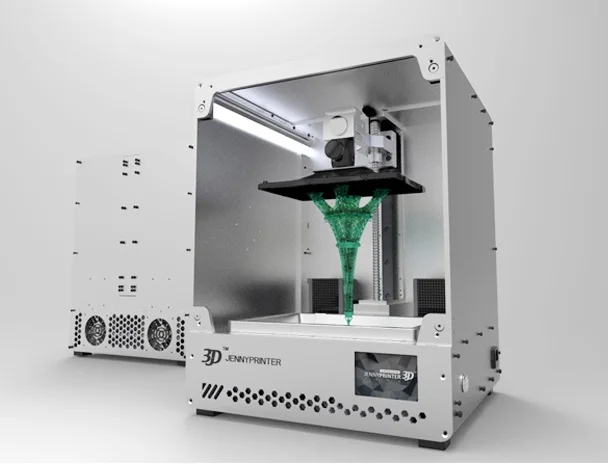

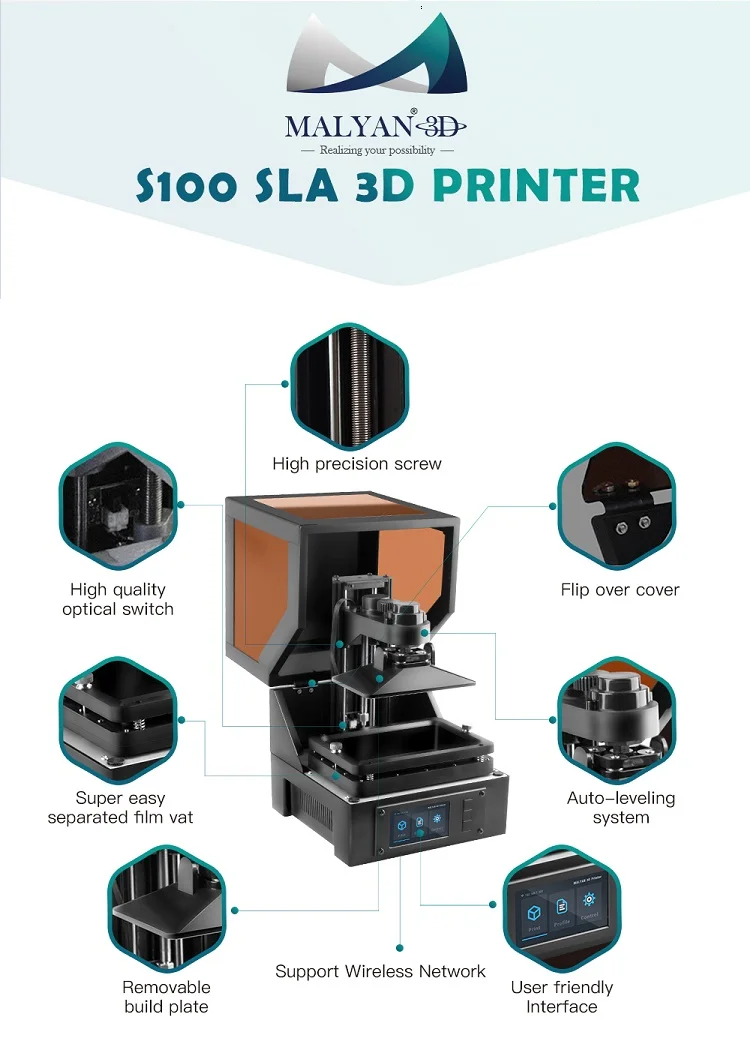

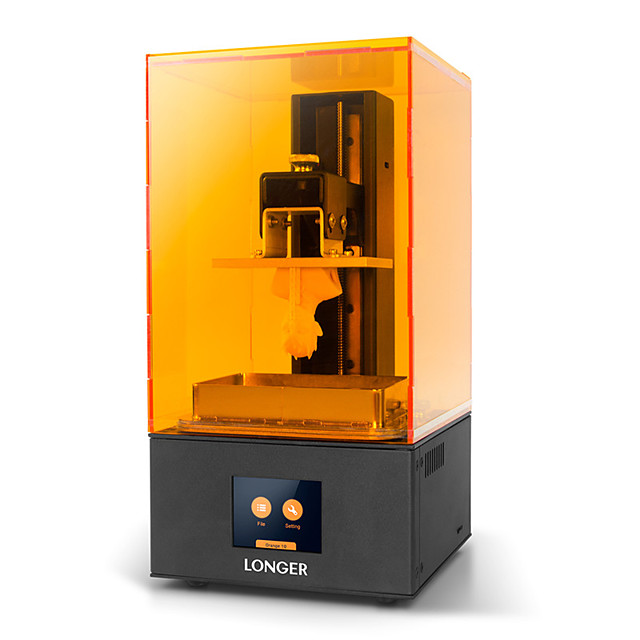

Sla 3d printer for sale

SLA DLP Resin 3D printers for sale at best price starts from $499 USD

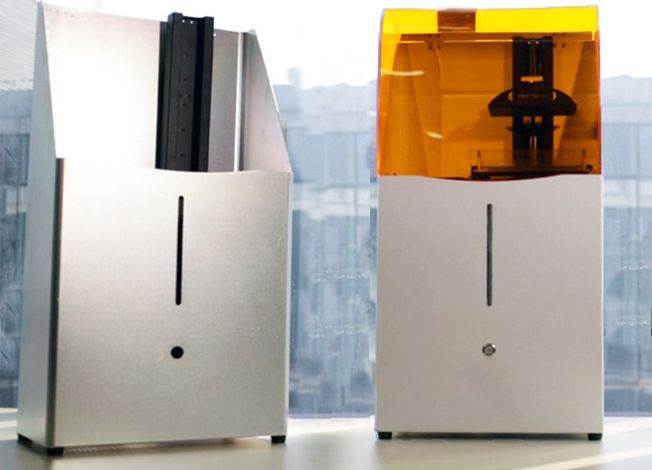

SLA DLP UV Resin 3D Printers

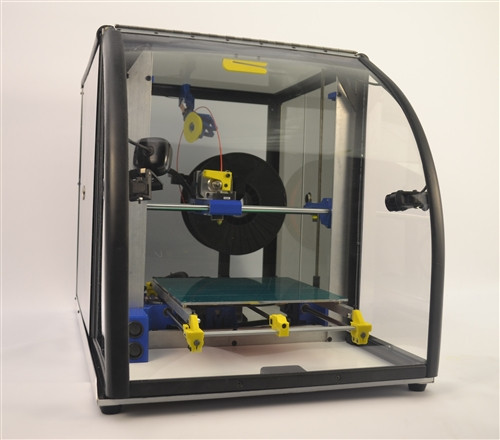

FDM 3d printers may be the most selling 3d printing technology but SLA/DLP (Stereolithography) printers are fast catching up. SLA printers use special photoactive resins which gives them an advantage over FDM, you can get superior print quality on these printers than its competitors and with time this technology is getting faster as well.

While both the technologies are still at its development state, they have their pros and cons, but if you are looking for high quality prints then there is no comparison to SLA technology.

In the resent past the cost of FDM printers have come down significantly making them favourites with people trying to understand and explore 3d printing, however a user still needs to ready to spend some heavy buck if he/she is looking for SLA printer. The good news though is that the prices of these printers and the resins (raw material) are coming down quickly and with lower prices and higher quality of prints these printers can soon easily take over the 3D printing industry by storm.

We at 3dprintersonlinestore feel that SLA printers have a huge potential and want to deliver the best of this technology to our customers. We have a huge range of SLA/DLP 3d printers which you can choose from, and also offer 3D printer Resins at an unbelievably reasonable prices.

