Mjf 3d printing

Multi Jet Fusion (MJF) | 3D Printing

Back

-

Materials

Materials by Service

Injection MoldingCNC Machining3D PrintingSheet Metal

Materials by Type

PlasticsMetalsElastomers

Related Links

Customer Supplied ResinsColors

Injection Molding Material Alternatives Guide

Struggling with thermoplastic material shortages? We created a detailed guide to resin substitutes for ABS, PC, PP, and other commonly molded thermoplastics.

Download

-

Resources

Design Tips Guides and Trend Reports Case Studies Design Aids Webinars and Trade Shows

Blog Videos FAQs Educators and Students Glossary

Industries Medical Aerospace Automotive Consumer Electronics Industrial Equipment

-

About Us

Who We Are Why Protolabs? Research and Development Cool Idea Award Partnerships Sustainability and Social Impact

Careers Investors Locations Press Procurement

Contact Us

Proto Labs, Inc.

5540 Pioneer Creek Dr.

Maple Plain, MN 55359

United StatesP: 877.479.3680

F: 763.479.2679

E: [email protected]Best-in-Class Online Quoting

After uploading your part design, you'll receive an online quote that includes manufacturing analysis to help improve part manufacturability. Within your quote, you can also adjust quantity and material and see price changes in real-time.

Learn More

Get a QuoteSign In

Upload a Part

Certifications

ISO 9001:2015 | AS9100D

Jump to Section→ Capabilities

→ MJF Materials

→ Compare Material Properties

→ Surface Finishes

→ Our MJF 3D Printers

→ What is Multi Jet Fusion 3D Printing?

Multi Jet Fusion is an industrial 3D printing process that produces functional nylon prototypes and end-use production parts in as fast as 1 day. Final parts exhibit quality surface finishes, fine feature resolution, and more consistent mechanical properties when compared to processes like selective laser sintering.

Common applications for Multi Jet Fusion are:

- parts requiring consistent isotropic mechanical properties

- functional prototypes and end-use parts

- complex and organic geometries with fine features

If you have any issues getting your guide, click here to download.

Multi Jet Fusion Booklet

This 104-page comprehensive booklet on HP’s Multi Jet Fusion Service, provides must-have insight into best practices and in-depth design guidelines on how to best produce your part using this technology.

United States of AmericaAfghanistanÅland IslandsAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBolivia, Plurinational State ofBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCongo, the Democratic Republic of theCook IslandsCosta RicaCôte d'IvoireCroatiaCubaCuraçaoCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland Islands (Malvinas)Faroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly See (Vatican City State)HondurasHong KongHungaryIcelandIndiaIndonesiaIran, Islamic Republic ofIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People's Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People's Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMacedonia, the Former Yugoslav Republic ofMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesia, Federated States ofMoldova, Republic ofMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRéunionRomaniaRussian FederationRwandaSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint Martin (French part)Saint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint Maarten (Dutch part)SlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSuriNameSvalbard and Jan MayenSwazilandSwedenSwitzerlandSyrian Arab RepublicTaiwan, Province of ChinaTajikistanTanzania, United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUkraineUnited Arab EmiratesUnited KingdomUnited States Minor Outlying IslandsUruguayUzbekistanVanuatuVenezuela, Bolivarian Republic ofViet NamVirgin Islands, BritishVirgin Islands, U. S.Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

S.Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

I agree to receive email messages containing service updates and Design Tips from Protolabs and its affiliates

Design Guidelines for Multi Jet Fusion

Our basic guidelines for Multi Jet Fusion include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

| US | Metric | |

| Maximum Part Size | 11.1 in. x 14.9 in. x 14.9 in | 284mm x 380mm x 380mm |

| Layer Thickness | 0.00315 in. | 80 microns |

| Minimum Feature Size | 0.020 in. | 0.5mm |

| Wall Thickness | 0.020 in. | 0.5mm |

Tolerances: For well-designed parts, tolerances of +/- 0. 012 in. (0.30mm) plus 0.1% of nominal length for each additional inch can typically be achieved. Note that tolerances may change depending on part geometry.

012 in. (0.30mm) plus 0.1% of nominal length for each additional inch can typically be achieved. Note that tolerances may change depending on part geometry.

Warpage: Larger part sizes (>7 in.) and parts with thin features are the most susceptible to warp. We recommend maintaining a uniform thickness of 0.125 in. (3.175mm) to ensure stability.

