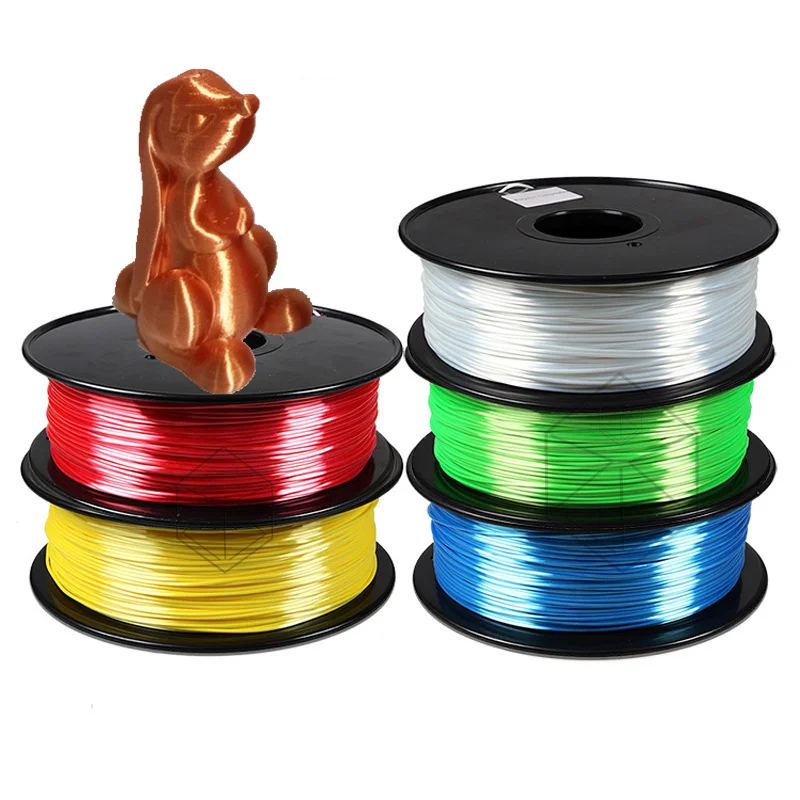

Types of filament for 3d printer

3D Printer Filament Types and Uses

WHITEPAPER

Filament Types

B.Diallo

Signup or download the pdf version to get notified when we publish the latest guides.

Share on facebook

Share on twitter

Share on linkedin

INTRODUCTION

The purpose of this guide is to introduce the different 3D printer filament types that are available and their uses. This can range from producing visual prototypes in industries such as design to helping you pick the right filament when you need to make functional prototypes.The guide is designed to be easy and clear with minimum complexity so it can be quickly referenced when needed.

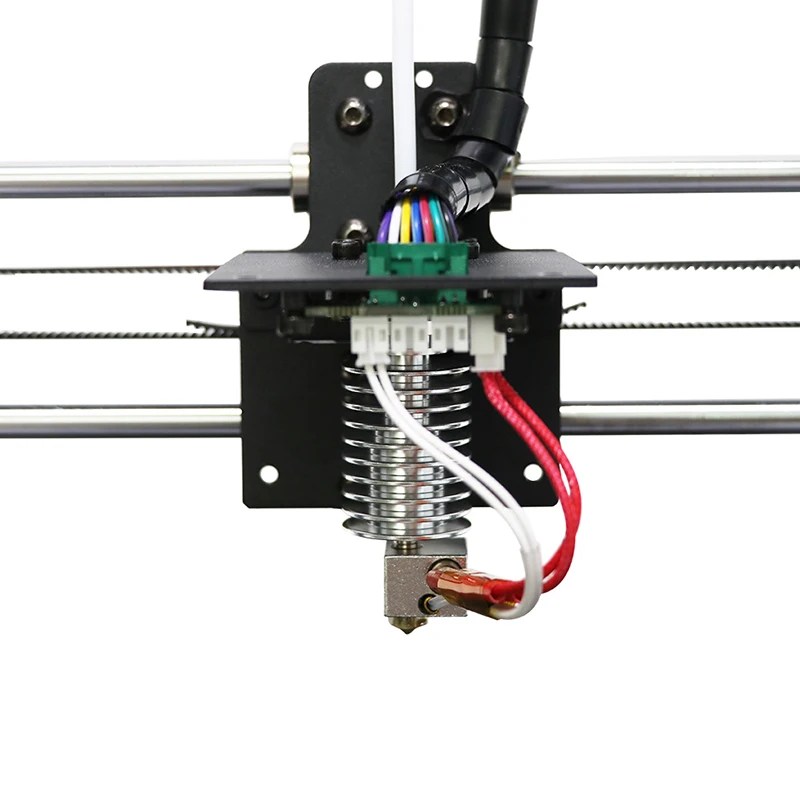

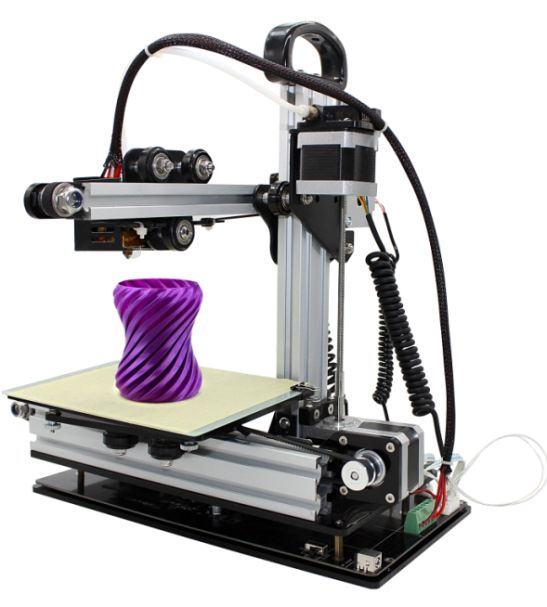

Currently we offer 8 standard filaments which are Engineering PLA, ABS filament , PETG filament , NYLON , a carbon fibre filament composite, PVA, HIPS , Flexible filament (TPU) and Polypropylene. However, due to the implementation of the market leading E3D hot-ends, the Bolt Pro can feasibly print with all current filaments in the market.

The guide will outline the unique characteristics of each filament, including specifications, the mechanical properties of each and how they are used depending on their use case.

The best 3D printer filament in the market is highly dependent on what the application is and each 3D printing material has its own advantages and disadvantages which we will explore in this guide. The main purposes is to have a simple guide to inform users what each filament is capable of and how best to maximise those attributes to achieve better 3D prints.

The guide is intended to be kept up to date to with any developments that occur and we recommend signing up to the white-paper newsletter so we can update you as developments occur.