Product Compare (0)

Filter

Sort By:

DefaultName (A - Z)Name (Z - A)Price (Low > High)Price (High > Low)Rating (Highest)Rating (Lowest)Model (A - Z)Model (Z - A)

Showing 1 to 25 of 44 (2 Pages)

Show:

255075100

QUICK VIEW

SALE

-50%

$109 USD$219 USD

(9 reviews)

(9 reviews)

QUICK VIEW

SALE

-40%

$119 USD$199 USD

(1 reviews)

(1 reviews)

QUICK VIEW

SALE

-35%

$129 USD$199 USD

(2 reviews)

(2 reviews)

QUICK VIEW

SALE

-65%

$139 USD$399 USD

(3 reviews)

(3 reviews)

QUICK VIEW

SALE

-57%

$149 USD$349 USD

(17 reviews)

(17 reviews)

QUICK VIEW

SALE

-25%

$149 USD$199 USD

(5 reviews)

(5 reviews)

QUICK VIEW

SALE

-60%

$159 USD$399 USD

(2 reviews)

(2 reviews)

QUICK VIEW

SALE

-47%

$159 USD$299 USD

(8 reviews)

(8 reviews)

QUICK VIEW

SALE

-58%

$169 USD$399 USD

(5 reviews)

(5 reviews)

QUICK VIEW

SALE

-46%

$170 USD$314 USD

(7 reviews)

(7 reviews)

QUICK VIEW

SALE

-30%

$189 USD$269 USD

(31 reviews)

(31 reviews)

QUICK VIEW

SALE

-53%

$189 USD$399 USD

(21 reviews)

(21 reviews)

QUICK VIEW

SALE

-56%

$199 USD$449 USD

(14 reviews)

(14 reviews)

QUICK VIEW

SALE

-30%

$209 USD$299 USD

(2 reviews)

(2 reviews)

QUICK VIEW

NEW

SALE

-23%

$229 USD$299 USD

(1 reviews)

(1 reviews)

QUICK VIEW

NEW

SALE

-20%

$239 USD$299 USD

(4 reviews)

(4 reviews)

QUICK VIEW

SALE

-40%

$299 USD$499 USD

(3 reviews)

(3 reviews)

QUICK VIEW

SALE

-36%

$319 USD$499 USD

(1 reviews)

(1 reviews)

QUICK VIEW

SALE

-20%

$319 USD$399 USD

QUICK VIEW

SALE

-59%

$329 USD$799 USD

(23 reviews)

(23 reviews)

QUICK VIEW

SALE

-18%

$329 USD$399 USD

(2 reviews)

(2 reviews)

QUICK VIEW

SALE

-41%

$340 USD$579 USD

(15 reviews)

(15 reviews)

QUICK VIEW

SALE

-42%

$349 USD$599 USD

(1 reviews)

(1 reviews)

QUICK VIEW

SALE

-26%

$369 USD$499 USD

(11 reviews)

(11 reviews)

QUICK VIEW

SALE

-20%

$399 USD$499 USD

(1 reviews)

(1 reviews)

This product has no stock!! Please enter your information to form bellow. We will send you notification when it is back!

We will send you notification when it is back!

Your Name

Your Email

Your Phone

Best resin 3D printers in 2022

What is the best resin 3D printer on the market?

Resin 3D printers are able to offer a very high level of detail and smooth surfaces. They are most commonly seen in dental labs and clinics as well as in jewelry workshops but are also increasingly popular with hobbyists and makers.

The way a resin 3D printer works depends on its technology: laser SLA (stereolithography), DLP (Digital Light Processing), or LCD-based (using an LCD screen to mask projected light).

All resin 3D printers involve the same workflows, however, requiring several post-processing steps such as resin removal and post-curing.

In this guide, we take a look at some of the best resin 3D printers available in each category (SLA, DLP, and LCD) and provide you with key concepts linked to resin 3D printing.

The best resin 3D printers (SLA/DLP/LCD)

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Prusa Research | Original Prusa SL1 | 120 × 68 × 150 mm4.72 × 2.68 × 5.91 in | Czech Republic | $ 1,6991 742 €1,505 £252,629 ¥ | Buy |

| Peopoly | Phenom | 276 × 155 × 400 mm10.87 × 6.1 × 15.75 in | China | $ 1,9991 899 €1,771 £297,237 ¥ | Contact |

| Formlabs | Form 3 | 146 × 145 × 185 mm5.75 × 5.71 × 7.28 in | United States | $ 3,4993 588 €3,100 £520,277 ¥ | Quote |

| UNIZ | SLASH 2 | 190 × 120 × 200 mm7.48 × 4.72 × 7.87 in | – | $ 3,5003 589 €3,101 £520,426 ¥ | Quote |

| FlashForge | Hunter DLP | 120 × 67 × 150 mm4. 72 × 2.64 × 5.91 in 72 × 2.64 × 5.91 in | China | $ 3,9994 100 €3,543 £594,623 ¥ | Quote |

| DWS | XFAB | 180 × 180 × 180 mm7.09 × 7.09 × 7.09 in | – | $ 6,6006 000 €5,847 £981,374 ¥ | Quote |

| B9Creations | B9 Core 550 | 96 × 54 × 127 mm3.78 × 2.13 × 5 in | – | $ 9,95510 207 €8,819 £1,480,239 ¥ | Quote |

| Asiga | MAX | 119 × 67 × 75 mm4.69 × 2.64 × 2.95 in | – | $ 10,99011 268 €9,736 £1,634,136 ¥ | Quote |

| ETEC | Envision One | 180 × 101 × 175 mm7.09 × 3.98 × 6.89 in | Germany | upon request | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Technology | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|

| Prusa Research | Original Prusa SL1 | LCD | 120 × 68 × 150 mm4.72 × 2.68 × 5.91 in | Czech Republic | $ 1,6991 742 €1,505 £252,629 ¥ | Buy on Prusa |

| Peopoly | Phenom | LCD | 276 × 155 × 400 mm10.87 × 6.1 × 15.75 in | China | $ 1,9991 899 €1,771 £297,237 ¥ | Contact manufacturer |

| Formlabs | Form 3 | SLA | 146 × 145 × 185 mm5.75 × 5.71 × 7.28 in | United States | $ 3,4993 588 €3,100 £520,277 ¥ | Get a quote |

| UNIZ | SLASH 2 | LCD | 190 × 120 × 200 mm7.48 × 4.72 × 7.87 in | – | $ 3,5003 589 €3,101 £520,426 ¥ | Get a quote |

| FlashForge | Hunter DLP | DLP | 120 × 67 × 150 mm4.72 × 2.64 × 5.91 in | China | $ 3,9994 100 €3,543 £594,623 ¥ | Get a quote |

| DWS | XFAB | SLA | 180 × 180 × 180 mm7.09 × 7. 09 × 7.09 in 09 × 7.09 in | – | $ 6,6006 000 €5,847 £981,374 ¥ | Get a quote |

| B9Creations | B9 Core 550 | DLP | 96 × 54 × 127 mm3.78 × 2.13 × 5 in | – | $ 9,95510 207 €8,819 £1,480,239 ¥ | Get a quote |

| Asiga | MAX | DLP | 119 × 67 × 75 mm4.69 × 2.64 × 2.95 in | – | $ 10,99011 268 €9,736 £1,634,136 ¥ | Get a quote |

| ETEC | Envision One | CDLP | 180 × 101 × 175 mm7.09 × 3.98 × 6.89 in | Germany | upon request | Get a quote |

Overview of the best resin 3D printers (SLA/DLP/LCD)

This overview is divided into three sections according to the resin 3D printers’ technology (SLA, DLP, or LCD).

