3D scanner news

News - 3D Scan Expert

The latest news about Reality Capture, 3D Scanning & Photogrammetry Products

3 years agoBy Nick Lievendag • News

Back in 2016, Occipital’s Structure Sensor was the second 3D scanner I ever reviewed. I liked it a lot back then and am still recommending it to people that want …

Read More

By Nick Lievendag • News

It’s Formnext again, meaning lots of news about 3D printing. But like last year, there are also many 3D scanner manufacturers present at the annual trade show.

One of them …

Read More

By Nick Lievendag • News

As you can imagine, I always get excited when new 3D scanners are introduced but that especially true when manufacturers are trying new technologies to make scanning easier, faster or …

Read More

By Nick Lievendag • News

With only 3 days left on Indiegogo, the Wunder360 S1 has pledged over $350,000 — 1760% of its original crowdfunding goal. At first glance, it’s just another action camera but …

Read More

By Nick Lievendag • News

A while ago I wrote a post stating that The Future of Mobile 3D Scanning is Software but now is a good time to ease that statement a bit. It’s no …

Read More

By Nick Lievendag • News

At the F8 developer’s conference this week, Facebook made multiple announcements around VR and 3D. And this year they’re also starting to focus on 3D capture which means they finally …

Read More

By Nick Lievendag • News

At Facebook’s annual F8 conference, the company revealed two new features that use 3D capture technology: 3D Photos and 3D Memories. In this post I’ll take a look at 3D …

Read More

By Nick Lievendag • News

I can think of quite a few professional use cases for a sensor like that but I’m quite certain not many consumers are going to pay $499 to make 3D …

Read More

By Nick Lievendag • News

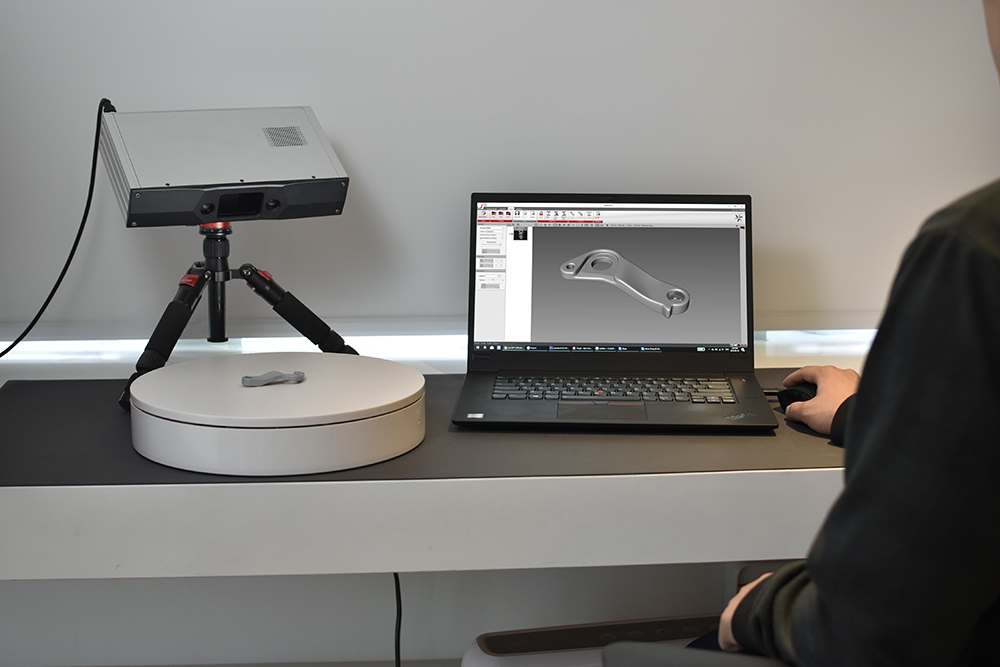

I have reviewed many desktop 3D scanners and I specifically like them in combination with a turntable. Being able to automate high-quality 3D scanning of small to medium objects is simply a time saver. But until now that automation has always been just partial since most objects require multiple scans from different height angles. That requires the operator to manually rotate the object or adjust the height of the scan head by using a tripod.

Being able to automate high-quality 3D scanning of small to medium objects is simply a time saver. But until now that automation has always been just partial since most objects require multiple scans from different height angles. That requires the operator to manually rotate the object or adjust the height of the scan head by using a tripod.

There are already solutions for completely automating object scanning but they’re usually a combination of an industrial grade handheld scanner (like the $19k Artec Space Spider) on an industrial grade robotic arm. That’s awesome technology but many companies don’t have the budget for either the scanner or the robotic arm.

On the other end of the spectrum there’s the $469 Matter and Form desktop 3D scanner — crowdfunded back in 2013 — but that device can only move the scanning head upwards and has a very small turntable so the use cases for professionals are limited.

A new 3D desktop scanner on KickStarter, named the D3D-s, aims to resolve this by borrowing some ideas from 3D printers. It puts a rotatable scanner head with high-resolution (5 megapixel) camera on rails that can move along 3 axis and also comes with a large turntable.

It puts a rotatable scanner head with high-resolution (5 megapixel) camera on rails that can move along 3 axis and also comes with a large turntable.

