Aura 3d ear scanner

Ear Impression Have Gone Digital with the AURA 3D Ear Scanner – guest post by Brian Fligor & Andrew McGrath

Taking an ear impression is perhaps the most common non-diagnostic procedure performed by audiologists, and is one of the first technical skills that students learn in audiology training programs. While common, taking ear impressions is also a very technically challenging and invasive procedure. The skills and techniques necessary for taking proper ear impressions take many years to develop, and even when performed by an experienced clinician, the patient can experience significant discomfort or, rarely, injury. Nevertheless, accurate ear impressions are vital to the successful fitting of any custom in-ear product, including hearing aids, earmolds, custom headphone sleeves, and noise protection earplugs.

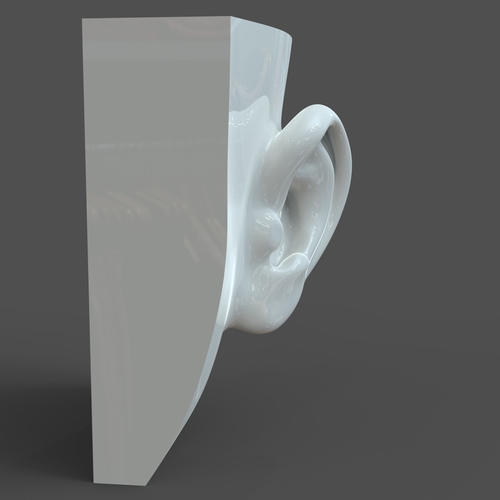

With the AURATM 3D Ear Scanner, Lantos Technologies is bringing the process of creating earmolds into the digital age. The first digital ear scanner of its kind (shown below), this device allows for quick, comfortable, and accurate digital impressions of the pinna and ear canal. The scanner captures the topology of the whole ear, from a complete concha to down the canal to within a few millimeters of the tympanic membrane. The AURATM 3D scanner provides a number of innovative and clinically relevant benefits that audiologists will appreciate. The AURATM 3D scanner consists of a hand-held scanner with retractable scope and proprietary LantosViewTM software. Housed within the scope is a high-resolution video camera with extremely wide field of view, allowing the scanner to also function as a high quality video otoscope, providing full visualization of the ear canal and the tympanic membrane.

When using the unit to obtain digital ear impressions, a small inflatable membrane is placed over the scope prior to insertion into the ear. The scope is placed into the ear canal in otoscope mode, which provides constant visualization of the ear canal and tympanic membrane, minimizing the risk of discomfort or injury, while allowing for precise placement of the scope into the ear canal. Once the scope is at the desired depth, the audiologist uses the scanner-mounted controls to inflate the membrane.

Once the scope is at the desired depth, the audiologist uses the scanner-mounted controls to inflate the membrane.

Housed within the scanner unit is a light-absorbing fluid medium, which flows into the membrane, inflating it gently but completely. As illustrated in the figure at the right, when inflated, the membrane conforms to the surface of the ear. Any hair in the ear canal is gently pushed out-of-the-way, as is modest amounts of cerumen, trapped between the ear canal wall and the external surface of the membrane. The scope, now within the inflated membrane and surrounded by the fluid medium, emits light which fluoresces the inside of the membrane. The LantosViewTM software compares the intensity of light in two different bandwidths to determine relative distances, which allows mapping of the surface of the ear with accuracy on the order of microns. This highly accurate digital image is stitched together in real-time, and is displayed in the user interface during scanning (click here for Lantos Technologies YouTube video). Once the scan is complete, the audiologist deflates the membrane and removes the scope from the patient’s ear.

Once the scan is complete, the audiologist deflates the membrane and removes the scope from the patient’s ear.