MJF Material Options

PA 12 Black

PA 12 Black is a high tensile strength nylon. Final parts are dyed black, and they exhibit quality surface finishes and slightly more isotropic mechanical properties when compared to SLS. When more detail is required, PA 12 can achieve smaller minimum feature resolution (0.02 in) as compared to SLS materials (0.03 in). PA 12 Black is the best material option for designs that incorporate living hinges.

Primary Benefits

- Near isotropic mechanical properties

- Economical material choice

PA 12 40% Glass-Filled Black

PA 12 40% Glass-Filled Black is a 40% glass-filled nylon. Final parts are dyed black. The biggest advantage offered by this material is heat deflection at 347°F (measured at 66 psi), ranking 2nd best after PA 12 Mineral-Filled.

Final parts are dyed black. The biggest advantage offered by this material is heat deflection at 347°F (measured at 66 psi), ranking 2nd best after PA 12 Mineral-Filled.

Primary Benefits

- Economical material choice

- Heat deflection

Compare MJF Material Properties

- US

- Metric

| Material | Color | Tensile Strength | Tensile Modulus | Elongation |

|---|---|---|---|---|

| PA 12 Black | Black | 7.1 ksi | 276 ksi | 8.5% |

| PA 12 40% Glass-Filled Black | Black | 4.35 ksi | 508 ksi | 8.5% |

| Material | Color | Tensile Strength | Tensile Modulus | Elongation |

|---|---|---|---|---|

| PA 12 Black | Black | 49 Mpa | 1,900 Mpa | 8. 5% 5% |

| PA 12 40% Glass-Filled Black | Black | 30 Mpa | 3,500 Mpa | 8.5% |

These figures are approximate and dependent on a number of factors, including but not limited to, machine and process parameters. The information provided is therefore not binding and not deemed to be certified. When performance is critical, also consider independent lab testing of additive materials or final parts.

Multi Jet Fusion Surface Finish

| Standard | A bead blast removes all powder and leaves a consistent overall texture. Parts are then dyed a standard black color. |

| Custom | Secondary options include a primer that can be applied as well as taps and inserts. |

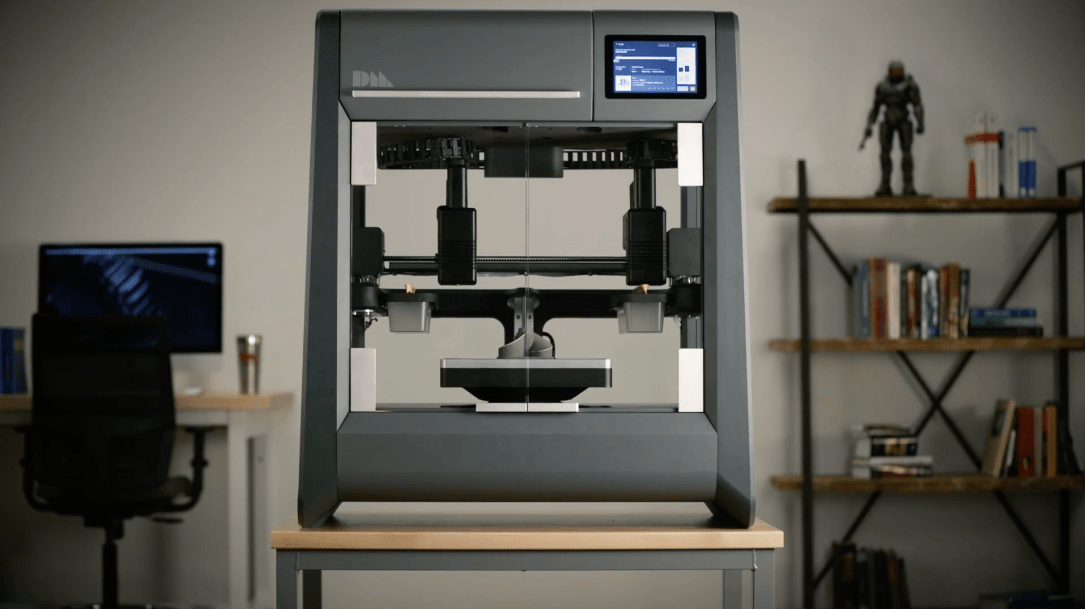

Our MJF 3D Printers

We use HP Jet Fusion 3D 4210 and 5210 machines that are capable of accelerated build speeds when compared to other powder-based additive manufacturing technology. The HP 3D printers produce commercial-grade parts with enhanced surface finishes and improved mechanical properties compared to other 3D printing technology.