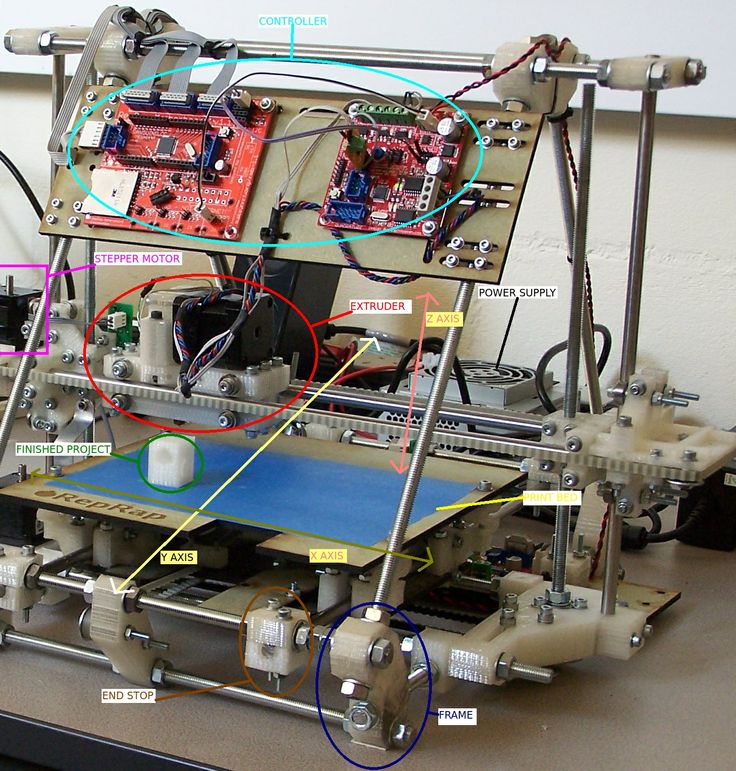

3D PRINTING GLOSSARY OF KEY TERMS

MATERIAL COMBINATION MATRIX

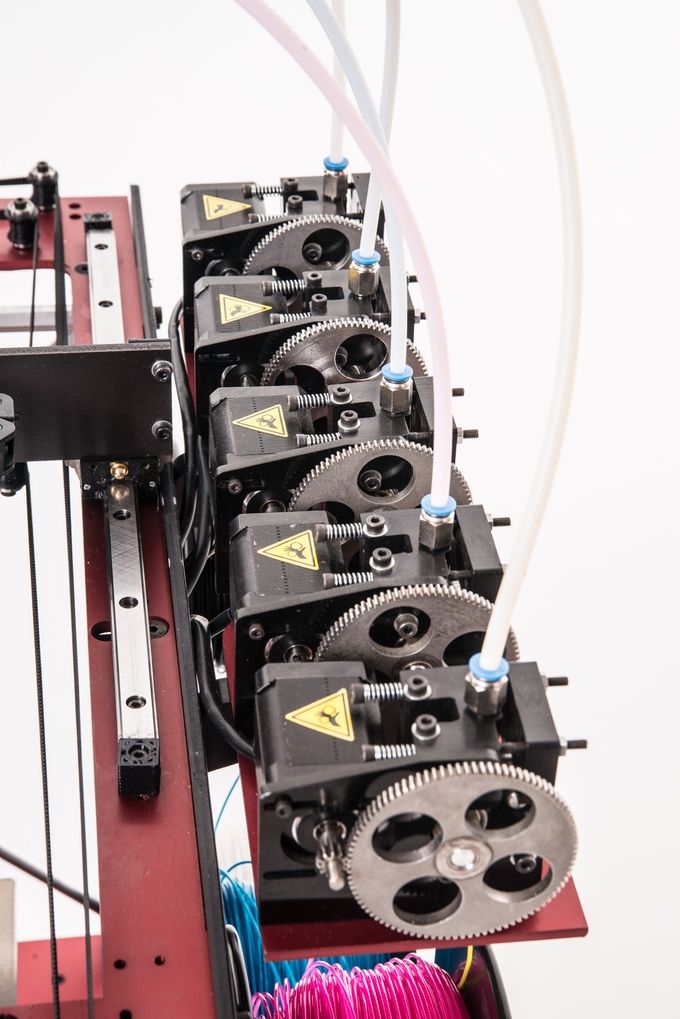

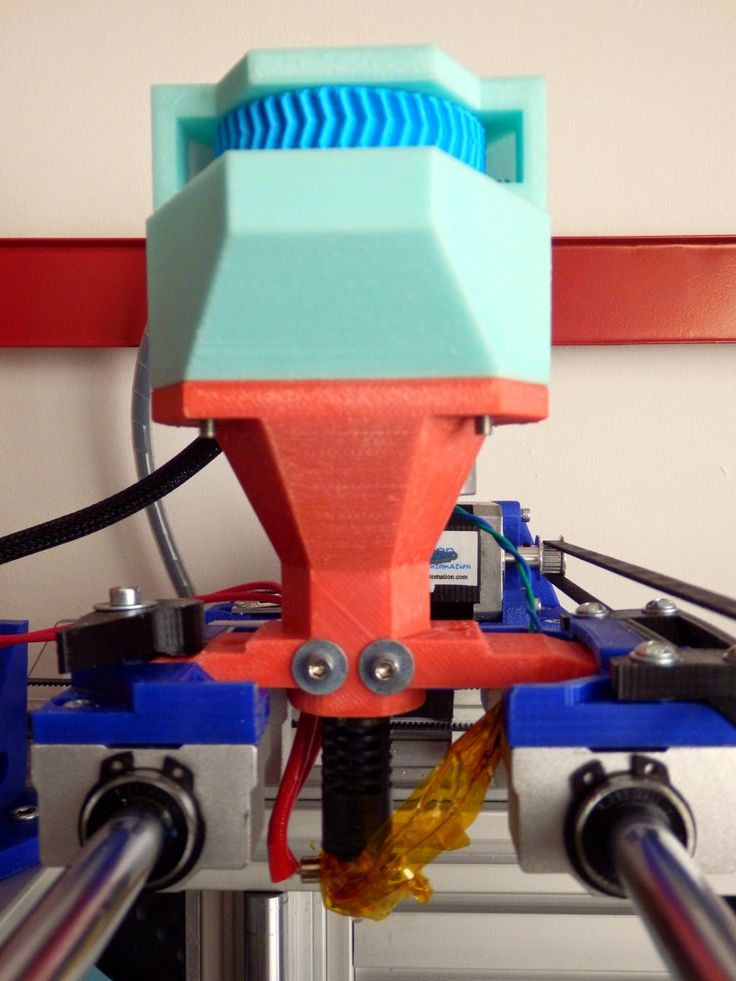

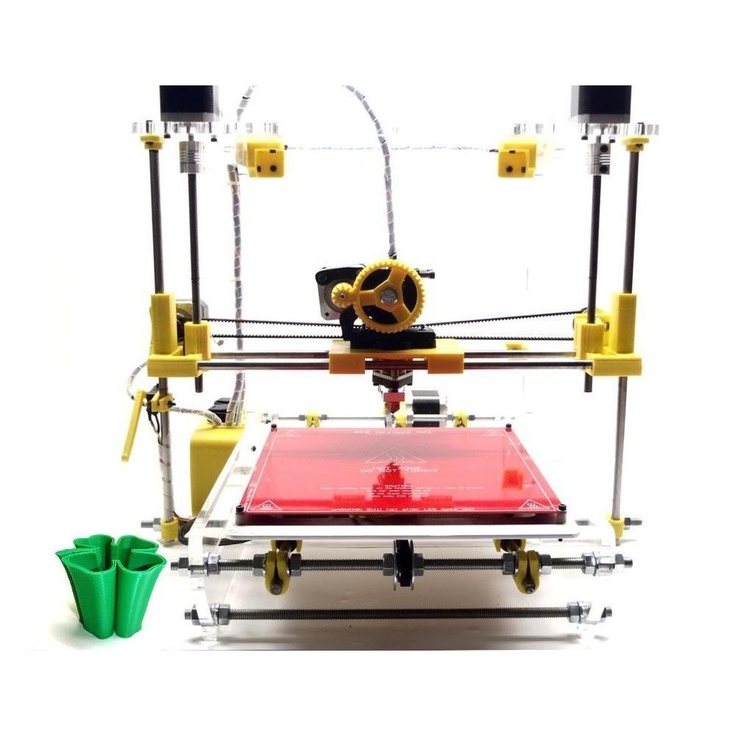

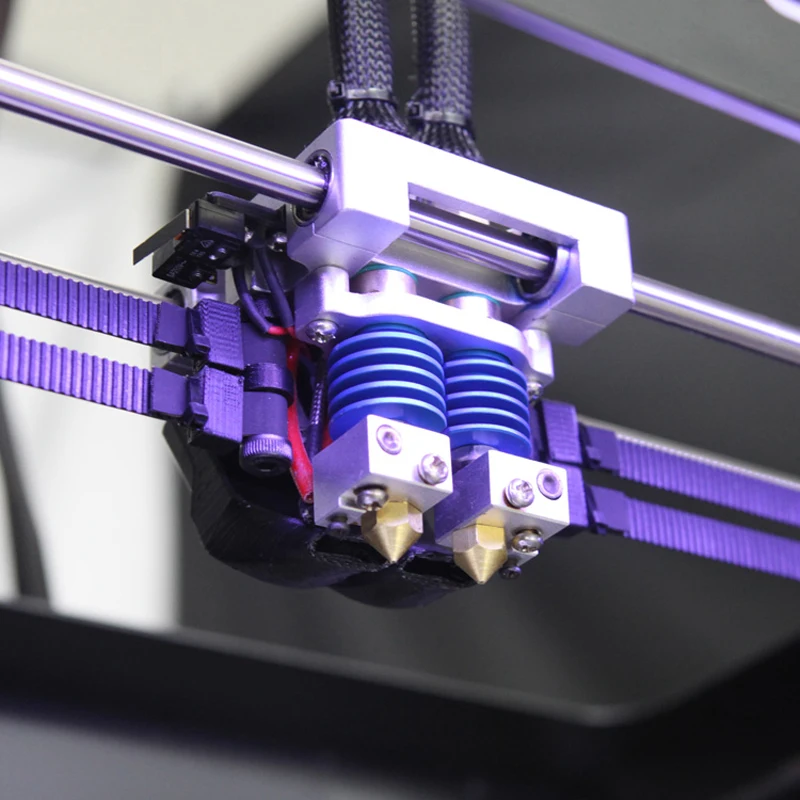

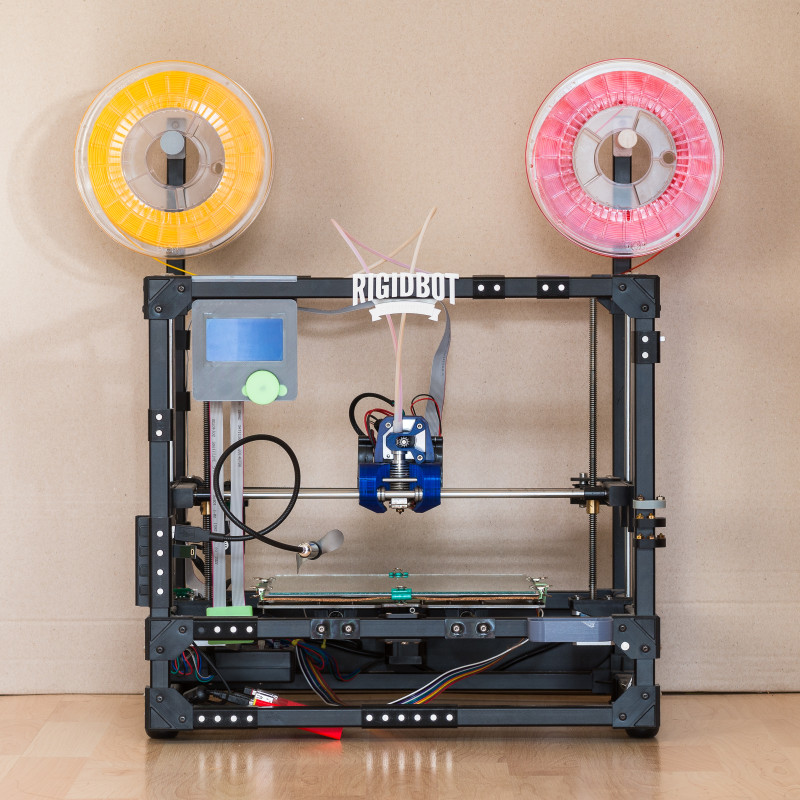

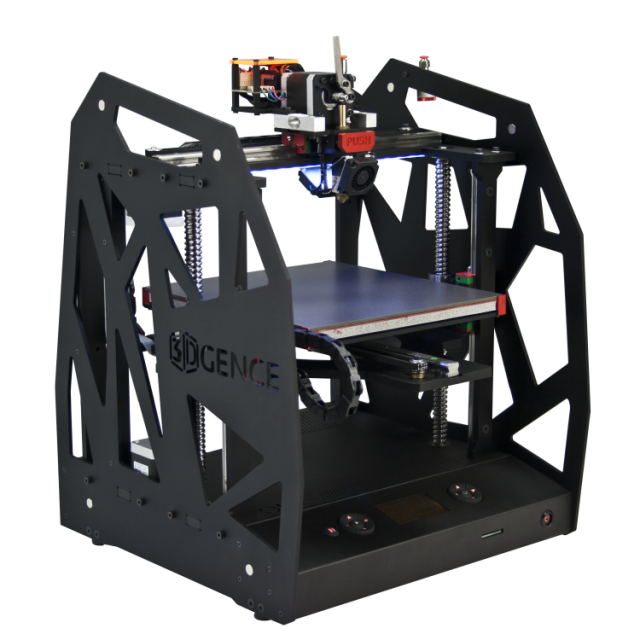

The great advantage of the Bolt Pro 3D printer is it comes with dual independent extruders (IDEX). This means that users have the option of combining two materials to use one as a support or to use different colours of the same material to create unique models.

This means that users have the option of combining two materials to use one as a support or to use different colours of the same material to create unique models.

However, each 3D printing material has unique material properties and these become increasingly important when attempting to combine two different types of filaments.

The matrix below highlights which combinations work well with each other and which 3D printer filament types do not work together and which materials that can be used as breakaway support.

DISTINGUISHING FEATURES EACH 3D PRINTER FILAMENT TYPESEPLA FILAMENT

Aesthetics : Engineering PLA filament can create great visual prototypes with the added option of post processing such as painting or being able to be sanded to create great models.

Ease of use: Engineering PLA is the easiest material to work with that does not have unique work-flow requirements.

ABS FILAMENT

Heat resistant : ABS has got high heat resistant properties which is useful for functional prototypes

Wear resistant: ABS models do not scratch easily and can last long if stored properly.

High Elasticity: Very flexible and can stretch.

PETG FILAMENT

UV Resistant : Many models degrade if left out in direct sunlight, PETG is the main exception in 3D printing.

Water Resistant : PETG models can be used to store liquids or be submerged without degrading.

PP FILAMENT

Chemical Resistant : PP is highly resistant to chemicals and cannot be combined to anything apart from itself.

Fatigue Resistant : PP models do not break easy from repeated flexural forces.

CARBON FIBRE FILAMENT

High Strength : Carbon is added to a base filament to increase strength and rigidity in the final model.

NYLON FILAMENT

Low Friction : Great for models that require movement without degrading.

FLEX FILAMENT

Elasticity: Elastic parts like phone cases and grips can be made with flex

HIPS FILAMENT

Soluble material : HIPS dissolves in citric based acids.

Impact Resistant : HIPS is highlight impact resistant and can withstand forces for various functional applications.

PVA

Soluble Support Material : PVA dissolves in water and is used for complex geometric models.

