Space marine 3d printer

Space Marine Stl - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 59 relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

Best Warhammer 40000 STL 3D Printing Files: Space Marine, Orks, Tanks

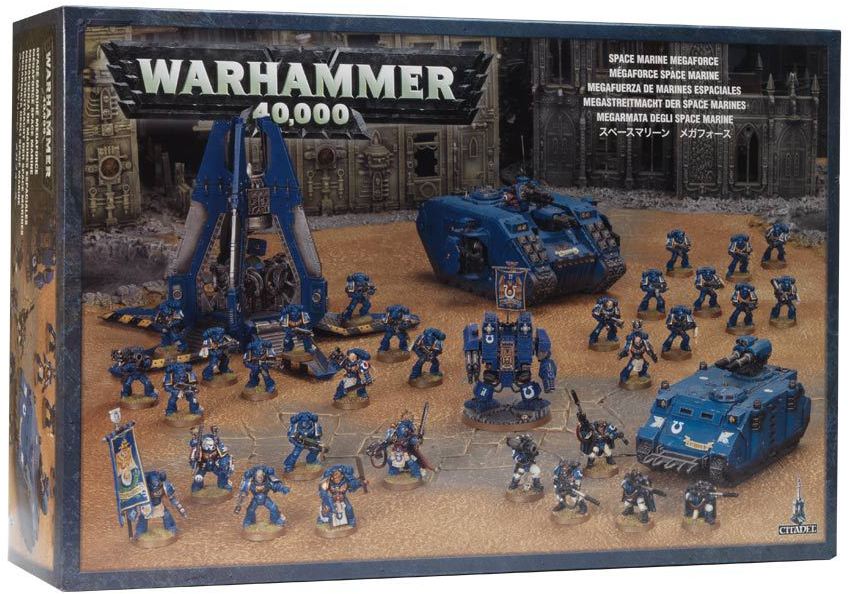

Who could think that a miniature wargame created in 1987 would gain the world’s fame and popularity? Well, today Warhammer 40K is one of the most successful games across the globe with millions of fans in Great Britain, USA and other countries. Thus, more and more people are in search of best Warhammer 40000 STL 3D printing files to download and craft at home.

Making miniature models of Space Marine, Ork, War Robot and other well-recognized characters from Warhammer 40K wargame is something rather affordable and merely awesome.

Warhammer 40000 STL 3D Printing Files

The market offers a wide variety of gaming models for Warhammer 40K. But these are mostly some parts-to-assemble. Thus, many fans choose to find high-quality Warhammer 40K STL file of their favourite character to make a unique figurine for the game.

You will find some fantastic Warhammer 40000 STL 3D printing files at Gambody. This premium 3D printing marketplace shares great models of Space Marine, tanks, helicopter and other projects designed by fans of the wargame.

16 Must-Make Warhammer 40K STL Models

Vehicles and warriors have their capabilities, which can be learned in the game rulebooks. Many of the original miniatures are only 4-6 inches, but some are way bigger. With Warhammer 40000 STL 3D printing files, it is possible to scale any project to your desired size.

With Warhammer 40000 STL 3D printing files, it is possible to scale any project to your desired size.

It is fun to play with size because this wargame is recommended to be played on a table of 1.2 meters (4 feet) wide. You can construct your custom field to fit all your 3D printed miniatures, figurines and vehicles. If you love video games more than a tabletop game, you can still 3D print great characters and vehicles to display in your collection.

Anyways, Gambody selected the sixteen most impressive models you can start building right away.

1. Warhammer 40k Space Marine STL

Space marine is not just a military man who can perform multiple-purpose roles in science fiction games. It is a separate Warhammer 40000 Space Marine game, which can influence your decision to 3D print more soldiers for your wargame.

These superhumans defence humanity. Knowing no fear, they can fight again and again. They suffer no pain even when wounded. You see how vital Warhammer 40K Space Marine character is in the wargame universe.

But not all space marines are loyal to the Emperor of Mankind. A Chaos Space Marine used to be a great soldier, but one day he chose to dedicate himself to Chaos. And Chaos Space Marine character STL 3D printing files can be downloaded at Gambody – Premium 3D printing marketplace.

