Types of metal 3d printing

Types of 3D Printing in Metal

Metal powder is the backbone of metal 3D printing. Though it’s difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. The vast majority of metal 3D printing technologies utilize metal powder. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. These methods vary greatly, ranging from using high energy lasers to fuse loose powder to extruding bound metal powder filament. In this article, we’ll take a look at the most heavily used types of metal 3D printing, how they work, and why they’re beneficial.

Powder Bed Fusion

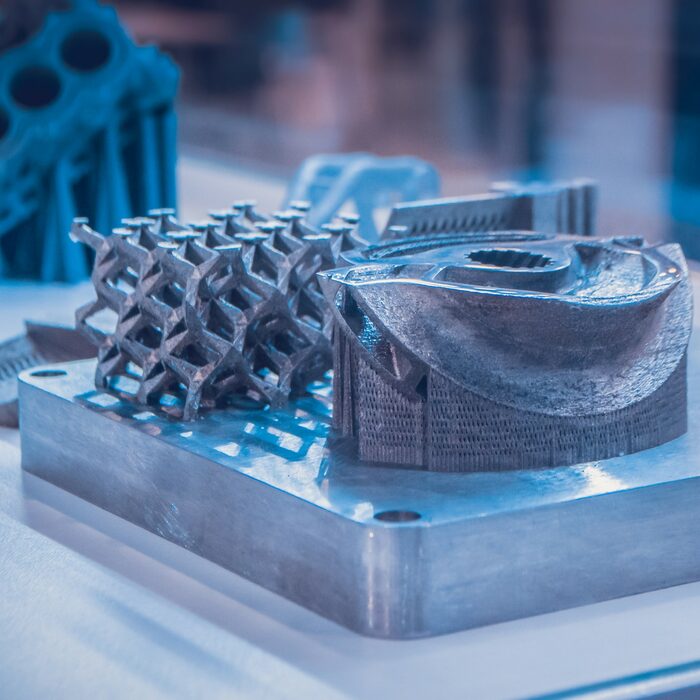

Known by many names, powder bed melting is currently the most common type of metal 3D printing. These machines distribute a fine layer of powder over a build plate and selectively melt a cross section of the part into the powder layer. There are two distinct types of powder bed melting techniques: Selective Laser Melting and Electron Beam Melting.

Selective Laser Melting (SLM)

Also known as: Direct Metal Laser Sintering (DMLS), Selective Laser Sintering (SLS), Direct Metal Printing (DMP), Laser Powder Bed Fusion (LPBF).

The majority of Powder Bed Fusion machines are Selective Laser Melting (SLM) machines. SLM machines use high powered lasers to fuse metal layers into parts. After a print, an operator removes the part (or parts) from the powder bed, cuts the part away from the build plate, and post processes the part. It’s the current standard for metal printing -- most companies in Metal AM today sell SLM machines.

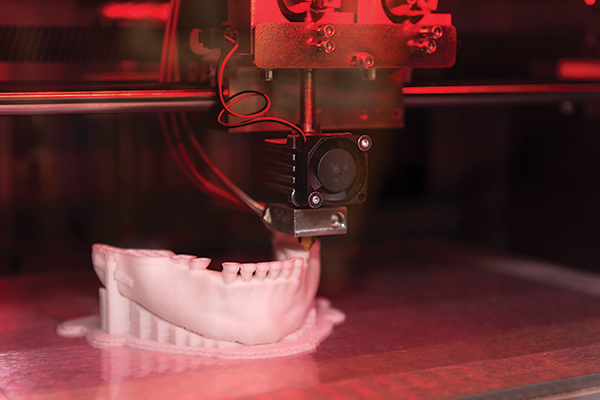

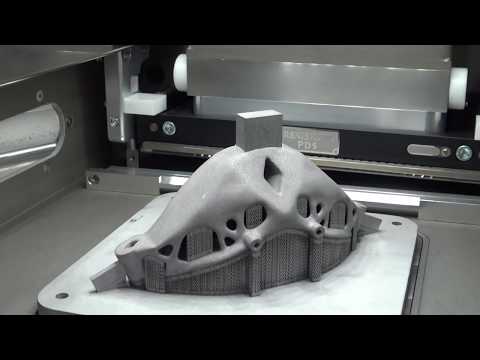

An SLM machine while printing.

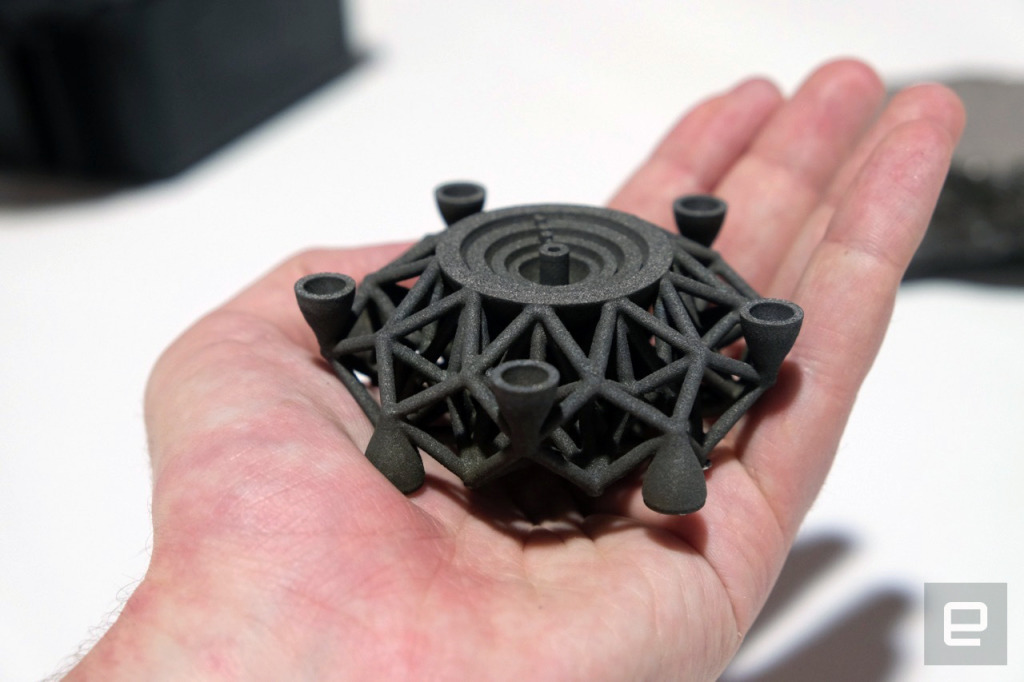

As the most mature variety of metal 3D printing, SLM is often considered the standard that other technologies are evaluated against. SLM printed parts are great for precise, geometrically complex parts that would not be otherwise machinable. They fit into a wide variety of applications: from dental/healthcare to aerospace. Build volumes range from very small (100mm cube) to large (800mm x 500mm x 400mm) and print speed is moderate. Precision of these machines is determined by laser beam width and layer height. Most materials available to be 3D printed today can be used on an SLM machine.