The best SLA 3D printers (laser stereolithography)

Formlabs has been one of the main players on the professional resin 3D printer market for years. The Form 3, evolution of the award-winning Form 1 and Form 2, is their latest model, along with the Form 3L (large volume). This professional liquid resin printer boasts an array of practical features that make it a great choice for many businesses.

This professional liquid resin printer boasts an array of practical features that make it a great choice for many businesses.

In the past, users have praised Formlabs’ hardware quality and precision, while criticizing the company’s decision to limit compatible materials to expensive Formlabs proprietary resins only. Today, the Form 3 features an “Open mode” that allows the use of generic materials.

Contact manufacturer Get a quote Add to comparison

The Phenom is an affordable and large-format LCD (MSLA) 3D printer that is suitable for hobbyists and professionals alike. An advantage of this resin 3D printer is large-format. The Peopoly Phenom 3D printer also exists in larger versions: Phenom L, Phenom Noir, Phenom XXL.

Contact manufacturer Get a quote Add to comparison

DWS Systems is specialized in manufacturing professional and industrial-grade resin 3D printers. The XFAB stereolithography 3D printer is their most affordable option, but is capable of delivering high-quality results. One of this SLA 3D printer’s most interesting characteristics is its cartridge resin system.

One of this SLA 3D printer’s most interesting characteristics is its cartridge resin system.

This makes material handling much easier and cleaner than with non-cartridge systems.

Contact manufacturer Get a quote Add to comparison

The best DLP 3D printers (Digital Light Processing)

This professional resin 3D printer boasts a number of user-friendly features including a touchscreen, automatic calibration, and Wi-Fi connectivity. FlashForge develops its own resins, but users may also use third-party materials.

With its special jewelry support mode, the Hunter DLP mainly targets jewelers.

Contact manufacturer Get a quote Add to comparison

B9Creations’ Core series of 3D printers all provide fine levels of detail for professionals. According to the manufacturer, the B9 Core 550 resin 3D printer offers faster printing speeds (100+ mm/hour) than most DLP 3D printers in the same price range.

This digital light processing 3D printer is available with a smaller build volume (B9 Core 530).

Contact manufacturer Get a quote Add to comparison

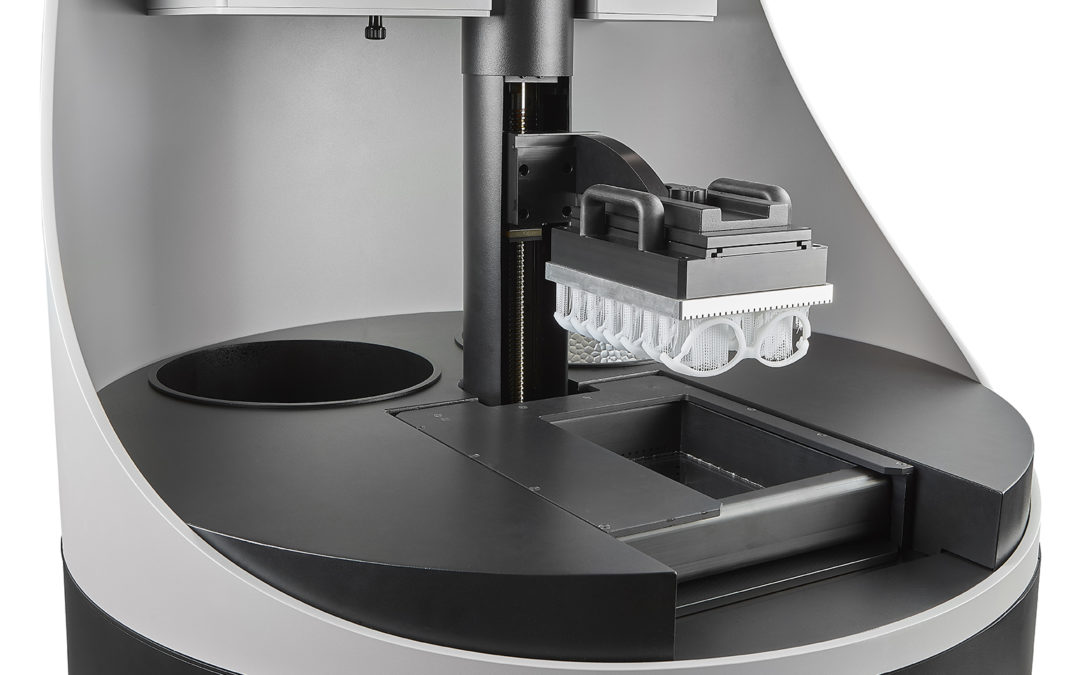

The Envision One is a professional resin 3D printer produced by ETEC. ETEC, a German company known as EnvisionTEC before its acquisition by Desktop Metal in 2021, manufactures professional DLP 3D printers. The ETEC Envision One uses CDLP 3D printing technology. This 3D printer offers a build volume of 180 x 101 x 175 mm.

Contact manufacturer Get a quote Add to comparison

The Asiga MAX is equipped with a resin level sensor, automatic calibration function and touch screen. Asiga also provides free lifetime technical support.

This 3D printer is particularly suitable for the medical and dental sectors, being compatible with silicone resins.

Contact manufacturer Get a quote Add to comparison

The best LCD 3D printers (liquid crystal display)

For many years, Prusa Research has been famous for manufacturing reliable 3D printers. The Original Prusa SL1 is Josef Prusa’s first resin 3D printer, but there is no doubt that it has been endowed with as much quality as the award-winning Prusa MK3 FDM 3D printers.

This LCD 3D printer– which is also available as a DIY kit– is packed with features such as a tilted print bed, auto calibration, vapor extraction, and more.

Buy on Prusa Get a quote Add to comparison

The SLASH 2 is a desktop resin 3D printer produced by UNIZ. UNIZ is a 3D printer manufacturer based in China. The UNIZ SLASH 2 uses resin 3D printing technology. This 3D printer offers a build volume of 190 x 120 x 200 mm.

Contact manufacturer Get a quote Add to comparison

Resin 3D printers under $1,000

As LCD screens are very affordable, they have been the key to bringing resin 3D printing to the masses. Indeed, more and more manufacturers are launching affordable desktop resin 3D printers with LCD 3D printing technology, and the price drop is radical.

These affordable resin 3D printers obviously can’t be expected to provide the same level of detail and accuracy as the professional 3D printers listed above. However, they are great as an introduction to resin 3D printing and they do produce good quality prints.

However, they are great as an introduction to resin 3D printing and they do produce good quality prints.

Read our full-length budget resin 3D printer article for a list of affordable machines (starting from $149).

Post-processing for resin 3D prints: necessary steps

Resin removal

Since the objects are printed within a tank of resin, resin drips off of the objects as they are lifted up and out of the tank. There’s always a layer of uncured resin left on the object, and it must be removed with IPA (isopropyl alcohol).

This can be done manually by dipping the part in an IPA bath and gently scrubbing the part with a soft brush, but it is quite time-consuming.

For users that produce resin parts on a regular basis, there are machines called resin washers, or resin cleaners. Ackuretta, for example, markets Cleani, a dual-tank resin cleaner that can wash both the parts and the printer’s platform (yes, that needs to be washed, too. ).

).

Post-curing

When removing a resin 3D printed part from the build plate, it is still soft and slightly malleable. To reach its final physical state the part must go through a post-curing step. This means exposing the object to heat or light. Various SLA post-curing techniques exist:

UV curing chamber / UV cure box

Professional users will definitely want to use a dedicated UV curing chamber for their parts in order to get the most out of the material (strength, for example). Most resin 3D printer manufacturers have UV curing chambers available separately.

