Common uses for 3d printers

25 (Unexpected) 3D Printing Use Cases

For years, hype around 3D printing captured audiences in the mainstream press. With visions of a future including a 3D printer in every home, these predictions were light on details and ultimately most did not come to fruition. However, the possibilities of 3D printing were undeniable, despite the youth of the technology and the relatively low number of use cases that were viable in the past.

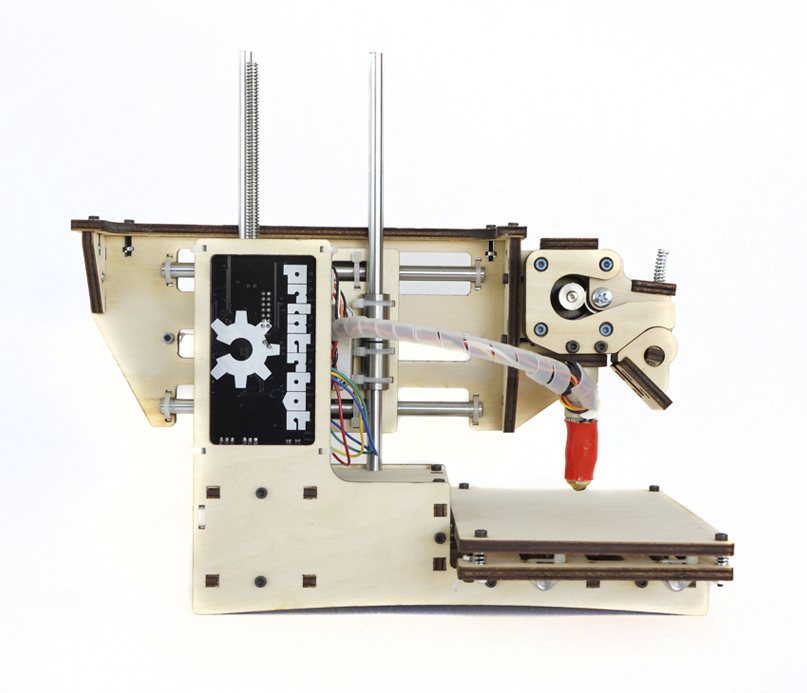

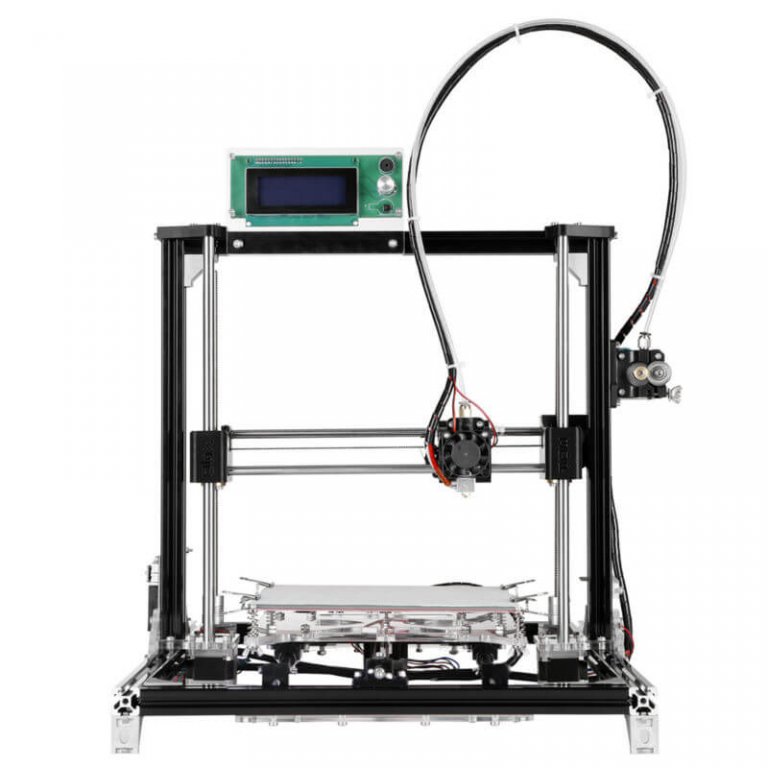

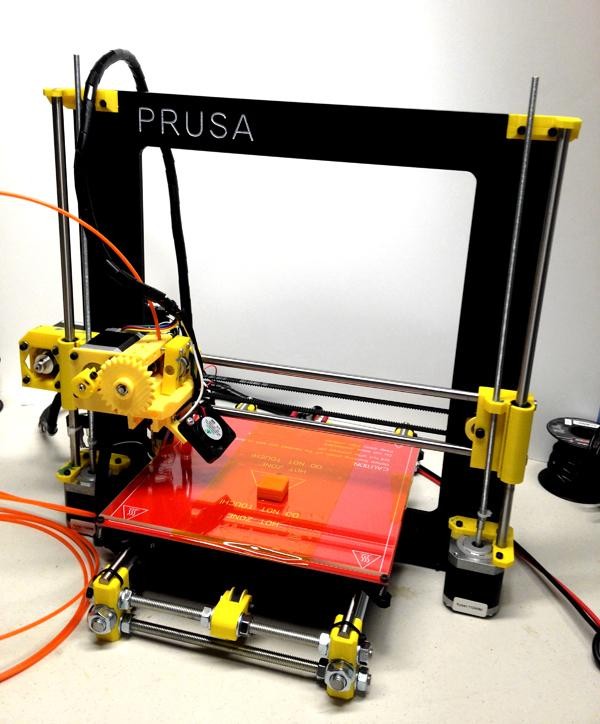

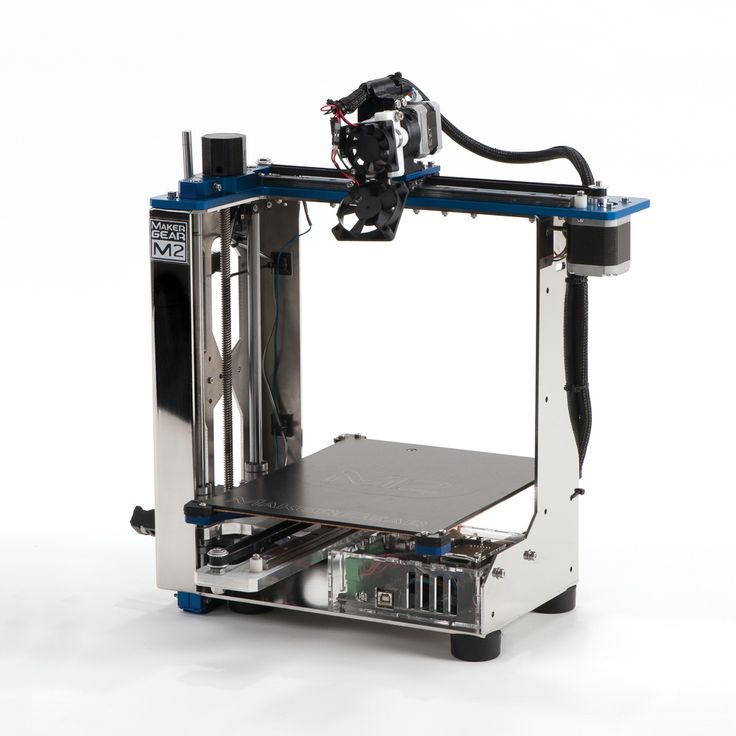

The initial hype masked legitimate and growing business applications for 3D printing. With a proliferation of high-performance desktop and benchtop machines being introduced into the market, we are now seeing a broader variety of businesses expanding their product offerings and delivering better results to customers.

What can you do with a 3D printer? Read on to discover 25 (often unexpected) 3D printing use cases that show the broad scope of possible applications for the technology.

Report

A new industry report that compares how recent and early adopters are using 3D printing for their business, and explores future trends of the technology.

3D printing can add enormous value to supply chains, unlocking a broad spectrum of production applications. The technology is growing more workable and affordable, with companies able to bring additive manufacturing in-house to support processes on the factory floor. New, resilient 3D printing materials are opening opportunities for the production of high precision, functional 3D prints that can stand in for final parts, offering customization opportunities that help designers radically push the boundaries of high-performance cars. Industrial design studio Vital Auto has put all of this technology to work creating high-fidelity prototypes and concept cars, rapidly working through iterations using a variety of advanced tools, including a large fleet of in-house 3D printers.

