Technology 3d printing

What is 3D Printing? - Technology Definition and Types

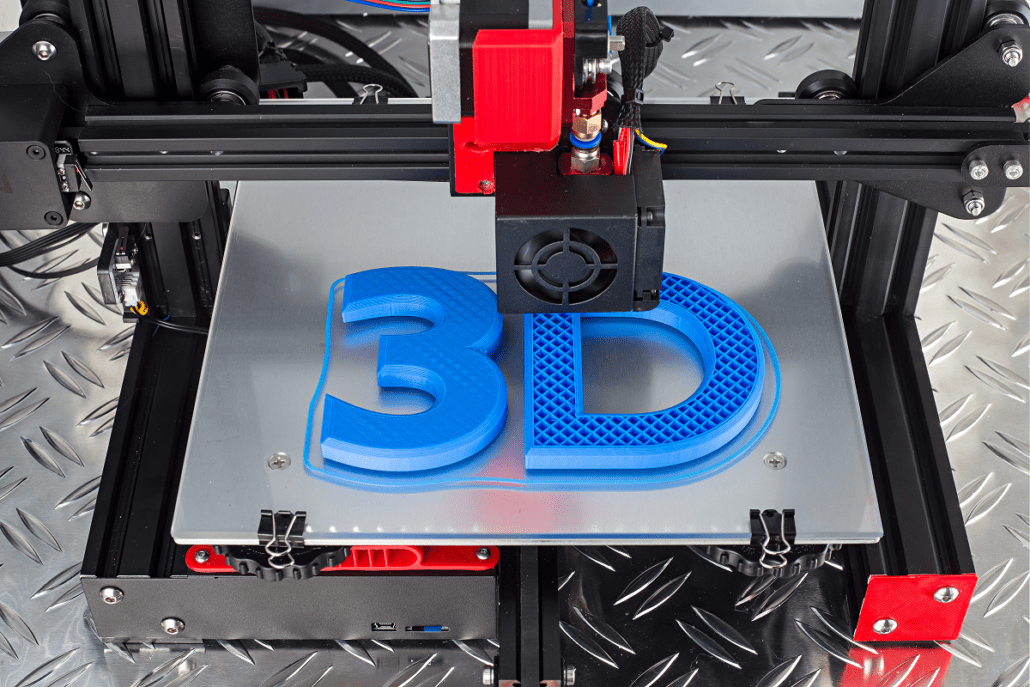

3D printing, also known as additive manufacturing, is a method of creating a three dimensional object layer-by-layer using a computer created design.

3D printing is an additive process whereby layers of material are built up to create a 3D part. This is the opposite of subtractive manufacturing processes, where a final design is cut from a larger block of material. As a result, 3D printing creates less material wastage.

This article is one of a series of TWI frequently asked questions (FAQs).

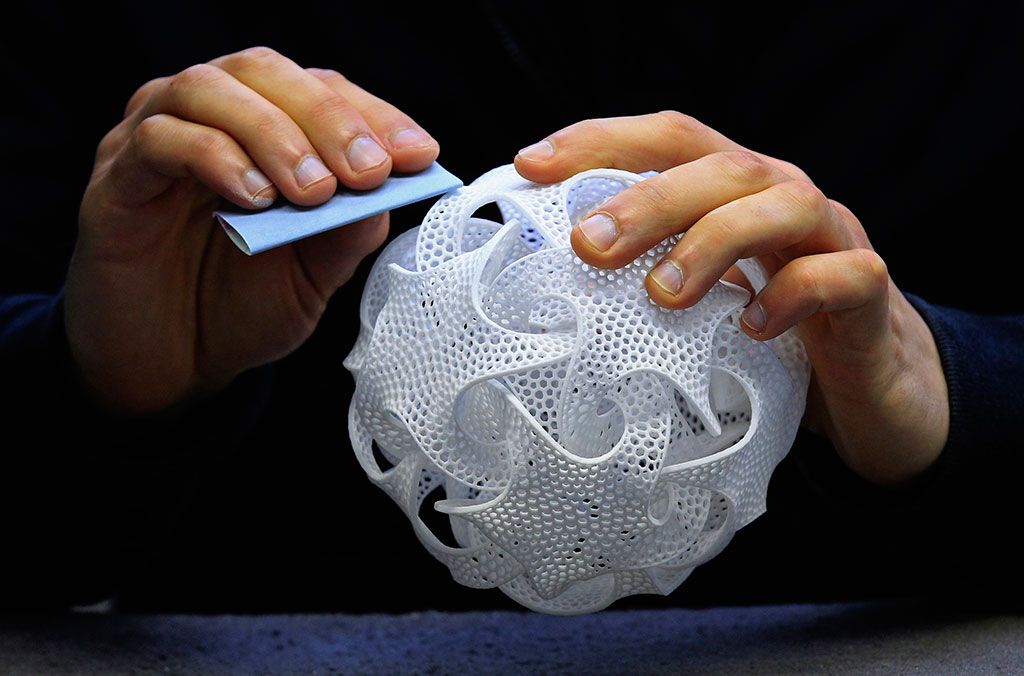

3D printing is also perfectly suited to the creation of complex, bespoke items, making it ideal for rapid prototyping.

Contents

- What materials can be used?

- History

- Technologies

- Process types

- How long does it take?

- Advantages and disadvantages

- What is an STL file?

- Industries

- Services

- FAQs

TWI

TWI is an Industrial Membership based organisation. TWI's experts can provide your company with an extension to your own resources. Our experts are dedicated to helping industry improve safety, quality, efficiency and profitability in all aspects of materials joining technology. Industrial Membership of TWI currently extends to over 600 companies worldwide, embracing all industrial sectors.

You can find out more by contacting us, below:

There are a variety of 3D printing materials, including thermoplastics such as acrylonitrile butadiene styrene (ABS), metals (including powders), resins and ceramics.

Who Invented 3D Printing?

The earliest 3D printing manufacturing equipment was developed by Hideo Kodama of the Nagoya Municipal Industrial Research Institute, when he invented two additive methods for fabricating 3D models.

When was 3D Printing Invented?

Building on Ralf Baker's work in the 1920s for making decorative articles (patent US423647A), Hideo Kodama's early work in laser cured resin rapid prototyping was completed in 1981. His invention was expanded upon over the next three decades, with the introduction of stereolithography in 1984. Chuck Hull of 3D Systems invented the first 3D printer in 1987, which used the stereolithography process. This was followed by developments such as selective laser sintering and selective laser melting, among others. Other expensive 3D printing systems were developed in the 1990s-2000s, although the cost of these dropped dramatically when the patents expired in 2009, opening up the technology for more users.

There are three broad types of 3D printing technology; sintering, melting, and stereolithography.

- Sintering is a technology where the material is heated, but not to the point of melting, to create high resolution items.

Metal powder is used for direct metal laser sintering while thermoplastic powders are used for selective laser sintering.

Metal powder is used for direct metal laser sintering while thermoplastic powders are used for selective laser sintering. - Melting methods of 3D printing include powder bed fusion, electron beam melting and direct energy deposition, these use lasers, electric arcs or electron beams to print objects by melting the materials together at high temperatures.

- Stereolithography utilises photopolymerization to create parts. This technology uses the correct light source to interact with the material in a selective manner to cure and solidify a cross section of the object in thin layers.

Types of 3D printing

3D printing, also known as additive manufacturing, processes have been categorised into seven groups by ISO/ASTM 52900 additive manufacturing - general principles - terminology. All forms of 3D printing fall into one of the following types:

- Binder Jetting

- Direct Energy Deposition

- Material Extrusion

- Material Jetting

- Powder Bed Fusion

- Sheet Lamination

- VAT Polymerization

Binder Jetting

Binder jetting deposits a thin layer of powered material, for example metal, polymer sand or ceramic, onto the build platform, after which drops of adhesive are deposited by a print head to bind the particles together. This builds the part layer by layer and once this is complete post processing may be necessary to finish the build. As examples of post processing, metal parts may be thermally sintered or infiltrated with a low melting point metal such as bronze, while full-colour polymer or ceramic parts may be saturated with cyanoacrylate adhesive.