Precision of these machines is determined by laser beam width and layer height. Most materials available to be 3D printed today can be used on an SLM machine.

While these machines are groundbreaking, a wide variety of facility and post processing requirements limit these machines to industrial users. SLM machines require trained professionals to operate them. Because of its intricate process, many parts need to be printed and tweaked a few times to yield results. After printing, most parts require significant post processing and heat treatment. In addition, the metal powder that these machines use is both extremely dangerous and expensive to handle: most fully baked SLM machines cost upwards of 1M dollars to implement and a dedicated technician to run.

Electron Beam Melting (EBM)

EBM machines use an electron beam instead of a laser to fabricate parts. GE Additive is the only company producing EBM machines. The electron beam yields a less precise part than SLM, but the process as a whole is faster for larger parts. These machines have almost all of the same constraints, costs, and issues as SLM machines, but are used more heavily in aerospace and medical applications than anywhere else. Similarly to SLM, EBM machines cost upwards of 1M to set up and require a dedicated technician to run.

These machines have almost all of the same constraints, costs, and issues as SLM machines, but are used more heavily in aerospace and medical applications than anywhere else. Similarly to SLM, EBM machines cost upwards of 1M to set up and require a dedicated technician to run.

Direct Energy Deposition

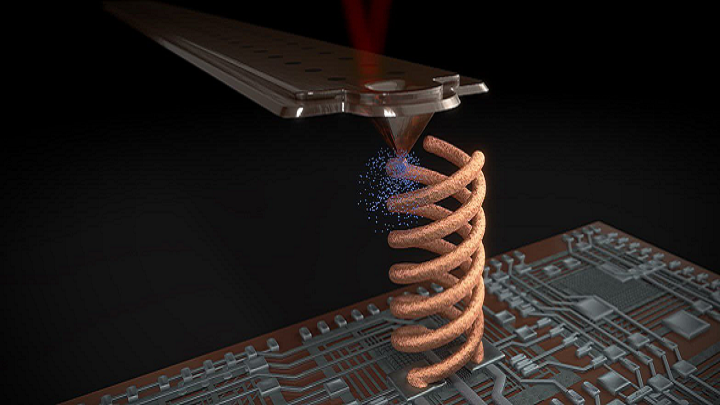

Direct energy deposition uses metal feedstock and a laser to fabricate parts. Unlike powder bed fusion, the stock (which can be powder or wire) and the laser both sit on a single print head that dispenses and fuses material simultaneously. The resultant parts are very similar to Powder Bed Fusion, with a few key differences and opportunities.

Powder DED

Also known as: Laser Material Deposition (LMD), Blown Powder

The sibling of Selective Laser Melting, Direct Energy deposition also uses a laser and metal powder to fabricate metal parts. Instead of spreading powder on a bed and melting it with a laser, DED machines precisely blow powder out of a print head onto a part, using an on-head laser to fuse it to the part in construction.

A BeAM DED 3D printer depositing and melting metal powder with a dual purpose print head.

As both machines use metal powder and a laser, parts printed with DED are very similar to those printed by SLM with one key exception: DED machines can utilize their unique powder distribution system to “heal” non printed parts that have deficiencies. Their available materials, post processing and powder management requirements are analogous to SLM, and machines also cost in the 1M dollar range.

Wire DED

Also known as: Electron Beam Additive Manufacturing, or EBAM

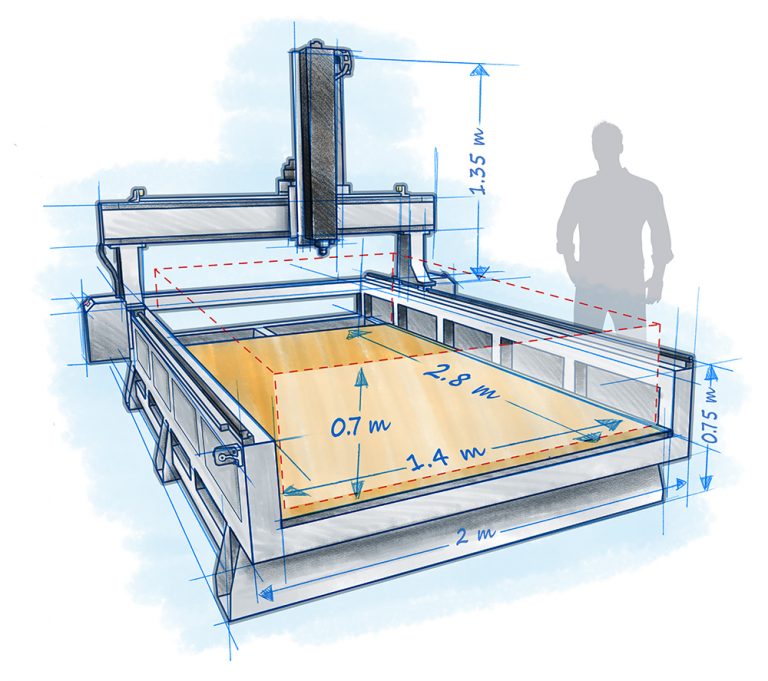

Wire DED machines use a laser to melt feedstock in a very similar manner to their powder DED relatives -- however, their feedstock is metal wire instead of blown powder. It’s a niche technology used with larger build volumes (as large as 5m x 1m x 1m) and faster print times at the expense of precision and quality. As a result, Wire DED parts are designed to be significantly larger and less precise than powder bed machines. These machines cost several million dollars per unit and are extremely uncommon in the space.

These machines cost several million dollars per unit and are extremely uncommon in the space.

Binder Jetting

Binder Jetting is a large scale, high fidelity method of metal 3D printing that may replace SLM as the premier loose powder based method of 3D printing. The field has exploded from a single manufacturer to a variety of companies (including AM industry leaders) in the last two years. Due to its speed and scalability, it may be the technology that propels metal additive manufacturing capabilities into production volumes.

The technology behind metal binder jetting reflects what a conventional (2D) printer uses to quickly jet ink onto paper. First, a binder jetting machine evenly distributes metal powder over its print bed, forming an unbound layer. Then, a jetting head much like one in a 2D printer distributes binding polymer in the shape of the part cross section, loosely adhering the powder. The process repeats until the machine yields a finished build of completed parts.

A Digital Metal binder jetting machine, capable of producing fine detail.