The HP 3D printers produce commercial-grade parts with enhanced surface finishes and improved mechanical properties compared to other 3D printing technology.

Why Use Multi Jet Fusion?

See how 3D printing with Multi Jet Fusion is ideal for functional prototypes and end-use, production parts.

How Does Multi Jet Fusion Work?

Multi Jet Fusion uses an inkjet array to selectively apply fusing and detailing agents across a bed of nylon powder, which are then fused by heating elements into a solid layer. After each layer, powder is distributed on top of the bed and the process repeats until the part is complete.

When the build finishes, the entire powder bed with the encapsulated parts is moved to a processing station where a majority of the loose powder is removed by an integrated vacuum. Parts are then bead blasted to remove any of the remaining residual powder before ultimately reaching the finishing department where they are dyed black to improve cosmetic appearance.

Resources

How to Use Multi Jet Fusion for Functional 3D-Printed Parts

Create functional prototypes and end-use production parts with HP’s 3D printing technology.

Read Design Tip

MJF vs. SLS: A Comparison of Polyamide 3D Printing Technologies

A look at the key differences between Multi Jet Fusion and selective laser sintering and how to determine the optimal process for your application.

Read Blog

OVR Technology

The medtech startup used Multi Jet Fusion (MJF) for prototyping as well as low-volume production for its pioneering product the OX1—a lightweight, scent-emitting device that attaches to the bottom of a VR head-mounted display.

Read Success Story

3D Printing Materials: Select the Right Plastic or Metal for Your 3D-Printed Part

Explore material properties available for plastic and metal 3D printing processes

Read Guide

Get an instant quote on your 3D printing design.

UPLOAD A PART

What is MJF (HP's Multi Jet Fusion) 3D printing?

Multi Jet Fusion (MJF) is a 3D printing process for building prototyping and end-use parts fast. This article explains how MJF works and its main advantages.

Today designers and engineers have a lot of options when it comes to the many 3D printing technologies and materials available. In this article, we spotlight Multi Jet Fusion (MJF), HP’s proprietary 3D printing technology as a viable solution for many complex and industrial applications. We get into how it works, its benefits and whether it’s the right technology for your parts.

If you’re interested in learning more about the 3D printing technology available through Hubs, head to our 3D printing service page.

HP Multi Jet Fusion printersWhat is Multi Jet Fusion (MJF) 3D printing?

Multi Jet Fusion (MJF) is a 3D printing process that speedily produces accurate and finely detailed complex parts with powdered thermoplastics.

As it can consistently and quickly deliver parts with high tensile strength, fine feature resolution, and well-defined mechanical properties, MJF 3D printing services have rapidly become the go-to additive manufacturing (AM) solution for industrial applications. It’s commonly used to manufacture functional prototypes and end-use parts, parts that need consistent isotropic mechanical properties, and geometries that are organic and complex.

For a quick and detailed reference, watch our video all about MJF.

How was MJF developed?

First introduced to the market in 2016, MJF was developed by HP Additive, building on the company’s expertise in inkjet printing technology and precision mechanics. The development of MJF can be traced back to several decades earlier, though.

In the 1990s, additive manufacturing (AM) was beginning its transition away from only being used solely for research and development. Real-world, industrial applications in manufacturing were in sight. However, speed quickly became a key obstacle in this transition. Compared to injection molding or metal stamping, for instance, most 3D printers took a long time to produce parts.

Real-world, industrial applications in manufacturing were in sight. However, speed quickly became a key obstacle in this transition. Compared to injection molding or metal stamping, for instance, most 3D printers took a long time to produce parts.

One approach early adopters of 3D printing technology took to speed up production was to use “farms” or arrays of multiple machines. The idea was to print in higher quantities with the extra machining power. HP opted for a more integrated, automation-focused approach.

In their global AM hub in Barcelona, HP developed a system that built parts layer by layer in a large bed of powder material, with additional machinery attached for seamless post-processing. Similar to Selective Laser Sintering (SLS) and other powder bed fusion designs, this system evolved into current MJF technology.

Multi-jet fusion print bedHow does Multi Jet Fusion work?

Using an inkjet array, MJF works by depositing fusing and detailing agents in a bed of powder material, then fusing them into a solid layer. The printer distributes more powder on top of the bed, and the process repeats layer by layer.