“We've used 3D printing from day one. We wanted to introduce it to our manufacturing processes, not only to reduce costs, but to give the customer more diversity with their designs and their ideas,” said Design Engineer Anthony Barnicott.

The automotive industry has seen the value additive manufacturing can add to multiple touch points in the creation of automobiles. This means going well beyond rapid prototyping to include:

- Creating custom, complex, and high-performance parts

- Producing tooling and manufacturing aids

- Manufacturing replacement parts and spare parts on demand

- Cutting costs and lead times by up to 90% compared to outsourcing

See How Concept Cars Are Created

Recent advancements in 3D printing technology have started to fundamentally change the audio industry, meaning that digital printing of custom fit ear devices for the audiology, noise protection, and consumer audiology industries has never been so affordable. In recent years, 3D printing manufacturers have brought skin-safe biocompatible materials to market, allowing for in-house production of ear models and headphone tips.

Custom fit offers a unique individual listening experience built around the earphone fitting exactly in the customers ear. This gives a secure fit that removes any possibility of earphones falling out of the ear, in addition to improved comfort and noise isolation.

This gives a secure fit that removes any possibility of earphones falling out of the ear, in addition to improved comfort and noise isolation.

“We are very excited about the concept of custom fit to deliver a custom experience to further enhance immersive listening. Formlabs shares Sennheiser’s drive for innovation – and improving the customer experience through this prototype is a testament to that mindset.”

Sennheiser Director AMBEO Immersive Audio, Veronique Larcher

The challenges that come with customized manufacturing can be overcome through the combination of Formlabs' disruptive printing technology and mobile scanning coupled with machine learning. This means customers can have easy access to custom fit earphones, with lead times reduced from four days to next day delivery or even same day.

Learn More About 3D Printing in Audiology

restor3D tools being printed, along side their final form.

Ten years ago, few people were talking about the huge impact 3D printing would have on the medical industry, from helping create advanced medical devices to patient-specific surgical guides. One company no one saw coming was restor3d, who leverages 3D printing capabilities to drastically improve surgical care by printing procedure-specific polymer instrumentation tailored to cervical spine implants.

One company no one saw coming was restor3d, who leverages 3D printing capabilities to drastically improve surgical care by printing procedure-specific polymer instrumentation tailored to cervical spine implants.

With a fleet of over 25 Formlabs 3D printers in its production line, restor3D is already printing the next generation of surgical tools. For surgeons using these tools, this procedure-specific, single packed sterile instrumentation system results in:

- Replacement of large, expensive surgical trays.

- Ability to iterate designs and quickly introduce new tools or features based on surgeon preferences.

- Dramatic reduction of supply chain and sterilization costs for hospitals.

Read How restor3d Is Creating Next Generation Tools

As much as 3D printing technology has developed in the past few years, there are even more high-impact, use cases currently in development. 3D printed organs is one of them.

Being able to easily create new organs has for decades been a dream for scientists working in regenerative medicine. While it remains in its early stages, the use of the 3D workflow to produce organic tissue eligible for transplant is bearing early fruit.

While it remains in its early stages, the use of the 3D workflow to produce organic tissue eligible for transplant is bearing early fruit.

Dr. Sam Pashneh-Tala from the University of Sheffield is leading the way. His research uses high-precision desktop stereolithography (SLA) 3D printing to enable the production of tissue-engineered blood vessels with a variety of geometries. This will allow for patient-specific vascular graft designs, improved surgical options, and provides a unique testing platform for new vascular medical devices for those suffering from cardiovascular disease—which is currently the number one cause of death worldwide.

“My differentiator is that I’m able to create blood vessels with geometries that are more closely matched to those found in the body. This offers the potential for improved surgical options and even patient-matched blood vessel designs. Without access to high-precision, affordable 3D printing, creating these shapes would not be possible, ” said Dr. Pashneh-Tal.

Pashneh-Tal.

Read About Tissue Engineering

The reconstruction of the three cities in the two different time periods consisted of over 650 segments, which were printed using Formlabs White Resin, each measuring 12x12cm.

As an industry already based on geometric design, prototyping, and modeling, architecture stands to gain enormously from advances in 3D printing technology.

On top of saving time during model production, the 3D printed models allow architects to anticipate the effects of certain design features with much greater certainty, e.g., by seeing a model produced with a fuller complement of materials, an architect can measure aspects such a light flow through the structure with higher precision.

But 3D printing’s use case goes beyond a single model: some firms are recreating entire towns. Institute of Architecture at the Hochschule Mainz - University of Applied Sciences. The result is an extraordinary exhibition that showcases six large-scale models of the cities, in the years 800 and 1250 AD. The models consist of over 650 parts, all of which were created using SLA 3D printing technology.

The models consist of over 650 parts, all of which were created using SLA 3D printing technology.

Learn About the Reconstruction of Medieval German Cities

The 990S TripleCell and the FuelCell Echo Triple.

The sport-footwear industry has long relied on technology to optimize the performance of their products, and with the digital workflow they have more options than ever in customization.

Large brands like New Balance, Adidas, and Nike, having recognized the power of additive manufacture, intend to mass produce custom midsoles made from 3D printed materials. As in other industries, the digital workflow will augment traditional methods of manufacture here—critical, highly-customized components of each product will be entrusted to the 3D printing, and the rest left to traditional means.

Given the unique properties required for footwear, New Balance worked with Formlabs to create a custom printing material which could resist the daily wear and tear faced by an athletic shoe. Shoe materials experience a variety of environments, with the additional need to withstand various levels of pressure thousands of times per day. Designed to create springy, resilient lattice structures, Rebound Resin has a much higher energy return, tear strength, and elongation than any other Formlabs material. Rebound Resin is strong enough to be used in gaskets, seals, and automotive interiors, but light and flexible enough for the sole of a shoe.

Shoe materials experience a variety of environments, with the additional need to withstand various levels of pressure thousands of times per day. Designed to create springy, resilient lattice structures, Rebound Resin has a much higher energy return, tear strength, and elongation than any other Formlabs material. Rebound Resin is strong enough to be used in gaskets, seals, and automotive interiors, but light and flexible enough for the sole of a shoe.

“One of the things that’s really exciting for us is that it provides a very different experience for the runner.”

Katherine Petrecca, General Manager of Footwear at the Innovation Design Studio, New Balance

See the 3D Printed New Balance Shoe

3D printing has already been integrated into the production of Hollywood films and is widely used for practical visual effects and costuming.

Whereas the creation of film's most fantastic creatures once required meticulous handcraft, the increased deadline pressure and time demands of modern moviemaking have made a quicker method of creating practical effects vital. Effects studios like Aaron Sims Creative now use a hybridized approach, practical effect-making enhanced by the digital workflow, to create new opportunities for collaboration and cut lead times on bringing ideas to life.

Effects studios like Aaron Sims Creative now use a hybridized approach, practical effect-making enhanced by the digital workflow, to create new opportunities for collaboration and cut lead times on bringing ideas to life.

“The Demogorgon was one of the first prints that we did using our Formlabs 3D printers, and we were amazed. Before that, we had always outsourced printing. So to be able to grow it in-house, and see a design that we helped create from the very beginning printed right in front of us, was kind of an amazing thing. It was like going back to the days when we used to sculpt with clay,” said Aaron Sims.

Read About How Aaron Sims Creative Builds Their Worlds

3D printing's artistic potential is not limited to physical artwork. It also has the power to bring entirely new dimensions to forms like dance and music. Given the design freedom inherent in 3D printing, even the most complex or unique instruments can be modified or created from scratch, at a fraction of the price of traditionally made instruments.

Having been around for centuries and barely changing, the violin’s form is recognizable to all. Violin music has evolved to such a high level that the instrument has attained an almost legendary status in our culture. But Formlabs engineer Brian Chan challenged himself to create a fully-functional acoustic violin, using a 3D printer and Formlabs White Resin.