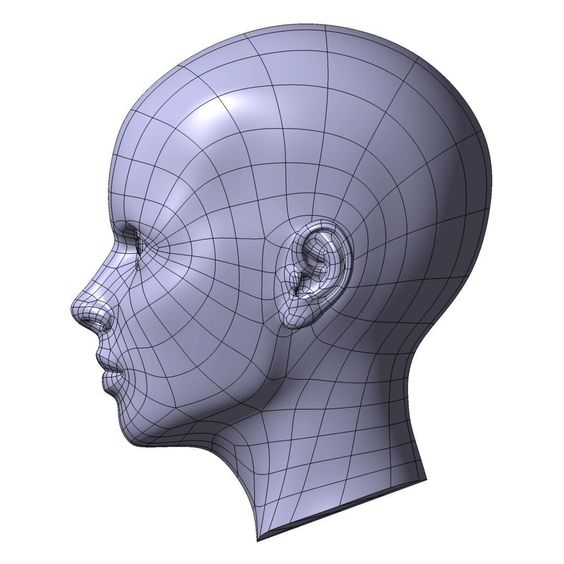

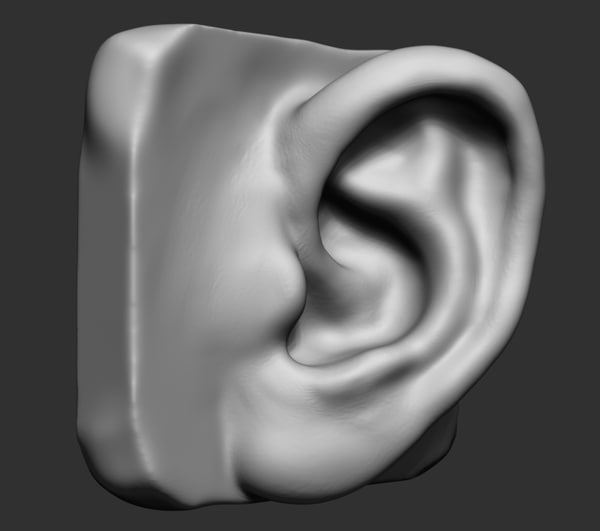

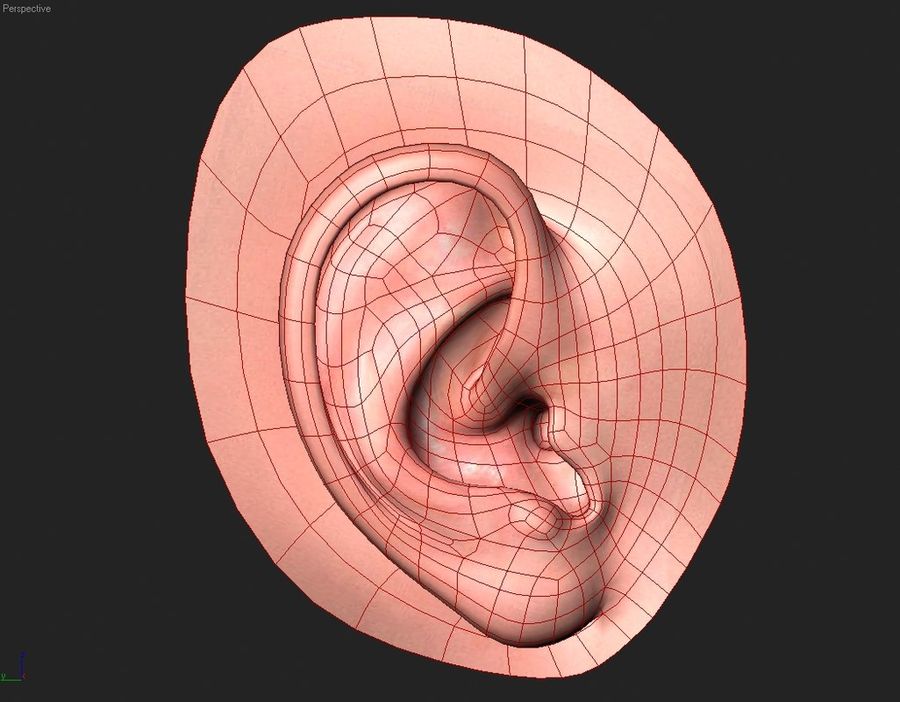

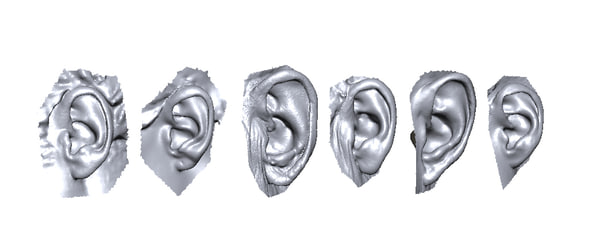

Once completed, the digital ear impression (shown left) is a three-dimensional representation of the external ear and ear canal, visible within the LantosView TM software. The file generated is an “.stl” file, a standard file format in the realm of high-resolution 3D printing. This impression can be manipulated, measured, and dissected for use as a clinical counseling tool. Hearing aid options that are available to the patient can be discussed in the context of the digital ear impression. Similarly, hearing aid styles that may not be an option for a particular patient, due to limitations in a specific individual’s ear anatomy, can be reviewed and the patient counseled with real data to support the audiologist’s recommendations.

As we know, the traditional process of obtaining an earmold impression is relatively time-consuming. Once the impression material is injected into the ear canal, it must be allowed to cure for five to ten minutes. In some patients, they tolerate both ears being impressed simultaneously; others find the experience of being completely “blocked up” off-putting and request the impressions be done sequentially. Often this results in considerable “down time” for the audiologist; for instance, very little communication can occur with the patient during this time. Once the impressions come out, they must be packaged and the hearing aid or earmold order form must be completed. The order form may need to be copied, and then is folded and placed inside the box with the impressions. The box is placed into a shipping bag, which also needs a shipping label, and then a package “pick-up” must be scheduled. If it is too late in the day, the pick-up may not occur until the next day. In a busy practice, this time-intensive procedure may be undertaken many times each day. The scanning procedure is similar in some ways to taking ear impressions, but without the discomfort often experienced by patients. Many audiologists will find that the skills they have developed in taking ear impressions translate easily to the ear scanning procedure.