This builds the part layer by layer and once this is complete post processing may be necessary to finish the build. As examples of post processing, metal parts may be thermally sintered or infiltrated with a low melting point metal such as bronze, while full-colour polymer or ceramic parts may be saturated with cyanoacrylate adhesive.

Binder jetting can be used for a variety of applications including 3D metal printing, full colour prototypes and large scale ceramic moulds.

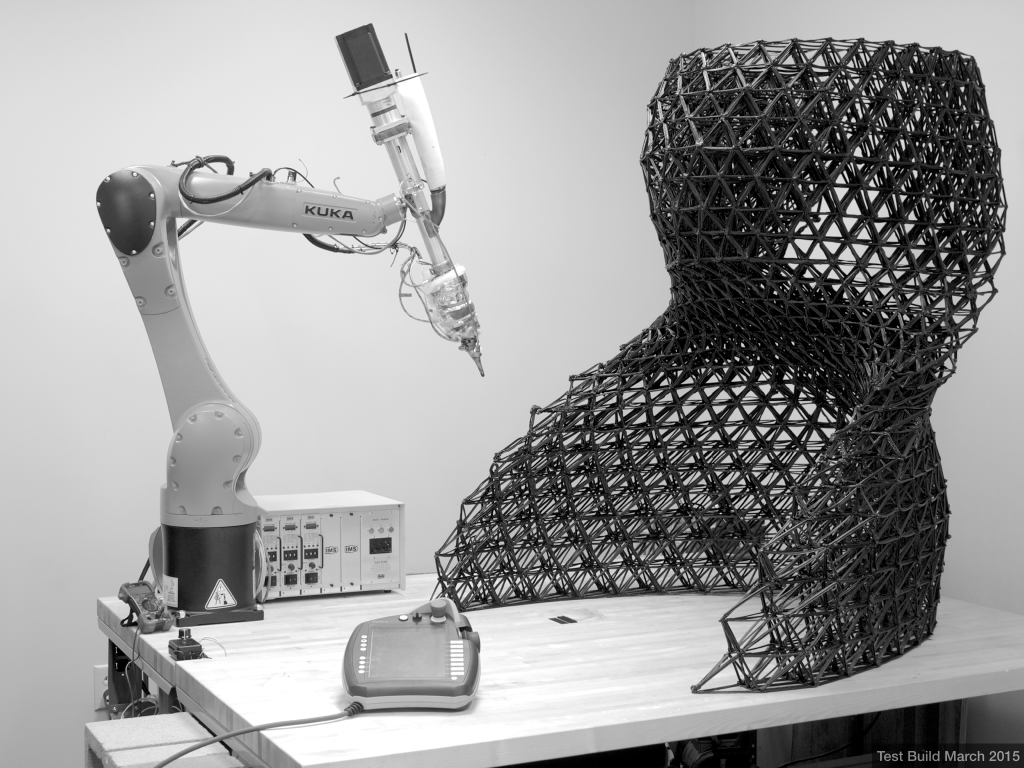

Direct Energy Deposition

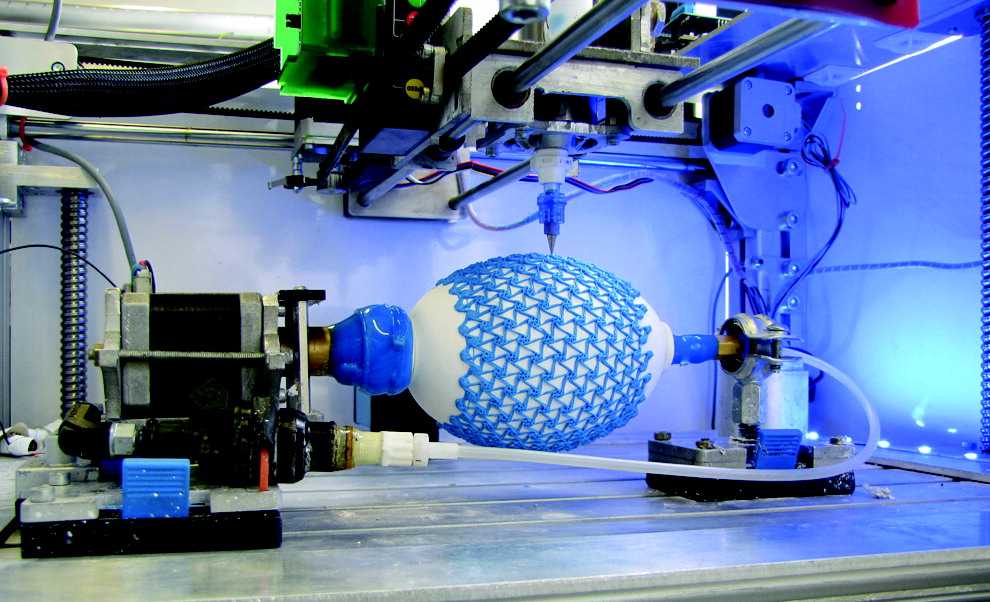

Direct energy depositioning uses focussed thermal energy such as an electric arc, laser or electron beam to fuse wire or powder feedstock as it is deposited. The process is traversed horizontally to build a layer, and layers are stacked vertically to create a part.

This process can be used with a variety of materials, including metals, ceramics and polymers.