Here is a step-by-step of how MJF builds parts:

-

The moveable build unit is placed into the printer

-

The material recoater carriage moves across the build area, depositing a thin layer of the powder material

-

The printing and fusing carriage moves across the build area, preheating the powder to a specific temperature to provide material consistency

-

An array of inkjet nozzles fuses agents onto the powder bed in areas that correspond to the part’s geometry and properties

-

After each layer is finished, the build unit retracts to create space for the next layer of material to be deposited

-

This process repeats until the build is completed

When the printing process finishes, the build unit contains the printed part and unfused powder. You use a separate processing station, attached to the moveable build unit, to cool and unpack the part, and recover excess powder for later use. Bead blasting helps to remove any of the remaining powder and allows you to move on to more cosmetic steps.

What materials does MJF use?

In general, you can split the materials used for MJF into rigid plastics and flexible plastics. Rigid plastics include Nylon PA11, Nylon PA12 and PP, while flexible plastics include Estane 3D TPU M95A. HP’s system focuses mainly on polyamide materials, developed by HP and its partners.

Here is a list of the MJF 3D printing materials available on the Hubs platform.

| Material | Description |

|---|---|

| HP PA 12 (Nylon 12) | Nylon 12 is a robust thermoplastic with all-around excellent physical properties and chemical resistance, ideal for functional prototypes and end-use applications. |

| Glass-filled HP PA 12 | Glass-filled nylon is reinforced with glass bead and creates parts with higher stiffness and thermal stability than standard nylon. |

How does MJF post-processing work?

Similar to other manufacturing processes, further processing is required before a part is ready for prototyping or end-use applications. However, post-processing with MJF is relatively light compared to other AM technologies.

When you finish a print job, you are left with a build unit filled with a three-dimensional bed of unfused powder, with the part buried inside.

These are the main steps in MJF post-processing:

-

Cooling: This takes place within the build unit, though HP offers module units for natural cooling, so the build unit can be used for a new print without having to wait for the powder and part to cool.

-

Recovering unfused powder: Once the build unit has cooled down, move it to the processing station and vacuum the unfused powder into a container for later use.

-

Bead blasting: Remove any remaining powder with bead blasting, air blasting or water blasting. You can do this manually or automatically, using a tumbler, ultrasonic cleaner or vibratory finishing machine.

After removing all residual powder material, you may have to go through more post-processing. This depends on the part. For instance, consider the post-processing required for casting processes. You may need to do more machining for features like mating surfaces, bores, tolerances exceeding the capabilities of MJF and internal threads. As well, meeting specific technical requirements may require you to sand the part by hand.

What are the advantages of MJF?

If you’re looking to create functional prototypes and relatively small production runs of end-use parts, then MJF should be your go-to solution. MJF is excellent for building much stronger parts than what SLS can produce. Parts built with MJF have tensile strengths of maximum XY and Z 48 MPa/6,960 psi with the ASTM D638 method.

As well, MJF is really good at producing mechanical properties in every direction of your part’s geometry. So if you’re making parts with complex, multifaceted designs that also come with smaller features that need to be sturdy, then MJF is the most viable option.

MJF produces functional parts for end-use without a lot of post-production required. Compared to other AM technologies, it’s faster and offers more robust automation, meaning far shorter lead times and high-quality surfaces with minimal human intervention.

To achieve its speediness, MJF consistently scans the surface of the part it’s printing every pass, even if you’re using it to print multiple parts at once. This provides quicker build speeds in comparison to other technologies, even with larger quantities of parts.

Why is MJF ideal for manufacturing end-use parts?