Noah J. stands behind this design. The armour and skulls on Chaos suit send chills down the spine. When you look at this model, you understand that it serves the Dark Gods.

2. Warhammer 40K Robot

Who is more powerful than a single warrior? Of course, war robots are. These characters wear suits with armour. Their both arms are turned into weapons. The machine soul is willing to fight and will never give in.

Adding an army of Warhammer 40K robots to your collection or tabletop game is a smart idea. They can help you protect your warriors from enemies and the Dark Gods.

Maker: John NixonJimmy Adam did a great job of designing a fantastic robot TAU XV109 Y’Vahra in a battle suit. This robot is believed to have quick reactions (in video games), and it looks stunning if painted.

This robot is believed to have quick reactions (in video games), and it looks stunning if painted.

Read also: Stunning Aquarium Decorations 3D Printed by Gambody Enthusiast Thomas Hlinka

3. Warhammer 40K Predator Tank

Battle tanks play a vital role in any wargame. If you have 3D printed space marines, you will most likely enjoy creating the Predator Destructor or Predator tank for them to employ.

This most common battle tank used in the popular wargame looks excellent as a 3D print. It has many great details, including laser cannons (blazooga) and heavy bolters.

Maker: Vaderciya (Thingiverse)According to Vaderciya, who designed and shared Warhammer 40000 Predator tank STL 3D printing files, it can take about 2-3 days to build this project.

4. Warhammer 40000 Space Marine Dreadnought

A professional war field requires using not only warriors but also building towers, bringing towering machines and heavy armour suits. Dreadnought is such a project.

This towering power armour can burn everything around it into ashes. In the game, it requires a warrior or other person to control it. Without a pilot, this Dreadnought is useless unless you 3D print it for your collection.

Maker: Bullets IeThe designer of Chaos character, Noah J., also designed an impressive version of Dreadnought. You can download this Warhammer 40K Dreadnought STL files and made a fantastic model.

5. Warhammer 40K Flyer & Base

Gamers who are fond of Warhammer 40000 wargame use warriors, tanks and flying vehicles.

Adding a flyer to your collection is a must. But it might not be enough to get Flyer STL files.

Makers: Vontragg; Sidequest_TTM (Thingiverse)Sometimes, it is also necessary to find 3D printing files of a flight base. Such bases can be scaled to fit all flyers from your collection.

6. Vulcan Tank Warhammer 40000

An army needs tanks to stand against the enemies. Fans of video and tabletop games who choose to 3D print an army of warriors and space marines might also like to add vehicles to their collection.

Vulcan tank is a brilliant project that can bring reality to your fantasy playtime. It is not huge unless you want to scale its STL files. It has many impressive details, and it is relatively easy to assemble.

Makers: Nate Worth and Daniel Velarde KübberJamy designed an outstanding tank for the famous tabletop game. Will you download Vulcan Tank STL files and add this model to your collection?

7. Warhammer 40k Space Marine Chaplain

Space marines need a leader, and their spiritual leader is Chaplain. This character always supports his brothers-warriors. So, the model will look impressive on your shelf alongside other 3D printed models.

Ale_x_x_x created a beautiful model of Chaplain. This warrior wears impressive armour with many great details. The character boasts fierce looks and has no mercy for enemies. He loves the war.

Maker: Nate WorthYou can download Warhammer Chaplain STL files. This 3D printing model can turn into a unique figurine.

8.

Warhammer 40K Helicopter Valkyrie Vendetta

Warhammer 40K Helicopter Valkyrie Vendetta Real fans of the game know that orks love to use deffkoptas as their primary aircraft. But this is not the only type of helicopters you can meet while playing Warhammer 40000.

Jimmy Adam came up with a brilliant idea to design a Valkyrie helicopter model. This heavy gunship can take part in the most dangerous missions. It can land and take off vertically, and it has many beautiful details to paint.

It is time to download Warhammer Valkyrie Vendetta helicopter STL files to equip your army of figurines with new weaponry.

9. Warhammer 40K Army

Be it a tabletop game round or video games; your wargame requires an army.