Parts printed on Binder Jetting machines require a post processing step called “sintering” to become fully metallic. In this process, the printed part is heated in an oven to just below its melting temperature. The binding material burns away and the metal powder unites into a full metal part. This process can be done in batches, meaning that it doesn’t significantly affect throughput.

Vacuum furnaces are usually massive, industrial grade machines.

Binder Jetting holds two main advantages over Selective Laser Melting. First, machines CAN print much faster by using multiple heads to jet in several places simultaneously. Second, the machine can make tens or even hundreds of the same part in one build. These parts can be sintered in a large furnace to achieve a manageable batch production infrastructure. As a result Binder Jetting is significantly faster on a per part basis than any other type of metal printing. With this speed (and powder management requirements) comes massive costs -- currently, the only machines in this space cost well over a million dollars.

With this speed (and powder management requirements) comes massive costs -- currently, the only machines in this space cost well over a million dollars.

Bound Powder Extrusion

Also known as: Atomic Diffusion Additive Manufacturing, Bound Powder Deposition

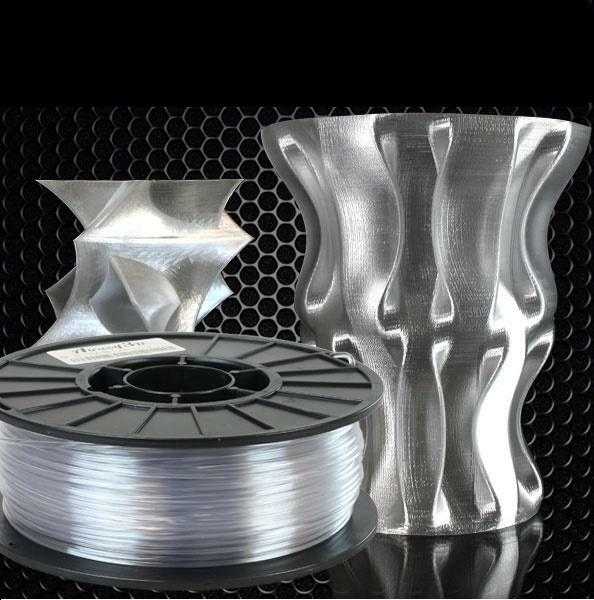

Bound Powder Extrusion (BPE) is an exciting newcomer to the metal additive manufacturing space. Unlike almost every other major 3D printing process, BPE machines do not use loose metal powder. Instead, the powder is bound together in waxy polymers in the same way that metal injection molding stock is created. The result is a material that’s much safer and easier to use than loose powder: bound powder extrusion material can be handled by hand and does not require the safety measures that loose powder machines do. BPE filament is extruded out of a nozzle in a manner very similar to standard FFF 3D printing, yielding a “green” part that contains metal powder evenly distributed in waxy polymer. After printing, BPE has two post processing steps: first, the polymer is mostly dissolved in a “wash” machine; second the washed part is sintered in an oven (similar to binder jetting). During the sintering process, the part shrinks to account for the space opened up by the dissolved binder, yielding a fully metallic part.

During the sintering process, the part shrinks to account for the space opened up by the dissolved binder, yielding a fully metallic part.

The Metal X printing system contains a metal 3D printer, part washing station, and sintering furnace.

As a filament based printing process, the part constraints of BPE parts closely mirror those of conventional FFF plastic printing: it works well for almost all part geometries, and can print with open cell infill. Parts printed on BPE systems still often require post-processing -- heat treatment for parts that need advanced properties (though this is required for every metal), and post machining/polishing for enhanced surface finishes -- but there’s no powder management and reduced facility requirements. BPE machines leverage a simpler process to be much more affordable than all other major types of metal 3D printing, with machines costing between $120,000 and $200,000. The Markforged Metal X uses this process -- to learn more about this process, check out this article on the Metal X process.

Metal 3D Printing: An Overview of the Most Common Types

Metal 3D printing is considered the apex of all 3D printing. When it comes to strength and durability, there’s nothing quite like metal. The first patent for metal 3D printing was DMLS (direct metal laser sintering) and it was filed in the 1990s by the German company EOS. Ever since then, engineers have come up with other methods for printing with metal, some of which are entirely unique and some that are just different enough from DMLS to be awarded their own patents. It can be tricky telling them apart, so we’re here to help!

Every metal 3D printer will generally fall into one of these four categories (with a few exceptions that will be covered at the end): powder bed fusion, binder jetting, direct energy deposition, and material extrusion.

Metal Powder Bed Fusion

This category includes DMLS (direct metal laser sintering), SLM (selective laser melting), and EBM (electron beam melting) machines.

Metal parts produced using PBF melting technology are free from residual stresses and internal imperfections, making them ideal for demanding applications found in the aerospace and automotive industries.

The history and categorization of PBF metal 3D printers get a bit messy and it mostly relates to the difference between sintering and melting.

Here’s where it gets tricky: most of the companies that claim to be using DMLS are technically using melting technology.

Difference Between Metal Sintering and Melting

Sintering uses a combination of heat and pressure to make particles stick together. Melting uses high enough temperatures to cause the particles to fully melt and join together. Sintered parts have high porosity and require heat treatments to be strengthened, though they’ll never be as strong as forged metal parts; melted parts are nearly fully solid and don’t require heat treatments. In the image below you can see the difference between a sintered and melted part. The particles of the sintered part are simply touching real well but there are large gaps between them throughout the body. In contrary to the melted image on the right. The particles seen are melted and the body is a far more cohesive solid mass with no visible voids.

The particles of the sintered part are simply touching real well but there are large gaps between them throughout the body. In contrary to the melted image on the right. The particles seen are melted and the body is a far more cohesive solid mass with no visible voids.

When EOS came up with the term DMLS, they were actually sintering and using the heat treatments afterward, but since then they’ve started using stronger lasers that do fully melt. They just hung on to DMLS term, likely because it was already popular and users don’t like having to remember a dozen different acronyms.

With all that in mind, understand that we sorted the companies based on the terminology used on their websites.

So, long story short, while SLM and DMLS are technically different and the industry uses both terms, nowadays most metal 3D printing companies use a form of melting instead of sintering.

EBM uses a high-power electron beam, rather than a laser, to melt the metal powder; electron beams produce more energy and higher temperatures than lasers so they can handle (and are limited to) high-temp superalloys.

Several industries rely on parts created on metal powder bed fusion 3D printers. Medical professionals and surgeons use these 3D printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft, and industrial manufacturers use them for custom tooling equipment.

