How much does an industrial 3d printer cost

How Much Does a 3D Printer Cost?

In-house 3D printing is a versatile solution for a wide range of applications, from high-resolution models to rapid prototyping, rapid tooling for traditional production processes, manufacturing aids, and even end-use parts in manufacturing.

When you consider investing in a 3D printer, however, viability typically boils down to a simple question: does it make economic sense for your business? How much does a 3D printer cost and how much time and cost can you actually save with it for your business?

3D printer prices range from about $200 to $500,000+ depending on the printing process, materials, and the level of sophistication of the 3D printing solution.

In this guide, we’ll walk you through the 3D printing costs for different technologies, compare outsourcing with in-house production, lay out the various factors you should account for to calculate cost per part, and look at considerations beyond cost when comparing various 3D printing solutions and other production methods.

Interactive

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

Calculate Your Savings

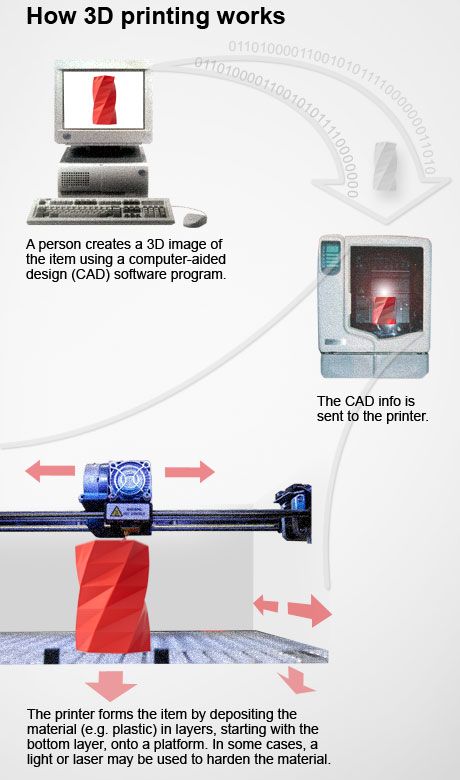

The three most established plastic 3D printing processes today are fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS).

Each 3D printing technology has its pros and cons—here's an infographic for a quick comparison:

Download the high-resolution version of this infographic here. Would you like to learn more about FDM, SLA, and SLS 3D printing technologies? Check out our in-depth guide.

3D printer prices have dropped significantly in recent years, and today, all three technologies are available in compact, affordable systems.

As a rule of thumb, FDM 3D printers will create the cheapest parts if you’re printing only relatively simple prototypes in limited numbers. SLA resin 3D printers offer higher resolution, better quality, and a wide variety of 3D printing materials at a slight premium, but the difference quickly diminishes when you print complex designs or larger batches due to the less labor-intensive post-processing. Lastly, SLS 3D printing is the most cost-effective process for producing medium to large volumes of high-quality functional parts.

Lastly, SLS 3D printing is the most cost-effective process for producing medium to large volumes of high-quality functional parts.

Comparing the overall cost of different 3D printers goes beyond sticker prices -- these won’t tell you the full story of how much a 3D printer costs and how much your printed part will cost. 3D printing material and labor costs have a significant influence on cost per part, depending on the application and your production needs.

Let’s look at all the different factors and costs for each process.

