3D print heart

Boston University's new 3D printed mini human heart beats on its own

0Shares

A research team led by Boston University has used 3D printing technology to develop a miniature replica of a human heart – and it beats like the real thing.

Named the cardiac miniaturized Precision-enabled Unidirectional Microfluidic Pump, aka the miniPUMP, the device was created using a combination of stem cell-derived human heart cells and micro-scale 3D printed acrylic parts. Designed to behave like a real heart chamber, the miniPUMP doesn’t rely on any external sources of power, instead beating by itself thanks to its live tissue.

The researchers believe their heart chamber replica could serve as a testbed to study how the organ works in the human body. It can be used to track how the heart grows in an embryo, how heart tissue is affected by diseases, and how effective new medications are in treating said diseases, all without the need for human testing.

“We can study disease progression in a way that hasn’t been possible before,” says Alice White, a Boston University College of Engineering professor. “We chose to work on heart tissue because of its particularly complicated mechanics, but we showed that, when you take nanotechnology and marry it with tissue engineering, there’s potential for replicating this for multiple organs.”

The challenge of studying the heart

According to the Centers for Disease Control and Prevention, heart disease is the leading cause of death for both men and women in the US, with around 659,000 mortalities every year. That’s one in four deaths. As such, there’s an urgent need to study the vital organ.

However, due to its inaccessible location in the human body, the heart is a tricky thing to study as it can’t just be removed, examined, and replaced on a whim. To address this, researchers have tried several alternative approaches: they’ve manually pumped blood through cadaver hearts and they’ve spring-loaded lab-grown heart tissues to make them expand and contract. Unfortunately, we’re yet to find a suitable lifelike proxy as reanimated hearts can’t beat indefinitely and springs don’t contract like real muscle fibers.

Unfortunately, we’re yet to find a suitable lifelike proxy as reanimated hearts can’t beat indefinitely and springs don’t contract like real muscle fibers.

With innovations like the miniPUMP, researchers could eventually mimic and study diseases such as hypertension and valve disease in a more accurate manner. The device is also expected to streamline the drug development process for upcoming medicines, enabling lab-based testing in lieu of costly and tedious human trials.