You can display an impressive gun squad on a shelf or use it in the scenery.

Maker: tehrazorback (CGTrader)There are Warhammer 40000 army STL 3D printing files to download and turn into stunning armed figurines.

10. Warhammer 40K Flamethrower Tank

War video games create fantastic arsenals for gamers. You can find a stunning Flamethrower tank among Warhammer 40000 STL 3D printing files on Gambody.

You can find a stunning Flamethrower tank among Warhammer 40000 STL 3D printing files on Gambody.

Jamy designed this model of Malcador Infernus. While this vehicle appeared only as of the second-line armed forces, the Imperial warriors still used it in battles.

Maker: John NixonThe second name of Malcador Infernus is the Flame Assault Tank or Flamethrower. It comes with a fuel trailer. Still, this 3D printed model will not explode all of a sudden as it can happen in the video game.

11. Warhammer 40K Scenery 3D Print

Recreation of your favourite scenes from the wargame takes many hours, patience and passion for what you are doing.

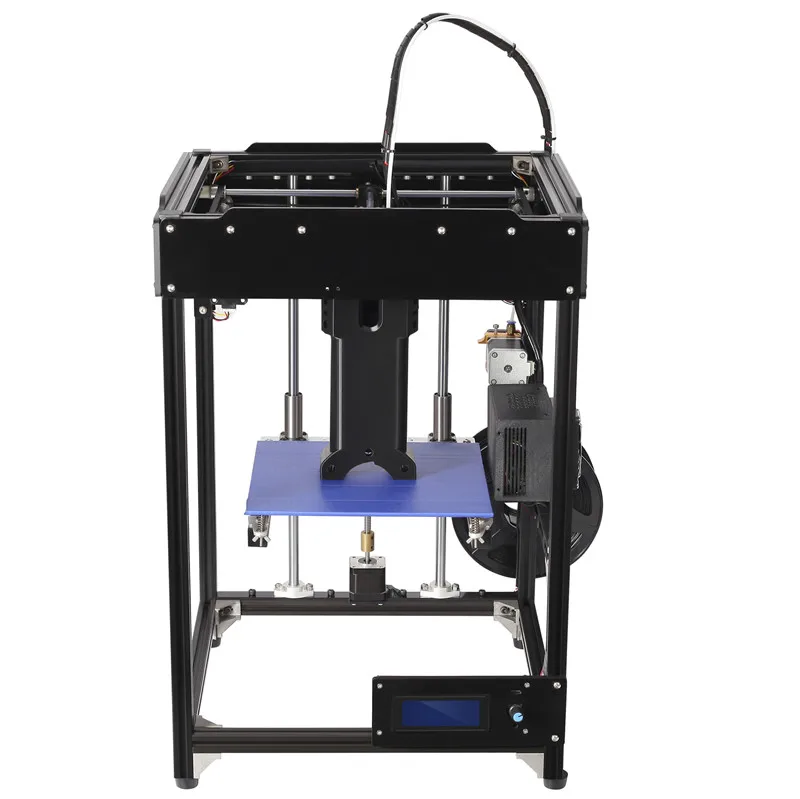

With an affordable 3D printer for beginners or advanced users, it is possible to make fantastic scenery for Warhammer 40000 tabletop wargame or photo zone.

You can build houses, bunkers, towers, fortresses, walls, defence gun, etc.

Here are some stunning ideas of what can be crafted at home:

Source: Thingiverse12.

Chaos Space Marine Mask

Chaos Space Marine Mask Masks can be a part of Halloween, Christmas, New Year or cosplay costume. They can also become your personality while playing your favourite computer or tabletop game. For example, when you gather with your friends or connect online to the server of Warhammer 40K, you can put on a 3D printed Chaos space marine mask and pretend to be this character.

The designer of this mask is Drake Crude. The model is the reflection of the Chaos’ fury and rage. It might help you to take essential decisions during game battles.

It is simple to print and requires minimum supports. Download the Chaos mask STL 3D printing files and create a stunning wearable accessory for your next gameplay.