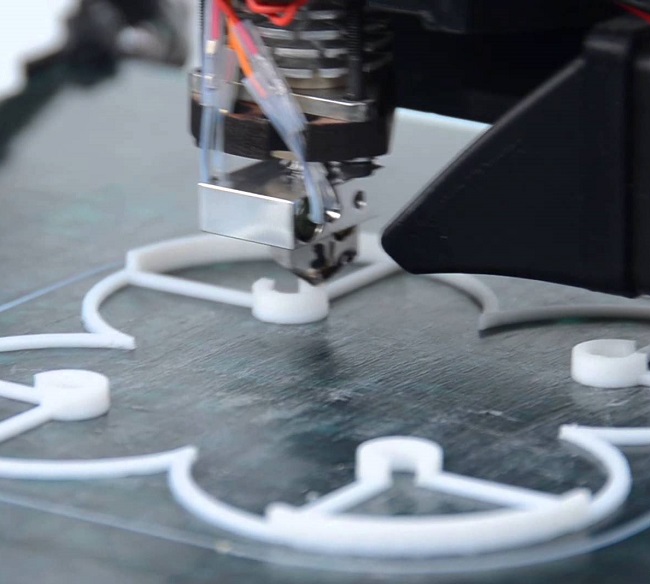

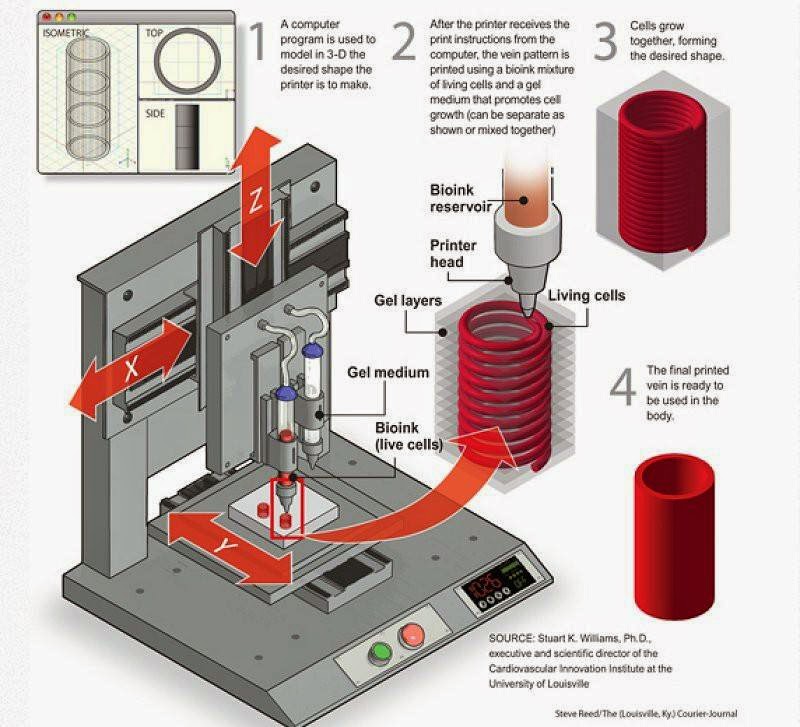

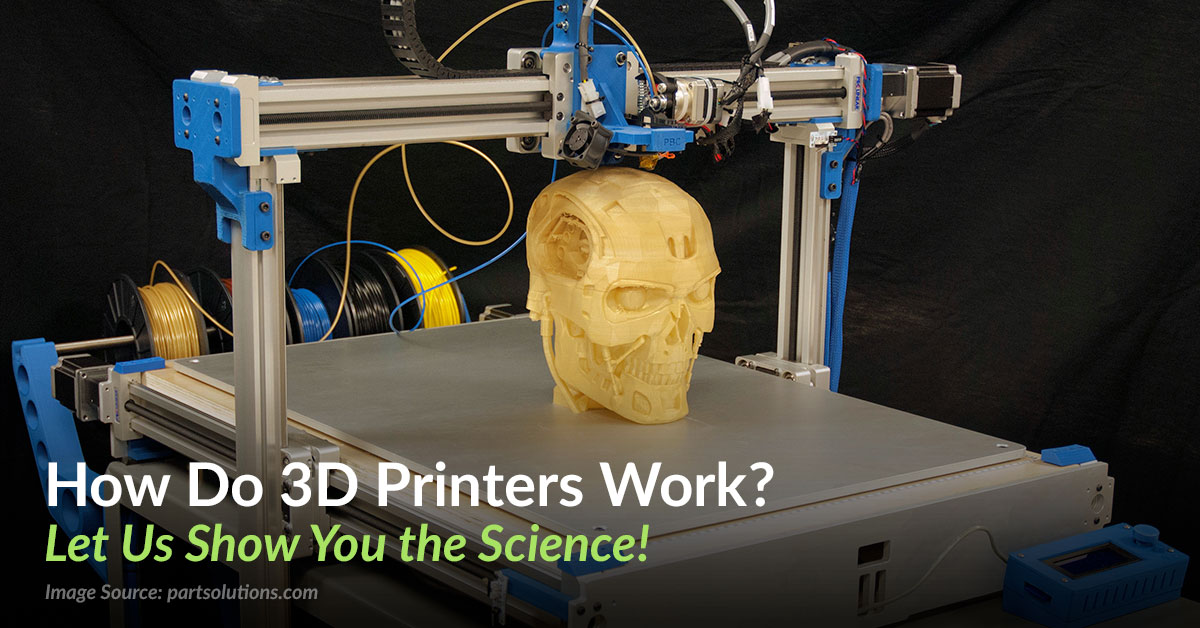

FDM, also known as fused filament fabrication (FFF), is a printing method that builds parts by melting and extruding thermoplastic filament, which a printer nozzle deposits layer by layer in the build area.

FDM is the most widely used form of 3D printing at the consumer level, fueled by the emergence of hobbyist 3D printers. Professional and industrial FDM printers are, however, also popular with professionals.

