engineering. The mass of individual products is reduced by 40–50% without loss of strength.

Souvenirs and toys are successfully printed in Russia using 3D printing technology

3D printing is also used in advertising printing. For example, for the production of souvenirs. Advertising agencies involved in cross-marketing willingly order a range of services, which includes both traditional production of business cards or flyers, as well as innovative solutions.

An overview of 5 modern 3D printers that appeared on the market in 2017, see the video:

Results

- 3D printing is in demand in almost all areas (industry, medicine, education, energy).

- In some industries, additive technologies are already actively used, in others they are just being introduced.

Learn more