In some patients, they tolerate both ears being impressed simultaneously; others find the experience of being completely “blocked up” off-putting and request the impressions be done sequentially. Often this results in considerable “down time” for the audiologist; for instance, very little communication can occur with the patient during this time. Once the impressions come out, they must be packaged and the hearing aid or earmold order form must be completed. The order form may need to be copied, and then is folded and placed inside the box with the impressions. The box is placed into a shipping bag, which also needs a shipping label, and then a package “pick-up” must be scheduled. If it is too late in the day, the pick-up may not occur until the next day. In a busy practice, this time-intensive procedure may be undertaken many times each day. The scanning procedure is similar in some ways to taking ear impressions, but without the discomfort often experienced by patients. Many audiologists will find that the skills they have developed in taking ear impressions translate easily to the ear scanning procedure. The scan takes about 45-60 seconds per ear.

The scan takes about 45-60 seconds per ear.

Digital ear scanning eliminates many of the time-consuming steps outlined above. The digital scan can be sent electronically to the hearing aid or earmold manufacturer, reaching them almost instantly, and possibly cut shipping costs in half. This can facilitate online ordering, and may be integrated directed into the manufacturers’ existing shell/earmold fabrication process.

Many audiologists remember the impact that digital signal processing had on the quality of hearing aid technology. The Lantos AURATM 3D Ear Scanner is the next generation of ear impressions. Ear impressions have gone digital, allowing for a more interactive patient experience and a more rapid transition from audiogram to hearing aid fitting. Visit Lantos Technologies at AudiologyNOW! March 26-28, 2014, at booth 1614 to see the AURATM 3D ear scanner in action!