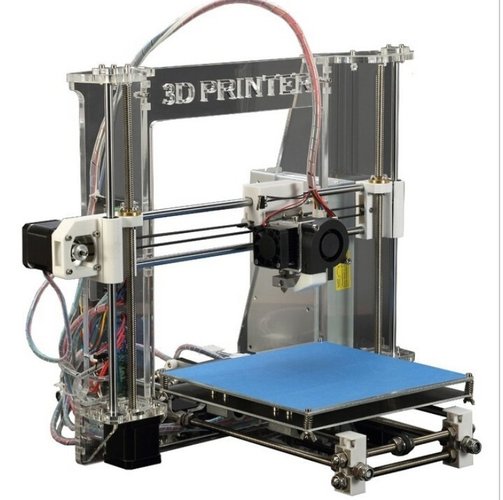

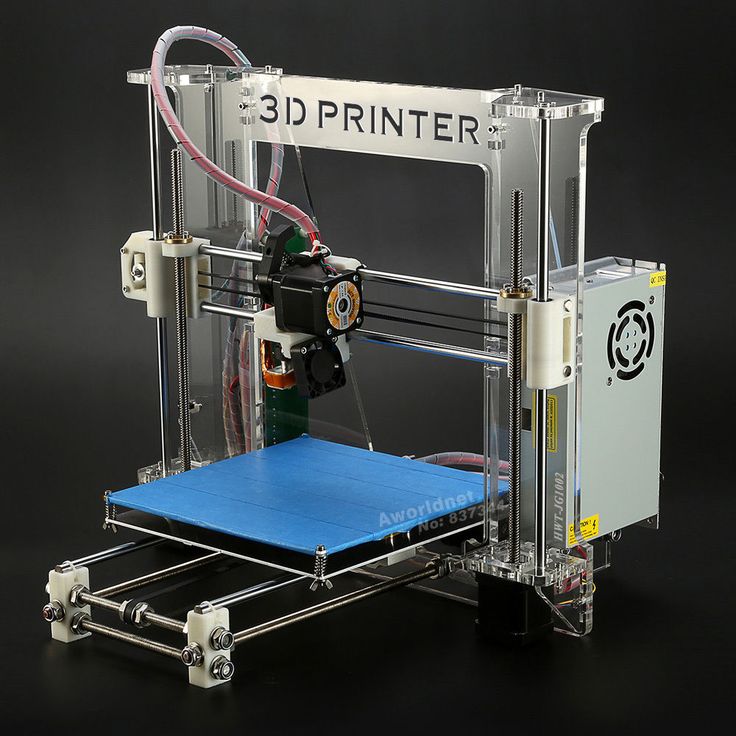

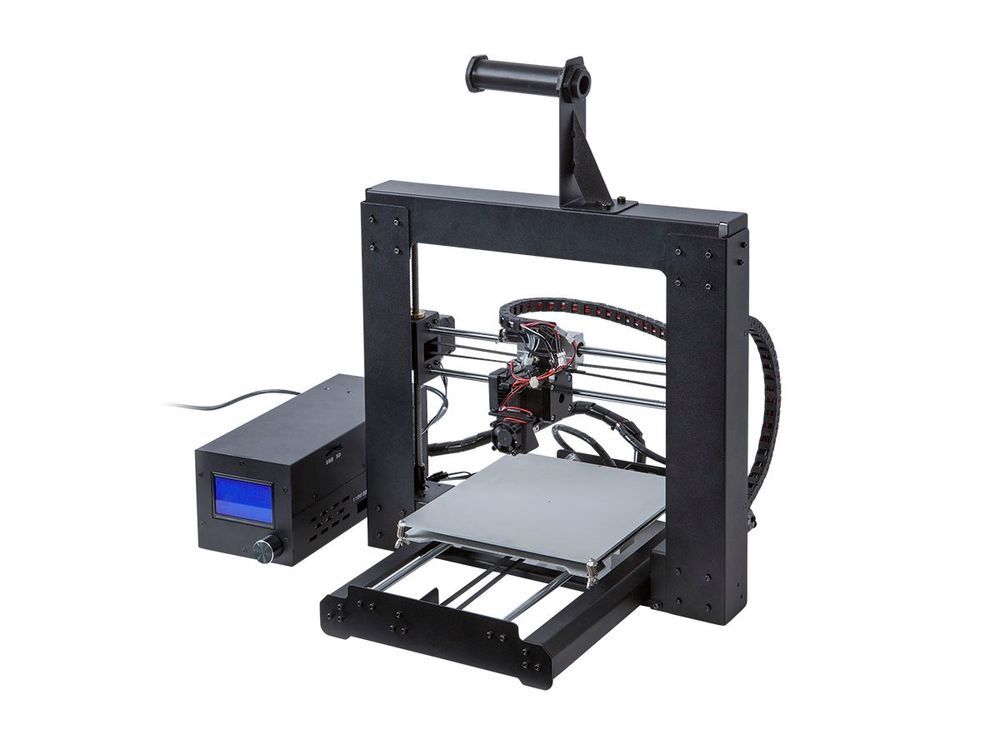

The lowest cost 3D printers are almost exclusively FDM printers. Prices for the cheapest entry-level DIY FDM 3D printer kits start at around $200. However, most of these models are more like toys or DIY projects themselves that require you to spend a considerable amount of time assembling, tweaking, and calibrating the printer. Print quality is highly dependent on the success of these steps and still, these machines will require you to do repairs and regular maintenance to keep them running, so they are only recommended for anyone with an (in progress) engineering degree and lots of time and patience.

Prices for the cheapest entry-level DIY FDM 3D printer kits start at around $200. However, most of these models are more like toys or DIY projects themselves that require you to spend a considerable amount of time assembling, tweaking, and calibrating the printer. Print quality is highly dependent on the success of these steps and still, these machines will require you to do repairs and regular maintenance to keep them running, so they are only recommended for anyone with an (in progress) engineering degree and lots of time and patience.

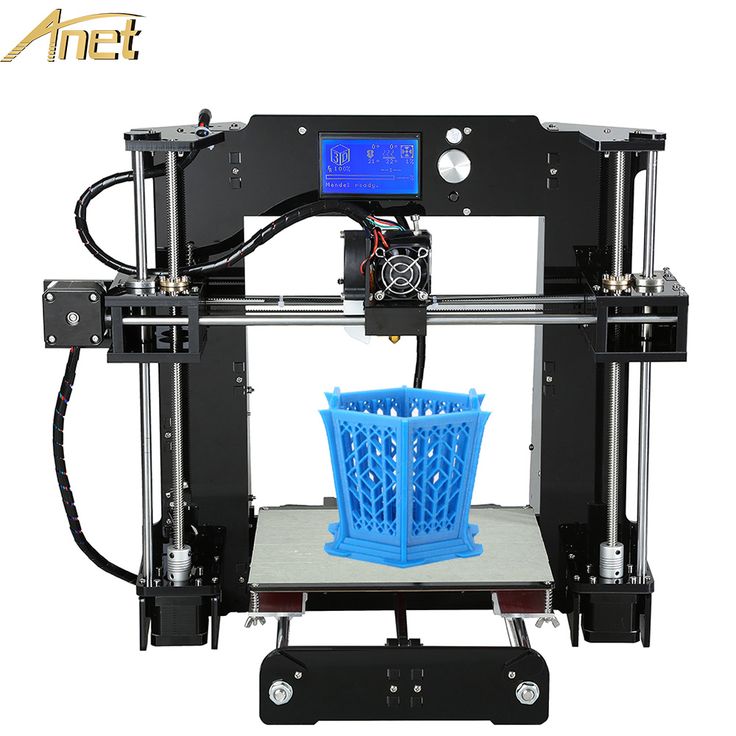

Hobbyist FDM 3D printers which cost around $500-$1,500 might come as a kit or assembled, require slightly less tweaking, but they still share much of the same disadvantages as the lowest-cost 3D printers. Some models closer to the top of this range will offer bigger build volumes and also more material options beyond low-temperature materials like PLA.

Professional FDM 3D printers start around $2,500, and large-format professional FDM printers start around $4,000, while the most advanced industrial FDM printers can easily cost more than $10,000. Most of these printers will come assembled and calibrated out of the box, or they can auto-calibrate themselves. Printers in this category offer better print quality, a wider range of materials, larger build volumes, better reliability, and are easier to use and maintain. Unlike lower-cost printers, manufacturers of professional 3D printers also offer customer support to troubleshoot issues.

Most of these printers will come assembled and calibrated out of the box, or they can auto-calibrate themselves. Printers in this category offer better print quality, a wider range of materials, larger build volumes, better reliability, and are easier to use and maintain. Unlike lower-cost printers, manufacturers of professional 3D printers also offer customer support to troubleshoot issues.

Regarding materials, FDM 3D printing material costs range from around $50 to $150/kg for most standard and engineering filaments and $100-200/kg for support materials. Cheaper alternatives might be available, but once again, with a trade-off in terms of quality.

Lastly, FDM printing can be highly labor-intensive. Many designs, especially complex models, require support structures for successful printing, which need to be removed manually or by dissolving the structures in case of soluble supports. To obtain a high-quality finish and remove layer lines, parts require lengthy manual post-processing, such as sanding.

SLA 3D printers use a laser to cure liquid resin into hardened plastic in a process called photopolymerization. SLA is one of the most popular processes among professionals due to its high resolution, precision, and material versatility.

SLA parts have the highest accuracy, the clearest details, and the smoothest surface finish of all plastic 3D printing technologies, but the main benefit of SLA lies in its versatility. SLA resin formulations offer a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

SLA 3D printing offers a wide range of materials for a variety of applications.

While SLA technology used to be available only in large, complex industrial 3D printers that cost more than $200,000, the process has become much more accessible. With the Formlabs Form 3+ printer, businesses now have access to industrial-quality SLA for just $3,750. Large-format SLA with the Form 3L starts at just $11,000.

SLA 3D printers will come assembled and calibrated out of the box. They’re professional tools that are reliable also for production and require barely any maintenance. Customer support is also readily available to troubleshoot issues in the unlikely event that something goes wrong.

In terms of material costs, SLA resins cost around $149-$200/L for most standard and engineering resins.

SLA printers are easy to use and many steps of the workflow like washing and post-curing can be mostly automated to reduce labor needs. Printed parts have a high-quality finish right off the printer and require only simple post-processing to remove support marks.

White Paper

In this free report, we look at how in-house large-format 3D printing with the Form 3L stacks up against other methods of production, chiefly outsourcing and using FDM printers. We also compare costs between methods, and review when it would be best to bring the Form 3L in-house.