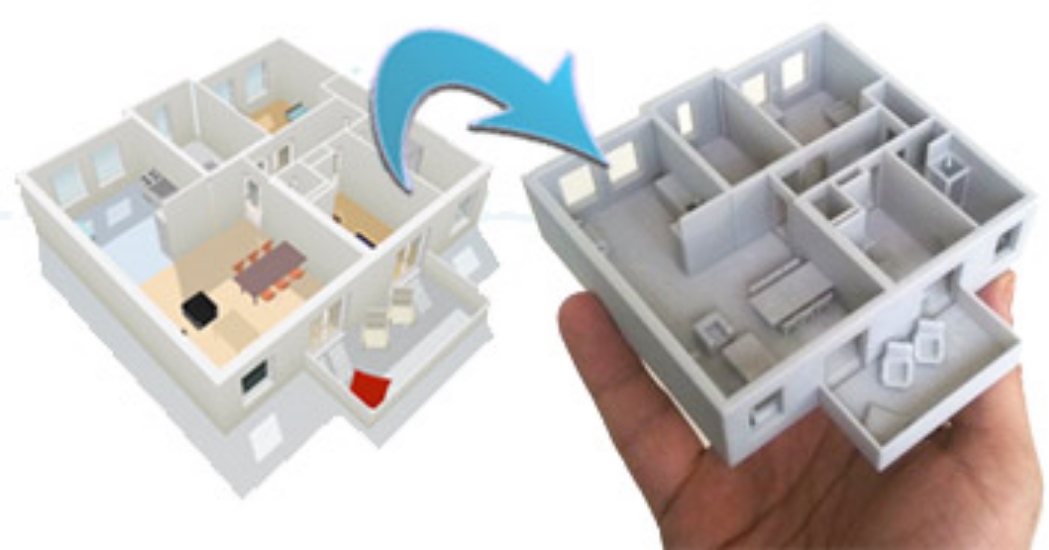

MJF distinguishes itself from other additive manufacturing processes as it’s designed to produce higher volumes of parts with great complexity, detail and structural integrity. MJF is a popular solution for manufacturing precise and durable electronic component housings, mechanical assemblies, enclosures, and jigs and fixtures.

In current MJF machines, the build unit is a rolling cart that’s attached to an included processing station. Once a part is complete, all you have to do is move the powder bed to the processing station to remove all the excess powder. Post-processing can be done in bulk, depending on the technical requirements of the part, and more often than not, there is minimal need for hand finishing. This makes it well suited for higher volume production runs of functional parts.

The powder bed system itself eliminates the need for supports, with parts being nested efficiently in the build area. After the part is complete, you can also use the unused powder again for future print production runs.

MJF vs SLS 3D printing: what’s the difference?

While selective laser sintering (SLS) is quite similar to MJF, the two technologies have a few key differences. SLS printers also deposit powder material in a build area layer by layer, however, the machine fuses materials by sintering powder particles together and to the underlying layer of the part with a laser.

You can modulate the laser’s power to alter the part’s material properties, though the parameters of this feature are limited. HP has a broad selection of chemical agents, providing more opportunities to alter the properties of each voxel of the part.

MJF vs. Injection Molding: which is better for your application?

MJF is not only a powerhouse compared to other AM technologies - it’s also a viable alternative to injection molding. With injection molding, you have to pay for the mold itself and undertake a lot of DFM analysis before producing the part. It’s also restrictive in terms of part geometry and the lead time is significantly longer, considering the time it takes to produce the mold and other processing steps.

By contrast, MJF allows for more expansive design freedom, with greatly reduced lead times. You can also make design changes rapidly with MJF, as you don’t have to rely on the mold. If you’re about to do a production run with injection molding, definitely consider MJF, especially if you are hoping to create high volumes of small to medium sides parts with complex geometries.

In general, MJF is preferable for creating prototypes and for small and medium production runs. You can print prototypes in a few days, and any MJF-printed part will have mechanical properties of the same caliber as injection molding.

3D printed part in dyed black + vapor smoothed surface finishingWhat are examples of Multi Jet Fusion in action?

One impressive use case for MJF comes from CNC Würfel, a manufacturing and process automation specialist for the automotive industry and medical technology, among other sectors. In 2017, CNC Würfel replaced milling machines and lathes with 3D printing for many of their components. This drastically cut production times and allowed for more time spent on testing prototypes.

This proved particularly effective in producing the company’s gripper adapter, a part used on conveyor belts that requires several complex parts and gripping systems. Traditional processes resulted in eight to ten weeks of lead time, and required extensive human knowledge and intervention that sometimes damaged the part.

To cut out many of the complexities of manufacturing the gripper adapter, CNC Würfel opted instead to 3D print it using MJF. This immediately proved beneficial, especially as it cut production times down from two months to easily under a week. Using MJF also saved the company a huge amount of money. The cost reduction for printing the part ended up being 95% compared to traditional manufacturing. As an additional benefit, the printed part was 84% lighter, yet still durable enough to take on its tasks.

Another strong use case for MJF is HP’s Z 3D Camera, developed to simplify real-time capture and visualization of documents and other objects. Prior to the invention of MJF, HP built the camera out of three separate injection molded parts, which led to weeks of prototyping and incurred costs for each part.