Get an Inside Look at Design Process

3D scanning, CAD, and 3D printing have been used to restore the works of some of history's most famous artists, returning works by the likes of Michelangelo and da Vinci to their former glory.

Art restoration projects can be enhanced by combining 3D printing and 3D scanning, two powerful technologies that allow builders to take physical objects, turn them into three dimensional shapes, make changes or restorations, and re-print the parts.

Mattia Mercante uses 3D replication to replace lost pieces of sculptures and fine artworks at the world-renowned Opificio institute in Florence, allowing museum visitors to experience the art as the artists intended.

For one 17th-century reliquary, Mercante scanned intricate frame details from elsewhere on the piece using an HP 3D Structured Light Scanner, and then replicated the missing pieces on a Formlabs 3D printer. The prints were painted to appear identical to the original decorations. Best of all, the restoration required minimum CAD modeling, and was fast and affordable compared to hand craft.

Learn More About Art Restoration

3D printing has as much potential utility in reconstruction as it does in production. The work of a forensic artist is often made difficult by incomplete evidence. Digital technologies can be of tremendous use in legal investigations and can augment the abilities of forensic artists to reconstruct accurate models of persons of interest or victims.

The digital workflow here involves turning CT scans into 3D prints to aid in identification. For instance, when investigators find just part of a skull as evidence, a printer can model and replicate the complete sample.

Reconstructions of the appearance of crime victims have already played a key role in attaining justice, proving once again the utility of 3D printing beyond considerations of design and productive efficiency.

Just like 3D printing can be used for preoperative planning, CT scans of crime victims can help detectives get up-close to bones. Digital CT scan and X-ray data of remains can be used to produce 3D-printed replicas of various body parts. Then, the pathologist can determine the full circumstances of a crime, from the number of participants to the nature of the weapon used.

Learn More About Solving Crime

3D printing's impact is not limited to improving workflows or enabling rapid prototyping. It can also change lives directly. With 30 million people worldwide in need of artificial limbs and braces, there is hope that 3D printing can provide new solutions where cost and specification have traditionally been hurdles.

3D printing can provide an affordable alternative that, like many related advances in medicine, can provide therapy that is much more closely tailored to a patient's needs. The affordability and customizability of 3D printing techniques can profoundly alter the quality of life for the better for those suffering from injury or disability, as we saw in this story of a father and son.

The affordability and customizability of 3D printing techniques can profoundly alter the quality of life for the better for those suffering from injury or disability, as we saw in this story of a father and son.

We saw this type of innovation first hand with Matej’s and Mateja’s son Nik, who was suffering from cerebral palsy. Matej set out with a simple goal: to enable Nik to walk. Months of research and development followed, resulting in a custom-made, 3D printed orthosis that provides support and correction exactly where Nik needs them, which finally helped him take his first steps independently. Watch the full video above and read their story.

Beyond prosthetics which return lost function to a user’s body, it is possible to 3D print devices which are, in some ways, even better than the limbs they are replacing. With 3D printing, this is no longer a future possibility about bionetic, robo-cop like body parts, but part of the latest in cutting-edge prosthetic production. Some firms, such as Psyonic, are already delivering advanced prosthetics.

Arm Wrestling With A Bionic Hand

Maybe people think of 3D printing as producing smaller items which you can hold. In recent years, firms have been exploring manufacture-scale additive workflows that can produce much larger functional components. In the last few years, various initiatives have gotten underway to create houses and larger structures that are entirely the product of 3D printing, opening new frontiers in sustainable living and construction.

3D printing technique gives freedom of form to architects, even with previously less malleable building materials like concrete. More broadly speaking, it allows fully sustainable and energy-efficient homes to be built that also meet modern comfort standards. Construction by this means could be entirely waste-free, as well as less expensive and environmentally costly as traditional methods.

While you will not be moving into a 3D printed house on the near horizon, you can experience 3D printed construction projects today. The MX3D Bridge in Amsterdam is currently open to foot traffic. According to dezzen.com, the “structure used 4,500 kilograms of stainless steel, which was 3D-printed by robots in a factory over a period of six months before being craned into position over the canal this year.”

The MX3D Bridge in Amsterdam is currently open to foot traffic. According to dezzen.com, the “structure used 4,500 kilograms of stainless steel, which was 3D-printed by robots in a factory over a period of six months before being craned into position over the canal this year.”

Source: www.dezeen.com

Read More About the 3D Printed Bridge

With one of the highest barriers-to-entry of any industry in the world, space travel is ripe for 3D printing innovation. Lowering prototyping costs for expensive, space-specific tools and machines will lower costs and allow smaller companies to help innovate in space.

Aerospace startup Relativity has tested the creation of aluminum rocket engines using additive manufacturing. If successful, this application would sharply reduce the costs and practical difficulties of space travel, opening up the field to new business and to a vast potential for growth.

Masten Space Systems is another changemaker for 3D printing in the aerospace industry: founded in 2004, the company specializes in vertical takeoff and vertical landing rocketry. The company is launching a mission to the moon in 2022 as part of the NASA Commercial Lunar Payload Services (CLPS) Project. Using Formlabs 3D printers, Masten produced plastic rocket engines for R&D testing.

The company is launching a mission to the moon in 2022 as part of the NASA Commercial Lunar Payload Services (CLPS) Project. Using Formlabs 3D printers, Masten produced plastic rocket engines for R&D testing.

The company has experience in 3D printing in both plastics and metals--they’ve even helped develop new custom metals for their NASA Tipping Point project. “We really like 3D printed rocket engines because they enable you to do a lot of things that you can't do in a traditional manufacturing process. In our goal to drive down costs and increase our effectiveness, we started looking at how we could use the Stereolithography printers, particularly once Ceramic Resin and High Temp Resin were released. Those have some rather attractive engineering properties for seeing if we could actually use them in a rocket,” Matthew Kuhns, chief engineer at Masten, said.

Formlabs’ High Temp Resin and Rigid 10K Resin are examples of materials with optimal engineering properties for aerospace applications. High Temp Resin is designed for functional prototyping in high heat applications while Rigid 10K Resin is the stiffest material in our engineering portfolio, making it suitable for industrial-grade prototypes.

High Temp Resin is designed for functional prototyping in high heat applications while Rigid 10K Resin is the stiffest material in our engineering portfolio, making it suitable for industrial-grade prototypes.

Read More About Masten Space Systems

Origin Labs, within the Innovation Hub, will have a space dedicated to 3D printing for students and the broader community.

Most institutions of higher education are focused on preparing their students for the workforce of the future. The Pennsylvania State University is focused on the current workforce as well and has recently invested millions of dollars into building the Eric J. Barron Innovation Hub, which serves the public as well as the University community.

The Appalachian mountain range in western and central Pennsylvania has historically been the center of the nation’s coal mining industry, and enjoyed a solid and prosperous economy in the first half of the twentieth century because of it. As global and domestic economies shifted away from coal, the Appalachian region suffered, with a higher rate of joblessness and one of the lowest household income rates in the country, as reported by the Appalachian Regional Commission.

Over the last two decades, leadership at the local and state levels have sought to change that through investments in manufacturing, education, and technology. The Appalachian Regional Commission offers $1 million grants to “support educational opportunities and institutions, especially by connecting skill development and workforce training with local and regional business interests and opportunities.”

As additive manufacturing rapidly expands in a wide range of businesses (as seen in this blog post!), hiring managers are looking for employees trained in working in digital spaces and fluent in CAD. Universities are looking to address this market lead by creating large and well funded innovation hubs.

See the Investment the Pennsylvania State University is Making

Besides training tomorrow’s workforce in CAD and 3D printing, universities are starting to see the benefits of deploying 3D printers across a wide range of educational disciplines.

At UMass Lowell, that meant modernizing its sculpting and 3D design courses for the 21st century. Enter Yuko Oda, who joined the university in 2017 and got started by ordering a multitude of 3D printers, including a Formlabs SLA machine.

Enter Yuko Oda, who joined the university in 2017 and got started by ordering a multitude of 3D printers, including a Formlabs SLA machine.

Yuko is able to take her passion for art and technology into the classroom, currently teaching sculpture, 3D modeling and animation, and interactive media. Most students know that they’re required to understand 3D animation and 3D modeling for future careers in various fields, including sculpture design for cinema. For studio artists, 3D modeling has become an essential skill.