Download Now

SLS 3D printers use a high-powered laser to fuse small particles of polymer powder. The unfused powder supports the part during printing and eliminates the need for dedicated support structures, which makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features.

Parts produced with SLS printing have excellent mechanical characteristics, with strength resembling that of injection-molded parts. As a result, SLS is the most common plastic 3D printing process for industrial applications.

SLS nylon parts are ideal for a range of functional applications, from engineering consumer products to healthcare.

Just like SLA, SLS used to be only available in large-format, complex 3D printing systems starting at about $200,000. With Formlabs’s Fuse 1 SLS printer, businesses can now access industrial SLS starting from $18,500, and $29,743 for a complete setup that includes a post-processing and powder recovery system.

Also similar to SLA printers, SLS printers will come assembled and calibrated out of the box. They are reliable and developed for 24/7 production, and come with advanced training and fast customer support.

Nylon materials for SLS printing cost around $100/kg. SLS requires no support structures, and unfused powder can be reused, which lowers material costs.

SLS is the least labor-intensive plastic 3D printing process in a production setting as parts have great quality right out of the printer and require only simple cleaning to remove excess powder.

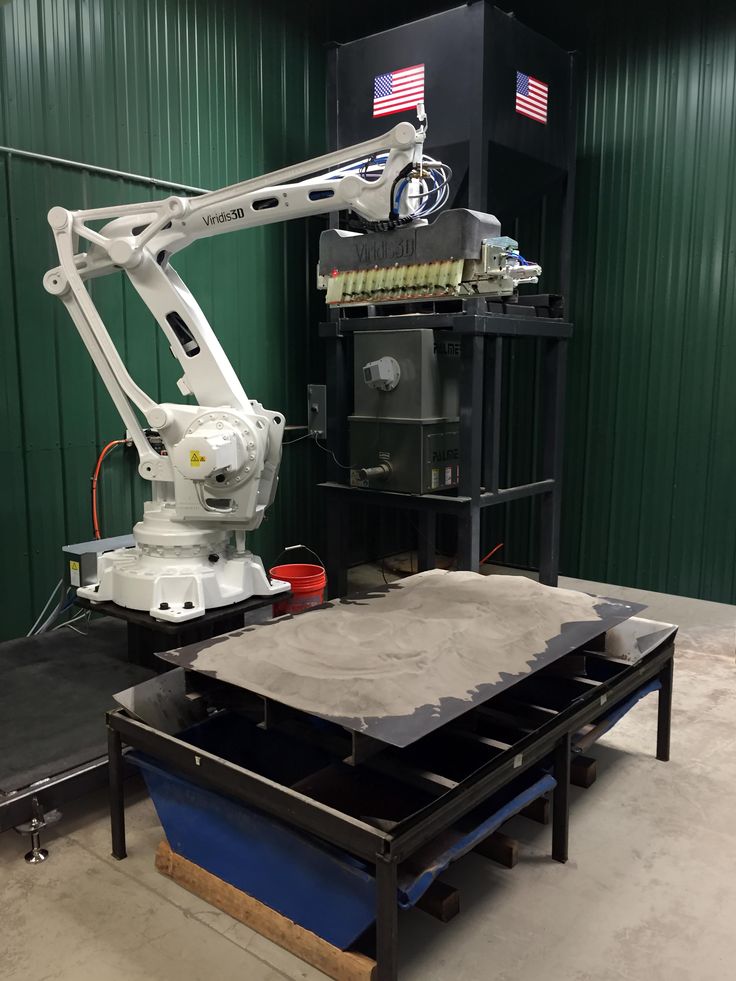

Beyond plastics, there are multiple 3D printing processes available for metal 3D printing.

-

Metal FDM

Metal FDM printers work similarly to traditional FDM printers, but extrude metal rods held together by polymer binders. The finished “green” parts are then sintered in a furnace to remove the binder.

SLM and DMLS printers work similarly to SLS printers, but fuse metal powder particles together layer by layer using a laser instead of polymers. SLM and DMLS 3D printers can create strong, accurate, and complex metal products, making this process ideal for aerospace, automotive, and medical applications.

SLM and DMLS 3D printers can create strong, accurate, and complex metal products, making this process ideal for aerospace, automotive, and medical applications.

While metal 3D printer prices have also begun to decrease, with costs ranging from $100,000 to $1 million, these systems are still not accessible to most businesses.

Alternatively, SLA 3D printing is well-suited for casting workflows that produce metal parts at a lower cost, with greater design freedom, and in less time than traditional methods.

White Paper

Get design guidelines for creating 3D printed patterns, walk through the step-by-step direct investment casting process, and explore guidelines for indirect investment casting and sand casting.

Download the White Paper

The various plastic and metal 3D printing processes have unique qualities that make them suitable for different applications. Here's a quick breakdown.

| Fused Deposition Modeling (FDM) | Stereolithography (SLA) | Selective Laser Sintering (SLS) | Metal FDM | Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) | |

|---|---|---|---|---|---|

| Resolution | ★★☆☆☆ | ★★★★★ | ★★★★☆ | ★★☆☆☆ | ★★★★☆ |

| Accuracy | ★★★★☆ | ★★★★★ | ★★★★★ | ★★★☆☆ | ★★★★★ |

| Surface Finish | ★★☆☆☆ | ★★★★★ | ★★★★☆ | ★★☆☆☆ | ★★★★☆ |

| Throughput | ★★★★☆ | ★★★★☆ | ★★★★★ | ★★★☆☆ | ★★★★☆ |

| Complex Designs | ★★★☆☆ | ★★★★☆ | ★★★★★ | ★★★☆☆ | ★★★★★ |

| Ease of Use | ★★★★★ | ★★★★★ | ★★★★☆ | ★★★★☆ | ★☆☆☆☆ |

| Build Volume | Up to 300 x 300 x 600 mm (desktop and benchtop 3D printers) | Up to 300 x 335 x 200 mm (desktop and benchtop 3D printers) | Up to 165 x 165 x 300 mm (benchtop industrial 3D printers) | Up to 300 x 200 x 200mm | Up to 400 x 400 x 400 mm |

| Price Range | DIY printers 3D printer kits start around $200, hobbyist printers range from $500-$1,500. Professional FDM 3D printers start around $2,500, and large-format professional FDM printers start around $4,000. Professional FDM 3D printers start around $2,500, and large-format professional FDM printers start around $4,000. | Professional desktop printers start at $3,750, large-format benchtop printers offer a bigger build volume for $11,000. | Benchtop industrial SLS systems start at $18,500, and traditional industrial printers are available from $100,000. | Metal FDM printers start from $100,000, but the full solution that includes a furnace goes well beyond that. | DMLS/SLM solutions start around $200,000. These printers also come with stringent facility requirements which may increase the costs further. |