Metal PBF Pros

- Nearly any geometry can be fabricated with high precision

- Wide range of metals, including the lightest titanium alloys and the strongest nickel superalloys that are difficult to process with traditional manufacturing technologies

- Mechanical properties are as good as (and sometimes better than) forged metals

- Can be machined, coated, and treated like traditionally-fabricated metal parts

Metal PBF Cons

- High cost of materials, machinery, and operation

- Parts must be attached to the build plate with support structures (to prevent warping) that produce waste and require manual post-processing to remove

- Limited build sizes (though they’re getting steadily larger)

- Handling of metal powders can be dangerous and requires strict process controls

Metal Binder Jetting

Binder jetting, like laser sintering, can handle more than metal materials. Sand, ceramic, and full-color objects are also possible with the technology. Because metal binder jetting machines operate at room temperature, warping does not occur and supports are not necessary. As such, binder jetting machines can be much larger than powder bed fusion machines and objects can be stacked to use the entirety of the build chamber, so it’s a popular choice for small batch production runs and on-demand replacement parts.

Sand, ceramic, and full-color objects are also possible with the technology. Because metal binder jetting machines operate at room temperature, warping does not occur and supports are not necessary. As such, binder jetting machines can be much larger than powder bed fusion machines and objects can be stacked to use the entirety of the build chamber, so it’s a popular choice for small batch production runs and on-demand replacement parts.

Metal Binder Jetting Pros

- Large build volume

- Parts don’t need to be attached to a build plate so they can be nested to make use of all available build volume

- Fewer restrictions on geometry because supports generally aren’t needed

- Larger parts are possible because warping doesn’t occur

- Very fast printing

- Lower cost than powder bed fusion metal printing

Metal Binder Jetting Cons

- Parts must go through a time-consuming debinding and furnace sintering process after printing

- High cost of machines and materials

- Higher porosity than powder bed fusion so mechanical properties are not as good

- Small material selection

Direct Energy Deposition

DED 3D printing systems are also known as LENS (laser engineered net shaping) and DMD (direct metal deposition) machines. They can work with metal wire or metal powder and melting can be achieved with a plasma arc, laser, or electron beam. It’s very similar to welding so one of its primary applications is repairing and adding features to existing metal parts.

They can work with metal wire or metal powder and melting can be achieved with a plasma arc, laser, or electron beam. It’s very similar to welding so one of its primary applications is repairing and adding features to existing metal parts.

DED Pros

- Metal wire is the most affordable form of metal 3D printing material

- Some machines can work with two different metal powders to create alloys and material gradients

- 5- and 6-axis motion enables the production of overhangs without the use of support materials

- It’s possible to repair broken metal parts and add new components to objects

- Large build volume

- Efficient material usage

- Parts have high density and good mechanical properties

- Fast printing

DED Cons

- Printed parts have poor surface quality so machining and finishing is usually necessary

- Small details are difficult or impossible to achieve

- High cost of machinery and operation

Metal Material Extrusion

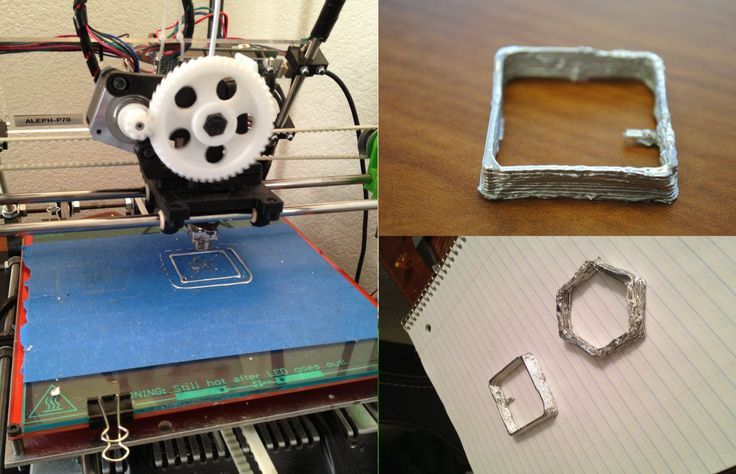

This technology was specifically created to make metal 3D printing cheaper and more accessible and it’s done just that. Small and medium businesses have rapidly adopted material extrusion with metal, largely because it’s so affordable. Design studios, machine shops, and small manufacturers use metal material extrusion machines to iterate designs, create jigs and fixtures, and complete small production runs. The latest development in this space is metal filaments that will work in most desktop FDM 3D printers, making metal 3D printing accessible to nearly everyone.

Small and medium businesses have rapidly adopted material extrusion with metal, largely because it’s so affordable. Design studios, machine shops, and small manufacturers use metal material extrusion machines to iterate designs, create jigs and fixtures, and complete small production runs. The latest development in this space is metal filaments that will work in most desktop FDM 3D printers, making metal 3D printing accessible to nearly everyone.

This is how material extrusion with metal works:

1) Either polymer filament or rods impregnated with small metallic particles are 3D printed layer-by-layer in the shape of your design.

2) The 3D printed part is then washed to remove some of the binder.

3) The part is then put in a sintering furnace which fuses the metallic particles into solid metal.

Now the final parts are ready for use. It can be processed and treated just like any other metal part. The image below shows a replica of Vortic Watch Co.’s watch case printed in 17-4PH Stainless Steel on Desktop Metal Studio (left) and MarkForged Metal X (right) material extrusion systems.

Metal Extrusion Pros

- Most affordable method of 3D printing metals

- Functional prototypes are possible

- Easy and safe to operate

Metal Extrusion Cons

- Parts must go through the same debinding and sintering process as binder jetting parts

- More restrictions on geometry and supports are necessary to prevent warping

- Parts have high porosity and don’t achieve the same mechanical properties of forged metals

- Parts are not as dense as you would achieve with PBF or DED

- Less accurate due to shrinkage in furnace

Other Metal Printing Types

Joule Printing

Joule Printing from Digital Alloys looks a lot like DED but the metal wire is melted by running a current through it rather than heating it with an arc or beam. This enables much faster printing as the company has demonstrated printing up to 2kg of titanium per hour.

Liquid Metal Additive Manufacturing

Vader Systems created Liquid Metal Additive Manufacturing where 1,200°C liquid metal droplets are deposited in a manner much like an inkjet printer.

Electrochemical Deposition

Exaddon has a nano-scale metal 3D printer called CERES that can make metal objects smaller than the width of a human hair using electrochemical deposition.

DLP metal printing

ADMATEC and Prodways are examples of companies that offer metal DLP printing technologies. Similar to metal material extrusion, metal powder is mixed in with the photopolymer resin. 3D Printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method.

Cold Spray Metal Printing

Cold Spray Metal Printing was originally used by NASA to build metal objects in space. Key feature is that it’s the fastest method of metal 3D printing in the world (think of 6kg of aluminum or copper per hour) downside is that it’s not that accurate.:quality(80)/images.vogel.de/vogelonline/bdb/1491000/1491076/original.jpg) Australian companies Titomic and SPEE3D are frontrunners in this technology.