Material Extrusion

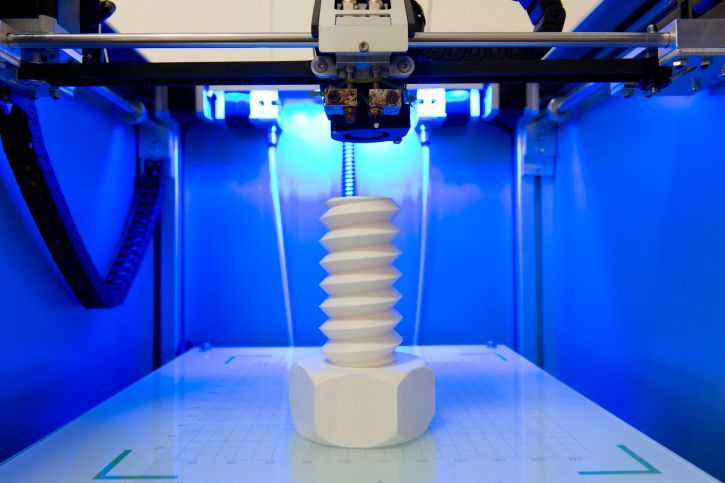

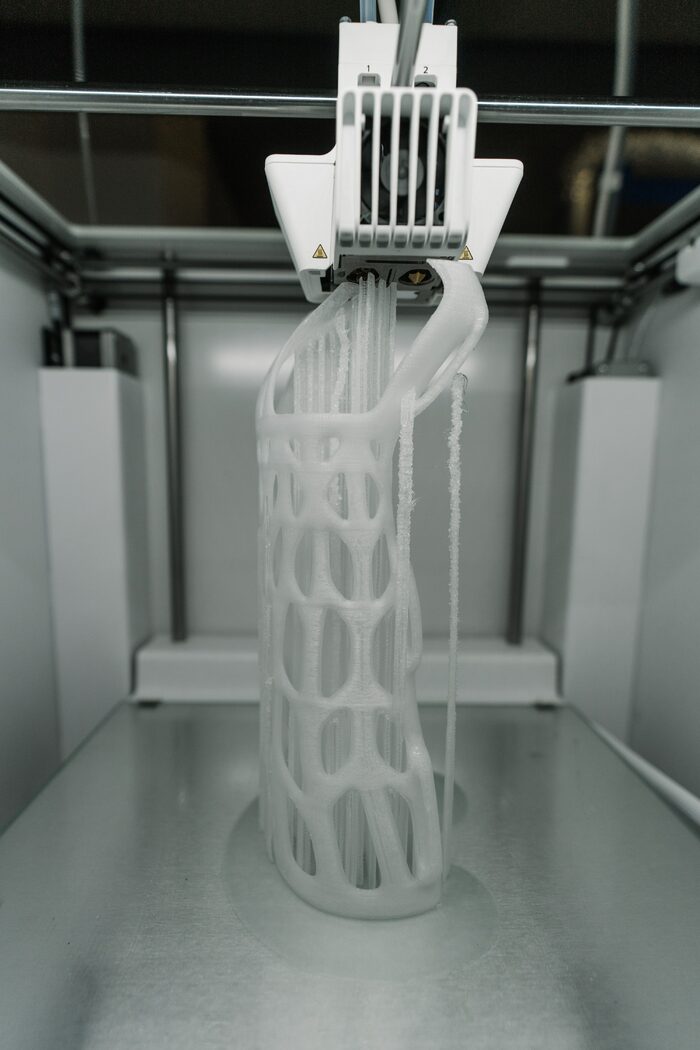

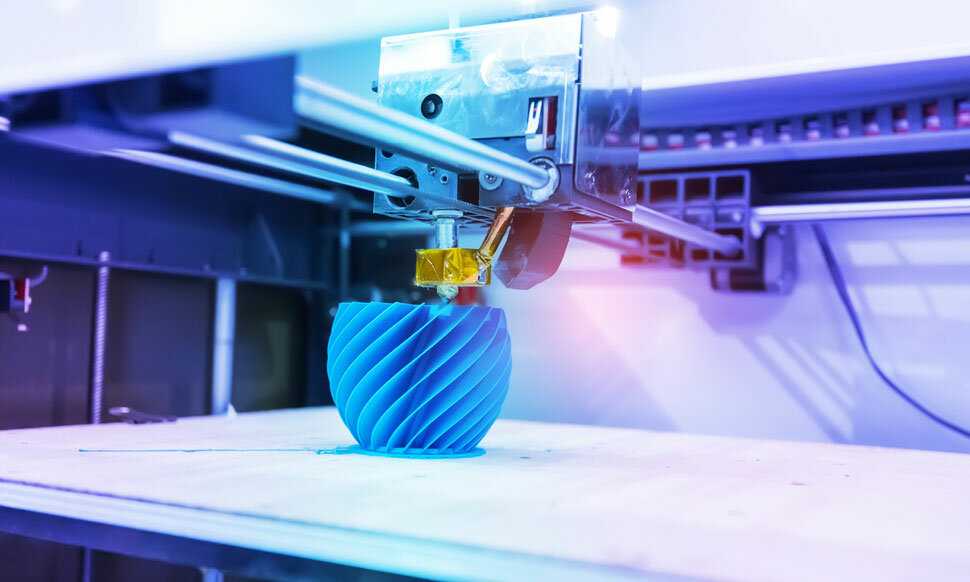

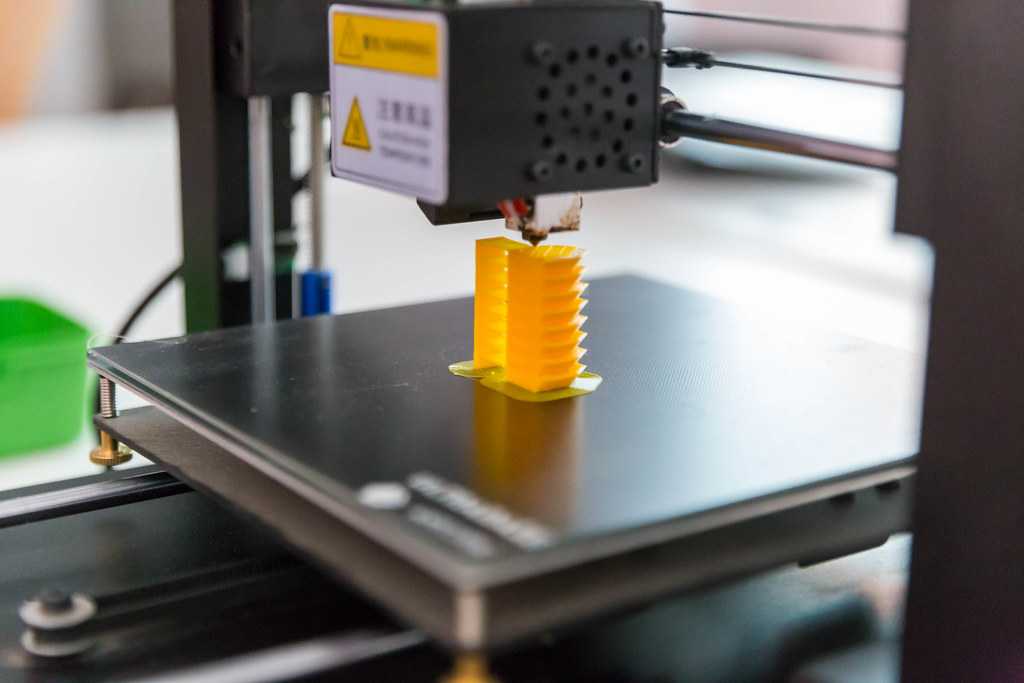

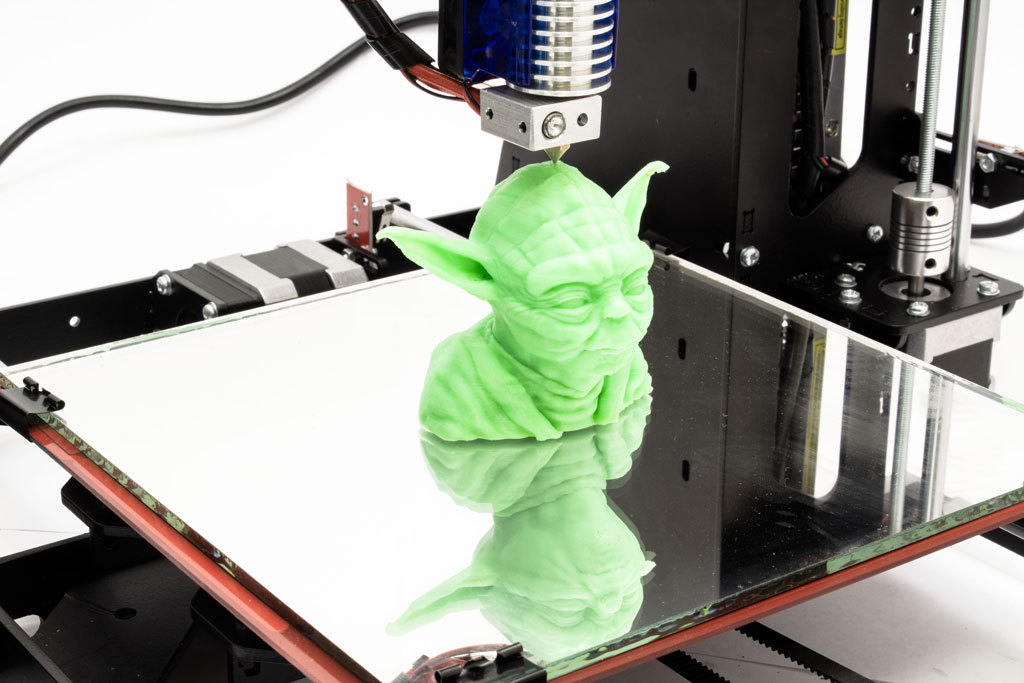

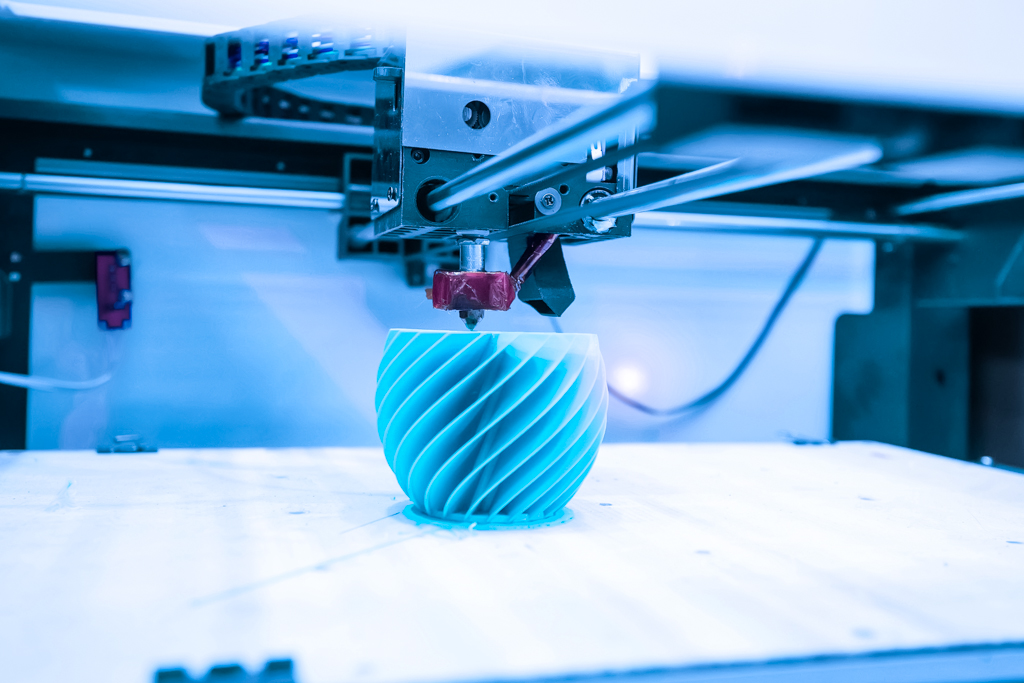

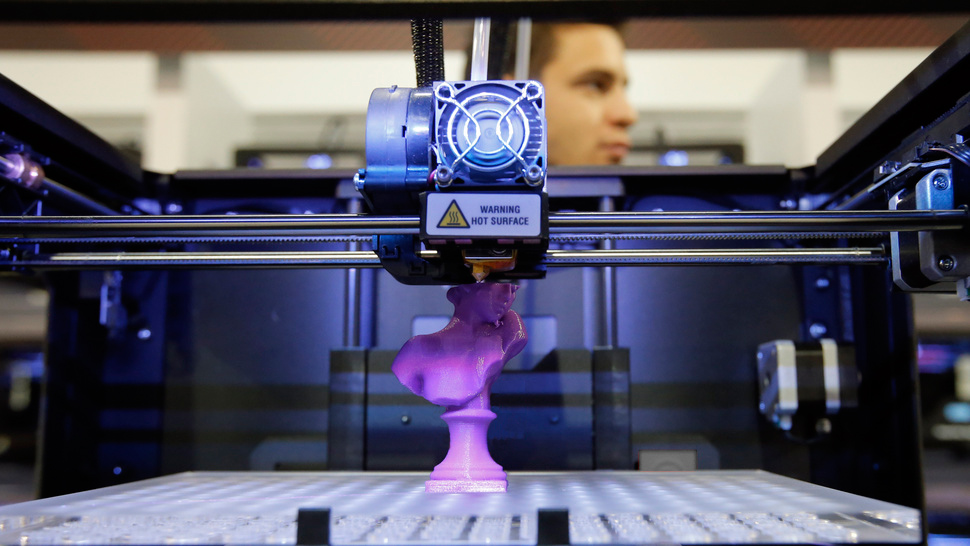

Material extrusion or fused deposition modelling (FDM) uses a spool of filament which is fed to an extrusion head with a heated nozzle. The extrusion head heats, softens and lays down the heated material at set locations, where it cools to create a layer of material, the build platform then moves down ready for the next layer.

The extrusion head heats, softens and lays down the heated material at set locations, where it cools to create a layer of material, the build platform then moves down ready for the next layer.

This process is cost-effective and has short lead times but also has a low dimensional accuracy and often requires post processing to create a smooth finish. This process also tends to create anisotropic parts, meaning that they are weaker in one direction and therefore unsuitable for critical applications.

Material Jetting

Material jetting works in a similar manner to inkjet printing except, rather than laying down ink on a page, this process deposits layers of liquid material from one or more print heads. The layers are then cured before the process begins again for the next layer. Material jetting requires the use of support structures but these can be made from a water-soluble material that can be washed away once the build is complete.

A precise process, material jetting is one of the most expensive 3D printing methods, and the parts tend to be brittle and will degrade over time. However, this process allows for the creation of full-colour parts in a variety of materials.

However, this process allows for the creation of full-colour parts in a variety of materials.

Powder Bed Fusion

Powder bed fusion (PBF) is a process in which thermal energy (such as a laser or electron beam) selectively fuses areas of a powder bed to form layer, and layers are built upon each other to create a part. One thing to note is that PBF covers both sintering and melting processes. The basic method of operation of all powder bed systems is the same: a recoating blade or roller deposits a thin layer of the powder onto the build platform, the