| Material Costs | $50-$150/kg for most standard and engineering filaments, and $100-200/kg for support materials. | $149-$200/L for most standard and engineering resins. | $100/kg for nylon. SLS requires no support structures, and unfused powder can be reused, which lowers material costs. | Depends on the material and the technology. Significantly higher than plastics. Significantly higher than plastics. | Depends on the material and the technology. Significantly higher than plastics. |

| Labor Needs | Manual support removal (can be simplified in some cases with soluble supports). Lengthy post-processing is required for a high-quality finish. | Washing and post-curing (both can be mostly automated). Simple post-processing to remove support marks. | Simple cleaning to remove excess powder. | Washing and sintering (both can be mostly automated). Optionally machining and other surface treatments. | Stress relief, support removal, heat treatment, as well as machining, and other surface treatments. |

| Materials | Standard thermoplastics, such as ABS, PLA, and their various blends. | Varieties of resin (thermosetting plastics). Standard, engineering (ABS-like, PP-like, silicone-like, flexible, heat-resistant, rigid), castable, dental, and medical (biocompatible). | Engineering thermoplastics, typically nylon and its composites (nylon 12 is biocompatible + compatible with sterilization). | Stainless steel, tool steel, inconel, copper, titanium. | Stainless steel, tool steel, titanium, cobalt chrome, copper, aluminum, nickel alloys. |

| Ideal applications | Basic proof-of-concept models, low-cost prototyping of simple parts. | Highly detailed prototypes requiring tight tolerances and smooth surfaces, molds, tooling, patterns, medical models, and functional parts. | Complex geometries, functional prototypes, short-run or bridge manufacturing. | Strong and durable parts, tooling, and manufacturing aids. | Strong, durable parts with complex geometries; ideal for aerospace, automotive, and medical applications. |

Calculating cost per part requires accounting for the costs of equipment ownership, material, and labor. It’s helpful to understand the factors that influence each of these cost components, and the questions to ask to evaluate alternative production methods and uncover hidden costs.

Fixed costs, such as the 3D printer cost, service contracts, installation, and maintenance, together make up the equipment ownership cost. These expenses occur regardless of whether your 3D printer stands idle or produces dozens of parts a week.

Distribute equipment ownership costs over individual parts by adding up all of the forecasted fixed costs over the lifetime of the machine and divide the sum by the number of parts that it is expected to produce. As a rule of thumb, the higher the productivity and utilization of your 3D printer, the lower the equipment ownership cost on a per-part basis.

Desktop 3D printers have achieved tremendous progress in recent years in lowering equipment ownership costs. With a price point 10-100 times lower than traditional industrial 3D printers and the capability to produce thousands of parts over their lifetime, the equipment ownership cost can become negligible.

Questions to ask:

-

Are there installation, training, or further initial expenses beside the cost of the machine?

-

Is there a (mandatory) service contract? What does it include?

-

Beyond the machine, what accessories and tools are required to create final parts?

-

What are the maintenance needs of the machine within the normal range of activity? What’s the expected annual cost of maintenance? How does it change if production levels rise?

Raw 3D printing materials and other consumables required to create parts are variable costs. These costs are highly dependent on the number of parts you’re producing.

These costs are highly dependent on the number of parts you’re producing.

Measure material cost by calculating the amount of 3D printing material that’s required to create a single part, and multiply it by the cost of the material. Calculate in waste and any other consumables that are needed. While equipment ownership costs decrease as production grows, material costs for 3D printing tend to flatten out quickly.

Make sure to clarify what materials you’ll need to create the given parts, as the cost of consumables for 3D printing varies. Also note that some 3D printers only work with proprietary materials, and thus limit your third-party material options.

Questions to ask:

-

What is the cost of each type of 3D printing material?

-

How much material is required to create a given part, including waste?

-

What’s the shelf life of the materials?

-

Are there other consumables required to create the parts?

-

Can the machine work with third-party materials?

While 3D printing can replace the complex workflows of traditional manufacturing methods and lead to substantial time savings, depending on the 3D printing technology, it can still be a fairly labor-intensive process.

Professional desktop 3D printers are generally optimized for ease of use. DIY 3D printers and hobbyist printers often require more tinkering to get the settings dialed in, whereas regular maintenance or changing materials on traditional industrial machines can involve time-consuming tasks that require a skilled operator.

Post-processing workflows vary by 3D printing process, but in most cases include cleaning parts and removing supports or excess material. There are solutions to automate some of these tasks; for example, Formlabs Form Wash and Form Cure simplify the washing and post-curing workflow for Formlabs SLA 3D printers, and Fuse Sift offers a turnkey post-processing and powder recovery system for the Fuse 1 SLS printer.

To achieve high-quality parts, more advanced processes like SLA and SLS don’t require time-consuming steps, but FDM parts will need lengthy manual post-processing to improve the quality and remove layer lines.

Questions to ask:

-

What is the entire workflow for producing parts? What are the specific steps required to set up a print, change materials, and post-process parts?

-

How much time does it take to post-process a given part?

-

Are there any tools or devices available to automate some of these tasks?

Outsourcing production to service bureaus or labs is recommended when you require 3D printing only occasionally, and for parts that are large or call for non-standard materials. Bureaus generally have several 3D printing processes in-house such as SLA, SLS, FDM, and metal 3D printers. They can also provide advice on various materials and offer value-added services such as design or advanced finishing.

Bureaus generally have several 3D printing processes in-house such as SLA, SLS, FDM, and metal 3D printers. They can also provide advice on various materials and offer value-added services such as design or advanced finishing.

The main downsides of outsourcing are cost and lead time. One of the greatest benefits of 3D printing is its speed compared to traditional manufacturing methods, which quickly diminishes when an outsourced part takes multiple days or even weeks to arrive. With growing demand and production, outsourcing also rapidly becomes expensive.

Desktop 3D printers are great when you need parts quickly. Depending on the number of parts and printing volume, investment into a professional 3D printer can break even within months.With desktop and benchtop machines, you can pay for just as much capacity as your business needs, and scale production by adding extra units as demand grows without making a significant investment in a large-format 3D printer. By using multiple 3D printers, you also get the flexibility to print parts in different materials simultaneously. Service bureaus can still supplement this flexible workflow for larger parts or unconventional materials.

Service bureaus can still supplement this flexible workflow for larger parts or unconventional materials.

Try our interactive 3D printing ROI calculator to see how much time and cost you can save when 3D printing on Formlabs 3D printers compared to outsourcing.

Investment, materials, and labor costs are relatively easy to calculate. But what about indirect costs and factors that are hard to quantify, but still influence your business? Let’s look at some of the key considerations when comparing desktop 3D printing to outsourcing or other production methods.