13. Warhammer 40000 Killa Kans

Making an Orkish walker Killa Kan for your tabletop game is much fun. There are different designs of such 3D printing model, so you can choose whatever you like more.

Maker: ChrisFor example, look at this design of alternative Killacan offered by Chris. It requires some cleaning to remove all the supports after 3D printing it. But once you make it and paint it, the figurine should look great on your battlefield.

It requires some cleaning to remove all the supports after 3D printing it. But once you make it and paint it, the figurine should look great on your battlefield.

Here is the Killacan’s creation video:

14. Warhammer 40K Ork STL Files

It is time to add some Orks to your collection of 3D printed Warhammer 40000 figurines. Fans of the game designed multiple versions of these characters.

You can download a hulking boss of Orks STL 3D printing files to make a leader for your army. It is a unique combination of great Hulk and Grimgor orc from Orcs & Goblins. A neat idea from Polarcupz.

Maker: PolarcupzThere is also a useful guide on how to speed-paint Orks figurines from Chrispy. It can help to finish your collection of Ork warriors.

It can help to finish your collection of Ork warriors.

15. Warhammer 40000 Token STL 3D Printing Files

There is no need to worry if you cannot find the official wargame tokens for your collection. You can 3D print a token set for your personal needs or gameplay.

For example, it is simple to download Apocalypse tokens STL files. This project is fast to make. It prints without issues, and it will surely last longer than the official cardboard tokens if made with plastic.

Maker: Kallsu (Thingiverse)The collection looks impressive once printed and painted.

16. Warhammer 40K Primaris Aggressors & Movement Tray

With a 3D printer at home, it is possible to create just anything, including your own Primaris Aggressor Squad.

These space marines have limited weaponry. Still, they are fierce warriors who can quickly kill all the enemies once they get close. Primaris Aggressors are great at firing at the opponents and turning them into ash.

Download Warhammer 40000 Primaris Aggressors STL files and start making your squad. It is also simple to make a movement tray for your 3D printed wargame figurines.

These are some fantastic Warhammer 40000 STL 3D printing files you can use for your projects. Show your 3D printed models in Gambody Facebook community. It is an excellent place to search for ideas, share your painting tips, printing settings and photos of your crafts.

Read also: October Trending 3D Printing Models STL Files to Download

(Visited 66,104 times, 1 visits today)

Author

TPU engineers created the design of the first Russian 3D printer to work in space

1210

Bookmark

Tomsk Polytechnic University engineers have completed the development of the first Russian 3D printer for printing in zero gravity. The work was carried out by order of the Energia Rocket and Space Corporation named after S.P. Korolev (RKK Energia; part of the Roscosmos State Corporation) together with specialists from the corporation and Tomsk State University.

The work was carried out by order of the Energia Rocket and Space Corporation named after S.P. Korolev (RKK Energia; part of the Roscosmos State Corporation) together with specialists from the corporation and Tomsk State University.

Two flight models of the printer were handed over to the customer. According to Roscosmos, one of them will be sent to the International Space Station (ISS) in June 2022. With its help, Russian cosmonauts will be able to make the parts necessary to work with the station equipment. The second sample will remain on Earth.

The development of the printer with all the necessary steps took just over three years. The specialists of the Tomsk Polytechnic University were faced with the task of making an apparatus that would allow them to quickly and directly at the station create the small parts needed by astronauts so that they would not have to be delivered from Earth.

The main scientific and engineering challenge was that 3D printing in zero gravity is different from terrestrial conditions. When printing on Earth, gravity makes a significant contribution to the “gluing” of layers during the layer-by-layer formation of a part. The lack of gravity requires changes in both technology and printer design.

When printing on Earth, gravity makes a significant contribution to the “gluing” of layers during the layer-by-layer formation of a part. The lack of gravity requires changes in both technology and printer design.

The engineers of the Tomsk Polytechnic University had the entire design of the printer, the electronic “stuffing” was developed by the scientists of the Tomsk State University.

A 3D printer is about the size of a small analog TV. This is a block-modular design, all components of which are assembled in one housing.

Based on a given 3D model, the printer prints the desired object in layers from thermoplastic polymers. Parts made in this way are very strong, but at the same time light.