Brian Fligor, Sc.D., is Chief Audiology Officer at Lantos Technologies, Inc. , Wakefield, MA. Prior to joining Lantos, Dr. Fligor was Director of Diagnostic Audiology at Boston Children’s Hospital and Assistant Professor at Harvard Medical School. He is adjunct faculty at Northeastern University and Salus University, a member of the Children’s Oncology Group, and founder and past-chair of the Music-Induced Hearing Disorders Taskforce for the National Hearing Conservation Association. He was a member of the Board of Directors of the American Academy of Audiology 2009-2012. Dr. Fligor’s publications on hearing loss risk from music received considerable popular media attention, including being spoofed on the David Letterman Show in 2005. His publications on ototoxicity have helped shape the JCIH Position Statement (2007) and helped shape a new unified international chemotherapy ototoxicity grading scale. He holds a B.S. in Biomedical Engineering and Sc.D. in Audiology from Boston University.

, Wakefield, MA. Prior to joining Lantos, Dr. Fligor was Director of Diagnostic Audiology at Boston Children’s Hospital and Assistant Professor at Harvard Medical School. He is adjunct faculty at Northeastern University and Salus University, a member of the Children’s Oncology Group, and founder and past-chair of the Music-Induced Hearing Disorders Taskforce for the National Hearing Conservation Association. He was a member of the Board of Directors of the American Academy of Audiology 2009-2012. Dr. Fligor’s publications on hearing loss risk from music received considerable popular media attention, including being spoofed on the David Letterman Show in 2005. His publications on ototoxicity have helped shape the JCIH Position Statement (2007) and helped shape a new unified international chemotherapy ototoxicity grading scale. He holds a B.S. in Biomedical Engineering and Sc.D. in Audiology from Boston University.

Andrew P. McGrath, Au.D., is the Global Training Manager at Lantos Technologies, Inc. Prior to joining Lantos, Dr. McGrath was the Director of the Department of Audiology at Women & Infants Hospital in Providence, RI. He has held faculty appointments at the Yale University School of Medicine, the Brown University Alpert Medical School, and the University of Rhode Island. Dr. McGrath has extensive experience working both in private audiology practice and in hospital-based audiology practices, with expertise in electrophysiology, vestibular disorders, pediatric audiology, and adult and pediatric amplification.

Prior to joining Lantos, Dr. McGrath was the Director of the Department of Audiology at Women & Infants Hospital in Providence, RI. He has held faculty appointments at the Yale University School of Medicine, the Brown University Alpert Medical School, and the University of Rhode Island. Dr. McGrath has extensive experience working both in private audiology practice and in hospital-based audiology practices, with expertise in electrophysiology, vestibular disorders, pediatric audiology, and adult and pediatric amplification.

Like this:

Like Loading...

This entry was posted in Audiology, Guest Blog Posts, Hearing Instrument Technology, Impression Material and tagged Andrew McGrath, Audiology, Aura 3D Ear Scanner, Brian Fligor, digital ear impressions, ear mold impressions, hearing aids, Lantos Technologies. Bookmark the permalink.

Lantos Technologies

-

Deliver the experience patients prefer with Lantos 3D Ear Scanning.

It’s time to elevate your standard of patient care.

Lantos helps your practice increase profitability and patient retention with cutting-edge scanning technology. Grow your practice and provide your patients with the best solutions for their hearing care.

Learn How

-

Lantos hearing care technology was created & developed at MIT.

Our scanners are backed by more than 30 patents and use the most advanced camera systems to capture over 1 million data points with each scan.

Every patient deserves the highest quality and most accurate, personalized experience when it comes to hearing health care. At Lantos, know that hearing solutions are not one size fits all.

Find a Scanner

-

Single-use, biocompatible membranes create an optimal experience.

Make traditional silicone earmold impressions a thing of the past.

Lantos 3D scanners use advanced, proprietary membrane technology that offers a comfortable and safe experience for your patients and providers.

Find out More

Bring 3D ear scanning into your practice to provide custom solutions for your patients.