powder bed surface is then scanned with a heat source which selectively heats the particles to bind them together. Once a layer or cross-section has been scanned by the heat source, the platform moves down to allow the process to begin again on the next layer. The final result is a volume containing one or more fused parts surrounded by unaffected powder. When the build is complete, the bed is fully raised to allow the parts to be removed from the unaffected powder and any required post processing to begin.

Selective laser sintering (SLS) is often used for manufacture of polymer parts and is good for prototypes or functional parts due to the properties produced, while the lack of support structures (the powder bed acts as a support) allows for the creation of pieces with complex geometries. The parts produced may have a grainy surface and inner porosity, meaning there is often a need for post processing.

Direct metal laser sintering (DMLS), selective laser melting (SLM) and electron beam powder bed fusion (EBPBF) are similar to SLS, except these processes create parts from metal, using a laser to bond powder particles together layer-by-layer. While SLM fully melts the metal particles, DMLS only heats them to the point of fusion whereby they join on a molecular level. Both SLM and DMLS require support structures due to the high heat inputs required by the process. These support structures are then removed in post processing ether manually or via CNC machining. Finally, the parts may be thermally treated to remove residual stresses.

Both DMLS and SLM produce parts with excellent physical properties - often stronger than the conventional metal itself, and good surface finishes. They can be used with metal superalloys and sometimes ceramics which are difficult to process by other means. However, these processes can be expensive and the size of the produced parts is limited by the volume of the 3D printing system used.

Sheet Lamination

Sheet lamination can be split into two different technologies, laminated object manufacturing (LOM) and ultrasonic additive manufacturing (UAM). LOM uses alternate layers of material and adhesive to create items with visual and aesthetic appeal, while UAM joins thin sheets of metal via ultrasonic welding. UAM is a low temperature, low energy process that can be used with aluminium, stainless steel and titanium.