“Behind this work is the work of a large team of researchers and engineers from Tomsk Polytechnic University. It was a non-trivial task - to create a reliable lightweight device that works in conditions very different from those on earth, ”says the acting. Rector of TPU Dmitry Sednev .

“Software developed by TSU scientists and engineers for the first Russian space 3D printer will allow participants in space expeditions to reach a new level of performing tasks in space using additive technologies,” said the rector of TSU Eduard Galazhinsky .

The working chamber of the printer, in which the printing process takes place, is completely sealed. It is equipped with systems of thermal control, ventilation, circulation and air purification. This is important for removing the products of thermal decomposition of plastic from the atmosphere of the working chamber and ensuring the safety of the station crew. In conventional printers, such elements are not provided.

“The participation of Tomsk polytechnics in the project will not end with the development itself. In the future, we plan to participate in the training of astronauts in 3D printing, how to work with the device. And when the experiment takes place directly on board the ISS, it is planned that the polytechnics will participate in the processing of the results,” notes Dmitry Sednev .

Information and photos provided by the press service of Tomsk Polytechnic University

Posted by Natalya Safronova

3D printer Space TPU

Information provided by the Information Agency "Scientific Russia". Mass media registration certificate: IA No. ФС77-62580, issued Federal Service for Supervision of Communications, Information Technology and Mass Communications on July 31, 2015.

SCIENCE FOR CHILDREN

On the first day of the festival SCIENCE 0+, scientists gave lectures to schoolchildren in Moscow RAS 10/11/2022 – Live broadcast!

16:30 / Science and Society

Russian innovative test for diagnosing tuberculosis included in WHO recommendations

15:35 / Health, Medicine

The largest popular science exhibition in Russia will be held on October 8-9 in Moscow at the Expocenter

15:30 / Science and society

Swiss scientists have discovered a new function of the cerebellum

5:30 / Neurosciences

Miniature permanent magnets can be printed on a 3D printer

14:30 / Physics

Innovations in the system of state scientific attestation were discussed at the meeting of the HAC Advisory Committee

14:10 / Science and society, Education, Expert talk

Scientists have proven for the first time that the number of stem cells in the kidneys decreases with aging

13:30 / Biology, Medicine

MIPT scientists are close to solving the main problem of cryonics

12:30 / Physics

In memory of the great scientist. Science in the global world. "Obvious - incredible" broadcast 05/10/2008

Science in the global world. "Obvious - incredible" broadcast 05/10/2008

03/04/2019

In memory of the great scientist. Nanotechnologies. "Obvious - unbelievable" broadcast 08/3/2002

03/04/2019

Remembering Sergey Petrovich Kapitsa

02/14/2017

In space with your own printer

3D printing technologies are now increasingly used in industry, both for creating mock-ups and prototypes, and for finished products. The rocket and space industry is a rather conservative industry, and although the plastic printer has already made its way to the International Space Station, can 3D printing replace traditional ways of processing materials? We understand this issue together with NUST MISIS, a partner of this material.

On the ground

Rocket engine nozzles look very simple in appearance - most often as a metal hollow cone with smooth contours. However, they must withstand extremely high temperatures and pressures, so in many cases rocket engines use active cooling - fuel is continuously pumped through thin channels in the walls of the nozzle (which then enters the combustion chamber). Creating rocket nozzles with many thin channels in the walls, while maintaining mechanical strength, is a non-trivial production task that requires complex equipment and many processing steps.

However, they must withstand extremely high temperatures and pressures, so in many cases rocket engines use active cooling - fuel is continuously pumped through thin channels in the walls of the nozzle (which then enters the combustion chamber). Creating rocket nozzles with many thin channels in the walls, while maintaining mechanical strength, is a non-trivial production task that requires complex equipment and many processing steps.