UV nail lamp

For small parts, nail UV lamps can do the trick. There are dozens of nail UV lamps available for less than $50.

DIY UV curing chamber

Crafty people also have the possibility to make their own UV curing station!

How do resin 3D printers work and what are the differences between LCD, DLP, and SLA 3D printing?

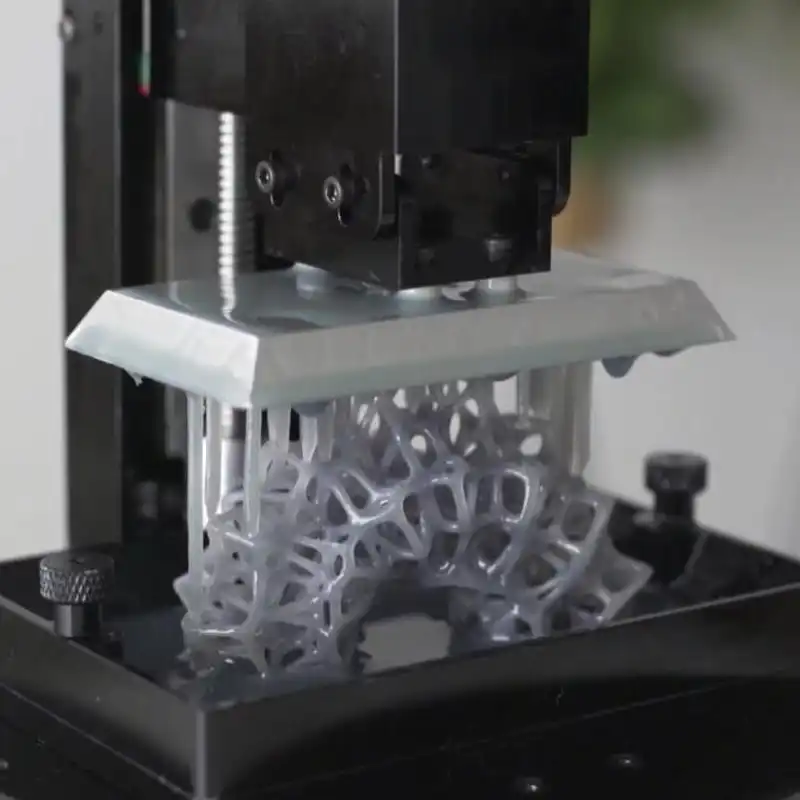

SLA 3D printers, LCD 3D printers, and DLP 3D printers all use liquid resin as a 3D printing material. The resin, a photopolymer, becomes solid when cured (activated) by a specific light source.

The resin, a photopolymer, becomes solid when cured (activated) by a specific light source.

That light source cures the liquid resin, which is stored in a tank or vat, to form the object layer after layer.

The resin solidification process (photopolymerization) is at the core of three main 3D printing technologies:

- Laser-based Stereolithography (SLA): a UV laser cures the resin in the tank to form the object point by point.

- Digital Light Processing (DLP): the resin is cured by a light projector one whole layer at a time. The light shines in a specific shape depending on the layer.

- Liquid Crystal Display (LCD) or Masked SLA (MSLA): An array of LED lights shine through an LCD screen. The LCD screen acts as a mask or stencil between the LED and the bottom of the resin tank, only letting light through in specific shapes.

All of these resin-based 3D printing technologies form part of the same family: stereolithography. That’s why some manufacturers include “SLA” in the name of their 3D printers, while they actually use DLP or LCD-based technology.

That’s why some manufacturers include “SLA” in the name of their 3D printers, while they actually use DLP or LCD-based technology.

Laser-based SLA 3D printing technology

An SLA 3D printer cures the liquid resin spot by spot with a laser, so it is potentially more precise than DLP 3D printing.

Contrary to DLP 3D printing, the build volume is completely independent of the resolution of the 3D print. A 3D print with a laser stereolithography 3D printer can be of any size and resolution.

DLP 3D printing technology (digital light processing)

DLP 3D printers use a light projector. The layer’s shape is defined by reflecting or deflecting light with mirrors. With DLP, the 3D printer is able to cure a whole layer of resin at once. Therefore, a DLP 3D printer can potentially 3D print faster than an SLA 3D printer, as an entire layer is exposed all at once instead of one spot at a time with a laser.

However, a DLP 3D printer’s resolution depends on its projector and how many pixels/voxels are available (a full HD projector usually offers 1080p). A 3D printer with a large build volume has a fixed number of pixels, making it impossible to 3D print small details when building at full scale.

The projector used by the DLP 3D printer is less expensive and easier to change than the laser used by SLA 3D printers.

LCD-based resin 3D printing technology

Most LCD resin 3D printers use an LCD screen as a photomask– like a stencil– above another light source (LED, UV…). This is where LCD resin 3D printing is different than DLP 3D printing, which makes use of mirrors or other complex systems to direct the light into a certain shape. The technology is also called Masked Stereolithography (MSLA).

Since LCD screens are inexpensive, this technology has made resin 3D printing much more affordable than before and there are now dozens of low-cost, budget resin 3D printers available for a couple of hundred dollars.

In some cases, the light emitted by an LCD screen is used to directly cure the daylight-sensitive resin.

What is best between LCD, DLP, and SLA 3D printers?

The answer depends on the user’s needs in precision, speed, and budget. We can highlight that:

- Laser SLA 3D printers are best for 3D printing highly detailed and intricate 3D prints, big or small.

- LCD and DLP 3D printers are best for 3D printing batches of small parts, or quickly 3D printing large parts without too many details.

- LCD-based 3D printers are generally much more affordable than SLA and DLP 3D printers.

Main resin 3D printing applications

Samples by La Bête à Pois, SprintRay, and Photocentric (top to bottom). Source: AniwaaResin 3D printers mostly target professional users. Indeed, they are suited for specific applications requiring high levels of detail and top-quality finishes. These applications include:

These applications include:

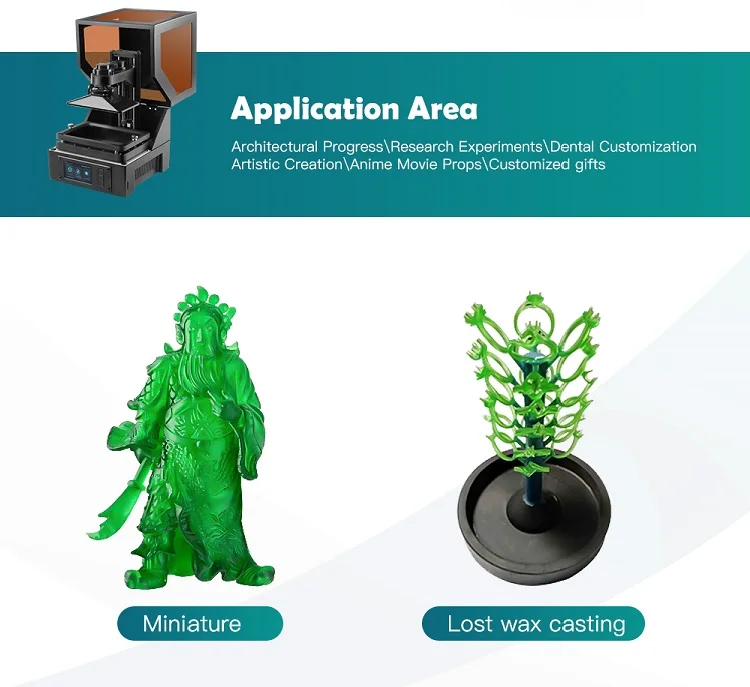

Resin 3D printers for jewelry

Jewelers use high-precision 3D printers to create molds with the lost wax technique and create incredible jewels.