Australian companies Titomic and SPEE3D are frontrunners in this technology.

Ultrasonic Consolidation

Ultrasonic Consolidation or Ultrasonic Additive Manufacturing (UAM) 3D printers bond thin layers of metal foil together using sound, machining away the excess for each layer before bonding the next layer of foil, so it’s a combination of additive and subtractive manufacturing. Fabrisonic’s line of SonicLayer 3D printers use this technology.

LENS

LENS is a laser-based method which necessitates a very controlled environment. The process requires a hermetically sealed chamber, typically purged of oxygen with the use of Argon. This keeps levels of oxidation as low as humanly possible.

LENS lasers can range from 500W to 4kW. The process has been used to process titanium, stainless steel and Inconel. Despite the difficulties of maintaining the oxygen free chamber, LENS allows users a degree of accuracy and control that few additive manufacturing methods are able to.

Electron Beam Freeform Fabrication

Originally developed by NASA a decade ago, EBF3 is a method primarily used in the aerospace industry. This method can craft surprisingly complex geometric shapes with no material waste whatsoever and has the ability to create lightweight shapes boosting fuel conservation.

Laser Metal Deposition

LMD is in many ways similar to melting technologies. The technology deposits powders and uses lasers to heat them into shape onto a platform. The core difference appear upon closer inspection. For example, this method utilizes a constant powder stream being melted. It uses twin streams of powders and another pair of shaping gas streams in the procedure. It is useful for strengthening, repair, regeneration or direct manufacturing.

Metal 3D printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. Curious about how 3D printing can benefit your business? Look no further than our own additive manufacturing consultancy or 3D printing service.

Steel 3D Printing - A Quick Guide / Sudo Null IT News

Any metal 3D printing technology can print with steel. This is the most popular material. But which steel grades and which technology is best for your application? Will printed steel parts really be as strong and durable as traditionally made parts?

Let's see how a 3D printed steel part is revolutionizing manufacturing and opening doors to new applications in aerospace, medical equipment, automotive, tool making, heavy industry, architecture and more. In addition, more affordable desktop printers are expanding the scope and scope of real steel 3D printed parts.

Strength of steel printed parts.

Cast steel part (left), 3D printed version (center). On the right, a fully 3D printed hinge requires no assembly. (Source: Desktop Metal) The most common question when it comes to a 3D printed metal model is "Will it be as strong as a forged or cast part?" ?". The short answer is yes... and no.

3D printed steel parts can be just as strong, and sometimes even stronger, than those made in the traditional way. It depends on many factors such as: end use, type of steel, choice of 3D printing method, post-processing and shape of the part. Also, the comparison depends on which of the strength characteristics you focus on: tensile strength, static load strength, fatigue strength, etc.

Parts printed from steel are used in the aerospace industry, for the military, and also, for example, for the manufacture of a footbridge, shown below. Therefore, the strength of printed products is beyond doubt, but let's take a closer look.

Queen Maxima of the Netherlands officially opens a 3D printed metal bridge. Photo by Adriaande Groot (Source: MX3D) A 3D printed or laser powder sintered (LPBF) steel part has a finer grain structure than cast metal products. This provides better tensile strength characteristics, but in other respects the cast parts are currently still stronger. Most often, LPBF 3D printing is used to replace cast components, but in some cases, 3D printed components can replace forged parts.

Most often, LPBF 3D printing is used to replace cast components, but in some cases, 3D printed components can replace forged parts.

One study showed that, under certain conditions, stainless steel parts made using LPBF 3D printers were three times stronger than parts made from the same steel using the traditional method.

In experiments comparing 3D printed steel parts to traditionally made steel parts, researchers create identical parts using two methods and compare their performance. However, head-to-head comparison of details is only part of the big picture.

The main advantage of printing with steel is not only its strength, but also the unique ability to create internal channels and lattice fillings in parts, which is impossible using traditional manufacturing methods. Metal 3D printing makes it possible to produce parts faster than traditional production, since this method does not require the use of special equipment and tools, it allows you to create assemblies as a whole, eliminating the need for subsequent assembly and welding. Designing a printed part usually means that less metal is needed to make it, and therefore less weight, for the same strength.

Designing a printed part usually means that less metal is needed to make it, and therefore less weight, for the same strength.

Steel 3D printing is also more stable and cost effective as it reduces waste. When using subtractive manufacturing methods, such as CNC machining, you make a part by cutting it out of a large one, with a lot of waste. With additive manufacturing, you only use the material you need to make the finished product.

Steel 3D printing is not intended to replace traditional methods in all areas, but it may be a better choice for a wide range of applications. Particularly when the required parts are unique and designed for specific applications, such as rocket engines, racing cars or the oil and gas industry. 3D printing is the fastest and most flexible technology for mass production and prototype production. For military and industrial applications, steel 3D printing is a faster and more efficient way to create individual parts for vehicles and machines. Stainless steel 3D printing is rapidly finding applications in medicine to create unique surgical instruments and implants.

Stainless steel 3D printing is rapidly finding applications in medicine to create unique surgical instruments and implants.

If you know what characteristics your final product should have (tensile strength, compressive strength, hardness, density, etc.), then all these parameters can be incorporated into the product at the production stage.

Types of steel for 3D printing

Metal powder is the most used metal material for 3D printing (Source: GKN Additive)There are thousands of different grades of steels and alloys with different mechanical properties, used in traditional manufacturing but in 3D printing there are only a few dozen of them, and some of them are unique, created specifically for this technology. Among the steel options, the following can be distinguished:

-

Stainless steel (316L, 304L , 17-4PH, 15-5PH, 420, 254, Ph2, GP1, 630, 410).

-

Tool steel (D2, M2, h23, h21, MS1, 1.2709).

-

Low alloy steel (4140).

-

Structural alloyed (20MnCr5).

Recently, unique alloys have been developed specifically for 3D printing, designed to solve the problems that occur with classical production methods.

For example, 3D printer manufacturer Desktop Metal released a patented stainless steel in 2022 that the company says combines the tensile strength, ductility, and corrosion resistance of 13-8 PH stainless steel, combined with the hardness low alloy steel like 4140. The company says customers can go to market with this material and skip the galvanizing step to protect products from corrosion.

ExOne offers two special blends of steel and bronze that the company says allows 3D printed steel parts to achieve increased corrosion resistance while being easy to machine and polish.

While most of the metal powders used in 3D printing are similar to those used for other manufacturing methods, their numbers are on the rise as more companies adopt the technology. Some metal powder manufacturers, such as GKN, also make custom powders for specific 3D printing applications.

Some metal powder manufacturers, such as GKN, also make custom powders for specific 3D printing applications.