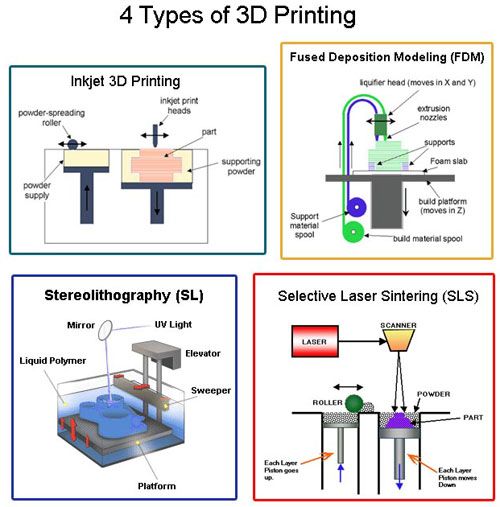

3D printing might be an ideal replacement for time-consuming manipulation, as it allows the creation of highly complex devices in just one operation. In 2015, NASA engineers decided to save taxpayers money by printing a full-scale rocket engine nozzle using selective laser sintering.

“Additive technologies give the space industry the same advantages as in other areas: it is simplicity, the ability to print products of any configuration. This is especially true for printing nozzles of rocket engines"

Alexander Gromov, professor at NUST MISIS,

project manager for the development of 3D printing technologies

Share

It took 10 days and 18 hours for NASA's Marshall Center Materials Processing Lab to print an engine nozzle out of a special copper alloy. In the process of work, they had to apply 8255 layers of copper powder. But the resulting nozzle could withstand temperatures of almost 3,000 degrees Celsius, since the cooling gas is pumped through the channels in its walls at a temperature of only 100 kelvins above absolute zero.

In the process of work, they had to apply 8255 layers of copper powder. But the resulting nozzle could withstand temperatures of almost 3,000 degrees Celsius, since the cooling gas is pumped through the channels in its walls at a temperature of only 100 kelvins above absolute zero.

NASA Printed Rocket Engine

NASA

Share

Not limited to printing, most recently, in March 2018, the Marshall Center conducted a fire test of an engine printed with improved technology that reduced production time.

While the state-owned space giants are just starting to experiment, "private traders" are already introducing additive technologies into mass production. RocketLab, a New Zealand-based company, uses 3D printing to make elements of the Rutherford rocket engine for the Electron launch vehicle.

The New Zealanders are printing a combustion chamber and a jacketed nozzle where propellant must circulate while the engine is running. The Rutherford engine was tested first on the stand, then during the space launch. The first rocket launch failed due to a failure in the communications system, and the second, in January 2018, was successful.

However, by the standards of large rockets, the RocketLab engine can be considered a dwarf, it has a thrust of about 2.5 tons and a mass of about 25 kilograms. To put into orbit a payload of only 200 kilograms, the first stage of the Electron rocket requires nine of these engines.

Several 3D printed metal elements are used in the much more powerful Merlin engines on SpaceX's heavy Falcon 9 rocket. However, the key elements of this engine are manufactured using quite traditional methods - milling, injection molding, hot forming.

Metal 3D printing method

Alexey Solonin, Head of the Department of Metal Science of Non-Ferrous Metals, NUST MISiS, explains that while printing with plastic is technically quite simple - you just need to heat the plastic “ink” and you can print, then printing a metal product requires carefully prepared raw materials .

“Preparing materials for printing in this case can be quite difficult. First of all, the powder particles for metal printing should be approximately the same size, without much scatter. The particles themselves should be close to spherical in shape, the powder should have good flowability. The quality of the final product depends to a very large extent on these qualities of the powder,” he says.

The most common method of 3D metal printing, laser sintering, consists in pouring powder from a container layer by layer of particles with a size of 40-60 microns. “This layer must be very even, which is why it is so important that the particles are of the same size and shape,” says Solonin. Then the laser beam "draws" the contour of the product, and those particles that have fallen under the laser beam are fused. Then the next layer is poured, and so the part is formed in layers. In some cases, an electron beam may be used instead of a laser beam.

Then the laser beam "draws" the contour of the product, and those particles that have fallen under the laser beam are fused. Then the next layer is poured, and so the part is formed in layers. In some cases, an electron beam may be used instead of a laser beam.