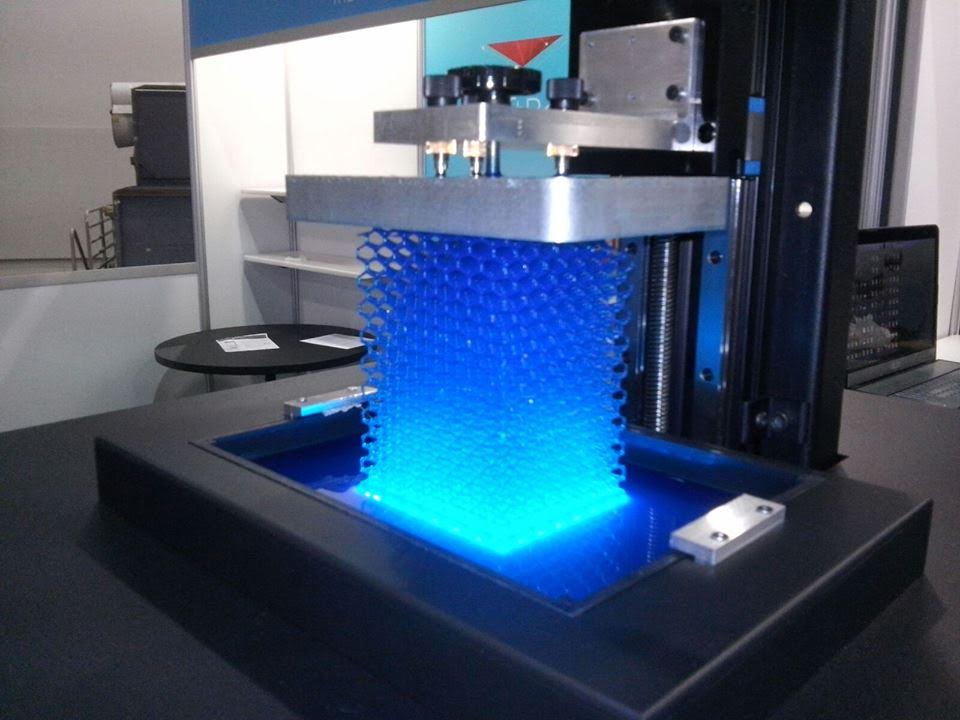

VAT Photopolymerization

VAT photopolymerization can be broken down into two techniques; stereolithography (SLA) and digital light processing (DLP). These processes both create parts layer-by-layer through the use of a light to selectively cure liquid resin in a vat. SLA uses a single point laser or UV source for the curing process, while DLP flashes a single image of each full layer onto the surface of the vat. Parts need to be cleaned of excess resin after printing and then exposed to a light source to improve the strength of the pieces. Any support structures will also need to be removed and additional post-processing can be used to create a higher quality finish.

These processes both create parts layer-by-layer through the use of a light to selectively cure liquid resin in a vat. SLA uses a single point laser or UV source for the curing process, while DLP flashes a single image of each full layer onto the surface of the vat. Parts need to be cleaned of excess resin after printing and then exposed to a light source to improve the strength of the pieces. Any support structures will also need to be removed and additional post-processing can be used to create a higher quality finish.

Ideal for parts with a high level of dimensional accuracy, these processes can create intricate details with a smooth finish, making them perfect for prototype production. However, as the parts are more brittle than fused deposition modelling (FDM) they are less suited to functional prototypes. Also, these parts are not suitable for outdoor use as the colour and mechanical properties may degrade when exposed to UV light from the sun. The required support structures can also leave blemishes that need post processing to remove.

The printing time depends on a number of factors, including the size of the part and the settings used for printing. The quality of the finished part is also important when determining printing time as higher quality items take longer to produce. 3D printing can take anything from a few minutes to several hours or days - speed, resolution and the volume of material are all important factors here.

The advantages of 3D printing include:

- Bespoke, cost-effective creation of complex geometries:

This technology allows for the easy creation of bespoke geometric parts where added complexity comes at no extra cost. In some instances, 3D printing is cheaper than subtractive production methods as no extra material is used. - Affordable start-up costs:

Since no moulds are required, the costs associated with this manufacturing process are relatively low. The cost of a part is directly related to the amount of material used, the time taken to build the part and any post processing that may be required.

The cost of a part is directly related to the amount of material used, the time taken to build the part and any post processing that may be required. - Completely customisable:

Because the process is based upon computer aided designs (CAD), any product alterations are easy to make without impacting the manufacturing cost. - Ideal for rapid prototyping:

Because the technology allows for small batches and in-house production, this process is ideal for prototyping, which means that products can be created faster than with more traditional manufacturing techniques, and without the reliance on external supply chains. - Allows for the creation of parts with specific properties:

Although plastics and metals are the most common materials used in 3D printing, there is also scope for creating parts from specially tailored materials with desired properties. So, for example, parts can be created with high heat resistance, water repellency or higher strengths for specific applications.

The disadvantages of 3D printing include:

- Can have a lower strength than with traditional manufacture:

While some parts, such as those made from metal, have excellent mechanical properties, many other 3D printed parts are more brittle than those created by traditional manufacturing techniques. This is because the parts are built up layer-by-layer, which reduces the strength by between 10 and 50%. - Increased cost at high volume:

Large production runs are more expensive with 3D printing as economies of scale do not impact this process as they do with other traditional methods. Estimates suggest that when making a direct comparison for identical parts, 3D printing is less cost effective than CNC machining or injection moulding in excess of 100 units, provided the parts can be manufactured by conventional means. - Limitations in accuracy:

The accuracy of a printed part depends on the type of machine and/or process used. Some desktop printers have lower tolerances than other printers, meaning that the final parts may slightly differ from the designs. While this can be fixed with post-processing, it must be considered that 3D printed parts may not always be exact.

Some desktop printers have lower tolerances than other printers, meaning that the final parts may slightly differ from the designs. While this can be fixed with post-processing, it must be considered that 3D printed parts may not always be exact. - Post-processing requirements:

Most 3D printed parts require some form of post-processing. This may be sanding or smoothing to create a required finish, the removal of support struts which allow the materials to be built up into the designated shape, heat treatment to achieve specific material properties or final machining.

An STL file is a simple, portable format used by computer aided design (CAD) systems to define the solid geometry for 3D printable parts. An STL file provides the input information for 3D printing by modelling the surfaces of the object as triangles that share edges and vertices with other neighbouring triangles for the build platform. The resolution of the STL file impacts the quality of the 3D printed parts - if the file resolution is too high the triangle may overlap, if it is too low the model will have gaps, making it unprintable. Many 3D printers require an STL file to print from, however these files can be created in most CAD programs.

Many 3D printers require an STL file to print from, however these files can be created in most CAD programs.

Due to the versatility of the process, 3D printing has applications across a range of industries, for example:

Aerospace

3D printing is used across the aerospace (and astrospace) industry due to the ability to create light, yet geometrically complex parts, such as blisks. Rather than building a part from several components, 3D printing allows for an item to be created as one whole component, reducing lead times and material wastage.

Automotive

The automotive industry has embraced 3D printing due to the inherent weight and cost reductions. It also allows for rapid prototyping of new or bespoke parts for test or small-scale manufacture. So, for example, if a particular part is no longer available, it can be produced as part of a small, bespoke run, including the manufacture of spare parts. Alternatively, items or fixtures can be printed overnight and are ready for testing ahead of a larger manufacturing run.

Medical

The medical sector has found uses for 3D printing in the creation of made-to-measure implants and devices. For example, hearing aids can be created quickly from a digital file that is matched to a scan of the patient's body. 3D printing can also dramatically reduce costs and production times.

Rail

The rail industry has found a number of applications for 3D printing, including the creation of customised parts, such as arm rests for drivers and housing covers for train couplings. Bespoke parts are just one application for the rail industry, which has also used the process to repair worn rails.

Robotics

The speed of manufacture, design freedom, and ease of design customisation make 3D printing perfectly suited to the robotics industry. This includes work to create bespoke exoskeletons and agile robots with improved agility and efficiency.

TWI has one of the most definitive ranges of 3D Printing services, including selective laser melting, laser deposition, wire and arc additive manufacturing, wire and electron beam additive manufacturing and EB powder bed fusion small-scale prototyping, and more.