ENGINEERING PLA FILAMENT

ENGINEERING POLY-LACTIC ACID

Engineering PLA is a version of PLA filament formulated to have higher mechanical properties like strength than standard PLA. It is catered to the high demands of current 3D printing industries that need a filament that is both easy to use, sticks well to the print bed and still has the ability to print high-quality prints without much hassle. We highly recommend Engineering PLA for new 3D printing users due to its high predictability when in use.

We highly recommend Engineering PLA for new 3D printing users due to its high predictability when in use.

Material Properties

Strength

Engineering PLA strength is greater than the standard PLA and has great impact resistance for many use cases. Users can create great models and use EPLA to create tooling easily for their enterprise.

Ease

Engineering PLA has a low melting temperature and can benefit aesthetically from active cooling. This makes it a great filament to start with since it isn’t prone to warping like ABS.

Accuracy

EPLA is not prone to warping or cracking like other filaments, therefore tolerances are easier to achieve in comparison to other filaments.

Biodegradable

EPLA is derived from natural sources such as sugar-cane or corn. This makes it biodegradable and will degrade within 6-12 months if it is discarded.

Disadvantage

EPLA has some degradation issues where the colour fades as time passes, especially if it is exposed to direct sunlight.

Disadvantage

EPLA does not have much heat resistant properties and it begins to soften at 60ºC.

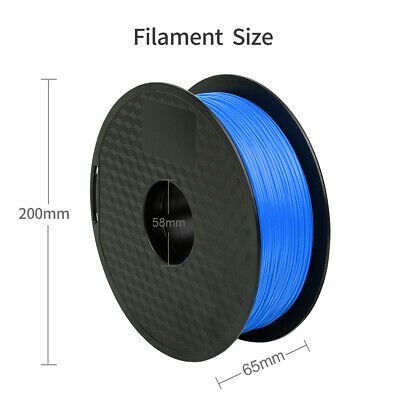

Material SpecificationsSpool Information

Outer Diameter200 mm

Centre Hole DiameterWidthThumbscrew TensionFilament Information

Filament Diameter1.75 mm( ± 2%)

Filament WeightFilament LengthSpecific Gravity1.27 g/cm³

PRINTING CHECKLISTExtrusion

Temperature

±210 ºC

Temperature management is key with any print object. If the temperature is too high then the printing process will include a lot of oozing and mess. If instead, prints are not adhering to the bed and you are getting blobs, then the temperature may be too low.

Bed Adhesion

Temperature

±40 ºC

Engineering PLA adheres to the print surface easily. It is one of the few filaments that does so . It doesn’t require a heated bed but it is recommended due to it helping to stabilise the temperature evenly. This is very key in the early stages of the printing process. EPLA doesn’t require a heated bed but it is recommended to

It doesn’t require a heated bed but it is recommended due to it helping to stabilise the temperature evenly. This is very key in the early stages of the printing process. EPLA doesn’t require a heated bed but it is recommended to

use one at temperatures between 40-60 ºC.

Bed

Adhesion

Options

Moisture & Storage

EPLA is not highly hygroscopic and does not require specialised storage set-ups and can be stored in is original filament box, ideally in a sealed bag with a moisture desiccant.

Drying before Printing

EPLA can be dried in an oven if it is not stored properly at a maximum temperature of 50 ºC for 6-12 hours.

Cooling

Cooling works well for EPLA prints because it is less likely to warp significantly in comparison to other filaments.

Your First Layers

EPLA has good inter layer bonding meaning that layer height adjustments mainly affect the aesthetics of the model.

Speeds

There are a number of printing speeds that can be adjusted for the printing process with EPLA which will reduce lead times but can reduce print quality. After gaining experience, this can help you determine how to achieve the desired results at a shorter time frame.

Skirt / Brim

Not required, but helps to reduce issues for larger

parts.

Support

Material

PVA or Breakaway

Priming Pillar

Used when printing with scaffold or dual colour models.

INDUSTRY EXAMPLE PRINT

Aircraft Bracket 3D Model

Engineering PLA parts are a great way to test out the aesthetics of a part. Once printed, parts can be easily painted to create parts with good tolerances to check fit and form for any project.

The part seen here is a topology optimised bracket for a aircraft which was printed using a breakaway support that was easily removed with a pair of pliers.

Engineering PLA has also great dimensional accuracy to test out various designs and how they can fit together to create a final product. It is easy to print and users can create many parts quickly using mirror mode on the Bolt Pro which can print two parts at once.

3D MODEL

FINAL PRINT

Previous

Next

ABS FILAMENT

ACRYLONITRILE BUTADIENE STYRENE

ABS filament is widely used already in standard manufacturing and this is due to it being highly durable and with the benefit of great strength. It is used to create visual prototypes, functional prototypes, tooling and also moulds that can be burnt away.

Although popular, ABS does have some caveats that need to be taken into consideration. It produces fumes when melted and needs to be enclosed during the printing process. Additionally, it is highly prone to warping due to high shrinkage during cooling and requires a heated print bed.

Material Properties

Strength

ABS offers great strength for parts and is often used to create tooling. It is more durable than EPLA and is often chosen because of this despite it having more stringent print settings.

Heat Resistant

Another desired property that ABS offers is it is highly heat resistant, which makes it ideal for a wide range of engineering needs.

Impact Resistant

ABS offers parts that are less brittle than EPLA parts. It is slightly more ductile, which creates parts that can withstand high impact situations.

Rigid

ABS printed parts are also highly rigid and do not bend easily. This property compounded with its strength properties means that parts can withstand stresses far more than EPLA.

Disadvantage

ABS can warp significantly during the printing process. This is especially pronounced at the edges of your model as some areas cool faster than others which can pull the model of the print bed. This can be mitigated with proper adhesion techniques.

Disadvantage

Due to shrinkage, ABS has lower dimensional accuracy in comparison to EPLA or HIPS for example.

Material SpecificationsSpool Information

Outer Diameter200 mm

Centre Hole DiameterWidthThumbscrew TensionFilament Information

Filament Diameter1.75 mm( ± 2%)

Filament WeightFilament LengthSpecific Gravity1.04 g/cm³

PRINTING CHECKLISTExtrusion

Temperature

±230 ºC

ABS requires higher temperatures to be extruded. It is more sensitive to temperature during the printing process. One thing to note is ABS produces fumes when heated and requires printing with the enclosure closed.

Bed Adhesion

Temperature

±90 ºC

ABS has significant shrinkage when it is cooled. Because of this , it can causes warping where certain areas cool faster, shrink and pull on the layer structure when it is still molten. A heated print bed allows for these areas to remain temperature stable and reduces shrinkage. The addition of the flex-plate gives you the feature of easily being able to remove parts without damage. Printing larger parts can also face significant warping, therefore the best approach is to print parts using the enclosure after you ensure that the first layer is optimised. This will involve accurate bed levelling and using skirts and brims to help check that the extrusion process is proceeding accordingly.

A heated print bed allows for these areas to remain temperature stable and reduces shrinkage. The addition of the flex-plate gives you the feature of easily being able to remove parts without damage. Printing larger parts can also face significant warping, therefore the best approach is to print parts using the enclosure after you ensure that the first layer is optimised. This will involve accurate bed levelling and using skirts and brims to help check that the extrusion process is proceeding accordingly.

Bed

Adhesion

Options

Moisture & Storage

ABS is hygroscopic and requires to be stored away from open air. A good indication of too much moisture in the filament is excess fumes and oozing occurring while printing. Storing it with Silica bags will aid in the removal of excess moisture.

Drying before Printing

Although the filament softening temperature for ABS is at 80 ºC, the spool holder can be a different material and using an oven for 6-16 hours at 50 ºC should sufficiently dry the ABS filament and keep the spool intact.

Cooling

Considering that ABS has significant shrinkage during cooling, you should not use any cooling settings when printing otherwise your print will warp excessively.

Your First Layers

Increasing layer height may produce more visible plateauing because the effect of increasing layer heights which in the same vain increases the extrusion volume. This therefore needs to be taken into consideration when printing smaller parts.

Speeds

There are a number of printing speeds that can be adjusted for the printing process. For ABS it is good to keep speeds consistent during the printing process which will improve print quality.

Skirt / Brim

Recommended for ABS parts, both large and small.

Recommended for large surface area parts.

Support

Material

When printing with a support material, ABS goes best with HIPS due to the similar extrusion temperature. When printing is complete, HIPS is soluble in d-limonene and the model can be submerged in it where the HIPS dissolves away.

Priming Pillar

Required when using two materials such as HIPS as a support for ABS or a dual colour print.

INDUSTRY EXAMPLE PRINT

EDUCATIONAL MOLECULE PRINT

The model here was printed with ABS and HIPs as a support material. Although it is great for functional prototypes, it is also effective for visual parts because it can be post processed to achieve better visual fidelity.

Parts can be dropped and withstand various stresses which is great for long lasting prototypes or in this case a part that can be used for education demonstrations where it would likely face some wear and tear.

3D MODEL

FINAL PRINT

Previous

Next

PETG FILAMENT

POLYETHYLENE TEREPHTHALATE + GLYCOL

PETG is a very durable and a great material for a wide range of engineering requirements. Outside 3D printing, it is the most widely used plastic that is often used to create plastic liquid bottles.

Outside 3D printing, it is the most widely used plastic that is often used to create plastic liquid bottles.

This is due to its great ability to last and withstand abrasion. It offers parts that are strong and when printed with less infill, the parts are slightly flexible just like standard water bottles.

Material Properties

Strength

PETG is very strong and this allows it to withstand high pressures in comparison to other filaments. This is especially pronounce in load bearing applications.

Chemical Resistant

Considering its use in the creation of various containers, PETG is not affected by a wide selection of chemicals and this property is useful in certain engineering projects.

Impact Resistant

PETG has very high impact resistant properties with the added benefit of being ductile. This means its less brittle than ABS/EPLA and won’t break easily if a force is applied.

UV Resistant

In contrast to ABS, PETG parts aren’t affected as much by UV radiation and can withstand it better.

Disadvantage

Although strong, PETG parts scratch easy in comparison to other materials like PP.

Disadvantage

PETG can string a lot during the printing process.

Material SpecificationsSpool Dimensions

Outer Diameter200 mm

Centre Hole DiameterWidthThumbscrew TensionFilament Information

Filament Diameter1.75 mm( ± 2%)

Filament WeightFilament LengthSpecific Gravity1.27 g/cm³

PRINTING CHECKLISTExtrusion

Temperature

±230 ºC

PETG has a relatively high melting temperature. When it is molten, it has more elasticity properties than other non flexible filaments.

Bed Adhesion

Temperature

±70 ºC

PETG may have adhesion issues with standard beds, therefore it is recommended to use a heated bed. This will ensure proper adhesion and reduce warping during the printing process. To aid with adhesion, using a brim can help reduce possible warping especially with large surface area parts.

To aid with adhesion, using a brim can help reduce possible warping especially with large surface area parts.

Bed

Adhesion

Options

Moisture & Storage

PETG is highly resistant to liquids, this is not the same as being hygroscopic which PETG is and not storing it in a sealed air tight bag can affect print quality. A print with blobs and oozing is an indicator of this.

Drying before Printing

Similar to ABS, PETG has a high melting temperature but should be dried for 6-16 hours at 50 ºC if it is not stored properly to reduce moisture content.

Cooling

Cooling PETG is not required and is only beneficial for smaller parts with complex geometries.