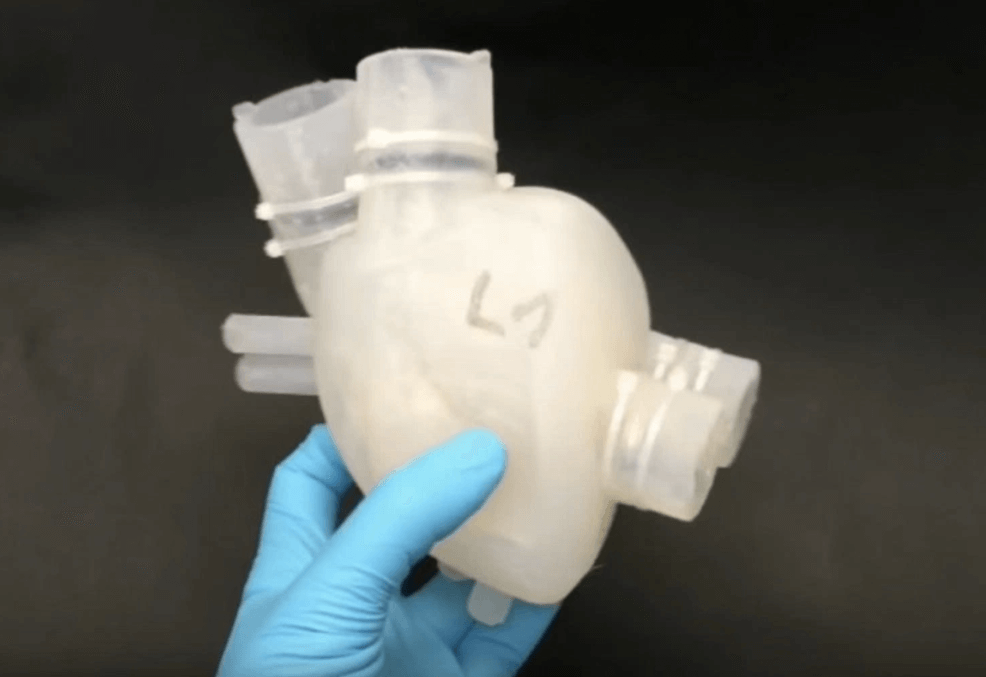

A large-scale replica of the 3D printed scaffold that supports the heart tissue. Photo via Christos Michas.How was the miniPUMP developed?

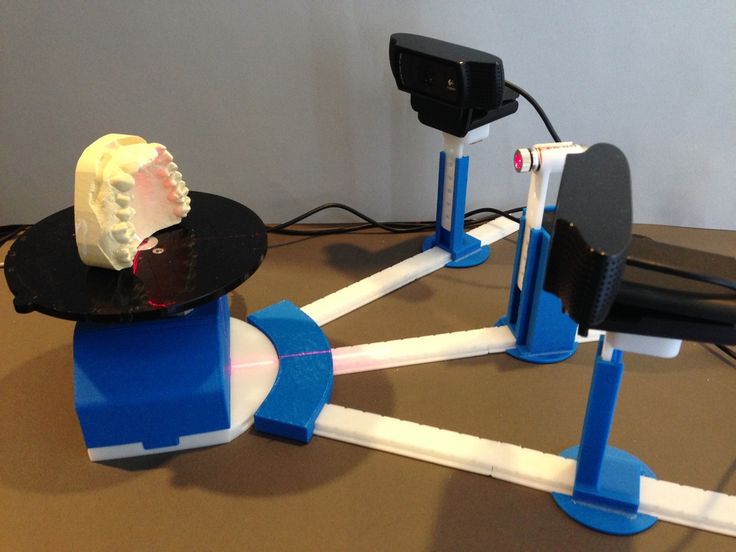

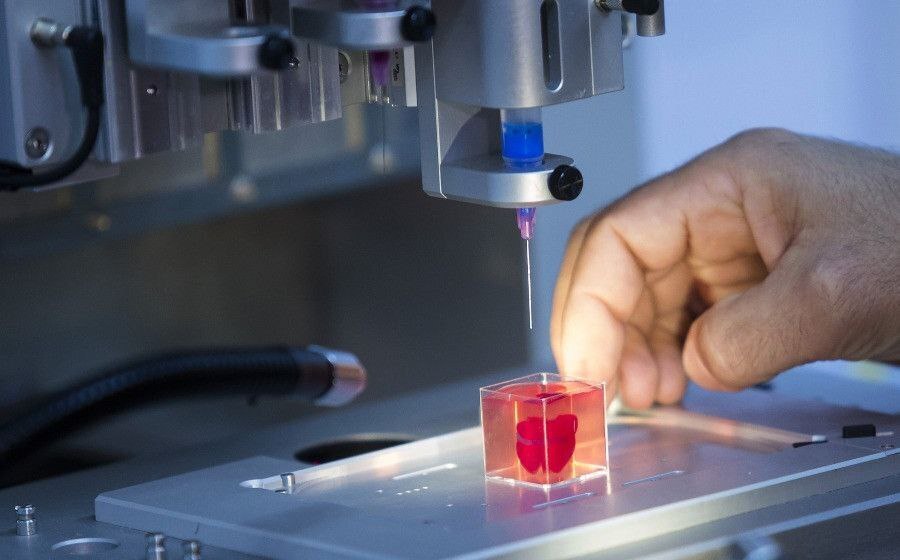

The miniPUMP measures just three square centimeters and features an acrylic scaffold 3D printed using two-photon direct laser writing, a very precise form of micro-SLA. The tiny acrylic valves within open and close to control the flow of fluid, while the miniature tubes serve as arteries and veins. To make the device beat, the researchers also integrated heart muscle cells called cardiomyocytes, which were differentiated from pluripotent stem cells.