Request a Free Consultation

How It WorksThe Lantos 3D Ear Scanning System uses patented technology to map the unique geometry of the ear. The Lantos membrane, which protects the camera and the patient’s ear canal, is placed into the ear where it gently inflates and conforms to the curves of the ear. This controlled environment inside of the membrane, free of wax and debris, facilitates the accurate capture of over one million data points. The single-use membrane ensures maximum safety and hygiene while delivering a deep, precise ear scan that can be used to make any custom-fit earpiece product.

Download Hearing Review Article

Membrane-based technology

1,000,000+ data points per ear

Developed at MIT

FDA 510K cleared

Protected by 70+ patents

Digital workflow efficiency and speed

Better Experiences, Better Outcomes

Lantos scanners generate accurate ear scans without the risk or discomfort of an old-fashioned silicone earmold impression.

Our software enables you to deliver products quickly and seamlessly through a complete digital workflow, from scanning to ordering.

The Lantos Cloud stores your patient scans so that you can order additional custom products without an additional office visit.

Hear what providers have to say about Lantos:“Our vision is that every patient gets a digital ear scan at intake, as part of the customized process and experience that they have with our practice. As a clinician, one of the benefits of Lantos scanning is that it really enhances the patient experience.”

Lindsay Carrick, AuD.

ENT Hearing Associates of Florida

Find a Scanner

3D scanner activates production of customized headphones

Problem

Today's fashionistas demand unique, bespoke items such as bespoke and one-of-a-kind pieces of clothing, personalized jewelry, and so on. So it's the turn of headphones to join the ranks of custom-made personalized accessories! D ears is the latest star in China's leading headphone supplier market, fully dedicated to designing and manufacturing custom personal headphones for high-end consumers. To create unique personalized headphones, you need to quickly and easily obtain accurate data on the shape of the ear canal of each client.

To create unique personalized headphones, you need to quickly and easily obtain accurate data on the shape of the ear canal of each client.

Solution

D ears wins hearts, minds and ears by offering customers customized earphones with SHINING 3D's EinScan-S 3D Scanner.

Our story begins when Zhenlong Ma and Jack, two design architects from Shanghai, noticed that 3D printed designs were appearing on architectural websites. Gradually, Zhenlong Ma had the idea to invest in a new commercial activity. He reflected: “After work or on the weekends, I will be attending 3D printing workshops with my partner Jack. We will gain a basic understanding of the possibilities offered by this new technology.”

“We found in the workshops that most of the other participants were material or mechanical engineers, programmers or salespeople. They focused entirely on material selection, equipment selection and 3D printing services, but no one paid attention to the design aspect of 3D printing. ” After much deliberation, Zhenlong and Jack approved their business plan and left the construction industry to start a new business, Hex Design Studio, now known as D ears.

” After much deliberation, Zhenlong and Jack approved their business plan and left the construction industry to start a new business, Hex Design Studio, now known as D ears.

In the course of business planning, Zhenlong and Jack thought long and hard about the possibilities for future business activities. They knew that 3D printing technology had a significant impact on many traditional areas of production, such as clothing and food. Both designers have greatly improved their modeling capabilities, already having CAD expertise from previous experience in the construction industry. Therefore, based on his know-how and in order to gain a competitive edge, Zhenlong decided to build a business on the design of customized headphones and jewelry.