How to print with steel

The strength, properties and applications of 3D printed steel products largely depend on which 3D printing technology you use. Some methods produce stronger parts, other methods provide better hardness or abrasion resistance, and some technologies are simply very fast.

Below are the main metal 3D printing methods, their properties and some of the most common application examples.

Fused Deposition Printing (FDM)

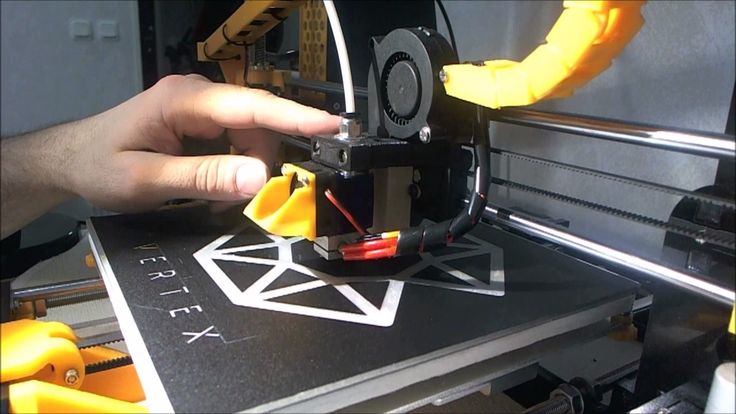

BCN3D's Epsilon printer extrudes metal filament from stainless steel (Source: BCN3D) as more printer manufacturers certify metallic filaments for use on their printers, such as Ultimaker, BCN3D, Makerbot, Raise3D. Raise3D has recently released a complete metal printing suite - Metalfuse (3D printer, debinding oven and sintering oven). This method is still much more popular for printing plastics, but with new plastic filaments filled with stainless steel powder, strong metal parts can be produced.

FDM media was once limited to thermoplastics. Companies like BASF Forward AM and The Virtual Foundry now offer metal filaments that can be used on almost any FDM printer as long as it has a hardened steel nozzle for abrasive media.

These materials are approximately 80% metal and 20% plastic. After printing, the post-processing process removes the plastic, resulting in 100% metal parts.

Due to the removal of the bonding plastic, FDM metal parts shrink during post-processing. The amount of shrinkage is constant and can be taken into account in CAD systems, which allows to obtain relatively accurate finished parts.

Forward AM's 316L Stainless Steel Ultrafuse filament produces finished parts with material properties that the company claims are comparable to injection molded metal parts.

(Source: BCN3D) While 3D printing with metallic materials may not be suitable for demanding applications such as aerospace, the economics of producing simple metal components without critical loads on an affordable FDM printer can outweigh the impossibility of applying them in some areas.

Metal prototype parts and finished parts that will not be subjected to extreme stress are ideal uses for this technology.

Bound Metal Deposition (BMD)

Desktop Metal's Studio System 3D printer used bonded metal bars that were extruded layer by layer to form a metal part (Source: Desktop Metal)Similar to FDM, Metal mesh deposition method (BMD) or bonded powder extrusion (BPE) is a 3D printing process based on extrusion. This method uses bonded metal rods or bonded powdered metal filaments, which consist of a much higher percentage of metal powder than the filaments used in FDM. As with FDM, post-treatment to remove the binder and heat treatment in a final sintering oven are required.

There are only a few 3D printers using this method such as Desktop Metal, Markforged and more recently 3DGence, but more companies are entering this market, so stay tuned. These printers are valued as a convenient solution for office 3D metal printing, they are more expensive than most FDM printers, but cheaper than the powder-based metal 3D printing technologies described below.

These printers use their own proprietary filament. Desktop Metal and Markforged offer four types of steel.

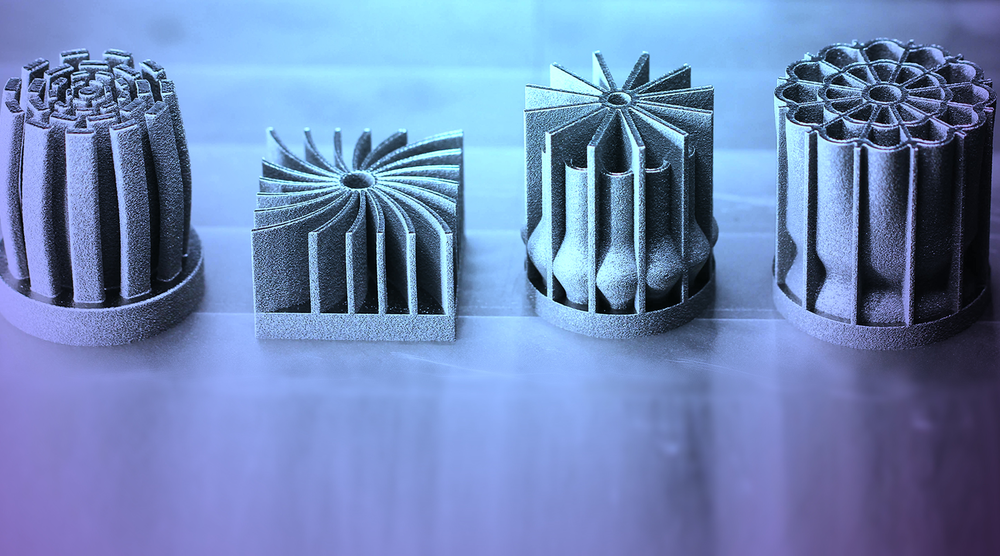

Ideal niches for this technology are metal prototype parts, where it is necessary to test the functionality of a part before mass production using traditional methods. Popular applications are molds, punching dies, nozzles, impellers, fasteners and heat exchangers.

For example, Shukla Medical uses Markforged's Metal X printer to print steel prototypes of its orthopedic implant removal instruments.

Laser powder sintering.

Laser powder sintering technology uses one or more lasers to melt powdered metal into a desired shape layer by layer (Source: GE Additive) metal printing. This technology is used by 80% of all metal 3D printers on the market.This method uses powerful lasers to selectively sinter metal powder layer by layer.

LPBF 3D printers are available in a wide range of sizes, prices and laser powers. These and other characteristics affect the properties of the finished part, print speed and other parameters of the finished products.

Steel and steel alloys are the most popular material for LPBF equipment and, unlike FDM and BMD, metal powders are commercially available as they are most commonly used in traditional production methods.

LPBF is a technology that maximizes the quality of a 3D printed part. Applications include aerospace components such as monolithic thrust chambers, rocket engine components and heat exchangers, molds, tools and other applications, as well as high wear parts and surgical instruments.

Binder Jetting

Binder Jetting 3D printing technology uses metal powder and a binder to form metal parts (Sorrce: ExOne) binder, and not with a laser. During post-processing, the binder is removed.Binder application stands out for its high printing speed compared to other 3D printing methods or traditional manufacturing, and metal parts made with this technology have material properties equivalent to those made by metal injection molding.