The decision to make the miniPUMP so small was a deliberate one, as the 3D printed acrylic scaffolds had to be strong enough to support the structure but thin enough to bend and move with the contracting heart tissue.

“The structural elements are so fine that things that would ordinarily be stiff are flexible,” adds White. “By analogy, think about optical fiber: a glass window is very stiff, but you can wrap a glass optical fiber around your finger. Acrylic can be very stiff, but at the scale involved in the miniPUMP, the acrylic scaffold is able to be compressed by the beating cardiomyocytes.”

As far as next steps go, the miniPUMP research team aims to refine the technology and find ways of manufacturing it reliably. The work can also eventually be applied to implantable patches that may fix defects in the heart, as well as other organs such as livers.

The project is being conducted as part of CELL-MET, a joint National Science Foundation Engineering Research Center in Cellular Metamaterials led by Boston University. The center’s ultimate goal is to create devices capable of regenerating diseased human heart tissue.

The center’s ultimate goal is to create devices capable of regenerating diseased human heart tissue.

The 3D printing of human heart replicas and models is something we’ve seen before. Just last month, researchers from the Technical University of Munich (TUM) and the University of Western Australia developed 3D printed artificial heart valves made from a patient’s own cells that grow as the individual ages. The approach hopes to overcome the drawbacks of conventional prosthetic heart valves, which only last a limited number of years and therefore require multiple replacement surgeries.

Elsewhere, researchers from the Chinese Academy of Sciences (CAS) recently converted a six-axis robotic arm into a 3D bioprinter and used it to fabricate a complex-shaped blood vessel scaffold. The 3D printed vascularized heart tissue remained alive and beating for six months, and could demonstrate a feasible method of bioprinting functional tissues and organs in the future.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a side view image of the miniPUMP being taken in the lab. Photo via Jackie Ricciardi.

Tags Alice White Boston University CELL-MET miniPUMP

Kubi Sertoglu

Kubi Sertoglu holds a degree in Mechanical Engineering, combining an affinity for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