Result

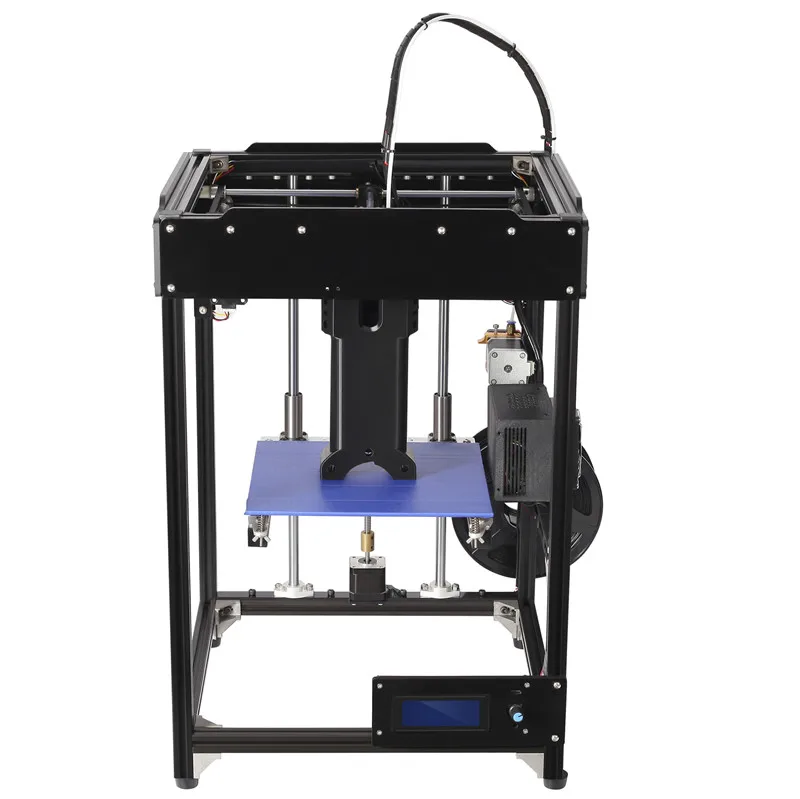

Zhenlong and Jack decided to focus entirely on the design and manufacture of custom-made headphones using 3D additive manufacturing technology. They chose the EinScan-S 3D Scanner for personalized, accurate 3D models of human ears and created each individual Hear Infinite headphone based on the unique models they received.

Up to now, their products have been successfully supported financially and socially on JD.com (China's largest online retail business-to-customer website), and they have won silver medals in First China's 3D Printing Ideal Contest.

D ears is now a dynamic and thriving business with a reputation as a leading supplier of luxurious, personalized headphones. SHINING 3D is proud to have contributed to the development of a new business venture where a creative idea becomes a reality through 3D scanning and printing.

【Manufacturing Process】

Principle: Use a 3D scanner to scan a pre-created ear print to create an accurate model of the headphone surface shape. This process ensures a perfectly matched fit for the 3D headphones.

Product:SHINING 3D EinScan-S 3D Scanner

The first step is to obtain an accurate impression of the ear canal in sterile clean conditions.

After removing and hardening the ear impression, we obtain the general shape. After a little processing and polishing, we get an exact original 3D implant.

After a little processing and polishing, we get an exact original 3D implant.

We then use the EinScan-S desktop 3D scanner to capture the finished shape. All we have to do is point and click, and then the scanning process turns the actual ear canal impressions into 3D digital models on our computer. Our EinScan-S has been designed to collect accurate 3D data so all of our digital models are 3D printable without the need for additional editing or optimization.

EinScan-S is equipped with both auto and free scan modes, and we can easily switch from one mode to another. To create ear implants, we use a turntable scan that takes less than 3 minutes. This is 3-4 times faster than the scan time of any other competitive 3D scanner, which really increases our design productivity.

Occasionally we use a simulation program to make small adjustments to the model.

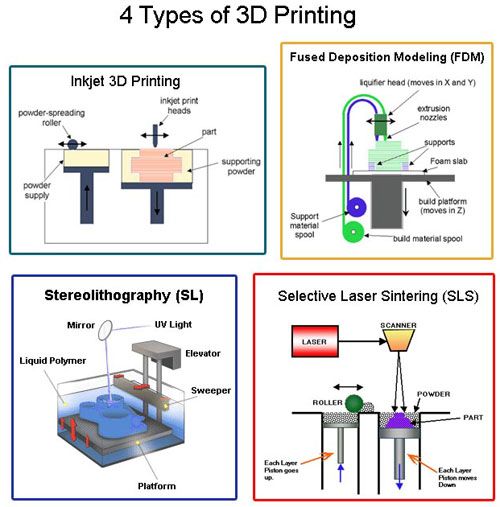

The next step is to 3D print the finished digital model using photosensitive resin.