Time savings: What if you could bring products to market months faster? Or cut the lead time for your products by days or weeks? 3D printing simplifies traditional prototyping and production workflows, helping you to save time and outpace the competition.

Better results: 3D printing allows you to create more iterations, fail faster, and achieve better end products. Finding and fixing design flaws early also helps to avoid costly design revisions and tooling changes in production.

Finding and fixing design flaws early also helps to avoid costly design revisions and tooling changes in production.

Communication: Having high-quality prototypes and parts allows you to better communicate with customers, clients, suppliers, and other stakeholders. Avoid confusion and costly mistakes.

IP protection: Do you work with sensitive information? Creating parts in-house means you won’t have to give away intellectual property (IP) to third parties, reducing the risks of leaks or IP theft.

Calculating cost per part, lead time, and comparing alternatives to figure out if a solution makes sense for your business would normally be the strenuous task of creating an elaborate spreadsheet and trying to gather all of the—often hidden—information from a manufacturer.

To skip this hassle, try our simple, interactive 3D printing cost calculator to calculate 3D printing cost and lead time on Formlabs 3D printers, and to compare time and cost savings to other production methods.

Calculate Cost and Time Savings

How much does a 3D printer cost? (2022 update)

David Durbin13 January 2022

Guide

| 3D printer category | Average price |

|---|---|

| Low-cost 3D printers | $100 - $400 |

| Hobbyist 3D printers | $400 - $1,000 |

| Enthusiast 3D printers | $1,000 - $3,000 |

| Professional 3D printers | $3,000 - $10,000 |

| Industrial 3D printer price | $10,000+ |

If you're wondering how much a 3D printer costs. Or, if a 3D printer is worth it. You're in the right place.

The good news is this: These days you can find almost any 3D printer for any budget.

And while the average 3D printer price across the market is around $400...

That average is pulled down because of the high volume of low-cost 3D printers sold.

So is it worth it to buy a 3D printer in 2022? If yes, what is the best 3D printer for the price? And are there price range “sweet spots” that you should look out for?

You can prepare yourself to answer these questions by asking yourself:

Am I looking for a hobby or a tool?

And you can get the full answers by reading below.

How much does a 3D printer cost? Low-cost 3D printer prices start from $100 to $400. Then hobbyist 3D printers will set you back by up to $1,000. The next level of enthusiast and professional 3D printer prices range between $1,000 to $10,000. After that, the sky’s the limit – with industrial 3D printer prices starting at $10,000 but quickly reaching $100,000 or $250,000 for specialist technologies.

If you're looking to find out exactly how much Ultimaker printers cost, you can request a quote to find out now.

Request a quoteDIY / Low-cost 3D printer price $100 - $400

Low-cost 3D printers are all about the novelty of the technology. They exist for newbies who want to say, "Hey – check out what I just 3D printed!" Almost all will come as kits that the buyer puts together. And while these machines might have beginner-friendly price tags... It won't be a beginner who can get them to produce a good 3D print. That's because manufacturing problems are too common to overlook. And these lead to a painful setup and user experience. Also, when asking how much does a basic 3D printer cost? This tier can save you money. But expect to pay more for modifications, upgrades, and repairs down the line. That said, if it's a choice between "having a 3D printer" and "not having a 3D printer", this tier offers the biggest bang for your buck.

And these lead to a painful setup and user experience. Also, when asking how much does a basic 3D printer cost? This tier can save you money. But expect to pay more for modifications, upgrades, and repairs down the line. That said, if it's a choice between "having a 3D printer" and "not having a 3D printer", this tier offers the biggest bang for your buck.

The Ultimaker Original was sold as DIY 3D printer that you put together yourself

Hobbyist 3D printer price $400 - $1,000

3D printers at this price range can produce some great parts and models. But that's only after you have set them up and dialed in their settings. In this way, they are aimed at hobbyists. (People who are happy to spend time watching tutorials and tweaking settings to improve their prints.) This also limits your flexibility. Over time, you might be able to 3D print well with a basic material like PLA. But don't expect to switch filaments too easily. While these machines are often delivered as kits, manufacturing problems are less common.

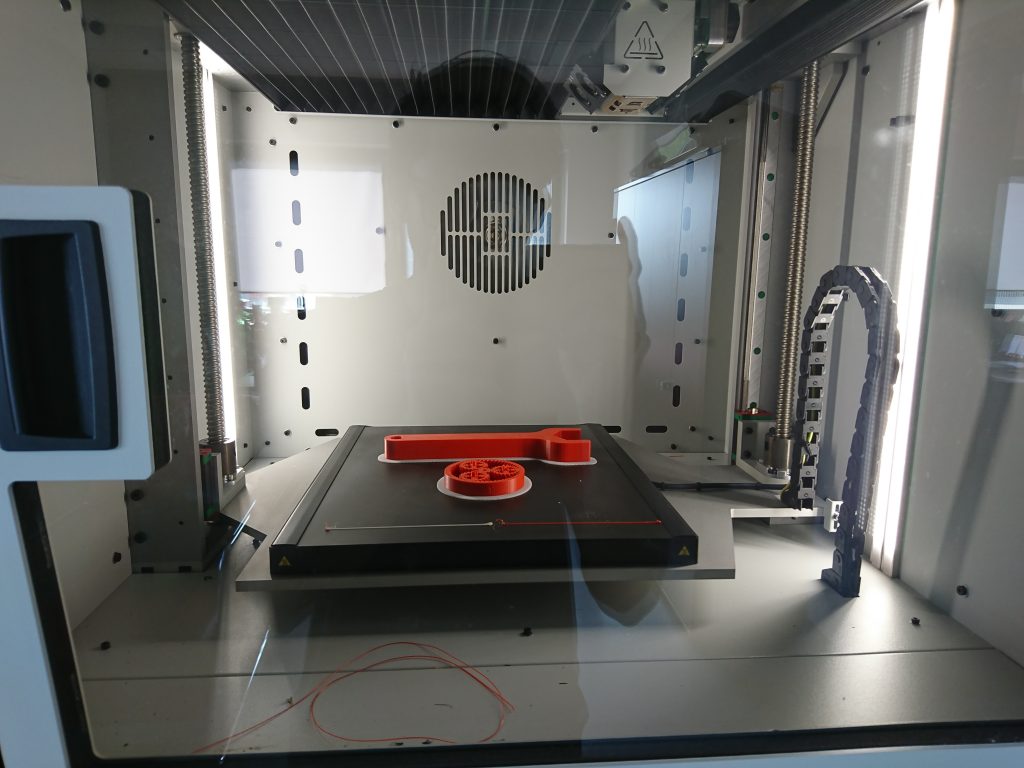

Enthusiast / Prosumer 3D printer price $1,000 - $3,000

Up until this price range, almost all the 3D printers will have had an open design. But now you will begin to see more partially and fully enclosed printers that increase safety and print reliability. This also marks the end of the hobbyist range. And the start of 3D printing becoming a useful production tool. Therefore, the enthusiast and prosumer category is great for lower and higher education customers who want to avoid spending time on maintenance. Plus, they present a smart option to 3D print cheaply at home. These machines can 3D print a handful of materials with good reliability. However, these will often be own-brand filaments with carefully tweaked settings. The best enthusiast 3D printers include hardware and software features taken from the professional 3D printer price tier. On which note...