SLA, DLP, and LCD 3D printers in dentistry

Dentists and dental labs are starting to use resin 3D printing to build dental crowns, mouth guards, surgical guides, and much more.

Resin 3D printing in medical and healthcare fields

SLA and DLP 3D printing can be used to create medical appliances such as hearing aids.

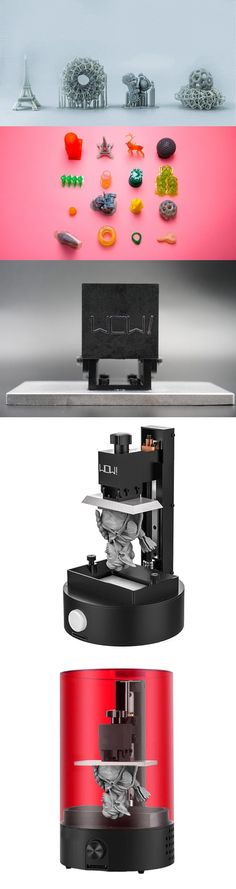

Hobbies: resin 3D printer for miniatures

Some tinkerers, DIYers, and cosplayers love 3D printing miniatures and figurines.

Key benefits and limitations of resin 3D printing

Benefits of LCD, DLP, and SLA 3D printing technologies

These are some of the advantages of 3D printing with resin:

- Ability to build small and very detailed parts or objects with fine, complex geometries

- Diversity of 3D printable resin materials (ceramic, metal, biocompatible, flexible, rigid, etc.

)

) - Smooth finish of the parts produced (no easily visible layers like with FFF 3D printers)

Limits of resin 3D printing

As with any technology, resin 3D printing has its limits:

- Post-processing is mandatory (removing delicate support structures, post-curing, resin removal, etc.) and requires a UV curing chamber for good results

- Requires time-consuming cleaning time (for the vat and for the 3D printed part)

- Very smelly and toxic fumes

- Safety precautions required when handling the material

Resin 3D printer price

Laser SLA resin 3D printer price

SLA 3D printer prices depend on many factors. The price for a basic SLA 3D printer kit like the Peopoly Moai usually starts at about $1,200. Industrial resin 3D printers, on the other hand, can reach several hundred thousand dollars.

DLP resin 3D printer price

The price of a DLP 3D printer generally starts around $2,000 or $3,000. DLP 3D printers with higher precision and more features cost around $10K to $20K. More expensive digital light processing 3D printers also exist.

DLP 3D printers with higher precision and more features cost around $10K to $20K. More expensive digital light processing 3D printers also exist.

LCD resin 3D printer price

LCD-based resin 3D printers are the most affordable resin 3D printer type. There are many LCD resin 3D printers available for under $1,000, and even under $300. Higher-quality LCD 3D printers may cost a few thousand dollars.

UV curing chamber price

Most resin 3D printer brands sell UV curing chambers separately, with prices starting around $300 to $500.

FAQ

What does SLA stand for in 3D printing?

In 3D printing, SLA stands for stereolithography.

What does DLP stand for in 3D printing?

In 3D printing, DLP stands for Digital Light Processing.

What does LCD stand for in 3D printing?

LCD stands for Liquid Crystal Display, which is a type of screen used in electronic devices (smartphone, TV, etc. ). A growing number of resin 3D printers use an LCD screen’s light to cure light-sensitive resin and form objects in 3D.

). A growing number of resin 3D printers use an LCD screen’s light to cure light-sensitive resin and form objects in 3D.

What is SLA resin made of?

SLA resin is a photopolymer material, which is mainly composed of monomers, oligomers, and photoinitiators. Depending on the “recipe”, the stereolithography resin can be plastic, ceramic, or even metal-based.

How much does a resin 3D printer cost?

A resin 3D printer can cost anywhere from $500 to over $250,000. However, there are many resin 3D printers available for under $10,000.

What is a resin 3D printer?

A resin 3D printer (stereolithography) is a machine that solidifies liquid resin layer by layer to form an object in 3D.

Where are resin 3D printers for sale?

There are resin 3D printers for sale on major e-commerce sites like Amazon, AliExpress, GearBest, and Banggood. Online retailers specialized in 3D printing also exist, such as MatterHackers.

Online retailers specialized in 3D printing also exist, such as MatterHackers.

Differences of SLA/DLP/LCD printers, printing examples, application

- Principle of operation

- PLASS

- BESSISE

- 0014

- Best DLP Printers

- Principle of operation

- Plus

- Bessions

- Printing

- Best LCD Printers

Currently, photopolymer printers can work on one of three technologies - SLA, DLP or LCD. Each of the technologies has its own advantages and disadvantages.

In order not to make a mistake with the choice of model, you need to understand which technology is suitable for printing specific products. For example, for a jeweler and a dentist, the main criterion will be accuracy, and for a person who plans to print figurines for his hobby, the quality of the surface and the not very expensive cost of consumables.

For example, for a jeweler and a dentist, the main criterion will be accuracy, and for a person who plans to print figurines for his hobby, the quality of the surface and the not very expensive cost of consumables.

SLA

SLA is one of the first patented 3D printing technologies. It was patented in 1986 by Charles Hull. DLP and LCD are similar in basic principles to SLA, but appeared much later.

How it works

As a material for printing, SLA printers use photopolymer resins - light-sensitive polymers that harden under the influence of a certain spectrum of UV radiation.

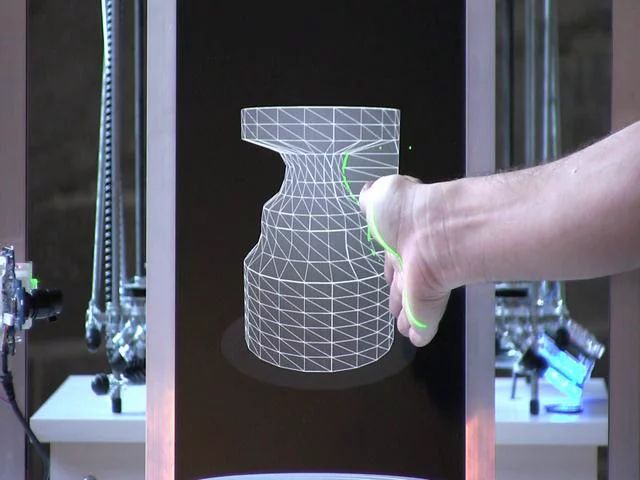

A laser beam is used as a “hardener”, which is focused on the desired point with the help of mirrors. The beam sequentially “draws” a slice of the model. So gradually, layer by layer, the model is “grown” on the desktop.

How SLA technology works

There are two options for the location of the printed table - top and bottom.

Top table

Visually it looks like an inverted FDM machine, the model is printed upside down on such a machine. The table moves during printing from the bottom up, the laser module is located at the bottom of the machine, under the polymer bath. The bottom of the bath is usually made of silicone - it transmits UV radiation well and practically nothing sticks to it.

Top position printer model

This is the most popular desktop SLA printer solution.

Table down

The laser module is located at the top of the printer above the resin bath, and the printing table, during printing, gradually lowers down, plunging into the resin.

Industrial SLA with table bottom

This arrangement is traditionally used in industrial machines with a large print area. The only inconvenience is that the bath must always be filled with a photopolymer. And when changing the type of resin, you will have to completely drain the entire photopolymer and thoroughly wash the bath.