“Students sculpt a 3D model, import it into Zbrush, then print in various resins, including Clear Resin. The ability for Formlabs machines to show intricacies that were modified in Zbrush is unparalleled when compared to other printers in the lab.”

Yuko Oda

One of the most promising new developments in sculpture is the integration of 3D printing and Virtual Reality (VR). This is especially salient for students intimidated by 3D design. VR is rapidly reducing barriers for 3D design, allowing artists and students to create with their hands in programs such as Oculus Medium. Yuko has taught 8th graders how to create a 3D object in 30 minutes in VR, and then print the artwork on a 3D printer. Even for seasoned sculptors, VR reduces the time it takes to go from an idea to a physical object, potentially opening up new areas of experimental art.

VR is rapidly reducing barriers for 3D design, allowing artists and students to create with their hands in programs such as Oculus Medium. Yuko has taught 8th graders how to create a 3D object in 30 minutes in VR, and then print the artwork on a 3D printer. Even for seasoned sculptors, VR reduces the time it takes to go from an idea to a physical object, potentially opening up new areas of experimental art.

Learn How How UMass Lowell Integrates Art and Technology

While caretakers at ZooTampa were performing a routine check-up on a 25-year-old great hornbill, they found a lesion at the base of the bird’s casque, the yellow helmet-like growth on top of the head. Further examination determined that the bird, named Crescent, was suffering from life-threatening cancer.

The cancer, located near the bird's skull, couldn't be removed because it housed part of the bird's sinuses. The team wanted to know if they could remove the casque, and replace it with a 3D printed replica designed specifically for this bird. Patient-specific prosthetics and devices have been used before in human procedures, but never for a great hornbill. Would it be possible, and if so, which materials would be safe for the bird?

Patient-specific prosthetics and devices have been used before in human procedures, but never for a great hornbill. Would it be possible, and if so, which materials would be safe for the bird?

ZooTampa says the successful 3D-printed “replacement beak,” was created using BioMed White Resin. This material is an opaque white material for biocompatible applications requiring long-term skin contact or short-term mucosal contact. Special among Formlabs SLA 3D printing materials, this medical-grade material is validated for short-term tissue, bone, and dentin contact.

3D Printing and Veterinary Medicine

During the COVID-19 pandemic and following supply chain crises of 2021/22, many firms turned to 3D printing to help keep machines online and products rolling off the factory floor. The expanded use of in-house 3D printing to create end-use parts, such as replacement parts for machines, has made additive manufacturing a key tool to address supply chain problems.

Formlabs commissioned the 2022 3D Printing Applications Report to better understand what, if anything, has changed recently among 3D printing users. The report demonstrates the shift in attitudes around 3D printing from an R&D and prototyping tool to an invaluable manufacturing technology needed to meet evolving consumer preferences and overcome supply chain challenges. Whether working to ease supply chain constraints, creating limited run products, or personalizing devices, businesses have been forced to rethink how they produce goods to meet customer demand.

The report demonstrates the shift in attitudes around 3D printing from an R&D and prototyping tool to an invaluable manufacturing technology needed to meet evolving consumer preferences and overcome supply chain challenges. Whether working to ease supply chain constraints, creating limited run products, or personalizing devices, businesses have been forced to rethink how they produce goods to meet customer demand.

End-use parts printed on the Fuse 1.

An IR sensor purge printed on the Fuse 1 in Nylon 12 Powder.

Building 3D printers is always an engineering challenge. Packing industrial-grade performance into an affordable, sleek desktop machine requires years of engineering and design work. This was especially true of Formlabs’ much anticipated selective laser sintering (SLS) 3D printer, the Fuse 1.

One of the tools Formlabs engineers used to prototype parts was the Fuse 1 itself. But the use of 3D printing didn’t stop at prototyping. Today, every single Fuse 1 unit shipped to customers contains multiple production parts printed directly on a Fuse 1 using Nylon 12 Powder.

Using the Fuse 1 SLS printer to prototype and create end-use parts offered three main advantages, according to Seth Berg, the engineer program manager overseeing the Fuse 1:

- The design freedom to create complex parts without internal support structures.

- Reducing supply chains by prototyping and creating end-use parts in-house.

- Eliminating outsourcing to achieve an affordable solution for small-batch production with a proven, versatile Nylon 12 material.

To see how the team did this, and which end-use parts on the 3D printer and 3D printers, watch the video below.

In May of 2020, Forbes ran an article titled: How 3D Printing Test Swabs Will Help Fulfill America's Shortage. They noted that the 3D printing industry has come together to tackle the COVID-19 swab shortage head on, with Formlabs, HP, Origin, Carbon, Desktop Metal and more working to ramp up swab production.

The impact of the COVID-19 pandemic required a global, concerted response. Through collaborating with USF and Northwell, Formlabs enabled a solution that has been deployed worldwide. With the accessible design, affordable equipment, and validated processes, the swab design enabled over forty million COVID tests in twenty five countries. Over the last year, Formlabs 3D printers have continued being used by governments and healthcare providers to improve patient testing and care. This global solution is just one example of how the agility of 3D printing can benefit the public good.

Through collaborating with USF and Northwell, Formlabs enabled a solution that has been deployed worldwide. With the accessible design, affordable equipment, and validated processes, the swab design enabled over forty million COVID tests in twenty five countries. Over the last year, Formlabs 3D printers have continued being used by governments and healthcare providers to improve patient testing and care. This global solution is just one example of how the agility of 3D printing can benefit the public good.

We saw this happen dramatically in Singapore, where Eye-2-Eye Communications ramped swab production to over 30,000 swabs per day to help keep the city safe.

“It has not only been an excellent opportunity to showcase the advantages of 3D printing for rapid design and development but it has also shown Formlabs effectiveness in being able to mass produce products in very short timeframes. Also, as we see spikes in cases across the globe it is reassuring to know we can scale our production relatively easily to meet demand if required,”said Chief Executive Officer of Eye-2-Eye Communications, Miles Podmore.

One controller with buttons printed on the Fuse 1 (left), and another with buttons injected molded (right).

One problem with creating custom aftermarket parts is these orders are typically low volume, and need to evolve in response to product updates by the original manufacturers. But with the rise of in-house 3D printing, custom manufacturing has sprouted in multiple industries.

Battle Beaver Customs is focused on delivering a premier gaming experience through custom gaming controllers. Their modifications make the controllers more responsive and more competitive, allowing players to increase their gaming potential and reach peak performance across a range of games. Rapid prototyping with the Fuse 1 SLS 3D printer allows Battle Beaver Customs to quickly change their mount and button designs. When building custom consumer products, quick turnaround times can pay dividends for businesses looking to stay ahead of their competitors. According to Head of Research and Design at Battle Beaver Customs, Michael Crunelle, the “Fuse 1 has been great for being able to make changes quickly, from concept to end-use part. Our competitors can’t keep up with us."

Our competitors can’t keep up with us."

JetBoatPilot, a marine parts and accessories manufacturer, has built a reputation as an authority in the industry by creating aftermarket products that improve the performance and low speed handling of jet powered boats.

JetBoatPilot utilizes the Form 3 SLA and Fuse 1 selective laser sintering (SLS) 3D printers to prototype and manufacture aftermarket parts. A newly designed and now top performing product, the Lateral Thruster 2.0, was designed and manufactured on the Fuse 1. Equipped with the Fuse 1 and Nylon 12 Powder, JetBoatPilot was able to cut costs by 6x compared to their previous manufacturing methods.“I probably would have made that (aluminum version) retail price somewhere in the $400 dollar range, maybe even $600 dollar range, if I really had pushed it. I wouldn't have sold nearly as many at $600. But now I'm selling it for $199 and the customer is happy as they can be. And I'm twenty times the cost of goods,” says JetBoatPilot founder Will Owens.

With 928 stores spanning across 48 countries, Lush Cosmetics is a retailer known globally for making creative and crowd pleasing products such as Massage Bars, Body Butters, Bath Bombs and more, attributes its success to being able to respond quickly to trends and customer demand.