Safer, more reliable, and low maintenance – Enthusiast 3D printers are a great option for schools

Professional 3D printer price $3,000 - $10,000

A lot changes at this price point. Instead of being a technology to tweak and adjust, these 3D printers focus on easy use and adoption. They become one tool among many in an engineer's or designer's toolbox – giving a growing number of businesses a new way to innovate. And that's why, at this price point, FFF 3D printing is at its most disruptive. The only way this can happen is for the 3D printer to work – and for it to work hard. Expect a factory-tested machine that you can leave running over the weekend and come back to a finished part on Monday morning. Plus, prints start being repeatable. For example, if you 3D print the same part on the same printer in two or more locations...the part quality should be almost identical. The user also has more flexibility. You can choose to print with a build material and a support material in the same print (called dual extrusion), offering more design freedom. And you gain a growing range of engineering-grade material options. These can include materials reinforced with carbon fiber or even metal.

Instead of being a technology to tweak and adjust, these 3D printers focus on easy use and adoption. They become one tool among many in an engineer's or designer's toolbox – giving a growing number of businesses a new way to innovate. And that's why, at this price point, FFF 3D printing is at its most disruptive. The only way this can happen is for the 3D printer to work – and for it to work hard. Expect a factory-tested machine that you can leave running over the weekend and come back to a finished part on Monday morning. Plus, prints start being repeatable. For example, if you 3D print the same part on the same printer in two or more locations...the part quality should be almost identical. The user also has more flexibility. You can choose to print with a build material and a support material in the same print (called dual extrusion), offering more design freedom. And you gain a growing range of engineering-grade material options. These can include materials reinforced with carbon fiber or even metal.

Professional 3D printers are workhorse tools for an increasing number of engineers and designers

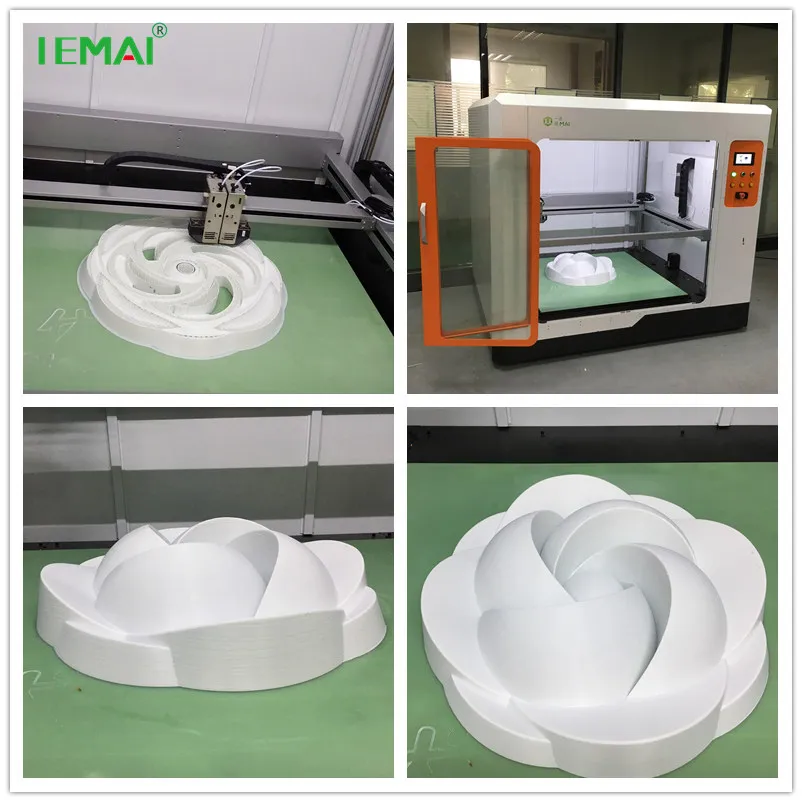

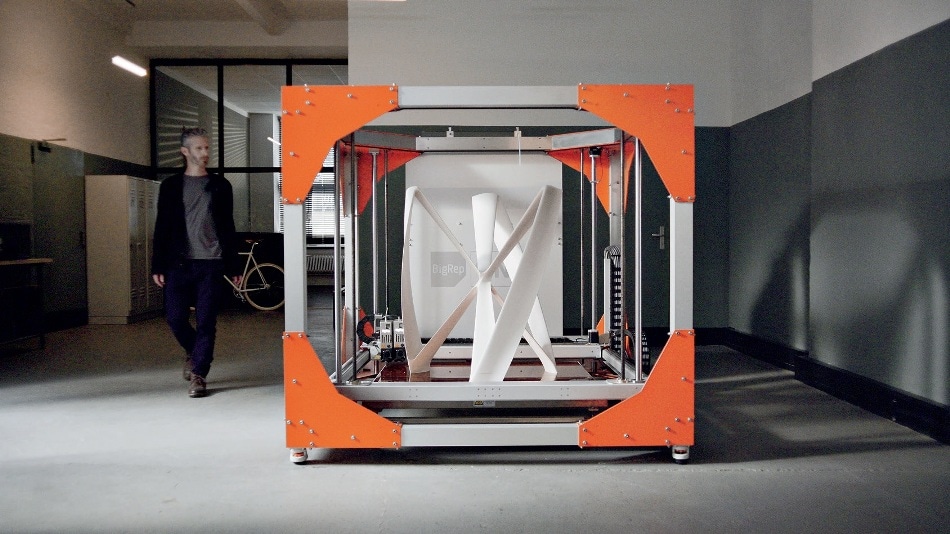

Industrial 3D printer price $10,000+

3D printers that cost tens or hundreds of thousands are made to do a few things at a high level of quality. This includes production technology for specific materials, like high-temperature polymers or metal. 3D printing these materials with a high success rate often requires you to stay within a manufacturer's material portfolio and software stack. If you are in the market for an enterprise-level machine, this will rarely be the first 3D printer your company buys. And you will know what's required to make the investment: a strong business case, competitor analysis, and a purchase order. You or your company may be happy to pay extra for increased speed, accuracy, and reliability. But also know that, the higher you go in this price bracket, the more you chase diminishing returns.