Pros

-

Large selection of consumables. Due to the growing popularity of photopolymer printing, many specific resins have appeared - from soft flexes to photopolymers with increased strength characteristics (for example, there is a very strong, biocompatible photopolymer for making temporary dental crowns).

Cons

-

Expensive consumables.

Print example

Cardiac muscle printed on Formlabs Form 3

SLA printed rings

Prototype Spoon

Butterfly figurine printed on Formlabs Form 3

Technical model

Snow shovel prototype. Made on Formlabs Form 3L

Top SLA printers

The leader in the production of SLA printers is Formlabs. In the Formlabs lineup, you can find both small desktop models and professional machines with a large print area.

In the Formlabs lineup, you can find both small desktop models and professional machines with a large print area.

Form 3

Formlabs Form 3

Specifications:

-

XY resolution: 25 µm

-

Laser spot size: 85 µm

-

Laser power: One 250mW laser

-

Working area size: 14.5×14.5×18.5cm

-

Layer thickness: 25 – 300 µm

This printer can be compared to a small professional machine. Despite its small dimensions, it can easily cope with the most complex models.

Formlabs Form 3L

Formlabs Form 3L Versus Form 3

-

XY resolution: 25 µm

-

Laser spot size: 85 µm

-

Laser power: One 250mW laser

-

Working area size: 33.

5×20×30cm

5×20×30cm -

Layer thickness: 25 – 300 µm

This printer allows you to print large format models or quickly produce small batches of products.

With the advent of faster and cheaper technologies, SLA printers have become less popular. They are mainly used in industries with high requirements for quality and print stability.

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Formlabs |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Formlabs |

DLP

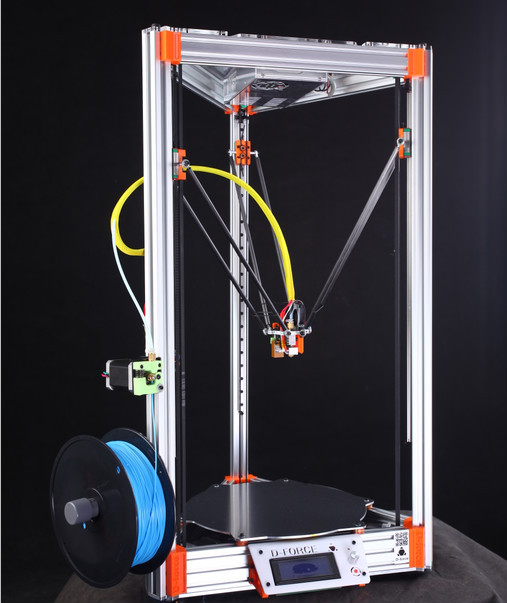

DLP technology is based on the principles of SLA, but instead of a laser, a projector is used as a source of UV radiation.

How it works

The material used is photopolymer resin, but unlike SLA, the light source is not a beam, but a DLP projector. This significantly speeded up printing, because the projector, unlike the beam, illuminates the entire layer at once.

How DLP technology works

The projector is located at the bottom of the printer, under the resin tank. The bottom of the container is usually made of a transparent, wear-resistant film. Such a film transmits UV radiation well, practically nothing sticks to it, and if it breaks, it can be easily replaced.

Pros

Cons

-

Parasitic light is possible. Exposure of the entire layer at a time can cause parasitic illumination of the resin.

-

projector resource. The projector is the heart of a DLP printer. Be sure to pay attention to the resource of the projector. For example, FlashForge Hunter claims a minimum projector life of 50,000 hours. This is a lot.

Printing example

A batch of rings printed with DLP technology

Ring patterns printed on FlashForge Hunter

Props for miniatures 28 mm

Jaw model made on FlashForge Hunter

Best DLP Printers

FlashForge Hunter

Specifications:

-

XY Resolution: 0.

0625mm

0625mm -

Print speed: 10mm/h

-

Light source: 405nm LED

-

Working area size: 120x67.5x150 mm

-

Layer thickness: 0.025-0.05mm

FlashForge is renowned for the quality of its printers. Hunter is no exception. It turned out to be a good “workhorse” capable of solving a variety of tasks.

DLP technology is used less and less. It is being stubbornly replaced by more affordable 3D printers based on LCD technology.