Finishing steps require manual drilling and bordering. After installation, the headphones are thoroughly tested for quality and sound frequency. Many Hear Infinite headphones are fully customizable for artistic applications such as spray toning, hand painting, diamond embellishment, and more. Package your pre-made headphones in an elegantly engraved box and you'll receive… custom-made Hear Infinite headphones, ready to give you a lifetime of exquisite listening pleasure!

D·ears uses the full range of 3D scanning, modeling and printing to create a compelling concept for a personalized consumer culture. SHINING 3D is proud that through its limitless technology, people develop their creativity to achieve their dreams.

SHINING 3D Team

Email:[email protected]

Tel:+86-571-82999050

Facebook: www.facebook.com/shining3d

Twitter: www.twitter.com/shining3d

Company: www.shining3d.com

Peel 3D 3D Scanner

Powerful tool for high-quality digitization of the human body

Order a test scan

- Branches

- Scanning step by step

- 3D Model Examples

- Hardware and software

- Where to buy?

3D human scan with peel 3D scanner

- Quickly and accurately capture individual color images of the body, taking into account all the features of the figure and texture of clothing

- Efficiently create 3D models of a full-length human or individual body parts for implants in medicine, fashion design, entertainment, fashion, and 3D printing of souvenirs and advertising layouts

- Refinement of the 3D model in the built-in software, easy removal / addition of individual elements for further printing of the object

If you need to perform a human scan, you can order it from our specialists.

Applications

Medicine

- creation of individual prostheses, orthoses, surgical templates, implants

- visualization and modeling of the result of transplantation, prosthetics and plastic surgery

Souvenirs

- making figurines of real people for 3D printing

- manufacture of personalized accessories and jewelery

- digitization of mini-copies of real objects, sculptures, busts

Entertainment, fashion

- creation of digital models of real people for computer games and other programs

- 3D clothing modeling, sizing improvement

- using 3D models for trying on clothes on websites

Project examples

Scanning the human body

Human body (whole)

Man in winter clothes

Saint Alphonse Liguori

More cases in different industries

Test the scanner for free and see how it performs for your needs Test scan

Human body scanning guidelines

Do you want to test the 3D scanner?

Order a scan in our office or make an appointment

for an online demo.

3D Human Scanning Solutions

3D scanner peel 3d Scanning a person is fast, easy and safe!

The compact peel 2, peel 2 CAD, Go!SCAN 20 scanners are professional solutions for digitizing objects up to 3 m with an accuracy of 0.1 mm and the ability to capture texture and color.

Go to directory

Software Unleash your creativity with this powerful 3D modeling software!

The peel 3d software product allows you to solve all the main tasks when processing scanned data.

Go to catalog

Why is it profitable to order

solutions from iQB Technologies

Exclusive distributor of peel 3d in Russia

Professional

3D scanners at the price of budget counterparts

Free test

3D scan of your part

Demo hall in Moscow: more than 10 scanners and 3D printers

Services for the implementation, maintenance and repair of 3D equipment

Training in the use of 3D scanners in prof. activities

activities

3D scanning services based on our own fleet of equipment

About

Rules for 3D human scanning

For the greatest similarity of the resulting 3D copy with the original object and the successful implementation of the process of digitizing a human figure, several important rules must be observed.

By adhering to these recommendations, you can always achieve the highest quality and realistic results. Order a peel 3d scanner from iQB Technologies and you will be able to make a high-precision 3D model of yourself or any other person, and then print it using 3D printing.

All scanner models are in stock in our warehouse.