To bring new, industry defining, highly-detailed cosmetics to life, Lush needed to turn to 3D printing for much more than prototyping new shapes. They’ve invested in a next-generation additive manufacturing center for mold creation, tooling, and end-use parts.

The Lush Cosmetics team vacuum forms using 3D printed molds in-house.

“We use our Formlabs 3D printers for a mix of mold creation, custom tooling, and end-use parts. We’re a reactive business and having this capability in-house means we don’t need to share designs externally as we own everything in the product development process,” said Damien Carter, Innovation Lab Manager at Lush Cosmetics.

See How Lush Cosmetics Operates

3D printing is unleashing new possibilities and business opportunities. What used to be too complex, prohibitively expensive, or impractical to produce with traditional methods is available at no extra cost with digital technologies, giving full control to designers and opening the door for fully customizable consumer products to become a reality.

What used to be too complex, prohibitively expensive, or impractical to produce with traditional methods is available at no extra cost with digital technologies, giving full control to designers and opening the door for fully customizable consumer products to become a reality.

A good example of this is Gillette’s Razor Maker™, which gives customers the opportunity to customize the handle of their razor by picking various designs, colors, or adding custom text.

“For Gillette, piloting Razor Maker™ represents a crucial step in our customization journey where new technology and new business models must come together in order to deliver products that are as unique as our consumers,” said Donato Diez, global brand manager for Gillette and Razor Maker™

Learn How Gillette Uses 3D Printing to Unlock Consumer Personalization

Dentistry has also been one of the most prominent drivers of 3D printing investment, desktop 3D printers are an increasingly common sight in dental labs and practices. As a matter of fact, the popular clear aligners, thermoformed on 3D printed molds, are possibly the single most successful use of 3D printing we've seen to date.

As a matter of fact, the popular clear aligners, thermoformed on 3D printed molds, are possibly the single most successful use of 3D printing we've seen to date.

Over the past ten years, 3D printing has so advanced in dental that now no new dental labs are opening without using some form of digital dentistry. With materials so good they can 3D print permanent crowns, full dentures, and more.

3D printing technologies thrive in an environment where our unique bodies require custom solutions. As a result, the dental industry is going through a rapid digital transformation with digital workflows bringing increased efficiency, consistently high quality, and lower costs to dental labs and practices.

Five Ways 3D Printing Has Redefined the Dental Industry

Next time you’re out for a night on the town, keep your eyes peeled for our next unexpected 3D printing use-case: 3D printing is coming to custom glasses frames.

Marcus Marienfeld AG set themselves apart from conventional glass frames, using different and unique production techniques to create their frames. Recently they started integrating selective laser sintering (SLS) 3D printing into the production line for frames in their Swiss workshop for printing end-use parts and rapid tooling for forming titanium.

Recently they started integrating selective laser sintering (SLS) 3D printing into the production line for frames in their Swiss workshop for printing end-use parts and rapid tooling for forming titanium.

“You get very inventive and imaginative when you have a 3D printer in-house. I can do things with little effort that I wouldn't otherwise try," said Marcus Marienfeld.

See the 3D Printed Glasses

Visualizing 3D printing-driven changes in the way things are made does not require the feats of imagination it once did. As workflows have developed over the last several years and gained footholds in various industries, we are beginning to see that revolutionary potential demonstrated.

From dentistry and across healthcare to consumer goods, architecture, and manufacturing, the public is interacting more and more with the end products of 3D printing. Making custom parts cost-efficient, cutting lead times and overheads, and empowering customers by bringing them closer to the products they want—we can only expect the influence of 3D printing to continue expanding.

Explore Formlabs 3D Printers

Top 3D Printing Applications Across Industries

4. ConstructionConstruction 3D printing offers various technologies that use 3D printing as the main way of fabricating buildings or construction components.

3D printing applications that are used in construction include extrusion (concrete/cement, wax, foam, and polymers), powder bonding (polymer bond, reactive bond, sintering) and additive welding. 3D printing in construction has a wide array of applications in the private, commercial, industrial and public sectors. Advantages of these technologies include allowing more complexity and accuracy, faster construction, lower labor costs, greater functional integration, and less waste.

The first fully completed residential building was constructed in Yaroslavl, Russia in 2017. 600 elements of the walls were printed in a shop and assembled on site, followed by completion of the roof structure and interior decoration for a total area of 298. 5 sq meters (3213 sq ft). The project represents the first time in the world the entire technological cycle had passed building requirements, from design, building permit, registration, to connection of all engineering systems. The building was not built just for presentation, today a real, normal family lives in it.

5 sq meters (3213 sq ft). The project represents the first time in the world the entire technological cycle had passed building requirements, from design, building permit, registration, to connection of all engineering systems. The building was not built just for presentation, today a real, normal family lives in it.

Concrete 3D printing has been in development since the 1990s, as a faster and less expensive way of constructing buildings and other structures. Large-scale 3D printers designed specifically for printing concrete can pour foundations and build walls onsite. They can also be used for printing modular concrete sections that are later assembled on the job site.

In 2016, the first pedestrian bridge was 3D printed in Alcobendas, Madrid, Spain. It was printed in micro-reinforced concrete at a length of 12 meters (39 ft) and width of 1.75 meters (5.7 ft). The bridge illustrates the complexities in the forms of nature and was developed by both parametric (using a set of rules, values, and relationships that guide the design) and computational design, allowing the optimal distribution of materials while maximizing structural performance.

It was a milestone in the international construction industry, being the first large-scale application of 3D printing technology in the field of civil engineering in a public space.

3D printing is used to produce architectural scale models, enabling a faster turnaround of the scale model and increasing the overall speed and complexity of the objects produced.

As a futuristic concept, 3D printing is being studied as a technology for constructing extraterrestrial habitats, such as habitats on the Moon or Mars. It has been proposed, using building-construction 3D printer technology, fabricating lunar building structures with enclosed inflatable habitats for housing human occupants inside the hardshell lunar structures. These habitats would need only ten percent of the structure to be transported from Earth, using local raw lunar materials for the other 90 percent of the structure.

5. Art and JewelryAn unexpected application of 3D printing technology has been in the world of art and jewelry making.

3D printers allow jewelry makers to experiment with designs not possible with traditional jewelry making methods. 3D printing also allows the production of individual, unique pieces of jewelry or customized pieces at a much lower cost, using 3D printing materials such as PLA (polylactic acid filament), gold or platinum.

3D printing technology has served to inspire artists all over the world. With metal 3D printing especially, artists now create beautiful intricate pieces.

Just a few examples of 3D printing technology in the arts include Banksy, the mysterious and famous British street artist, whose works’ have been rendered from 2D to 3D using powder binding 3D printing.

The Dutch artist Oliver van Herpt creates ceramic vases with 3D printing. From the Netherlands, Danny van Ryswyk creates eerie 3D printed sculptures, reminiscent of filmmaker Tim Burton’s characters. The digital artist Gilles Azzaro even makes the invisible visible by creating 3D images of voices using the sound waves from the voices.

Recently, the Prado Museum organized an exhibition of paintings by well-known artists rendered in 3D. The purpose was to allow visually impaired people to feel these works that were previously inaccessible to them.

These are just a few of the countless ways, from education to medicine to industry to the arts, that 3D printing technologies impact our world today.

Medical 3D Printing Application Overview

Contents:

- Medical 3D Printing Equipment Use

- Benefits of using 3D printers

- The main directions of the use of additive technologies in medicine

- Manufacture of surgical and other medical instruments

- Dentistry and prosthetics

- Student education and preparation for surgery

- 3D bioprinting of organs and tissues

- Production of medicines on a 3D printer

- Creating ovaries

- Making a model of the heart of a 4-year-old patient on a three-dimensional printer Zortrax M200

- Creation of a cranial implant

- Use of individual sensors

- Treatment of extensive wounds

- Creation of artificial corneas

- Manufacture of the Volt Bipolar Surgical Forceps for Laparoscopic Operations

- Hip replacement

- Fabrication of dental crowns

- Reconstruction of the auricle (cartilage fabrication)

- Production of dental impressions

- Construction of a medical exoskeleton

- Fabrication of the Cardiovascular Model

- Creation of prostheses

3D Printing in Medicine

3D printing was first used in the medical field to print dental implants in the early 2000s. Since then, the field of medical application of this electronic technology has expanded significantly and continues to develop. Now with its help, elements of the respiratory tract (nose, etc.) and the skeleton (jaw, joints, etc.), cell cultures, blood vessels, some parts of the eyes, organs (kidneys, bladder, etc.), tissues, medicines are produced. , layouts of biomolecules, bacteria, viruses and more.