The number of manufacturers producing metal-bonded inkjet 3D printers is much smaller than that of LPBF machines. Leading manufacturers include ExOne, Desktop Metal, Digital Metal, GE Additive and HP.

Leading manufacturers include ExOne, Desktop Metal, Digital Metal, GE Additive and HP.

Binder blasting is ideal for medium to high volume production of metal tools and spare parts.

In fact, HP claims that its Metal Jet 3D printer was designed specifically for mass production of 316L stainless steel products. HP has partnered with Parmatech to produce metal parts for the medical industry. Pennsylvania-based ExOne uses this technology to manufacture hard metal cutting tools and tool steels.

Electron Beam Melting (EBM)

(Source: GE Additive)Electron Beam Melting (EBM) is another powder cladding technology. It works in a similar way to selective laser melting (SLM), but instead of using a laser as the energy source, it uses a much more powerful beam of charged particles.

The recoater moves the powder onto the printing plate and an electron beam selectively melts each layer of powder. After each layer is printed, the plate is lowered and another one is applied on top of the previous layer.

EBM can be much faster than SLM, but SLM produces smoother and more accurate pieces. The electron beam is wider than the laser beam, so EBM cannot produce the same precise parts as SLM. Another difference is that the manufacturing process takes place in a vacuum chamber, which reduces the amount of impurities in the material that can lead to defects. That is why EBM is often chosen for printing components for the aerospace, automotive, defense, petrochemical and medical implant industries.

Titanium is the most popular metal for most EBM applications, however steel can be used.

Cold Spray

(Source: Impact Innovations)Cold spray 3D printing is done by injecting metal powders through a jet nozzle into a supersonic stream of pressurized gases such as air, nitrogen or helium. The process is called "cold" because the metal particles do not melt, but hit the metal substrate and adhere to its surface during the so-called plastic deformation.

Cold spray printed products are not prone to porosity, thermal cracking and other defects associated with melt-based technologies. This method has several advantages over other production methods. The technology is used in the military and aerospace industries around the world. For example, the US Army uses cold spray to repair the mounts of a worn Bradley 25mm steel turret gun.

This method has several advantages over other production methods. The technology is used in the military and aerospace industries around the world. For example, the US Army uses cold spray to repair the mounts of a worn Bradley 25mm steel turret gun.

In the automotive industry, cold spray steel is used for crash repairs because the high strength steel substrates in cars can be susceptible to thermal repair methods such as welding.

Direct Energy Deposition (DED) and Wire Arc Additive Manufacturing (WAAM)

WAAM Steel Parts from MX3D (Source: MX3D) Direct Energy Deposition (DED) uses welding powder or wire that enters through a nozzle and is fed into the power source to melt the metal. A melt region is created and applied to the substrate. DED is a new process, reminiscent of an old building technology known as "cladding", in which a coating is applied to a substrate, often for thermal insulation or weather resistance. DED is useful for fabricating large objects as a whole, as well as complex geometries that require extensive machining. DED can get such parts much closer to finished than traditional CNC machining.

DED can get such parts much closer to finished than traditional CNC machining.

Because DED uses a coating process, it can be used to add complex geometries to existing steel parts, thus combining complexity with cost reduction. For example, the French company AddUp advertises a rocket nozzle that uses a preformed large 304 stainless steel hopper cone printed with an isogrid structure, usually made from a larger piece by traditional methods.

A technology related to DED is wire-arc additive manufacturing (WAAM). Instead of powder, WAAM uses a metal wire that is melted by an electric arc. The process is controlled by robotic arms. WAAM is also capable of producing large-sized metal parts, as demonstrated by the Dutch company MX3D and its nine thousand-pound 41-foot stainless steel bridge in Amsterdam, as well as an oil and gas equipment repair part, proving that parts can be made in the field.

Micro 3D printing

Micro parts printed from steel (Source: 3D MicroPrint) Micro scale additive manufacturing, or micro 3D printing, can produce products with a resolution of a few microns (or less). There are three micro 3D printing methods to produce metal parts.

There are three micro 3D printing methods to produce metal parts.

LMM (lithography-based metal fabrication) is a light-based technology that creates tiny parts from raw materials, including stainless steel, for applications such as surgical instruments and micro-mechanical parts.

Electrochemical deposition is the latest micrometal 3D printing process developed by the Swiss company Exaddon. In this process, the printing nozzle applies liquid with metal ions, creating details at the atomic level.

A third micrometal 3D printing method is microselective laser sintering, in which a layer of metal nanoparticle ink is applied to a substrate, then dried to produce a uniform layer of nanoparticles.

German researchers have successfully tested micro SLS printing of hollow microneedles using 316L stainless steel.

Metal parts from 3D Systems, Desktop Metal, MX3D and Materalise.Metal 3D printing

Metal 3D printing can be considered one of the most enticing and technologically challenging areas of additive manufacturing. Attempts to print with metals have been made since the early days of 3D printing technologies, but in most cases they ran into technological incompatibilities. In this section, we will look at technologies that have been tested for printing both composite materials containing metals and pure metals and alloys.

Attempts to print with metals have been made since the early days of 3D printing technologies, but in most cases they ran into technological incompatibilities. In this section, we will look at technologies that have been tested for printing both composite materials containing metals and pure metals and alloys.

- 1 3D inkjet printing (3DP)

- 2 Lamination Printing (LOM)

- 3 Layered welding (FDM/FFF)

- 4 Selective Laser Sintering (SLS) and Direct Metal Sintering (DMLS)

- 5 Selective laser (SLM) and electron beam melting (EBM)

- 6 Direct laser additive construction (CLAD)

- 7 Free electron beam melting (EBFȝ)

3D inkjet printing (3DP)

How 3D inkjet printers (3DP) work

Inkjet 3D printing is not only one of the oldest additive manufacturing methods, but also one of the most successful in terms of using metals as consumables . However, it is necessary to immediately clarify that this technology allows you to create only composite models due to the technological features of the process. In fact, this method allows you to create three-dimensional models from any materials that can be processed into powder. The binding of the powder is carried out using polymers. Thus, finished models cannot be called fully "metal".

However, it is necessary to immediately clarify that this technology allows you to create only composite models due to the technological features of the process. In fact, this method allows you to create three-dimensional models from any materials that can be processed into powder. The binding of the powder is carried out using polymers. Thus, finished models cannot be called fully "metal".

At the same time, there is the possibility of converting composite models into all-metal models due to heat treatment in order to melt or burn out the binder material and sinter the metal particles. The models obtained in this way do not have high strength due to porosity. An increase in strength is possible due to the impregnation of the resulting all-metal model. For example, it is possible to impregnate a steel model with bronze to obtain a stronger structure.