Is a 3D printer worth it?

These five price tiers cover the majority of 3D printers sold today.

If you consider 3D printing as a hobby, 3D printing successfully will largely be paid for with your time and patience. If 3D printing needs to be a tool for you, then you will pay extra for a user experience that saves time and attention.

But it's also in this second category where 3D printing offers significant business value. And the right 3D printer can end up paying for itself with substantial time and cost savings.

The total cost of 3D printing

Finding the best 3D printer for the price, then, is not only about the machine you buy. The picture is bigger than just the initial price tag.

It's also about the software, accessories, materials, and service that go with it. Together, these contribute to an easy-to-use, time and cost-saving 3D printing experience.

The Ultimaker platform creates a seamless flow between hardware, software, and materials

For example, every Ultimaker 3D printer works seamlessly with Ultimaker Cura, which is updated every few months. They also ship with a suite of free online tools and e-learning courses. Together these resources transform your ability to click-and-print with up to 239 materials.

They also ship with a suite of free online tools and e-learning courses. Together these resources transform your ability to click-and-print with up to 239 materials.

So it's no surprise that hundreds of leading companies – from Ford to L'Oréal – 3D print day and night with the Ultimaker platform to drive innovation and sustain their competitive advantage.

If you would like to do the same, click below to find out more.

Discover Ultimaker 3D printers

Industrial 3D ceramic printers

SLS-C ceramic 3D printer

SLS-C industrial 3D printer specifications for ceramics

| Model | SLS-250С | |

| CO2 laser, Power W | 55 | 100 |

| Scan speed | 5 m/s | 5 m/s |

| Print Layer Thickness | 0. | 0.06-0.15mm |

| Laser spot size | ≤0.4mm | ≤0.2mm |

| Print Accuracy | ±0.2mm | ±0.1mm |

| Print chamber size mm | 250*250*250 | |

| Powder supply | Two pistons on both sides | |

| Print material | Corundum, zirconium oxide, silicon carbide and other ceramic materials with the addition of a binder nanopowder. | |

| Operating system | Windows XP | |

| Software | HUST 3DP | |

| File Format | stl, layer thickness change, scanning. | |

| 3D printer dimensions mm | 1650*900*1800 | |

| Power supply | 3 phase, 4 lines with earth, 380V ±10%, 50Hz | |

| Working temperature | 18-25°C | |

| Operating Humidity | Not more than 60% | |

| Power input kW | 3 | four |

Catalog

Download >>> View >>>

Video

Related products

3D printer SLA-600

Industrial stereolithographic 3D printers SLA on photopolymer resin

Industrial 3D printers for metal printing using EBM technology

Equipment for the production of metal powders for 3D printers using induction vacuum melting and gas atomization

Industrial 3D printers for metal printing SLM

Industrial 3D Metal Printers LMD

Industrial 3D printers for printing sand in a resin shell for injection molds and polystyrene

Industrial 3D printers for printing with nylon (polyamide) and polypropylene powder

Auxiliary equipment for additive 3D manufacturing and prototyping

Industrial Metal 3D Printers

Technology | Benefits | Usage examples | Equipment selection

Metal 3D printing is rightfully considered one of the most promising technologies that can replace traditional production methods in the near future. metal 3D printers are already appearing today in industrial plants, construction sites, design offices and other industries.

metal 3D printers are already appearing today in industrial plants, construction sites, design offices and other industries.

Industrial metal 3D printers are the product of the most technologically sophisticated additive manufacturing line . Attempts to 3D print with metal were made in the early stages of 3D printing, and over the past decade have made a tremendous leap in this direction.

Technologies

With the advent of metal 3D printers , the hegemony of traditional technologies was somewhat shaken, but a decade ago, few believed in the possibility of printing, and few imagined that the question of a comprehensive replacement of technologies and means of creating products in metallurgical production would arise .

Today the situation has changed radically. The technology used in the best printers for 3D printing with metal has already proven its effectiveness.

Selective Laser Melting (SLM)

This technology allows you to create objects of any geometric shape from metal powder. The principle is based on the ability to create metal models by layer-by-layer melting of powders of various metals and alloys. Such materials include titanium, stainless and tool steels, chromium and alloys, as well as other raw materials.

Machines using SLM technology, such as SLM 280HL and Realizer SLM 250, allow you to create high-precision metal parts of any complexity and geometry directly from a digital model. This technology is excellent for manufacturing high-precision parts and assemblies of various designs. At the same time, 3D printers based on SLM technology provide a huge performance and cost advantage over traditional metal fabrication technologies.

Benefits of

Talking about the prospects of 3D printing with metal can take a long time, but initially it is worth considering in more detail what a modern metal 3D printer is like. Until two decades ago, mold casting was seen as the only cost-effective way to make 3D products. Years passed before the 3D metal printer appeared, able to compete with, and in the long term to replace traditional methods of metal production.

Until two decades ago, mold casting was seen as the only cost-effective way to make 3D products. Years passed before the 3D metal printer appeared, able to compete with, and in the long term to replace traditional methods of metal production.

So, what are the benefits of 3D printing with metal over conventional production methods?

1. More complex shapes and designs.

Additive technologies give you more design freedom. 3D printing is able to produce much more complex products than the longer standard process can offer. metal 3D printers can create components with pits, cavities, thin walls, and closed objects.

2. Low cost.

The 3D Printer's metal printing process does not require any additional tools. Therefore, it is easy to replace the complex and expensive processes of stamping, mold casting. This will not only reduce costs, but also free up funds for further development of the enterprise.

industrial metal 3D printers create products using less kW of energy and generating much less waste. It also reduces costs and eliminates the need to install environmentally friendly equipment.

3. Any combination of materials.

Metal printing technologies allow the use of any combination of powder materials for the needs of the automotive and aircraft industries, the space industry, as well as other types of production. Mixing of various materials based on titanium, nickel and aluminum, as well as various alloys, makes it possible to obtain new components and assemblies in terms of their thermal conductivity, electrical conductivity and other characteristics.

Application examples

Enhancement 9The 0242 industrial metal 3D printer has enabled these machines to replace entire sectors of traditional manufacturing.

For example, thanks to the SLM 500 HL 3D printer, NASA specialists successfully tested titanium nozzles for rocket engines, and a few weeks ago, Elon Musk, the head of the private space company SpaceX, presented the new Dragon v2 orbiter, which also uses engines with 3D printed parts.

08-0.2mm

08-0.2mm  3D visualization

3D visualization