Scientists Create First Full-Size 3D Printed Human Heart Model

Embed share

Scientists Create First Full-Size 3D Printed Human Heart Model

by VOA

No media source currently available

0:00 0:06:14 0:00

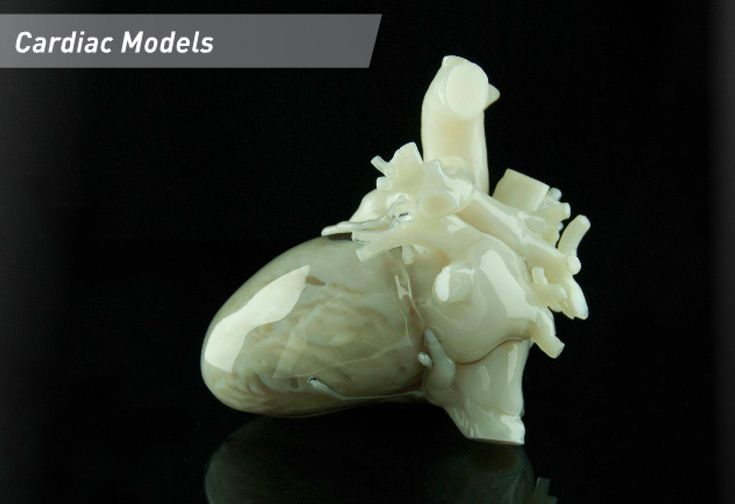

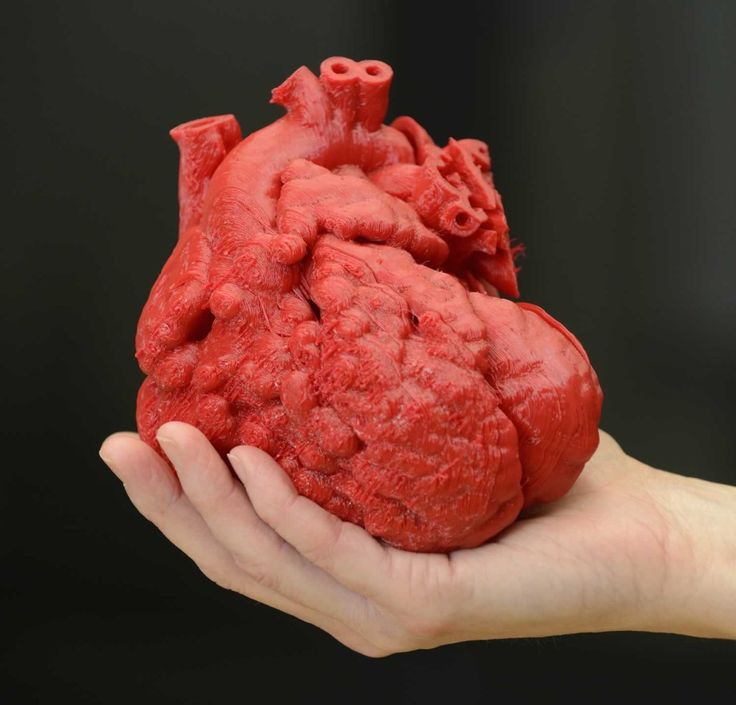

American researchers say they have created the first full-size human heart model using 3D printing technology.

The model was made with a specially developed 3D printer that uses biomaterials to produce a structure and tissues similar to a real human heart.

The researchers say the model heart can be a useful tool to train medical professionals in operations related to human heart function. It could also be used as a basis for new research on ways to use 3D printing technology to produce fully operating hearts to replace in people.

The research was led by an engineering team at America’s Carnegie Mellon University. Results were recently published in a paper in ACS Biomaterials Science and Engineering.

The team was led by biomedical engineering professor Adam Feinberg. The team had already developed a 3D printer that could “bioprint” collagen. Collagen is the main structural protein that is found in tissues throughout the human body.

The goal of the latest project was to use this same bioprinting technology to create a realistic, full-size model of a human heart.

Feinberg said in a statement his team was able to create such a model that doctors can carefully examine to prepare for heart operations. But the newly-created models also permit the doctors to “manipulate” the heart, to experience similar reactions to working with real tissue, he added.

Scientists have made 3D printed models of the human heart before. But those models were made of harder substances – such as plastic or rubber – that were not effective in copying the soft tissue material found in the human heart.

The new 3D printing process was also not easy, the Carnegie Mellon team said. This is because soft materials, such as collagen, start out as a liquid. When such substances are printed in air, they quickly collapse during the process.

So the researchers came up with their own method to 3D print soft materials. The method uses a gelatin substance to surround the structures during the printing so they do not collapse.

The team’s new model heart is made from a material called alginate, a soft, natural substance made from seaweed. The researchers say alginate has very similar properties to tissues that make up the human heart.

The researchers say alginate has very similar properties to tissues that make up the human heart.

For example, the researchers tested the 3D printed material with sutures, which doctors use to close up wounds during operations. The team said the alginate was able to stretch to support the sutures.

Once they had perfected the process, the researchers made additional changes to the 3D printer to produce larger objects. They were able to use MRI images from a patient to model and print a full-size human heart. MRI stands for magnetic resonance imaging, a system for producing electronic pictures of the organs inside the body.

Feinberg’s team has also experimented with pieces of tissue designed to copy the function of individual heart elements - such as valves that open and close and realistic blood vessels.

The researchers say they also successfully 3D printed a model of a heart artery that could be used to train doctors. The group says the same methods could be used to create other realistic organ models as well, such as livers or kidneys.

The group says the same methods could be used to create other realistic organ models as well, such as livers or kidneys.