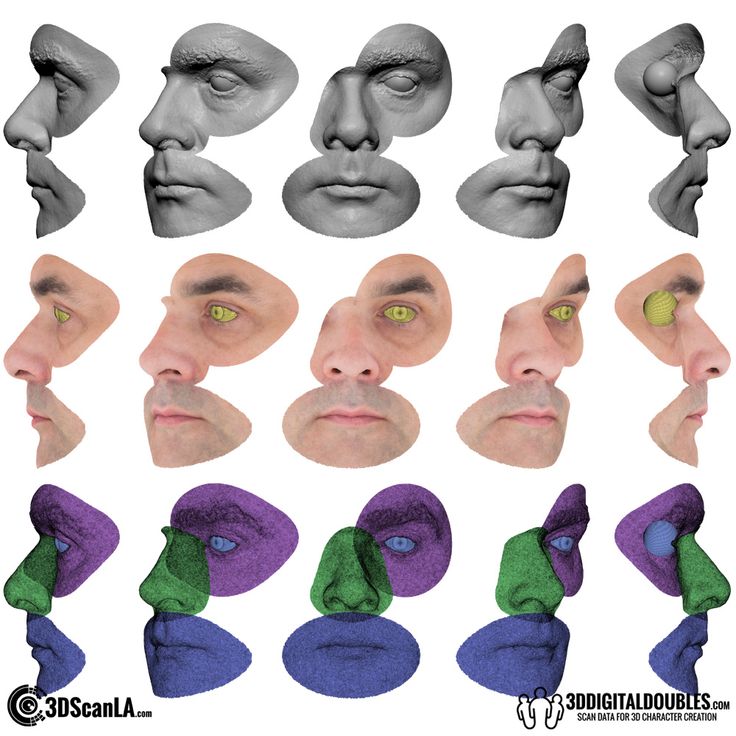

- Scan each body part once, especially when scanning a human face. If you scan the face several times in a row, the program will recreate the model as something in between all the received 3D scans.

As a result, you will get an option that is completely different from the original face of the person being scanned.

As a result, you will get an option that is completely different from the original face of the person being scanned. - In the process of work, the person being scanned must absolutely not move - otherwise, any movement, whether it be tilting, turning the head or stepping from foot to foot, can lead to image deformation. It is advisable to freeze in one position for a while and remain motionless until the very end of the procedure.

- If you want to create a figurine using 3D scanning, then you do not need to use additional light. To get a high-quality 3D figurine, LED flashes are enough.

- When using a turntable, its speed must be made as slow as possible. Thus, a 3D scan of a person will be much more accurate, and difficult places such as palms or ears will be much easier to scan.

The process of scanning a person with a 3D scanner

If you need to scan a person, you can order a scan of any part of the body from us at a bargain price.

The process of 3D scanning and modeling in software generally takes from 10 minutes to several hours.

The obtained data of 3D scanning of the human body is processed in specialized software: errors are corrected, problem areas are eliminated. The finished 3D model with an accurate texture and a clear rendering of the smallest details, if necessary, is sent for 3D printing. At the same time, a high-precision copy of a person can be obtained on a 3D printer, which in the future can become a memorable gift or souvenir. It is possible to scan with the transfer of the color of the object.

Also, the finished model can be used to create individual products that are ideally suited to the human figure.

It should be mentioned that 3D human scanning is completely safe, painless and does not harm the human body.

Scanner options

3D scanners for scanning a person are divided into:

-

Optical:

Optical 3D scanning technology uses a lamp flash designed to take measurements with the highest accuracy.

Projection distortions of the object are recorded by the scanner's video cameras, thereby allowing to determine the shape and dimensions of the scanned object, and then transferred to a specialized PC program for further processing.

Projection distortions of the object are recorded by the scanner's video cameras, thereby allowing to determine the shape and dimensions of the scanned object, and then transferred to a specialized PC program for further processing. Optical 3D scanners are fast, allowing you to scan people even in motion and in full growth.

Scanning a person with a 3D scanner using this technology takes from two minutes when using a special cell and up to 20 minutes when using a handheld scanner.

Most optical handheld devices are capable of color scanning and texture reproduction of the original model and various details, including jewelry and clothing.

-

Laser:

Traditional laser scanners, as a rule, are developed for the tasks of metrological measurements, and therefore require special reflective marks to be fixed on or near the object, the position of which is read by the device for precise positioning.

Learn more