LCD

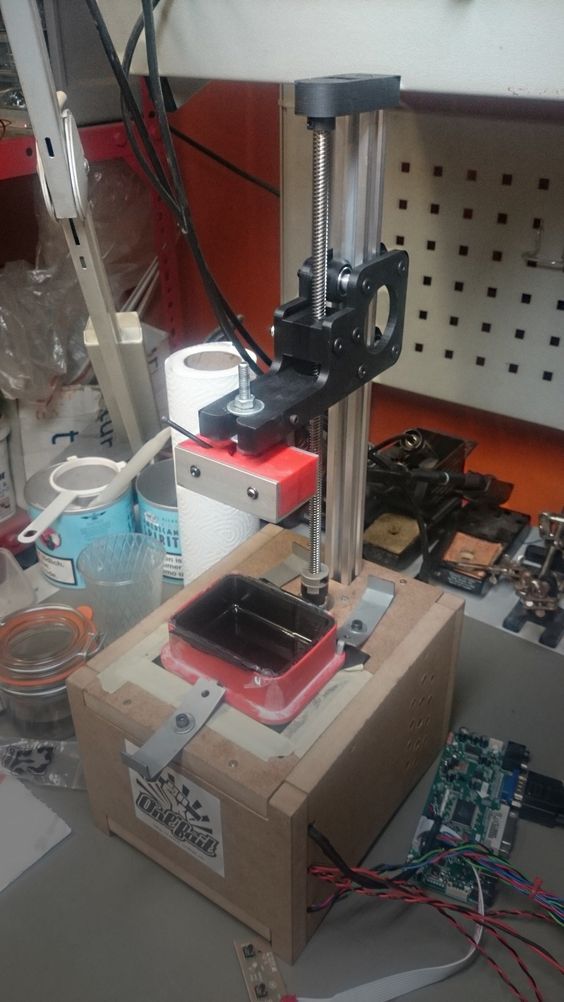

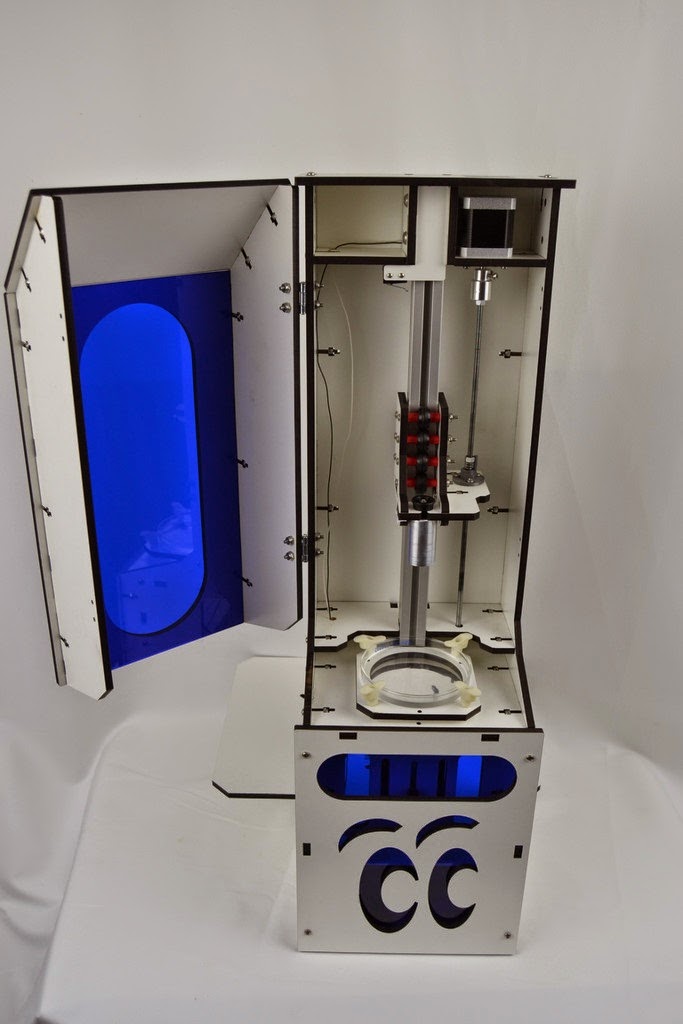

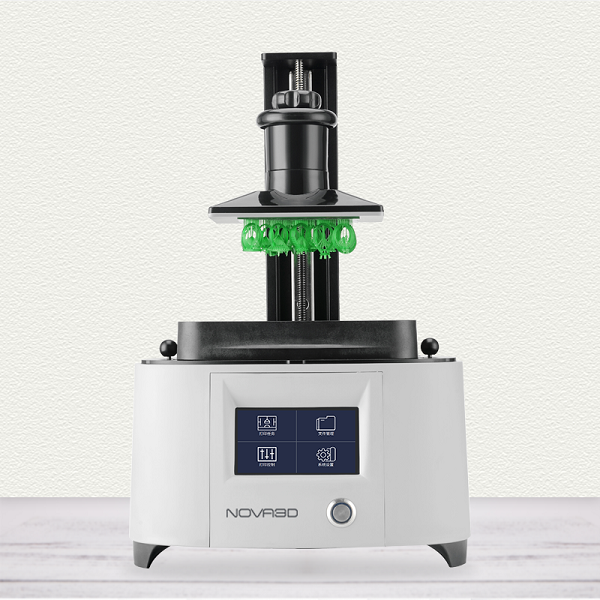

LCD technology is the youngest among photopolymer printers. Initially, LCD appeared as a more affordable analogue of DLP technology, suitable for home use.

The first LCD printers had a number of unpleasant children's sores (uneven illumination of the working area, etc.), which over time were resolved or compensated. With the development of technology, in addition to models for home use, devices have appeared that are not inferior in accuracy to DLP and can be used for production tasks.

How it works

The technology almost completely copies DLP, only LEDs are used instead of a projector. Under the bath is an LCD display (similar to the display of a smartphone or tablet), which dims in some places, allowing light to pass through only in the right places.

How LCD technology works

Since the module with the screen and LEDs is located at the bottom of the printer, the bottom of the resin tank is transparent. As with DLP, transparent film is usually used.

Pros

Cons

-

Less accurate. Budget models are good for printing miniatures or figurines, but their accuracy may not be enough for, for example, jewelry.

-

The print quality may not be the same over the entire printable area. Since an array of LEDs is used as the UV source rather than a single light source, the work area may be illuminated unevenly. This problem can be solved programmatically or physically.

Print example

Small miniature made with Anycubic Photon Mono

Troll printed on LCD machine

Model switchgear busbars made of soft polymer

Castle model made on Phrozen Sonic Mini 4K

Figurine made with Anycubic Photon Zero

Troll printed on LCD printer

Best LCD Printers

Anycubic Photon Zero

Anycubic Photon Zero

Specifications:

-

LCD display resolution: 854x480 px

-

XY Positioning Accuracy: 0.1155mm

-

UV wavelength: 405 nm

-

Working area size: 97x54x150 mm

-

Layer thickness: 0.

01-0.2mm

01-0.2mm

Budget model focused on home use. Good for home use.

Anycubic Photon Mono

Specifications:

-

LCD display resolution: 2560x1620 (2K)

-

XY Positioning Accuracy: 0.051mm

-

UV wavelength: 405 nm

-

Working area size: 130x80x165 mm

-

Layer thickness: 0.01-0.15mm

Anycubic Photon Mono is already a more serious device. Thanks to the LCD display of higher resolution, it was possible to increase the accuracy and quality of the finished models.

Phrozen Sonic Mini 4K

Phrozen Sonic Mini 4K

Specifications:

-

LCD resolution: 6.1" 4K Mono LCD

-

XY positioning accuracy: 35 microns

-

UV wavelength: 405 nm

-

Working area size: 134x75x130 mm

-

Layer thickness: 0.

01-0.30mm

01-0.30mm

Mono LCD matrix, with high resolution, allows you to print very quickly and accurately.

Wanhao GR1

Specifications:

-

LCD resolution: 6.3" 2K HD

-

XY Positioning Accuracy: 0.055mm

-

UV wavelength: 405-410nm

-

Working area size: 140x78x200 mm

-

Layer thickness: 35-100 microns

The larger working area allows you to make more models at once, and a special UV-LED matrix ensures uniform illumination.

LCD printers are successfully capturing the market by displacing more expensive DLP and SLA printers. This of course contributes to their availability and a wide variety of models.

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Wanhao |

Application

Dentistry

Precision is very important in dentistry. A slight distortion of even 0.1 mm can make the painstaking work of making a crown or prosthesis useless.

A slight distortion of even 0.1 mm can make the painstaking work of making a crown or prosthesis useless.

Jaw model

3D printed aligner

In addition to the accuracy of the printer, the material chosen also plays an important role. It is necessary to use special resins with a small percentage of shrinkage.

Jewelery

The full potential of photopolymer printers is revealed in the jewelry industry. In addition to precision, detail and perfect surface quality are very important.

Ring made of burn-out photopolymer

From model to finished product

Previously, such products had to be very painstakingly cut by hand or made from wax on high-precision CNC machines. Now it is enough to make a digital model and, with the help of a printer and burnt resin, quickly produce the required number of products ready for casting.

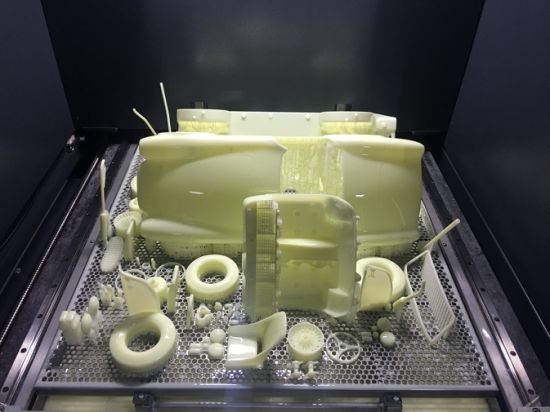

Prototyping

Printing prototypes, making master models, etc.

Helmet and other photopolymer prototypes

Prototype housings

FDM technology is not suitable for everything. Sometimes you need to quickly make a model of a future product with a smooth surface, professional photopolymer printers can easily cope with this task.

Hobby

Affordable photopolymer printers have become a great help for miniature lovers. It is much easier to model and print a 28 mm action figure of your favorite hero than to make it by hand for a long time and painstakingly.

Soviet motorcyclist in 28mm scale

“Spare parts” for miniature 28mm

And large decorative figurines are more accurate compared to FDM printing. After the LCD printer, you do not have to sand the model for a long time to smooth out the layers.

bust of a girl

Modeling

For large and sketchy layouts, FDM printers can be used, but their accuracy is not enough for making small parts. Having a 3D model, you can quickly make a very accurate and detailed layout of a building or an entire block.