Your First Layers

Layer height for PETG is a dependent on the requirement of the model. Smaller layer heights improve the overall aesthetics of the object.

Speeds

Optimising print speeds also can improve surface finish and how glossy the model becomes. PETG is prone to oozing and stringing therefore slower speeds can help. Furthermore, it is difficult to get good bridging with PETG because of this and needs to be taken into consideration when choosing what model to print.

PETG is prone to oozing and stringing therefore slower speeds can help. Furthermore, it is difficult to get good bridging with PETG because of this and needs to be taken into consideration when choosing what model to print.

Skirt / Brim

Not require, but if your model has issues adhering to the print bed, this may aid in reducing warping issues.

Support

Material

PVA or PETG breakaway.

Priming Pillar

Used when printing dual colour or with breakaway support.

INDUSTRY EXAMPLE PRINT

FUNCTIONAL PROTOTYPES

PETG is most associated with the production of bottles or containers because of its great chemical resistant properties. Apart form that however it has many other uses cases, especially in additive manufacturing.

One use case is to print outdoor brackets for various applications where a part is needed to withstand the effects of wear and tear where other thermoplastics would degrade rapidly if exposed to similar conditions.

Furthermore, it can also be used to create snap to fit components because PETG is ductile, especially when parts are thinner, while increasing infill makes it more stiff and rigid.

3D MODEL

FINAL PRINT

Previous

Next

NYLON FILAMENT

POLYMIDE

Nylon filament is a material that offers high durable and strong printed parts. Additionally, when printed at lower infill amounts, it can create slightly flexible parts.

Although similar to PETG, it offers far greater durability for engineering functional parts with the slight advantage of offering very low coefficient of friction parts.

Material Properties

Strength & Durability

Nylon is one of the strongest and most durable filaments on the market. It offers parts that can resist wear and tear and also offer great tensile strength.

Low Friction

Having a low coefficient of friction means that Nylon is a great material for producing parts like gears or parts that require motion.

Impact Resistant

Nylon parts have great impact resistance and can absorb impact forces with minimum deforming. They give users versatile options for prototyping applications.

Heat Resistant

Nylon allows for the creation of various engineering parts that can withstand high temperatures. Combining this attribute with the low friction feature can create strong functional prototypes.

Disadvantage

Achieving optimum bed adhesion can be challenging when printing with Nylon.

Disadvantage

Nylon is highly hygroscopic which will affect print quality if the filament is not dried properly.

Material SpecificationsSpool Information

Outer Diameter200 mm

Centre Hole DiameterWidthThumbscrew TensionFilament Information

Filament Diameter1.75 mm( ± 2%)

Filament WeightFilament LengthSpecific Gravity1.08 g/cm³

PRINTING CHECKLISTExtrusion

Temperature

±250 ºC

Nylon has a high extrusion temperature but be mindful of this since it can string and ooze more if the temperature is too high. If the temperature is too low, then it will have trouble adhering to the print bed.

If the temperature is too low, then it will have trouble adhering to the print bed.

Bed Adhesion

Temperature

±90 ºC

Due to its material properties, Nylon does not adhere well with most surfaces including BuildTak and needs higher heated bed temperatures. Nylon can warp significantly during the printing process and requires J8567 stickers to keep the first layer stuck to the build-plate.

This issue also transfers to the later stages of the printing process and can lead to cracking as some layers peel away from others. To reduce this issue, we recommend printing with the enclosure closed to reduce temperature changes and prevent cracking.

Bed

Adhesion

Options

Moisture & Storage

If Nylon filament is not stored correctly, printed models will have a rougher texture and you may face lots of oozing. You may hear popping or cracking sounds that indicate that it has absorbed too much moisture.

Drying before Printing

If the quality of your models are low, then drying Nylon filament in an oven for a period of 6-16 hours at 50 ºC and this should remove most of the exess moisture that has been absorbed.

Cooling

Nylon does not require cooling which can cause cracking due to shrinkage .

Your First Layers

Nylon does not have any layer height requirements apart from aesthetics. However, Nylon parts can crack, therefore increasing the shell layers can help reduce this.

Speeds

Nylon can warp and crack during the printing process and this can be reduced if inter layer bonding is increased. This is done with slower printing speeds that gives the filament time to bond correctly. Printing at higher speeds can create print failures more often.

Skirt / Brim

Not required, but helps to reduce issues, for larger parts.

Support

Material

It is recommended to use breakaway support with Nylon.

SPORT NYLON PRINT

As mention, Nylon parts have very low friction properties making it a great choice for a surfboard fin prototype. A part printed with Nylon also has the added benefit of being able to withstand high stresses which makes it ideal for tooling and functional parts that can be tested to gauge how well a design can perform in controlled situations.

3D MODEL

FINAL PRINT

Previous

Next

FLEX FILAMENT

Thermoplastic polyurethane (TPU)

Flexible filament (TPU) is created by combining a standard polymer with rubber. This creates a filament that is very similar to what is used in standard manufacturing for parts in automobiles and many household items.

The printed objects that can be created are not only flexible, but have higher elasticity than most of the other slightly flexible filaments available.

Material Properties

Elasticity

TPU parts are both highly elastic and flexible which offers a unique combination of 3D printing applications for both visual and functional prototypes.

Chemical Resistant

Parts produced with TPU are resistant to most standard chemical solutions which opens it up for a range of uses to create long lasting parts.

Impact Resistant

Flex parts are highly impact resistant due to its elastic rubber like properties.

Heat Resistant

Due to its abrasion resistant properties, coupled with the elasticity, flex parts will last and endure various stress depending on the build direction.

Disadvantage

TPU is challenging to print with because it strings significantly and can ooze. This is due to its elasticity properties making it harder to work with.

Disadvantage

TPU prints cannot be post processed after printing which can be a minus for visual prototypes.

Material SpecificationsSpool Information

Outer Diameter200 mm

Centre Hole DiameterWidthThumbscrew TensionFilament Information

Filament Diameter1. 75 mm( ± 2%)

75 mm( ± 2%)

1.20 g/cm³

PRINTING CHECKLISTExtrusion

Temperature

±230 ºC

Printing with Flex may involve some testing with the optimum temperature. Due to its properties, it may string if the temperature is to high and create messy prints.

Bed Adhesion

Temperature

±70 ºC

Flex filament may face some adhesion issues when printing and requires a relatively hot heated bed to ensure the filament stays on the print surface.

Bed

Adhesion

Options

Moisture & Storage

TPU absorbs moisture very easily and requires drying before printing. Additionally using a poly-box during the printing process will also aid in keeping the material dry during the printing process which is crucial for parts that require longer lead times.

Drying before Printing

To dry TPU, it should be heated in a oven for 12 hours to reduce moisture content at 50 ºC.

Cooling

It is recommended to use cooling for TPU since it is very viscous when molten and needs to be cooled to set it during the printing process.

Your First Layers

TPU is a challenging material to print with. It has higher risk of being plagued with blobs and oozing which can create rough parts. Additionally, it has poor bridging characteristics and prints better with objects that require consistent extrusion where there are less stops and starts of the extrusion process.

Speeds

TPU prints better with slow speeds. This again is due to its ability to stretch without breakage when molten which causes oozing and stringing. Faster speeds can lead to this and slower speeds allows the material to adhere better and settle per layer .

Skirt / Brim

Not require, but helps reduce issues, for larger parts.

Support

Material

PVA but take into consideration that objects with too many overhangs will be difficult when printing with Flex.

Priming

Pillar

Required when printing with support.

INDUSTRY EXAMPLE PRINTPRODUCT ACCESSORIES FLEX PROTOTYPE

TPU is often used to create parts that need to be elastic. One great use case is printing phone covers but it can also be used on other industries for example in the creation of car panel designs, shoe designs and for medical devices.

3D MODEL

FINAL PRINT

Previous

Next

PP FILAMENT

Polypropylene

PP is a recent addition in the 3D printing world and offers some unique properties that make it an important material for engineering purposes. It is a semi crystalline polymer which means on a molecular level, once the material cools, it retains its molecular structure which has attributes of added strength and durability.If printed with lower infill settings, it can create flexible parts that have almost no bending failure properties, while increasing infill can create more rigid parts , but both types retain their material properties.

Material Properties

Heat Resistant

PP has great heat resistant properties meaning it is ideal for engineering applications. This mainly due to its melting temperature which is at 164 ºC.

Chemical Resistant

PP is not affected by most solvents and is often used to create containers for various chemicals.

Impact Resistant

Because off the semi-crystalline structure, PP is highly resistant to impacts. The flexibility features also make it useful since it is often used to create hinges in standard manufacturing.

Heat Resistant

PP is highly resistant to wear and can create parts that do not erode easily with heavy use. Furthermore, parts created are strong while being lightweight.

Disadvantage

PP does not bond well with any other material and this means it is not possible to print with standard adhesion methods apart from PP based adhesive products

Disadvantage

PP models cannot be post processed due to its adhesion issues.

Spool Information

Outer Diameter200 mm

Centre Hole DiameterWidthThumbscrew TensionFilament Information

Filament Diameter1.75 mm( ± 2%)

Filament WeightFilament LengthSpecific Gravity0.89 g/cm³

PRINTING CHECKLISTExtrusion

Temperature

±220 ºC

PP quickly settles back to its original molecular structure once it cools and therefore printing with it requires high temperatures. This ensures it flows smoothly during the printing process.

Bed Adhesion

Temperature

±80 ºC

Polypropylene is semi-crystalline which means it doesn’t adhere to any other material well. This brings about a problem because it won’t adhere to any print surface, other than its own. Therefore printing with PP requires the use of Tesa PP 57167 tape but not directly on the BuildTak Surface. Instead if you remove the Flex Plate and flip it around and use the tape on the sheet metal side to print on.

Instead if you remove the Flex Plate and flip it around and use the tape on the sheet metal side to print on.

Bed

Adhesion

Options

Moisture & Storage

PP is highly resistant to a lot of things . Although it is not hygroscopic its still recommended to store PP away from moisture. Keep your filament dry and away from direct sunlight.

Cooling

Cooling is not required for PP parts unless they are small and have complex geometries.

Your First Layers

PP can warp significantly during the printing process. Using larger layer heights increase the likely-hood of this since at the edges, the stresses that are created as the material cools can cause more warping with larger heights. Smaller layers create less stress and improve interlayer bonding.

Speeds

Printing with Polypropylene at higher speeds creates rough edges and parts that have poor adhesion between layers .Although this is true for all filaments, the effects are more pronounced with PP due to its material properties.

Skirt / Brim

Not required, but helps to reduce issues, for larger parts.

Support

Material

INDUSTRY EXAMPLE PRINTAUTOMOTIVE INDUSTRY PRINT

Carbon filament parts in 3D printing are often used as functional prototypes or as housings for models that need to withstand high impact forces. It is also often used to create levers because of its increased rigidity which is due to small carbon bits added to the base material in the spool.

3D MODEL

Research at Brigham Young University (CMR@BYU),

FINAL PRINT

Previous

Next

PVA FILAMENT

Scaffold

PVA is used as a soluble support material during printing complex parts. It works as a bridge material between open areas of the print which would otherwise deform.

Although it is possible in slicer software to use the same material as support, this often requires extra post processing to remove the break-away support and with some objects, this can create rough 3D prints.

