Stepper 3d printer

3D Printer Stepper Motors & Stepper Drivers

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

-

Anycubic Stepper Motor 5 Model types- Original spare part

- By Anycubic

-

BondTech NEMA17 Pancake Stepper 25mm- Removable cable

- High torque

- Original Bond Tech

-

BondTech Heatsink- Better heat dissipation

- Self-adhesive backing

-

BIGTREETECH Stepper Motor Driver 9 Model types- High-quality

- Different versions available

- Upgrade option

-

Creality Stepper Motor 8 Model types- Original spare part

- From Creality 3D

-

FLSUN Stepper Motor 3 Model types- Original spare part

-

BondTech NEMA17 Pancake Stepper 22mm- Fixed cable

- High torque

- Original Bond Tech

-

BondTech NEMA17 Geared Stepper- Planetary gear

- High torque

- Original Bond Tech

-

BIGTREETECH EZ Stepper Driver 2 Model types- 2-in-1 driver and heatsink

- Quiet movements

- Very durable

-

BIGTREETECH EZ Driver Connector- Adapter for increased compatibility

-

E3D Hemera XS Motor- Original spare part

- For E3D Hemera XS

- Including drive gear

-

BIQU Stepper Driver- Original spare part

-

E3D Hemera Motor- Original spare part

- For E3D Hemera

- Including drive gear

-

Zortrax Extruder Motor Set- Original spare parts

-

Artillery Stepper Driver- Original spare part

- From Artillery

-

Artillery Stepper Motor- Original spare part

- From Artillery

All prices incl. VAT.

What is the Best Stepper Motor/Driver for Your 3D Printer? – 3D Printerly

If you’ve wondering just which stepper motor/driver is best for your 3D printer, you’re in the right place. It’s a quite overlooked part of a 3D printer and it deserves a bit more of an informed decision rather than just sticking with what your printer came with.

Many people have reported prints improving after installing a better stepper motor on their 3D printer so which one is best for your 3D printer?

For such an essential part of a 3D printer, I’ve wondered which stepper motor is the best so I created this post to find that out so read along for the answers.

For the people that came for a quick answer, the best stepper motor for your 3D printer is going to be the StepperOnline NEMA 17 Motor. It’s highly rated on Amazon and is the #1 listing for Electric Motor Mounts. Low noise, long lifetime, high performance and no loose steps!

Many have described it as a plug-and-play motor but it does require a bit of know-how, but shouldn’t take too long at all to install. Once you install this stepper motor, any slip problems you’ve had previously should be dealt with easily.

Once you install this stepper motor, any slip problems you’ve had previously should be dealt with easily.

If you are looking for the best stepper motor driver, I’d go for the BIGTREETECH TMC2209 V1.2 Stepper Motor Driver from Amazon. It significantly reduces noise in 3D printers and produces much smoother movements overall.

Now let’s get into what makes a stepper motor so important.

What are the Key Functions of a Stepper Motor?

Under the hood of every 3D printer out there, you’ll find a stepper motor.

The proper definition of a stepper motor is a brushless DC electric motor that divides a full rotation into an equal number of steps. The position of the motor can be ordered to move and hold at certain steps and used at your desired torque and speed.

In simpler terms, stepper motor is what the motherboard uses to communicate to the motors of your 3D printer to make it move around the various axes. It gives the precision, speed and positioning of how things move so it’s a very vital component of a printer.

The reason stepper motors are used in 3D printers is because of their wide range of benefits such as low cost, high torque, simplicity, low maintenance while being highly reliable, and works in just about any environment.

Also on the technical side of things, they are very reliable because there are no contact brushes in the motor, meaning the life of the motor depends solely on the longevity of the bearing.

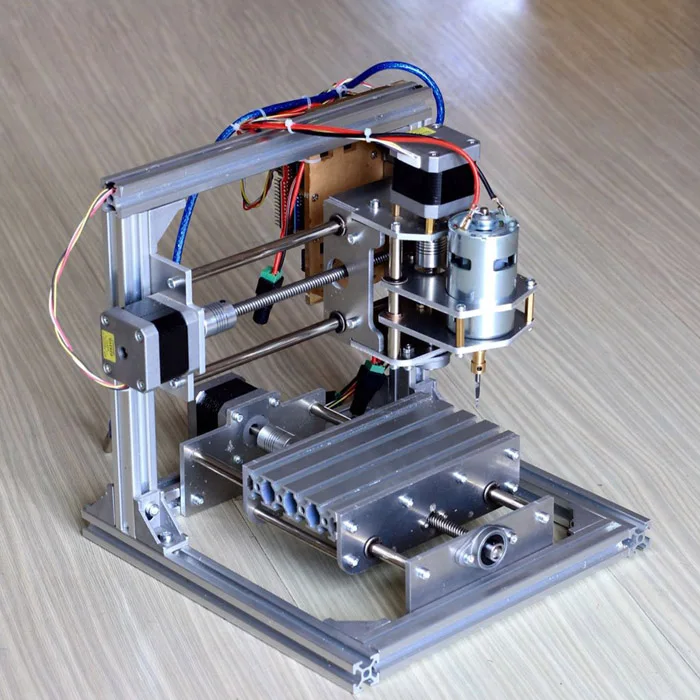

Stepper motors are also used in medical instruments, engraving machines, textile equipment, packaging machines, CNC machines, robotics and much more.

What Makes a Stepper Motor Better Than Others?

Now it’s important to know that there are many different sizes, styles and characteristics that a stepper motor can give you.

The factors that are important to us are the ones that work best for a 3D printer specifically. Since we need to consider how much work the motor is going to be doing, we take a few things into account.

The main factors that make a stepper motor better than another are:

- Torque rating

- Size of motor

- Step count

Torque Rating

Most stepper motors have a torque rating which roughly translates to how powerful the motor is. Usually, the bigger the size of the motor, the more torque rating you’ll have because they have a better ability to deliver power.

You do have smaller 3D printers such as the Prusa Mini which would require less torque than lets say, an Anycubic Predator Delta Kossel so do keep the size of your printer in mind.

Size of Motor

You have a wide range of sizes for stepper motors, but many can definitely be too strong for a simple 3D printer, which doesn’t require too much performance.

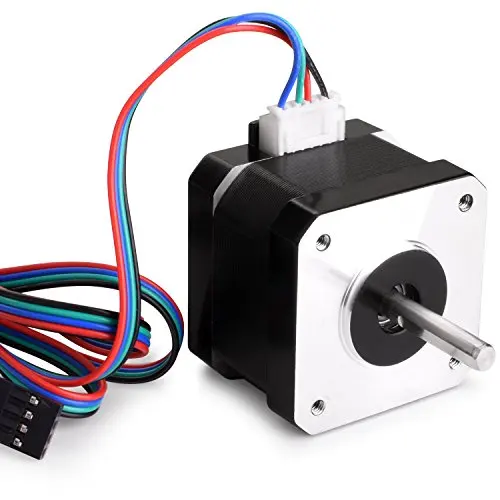

For 3D printers, we generally go for the NEMA 17 (face plate dimensions 1.7 by 1.7 inches) because they are large enough to get the job done.

You would usually use larger NEMA motors in products that require industrial applications or CNC machines. Do keep in mind that NEMA simply describes the size of the motor and not it’s other characteristics. Also, two NEMA 17 motors could be very different and are not necessarily interchangeable.

Do keep in mind that NEMA simply describes the size of the motor and not it’s other characteristics. Also, two NEMA 17 motors could be very different and are not necessarily interchangeable.

Step Count

The step count is what gives us the precision that we need in terms of movement or positioning resolution.

We call it the number of steps per revolution and it can range anywhere from 4 to 400 steps with the common steps counts being 24, 48 and 200. 200 steps per revolution translates to 1.8 degrees per step

For you to get a high resolution, you will have to sacrifice speed and torque. Basically, a high step count motor will have lower RPMs than another motor of a lower step count of comparable size.

If you need higher step rates to turn the motors efficiently, it will require more power so the torque comes in lower and vice versa. So if you want great precision of movement, you will need high step counts therefore reducing the amount of torque you have.

Best Stepper Motors You Can Buy Now

NEMA-17 Stepper Motor

StepperOnline NEMA 17 Motor as recommended at the start of this post is a great choice for a stepper motor. Thousands of happy customers have used this stepper motor with great success with its high quality and flexible customization.

Thousands of happy customers have used this stepper motor with great success with its high quality and flexible customization.

It comes neatly packaged and is a bipolar, 2A motor with a 4-lead and 1M cable/connector. The only downside here are the cables are non-detachable. Do note that the colors of the cables don’t necessarily mean they are a pair.

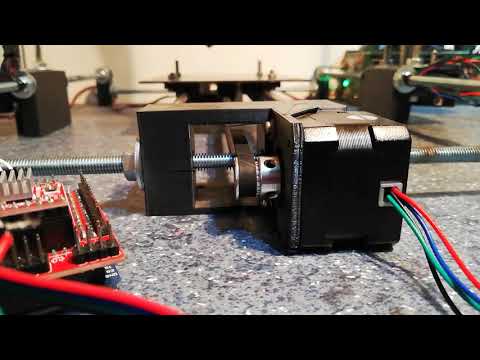

The way to determine wire pairs is to spin the shaft, then touch two wires together and spin it again. If the shaft was more difficult to spin, those two wires are a pair. Then the other two wires are a pair.

Once you do install this stepper motor, your performance should be second to none and smooth for years to come.

Usongshine NEMA 17 Motor is another choice that is well-liked between 3D printer users and is slightly smaller than the above choice. This high torque stepper motor is made of high quality steel and has great performance.

A few advantages of this stepper motor is its effective thermal conductivity and quality control for each stepper motor that’s sold. You get your stepper motor (38mm), 4pin cable and connector a strong/quiet device to assist you in your 3D printing journey.

You get your stepper motor (38mm), 4pin cable and connector a strong/quiet device to assist you in your 3D printing journey.

The wiring is better set out, with the black and red wires being A+ & B+ then the green and blue wires being A- & B-.

Customer service is also at the forefront of their product so you have good peace of mind after your purchase.

Even at print speeds of 120mm/s+ this stepper driver will deliver amazing performance every time.

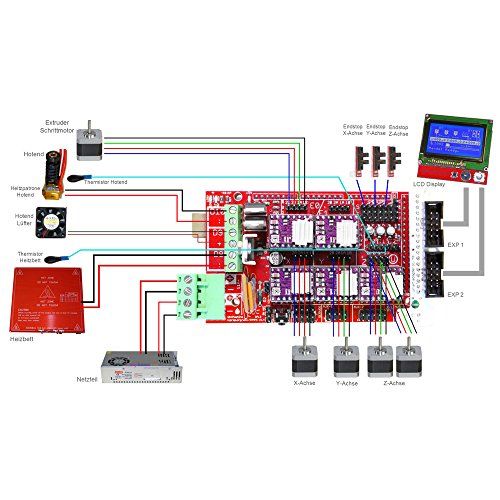

Best Stepper Motor Driver for 3D Printers (Upgrades)

Kingprint TMC2208 V3.0

There are many stepper motor drivers out there you can get for your 3D printer, but you’ll want to get one that works well for your particular machine.

The Kingprint TMC2208 V3.0 Stepper Damper with Heat Sink Driver (4 Pack) from Amazon is a great choice that many users have loved using. One user said he went from using standard drivers to these, and the difference in noise and control was astounding.

Previously, he had a very noisy 3D printer that also had jitters throughout the printing process, but now, the printing is silent and really smooth. They have a good large exposed heatsink area, so the installation is made a little easier.

They have a good large exposed heatsink area, so the installation is made a little easier.

The difference between these and classic 4988 steppers are huge. Another nice feature that has been added to this is the pin headers for UART access, so you don’t have to solder them on yourself.

One user mentioned how she didn’t realize 3D printing could be so silent, making a really dramatic difference in noise. If your 3D printer vibrates a lot, even to the point where your table vibrates like another user, you’ll want to get these installed as soon as possible.

After installing this, the loudest thing on people’s 3D printers are the fans.

BIGTREETECH TMC2209 V1.2 Stepper Motor Driver

BIGTREETECH is a very well-known 3D printer accessories company that produces really reliable and useful parts. If you are looking for some of the best stepper motor drivers, you’ll want to look into getting yourself the BIGTREETECH TMC2209 V1.2 Stepper Motor Driver from Amazon.

They have a 2.8A peak driver, made for SKR V1.4 Turbo, SKR V1.4, SKR Pro V1.2, SKR V1.3 Motherboard, and comes with 2 pieces.

- The motor makes it very hard to lose steps; ultra-quiet mode

- Has a large thermal pad area to reduce the temperature of the work

- Prevents motor shake

- Supports stall detection

- Supports STEP / DIR and UART mode

The TMC2209 is an upgrade over the TMC2208 in that it has an increased current of 0.6A-0.8A, but also increases the function of stall detection. It has some cool technology within the part such as SpreadCycle4 TM, StealthChop2TM, MicroPlyer TM, StallGuard3TM & CoolStep.

These do things such as give more control, reduce noise, and provide a smoother operation.

One user said they paired these stepper motor drivers with the SKR 1.4 Turbo, along with a new screen and now their 3D printer is smooth and silent. You won’t regret making this great upgrade if you are facing issues of noise and large vibrations.

stepper motor choice, which is better

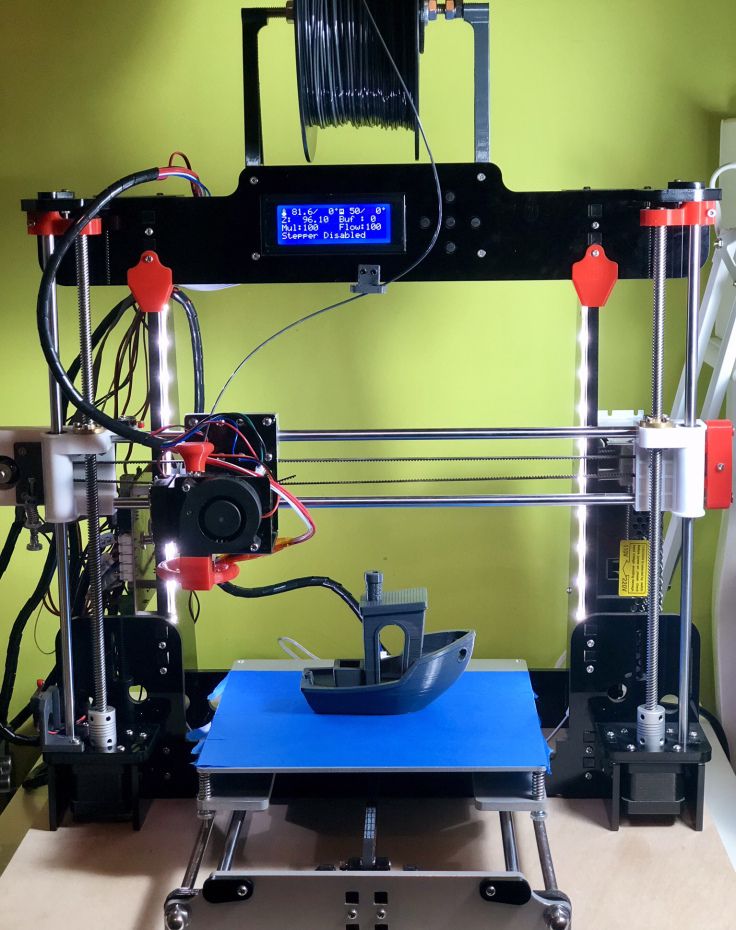

With the advent of 3D printers, people's lives have become much easier. Devices are successfully used in many areas - dentistry, industry, jewelry and medicine. Now a 3D printer is not a luxury item, but a design that is quite affordable. But still there are those who decide to independently manufacture printing presses. Next, let's talk about how to choose a stepper motor for a future 3D printer and what features should be taken into account.

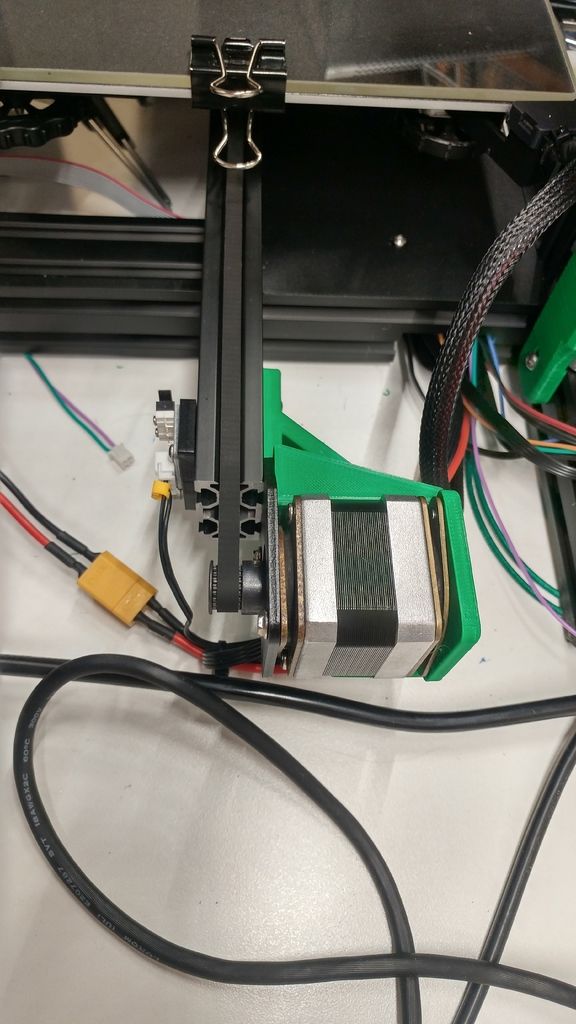

Motor on a 3D printer

In the design of a 3D printer, the main function for the movement of the extruder along the axes is performed by stepper motors. They have low weight and high torque.

A stepper motor is a motor without a commutator, whose rotation is not smooth, but discrete (in steps). By setting the speed and duration of the pulses, you can make the device rotate in a certain direction. In this case, it is possible to adjust the direction of rotation and the number of revolutions of the rotor.

If we talk about the design of such devices, then there are three main types:

- Motors with variable magnetic resistance - have several poles on the stator and a rotor made of soft material, and 3 windings independent of each other. This type is practically not used.

- Permanent Reluctance Motors - Includes stator and magnetized rotor. Such motors have 24 to 48 steps per revolution.

- Devices combining variable and constant magnetic resistance (hybrids) - combination of the best properties of an alternating and constant rotating motor. The number of steps is from 100 to 400.

The hybrid engine is the most common design, which, in turn, is divided into unipolar and bipolar types.

Which stepper motors to choose for a 3D printer: the best options

When buying a rotator for a 3D printer, you should pay attention to the following parameters:

- rotating structure size;

- holding torque - from 2.

5-4 kg/cm;

5-4 kg/cm; - rated current - optimal version for 1.7 A;

- Shaft - Diameter must match the design of the printer.

The most common motors that are installed on the design of the printing device are bipolar with four leads. Such structures in the event of a breakdown are easy to find and replace.

NEMA marked rotary motors are installed in 3D printers.

NEMA is a National Electrical Manufacturers Association that standardizes rotating devices in terms of flange size and fit. This standard allows different manufacturers to produce engines according to certain parameters, depending on the marking.

Most popular models in the NEMA series:

- NEMA 17 with 42*42mm flange;

- NEMA 23 with 57*57mm flange;

- NEMA 34 size 86*86mm.

Stepper motor drivers for 3D printer

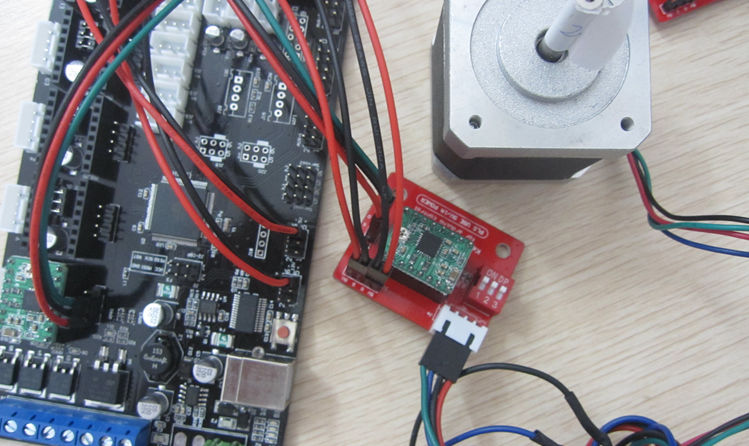

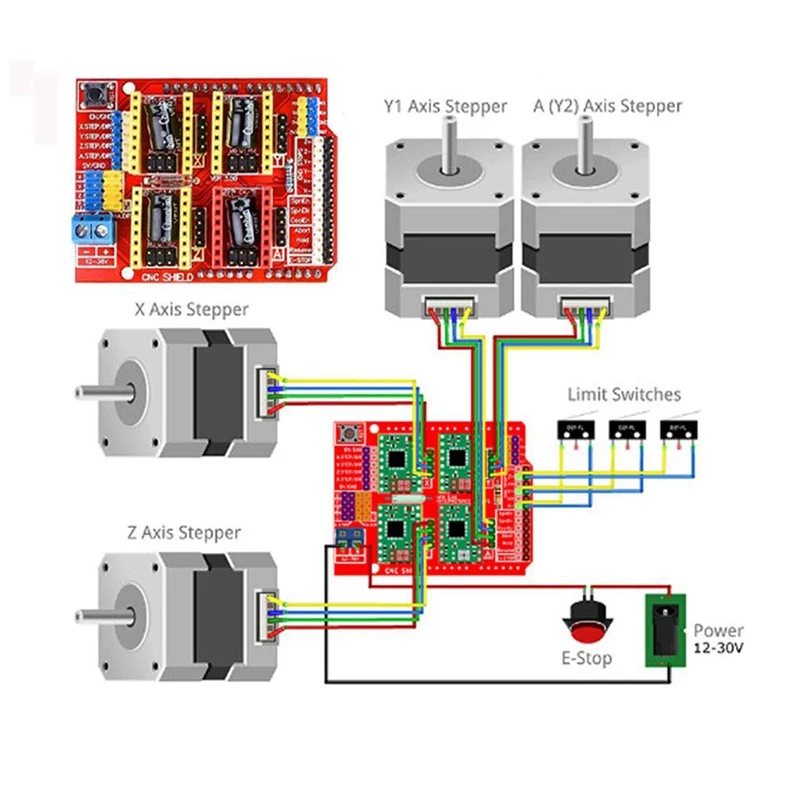

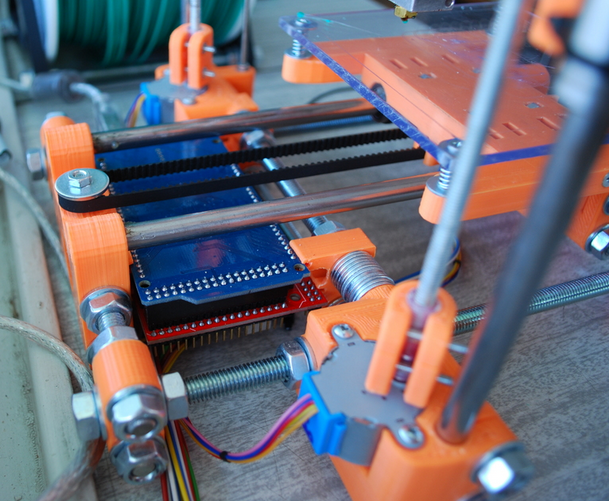

To control motors in 3D devices, drivers installed in the board slot were developed.

There are several types of drivers:

- Constant voltage - such drivers are inefficient and are used in a product with low speeds.

- Two-Level - These controllers support stepping and half stepping. They reduce engine heat and are efficient in operation.

- PWM drivers are the most popular on the market. They are highly intelligent and have many additional features.

Also, when choosing a driver, you should pay attention to the following parameters:

- current strength;

- supply voltage;

- availability of optoisolated inputs;

- availability of resonance suppression mechanisms;

- availability of protocols necessary for engine operation;

- surge protection;

- micro stepping;

- driver quality.

It is quite possible to assemble a high-quality 3D printer if you follow the recommendations and carefully study the design devices. It is quite possible that such a printing press will cost its owner less. But for beginners, we recommend ordering ready-made 3D devices in specialized stores. So you can learn the basics of 3D printing and get acquainted with the printer device. Good luck!

But for beginners, we recommend ordering ready-made 3D devices in specialized stores. So you can learn the basics of 3D printing and get acquainted with the printer device. Good luck!

- May 17, 2021

- 4313

Get a specialist consultation

Medical engines for 3D printers

Step engine NEMA17 1.8 ° 40 mm

Article: NEMA17-42J18408

Twist 4 kg*cg

Engine: Hybreedomic step: Hybreedomic step: Hybreedom °Rated current/phase: 0.8 A0003

Code: Nema17-JK42HS40-1704

Torque 4 kg*cm

Engine type: hybrid Angular step: 1.8°Rated current/phase: 1.7 AResistance/phase: 1.65 Ohm Inductance/phase: 3.2 mH

1 300 ₽

Stepper motor Nema17 1.8° 60 mm

Code: Nema17-60mm-6kg

Torque 6 kg*cm

*cm Case length: 60mm

Available

2 520 ₽

Step engine NEMA23 1.8 ° 56 mm

Article: NEMA23-56MM-12KG-6

Twist 12 kg*cg

Engine type: hybridomal voltage: 3. 3 Bulova Step: 1.8: 1.8: 1.8: 1.8 °Rated current/phase: 2.5 AResistance/phase: 1.6 Ohm , current 1.0 A, torque 8.6 kg*cm, shaft 8 mm

3 Bulova Step: 1.8: 1.8: 1.8: 1.8 °Rated current/phase: 2.5 AResistance/phase: 1.6 Ohm , current 1.0 A, torque 8.6 kg*cm, shaft 8 mm

Motor type: hybrid Rated voltage: 6.0 V Angular step: 1.8° Rated current/phase: 1.0 A Resistance/ phase: 6.0 Ohm

In stock 150mm-130kg

Torque 130kg*cm

Engine Type:HybridRated Voltage:7.2V Angular Step:1.8°Rated Current/Phase:4 AResistance/Phase:1.0 ohm

Available

stepper motor NEMA 17

Article: MM-Anti-Vibro-Nema17

Available

Holder for stepper motor NEMA 17

Code: RKP-MB42Al-Flat

Holder aluminum for stepper motor 42 series

In stock

Holder for stepper motor NEMA 17

Article: RKP-MB42A

Aluminum holder for stepper motor 42 series

In stock 42 series

In stock

Stepper motor Nema14 1.8° 34 mm

Code: Nema14-14HY3408

Torque 1.83 kg*cm

AS resistance/phase: 6.5 ohm

On request

Stepper motor Nema14 1. 8° 34 mm

8° 34 mm

Code: Nema14-14HY0007-20

Torque 0.91 kg*cm Assotiation/phase: 1.86 ohm

On order

1 330 ₽

NEMA16 1.8 ° 38 mm

Article: NEMA16-FL39ST38-0504A

Twist the moment 2.9 KG

Engine type: Hybridine oil-oil: 12 Angular pitch:1.8°Rated current/phase:0.5AResistance/phase:24 ohm

On request

Stepper motor Nema17 1.8° 34 mm

Code: Nema17-17HS1011-20B

Torque 3.2 kg*cm

3.2 Obvying moment: 3.2 kg*cm

Under order

1 400 ₽

NEMA17 1.8 ° 40 mm 40 mm

Article: NEMA17-17HS4401S

Twist 4.2 kg*cg

Engine type: hybridominomal voltage: 3.6 hybridominominomas: 3.6 Angular pitch:1.8°Rated current/phase:1.5AResistance/phase:2.4 ohm

under order

1 600 ₽

Step engine NEMA17 0.9 ° 48 mm

Article: NEMA17-17HD48002H-22B

Twist 4.4 kg*cg

engine type: 0.9 ° nominal current/phase: Phaz 1.68 ASOPENTION/Phase: 1.65 Omin productivity/phase: 4. 1 mg

1 mg

On order

1 500 ₽

Medical engine with two shafts NEMA17 1.8 °

Article: NEMA17-40MM-DS

with 2 shafts, CC 1.5 A, torque 4.5 kg*cm, shaft 5 mm

Motor type: hybrid Rated voltage: 3.3 Angular step: 1.8° Rated current/phase: 1.5 A Resistance/phase: 2.2 Ohm

On request : Nema17-60mm-DS

With 2 shafts, current 1.5 A, torque 6 kg*cm, shaft 5 mm 1.8 ohm

On request

2 380 ₽

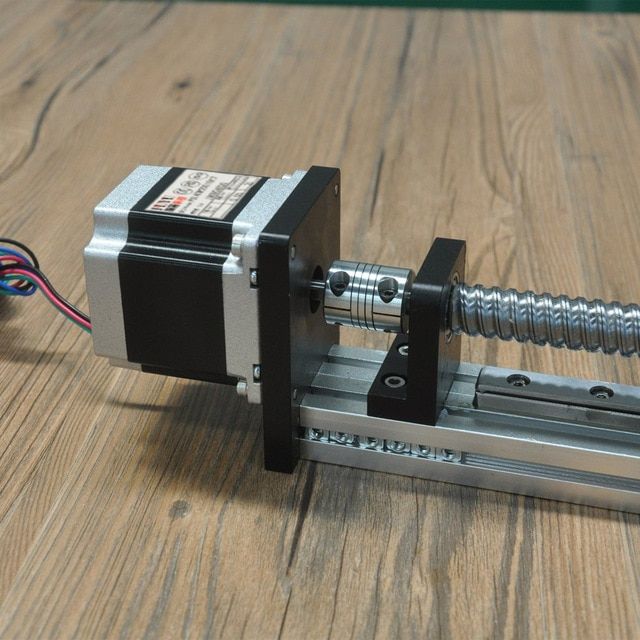

Stepper motor Nema17 1.8° with screw T8 295 mm and nut

Code: Nema17-42HS40-1004YAL

Linear motion system assembly.

Motor type: hybrid Rated voltage: 3.9 V Angular step: 1.8° Rated current/phase: 1.0 A Resistance/ phase: 3.9 Ohm

Custom order : Nema23-76mm-DS-8

With 2 shafts, current 2.5 A, torque 17.5 kg*cm, shaft 8 mm

Motor type: hybrid Angular step: 1.8° Rated current/phase: 2.5 A Holding torque: 17.5 kg*cm Case length: 76 mm

On request 40x40x11.3-B

Radiator 40 x 40 x 11.