Former Carnegie Mellon student Eman Mirdamadi was another lead researcher on the project. He admitted that “major hurdles” still prevent the bioprinting process from producing a full-sized, functional human heart. But the latest progress helps establish the “foundational groundwork” for such efforts, he said in a statement.

I’m Bryan Lynn.

Bryan Lynn wrote this story for VOA Learning English, based on reports from Carnegie Mellon and ACS Biomaterials Science and Engineering. was the editor.

We want to hear from you. Write to us in the Comments Section, and visit our Facebook page.

Quiz - Scientists Create First Full-Size 3D Printed Human Heart Model

Start the Quiz to find out

Start Quiz

______________________________________________________________

Words in This Story

3D printing – n. the process of printing a solid object from a digital model by printing many separate layers of the object

the process of printing a solid object from a digital model by printing many separate layers of the object

function – n. the way in which something works or operates

manipulate – v. to control something using the hands

gelatin – n. a clear substance made from animal bones that is used to make some foods and other substances

seaweed – n. a type of plant that grows in the sea

suture – n. a stitch used to sew up a cut or wound in a person's body

valve – n. a part of the heart that controls the amount of blood flow

artery – n. a thick tube that carries blood from the heart to other parts of the body

hurdle – n. a problem that has to be dealt with before further progress is made

groundwork – n. work that is done in preparation for work that will be done later