Additive Manufacturing

TWI provides companies with support covering every aspect of metal additive manufacturing (AM), from simple feasibility and fabrication projects to full adoption and integration of metal AM systems.

Laser Metal Deposition

TWI has been developing LMD technology for the last ten years. For full details of our capabilities in this area, and to find out more about the process and the benefits it can bring to your business.

Selective Laser Melting

TWI has been developing selective laser melting technology for the last decade. Find out full details of our capabilities in this area and the benefits it can bring to your business.

Can 3D Printing be used for Mass Production?

While there have been great advances in 3D printing, it still struggles to match other manufacturing techniques for high volume production. Techniques such as injection moulding allow for much faster mass production of parts.

Where is 3D Printing Heading in the Future?

As 3D printing technology continues to improve it could democratise the manufacture of goods. With printers becoming faster, they will be able to work on larger scale production projects, while lowering the cost of 3D printing will help its use spread outside of industrial uses and into homes, schools and other settings.

Which 3D Printing Material is most Flexible?

Thermoplastic polyurethane (TPU) is commonly deemed to be the most flexible material available to the 3D printing industry. TPU possesses bendable and stretchy characteristics that many other filaments do not have.

Which 3D Printing Material is the Strongest?

Polycarbonate is seen as the strongest 3D printing material, with a tensile strength of 9,800 psi, compared to nylon, for example, with just 7,000 psi.

Why is 3D Printing Important?

3D printing is important for the many benefits it brings. It allows users to produce items that have geometries which are difficult or impossible for traditional methods to produce. It also allows users with a limited experience to edit designs and create bespoke, customised parts. On-demand 3D printing also saves on tooling costs and provides an advanced time-to-market. 3D printing is important for industries such as aerospace, where it can create lightweight yet complex parts, offering weight saving, the associated fuel reductions and a better environmental impact as a result. It is also important for the creation of prototypes that can advance industry.

It also allows users with a limited experience to edit designs and create bespoke, customised parts. On-demand 3D printing also saves on tooling costs and provides an advanced time-to-market. 3D printing is important for industries such as aerospace, where it can create lightweight yet complex parts, offering weight saving, the associated fuel reductions and a better environmental impact as a result. It is also important for the creation of prototypes that can advance industry.

Will 3D Printing Replace Traditional Manufacturing?

3D printing has the capability to disrupt traditional manufacturing through the democratisation of production along with the production of moulds, tools and other bespoke parts. However, challenges around mass production mean that 3D printing is unlikely to replace traditional manufacturing where high volume production of comparatively simple parts is required.

Are 3D Printing Fumes Dangerous?

3D printing fumes can be dangerous to your health as the process produces toxic filament fumes. These emissions are produced as the plastic filaments are melted to create the product layer-by-layer. However, correct procedures such as ensuring sufficient ventilation or using extractors can solve this issue.

These emissions are produced as the plastic filaments are melted to create the product layer-by-layer. However, correct procedures such as ensuring sufficient ventilation or using extractors can solve this issue.

Related Frequently Asked Question (FAQs)

What are the Pros and Cons of 3D Printing?

The demand is growing due to some of the revolutionary benefits that it can provide. Like almost all technologies it has its own drawbacks that need considering.

How Long Does 3D Printing Take?

There are several factors that determine the time it takes to 3D print a part. These include the size, height, complexity and the printing technology used.

Can 3D Printing Use Metal?

Yes, it is possible to 3D print items from metal. There are several types of process which fall under the heading of metal additive manufacturing.

What is Additive Manufacturing?

Additive manufacturing (AM) is a computer controlled process that creates three dimensional objects by depositing materials, usually in layers.

Types of 3D Printing Technology Explained

Multi Jet Fusion (MJF)

Similar to SLS, Multi Jet Fusion also builds functional parts from nylon powder. Rather than using a laser to sinter the powder, MJF uses an inkjet array to apply fusing agents to the bed of nylon powder. Then a heating element passes over the bed to fuse each layer. This results in more consistent mechanical properties compared to SLS as well as improved surface finish. Another benefit of the MJF process is the accelerated build time, which leads to lower production costs.

Fused Deposition Modeling (FDM)

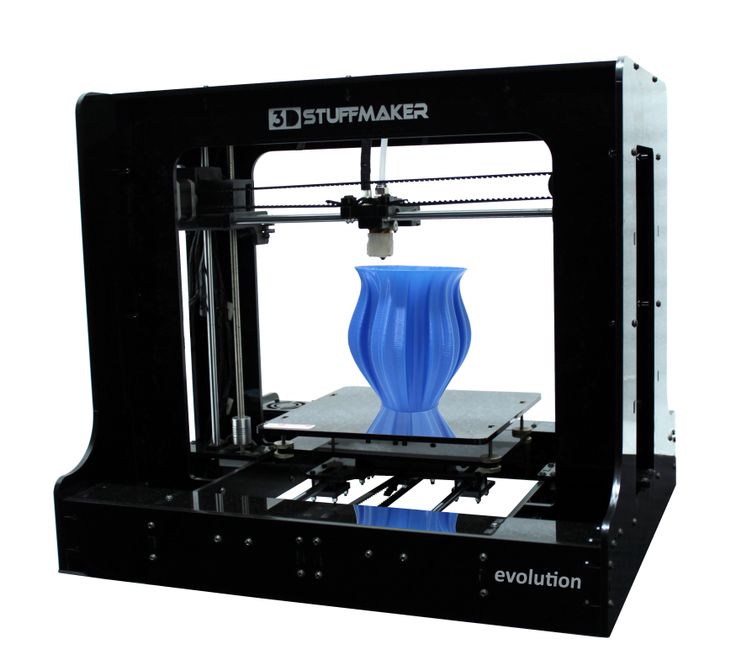

Fused deposition modeling (FDM) is a common desktop 3D printing technology for plastic parts. An FDM printer functions by extruding a plastic filament layer-by-layer onto the build platform. It’s a cost-effective and quick method for producing physical models. There are some instances when FDM can be used for functional testing but the technology is limited due to parts having relatively rough surface finishes and lacking strength.

Metal 3D Printing Processes

Direct Metal Laser Sintering (DMLS)

Metal 3D printing opens up new possibilities for metal part design. The process we use at Protolabs to 3D print metal parts is direct metal laser sintering (DMLS). It’s often used to reduce metal, multi-part assemblies into a single component or lightweight parts with internal channels or hollowed out features. DMLS is viable for both prototyping and production since parts are as dense as those produced with traditional metal manufacturing methods like machining or casting. Creating metal components with complex geometries also makes it suitable for medical applications where a part design must mimic an organic structure.

Electron Beam Melting (EBM)

Electron beam melting is another metal 3D printing technology that uses an electron beam that's controlled by electromagnetic coils to melt the metal powder. The printing bed is heated up and in vacuum conditions during the build. The temperature that the material is heated to is determined by the material in use.

When to Use 3D Printing

As stated earlier, there are a couple common denominators among 3D printing applications. If your part quantities are relatively low, 3D printing can be optimal—the guidance we give our 3D printing service customers is usually 1 to 50 parts. As volumes start to near the hundreds, it’s worth exploring other manufacturing processes. If your design features complex geometry that is critical to your part’s function, like an aluminum component with an internal cooling channel, 3D printing might be your only option.

Selecting the right process comes down to aligning the advantages and limitations of each technology to your application’s most important requirements. In the early stages when ideas are being thrown around and all you need is a model to share with a colleague, those stair-stepping surface finishes on your part aren’t of much concern. But once you hit the point where you need to conduct user testing, factors like cosmetics and durability start to matter. Although there is no one-size-fits-all solution, properly utilizing 3D printing technology throughout product development will reduce design risk and, ultimately, result in better products.