PVA gives more flexibility and options for complex parts and can aid in producing complex parts in one pass unlike other manufacturing processes.

Material Properties

Water Soluble

PVA is soluble in water which means post processing is relatively easy. Depending on the amount used, all that is needed is to submerge the model in water for a few hours and the PVA melts away.

Great for Overhangs

Parts that require large overhangs for example arches, will need the use of PVA to support the print.

Disadvantage

PVA needs to be stored in a airtight container because it is highly hygroscopic which will make the printing process difficult.

Disadvantage

PVA can cause clogging of the nozzles during the printing process. This is especially pronounced when the printing process requires the heated extruder to remain stationary for long periods of time.

Material SpecificationsSpool Information

Outer Diameter200 mm

Centre Hole DiameterWidthThumbscrew TensionFilament Information

Filament Diameter1. 75 mm( ± 2%)

75 mm( ± 2%)

1.19 g/cm³

PRINTING CHECKLISTExtrusion

Temperature

±215 ºC

PVA extrudes at a temperature slightly higher than EPLA which makes it the ideal material to use as for support. This is due to both materials being able to adhere to each other without issues. Larger temperature differences may cause issues when printing with support materials.

Bed Adhesion

Temperature

±40 ºC

As mentioned before, PVA and EPLA go well together and PVA adheres well with the print bed at around 40 ºC.

Bed

Adhesion

Options

Moisture & Storage

PVA is highly hygroscopic and this makes it prone to oozing during the printing process. This can affect your model significantly by blocking paths that the extruder has to work on and resulting in deformed parts.

Drying before

Printing

PVA has a relatively low melting point and needs to be dried if necessary at 45 ºC for 4-6 hours to dry.

Cooling

It is recommended to use cooling for PVA which helps to solidify it quicker so as to aid as a support structure during printing.

Prime Pillar

The purpose of a Prime pillar is twofold. It is a rectangular 3D part that is printed at the front of a model. It is only used when printing with two materials using the two extruder and is printed each time the extruder change. Its purpose is to prime the extruder to ensure they are properly heated and extruding properly. Additionally, it cleans the nozzles to remove excess dried filament, especially for material that oozes easily.

Skirt / Brim

Recommended

Support

Material

1. E-PLA works well, especially for large parts

2. TPU

3. PET/Co-polyesters

PVA SUPPORT PRINTEPLA MOLECULE MODEL WITH PVA SUPPORT

There are various separate settings that can be adjusted in your slicer software for support structures. You add your own or the software can automatically plot them for you. As you gain experience, you will start to understand different aspects so you can use less support depending on your model.

You add your own or the software can automatically plot them for you. As you gain experience, you will start to understand different aspects so you can use less support depending on your model.

SUPPORT MODEL

FINAL PRINT

HIPS FILAMENT

High Impact Polystyrene

HIPS is a filament that can both be used as a support material and also to create 3D prototypes. In terms of mechanical properties, it is very similar to ABS where it is often used as a support material due to the similar temperature properties allow both materials to stick to each other.

With HIPS you can create parts with great dimensional accuracy and like ABS , it can be machined further or painted in the post processing stage.

Material Properties

Dissolves in D-Limonene

HIPS dissolves in citrus based acids like D-Limonene where it can be used as a support material for complex parts that are made from namely ABS.

Great for ABS Overhangs

HIPS is a great support materials for complex ABS geometric 3D prints in the same way how PVA works well with PLA. This is due to it being able to adhere well to ABS during printing allowing for smooth parts once removed.

Impact Resistant and Easy to Print

HIPS is highly impact resistant and can be used to create proof of concept functional parts. HIPS creates great looking 3D prints and it is also inexpensive, which means it is ideal for rapid prototyping models.

Durable, Strong & Lightweight

HIPS is highly strong and also lightweight meaning it can be used to create a variety of functional prototypes.

Disadvantage

HIPS can face warping issues that can make it challenging to print.

Disadvantage

HIPS is hygroscopic and needs to be stored in a airtight bag.

Material SpecificationsSpool Information

Outer Diameter200 mm

Centre Hole DiameterWidthThumbscrew TensionFilament Information

Filament Diameter1. 75 mm( ± 2%)

75 mm( ± 2%)

1.03 g/cm³

PRINTING CHECKLISTExtrusion

Temperature

±230 ºC

HIPS has a high melting temperature and this makes it a great support material for ABS parts which would normally melt PVA support.

Bed Adhesion

Temperature

±90 ºC

HIPS can warp and in order to help it adhere to the print bed, a high temperature setting will allow it to remain fixed during the printing process.

Bed

Adhesion

Options

Moisture & Storage

With any filament, it is highly recommended to store HIPS in a sealed bag since it will allow for the material to last and create better prints.

Drying before Printing

HIPS has a low sensitivity to moisture but if not stored properly then it should be dried in a oven for a period of 6-12 hours at 50 ºC.

Cooling

HIPS does not require cooling, however when printing smaller parts it can be beneficial.

Your First Layers

HIPS is relatively easy to print with and works similar to EPLA in terms of easy of use apart from the higher temperature requirements.

Speeds

TPU prints better with slow speeds. This again is due to its ability to stretch without breakage when molten which causes oozing and stringing. Faster speeds can lead to this and slower speeds allows the material to adhere better and settle per layer .

Skirt / Brim

Recommended for large parts and parts with a narrow base.

Support

Material

HIPS can be used as a support material for ABS prints.

Priming

Pillar

When using HIPS as a support material, the best process is to use a prime pillar which helps with ensuring extrusion settings and temperature settings are correct during each new layer pass. This is due to the switching of the extruder hot-ends for each new layer.

ENGINEERING ABS PRINT WITH HIPS

HIPS as a support material has various settings similar to PVA apart from the extrusion temperature. One key though that is different is that HIPS is also great as a prototyping material which can create great models. It has a smooth finish and great mechanical properties which means you can achieve functional prototypes with it as well.

3D MODEL

FINAL PRINT

Previous

Next

CARBON FILAMENT

PETG+Carbon

One key distinction that needs to made is that Carbon filament is not the same as standard carbon fibre. Carbon filament is created by combining shorter carbon fibre with another common material like PetG which is then used to create the carbon filament spool. Despite this, the printed object still benefits from the strength properties while still remaining lightweight. It has improved tensile strength and can create really rigid parts.

It has improved tensile strength and can create really rigid parts.

One key note before printing is carbon filament requires the Bolt Pro NozzleX hot-ends which are abrasion resistant. Using standard nozzles will damage them and lead to clogging.

Material Properties

Strength

Carbon printed parts offer really high strength parts that are stiff and very rigid. These parts can be used with great effect for functional prototypes.

Lightweight

The added benefit of using carbon filament is in conjunction with the strength properties, parts are also extremely lightweight which opens up a wide range of use cases for engineering.

Impact Resistant

Parts produced with carbon filament have impact resistance which is comparable or even exceeds other printing materials in the market.

Durable and Heat Resistant

Unlike ABS and PLA, carbon printed parts have the additional benefit of being very abrasion resistant which offers longer lasting parts that look good and function well with great heat resistant.

Disadvantage

Carbon filament is abrasives and can clog and ruin non specialised nozzles.

Disadvantage

Carbon prints are an abrasive finish and cannot be post processed.

Material SpecificationsSpool Information

Outer Diameter200 mm

Centre Hole DiameterWidthThumbscrew TensionFilament Information

Filament Diameter1.75 mm( ± 2%)

Filament WeightFilament LengthSpecific Gravity1.19 g/cm³

PRINTING CHECKLISTExtrusion

Temperature

±230 ºC

Since the carbon filament is mixed with PETG, the print settings mostly reflect the same setup. One thing to be mindful is carbon can clog a lot and requires specialised metallic nozzles.

Bed Adhesion

Temperature

±70 ºC

Carbon has an average chance of warping during the printing process and requires the printing environment to be enclosed to maintain a constant temperature. The bed temperature settings are similar to PETG again as that is the base material in the filament spool and needs to be high enough to adhere properly to the build surface.

The bed temperature settings are similar to PETG again as that is the base material in the filament spool and needs to be high enough to adhere properly to the build surface.

Bed

Adhesion

Options

Moisture & Storage

Storage of carbon requires it to be sealed and stored away from sunlight to uphold its quality.

Cooling

Carbon does not require cooling when printing.

Your First Layers

As with PETG, layer heights are highly dependent on the type of model that is being printed. This is mainly due to the combination of both materials that can create varying results during the printing process. Another matter to note is the size of the hot-end needs to be at least 0.4mm which is due to the carbon fibres that can build up with smaller nozzle sizes and create clogs during the printing process.

Speeds

Carbon prints work well with lower speeds and may not have the same fast speed settings that are available with filaments like ABS and PLA. This is mainly due to the fibres that can clog the extruder, especially if they build up.

This is mainly due to the fibres that can clog the extruder, especially if they build up.

Skirt / Brim

A skirt or brim is recommended when printing carbon

Support

Material

Breakaway support is recommended for carbon filament.

INDUSTRY EXAMPLE PRINTTOOLING PRINT EXAMPLE

PP is very strong and durable plastic that has great fatigue resistant properties. For this model, we chose to print a compliant pliers designed by BYU CMU which operates without the use of multiple parts to create a functional tool or part. This is a great use case for PP because it has great wear and tear resistance and can be both ductile and more stiff when printed with higher infill to create a wide range of different parts.

3D MODEL

FINAL PRINT

Previous

Next

Share on facebook

Facebook

Share on twitter

Twitter

Comparison & List of 3D Materials

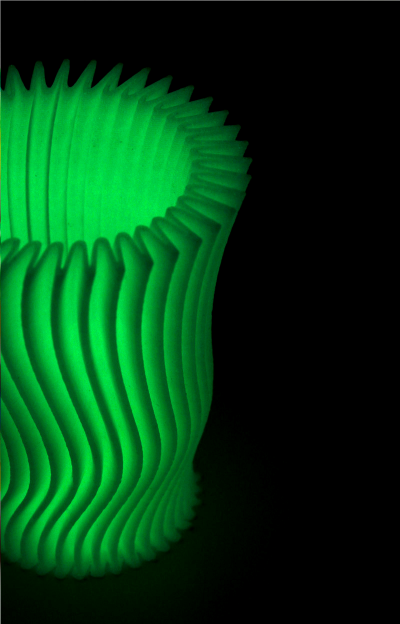

Image from FlickrBelow you will find information on 16 different types of 3D printing materials. Chances are that even if you are a 3D printing expert you will learn something new in this guide. You can try magnetic, glow-in-the-dark, or even conductive filaments.

Chances are that even if you are a 3D printing expert you will learn something new in this guide. You can try magnetic, glow-in-the-dark, or even conductive filaments.