Living heart printed on a 3D printer - Kommersant FM - Kommersant

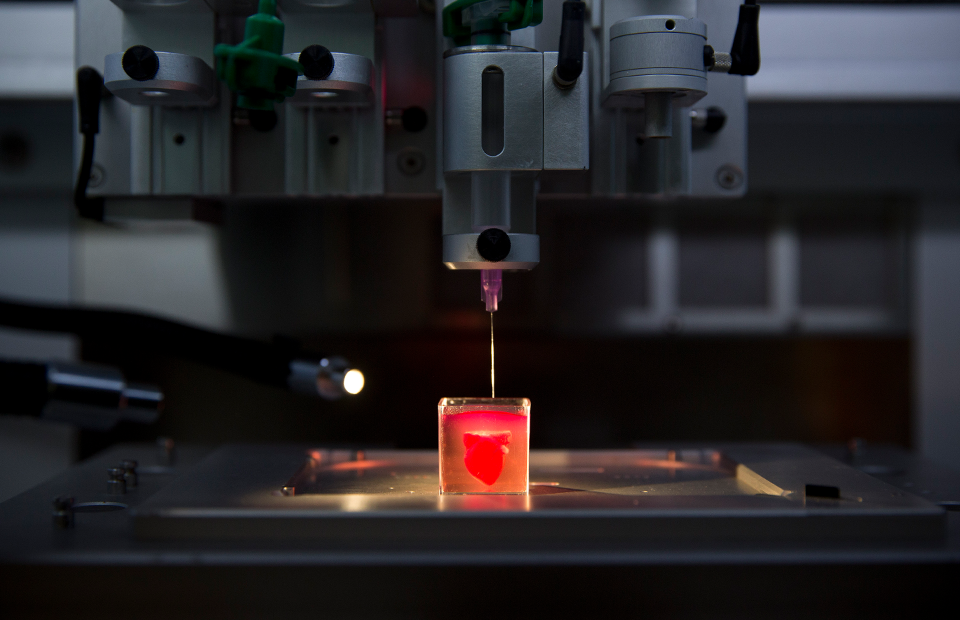

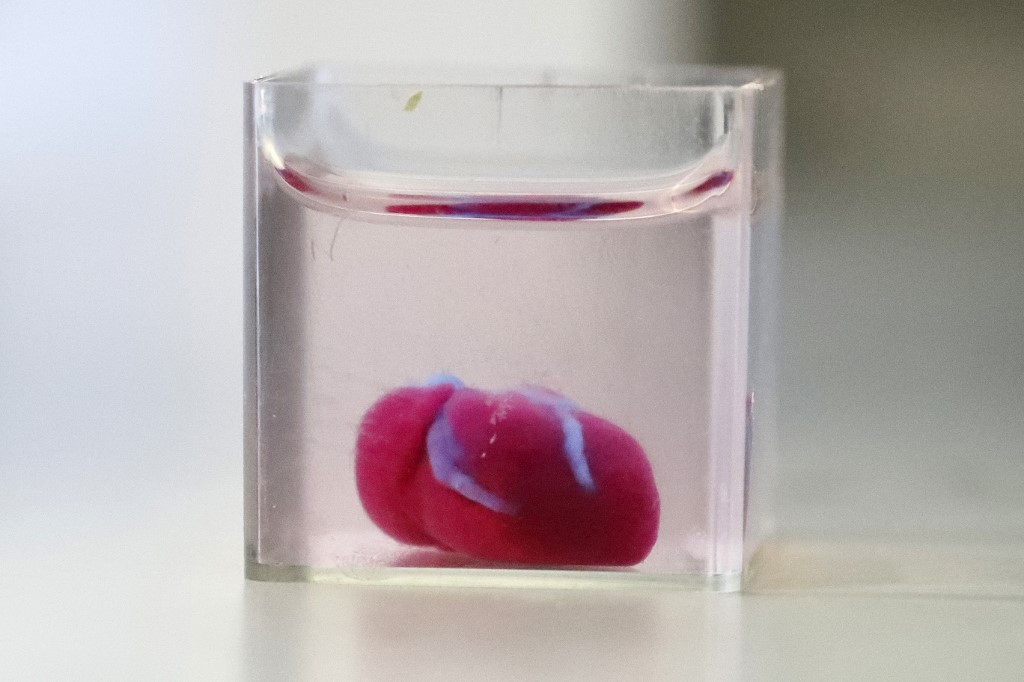

In Israel, for the first time in the world, a living heart was created on a 3D printer, which consists of tissues and blood vessels, and also has cameras. True, at the moment it can only suit a rabbit because of its small size. But scientists from the University of Tel Aviv are confident that in the future they will be able to print a heart for a person. How did you manage to create an organ on the printer? And can we talk about a revolution in medicine? Anna Nikitina and Gleb Silko will tell.

True, at the moment it can only suit a rabbit because of its small size. But scientists from the University of Tel Aviv are confident that in the future they will be able to print a heart for a person. How did you manage to create an organ on the printer? And can we talk about a revolution in medicine? Anna Nikitina and Gleb Silko will tell.

Photo: Yaroslav Chingaev, Kommersant / buy photo

The world's first 3D-printed heart resembles a berry: its size is about 2.5 cm, although it took more than three hours to print. However, even now the achievement of Israeli scientists is called a medical breakthrough. The heart is made from human fat cells and connective tissue. Previously, synthetic substances were used for this.

In the future, this new technology will not only solve the problem of the shortage of organs for transplantation, but will also facilitate the transplantation process as much as possible, says Israeli journalist Sasha Vilensky: “The most global problem is the rejection of a transplanted organ by the body. There is always such a danger. But the whole point of interest is that in the case of a 3D printer, we are dealing with what is grown and printed from the cells of the patient himself, thus simply removing the issue of rejection. This is genius".

There is always such a danger. But the whole point of interest is that in the case of a 3D printer, we are dealing with what is grown and printed from the cells of the patient himself, thus simply removing the issue of rejection. This is genius".

The problem of organ shortages around the world is really acute. In Russia, for example, in 2017, there were only 900 donors per 6 million people. And the most complex organ - the heart - was transplanted 250 times in a year, while it required almost 2 million people. The experience of Israeli scientists in printing hearts is impressive, and it can be used in other countries, says Yousef Hesuani, executive director of the 3D Bioprinting Solutions laboratory. True, according to him, it is still too early to talk about a revolution in medicine: “Scientists have used a very interesting material based on collagen - this is a protein in the body of mammals. In addition, it is from the point of view of creating a complex three-dimensional structure that the researchers are great, they did a really good job. However, the form does not yet determine the function, especially if we are talking about such a complex organ as the heart.