Share

American startup Relativity Space has gone the furthest. Its founders intend to develop a fully 3D printed rocket. We are talking about the mass use of parts created using selective laser sintering technology using a specially designed 3D printer based on Kuka robotic arms. According to the authors of the project, they managed to reduce the total number of rocket parts from 100,000 to 1,000, but this is not the most exciting of their promises. Startups intend to create a fully autonomous rocket factory and promise to be the first to build a rocket on Mars in the future.

Startup Relativity Space intends to create a deserted rocket factory

Relativity Space

Share

So far, they have already developed the Aeon 3D printed engine and even tested it with the help of NASA experts.

In the field of satellite construction, there are still some experiments on the production of parts using additive technologies. In particular, by order of the European Space Agency, small parabolic antennas, solar array deployment mechanisms, elements of an imaging system, and the body of a small satellite of the CubeSat standard were built.

Three-dimensional printing in this case allows to reduce the weight of the device, reduces the total number of parts, opens up new possibilities in the design of parts based on topological optimization, allows you to replace wire loops with conductive threads stretched straight through the walls of the structure.

3D printed solar cell opening mechanism element

ESA

Share

3D printed satellite camera prototype

ESA

Share

3D printed satellite dish

ESA

Share

These products have not yet been launched into space, although it is possible that the results obtained will find application in future satellite platforms.

And in space

While the development of 3D printing is hindered by the conservatism of space technology manufacturers. Indeed, in order to start using a new structural element, it is necessary to conduct its multiple tests on Earth, then launch it into space and, based on the results, be convinced of the direct benefits that the novelty will provide compared to analogues of previous years. Therefore, for the time being, it seems easier for engineers to use already proven technologies and established production chains.

However, there are situations in which it is impossible to assemble the device we need from dozens of different components produced using dozens of different technologies in different parts of the country - for example, on board a space station. Therefore, relevant experiments are already being carried out - the ISS has its own 3D printer for printing with ABS plastic. With its help, astronauts successfully printed a ratchet key, confirming the fundamental possibility of creating new products right in orbit.

But the use of 3D printing will become almost inevitable for future interplanetary travelers who cannot afford to ask the Earth for the delivery of the necessary tool - simply because it will take several years to deliver the package to the addressee.

Private company Deep Space Industries, which intends to mine minerals on asteroids, in 2013 undertook the development of a 3D printer that can print metal in zero gravity. As a raw material, DSI intended to use the main material of which metal asteroids are composed - an iron-nickel alloy. However, today all references to this development have been removed from the DSI website.

Another company that has set its sights on asteroids, Planetary Resources, also sees a future in using space resources for orbital manufacturing. The company conducted an experiment and printed a small design in the earth's laboratory, using a metal meteorite crushed into powder as a material.

Dome imprinted with meteorite material

Planetary Resources

Share

The Russian company Anisoprint is developing a technology for 3D printing from composites, and considers the printing of composite elements of spacecraft in orbit as a possible area of its application. Another Russian startup, 3D Bioprinting Solutions, plans to conduct an experiment on the Russian segment of the ISS with biofabrication of body tissues. It is assumed that the conditions of microgravity will allow the formation of stable three-dimensional structures and full-fledged tissues and even organs that cannot be created in the conditions of Earth's gravity. While the experiment is being prepared on Earth, the launch is scheduled for October 2018.

On Earth, 3D printers can already handle not only small items, but also entire houses. Similar experience is proposed to be applied in the creation of extraterrestrial settlements or scientific bases. In the USA, Russia and other countries, developments and experiments are being carried out in this direction.

In the USA, Russia and other countries, developments and experiments are being carried out in this direction.

The European firm Foster and Partners, commissioned by ESA, carried out design work on the design of a lunar base printed from regolith. As a confirmation of the proposed technology, the company ordered the printing of one block of volcanic basalt using a D-Shape construction printer.

Professor Alexander Gromov notes that 3D printing will be in great demand in manned interplanetary expeditions, because with the help of this technology, anything can be made. "Difficulty only that there is no printer that would print everything from everything, or, in other words, from heterostructural and heterogeneous materials, that is, heterogeneous in structure and composition,” he says.

According to him, NUST MISIS is now a project to develop such a printer is being implemented.