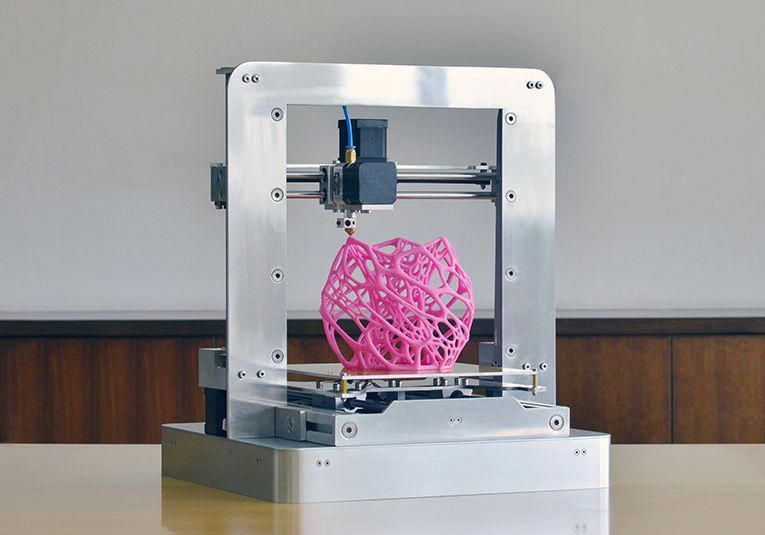

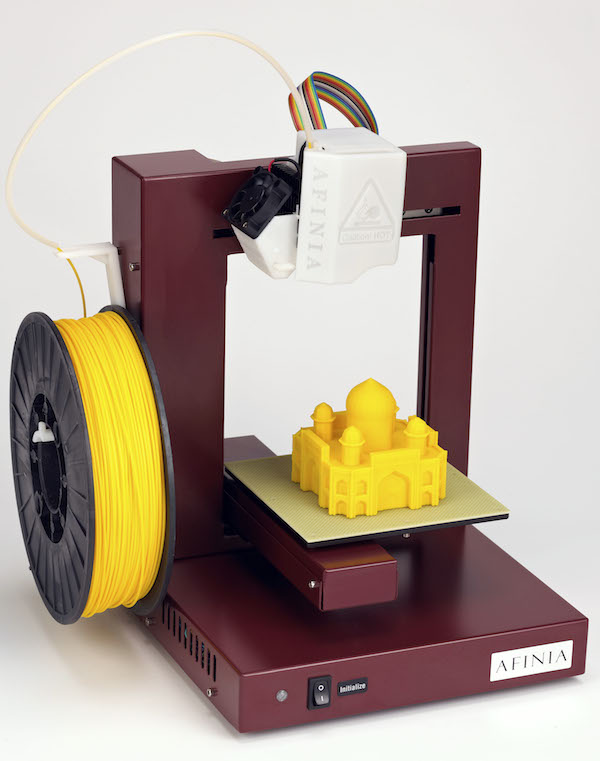

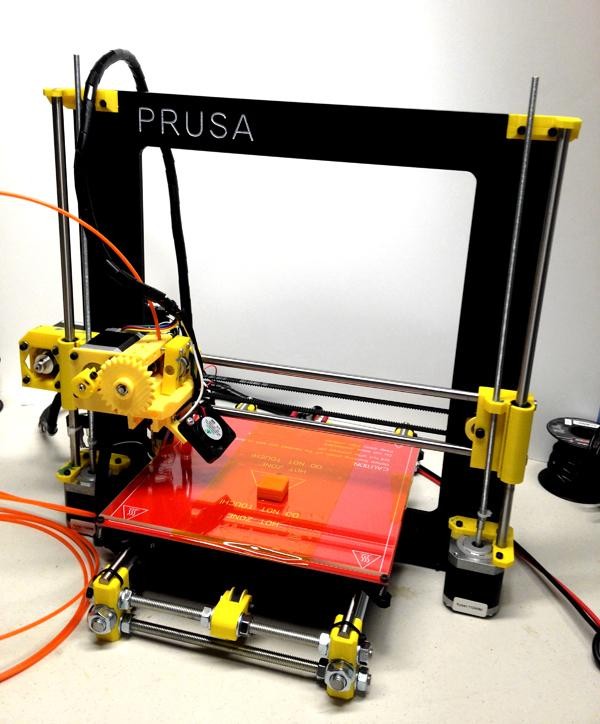

Before we get into 3D materials, it helps to look at the 2D printing process we’ve all come to know. All printers need some kind of substance to print with. For 2D printing, we’re most familiar with inkjet printers that use liquid inks. These machines extrude ink through microscopic nozzles onto papers. 2D laser printers also print to papers. Instead of ink, they use a toner cartridge filled with a special type of fine powder and a heated fuser. 2D printing produces two-dimensional, flat, results that have width and height but no depth (thickness). Pigment-based and solid inks are other materials used for printing in 2D. Today, we can also print in 3D with special machines and printing materials.

2D Printing Compared to 3D Printing

There’s a distinct difference between the two technologies. 3D printers build real-world objects, whereas 2D printers publish text and graphics on papers. Before either machine can print, they need computer-generated, digital files. These files tell the machines what to produce and how to print it based on user preferences. Both types of printers use inks, or materials, to carry out the job. That’s pretty much where the familiarities end. 2D printers can’t build layers to produce real-world objects.

Before either machine can print, they need computer-generated, digital files. These files tell the machines what to produce and how to print it based on user preferences. Both types of printers use inks, or materials, to carry out the job. That’s pretty much where the familiarities end. 2D printers can’t build layers to produce real-world objects.

One of the most important parts of 3D printing is to use the right kind of material for the job in hand. In this guide we look at the range of 3D materials, also called filaments, a 3D printer uses, starting with the most popular. We’ll also cover their uses along with pros and cons for each type. This will help you to make better informed decisions when buying your 3D printer filaments. Before you print anything in 3D, there are a few basic questions you should ask yourself, the main ones include:

- Strength: How strong does your printed part have to be?

- Flexibility: How flexible does your part need to be?

- Accuracy: How important is precision to your 3D part?

- Special conditions: Any other conditions that apply to your 3D model

These are the 3D printing materials that are covered in this guide:

- ABS Filament

- PLA Filament

- PET Filament

- PETT Filament

- Nylon Filament

- PVA Filament

- Sandstone Filament

- Wood Filament

- Metal Filament

- HIPS Filament

- Magnetic Iron Filament

- Conductive Filament

- Carbon Fiber Filament

- TPE Filament

- Glow in the Dark Filament

- Amphora Filament

3D Filament Defined

3D filaments are special types of plastics called thermoplastics. Once heated to the right temperature, thermoplastics become flexible. It’s this pliability that allows the printer to sculpt the filament to create your shapes before it cools down. In 2017, the two common types of 3D filaments are:

Once heated to the right temperature, thermoplastics become flexible. It’s this pliability that allows the printer to sculpt the filament to create your shapes before it cools down. In 2017, the two common types of 3D filaments are:

- ABS (Acrylonitrile Butadiene Styrene)

- PLA (Polylactic Acid)

Don’t Miss: Best 3D Printing Filament Brands.

These are not the only 3D filaments available. We’ll look at other types later in the guide. For now we’ll focus on ABS and PLA, and see what makes them such popular choices. For each material we’ll start with a short introduction followed by the average price, print temperature, and applications. At the end of each 3D material we’ll list its pros and cons. Also worth noting is that not all 3D printers can utilize both ABS and PLA. Some can, but not all, so you need to know your 3D printer capabilities as well as the abilities of the 3D filaments.

1. ABS 3D Filament

PRICE STARTING FROM: $20 for 1. 75 mm, 1kg spool

75 mm, 1kg spool

ABS is popular for good reasons. It’s tough, and has impact-resistant properties. It’s this strength and moderate flexibility that makes it such a great choice for printing in 3D. It’s also easy to extrude from the printer’s nozzles, which makes it an easy material to work with.

Don’t Miss: Best ABS Filaments.

ABS print temperature range: 210°C – 250°C (high)

Applications

ABS is a great choice for printing plastic automotive parts, moving parts, musical instruments, kitchen appliances, electronic housings, and various toys, like LEGO. It has other applications too, aside from 3D printing. For example, traditional manufacturers use ABS to make plastic wrap, water bottles, and cups, to name a few uses. Despite its popularity for 3D printing, ABS is not the best filament for most home users. This is because it has a high melting point that needs to print on a heated surface, or bed. A heated printer bed is not something a lot of budget-range 3D printers come equipped with. Printing with ABS also produces unpleasant fumes that can irritate some people. Needless to say, good ventilation is essential. These things combined make ABS a material favored more by professionals than amateur users.

Printing with ABS also produces unpleasant fumes that can irritate some people. Needless to say, good ventilation is essential. These things combined make ABS a material favored more by professionals than amateur users.

Check Price of ABS Filament on Amazon

The Pros

- A durable, strong 3D filament

- Quite flexible and lightweight

- Cheapest thermoplastic available at the time of writing

- Most favored material among professional 3D printers and keen armatures

The Cons

- ABS is petroleum-based, making it a non-biodegradable material

- Needs a high temperature to reach its melting point

- Creates unpleasant fumes, most notable in poorly ventilated spaces

2. PLA 3D Filament

PRICE STARTING FROM: $20 for 1.75 mm, 1kg spool

PLA (Poly Lactic Acid) is popular for amateurs and professionals alike. It’s a special type of thermoplastic made from organic materials, namely cornstarch and sugarcane. The main benefits of PLA are that it’s safer and easier to use, and with no toxic fumes to worry about. Some users even find the sweet smell of the sugar-based filament pleasant. Compared to ABS, PLA produces 3D parts which are more aesthetically pleasing. This finish is thanks to its unique sheen and smooth appearance.

The main benefits of PLA are that it’s safer and easier to use, and with no toxic fumes to worry about. Some users even find the sweet smell of the sugar-based filament pleasant. Compared to ABS, PLA produces 3D parts which are more aesthetically pleasing. This finish is thanks to its unique sheen and smooth appearance.

You might think it sounds like the perfect solution, but there are some drawbacks. For one, the melting point of PLA is much lower than ABS, and that makes it weaker. This matters if you’re printing moving parts or exposing the parts to high temperatures. Both of these things can result in the 3D objects, cracking, warping or even melting. If none of the above applies to you and your 3D projects, then PLA should be your filament of choice. It will award you with superior print details and is also less prone to printing errors during the build process.

Don’t Miss: Best PLA Filaments.

PLA print temperature range: 180°C – 230°C (low)

Applications

PLA has wide-ranging uses. At the professional level, PLA filament uses include medical suturing (stitching). We can also see PLA used for various surgical implants, including surgically implanted pins, rods, screws, and mesh. The applications work thanks to the material’s degradable properties. All the aforementioned 3D printed parts break down in the human body. They can take anywhere between six months to two years, depending on the part and its purpose. At the amateur level, PLA filament is great for producing a whole range of consumer items. Other benefits of PLA are that it prints faster than ABS, and there’s no need for a heated printer bed. The end products are a decent strength, durable, and offer some degree of impact resistance. Aside from 3D printing, other products that use PLA include food packaging, disposable tableware, and diapers, as a few examples.

At the professional level, PLA filament uses include medical suturing (stitching). We can also see PLA used for various surgical implants, including surgically implanted pins, rods, screws, and mesh. The applications work thanks to the material’s degradable properties. All the aforementioned 3D printed parts break down in the human body. They can take anywhere between six months to two years, depending on the part and its purpose. At the amateur level, PLA filament is great for producing a whole range of consumer items. Other benefits of PLA are that it prints faster than ABS, and there’s no need for a heated printer bed. The end products are a decent strength, durable, and offer some degree of impact resistance. Aside from 3D printing, other products that use PLA include food packaging, disposable tableware, and diapers, as a few examples.