Switching to MJF to produce the camera sped up production, as new technology allowed HP to print a single assemblage as opposed to three parts. According to HP, this pivot also reduced the price per part from $2.42 to $0.36, and transformed the prototyping duration from weeks to days. As well, the design freedom that comes with MJF gave HP the opportunity to optimize the orientation of the camera, which raised the quality of the end product.

MJF: Handy tips and tricks

Here are some hands-on best practices for getting the most out of MJF technology.

-

Reinforce thin-walled or large, flat surfaces with ribs or gussets, and surround holes with raised bosses when possible.

-

Be aware that raised text and cosmetic features smaller than 0.5 mm might not survive secondary post-processing. Check the DFM analysis in your part quote for these details.

-

The walls of your part should be between 2.5 and 12.7 mm thick. Going above or below this may affect the tolerances of your part.

-

Make sure to clearly identify cosmetic surfaces so the manufacturer avoids features like stair-stepping on oblique angles of the part.

Ready to transform your CAD file into a custom part? Upload your designs for a free, instant quote.

Get an instant quoteMJF service

How MJF works

Multi Jet Fusion MJF, known as HP 3D printing, is an industrial 3D printing process that produces functional nylon prototypes and finished production parts in as little as 1 day. Multi Jet Fusion uses an ink jet to selectively apply fusers and detailing agents to a layer of nylon powder, which are then fused into a continuous layer by heating elements. After each layer, the powder is spread over the bed and the process is repeated until the part is complete. This highly efficient method allows the creation of complex geometrically shaped functional parts as thin as 80 microns in one go – with mechanical properties comparable to injection molded parts. nine0005

-Speed - more than 10 times faster than conventional systems;

- Ability to compete on IM cost in some cases;

- Excellent dimensional accuracy and detail;

- Reliable mechanical properties;

- Great for prototype and amplifier; Production;

MJF Design Guide and

Capabilities Fohan's core recommendations for stereolithography include important design considerations to help improve part manufacturability, improve appearance, and reduce overall production time. nine0004

| Maximum part size | 284 mm x 380 mm x 380 mm | 11.1" x 14.9" x 14.9" |

| Layer thickness | 80 micron | 0.00315" |

| Minimum object size | 0.5 mm | 0.020" |

| Wall thickness | 0.508 mm | 0.020" |

MJF approvals | For well designed parts, tolerance is +/- 0.012 in. (0.30 mm) plus +/- 0.002 in./in. (0.002 mm/mm) per additional inch is usually achieved. Note that tolerances may vary depending on part geometry. | |

Material options MJF

| nine0002 Post-cured Measurement | |||

| Material Model Number | PA11 | PA12 | PA12GB |

| Benefits |

|

|

|

These figures are approximate and depend on a number of factors, including but not limited to machine and process parameters. Therefore, the information provided is not binding and is not considered certified. If performance is critical, also consider independent laboratory testing of additive materials or finished parts. nine0163

If you want to know more about this material technology, click here

Fahan MJF Service Successful Cases

3D printing services | Guaranteed quality, on-time delivery

What is 3D Printing Services?

3D Printing Services refers to each manufacturing technology that creates additively 3D printed parts in layers from the CAD field. nine0005

It is beneficial to provide consumers with direct production design via printer or computer.

What's more, getting high-quality 3D printing parts at a low price seems quite possible thanks to six different 3D printing machines.

What are the benefits of 3D printing?

3D printing can benefit you in the following ways:

Demanding print materials

3D printing technology allows us to print complex parts, which means that whether you need a tiny or a large product, you you can get it easily. nine0005

Flexible products

Sometimes you may need 3D printed flexible parts. With 3D printing, you can easily produce any product with great flexibility.

Smooth parts

3D printing machines provide you with 3D printed parts that have an extremely smooth surface after going through every step of the part's production.

Fast manufacturing

3D printing machines allow you to quickly produce parts and prototypes within an hour through accelerated 3D prototype printing processes. nine0005

Lightweight products

In addition to metal parts and prototypes, you can also use 3D printers to make lightweight plastic prototypes, depending on your requirements.

Waste minimization

3D printing technology minimizes material wastage and allows leftover materials from one part to be used in future production.

Strong parts

Using 3D printing techniques, you can create strong 3D printed plastic, elastomeric and metal parts, which are used to produce durable products. nine0005

Making decent parts

3D printed parts or prototypes are worth it.

Because parts have all the features you need at a low price, make your products worthwhile.

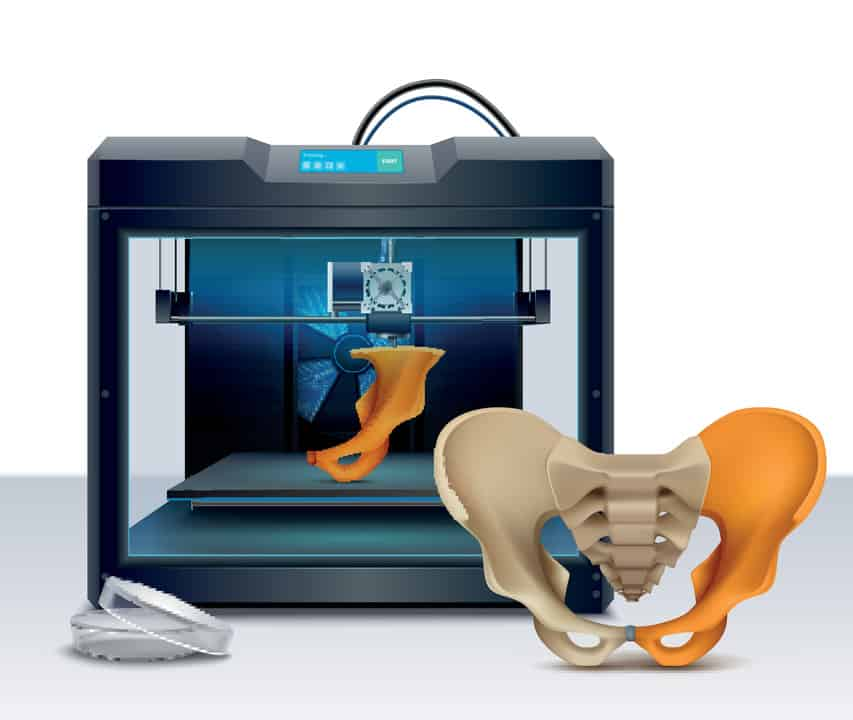

Modern Healthcare

3D printing machines are used to make numerous medical technologies and body parts such as the heart, kidneys, liver, fingers, feet, etc. so that the patient's body works properly. nine0005

precision

Parts produced by any 3D printing machine are incredibly accurate and can meet all your requirements and satisfy you completely.

What is the difference between 3D printing and additive manufacturing?

Additive manufacturing and 3D printing services differ from each other in the following ways:

3D printing specifically involves creating products by combining materials in layers.

Whereas additive manufacturing creates parts by adding material that may or may not be layers. nine0005

How many types of 3D printing technologies are there?

Among the many types of 3D printing technologies, the following seven are the most commonly used.

SLA 3D printing

SLA is also called stereolithography machine. It is a method of creating parts, models, templates and prototypes by connecting layers.

Typically a photochemical process in which light binds polymeric materials to form 3D printed products. nine0005

In addition, SLA-3D printing technology creates parts and prototypes for medical use, engineering use, and other development processes.

SLS 3D printing

Selective laser sintering or SLS is an additive manufacturing technology.

It uses a powerful laser to sinter tiny powder (polymer) particles into a solid structure that varies depending on the 3D printed model.

SLS is currently one of the most widely used 3D printing technologies around the world for many engineers and manufacturers. nine0005

The qualities included in SLS are the production of parts at low cost, high productivity, smooth surface, etc.

3D printing MJF

prototypes and details in almost 24 hours.

The manufactured parts or prototypes are of high quality, smooth surface, excellent resolution, high precision, precision, etc. layer. nine0005

Finally, the powder is scattered on top of the bed and the technique is repeated again until the piece is complete.

DLP-3D printing

DLP or Digital Light Processing is the same process as SLA and works with photopolymers.

The main difference between them is the light source they use to create parts and prototypes.

Also, Larry Hornbeck, an engineer at Texas Instruments, first invented the DLP printer at 1987 year.

However, projector-based DLP was developed by Digital Projection Ltd in 1997.

FDM 3D printing

Fused deposit modeling, FDM 3D printing, or Fused filament fabrication (FFF) are additive manufacturing technologies.

Layers of material are combined into a pattern to create a specific product or part.

The layers are fused by stacking on top of each other throughout the printing process and at the end form smooth finished parts. nine0005

In addition, it is an affordable and widely used 3D printer that produces various parts in different sizes.

PolyJet 3D printing

This is a powerful 3D printer that produces parts with a microscopic layer resolution of about 0.014 mm.