Model of the statue of V.I. Lenina

Printed and colored building layout

Summary

Despite all the advantages of photopolymer printers, there are small nuances that are common to all technologies.

Washing the model. After printing, the model must be washed from resin residues. The best way is an ultrasonic bath with alcohol, sometimes you can get by with a glass of isopropyl alcohol and a brush.

“Illumination” in the UV chamber. After rinsing, the model must be “additionally illuminated” in a UV chamber, otherwise the polymer will not gain the strength declared by the manufacturer.

To illuminate the model, you can use a regular UV lamp or a manicure machine. They will cost less than professional dryers, although it may take more time to “light up”. Before buying, make sure that the lamps shine in the desired UV spectrum.

strength of polymers. Despite the huge variety of resins, they are still inferior in strength to the plastic filaments used by FDM printers. The exception is some highly specialized resins.

For some, these nuances can be significant disadvantages, but despite this, photopolymer printers are used both as home printers and as work machines in various fields.

#Useful

Expert in additive technologies and 3D printing with over 5 years of experience.

Share

all materials

Do you have any questions?

Our specialists will help you with the choice of 3D equipment or accessories, consult on any questions.

3D printer models

Looking for 3D printer models? The Internet is filled with sites that offer them for free. We have collected the TOP 10 catalogs that you can use to search and download free models in STL format. We hope you can find what you are looking for.

We have collected the TOP 10 catalogs that you can use to search and download free models in STL format. We hope you can find what you are looking for.

- Yeggi

- Yobi 3D

- STLfinder

→ myminifactory.com

My Mini Factory is a 3D model depository operated by iMakr, an online store that sells 3D printers and accessories. It also has one of the biggest 3D printer shops in Central London. The site contains 3D models designed by professionals, and all models stored on it are checked for quality. You can also make a request for the desired model, which their designers will create and put in the public domain. Billing itself as a 3D printing social network, MyMiniFactory is a thriving community of makers who love to showcase their creations. Users vote for the best models, which allows popular creations to rise to the top of the list and gain popularity. The site presents models that are stored on its social network, as well as outside it, for example, on the Thingiverse and YouMagine sites.

→ thingiverse.com

The most popular and famous site among 3D printer users, Thingiverse is owned by MakerBot Industries, the creator of the popular Replicator 3D printer series. The site allows users to store and share 3D model files that are used with 3D printers. It's a very popular site and has a large community of people hosting various categories of files on it. So if you're looking for "cool" printable stuff, Thingiverse is worth a visit. It is a portal designed to provide its users with ways to share their designs and to help print 3D creations. The site has a system that tries to find out what you like. The more you interact with the site, downloading and evaluating various developments, the better its recommendations will be.

→ 3dshook.com

Another online community for 3D printing hobbyists showcasing interesting 3D printer accessories, electronics and most importantly 3D models. The site contains many very interesting models of cars and buildings, as well as various add-ons and spare parts for your 3D printer. A huge catalog of paid and free models for a 3D printer. There are original unique products. Convenient search, navigation, rubricator. 3DShook has over 40 categories and adds over 100 new models to its collection every month. On 3DShook you can always find something for your home, animals, kids or something special for yourself.

A huge catalog of paid and free models for a 3D printer. There are original unique products. Convenient search, navigation, rubricator. 3DShook has over 40 categories and adds over 100 new models to its collection every month. On 3DShook you can always find something for your home, animals, kids or something special for yourself.

→ youmagine.com

YouMagine catalog for 3D Systems Cube series consumer 3D printers. The site mainly offers various ways to buy 3D printer supplies and files, but it also has a number of cool free items available, mostly in the Kids section. Some of these elements can be customized by children using an online application. The company offers 3D modeling and publishing tools on its website for both hobbyists and professionals. The site offers a content warehouse where the community hosts and shares models. Registration is required to download files.

→ 123dapp.com

Autodesk 123D is a suite of computer-aided design (CAD) and 3D modeling tools aimed specifically at hobbyists. Along with the toolkit, Autodesk also has a website where users can record their designs and share them with other users. Many of these models can be downloaded and printed using Autodesk as a utility to interface with the MakerBot 3D printer. The goal of the Autodesk website is to "help engineers build products faster." The site offers tools to help them collaborate on their files. For the casual 3D printing enthusiast, the best part of the site is the large library of free files created by a community of over a million engineers. Registration on the site is required, but the number of files that are then available is worth it.

Along with the toolkit, Autodesk also has a website where users can record their designs and share them with other users. Many of these models can be downloaded and printed using Autodesk as a utility to interface with the MakerBot 3D printer. The goal of the Autodesk website is to "help engineers build products faster." The site offers tools to help them collaborate on their files. For the casual 3D printing enthusiast, the best part of the site is the large library of free files created by a community of over a million engineers. Registration on the site is required, but the number of files that are then available is worth it.

→ cgtrader.com

Being primarily a place to buy and sell a variety of 3D models (not necessarily just those designed for 3D printers), CGTrader does offer a selection of free models that can be used on 3D printers. The site has a system that tries to find out what you like. The more you interact with the site, downloading and evaluating various developments, the body will have better recommendations.

→ cults3d.com

A French community and marketplace where developers can share or sell their creations. The site has a collection of high quality models that you can download. Users can follow the work of the designers they like and get instant updates when a new creation is posted on the site. The site's name, Cults, is a backwards spelling of St. Luc, the patron saint of artists. The site also supports English. This is a relatively new community, so the number of its users is not very large yet.

→ instructables.com

The Instructables website is a community where users can share their DIY projects. This also includes products obtained using 3D printers. The site also provides explanations and instructions describing how to build 3D elements, and some designers take the time to answer questions from site members. Instructables allows users to store and organize their 3D printing projects. This is done to help them work together in the future. You can think of this site as a GitHub 3D printing site where users can share their files, discuss projects, and participate in them. The site also offers the ability to make a request, so if you can't find what you're looking for, you can ask the site's community about it.

You can think of this site as a GitHub 3D printing site where users can share their files, discuss projects, and participate in them. The site also offers the ability to make a request, so if you can't find what you're looking for, you can ask the site's community about it.

→ pinshape.com

Pinshape, a marketplace for 3D models, is similar in style (layout, look, and ability to capture likes) to the well-known site Pinterest. You can buy models from designers, or download them for printing yourself if they are offered for free. Pinshape allows users to host and share 3D model files on it. Basically, this site acts as an online store where you can buy 3D printed parts, or order your own 3D model to be printed. But if you look closely enough, you can find people who sell their products and also offer the files you need so you can print them yourself.

→ 3dfilemarket.com

A new and growing repository of 3D File Market models. All models are tested for suitability for 3D printing. You can download as many models as you like without registration, although you must provide your email address to access the 3D model files. This is a very simple site aimed at being a repository of model files for 3D printers, and nothing more. The basic design of the site allows users to put files on it for public access, and download files that they would like to use. The site contains many small, simple 3D models ready to be printed, as well as a good selection of everyday items and even spare parts for 3D printers.

All models are tested for suitability for 3D printing. You can download as many models as you like without registration, although you must provide your email address to access the 3D model files. This is a very simple site aimed at being a repository of model files for 3D printers, and nothing more. The basic design of the site allows users to put files on it for public access, and download files that they would like to use. The site contains many small, simple 3D models ready to be printed, as well as a good selection of everyday items and even spare parts for 3D printers.

Search engines for 3D models in various formats, including STL for a 3D printer. Use queries in English, these search services collect information about models from all over the Internet.

→ yeggi.com

Yeggi is a search engine that will browse major 3D printing sites to find files compatible with 3D printers. You can also browse some popular searches to get an idea of what the community is currently interested in.