Check Price of PLA Filament on Amazon

The Pros

- No harmful fumes, produces a sweet aroma when heated

- Easier to work with compared to ABS (great material for beginners)

- Compared to ABS, PLA is less prone to warping

- Available in special effects like glow-in-the-dark colors and translucency

The Cons

- Susceptible to clogging the printer nozzle

- Can attract moisture that makes it potentially brittle and more difficult to print

- Less sturdy overall than ABS

3.

PET FilamentImage from Bpet Filaments

PET FilamentImage from Bpet FilamentsPRICE STARTING FROM: $24.99 for 1.75 mm, 1kg spool

Today, PolyEthylene Terephthalate (PET) is a popular 3D material. Another common use for PET is in everyday plastic bottles. This plastic is both stable and harmless, emits no unpleasant or harmful odors, and is 100% recyclable. In its raw state, the filament has no color and is crystal clear. Once exposed to cold or heat the material quickly changes to a non-transparent state. A more advanced version if PET is a filament called PETG, also marketed as Amphora AM1800.

Don’t Miss: Best PETG Filament.

PETG print temperature range: 210°C – 230°C

Applications

PETT is on a list of FDA approved polymers. This makes it completely ‘food safe’, meaning it’s safe for products like cups, and plates, etc. Needless to say, common applications for PETT filament include food containers and various kitchen utensils.

Check Price of PETG Filament on Amazon

The Pros

- Strong, flexible, and with biocompatibility

- Does not warp

- Does not shrink

- Does not absorb moisture from the air

- Does not degrade in water

- FDA approved, food safe

- Prices for PETT are falling

The Cons

- Not an easy material for beginners to work with

- Nozzle and printer bed temperatures needs fine-tuning for best results

4.

PETT FilamentImage from 3D Prima

PETT FilamentImage from 3D PrimaPRICE STARTING FROM: $25.99 for 1.75 mm, 453.5g spool

PETT, whose long name is PolyEthylene Trimethylene Terephthalate, is what’s known as a T-Glase filament. Like PET (one ‘T’), it’s also a popular 3D printer material that’s food-friendly. The filament is non-biodegradable, though it is a recyclable material.

Don’t Miss: Best PETG Filaments.

PETT Print Temperature Range: 210°C – 230°C

Applications:

PETT is another of those FDA-approved polymers. This makes it safe for use with food. The majority of PETT applications are various food containers and other kitchen utensils.

Check Price of PETT Filament on Amazon

The Pros

- Strong and flexible

- Biocompatibility

- Does not warp or shrink during the printing process

- Does not absorb moisture or water from surrounding air

- Does not degrade in water

- FDA approved, food safe

- Impressive in bridging

- Prices for PETT falling

The cons

- Difficult material for beginners to work with

- Printer nozzle bed temperature requires fine tuning for best results

5.

Nylon FilamentImage from Taulman3D

Nylon FilamentImage from Taulman3DPRICE STARTING FROM: $39.99 for 1.75 mm, 1kg spool

Nylon filament, also called polyamide, is another popular choice. This is a synthetic polymer that’s stronger and more durable than ABS and PLA—and cost-effective. It’s also flexible, light, wear-resistant, and less brittle than both ABS and PLA. There are different kinds of nylon filament available, and what you choose will depend on which one suits your budget and needs. The difference between them is in the filament’s layer bonding abilities, tensile strength, and water absorption. You can also choose nylon filament that has a translucent or opaque finish and reduced shrinkage.

Don’t Miss: Best Nylon Filaments.

Nylon print temperature range: 210°C – 250°C (high)

Applications

Nylon filament is great to use in a whole variety of applications thanks to its strength, flexible properties, and durability. It’s particularly suited for various consumer products, tools, mechanical components, machine parts, structural parts, containers, and a much more.

Check Price of Nylon Filament on Amazon

The Pros

- Strong, durable and flexible

- Less brittle than ABS and PLA

- 100% thermoplastic material

- Filament can be re-melted and used again without any loss of bonding

The Cons

- Needs a high melting temperature

- Breaks down and emits toxic fumes when heated

- Absorbs moisture easily—proper storage is essential

6. PVA Filament

Image from Form FuturaPRICE STARTING FROM: $35.99 for 1.75 mm, 0.5 kg spool

PVA (long name Polyvinyl alcohol) is a good 3D filament that’s typical use is as a support material when printing with ABS or PLA. Support materials are necessary when printing 3D parts with notable overhangs. Without the support, these parts would be impossible to print or perfect. As a support material, PVA works best with printers that have duel extruders. This is a biodegradable, non-toxic material that easily dissolves in tap water. All popular desktop FDM printers can use PVA with a heated build platform as this prevents warping during the build process. For best results as a support material, the print bed temperature should not exceed 200 °C.

All popular desktop FDM printers can use PVA with a heated build platform as this prevents warping during the build process. For best results as a support material, the print bed temperature should not exceed 200 °C.

PVA print temperature range: 190°C – 220°C (low)

Applications

In 3D printing, PVA works as a support material (see above). Aside from 3D printing, PVA has many other applications. We can find it used as a thickener in paper adhesives, in personal hygiene products, as a mold-release agent, kid’s putty, and freshwater fishing products, to name a few.

Check Price of PVA Filament on Amazon

The Pros

- A biodegradable, non-toxic material

- Water soluble

- Good durability

- Makes otherwise difficult printing easy

The Cons

- Attracts water easily

- Can be difficult to source compared to other materials

- High cost compared to other 3D filaments

7.

Sandstone Filament (PLA + Brick)Image from Quora

Sandstone Filament (PLA + Brick)Image from QuoraPRICE STARTING FROM: $32 for 1.75 mm, 0.25 kg spool

Sandstone filaments offer a unique finish to your 3D printed parts. This is a PLA material that includes a fine chalk powder to produce a stone-like color and texture. It’s also possible to alter the surface characteristics simply by adjusting the printer’s extrusion temperature during the print process. With a little practice, you’ll be able to produce parts that are smooth, rough, or anywhere between the two. 3D sandstone material is a brick filament offered by various suppliers under different product names. The most well-known right now is LayBrick.

Sandstone print temperature range: 165°C – 210°C

Applications

The creative use of 3D sandstone filaments has few limits, though it’s fair to say that it has a pretty niche usage. It’s most popular for things like landscapes and architectural display models.

Check Price of Sandstone Filament on Amazon

The Pros

- Unmistakable sandstone appearance and finish

- No heated bed needed to print

- No warping or shrinking during the cooling process

The Cons

- Not a particularly durable or flexible material

- Parts can be brittle making them more prone to breaking and snapping

8.

Wood FilamentImage from Imgur

Wood FilamentImage from ImgurPRICE STARTING FROM: $30 for 1.75 mm, 1kg spool

It seems strange, but yes, 3D wood filaments are very real. It’s a great material for anyone who wants or needs to be more creative with their 3D printed projects. These filaments contain a careful mixture of recycled woods with a special binding polymer. The output model not only looks like real wood, it smells like it too. There’s no shortage of impressive examples online that illustrate the amazing finish wood filaments can produce when printed to perfection.

Wood print temperature range: 200°C – 260°C

Applications

What 3D print enthusiasts use wood filament for has no limits other than their creativity. Use it for décor, ornate boxes, tables and chairs, figurines, and whatever else catches the imagination.

Check Price of Wood Filament on Amazon

The Pros

- Contains actual wood fibers

- Produces unique wood-like objects in various shades and surfaces

- Higher temperatures will produce darker brown shades

- Altering 3D print temperatures stimulates the growth ring effect of trees

- Allows you to easily work with the finished part to achieve the required finish

The Cons

- Weaker, softer material compared to PLA

- Less flexibility and tensile length

- Easily breakable

9.

Metal Filament PLA / ABS

Metal Filament PLA / ABSPRICE STARTING FROM: $29 for 1.75 mm, 1kg spool (prices vary a lot depending on metal)

Metal filaments are in a league of their own—offering some very impressive, unique finishes to 3D printed parts. The materials consist of PLA combined with a higher percentage of fine metallic powders. The 3D printed parts look and feel just as they would if they had been made of 100% metals. Popular choices include aluminum, brass, bronze, copper, and stainless steel. Anyone who wants more of a creative effect can work on the end piece. For example, you can polish the finished part, or tarnish / weather it so that it looks even more genuine. Although they’re not pure 3D metal parts, they’re pretty close to the real thing.

Metal print temperature range: 195°C – 220°C (will vary depending on filament)

Applications

3D metal filament is perfect for hardware products, jewelry items, statues, replicas of artifacts, and much more. What you print with 3D metals depends a lot on the filaments you choose.

What you print with 3D metals depends a lot on the filaments you choose.

Check Price of Metal Filament on Amazon

The Pros

- Extremely durable

- Not soluble

- Unique metallic appearance and finish

- Little to no shrinkage while cooling

- No heated print bed needed

The Cons

- Not easy to print with for the inexperienced

- Need to fine-tune nozzle temperatures

- Need to regulate flow rate

10. HIPS Filament

Image from AdafruitPRICE STARTING FROM: $24.95 for 1.75 mm, 1kg spool

High Impact Polystyrene, HIPS for short, is a bright, white colored 3D biodegradable material. It’s safe to use, meaning it has no harmful effects for users who are in close contact with the filament. It’s safe with pets too. Like PVA, HIPS also works as great secondary (support) material. On its own, it’s tricky to use for creating 3D printed parts, especially with printers that don’t have a heated bed. As a support structure, a colorless solution called liquid hydrocarbon quickly dissolves the filament.

As a support structure, a colorless solution called liquid hydrocarbon quickly dissolves the filament.

Don’t Miss: Best HIPS Filaments.

HIPS print temperature range: 230°C – 250°C

Applications

For 3D printing, the most common application for HIPS is as a support material for other filaments (see above). Aside from 3D printing, other industries use HIPS because it’s a strong, ridged plastic that they can manipulate to suit their needs. The food industry uses it widely for packaging. Other uses include medicinal trays, signs, all kinds of kid’s toys, and much more.

Check Price of HIPS Filament on Amazon

The Pros

- Acts as an easily removable ABS support material

- When paired with ABS, HIPS is a great dual extrusion support structure

- Non-toxic at close range

The Cons

- Some issues with adhesion and curling

- Not easy to work with without a heated bed

11.

Magnetic Iron PLA Filament

Magnetic Iron PLA FilamentPRICE STARTING FROM: $35 for 1.75 mm, 500 g spool

As the name suggests, magnetic iron PLA filament has magnetic properties. This unique filament is PLA material infused with a powdered iron. It’s these iron particles that give the 3D parts their grainy gunmetal type finish. The objects will also stick to magnets, something that could be useful on various creative projects. It’s a specialist material that few will have a need for, but those who do work with it find PLA iron filament invaluable.

Magnetic iron PLA print temperature range: 195°C – 220°C

Applications

If you want to produce custom made fridge magnets, and other such novelties, magnetic iron PLA is for you. For home users, this is pretty much a novelty material. For more serious uses, magnetic filament is useful for making various DIY projects, sensors, and educational tools, etc.

Check Price of Magnetic Iron Filament on Amazon

The Pros

- Very strong and extremely durable

- Material is not soluble

- Little to no shrinkage during the cooling down process

The Cons

- Nozzle temperature needs fine-tuning

- Inflexible

- Heated bed not needed

- Material is expensive compared to other popular filaments

12.

Conductive PLAImage from Proto Pasta

Conductive PLAImage from Proto PastaPRICE STARTING FROM: $17.95 for 1.75 mm, 125 g (comes in various weights)

Anyone wanting to broaden their horizons in 3D printing may want to look to conductive PLA 3D printer filament. It’s a special type of 3D material that includes a conductive carbon particulate. Without getting too technical, this means the material is able to print low-voltage electrical circuits. These will typically include sensors and light-emitting diodes (LEDs). When combined with regular PLA filament and a dual-extrusion 3D printer, users can make simple circuit boards direct from the printer’s bed. Note that conductive ABS filament is also available for users who prefer to work with ABS.

Conductive PLA temperature range: 215°C – 230°C

Applications

Conductive PLA filament is perfect for open-source electronics platform Arduino projects. If you want to create circuits, LEDs, sensors, and various low-voltage projects, you’ll want explore this filament.

Check Price of Conductive Filament on Amazon

The Pros

- Users can produce low-voltage electronic circuits

- Not soluble

- Does not need a heated bed, though a heated bed will produce better results

The Cons

- Not very flexible or durable

- Repeated bending may break the material

- Shrinks somewhat during the cooling process

- High cost of filament

13. Carbon Fiber 3D Printer Filament

Image from Color FabbPRICE STARTING FROM: $29.99 for 1.75 mm, 500 g spool

Carbon Fiber PLA is an impressive 3D filament. The material contains tiny strands of carbon fiber which results in a material that has an excellent structure. It’s also rigid and has superior layer adhesion. Carbon Fiber PLA shares similar properties with standard PLA but it’s stiffer. It also offers more dimensional stability, which means warp-free printing. The downside to carbon fiber filament is that its abrasive nature speeds up the wear and tear of printer nozzles, especially those made of brass.

Don’t Miss: Best Carbon Fiber Filaments.

Carbon fiber print temperature range: 190°C – 230°C

Applications

Carbon fiber PLA filament is a great choice for producing high quality and strong objects. This includes items like protective casings, various mechanical parts, and many other high durability uses.

Check Price of Carbon Fiber Filament on Amazon

The Pros

- Prints quality parts

- Soluble and durable

- No heated bed needed

- Little warping and shrinkage during the cooling process

The Cons

- Material contains abrasive strands

- Excessive wear on printer nozzles, especially brass

- Regular users need to invest in harder metals for print nozzles

14. Flexible, TPE Filament

Image from Creative ToolsPRICE STARTING FROM: $31.99 for 1.75 mm, 1kg spool

TPE 3D printer filament is easily the most flexible of all the printer materials. It is ‘super stretchy’ because of the thermoplastic elastomers, or TPE for short. It has such high elasticity properties that it feels like real rubber, easily springing back into shape like an elastic band. TPE is great to use with most FDM 3D printers. If you need to fabricate stretchable 3D parts that can endure more punishment than any regular ABS or PLA, this is your material.

It is ‘super stretchy’ because of the thermoplastic elastomers, or TPE for short. It has such high elasticity properties that it feels like real rubber, easily springing back into shape like an elastic band. TPE is great to use with most FDM 3D printers. If you need to fabricate stretchable 3D parts that can endure more punishment than any regular ABS or PLA, this is your material.

Don’t Miss: Best TPE Filaments.

TPE print temperature range: 225°C – 235°C

Applications

There are wide ranging applications and industries which benefit from TPE filament. We can see it used in household appliances and the automotive sector. It’s also a popular for kid’s toys, wearables, and smartphone cases, etc. For commercial use, TPE is found in medical supplies, weather seals for windows and doors, electrical insulation, and the soles of footwear, to name a few.

Check Price of TPE Filament on Amazon

The Pros

- High elasticity properties and exceptional abrasion-resistance

- Smooth consistent diameter

- Bonds well between layers (vital for high-quality)objects)

- Durable material with little shrinkage during the cooling process

- No heated bed needed

The Cons

- 3D printing with TPE is difficult for the inexperienced

- Print nozzle needs fine-tuning for optimal performance

- Can extrude from nozzle inconsistently

15.

Glow in the Dark FilamentImage from Form Futura

Glow in the Dark FilamentImage from Form FuturaPRICE STARTING FROM: $17.99 for 1.75 mm, 1kg spool

The name needs little introduction as this fun filament does exactly what it says on the label—it glows in the dark. It won’t glow indefinitely though, as the 3D printed object needs exposing to a light source to charge it. Once charged it will emit light in whatever colors you have made your part in. A great use for this material it to decorate children’s bedrooms or to make Halloween themes, and other such creative ideas. It’s a safe, environmentally-friendly filament, making it harmless for everyone to use. One of the major drawbacks is that glow-in-the-dark material is abrasive. The problem with abrasive filaments is that they can quickly wear out nozzles, especially brass. If you plan to use glow-in-the-dark 3D printing material often, be sure to install a hardened steel nozzle.

Glow-in-the-dark print temperature range: 180-240 °C

Applications

Imagination drives many of the uses for this fun material. It’s popular for kid’s toys, wearable gadgets, custom phone cases, and many other novelty items. Some creative artists also find it a great medium to work with for artistic designs. Another, more practical use is for light switches as it makes them easy to find in the dark.

It’s popular for kid’s toys, wearable gadgets, custom phone cases, and many other novelty items. Some creative artists also find it a great medium to work with for artistic designs. Another, more practical use is for light switches as it makes them easy to find in the dark.

Check Price of Glow in the Dark Filament on Amazon

The Pros

- Environmentally friendly, safe to use, biodegradable

- Low shrinkage during the cooling process

- Durable

- No heated bed needed to print

- Similar to regular PLA, which makes printing easy

The Cons

- Not food safe

16. Amphora 3D Printer Filament

PRICE STARTING FROM: $00 for 1.75 mm, 1kg spool

Amphora is a great filament for anyone who wants to produce objects which are lustrous, bright, and opaque. The Eastman Chemical Company created this fancy material specifically for 3D printing. Most common thermoplastics have uses other than 3D printing technologies, but not this one.

Most common thermoplastics have uses other than 3D printing technologies, but not this one.

Amphora print temperature range: 220°C – 250°C

Applications

Amphora is more of a specialist type of lightweight, impact-resistant, 3D printer filament. Common applications include mechanical parts and other objects that need a material that is of excellent strength, highly flexible, and durable.

Check Price of Amphora Filament on Amazon

The Pros

- No notable odors during the printing process

- Strong material with a high melting point (higher than regular PLA)

- Better layer adhesion resulting in an improved finish

- Impressive performance for bridging gaps

- Little to no warping, cleaner overhangs overall

- FDA-approved, making Amphora food safe

The Cons

- Not an easy material to print with

- Printer nozzle and bed need fine tuning for best results

Choosing the Right 3D Printer Filament

This guide gives you a good insight into the different 3D printer filaments on the market. There are others, but the ones listed here are the most widespread, easy-to-source materials at the time of writing. Before you choose the right filament for your next job, you need to check a few boxes. For example, as well as knowing what you intend to build, you also need to understand your printer’s capabilities. Not all 3D printers are able of printing in all 3D materials.

There are others, but the ones listed here are the most widespread, easy-to-source materials at the time of writing. Before you choose the right filament for your next job, you need to check a few boxes. For example, as well as knowing what you intend to build, you also need to understand your printer’s capabilities. Not all 3D printers are able of printing in all 3D materials.

You also need to prepare for trial and error if you plan to experiment with some of the more tricky filaments. Another consideration is the diameter of the filament, either 1.75mm or 3mm. If you’re unsure, always opt for 1.75mm as it’s easier to work with. 3D filament storage is another crucial area to think about. These plastics can absorb moisture from the air which can mess with the printing process. When not in use, a good way to store your 3D filament is to use vacuum bags that have a double zipper line for better, airtight sealing.

And finally, don’t allow the cheapest of the cheap filaments tempt you as they could prove to be a false economy. Seriously, low-cost, low-grade 3D printing filaments are more likely to contain chemical impurities. These impurities can result in unsatisfactory printed parts and clogged-up printer nozzles.

Seriously, low-cost, low-grade 3D printing filaments are more likely to contain chemical impurities. These impurities can result in unsatisfactory printed parts and clogged-up printer nozzles.

It might all sound like a lot absorb, but none of this takes long to pick once you start to dabble.

Warning; 3D printers should never be left unattended. They can pose a firesafety hazard.

What is the best plastic for 3D printing? Let's figure it out together!

Plastic for 3D printing

After purchasing your own FDM 3D printer, as well as in the course of choosing it, it becomes necessary to choose the right plastic for 3D printing. But how to do this if you are new to 3D printing and have little to no understanding of this issue? Plastic for printing on a 3D printer is in most cases the main component of successful product reproduction. Therefore, we will not save on knowledge, and will tell you how to choose the best plastic for 3D printing.

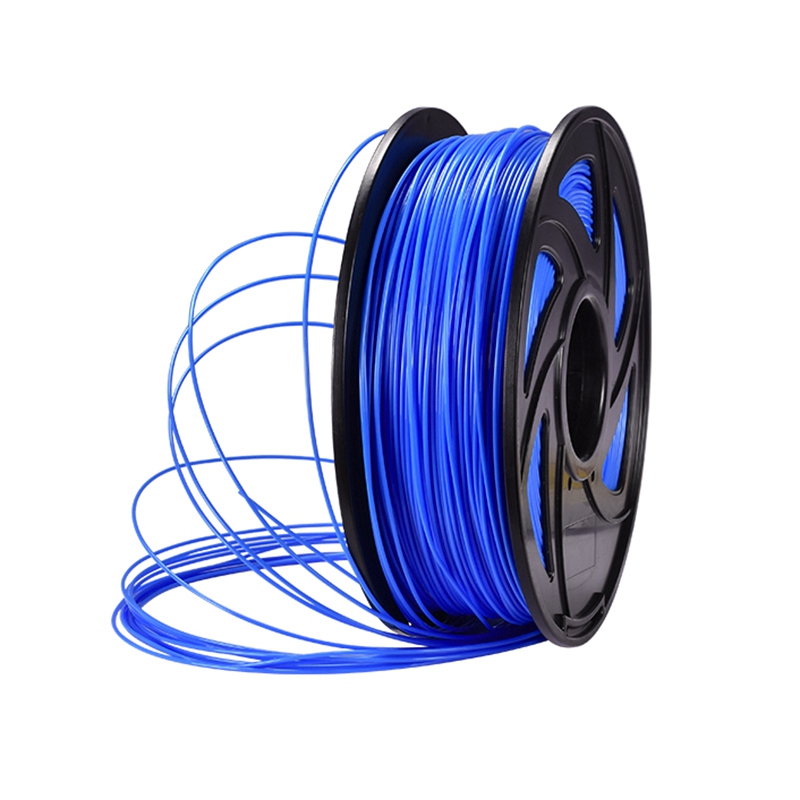

Types of plastic for a 3D printer

First of all, we need to consider the types of plastic for a 3D printer. Plastic for 3D printing, or filament, is produced in the form of a thin thread with a diameter of 1.75 mm and 3 mm. Most often, filaments with a thickness of 1.75 mm are used in the basic configuration, but some manufacturers of 3D printers provide the ability to install a 3 mm plastic feed system. Plastic for 3D printing has many varieties, among which the most common are ABS and PLA plastic.