However, the form does not yet determine the function, especially if we are talking about such a complex organ as the heart.

New approaches have been used, but unfortunately it is too early to say that there has been an incredible breakthrough in this area.

When, for example, the native organ is removed and a new one is transplanted, and the function is fully restored, this will become an unconditional revolution.”

Tel Aviv University itself, where the heart was printed, says that in the future the necessary organs can be printed directly in hospitals. Now similar developments are being carried out all over the world. Russian companies, for example, are trying to create an artificial liver and kidneys. True, this process is too expensive, and it is unlikely that in the near future the technology will be introduced on a mass level, says the director of the National Medical Center for Transplantation and Artificial Organs. Shumakova Sergei Gauthier: “What the Israeli doctors did is just great. This proves that these possibilities can really be used to create some kind of anatomical structures. As for other organs, such as the kidney and liver, our institute is also working on this. We also have bioprinters, but frankly, growing such tissue complexes is a rather complicated and expensive technology, which is very different from the traditional method of organ transplantation.”

This proves that these possibilities can really be used to create some kind of anatomical structures. As for other organs, such as the kidney and liver, our institute is also working on this. We also have bioprinters, but frankly, growing such tissue complexes is a rather complicated and expensive technology, which is very different from the traditional method of organ transplantation.”

There are already examples in the world when doctors managed not only to create artificial organs on a 3D printer, but also successfully transplant them, for example, a few years ago in Russia a thyroid gland was printed, which took root in a patient. And last year, scientists from Jerusalem implanted a prosthesis for the skull on a patient, and it was also created using three-dimensional technologies.

During this year, Israeli scientists plan to test printed hearts on rabbits and rats, and then start working on creating a human heart.

Dipol Press Center

April 23, 2019

subscribe subscribe

Printing a heart on a 3D printer - a few years ago, only science fiction writers could afford to use such a phrase. However, scientists from Tel Aviv University (Israel) managed to make a real technological breakthrough: for the first time in the world, they created a human heart using a medical 3D printer.

However, scientists from Tel Aviv University (Israel) managed to make a real technological breakthrough: for the first time in the world, they created a human heart using a medical 3D printer.

The adipose tissues of one of the patients served as the basis for creating the main organ of the human body artificially. Scientists have reprogrammed cell structures so that they turn into artificial stem cells, from which various types of tissues are formed in the human body. And connective tissues - glycoproteins - were processed into "ink" for a medical 3D printer in the form of a personalized hydrogel.

This is the first time this technology has been used: previous experiments to create an artificial heart using a printer involved the use of synthetic materials. The same organ has all the immunological, cellular, biochemical and anatomical properties characteristic of the human body.

The size of the printed heart is no larger than that of a rabbit. But it has everything necessary for life - blood vessels, ventricles and chambers. The cells of the new heart even contract, but not yet synchronously with each other, so the artificial organ is not able to pump blood, this has yet to be achieved.

But it has everything necessary for life - blood vessels, ventricles and chambers. The cells of the new heart even contract, but not yet synchronously with each other, so the artificial organ is not able to pump blood, this has yet to be achieved.

According to Israeli scientists, an artificial human heart of normal size, which will begin to beat for real and perform all its functions, will be created using this technology not earlier than in 5-10 years. However, in the next year or two, they plan to start experiments on animals, transplanting them with hearts printed on a printer.

End-stage cardiovascular diseases provide only one way to save the patient - heart transplantation. However, there is an acute shortage of donors for such complex operations, and patients have to wait a long time for a transplant. Given these circumstances, 3D printing of the heart opens up new perspectives in the field of transplantation, which will save the lives of many patients.