Although there is no one-size-fits-all solution, properly utilizing 3D printing technology throughout product development will reduce design risk and, ultimately, result in better products.

3D printing technologies

Today, there are many technologies for creating real objects from 3D models. The most common and affordable technology is plastic printing (FDM technology).

In our article, we give a classification of printing technologies and describe each of them.

At present, 3D printing technologies are divided into 4 main categories:

1. Extrusion - extrusion of molten material;

2. Photopolymerization - UV or laser curing of a polymer.

3. Printing by sintering and melting materials

4. Lamination - gluing material layers with subsequent cutting;

In addition, there are other technologies that do not fall into the above categories, we will talk about them at the end of this article.

- 1. Material extrusion

1. 1. Fused Deposition Modeling (FDM) 0020

1. Fused Deposition Modeling (FDM) 0020

The technology works on the principle of material deposition in layers. Plastic or metal filaments are unwound from a roll (cartridge) and fed into the print head (extruder). The extruder heats the filaments to a liquid state and extrudes the material through the nozzle, moving in the horizontal and vertical directions, layer by layer, forming an object.

Benefits of FDM 3D printing

- • Speed and ease of fabrication

- • availability;

- • safety, environmental friendliness and non-toxicity of most materials;

- • building accuracy;

- • ease of use and maintenance;

- • strength of parts;

- • easy disposal. 1.2. Spray modeling followed by layer milling (Drop On Demand Jet, DODJet)

The printhead sprays both consumables at the same time. Then a special milling head cools the sprayed layer and mechanically processes it. DODJet technology allows you to build high-precision models with an absolutely smooth surface. Since the spraying of the working layer occurs due to a mechanically moving head, the speed of manufacturing a prototype largely depends on the complexity of the printed model.

Media : Casting wax

- 2. Photopolymerization

2.1. Laser stereolithography ( Laser Stereolithography, SLA)

The technology involves the use of a special photopolymer - photosensitive resin as a model material. The basis in this process is an ultraviolet laser, which sequentially transfers the cross sections of the model onto the surface of a container with photosensitive resin.

The photopolymer hardens only in the place where the laser beam has passed. Then a new layer of resin is applied to the hardened layer, and a new contour is drawn with a laser. The process is repeated until the model is built. Stereolithography is the most popular rapid prototyping technology for high-precision models. It covers almost all branches of material production from medicine to heavy engineering. SLA technology allows you to quickly and accurately build a product model of almost any size. The quality of surfaces depends on the construction step. Modern machines provide a construction step of 0.025 - 0.15 mm.

The photopolymer hardens only in the place where the laser beam has passed. Then a new layer of resin is applied to the hardened layer, and a new contour is drawn with a laser. The process is repeated until the model is built. Stereolithography is the most popular rapid prototyping technology for high-precision models. It covers almost all branches of material production from medicine to heavy engineering. SLA technology allows you to quickly and accurately build a product model of almost any size. The quality of surfaces depends on the construction step. Modern machines provide a construction step of 0.025 - 0.15 mm. SLA-technology gives the best result in the manufacture of master models for the subsequent production of silicone molds and casting polymer resins in them, and is also used for growing jewelry master models.

Media : Photopolymer resin

2.2. Digital Light Processing (Digital Light Processing, DLP)

Media : Liquid Resin

2.3. Technology MJM (Multi-Jet-Modeling)

MJM - 3D printing technology is based on a layer-by-layer section of a CAD file into horizontal layers, which are sequentially sent to a 3D printer. Each layer is formed by a print head, which, through groups of nozzles, releases either molten (temperature about 80 C) photopolymer or molten wax onto a horizontal moving platform. The photopolymer or wax is melted in the material supply system before entering the print head. If 3D printing is performed from a photopolymer, then after each layer is printed, the platform on which the layer is grown slides behind the print head under an ultraviolet lamp. A flash of an ultraviolet lamp causes the reaction of the photopolymer, due to which the material hardens.

After that, the platform slides back under the print head and the layer formation cycle is repeated. The print head forms a new layer. Features of MJM technology is the ability to reproduce 3D models with high accuracy. The 3D printing process uses a support material: wax (supplied in separate cartridges). If 3D printing is made from photopolymer, then the support material is removed by means of high temperature: the part with support is placed in an oven with a temperature of ~60 C. If 3D printing is made from wax, then the support is removed using a special solution.

After that, the platform slides back under the print head and the layer formation cycle is repeated. The print head forms a new layer. Features of MJM technology is the ability to reproduce 3D models with high accuracy. The 3D printing process uses a support material: wax (supplied in separate cartridges). If 3D printing is made from photopolymer, then the support material is removed by means of high temperature: the part with support is placed in an oven with a temperature of ~60 C. If 3D printing is made from wax, then the support is removed using a special solution. It is also important that dyes can be added to the glue, and, therefore, it is possible to get not only a three-dimensional model, but also a multi-colored one.

Print material : Photopolymer resin, acrylic resin, casting wax

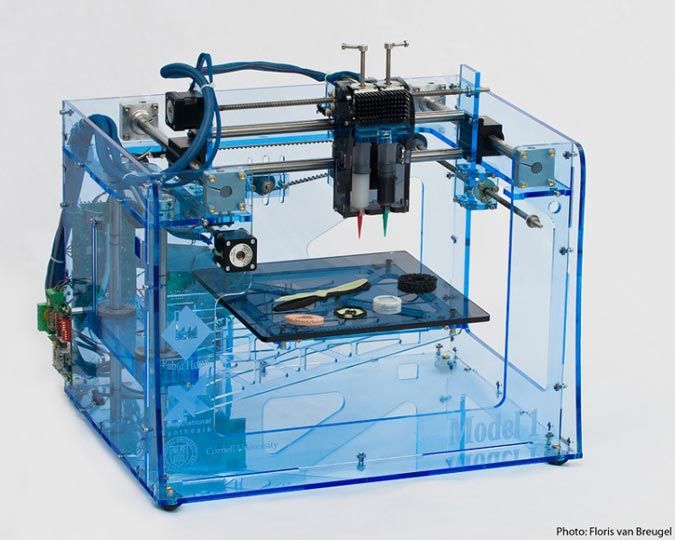

2.4. Polyjet technology (PolyJet, PJET)

PolyJet 3D printing is similar to inkjet printing of documents, but instead of inkjet on paper, PolyJet 3D printers emit jets of liquid photopolymer that forms layers on the build tray and is instantly fixed by ultraviolet radiation .

Thin layers are laid down sequentially and form an accurate three-dimensional model or prototype. Models are ready for use immediately upon removal from the 3D printer, no additional fixation is required. In addition to the selected build material, the 3D printer also jets a gel-like support material designed to support protrusions and complex geometries. It is easy to remove by hand or with water.

Thin layers are laid down sequentially and form an accurate three-dimensional model or prototype. Models are ready for use immediately upon removal from the 3D printer, no additional fixation is required. In addition to the selected build material, the 3D printer also jets a gel-like support material designed to support protrusions and complex geometries. It is easy to remove by hand or with water. PolyJet 3D printing technology has many advantages for rapid prototyping, producing stunningly fine details and smooth surfaces quickly and accurately. The technology uses a wide range of materials, including rigid opaque materials in hundreds of vibrant colors, transparent and colored translucent tones, flexible elastic materials, and specialized photopolymers for 3D printing in the dental, medical, and consumer goods industries.

Media : Photopolymer resin

- Selective Laser Sintering (SLS)

In this technology, models are created from powder materials due to the sintering effect using laser beam energy.