Models obtained in this way, even with metal impregnation, are not used as mechanical components due to their relatively low strength, but are actively used in the jewelry and souvenir industry.

Lamination printing (LOM)

Laminating 3D printer (LOM)

models.

Metallic foil can also be used as a consumable.

The resulting models are not all-metal, as their integrity is based on the adhesive used to bond the consumable sheets.

The advantage of this technology is the relative cheapness of production and the high visual similarity of the resulting models with all-metal products. Typically, this method is used for layout.

FDM/FFF

Model made of BronzeFill before and after polishing

The most popular 3D printing method has also not bypassed the use of metals as consumables. Unfortunately, attempts to print with pure metals and alloys have so far not led to significant success. The use of refractory metals runs into quite predictable problems with the choice of materials for the construction of extruders, which, by definition, must withstand even higher temperatures.

Printing with fusible alloys (for example, tin) is possible, but does not give enough high-quality output for practical use.

Thus, in recent years, the attention of consumables developers has switched to composite materials, similar to inkjet printing. A typical example is BronzeFill, a composite material consisting of thermoplastic (details not disclosed, but apparently PLA plastic is used) and bronze powder. The resulting models have a high visual similarity with natural bronze and can even be polished to a high gloss. Unfortunately, the physical and chemical properties of finished products are limited by the parameters of the thermoplastic binder, which does not allow classifying such models as all-metal.

Nevertheless, such materials can be used not only in the creation of models, souvenirs and art objects, but also in industry. Thus, the experiments of enthusiasts have shown the possibility of creating conductors and shielding materials using thermoplastics with a metal filler. The development of this direction can make it possible to print electronic circuit boards.

The development of this direction can make it possible to print electronic circuit boards.

Selective Laser Sintering (SLS) and Direct Metal Sintering (DMLS)

The most common method for creating all-metal 3D models involves the use of laser machines for sintering metal powder particles. This technology is referred to as Selective Laser Sintering or SLS. It should be noted that SLS is used not only for working with metals, but also with thermoplastics in powder form. In addition, metallic materials are often coated with more fusible materials to reduce the required power of laser emitters. In such cases, finished metal models require additional sintering in furnaces and impregnation to increase strength.

A variation of the SLS technology is Direct Metal Laser Sintering (DMLS), which, as the name implies, is focused on working with pure metal powders. These plants are often equipped with sealed working chambers filled with an inert gas for working with metals subject to oxidation, such as titanium. In addition, DMLS printers necessarily apply consumable heating to a point just below the melting point, which saves on the power of laser systems and speeds up the printing process.

In addition, DMLS printers necessarily apply consumable heating to a point just below the melting point, which saves on the power of laser systems and speeds up the printing process.

SLS, DLMS and SLM systems

The laser sintering process begins with the application of a thin layer of heated powder to the work platform. The thickness of the applied layers corresponds to the thickness of one layer of the digital model. Then the particles are sintered between themselves and with the previous layer. Changing the trajectory of the laser beam is carried out using an electromechanical system of mirrors.

When a layer is drawn, the excess material is not removed but serves as a support for subsequent layers, which allows you to create complex shapes, including hanging elements, without the need to build additional support structures. This approach, coupled with high accuracy and resolution, makes it possible to obtain parts that require almost no machining, as well as solid parts of a level of geometric complexity that is unattainable by traditional production methods, including casting.

Laser sintering allows you to work with a wide range of metals, including steel, titanium, nickel alloys, precious materials, etc. The only drawback of the technology can be considered the porosity of the resulting models, which limits the mechanical properties and does not allow achieving strength at the level of cast analogues.

Selective laser (SLM) and electron beam melting (EBM)

Despite the high quality of the patterns produced by laser sintering, their practical application is limited by the relatively low strength due to porosity. Such products can be used for rapid prototyping, prototyping, jewelry production and many other tasks, but are of little use for the production of parts that can withstand high loads. One solution to this problem has been the conversion of direct metal laser sintering (DMLS) technology to laser melting additive manufacturing (SLM) technology. In fact, the only fundamental difference between these methods is the degree of heat treatment of the metal powder: SLM technology is based on complete melting to obtain homogeneous models that are practically indistinguishable in physical and mechanical properties from cast counterparts.

An example of a titanium implant made using electron beam melting (EBM) technology

A parallel method that has achieved excellent results is electron beam melting (EBM). At the moment, there is only one manufacturer that creates EBM printers - the Swedish company Arcam.

EBM achieves accuracy and resolution comparable to laser melting, but with some advantages. Thus, the use of electron guns makes it possible to get rid of the delicate electromechanical mirror systems used in laser systems. In addition, the manipulation of electron beams using electromagnetic fields is possible at speeds that are incomparably higher compared to electromechanical systems, which, coupled with an increase in power, makes it possible to achieve increased productivity without significantly complicating the design. Otherwise, the design of SLM and EBM printers is similar to laser metal sintering machines.

The ability to work with a wide range of metals and alloys allows you to create small batches of specialized metal parts that are almost as good as samples obtained using traditional production methods. There is no need to create additional tools and infrastructure, such as molds and furnaces. Accordingly, significant savings are possible in prototyping or small-scale production.

There is no need to create additional tools and infrastructure, such as molds and furnaces. Accordingly, significant savings are possible in prototyping or small-scale production.

Laser and electron beam melting machines have been successfully used to produce items such as orthopedic titanium prostheses, gas turbine blades and jet engine injectors, among others.

Direct Laser Additive Building (CLAD)

How CLAD plants work

Not so much a 3D printing technology as a "3D repair" technology. The technology is used exclusively at the industrial level due to the complexity and relatively narrow specialization.

CLAD is based on the deposition of metal powder on damaged parts, followed by immediate welding with a laser. The positioning of the "print head" is carried out along five axes: in addition to moving in three planes, the head has the ability to change the angle of inclination and rotate around the vertical axis, which allows you to work at any angle.

Such devices are often used to repair large items, including manufacturing defects. For example, the installations of the French company BeAM are used to repair aircraft engines and other complex mechanisms.

Complete CLAD units use a sealed inert atmosphere working chamber for titanium and other oxidizable metals and alloys.

Free electron beam melting (EBFȝ)

How EBF printers work

Technology developed by NASA for use in zero gravity. Since the absence of gravity makes working with metal powders almost impossible, EBFȝ technology involves the use of metal threads.

The build process is similar to Fused Deposition 3D printing (FDM), but using an electron beam gun to fuse the consumable.

This technology will allow the creation of metal spare parts in orbit, which will significantly reduce the cost of delivering parts and provide the ability to quickly respond to emergency situations.