Since then, the field of medical application of this electronic technology has expanded significantly and continues to develop. Now with its help, elements of the respiratory tract (nose, etc.) and the skeleton (jaw, joints, etc.), cell cultures, blood vessels, some parts of the eyes, organs (kidneys, bladder, etc.), tissues, medicines are produced. , layouts of biomolecules, bacteria, viruses and more.

Printable 3D files allow users and researchers around the world to share their own scientific developments over the network, discuss interesting cases and the opinions of colleagues. And also independently or jointly with partners to improve three-dimensional prototypes without spending months and years reproducing objects from scratch.

Working on additive projects requires the integration of technologies from different scientific fields, including cell biology, medicine, mathematics, physics, engineering, biomaterials science, and industries.

Advantages of using 3D printers

Medical 3D printing has the following advantages:

- material and labor savings;

- 3D printing of structures of the highest level of complexity, completely similar to prototypes, lightening their weight;

- high print speed;

- high accuracy and detail, taking into account the anatomical parameters of a particular patient;

- a large number of innovative high-tech materials, including a wide range of consumables that are suitable for implantation in the body;

- cost reduction of medical products;

- reduction of production terms and, as a result, timely provision of medical care.

The main areas of application of additive technologies in medicine

The use of 3D printers in medicine can be divided into the following categories:

- Manufacturing of medical instruments.

- Printing of orthopedic products, frameworks and implants.

- Printing of 3D anatomical models for educational purposes and in preparation for operations.

- Creation of organs and tissues.

- Pharmaceutical research.

Manufacture of surgical and other medical instruments

In order to perform surgical interventions with minimal trauma for patients, surgeons try to use personalized instruments that are anatomically suitable for a particular person. 3D printing makes it possible to produce customized instruments and templates for surgery in just a few hours.

Additive technologies allow surgeons to customize finished instruments to the right shape and size for more productive, comfortable and safer work. Dentists have the opportunity to create, for example, personal guiding instruments in front of the patient to protect healthy teeth from damage when installing prostheses.

Dentists have the opportunity to create, for example, personal guiding instruments in front of the patient to protect healthy teeth from damage when installing prostheses.

Dentistry and prosthetics

Three-dimensional technologies have become a real breakthrough in the development of the medical products market and the field of dentistry in particular. First of all, they made it possible to scan the oral cavity in a three-dimensional format as accurately and in detail as possible. Secondly, with the help of 3D printing, it is possible to produce dental prostheses in full accordance with the anatomy of patients without additional fitting. A significant reduction in manual labor when working on veneers, bridges and crowns made it possible to expand the list of materials for prosthetics, reduce the required manufacturing tolerances and improve the quality of work in general.

Additive manufacturing is widely used in medicine to design complex individual and serial products: surgical implants, prostheses of any geometry, auxiliary structures, etc. Such structures are made by converting CT, MRI or X-ray images into three-dimensional models for 3D printing devices using specialized software. 3D technologies are especially in demand when it comes to the urgent production of non-standard prostheses and implants. The fact is that standard models often do not correspond to the specifics of the anatomy of patients. For example, neurosurgeons often face such a problem: human skulls have a unique shape, so it is extremely difficult to create a standard cranial implant. Before the advent of three-dimensional technologies and 3D-printed models, doctors finalized and customized implants, sometimes right during the operation. Now you don't need to do this. The most important advantage of printed prostheses is a perfectly precise connection with the body with virtually no risk of rejection.

Such structures are made by converting CT, MRI or X-ray images into three-dimensional models for 3D printing devices using specialized software. 3D technologies are especially in demand when it comes to the urgent production of non-standard prostheses and implants. The fact is that standard models often do not correspond to the specifics of the anatomy of patients. For example, neurosurgeons often face such a problem: human skulls have a unique shape, so it is extremely difficult to create a standard cranial implant. Before the advent of three-dimensional technologies and 3D-printed models, doctors finalized and customized implants, sometimes right during the operation. Now you don't need to do this. The most important advantage of printed prostheses is a perfectly precise connection with the body with virtually no risk of rejection.

Student education and preparation for surgery

3D models are a much better medium for teaching and training medical students than human cadavers. 3D mock-ups are more accessible, and 3D modeling helps to reproduce a wide range of pathologies relevant to the topic under study. For example, neuroanatomical 3D models are very useful for future neurosurgeons, as they provide the most complete picture of the most complex structures of the body, which cannot be achieved by studying two-dimensional images.

3D mock-ups are more accessible, and 3D modeling helps to reproduce a wide range of pathologies relevant to the topic under study. For example, neuroanatomical 3D models are very useful for future neurosurgeons, as they provide the most complete picture of the most complex structures of the body, which cannot be achieved by studying two-dimensional images.

Three-dimensional models printed on a 3D printer based on the results of hardware research allow taking into account the patient's anatomy when rehearsing operations. The use of a tangible three-dimensional model of the patient's organ gives the surgeon the opportunity to more thoroughly study the pathology or simulate surgery, which significantly reduces the risk of medical errors.

Production of organs and tissues by 3D bioprinting

Bioprinting is one of the types of 3D printing in medicine. Instead of metal or plastic, special printers use a syringe dispenser to apply "biological ink" (tissue spheroids), that is, layers of living cells or a structuring base for them, creating an artificial living tissue. For the "printing" of some tissues, stem cells, seaweed or porcine collagen protein are taken.

Organic materials obtained in this way are a good alternative to donor tissues and a valuable tool for medical research. They can be used for tissue regeneration, and in the future, for the restoration of organs directly in the patient's body.

3D bioprinting can be done using different technologies: inkjet, laser or extrusion. The most common method is 3D inkjet printing, where multiple printheads can be used to print different types of cells (muscle tissue, blood vessels, organ-specific cells). These cells are essential for building heterocellular organs and tissues.

3D drug production

3D technologies are used in personalized medicine and pharmaceutical research. With the help of 3D printing, you can fully control the dosage of various drugs and the composition of dosage forms with prolonged action and complex release profiles of active substances. Pharmacists have the opportunity to effectively analyze the pharmacogenetic profile of patients and other parameters. For example, gender, age and weight, to determine the optimal dose of drugs and their regimen. Based on the clinical response, the dosage may be adjusted if necessary.

Additive printing allows the production of personalized medicines according to new formulations, for example, complex multilayer tablets or capsules containing several active ingredients, and many other useful things.

Examples of the use of 3D printers in medicine

Ovarian printing

In 2017, American doctors and scientists at Northwestern University Chicago (USA) developed an artificial ovary that opens up opportunities for the full restoration of female reproductive function. During the study, a 3D-printed ovarian prosthesis was implanted into the body of an infertile laboratory mouse. As a result of the experiment, the “patient” acquired offspring, moreover, the mice turned out to be completely viable and after that they were also able to produce offspring.

It is currently unknown whether such an artificial ovary can be implanted in a woman, as human follicles grow much faster than mouse follicles.

Making a model of the heart of a 4-year-old patient on a Zortrax M200 3D printer

A team of experts from the Department of Pediatric Cardiology and Congenital Heart Diseases, together with colleagues from the Department of Radiology and Cardiac Surgery of the Medical University of Gdansk (Poland), used the Zortrax M200 3D printer to prepare for the execution surgery for the treatment of complex congenital heart disease in a four-year-old patient - tetralogy of Fallot.

The modern method of treating this pathology involves the supply of an artificial valve for implantation to the heart through a special catheter inserted through the femoral vein. This is an extremely complex operation that requires the surgeon to have the most complete and detailed knowledge of the anatomical characteristics of a real patient.

Previously, doctors could only rely on a three-dimensional computer model developed from MRI and CT images. However, these images were not enough to form a complete picture of the state of the organ and the likely problems that could occur during surgery. The use of a highly detailed physical copy of an organ (heart with cells, chambers, ventricles, blood vessels) can play a decisive role in the planning of the operation and be the main factor in its success.

The model of the heart was printed in the laboratory in 24 hours. Z-Ultrat material was used for 3D printing of the heart, and Z-Glass material was used for vessels. The operation was successful. The model was then handed over to the University for use as a teaching tool for students.

Creation of a cranial implant

Titanium bone implants are printed in single copies. It is when working with them that the advantages of 3D printers using selective laser melting (SLM) technology are best manifested. This method allows you to print implants of any shape with the highest accuracy in just a few hours.

Using custom sensors

In 2016, scientists from Washington University in St. Louis (USA) conducted a study on the use of flexible and movable silicone custom sensors. They printed three-dimensional copies of scanned models of the hearts of experimental animals and placed sensors around them. Three-dimensional sensors can be removed from the prototype and fixed to the human heart. With their help, you can monitor the work of the heart muscle in order to prevent the occurrence of strokes, heart attacks and other serious diseases. Individual sensors are used so far only outside the body, but scientists suggest that in the future it will be possible to introduce them into the human body.

Treatment of extensive wounds

Scientists at the Wake Forest Institute of Regenerative Medicine have developed a mobile 3D printer that can print skin cells grown from patient tissue directly over a wound.

Major burns are traditionally treated by grafting the patient's healthy skin over damaged skin. This method is quite traumatic, in addition, it cannot be applied in the absence of healthy skin on the body.

The ZScanner Z700 handheld scanner, developed by scientists, will determine the depth and size of the wound. Based on this data, 3D bioprinting equipment creates epidermal, dermal and subcutaneous skin cells at appropriate depths, completely covering the wound. The 3D printer consists of an extruder (print head) with eight nozzles with a diameter of 260 microns with independent dispensers, moving along three axes. Especially for this model of a 3D printer, scientists have developed a bioink based on epidermal keratinocytes and autologous dermal fibroblasts in a hydrogel carrier.

Printing of artificial corneas

A group of scientists from the School of Medicine of Kungpuk National University and Pohang University of Science and Technology in South Korea has developed a technology for 3D printing of an artificial cornea from a patient's tissue material (stem cells and decellularized corneal stroma) on a Nano Master SMP-III 3D bioprinter with microextrusion technology. The cornea, made on a 3D printer and filled with biomaterial, is cultivated for four weeks in an incubator at a temperature of 37 degrees.

The resulting material can completely replace the donor cornea. Its main advantage is full compatibility with the patient's tissues. Cellular 3D printing reproduces the natural microenvironment of the eye as closely as possible, allowing for natural transparency. Unlike traditional artificial corneas made of synthetic polymers and recombinant collagen, this material takes root just fine. In addition, its use will help reduce the waiting time for surgery, which is on average 6 years (for example, South Korea).

Manufacture of the Volt Bipolar Surgical Clamp for Laparoscopic Operations

In 2016, Bite developed a miniature 3D printed laparoscopic instrument for clamping and coagulating tissues and vessels, designed for minimally invasive surgery. The clamp has been successfully tested on porcine liver. The design of the instrument allows easy adjustment of the geometry of the tip and shaft, taking into account the anatomy of the patient and the specifics of the surgical intervention.

Hip prosthesis print

Employees of the Institute of Traumatology and Orthopedics. R.R. Vreden, together with colleagues from LETI (St. Petersburg), worked on the design of a titanium prosthesis of the hip joint. First, scientists made a model of the bone out of plastic based on computed tomography. Then the implant was designed and its positioning on the bone was corrected. The next step was planning the operation on a mock-up and, to top it off, printing the prosthesis on a 3D printer. The implant was successfully implanted in a patient with an almost completely destroyed hip joint, as a result of which the person regained the ability to walk independently.

Production of dental crowns

Using the Farsoon FS121M 3D printer, working on SLM technology, allows you to simplify and speed up the printing of dental crowns and other objects of complex shape. The equipment can print 160 metal crowns in just 3 hours. The highest precision of products is achieved through the use of a laser beam with a spot diameter of 40 microns and a fine powder.

Reconstruction of the auricle (cartilage production)

Using the Rokit Dr. 3D printer. Invivo 4D Premium with a syringe dispenser and consumables such as copolymer of glycolic and lactic acids (PLGA) and hydroxyapatite (HAp) can print the flexible structures needed for cartilage reconstruction. This technology is used in reconstructive surgery of the external ear.

Dental Impression Printing

The Raise3D Pro2 3D printer with FDM technology enables the production of orthodontic dental impressions. The huge advantage of this technique is the reduction of time spent with the patient. A 3D model is created using a volumetric scanner in just 1 minute. On its basis, a plastic prototype is printed, which is used by orthodontists for subsequent work. The technology is widely used by physicians at the French hospital Ortho 34.

Creation of a medical exoskeleton

Specialists from Barlomiej Gaczorek Design Studio have developed a model of a complex supporting exoskeleton for hands and printed its details on a Sinterit Lisa 3D SLS printer. The use of SLS selective sintering technology made it possible to achieve the highest precision of structural elements.

Making a model of the cardiovascular system

In rare forms of cardiovascular diseases, especially in newborns, the risk of making mistakes in the preparation of the therapy regimen is too high, which requires a detailed development of the treatment program. Specialists at the University Clinical Center in Gdansk (Poland) use the Sinterit Lisa SLS printer to work with complex diagnoses. Doctors have created a three-dimensional model of the cardiovascular system, designed for a detailed study of the anomaly and preparation for surgery.

Creation of prostheses

The use of FDM printers is indispensable in situations where it is necessary to facilitate and reduce the cost of manufacturing exclusive prostheses. Canadian designer Albert Fung has developed a 3D digital model of a prosthesis that has become the basis for the production of prosthetic hands for Sierra Leoneans affected by the civil war. Medical specialists in Sierra Lyon modify the CAD model based on the anatomy of each patient and print the products on a Raise3D Pro2 3D printer. Printing of such structures costs only 50 US dollars (for comparison, the cost of prostheses made using other technologies is several thousand dollars).

Conclusion

The field of application of 3D printing technology in medicine is full of achievements and is constantly expanding, resembling a real revolution in the field of healthcare. Additive manufacturing methods increase the productivity and cost-effectiveness of doctors' work, open up a lot of new opportunities and reduce waiting times. They allow the production of individual medical products and drugs, improve the quality of patient care, while making medical care more accessible.

3DTool sells trusted brands of 3D scanners and 3D printers for medical use.

Medical 3D printer overview

Use of 3D printing in medicine

Source: docwirenews. com

3D printing has been used in medicine since the early 2000s, when this technology was first used to make dental implants. Since then, the use of 3D printing in medicine has expanded significantly, with doctors around the world describing ways to use 3D printing to produce ears, skeletal parts, airways, jawbones, eye parts, cell cultures, stem cells, blood vessels and vasculature, tissues and organs, new dosage forms and much more.

Source: zortrax.com

Using files with models for 3D printing provides an opportunity for the exchange of work among researchers. Instead of trying to reproduce the parameters described in scientific journals, doctors can use and modify ready-made 3D models. To this end, in 2014, the National Institutes of Health established the 3dprint.nih.gov exchange to facilitate the exchange of open source 3D models for medical and anatomical devices, custom equipment, and mock-ups of proteins, viruses, and bacteria.

Source: 3dprint.com

Modern medical use of 3D printing can be divided into several broad categories: tissue and organ fabrication, prostheses, implants and anatomical models, instrument printing, and pharmaceutical research.

Top five uses for 3D printing in medicine

Operational preparation and student education

Source: 3dprint.com

Taking into account individual differences and features of the anatomy of a particular human body, it is possible to use 3D printed models for the preparation of surgical operations. Having a doctor have a tangible model of a particular patient's organ, made, for example, based on the results of CT (computed tomography) for study or to simulate an operation, significantly reduces the risk of medical errors.

Source: openbiomedical.org

The use of 3D models for training surgeons and students is preferable to training on cadavers, as it does not create problems in terms of availability and cost of objects. Cadavers often lack appropriate pathology, so they are more suitable for anatomy lessons than for presenting a patient with a disorder appropriate to the topic under study. With the help of 3D printing, it is possible to create a model of any organ with any known pathology.

Source: ncbi.nlm.nih.gov

two-dimensional images.

Bioprinting of tissues and organs

Source: hbr.org

Bioprinting is one of the many types of 3D printing used in the medical field. Instead of printing using plastic or metal, bioprinters use a syringe dispenser to apply bioink (layers of living cells or a structuring base for them) to create artificial living tissue. In addition to being used as an alternative to donor tissues, such tissue constructs or organoids can be used for medical research.

Source: press.ginkgo3d.com

Although 3D bioprinting systems can be laser, inkjet, or extrusion, inkjet bioprinting is the most common. Multiple printheads can be used to accommodate different types of cells (organ-specific, blood vessel cells, muscle tissue), which is a major challenge in the fabrication of heterocellular tissues and organs. 3D printing with biological materials can be used to regenerate tissues, and in the future, organs, directly on the patient.

Printing Surgical Instruments

Volt Grip Details, Source: bitegroup.nl

Modern surgeons are trying to perform operations with as little trauma to the patient as possible, so they very often require a personalized instrument. The use of 3D printing makes it possible to create such tools within hours.

Volt capture model visualization, Source: bitegroup.nl

Now the doctor can independently modify the finished model, giving it the necessary size and shape for convenience and efficiency. Dentists can now create, for example, individual guides right in front of the patient, eliminating the possibility of damage to healthy teeth during prosthetics.

About the clamp Volt, from the photos above, read further in the section “Usage examples”.

Here's how students at Duke University in Durham, North Carolina create tools using metal 3D printing.

"Printing" drugs

Source: mdpi.com

3D printing technologies are already being used in pharmaceutical research and personalized medicine, and their scope is constantly expanding. 3D printing enables precise dose control of drugs and the production of dosage forms with complex drug release profiles and prolonged action. Now pharmacists can analyze a patient's pharmacogenetic profile and other characteristics such as age, weight, or gender to determine the optimal dose and sequence of medications. If necessary, the dose may be adjusted, depending on the clinical response. With 3D printing, it is possible to produce personalized medicines in completely new formulations, such as tablets containing multiple active ingredients, either as a single mixture or as complex multi-layered tablets.

Prosthetics and dentistry

Source: eos.info

3D printing has been successfully used in medicine for the manufacture of complex custom prostheses or surgical implants. Implants and prostheses of any possible geometry can be made by converting X-ray, MRI or CT images into a 3D printable model using special software.

The rapid production of custom implants and prostheses solves a pressing problem in orthopedics, where standard implants often do not fit the patient. This is also true in neurosurgery: skulls are individually shaped, so it is difficult to standardize a cranial implant. Previously, surgeons had to use various tools to modify and fit implants, sometimes right during the operation. The use of 3D printers makes this procedure unnecessary. Additive technologies are especially in demand when it is necessary to urgently manufacture implants.

A real revolution in dentistry occurred with the advent of 3D technologies.

Source: hypowerfuel.com

First, complete and accurate 3D scanning of the oral cavity is now possible. Secondly, the use of 3D printing has made it possible to create prostheses that absolutely fit the anatomy of the patient, without the need for a long and unpleasant fit. The radical reduction in the share of manual labor in the manufacture of prostheses or veneers has reduced the required tolerances in production, expanded the list of materials used and increased patient satisfaction with the results of the doctor's work.

Application examples

Printing a model of the heart of a four-year-old patient, Zortrax M200 3D printer

In the photo: the assembled heart model. Source: zortrax.com

At the Medical University of Gdansk (Poland) to prepare for an operation to treat a complex congenital heart disease (Fallot's tetrad - malfunction of the pulmonary artery heart valve) in a four-year-old patient, specialists from the Department of Pediatric Cardiology and Congenital Heart Diseases , together with colleagues from the Department of Cardiac Surgery and Radiology, used the Zortrax M200 3D printer.

Photo: artificial pulmonary valve. Source: zortrax.com

The modern method of treatment consists in inserting a catheter through the femoral vein, through which an artificial valve is fed to the heart for implantation. This is a very complex operation that requires the doctor to have detailed knowledge of the individual characteristics of the patient's anatomy.

In the photo: a heart model during printing. Source: zortrax.com

Until now, doctors could only rely on a 3D model on a computer screen created from CT and MRI images, and such a reconstruction is not always enough to get a complete picture of the real organ and possible complications .

Source: zortrax.com

Having a highly detailed tactile model of a patient's living organ in preparation for surgery can be critical to its success. Even experienced surgeons have appreciated the potential of the new technology. Previously, it was difficult to notice individual features and deformations, now it has become tangible and accessible for closer study.

The model was printed within 24 hours. The Z-ULTRAT material was used to print the heart, and the Z-GLASS material was used to print the vessels. After a successful operation, the model was transferred to the University for student training.

Artificial corneas made on the Nano master SMP-III 3D bioprinter

Source: europepmc.org

In South Korea, about 2000 patients are waiting for corneal donation, and the waiting time for surgery is an average of six years. For patients who cannot find a suitable donor, it is possible to implant artificial corneas consisting of recombinant collagen and synthetic polymers. Unfortunately, they often do not take root and are not completely transparent. This is due to the special structure of the cornea in the form of lattice collagen fibrils, which has not yet been able to be reproduced. A team of researchers from Pohang University of Science and Technology and Kungpuk National University School of Medicine in South Korea have developed a method to 3D print an artificial cornea using patient tissue material.

Source: ithl.co.kr

3D bioprinter with Nano master SMP-III microextrusion system, Musashi Engineering, Tokyo, Japan, with the following parameters:

-

print speed 130mm/min;

-

extrusion speed 0.0024 mm/s;

-

nozzle diameter 0.29 mm;

-

print temperature 4 °C.

The printed and biofilled cornea was then cultured in an incubator at 37 °C for four weeks.

Source: europepmc. org

A 3D-printed artificial cornea made from decellularized corneal stroma and patient stem cells could completely replace a donor cornea in eye surgery. Since such a cornea is made up of materials derived from the patient's own tissues, it is completely compatible. Cellular 3D printing technology replicates the natural microenvironment of the eye, resulting in transparency similar to that of the human cornea.

Pohang University of Science and Technology Professor Jina Jang said:

"We are confident that this technology will restore vision to many patients suffering from corneal diseases."

Wake Forest Institute for Regenerative Medicine, mobile 3D printer for treating extensive wounds

the place of the damaged. In addition to the fact that this method is additionally traumatic for the victim, in some cases there may not be healthy skin left on the body at all for use. Wake Forest School of Medicine has developed a printer that can print skin cells grown from patient tissue directly onto a wound.

Source: 3dnatives.com

The ZScanner Z700 handheld 3D scanner is used to determine the size and depth of a wound. Based on this information, the 3D printer prints subcutaneous, dermal and epidermal skin cells at appropriate depths to completely cover the wound.

Source: 3dnatives.com

The 3D bioprinting system developed by scientists consists of a three-axis moving print head with eight nozzles with a diameter of 260 microns with independent dispensers. Specifically for this device, the researchers created a bioink consisting of autologous dermal fibroblasts and epidermal keratinocytes in a hydrogel carrier.

Bite

Volt Bipolar Surgical Forceps for Laparoscopic Surgery stop bleeding during surgery. It was created for use in minimally invasive (sparing) surgery in 2016 and successfully tested on pig liver.

Source: bitegroup.nl

The design of the device allows easy adjustment of the shaft and tip geometry depending on the patient's anatomy and surgical requirements. Maneuverable shank - ±65° for lateral movements and ±85° up and down. Flexural stiffness of 4.0 N/mm for connection 1 and 4.4 N/mm for connection 2, significantly higher than previously available guided tools. The tip consists of two 3D printed titanium movable jaws with an opening angle of up to 170°. The instrument is connected to an Erbe electrosurgical unit and is able to successfully coagulate tissue at a temperature of 75 °C, reached in 5 seconds.

Conclusion

Source: intermercados.com.br

The use of additive technologies in medicine is expanding so rapidly that it is more like a revolution in healthcare.