Unlike the SLA process, in this case the laser beam is not a light source, but a heat source. Getting on a thin layer of powder, the laser beam sinters its particles and forms a solid mass, in accordance with the geometry of the part. Polyamide, polystyrene, sand and some metal powders are used as materials. A significant advantage of the SLS process is the absence of so-called supports when building a model. In the SLA and MJM processes, when building overhanging elements of a part, special supports are used to protect freshly built thin layers of the model from collapse. In the SLS process, there is no need for such supports, since the construction is carried out in a homogeneous mass of powder. After building, the model is extracted from the powder array and cleaned.

Unlike the SLA process, in this case the laser beam is not a light source, but a heat source. Getting on a thin layer of powder, the laser beam sinters its particles and forms a solid mass, in accordance with the geometry of the part. Polyamide, polystyrene, sand and some metal powders are used as materials. A significant advantage of the SLS process is the absence of so-called supports when building a model. In the SLA and MJM processes, when building overhanging elements of a part, special supports are used to protect freshly built thin layers of the model from collapse. In the SLS process, there is no need for such supports, since the construction is carried out in a homogeneous mass of powder. After building, the model is extracted from the powder array and cleaned. The leading manufacturers of SLS machines are Concept Laser (Germany), 3D Systems (USA) and EOS GmbH (Germany).

Print material : Thermoplastic, metal powder, ceramic powder, glass powder

3.

2. Direct Metal Selective Laser Melting (Direct Metal Selective Laser Melting, SLM)

2. Direct Metal Selective Laser Melting (Direct Metal Selective Laser Melting, SLM) Thin layers of quality metal powder are evenly distributed using a special coating mechanism, the platform on which the powder is located can be lowered vertically. The entire process takes place inside a chamber that maintains tight control of atmospheric inert gases such as argon, nitrogen and oxygen below 500 ppm. Each layer is then formed by selectively exposing the powder surface to lasers using two high-frequency X- and Y-axis scanners. The process is repeated layer by layer until the part is complete.

Media : Virtually any metal alloy in granular/crushed/powder form

3.3. E electron beam melting (Electron Beam Melting, EBM)

The technology is the manufacture of parts by melting metal powder applied layer by layer with a powerful electron beam in vacuum.

Unlike some methods of metal sintering, parts are obtained without voids, very durable.

Unlike some methods of metal sintering, parts are obtained without voids, very durable. The technology makes it possible to produce parts of any geometric shape with the parameters of the material used. The EBM machine reads data from a 3D model, usually located in a CAD file, and builds it up layer by layer. These layers are fused together using a computer controlled electron beam. In this way he builds whole parts. The process takes place in a vacuum, which makes it suitable for the manufacture of parts from materials that are highly susceptible to oxygen, such as titanium.

An important advantage is that the powder is a pure end material without any fillers. So you do not need to subject the printed part to additional heat treatment.

EBM operates at temperatures typically between 700 and 1000°C. Parts are ready almost immediately after cooling.

Titanium alloys, as noted above, are easily processed by this technology, making it a suitable choice for the medical implant market.

Print material : Titanium alloys

3.4. Selective Heat sintering (Selective Heat Sintering)

In order to be able to heat flow, special ultraviolet lamps are used in this technology. One of the main advantages is that for a given wavelength of infrared radiation, it is possible to select 2 types of material: one will transmit heat, and the other will reflect. Also, one of the main properties of IR radiation is the ability to choose a wavelength at which a particular material will absorb or reflect all radiation.

It is interesting to note that one 100 micron (0.1mm) thick layer is printed in just 1-2 seconds. This technology is a real breakthrough in high-speed printing. It is important to emphasize that the model is formed from powder, and all unused powder can be reused.

This technology allows you to make models of the most complex geometric shapes, and also allows you to print several parts at the same time.

Media : Thermoplastic powder

3.5. Powder bed and inkjet head 3d printing, Plaster-based 3D printing, 3DP

), which is introduced into the powder. For these purposes, a print head similar to the head of an inkjet 3D printer is used.

The technology is very simple: there is a layer of powder, a print head passes over it and selectively (according to the cross-sectional shape) applies a special binding liquid. A fresh layer of powder spreads over the entire surface of the model, and the process is repeated. When the model is completed, unbound powder is automatically removed.

Printing Material : GIPS, gypsum composite, gypsum powder

- 4. Production of objects using lamination (Laminated Object Manaufacturn, Lom)

9000 9000 9000 9000 9000 , metal foil, polyethylene film

- 3D- printing from Mcor Technologies

Press material : Standard office paper

- Contour manufacturing (Contour Crafting, CC)

- FDM / FFF

- SLA

- SLM

- SLS0018 SLM

- SLS

- CJP

- PolyJet

- Various types of plastics (durable, flexible, heat resistant, etc.)

- Strength and durability of finished products

- Large Camera 3D Printers

- Low cost and high productivity

- Various types of plastics (durable, flexible, heat resistant, etc.)

- Strength and durability of finished products

- Large Camera 3D Printers

- Low cost and high productivity

- Materials: polymer resins with different properties

- Laser curing

- High print speed

- High precision and detail

- Smooth surfaces

- Materials: polymer resins with different properties

- Laser curing

- High print speed

- High precision and detail

- Smooth surfaces

- Working with various metals and alloys

- Unique Product Features

- Any geometry

- Working with various metals and alloys

- Unique Product Features

- Any geometry

- Material: polyamide powders

- Any geometry

- Durability and accuracy

- High performance

- Material: polyamide powders

- Any geometry

- Strength and precision

- High performance

- Composite powder based on gypsum

- 3D full color CMYK

- Realistic prototypes for visual evaluation

- Complex geometries

- Low cost

- Composite powder based on gypsum

- 3D full color CMYK

- Realistic prototypes for visual evaluation

- Complex geometries

- Low cost

- Photopolymer materials with different properties (transparent, rubber-like, biocompatible, etc.

Learn more

Printing

Guide for 3D-printing 3D- equipment since 2010

+7 495 646-15-338 800 333-12-82

3D scanners3D printersSoftwareServices

0004 Blog

Contacts

Today, there are about 10 major 3D printing technologies. They differ in speed, accuracy, material used and other parameters. The choice of 3D printing technology depends on the tasks that you set for the 3D printer, on the requirements for the resulting products.

FDM (Fused Deposition Modeling) / FFF (Fused Filament Fabrication)

Operating principle: layer-by-layer construction of a product from molten plastic material.

Features:

More about FDM technology >>

FDM (Fused Deposition Modeling) / FFF (Fused Filament Fabrication)

Operating principle: layer-by-layer construction of a product from molten plastic material.

Features:

More about FDM technology >>

SLA (stereolithography)

Operating principle: layer-by-layer curing of a liquid polymer material under the action of a laser beam.

Features:

Learn more about SLA technology >>

SLA (stereolithography)

Operating principle: layer-by-layer curing of a liquid polymer material under the action of a laser beam.

Features:

More about SLA technology >>

SLM (Selective Laser Melting)

Other names: DMP, DMLS, EBM, etc.

Operating principle: layer-by-layer fusion of metal powders under the influence of a laser

Features:

More about SLM technology and its analogues >>

SLM (Selective Laser Melting)

Other names: DMP, DMLS, EBM, etc.

Operation principle: layer-by-layer fusion of metal powders under the influence of a laser

Features:

More about SLM technology and its analogues >>

SLS (Selective Laser Sintering)

Principle: layer-by-layer sintering of polyamide powders under the influence of a laser

Features:

Find out more about the SLS technology >>

SLS (Selective Laser Sintering)

Operating principle: layer-by-layer sintering of polyamide powders under the influence of a laser

Features:

Learn more about SLS technology >>

CJP (Color-Jet Printing)

Function: layer-by-layer bonding and coloring of composite powder

Features:

More about CJP technology >>

CJP (Color-Jet Printing)

How it works: layer-by-layer bonding and coloring of composite powder

Features:

Learn more about CJP technology >>

PolyJet

How it works: curing liquid photopolymer material under UV radiation

Features: