State of the art 3d printers

Stratasys Introduces State-of-the-art 3D Printer for High-end Fashion and Design :: Stratasys Ltd. (SSYS)

J850 TechStyle 3D printer enables haute couture and luxury brands to 3D print on fabric — achieving new levels of creativity in fashion and design

EDEN PRAIRIE, Minn. & REHOVOT, Israel--(BUSINESS WIRE)-- Stratasys Ltd. (NASDAQ: SSYS), a leader in polymer 3D printing solutions, today announced the industry’s first 3D printer designed specifically for printing direct-to-textile. The Stratasys J850™ TechStyle™ 3D printer, the company’s newest PolyJet™ printer, is being launched to meet the unique needs of design and fashion manufacturers, which include 3D printing for high-end, premium textiles and clothing, bags and accessories and footwear.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20220502005108/en/

SSYS 2Y22 Design by Jasna Rokegem and Travis Fitch (Photo: Business Wire)

Stratasys is providing designers and fashion brands with the ability to differentiate their manufacturing practices through the unique versatility and productivity of the Stratasys 3DFashion solution which includes the J850 TechStyle 3D printer, workflow software and materials that support the individual needs of fashion manufacturers. This solution opens unlimited possibilities for fashion manufacturers to personalize and customize 3D-printed fabric pieces – including limited editions and digital automation, all while reducing time-to-market.

Lidewij Edelkoort, world-renowned fashion specialist and trend forecaster, said there has long been interest in a 3D printer for fabric and garments, with countless potential creative applications for fashion designers. She expects an enthusiastic industry response as a result, saying; “From decorative craft to creative engineering comes this hybrid machine from Stratasys, as an answer to a million prayers, allowing the ascension of embellishment for an inclusive following.”

To further extend the reach of the J850 TechStyle 3D printer, Stratasys has joined forces with a series of partners, including Dyloan and the D-house in Milan. A top innovation center of excellence for evolving fashion technology, D-house demonstrates the versatility of 3D printing applications from concept design through production using Stratasys 3DFashion technology.

“As far back as 2019, I predicted that in just a couple years we would see 3D printing incorporated into high-end fashion houses,” said Stratasys Art, Design and Fashion Director Naomi Kaempfer. “That time is here. We learned and modified those early designs, and created a new, dedicated printer using 3DFashion technology that is allowing fashion designers to create without limits. This is just the beginning of the journey as we continue to evolve this technology and pioneer new fashion design innovations.”

The J850 TechStyle 3D printer is designed to print directly on a variety of fabrics and garments, including denim, cotton, polyester, linen and leather at volumes ranging from single pieces to the tens of thousands.

“I gravitate toward new technologies that afford me an opportunity to create something original. With Stratasys 3D fashion printing technology, the possibilities are endless. Honestly, it provides a chance to experiment, and I feel like I have only scratched the surface of what is possible,” said Karim Rashid, fashion designer and SSYS 2Y22 REFLECTION collection contributor.

A variety of materials are available for the J850 TechStyle 3D printer including Agilus30™ CMY color materials for full-color, flexible printing and the Vero™ ContactFlex, a transparent coating that can be used to create a soft touch, silky feel. Stratasys VeroVivid™ resin material allows fashion houses and designers to print on textiles in over 600,000 unique colors, with multiple shore values, simulating different textures and finishes.

The upcoming SSYS 2Y22 collection reflects the last two years of the COVID-19 pandemic and the innovation and influences of this time on fashion and design. The collection will include new works by seven top design teams, such as high-end dresses and suits, daywear, lighting, luxury packaging, handbags, accessories and shoes. The J850 TechStyle 3D printer and the SSYS 2Y22 collection will be on display at Milan Design Week from June 6 -12, 2022.

The J850 TechStyle 3D printer is available now and more information is available online.

Stratasys is leading the global shift to additive manufacturing with innovative 3D printing solutions for industries such as aerospace, automotive, consumer products and healthcare. Through smart and connected 3D printers, polymer materials, a software ecosystem, and parts on demand, Stratasys solutions deliver competitive advantages at every stage in the product value chain. The world’s leading organizations turn to Stratasys to transform product design, bring agility to manufacturing and supply chains, and improve patient care.

To learn more about Stratasys, visit www.stratasys.com, the Stratasys blog, Twitter, LinkedIn, or Facebook. Stratasys reserves the right to utilize any of the foregoing social media platforms, including the company’s websites, to share material, non-public information pursuant to the SEC’s Regulation FD. To the extent necessary and mandated by applicable law, Stratasys will also include such information in its public disclosure filings.

Stratasys, J850, TechStyle, PolyJet, 3DFashion, Agilus30, mindful manufacturing, Vero and VeroVivid are trademarks or registered trademarks of Stratasys Ltd. and/or its affiliates. All other trademarks are the property of their respective owners, and Stratasys assumes no responsibility with regard to the selection, performance, or use of these non-Stratasys products.

Attention Editors, if you publish reader-contact information, please use:

- USA +800-801-6491

- Europe/Middle East/Africa +49-7229-7772-0

- Asia Pacific +852 3944-8888

View source version on businesswire.com: https://www.businesswire.com/news/home/20220502005108/en/

Stratasys Corporate & North America

Heather Morris

[email protected]

+1 612-875-2751

Investor Relations

Yonah Lloyd

[email protected]

+972-74-745-4919

Europe, Middle East, & Africa

Jonathan Wake / Miguel Afonso, Incus Media

stratasys@incus-media. com

com

+44 1737 215200

Brazil, Central America and South America

Erica Massini

[email protected]

+55 (11) 2626-9229

Israel

Rosa Coblens

[email protected]

+852-9189-7273

Source: Stratasys Ltd.

Released May 2, 2022

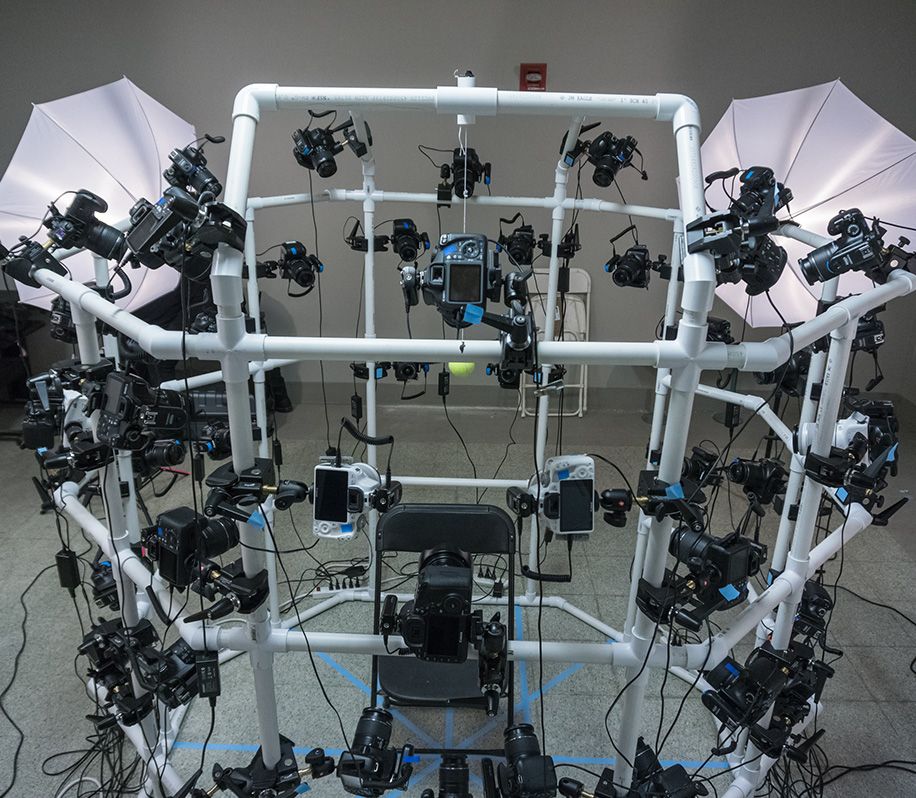

State-of-the-art 3D Technologies — urdesignmag

Have you ever wondered how widespread 3D technology is? Three-dimensionality is used in many areas. Both in software and the production of objects, the so-called 3D printing, as well as in games, movies, and even sound. We assign the term 3D to its fields of application and provide an overview of how widespread 3D technology is today.

As a term for diverse application possibilities, 3D is finding its way into more and more areas of professional and private everyday life. In addition to 3D printing technology in industrial manufacturing and private do-it-yourself workshops and makerspaces, 3D software and digital 3D applications are becoming more and more popular with increasing hardware options.

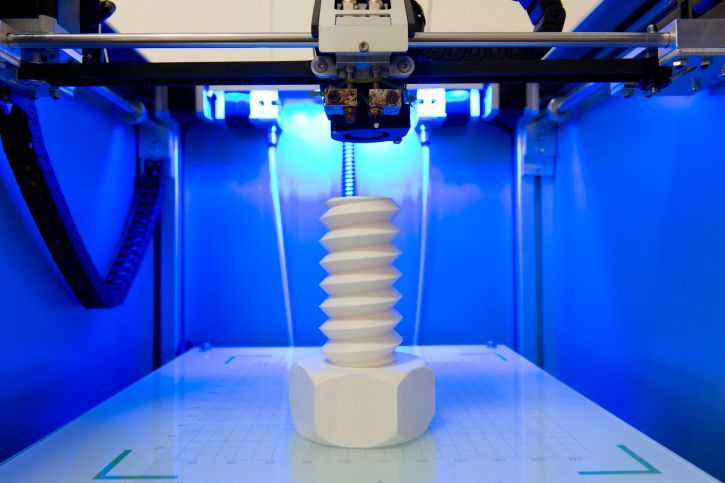

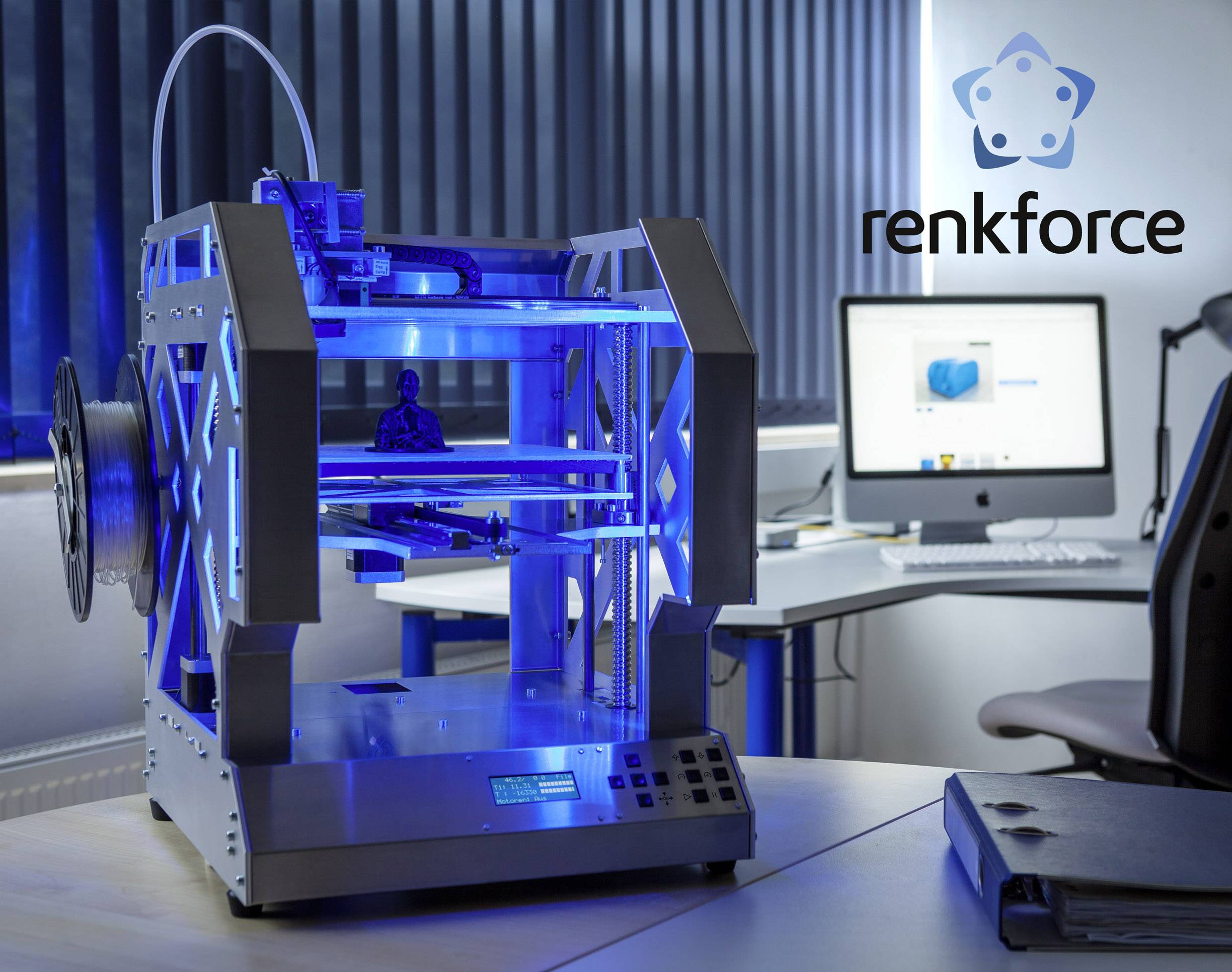

3D printers

The term “3D printing” can refer to a variety of processes in which the material is deposited, joined, or solidified under computer control to create a three-dimensional object.

In the 1980s, 3D printing techniques were considered suitable only for the production of functional or aesthetic prototypes, and a more appropriate term for this at that time was rapid prototyping. One of the key advantages of 3D printing is the ability to produce very complex shapes or geometries that would otherwise be impossible to build by hand.

From the library celebration to the school project to the open day in the company – even entire trade fairs are now attracting makers, do-it-yourselfers, and increasingly interested parties from all over the world. And the 3D printers are always the focus of attention. These machines, which are getting smaller, faster and above all cheaper, are conquering more and more living rooms, offices and workshops

3D Technology In Games

More and more online casinos are using 3D games. The widespread use of 3D glasses, but also ever better 3D technologies, make 3D games a unique gaming experience.

The widespread use of 3D glasses, but also ever better 3D technologies, make 3D games a unique gaming experience.

We are not only enjoying the third dimension in cinema but now in games of all kinds. Although retro games are popular, there are also those who are conscious of new technologies. 3D slots games offer exactly that modern gaming feel. The third dimension is also revolutionizing the roulette game that has been known since the 17th century.

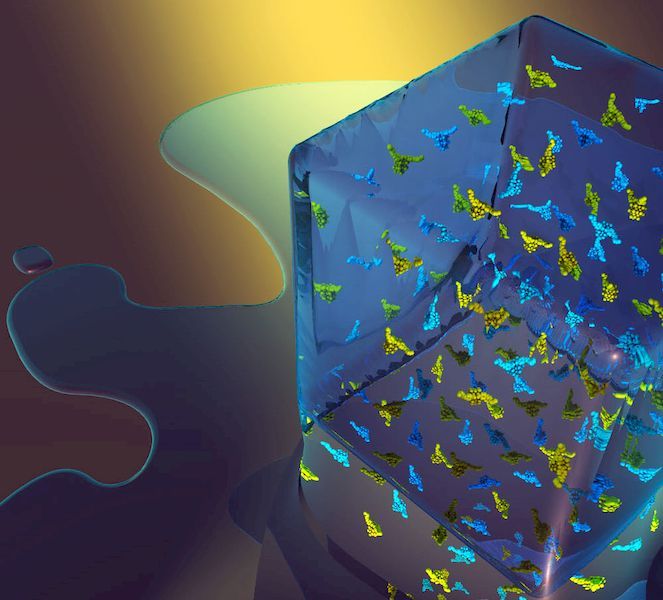

3D Technology for VR

However 3D technology isn’t just for video games. It is also used in the field of virtual reality, especially for the education system. While recreational activities, such as using the VR glasses or experimenting with your own 3D printer, are among the modern recreational activities 3D for eyes and ears is no longer a technological novelty and is known to everyone. In addition, when it comes to the educational systems 3D technology is used in printing a variety of classworks and ongoing works, such as cataloguing and archiving artifacts and relics.

This technology is so accessible and affordable that it is easier to use it for educational purposes. Because of the 3D technology, museums, libraries, labs, and others offer a more expansive world, without the idea of leaving the building. This accessibility is all because of the re-emergence of virtual reality.

3D Technology In Robotics

Maker Nathan Seidle has succeeded in creating a robot that could crack the number combination from a safe in less than 30 minutes. A person would need 119 days to try out all combinations. More so, the self-made robot costs just over 150 euros to produce.

Besides, there are two main drivers that push the 3D development in Robotics. One of them is the need to additively create large objects, and the other is the opportunity to achieve more automated and integrated production with 3D printing. The combination of 3D technology with printing is one of the solutions for moving towards greater digitalisation and smart manufacturing in the world of manufacturing technologies.

Comments

comments

3d printingRoboticsVirtual RealityVR

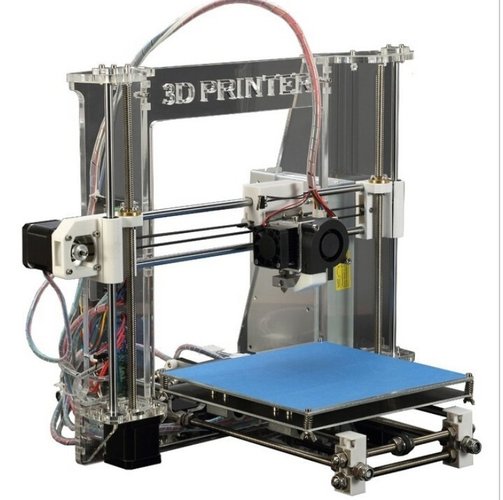

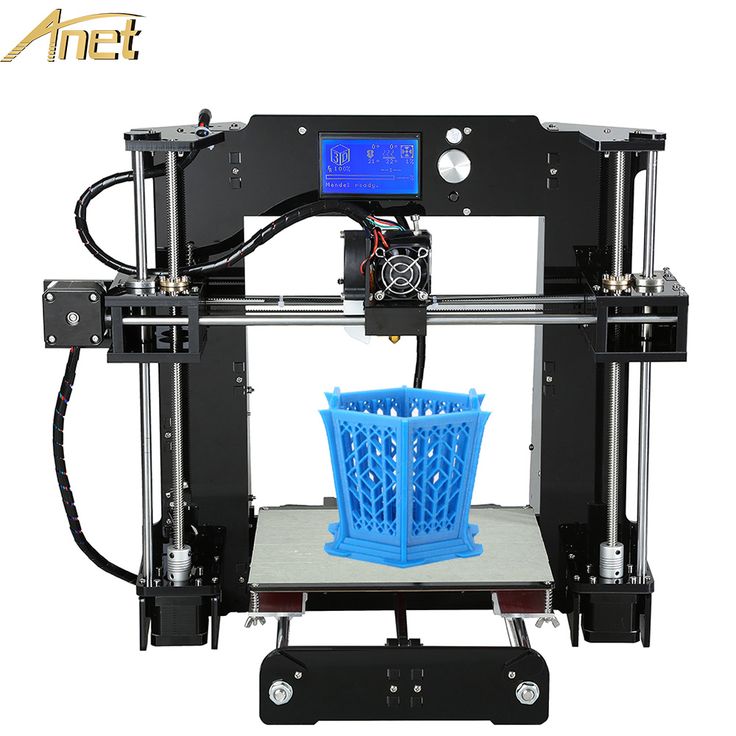

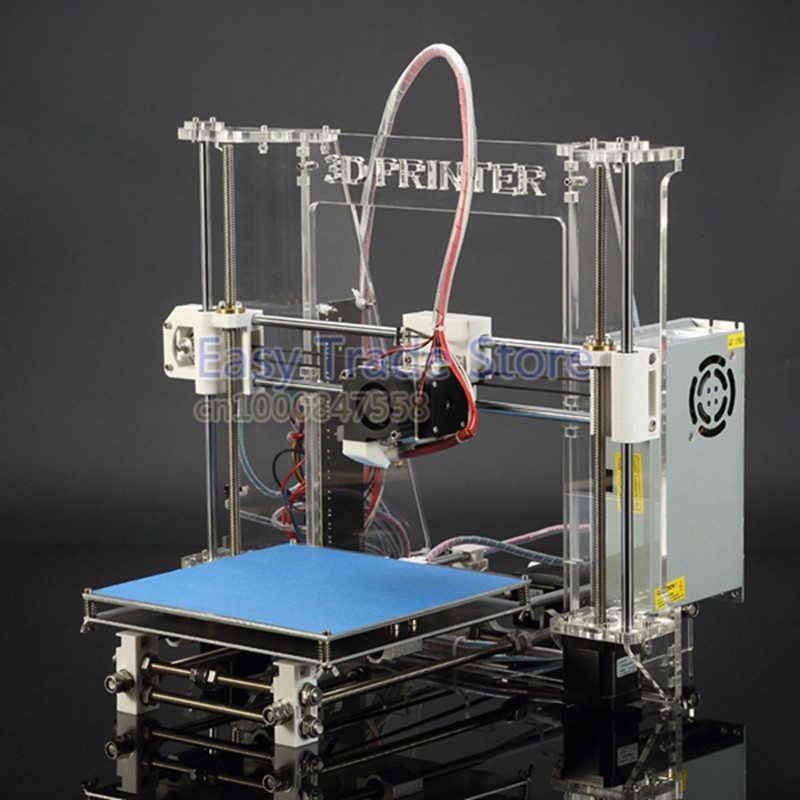

Which 3D printer to choose for home and hobby use

A few years ago, 3D printers were bulky industrial machines, but now 3D printing is becoming more accessible for home use. When buying their first printer, many are disappointed. This may be due to the unsatisfactory quality of the resulting models or the complex setup and maintenance of the 3D printer.

In the reviews that are found on the Internet, printers are often shown after a lot of upgrades or a long selection of settings for printing. This is not at all the result that a beginner who first got acquainted with 3D printing will get.

In order not to be disappointed, before buying, you need to understand which model is suitable for your tasks. First of all, it is worth deciding what the printer will be used for. What is the main property that finished products should have? What is more important, the physical properties of the model or the ideal surface and detail? Not only the model depends on this, but also the technology by which the 3D printer will work.

Which technology to choose? FDM or LCD?

If you need to make a small detailed figurine with a perfectly smooth surface, you should pay attention to models that work on LCD technology (LCD works on a principle similar to DLP - Digital Light Processing or “digital light processing”).

LCD prints using a photopolymer resin that cures under UV light. This makes it possible to produce without deformation, even small and thin products that cannot be manufactured using FDM technology.

Resin model

Now on sale there are many photopolymer resins with different properties. A few years ago the choice was not great. Basically, finished products were not strong enough for use in functional models. Now engineering resins have begun to appear on sale. Products from them are not inferior in strength to models made using FDM technology from ABS or even nylon.

If it is necessary to manufacture large products with different properties, or the tasks will be very diverse, then the choice is with FDM technology. But it is important to understand that finished products will not have a perfectly smooth surface. Of course, you can polish the model, but this is additional time and labor costs.

But it is important to understand that finished products will not have a perfectly smooth surface. Of course, you can polish the model, but this is additional time and labor costs.

FDM technology builds a model using molten plastic filament, which is fed from the print head. The print head (extruder) “grows” the model layer by layer on the printing table.

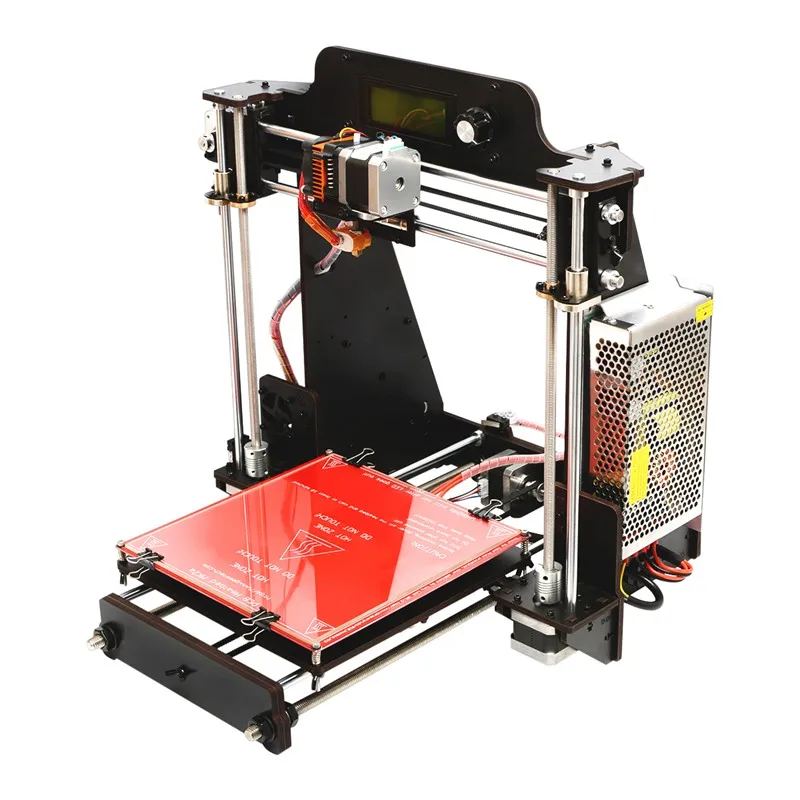

FDM Models

FDM technology became widespread much earlier than DLP. Thanks to this, a wide variety of 3D printers and consumables for them has appeared. You can find many decorative plastics that mimic various materials, or engineering plastics for making functional models or mock-ups.

Choosing an LCD printer

Photopolymer printers work on one of 3 technologies - DLP, LCD or SLA.

As home printers, devices based on LCD technology are usually used due to their availability and low price.

Printer design

SLA technology appeared the very first among photopolymer printers. With the help of a point-focused beam, the desired areas of the resin are gradually illuminated. This is repeated layer by layer.

With the help of a point-focused beam, the desired areas of the resin are gradually illuminated. This is repeated layer by layer.

How SLA 9 works0018

Since the surface of the model is perfectly smooth, SLA has become used in the jewelry and dental industries.

Pros:

Cons:

DLP technology appeared later than SLA, but it is very similar to it. The main difference is that the light source is not a focused beam, but a projector. This made it possible to illuminate the entire layer at once, which significantly accelerated the production of models. The quality of the surface was slightly inferior to SLA, but modern DLP printers, in terms of the quality of models, are almost as good as SLA technology.

How DLP works

Pros:

-

Faster production of models due to the illumination of the entire layer

-

Consumables are slightly cheaper than SLA

-

High surface quality (although may be inferior to SLA)

Cons:

LCD technology is the youngest of all. The DLP principle is taken as a basis, but an LCD display is used as a matrix or illumination pattern. LEDs are used as a source of UV light in LCD technology. Thanks to inexpensive components, we managed to get a simple, but high-quality and affordable photopolymer printer.

The DLP principle is taken as a basis, but an LCD display is used as a matrix or illumination pattern. LEDs are used as a source of UV light in LCD technology. Thanks to inexpensive components, we managed to get a simple, but high-quality and affordable photopolymer printer.

How the LCD printer works

Pros:

-

small cost

-

Cheap parts

Cons:

-

Low accuracy compared to SLA and DLP (for jewelers and dentists, the quality of LSD prints may not be enough, although more and more accurate models appear with the development of technology)

-

Possible stray light

-

The quality of models may decrease at the edges of the printable area (this can be corrected programmatically)

Resins that are used as a consumable for photopolymer printing can smell strongly and unpleasantly during operation.

Try to use the printer in a well-ventilated area, or choose a printer with a sealed cabinet and filter.

When choosing an LCD printer, pay special attention to the rigidity and positioning accuracy of the platform along the Z axis. If there are poor quality guides along the Z axis or even a slight play, then the surface quality of the finished model may turn out to be sloppy or the model will turn out to be unevenly striped.

Rating of the best LCD 3D printers for home

Anycubic Photon Mono

This is an LCD printer with a matrix that allows you to increase the speed and accuracy of printing. Anycubic Photon Mono will be a good helper for hobbyists and modellers.

Anycubic Photon Mono SE

Anycubic Photon Mono SE has an unusual parallel light source. This minimizes distortion at the edges of the printable area. You can effectively use the entire working area of the machine and produce many small models at a time.

Phrozen Sonic Mini 4K

Model with high resolution LCD display and large print area. The monochrome display transmits UV rays better and allows you to print much faster than similar devices with a conventional display. The manufacturer claims a screen life of more than 2000 hours. Phrozen Sonic mini 4k is suitable for almost any task.

Wanhao GR1

Wanhao GR1 has high precision and large print area (140x78x200mm). The manufacturer tried to reduce distortion at the edges of the display, this allows you to make the most of the entire work area. High precision and large print area make Wanhao GR1 not only for hobby use, but also for production.

Anycubic Photon Zero

Small and very budgetary LCD device. Its resolution and small working area (total 97x54x150 mm) is enough for printing small miniatures, figurines or small engineering models. Anycubic Photon Zero is a good choice for beginners who want to get into photopolymer printing without spending a lot of money.

Choose FDM printer

If you plan to produce large and varied functional models or experiment, a 3D printer that prints using FDM technology is an excellent choice.

First, decide on the size of the printable area and the properties that the finished model should have. After all, some materials require a closed chamber or good airflow to work.

Some printer models can be “upgraded” in the future. For example, if necessary, buy spare parts for a closed case, put a nozzle of a different diameter, or change the thermal barrier to an all-metal one. But not all manufacturers provide for the possibility of such upgrades.

Printer design

Despite the same principle of operation, there are several different mechanics, which have their pros and cons.

Kinematics “Prusa” (Prusa)

Perhaps the most popular kinematics among home FDM devices. Mainly due to its simplicity and low cost. The main feature is the table that moves along the Y axis, while the extruder moves along the rest of the axes. Because of this, such kinematics was nicknamed “dragstol”.

The main feature is the table that moves along the Y axis, while the extruder moves along the rest of the axes. Because of this, such kinematics was nicknamed “dragstol”.

Prusa kinematics

Pros:

Cons:

-

Slow print speeds. A massive table with a model is forced to constantly move along the Y axis, because of this, print quality will be worse at high speeds.

-

Some models have design flaws (for example, insufficient frame rigidity), they can be fixed, but for this you will have to be a little inventor. Or find a ready-made solution on the Internet.

This category also includes 3D printers with console kinematics. The same prusa, only halved. Because of this, the frame is less rigid, but the printer itself is more compact.

Kinematics Ultimaker

The extruder moves along the X-Y axes, and the table only along the Z axis. All motors are trying to be fixed on the body to lighten the weight of the moving mechanisms, thanks to which it is possible to achieve high print quality at high speeds.

All motors are trying to be fixed on the body to lighten the weight of the moving mechanisms, thanks to which it is possible to achieve high print quality at high speeds.

Ultimaker kinematic diagram

Pros:

Cons:

H-BOT or Core-XY

These are 2 similar but more complex kinematics - the table moves only along the Z axis, and the extruder along the X-Y. But to move the extruder, 1 or 2 long belts and 2 stepper motors work in concert.

Example Core-XY kinematics

Pros:

-

High print quality

-

High print speeds without loss of quality.

-

Can be easily closed completely

Cons:

MakerBot Kinematics

Similar to Ultimaker kinematics, but one of the motors is located on the Y or X axis carriage.

Pros:

Cons:

Delta

Deltas do not have the usual XYZ axes. There are 3 columns in the deltas, along which the carriages move, and the position of the extruder in space is calculated using a complex formula. The table is usually statically fixed to the body.

Delta printer example

Pros:

Cons:

Nuances of choosing an FDM 3D printer

In addition to kinematics, when choosing a printer, it is important to consider some design features.

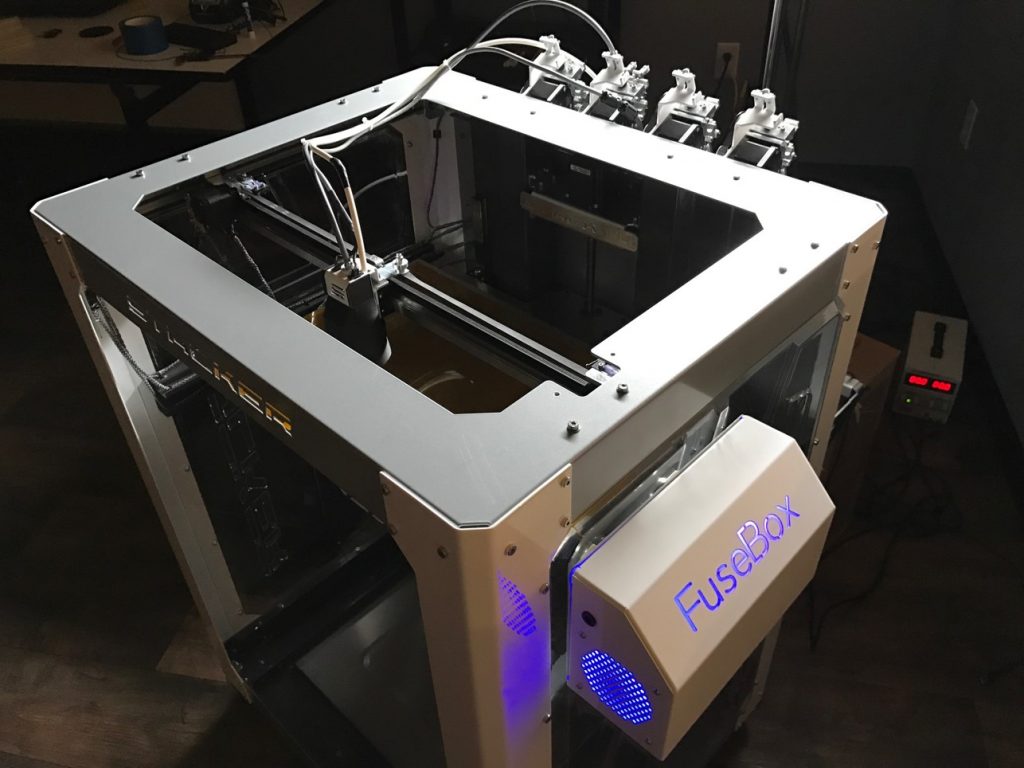

One or two extruders?

Two extruders can be used for dual color printing, but most commonly the second extruder is used for solvent support printing. If you need to print complex parts with internal cavities, then you should choose a dual extruder printer.

Closed or open printer?

Printing of functional models and parts uses plastic, which usually requires a closed chamber. If you plan to print functional prototypes or various models, you should look at printers with a closed chamber.

If you plan to print functional prototypes or various models, you should look at printers with a closed chamber.

Bowden or direct?

There are 2 types of material supply to the print head of the printer - bowden and direct.

In a bowden, the feed mechanism motor is located on the printer body. This allows you to reduce the weight of the extruder and print at higher speeds without losing quality. But because of the long tube, printing with very soft plastics can be problematic.

Bowden feed pattern

In direct feeding, the motor and feed mechanism are located on the extruder. This increases the weight of the print head, but allows you to print with any kind of plastics.

Direct feeding scheme

Heated table or not?

The heating of the table improves the adhesion of the first layer of the model. And engineering plastics cannot be printed without a heated table.

And engineering plastics cannot be printed without a heated table.

Many manufacturers add useful additional features. They do not affect the quality of the print, but save time and nerves. The most useful additional functions are the filament presence sensor and remembering the print location after a power outage.

Filament sensor.

It will automatically pause printing if the plastic runs out. When there is a little plastic left on the spool, this feature will allow you not to stand over the guard printer until the old spool runs out in order to have time to push in a new bar “on the go”.

Power outage protection.

Remembering where to print when the power goes out can save you a lot of nerves when printing large models. You won't have to worry that after a power outage, you will have to run the model again for many hours or cut and reprint a piece of the model. It is especially disappointing to throw away a complex underprinted model with supports due to a one-minute outage.

There are also many extras. features that make using the printer more comfortable. For example, automatic calibration, touch screen, Wi-Fi and others.

Rating of the best FDM 3D printers for home

Anycubic Mega Zero 2.0

Inexpensive model with Pryusha kinematics. Good for getting started with 3D printing without a big investment. Despite the low cost, Anycubic Mega Zero 2.0 has a heated table and a resume function after a power outage. Thanks to direct feed, printing with soft materials should not be difficult.

Creality3D Ender 3 Pro

A very popular device due to its low price. But despite this, the Ender 3 Pro has a heated table and a decent print area. Can be sold assembled or as a DIY kit.

Flash Forge Finder

Small home appliance intended for children or educational institutions. The Finder doesn't have a heated table, but it does have a calibration assistant, a Wi-Fi module, and other extras that make getting to know it a lot easier. All moving and heated elements are hidden as much as possible in the case so that the child cannot get burned.

All moving and heated elements are hidden as much as possible in the case so that the child cannot get burned.

Wanhao Duplicator 6 Plus

Wanhao Duplicator 6 Plus was based on Ultimaker kinematics, but instead of bowden feed, they made direct. Because of this, it will not be possible to print super fast, without quality loss, but there will be no problems with printing with soft types of plastics. There are 2 trim levels - with a closed case and without.

Flashforge Dreamer

The Dreamer is a closed body dual extruder printer with MakerBot kinematics. Thanks to this, he can cope with printing models of any complexity. Using a second extruder for soluble support, models with complex geometries can be produced. A good choice for engineers and those who like to experiment with different materials.

FlyingBear Ghost 5

Most commonly sold as a kit (assembly kit). Assembly usually does not cause any great difficulties, even for people far from electronics or mechanics. Flying Bear is equipped with a filament sensor, a function to resume printing after a power outage and Wi-Fi connectivity.

Flying Bear is equipped with a filament sensor, a function to resume printing after a power outage and Wi-Fi connectivity.

The Flying Bear makes a great first printer for the novice user who is ready to build their own printer.

Totals

In order for the printer not to become a useless toy, you should clearly understand what it is for.

For a fan of miniatures or detailed figurines, a photopolymer printer is a good choice. A small work area is more than offset by the detail that cannot be obtained using other technologies.

For an engineer or a fan of experiments, an FDM machine with a closed chamber and two extruders is well suited. This will allow you not to limit yourself in the choice of plastics and comfortably experiment with any materials.

For a beginner who has not yet decided whether he needs 3D printing, you can opt for inexpensive machines with slick kinematics. Due to their great popularity, you can find a lot of upgrades and reviews on them. In the future, it will be possible to modify the printer for specific tasks or change it to a more suitable model.

In the future, it will be possible to modify the printer for specific tasks or change it to a more suitable model.

For a child, safety is paramount. As the first children's printer, models without a heated bed are suitable, in which the main emphasis is on printing with safe PLA plastic. Or models in which all moving and heating mechanisms are hidden in the case.

A 3D printer is a handy tool, and whether it brings joy or frustration depends on the user.

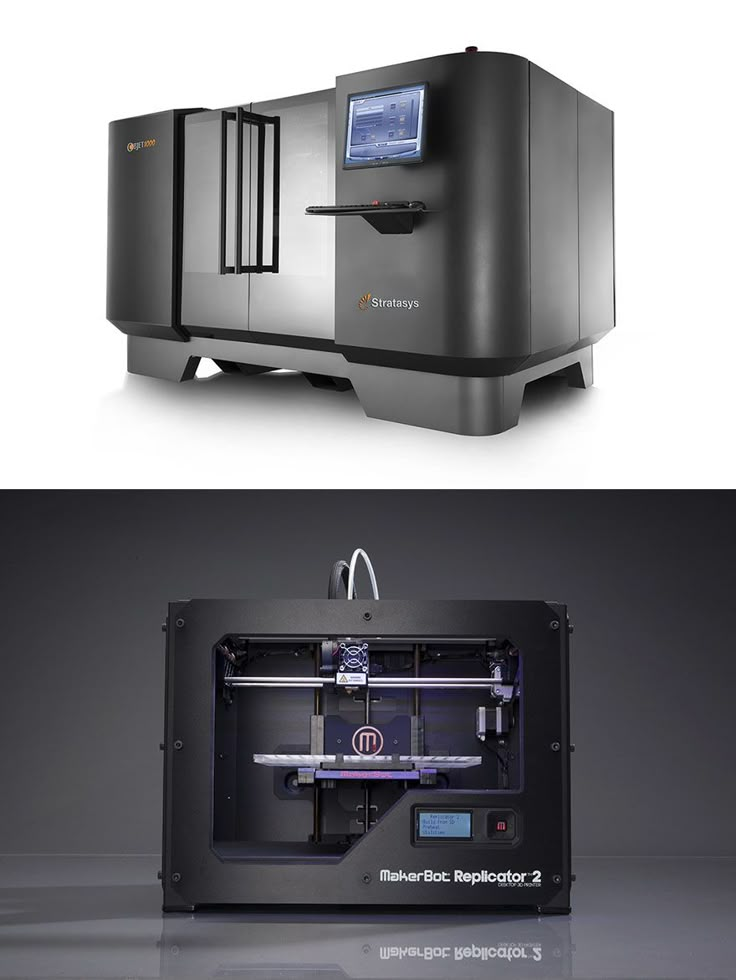

The most expensive 3D printers in the world

- home

- News AT

- World

- The most expensive 3D printers in the world

Various technologies do not stand still, they are constantly evolving. This article proposes to consider the evolution of industrial 3D printers today, which are the most expensive in the world and why.

3D printers are unique in terms of the variety of different 3D printing methods, materials used and their applications. You can spend as little as $100 to get a reliable 3D printer to make a huge variety of parts from affordable plastic material. On the other hand, you can spend over a million dollars to buy a 3D printer to 3D print parts with large and complex construction geometries. They can be used in the aerospace industry, the production of space satellites or miniature biocompatible devices for medical purposes. The most expensive 3D printers on the market today use 1 to 12 powerful lasers to fuse metal powder, sinter polymer materials, or polymerize resin, and 3D printing from a given 3D model occurs by applying the powder layer by layer, which is a process additive manufacturing.

You can spend as little as $100 to get a reliable 3D printer to make a huge variety of parts from affordable plastic material. On the other hand, you can spend over a million dollars to buy a 3D printer to 3D print parts with large and complex construction geometries. They can be used in the aerospace industry, the production of space satellites or miniature biocompatible devices for medical purposes. The most expensive 3D printers on the market today use 1 to 12 powerful lasers to fuse metal powder, sinter polymer materials, or polymerize resin, and 3D printing from a given 3D model occurs by applying the powder layer by layer, which is a process additive manufacturing.

It can be noted that the size of the 3D printer does not determine how expensive the 3D printer will be. Today, the price often depends on advanced patented technologies and features that allow a 3D printer to produce fast and high-quality 3D-printed parts without requiring special technical knowledge from the operator.

Some of the most expensive printers are not even for sale. Carbon 3D's 3D printers are available for rent only, which allows them to be used by many users. Others use their 3D printers on a project-by-project basis, such as the Vulcan construction printer from homebuilder Icon 3.

Stargate, the world's largest metal 3D printer built by Relativity Space to 3D print rockets, it's not for sale, but if it was, it would definitely be on our list. Many of the most exciting technologies in 3D printing can only be used for custom 3D printing, not for purchase. (Source: Relativity Space)

Let's look at the criteria that affect the cost of a modern industrial 3D printer.

Features 3 D -Printers affecting their price:

- The uniqueness of the technology when creating

- How automated the processes in the 3D printer

- The size of the working chamber

- Objects allowing the quality control

- software

- Numerous controls and adjustments

- Controlled environment inside the working chamber (use of inert gas, the possibility of heating/cooling the working platform)

Breaking down these features:

Features that drive up the price of 3D printers include software tuned to a specific printer technology, real-time 3D printing control systems, and anything that automates processes that sometimes are performed manually in cheaper systems (layer leveling, subsequent post-processing or powder sieving) or processes that require knowledge of metallurgy or polymers.

Production technology requiring a vacuum chamber in a 3D printer, filling the working chamber with an inert gas, or printers that are certified for use in clean rooms and having these characteristics are significantly reflected in the final price of this equipment.

The materials used in the 3D printing process also have a significant impact on the final cost of a 3D printer. Many 3D printers only work with proprietary materials that have been developed by the manufacturer for that 3D printer. They can be metal powder, special resins filled with carbon fiber particles, and unique polymer powders. At this point in time, it is possible to 3D print anything from pure gold to advanced engineering plastics on 3D printers, even in the harsh environment of space.

There are 3D printers that can 3D print multiple materials in one job, and there are multicolor 3D printers that are also in the higher price segment.

THE MOST EXPENSIVE 3 D -PRINTERS

The 3D printer manufacturers discussed below are reluctant to publish exact prices for their products. This is due not only to competition, but also to the fact that 3D printers have a basic package, as well as a package with additional options according to customer requirements. That said, with that in mind, below is a look at some of the most expensive 3D printers available today - all costing over half a million US dollars - and what they provide.

This is due not only to competition, but also to the fact that 3D printers have a basic package, as well as a package with additional options according to customer requirements. That said, with that in mind, below is a look at some of the most expensive 3D printers available today - all costing over half a million US dollars - and what they provide.

E-PLUS3D EP-M450H

3D printer EP-M450H LPBF (Source: E-Plus 3D)

Chinese company E-Plus3D produces industrial metal 3D printers with a large construction of construction for additive manufacturing for various industries in the country. These 3D printers are used in the aerospace, automotive, electronics, and engineering industries to produce not only large-sized parts such as heavy-duty molds, but also mass-produced parts.

The EP-M450H Metal 3D Printer is the company's largest 3D printer with a build chamber of 456 x 456 x 1080 mm, producing 99.9% density metal parts from a wide range of materials at a speed of 55 cm³ per hour.

XJet Carmel 1400C

Israeli company XJet has developed a unique ceramic 3D printing technology. NanoParticle Jetting (NPJ) technology allows the production of metal and ceramic parts with a high level of detail, smooth surface roughness and geometric accuracy. The high cost of this 3D printer is not only due to the technology itself, patented materials that make this printer a serious investment, but also to the advanced automation of the 3D printer itself, which makes it easy to use.

Carmel 1400C, equipped with one of the largest 1,400 cm² work platform in the industry, which allows the production of several ceramic parts at the same time.

SLM Solutions NXG Xll 600

NXG XII 600 Large Metal 3D Printer (Source: SLM Solutions) range of printers, but its NXG Xll 600 is what the company says is a revolution in industrial additive manufacturing. The NXG XII 600 was designed for high-volume additive manufacturing and features the industry's first 12 1,000W lasers with a 600x600x600 build chamber. Lasers provide high build speed up to 1000 cm 3 /h and capacity not available for other machines.

Lasers provide high build speed up to 1000 cm 3 /h and capacity not available for other machines.

In addition to lasers, the NXG Xll 600 has all the benefits that SLM Solutions customers have been asking for over the years, including automatic start-up, laser focusing, closed powder feed and material screening, and other latest developments.

UpNano NanoOne Bio

The Austrian company UpNano has developed a two-photon 3D printer using hydrogel-based bio-ink, which allows direct printing of 3D structures containing living cells, both at the meso- and microscale. The NanoOne Bio printer is based on the NanoOne line of laser printers capable of creating structures of 12 orders. The new hydrogel is the only commercially available resin that allows live cells to be embedded directly from culture plates into 3D printed structures for biological applications.

UpNano claims that the combination of X Hydrobio INX U200 and NanoOne Bio opens up new possibilities in biomedical research and development, both in industry and academia, allowing pharmaceutical companies and research institutes to create cell models that mimic natural growth conditions in the body person.

Black Buffalo 3D

Black Buffalo's new 1G construction printer (Source: Black Buffalo)

Black Buffalo 3D, an American company based in South Korea, officially unveiled its Nexcon 1G earlier this year, which is a 3D printer for building houses and other large concrete objects. The printer can create a 92.9 square meter structure in less than 20 hours. It uses Black Buffalo's patented cementitious material, the company calls it ink, that can be dyed to a chosen color and is also customizable to 3D print locally according to the temperature, humidity and altitude conditions of the area.

The Nexcon 1G is a modular 3D construction printer that can be extended along the X, Y and Z axes to scale up (or down) a project up to three stories high. The 1G printer is unique in that users can reposition the base rails and move the printer to a new printable area without having to remove the X or Z axis.

Optomec LENS 860

Energy Deposition (DED), which allows the recovery of large titanium components, such as those used in aircraft engines. Optomec offers several models of 3D printers that have large build chambers like 860x600x610 and laser power of 3 kW.

Optomec offers several models of 3D printers that have large build chambers like 860x600x610 and laser power of 3 kW.

The LENS 860 machining systems are ideal for the fabrication, repair or coating of medium to large metal parts.

ExOne S-Max Pro

While many ExOne printers (now owned by Desktop Metal) are still very affordable given that high volume 3D printers can cost quite a few zeros.

3D printers are used to 3D print complex and detailed sand molds and cores for foundries producing large metal parts for industrial use. The S-Max Pro features a 1,260 liter build chamber for fast 3D printing of sand molds and cores. A new automated print head enables fast 3D printing, while improved sand compaction ensures the density and strength of complex sand mold designs. As the most advanced system in the ExOne family of sand 3D printers, the S-Max Pro is focused on continuous 24/7 production and offers Industry 4.0 integration with cloud connectivity and real-time machine monitoring.