It produces fairly thin walls and extremely complex geometries using modern and high quality material.

In addition, it provides you with smooth, accurate, accurate and high quality prototypes, products and tools. nine0005

The PolyJet was first introduced by Rami Bonen, Gershon Miller and Hanan Gotait in 1998 with Objet Geometries Limited.

SLM 3D printing

Selective laser melting or SLM is a special 3D printing machine that uses a high power density laser source.

It uses a laser to fuse and melt metal powders and produces almost net-like products and almost full density prototypes. nine0005

Remember that SLM Services are specifically designed for the production of metal alloys.

Which industries often use 3D printing services?

Industry frequently uses 3D printing services in the following sectors:

Educational industries

print.

Everyone needs some kind of machines, such as printers and computers, as well as research tools, in order to properly run their institute. nine0005

Robotics

To prepare successful robots, 3D printing is used to make strong robot parts, their setup and grips, and costly sensor mounts.

Simply put, from their fingers to whole parts of robot components, to reduce the weight and overall performance of robots.

Aerospace

Serving 3D printed products with high precision and premium quality is one of the most important aspects of the aerospace industry. nine0005

Because there are hundreds of people traveling at the same time, there should be no chance for any errors.

As you already know, the aerospace industry has some of the highest product quality standards.

Automotive

3D printing services play an important role in the development of new vehicles because every vehicle needs parts and can be made with a 3D printing machine. nine0005

Therefore, these 3D printing services not only allow you to see moving cars, but also tools with which they can repair and prepare new car parts.

Manufacturing industry

Various options and designs offered by the manufacturing industry are based on 3D printing technology.

3D printing services have improved our lives in a new and modern way with state of the art production facilities that are produced in many styles every day. nine0005

Is 3D printing suitable for rapid prototyping?

Yes, 3D printing techniques are ideal for rapid prototyping because they allow prototypes and other products to be produced much faster than conventional processes.

3D printing provides you with the perfect service to create reliable, fast and high quality prototypes and products in a very short time.

In addition, rapid prototypes help designers present more concepts to clients. nine0005

3D printing compared to XNUMXD printing. CNC machining, which is better for small batch production?

3D printing and CNC machining are both better suited for certain types of small quality production.

CNC machines perform better than 3D printing machines in some areas in producing small quality products, while 3D printing performs better in other areas.

Engineers and manufacturers are likely to use both CNC and 3D printing technologies due to their smoother surface finish and other properties. nine0005

3D printing compared to XNUMXD printing. CNC machining, which is better for mass production?

Among 3D printing and CNC machining, the better for mass production depends on conditions and scenarios.

Because of their qualities such as smoothness, accuracy, precision and durability, manufacturers and engineers prefer them both for mass production.

However, both can sometimes outperform each other, allowing them to produce different prototypes or products. nine0005

3D printing compared to XNUMXD printing. CNC Machining, which is suitable for my project?

Both 3D printing and CNC machining can suit your project; both are competitive machines in a variety of materials such as plastic and metal.

If the project is plastic, 3D printing is the recommended option for your project; however, plastics can also be used in CNC.

If your project is metal related, it is recommended to use CNC machining to get a better and more durable project. nine0005

Plastic injection molding or 3D printing: how to choose the right technology?

To choose the right technology among plastic injection molding and 3D printing for prototyping, you need to know how they work.

Plastic injection molding uses a mold filled with molten material and solidifies to make 3D printed parts and products.

Speaking of 3D printing technology, it is an additive manufacturing method in which parts are made by stacking layers of material on top of each other. nine0005

Does DEK offer 3D printing services?

DEC has been offering 3D printing services such as SLA, SLS, DLP, MJF and PolyJet for over 21 years.

We have delivered over 72 million 3D printing parts to over 2300 customers worldwide with ninety-nine point nine percent (99.9%) satisfaction.

With their top-notch features including accuracy, accuracy, strength and flexibility, we are able to serve our customers with the best services. nine0005

Does DEK offer surface finishing after 3D printing?

Yes, DEC offers surface finishing services after 3D printing services on our powerful machines.

In addition, speaking of DEK engineers, we have first class and very experienced engineers and manufacturers.

In terms of hardware, DEK uses the latest 3D printing technology with all the modern features as we introduce you to the world of 3D printing.

Does DEK offer assembly services after 3D printing? nine0181

Yes, DEK offers assembly services after the preparation of ordered 3D printing services.