Read More

5 years agoBy Nick Lievendag • News

While Sony just released a new smartphone at MWC to accompany the few Xperia phones that can be used exclusively with its real time photogrammetry app 3D Creator, Qlone just started …

Read More

3D Scanning News | Artec 3D scanners

Luxembourg film star Sophie Mousel scanned with Artec Leo and Space Spider to create exquisite visual effects

Luxembourg-based 3D scanning company Artec 3D collaborates with Sophie Mousel and Wady Films to build sophisticated CGI effects for new film Restless, which will be released end 2023.

On scanning a helicopter: Artec 3D featured on RTL news

Luxembourg-based news outlet RTL interviews Artec 3D CEO Art Yukhin on creating a full-scale 3D model of a helicopter with Artec 3D scanners.

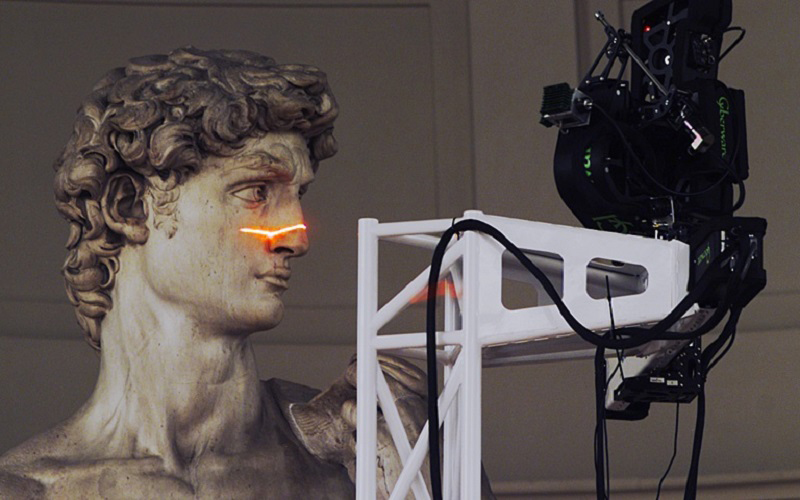

Artec 3D CEO Art Yukhin talks to BBC Click about preserving Ukrainian cultural heritage

As the humanitarian crisis persists in Ukraine, Artec 3D continues to provide support for those affected. One major way: using Artec 3D technology to digitally preserve treasured cultural heritage.

Artec Studio 17.1 is here!

Find out what’s new in Artec Studio 17.1, a not-so-minor update to a powerful software solution whose CAD, metrology, and inspection functionality is expanded with every new release.

Artec 3D launches Metrology Kit, enabling up to 2 microns accuracy for inspection and deformation analysis in aerospace, automotive, and oil and gas industries

SANTA CLARA, Calif. , October 3, 2022 – Artec 3D, a world-renowned developer and manufacturer of professional 3D hardware and software, today announces the release of the Artec Metrology Kit, a 3D optical coordinate

, October 3, 2022 – Artec 3D, a world-renowned developer and manufacturer of professional 3D hardware and software, today announces the release of the Artec Metrology Kit, a 3D optical coordinate

Artec 3D announces collaboration with the Human Rights Conduct Department of the National Police of Ukraine

Using their position as a global leader in the 3D scanning industry, Artec is ready to provide high-end solutions that would facilitate forensic documentation of evidence of war crimes, crimes against humanity, and genocide committed throughout the territory of Ukraine.

How Artec 3D is actively supporting Ukraine

From the very beginning of the war in Ukraine, Artec 3D has focused its global operations on helping to support the people of Ukraine, to meet their immediate and most urgent needs.

On the air: How Luxembourg’s Artec 3D & Ukraine’s KODA are supplying Ukraine with 3D scanners & software, and more

In an interview with Luxembourg’s RTL radio, Artec 3D president and the company’s Ukrainian partner spotlight their ongoing relief efforts for Ukraine, encouraging other businesses to follow suit.

Winners of Artec 3D and Luxembourg University SHARP challenge announced at CVPR in New Orleans

Spearheading advancements in AI through a competition for data recovery and completion using 3D technology

Prime Minister of Montenegro and Artec 3D CEO agree to develop first IT hub on the Adriatic coast

Artec 3D, world-renowned developer and manufacturer of professional 3D scanners and software, will lead the development of an IT hub on the Adriatic coast.

Artec 3D launches Artec Studio 17, offering full inspection and reverse engineering workflows, as well as groundbreaking CGI features and UX updates

Artec 3D, a world-renowned developer and manufacturer of professional 3D scanners and software, today announces the release of Artec Studio 17 (AS17), the newest iteration of its award-winning 3D scanning software.

Artec 3D opens new office in Montenegro to attract more talent to its multinational team

Artec 3D, a world-renowned developer and manufacturer of professional 3D hardware and software, today announces the opening of a new European office located on the Adriatic coast in Montenegro, Bar, which will serve as a hub for research & development and marketing.

Artec 3D Announces 2022 Class of Gold Certified Ambassadors and Partners

Artec 3D, a world-renowned developer and manufacturer of professional 3D hardware and software, today announces its list of 2022 Gold Certified Ambassadors and Partners. The list is comprised of companies with exceptional knowledge of 3D scanning that have demonstrated world-class customer service.

Artec 3D partners with Scan the World to create 3D-printable ecosystem of museum artifacts

Being hosted on Google Arts & Culture, the digital collection will feature artifacts from museums across the world

Artec Studio 16 nominated in TCT Software Awards 2022

Our professional software for scanning and 3D data processing has been chosen as one of six finalists in the 2022 TCT Awards Software category.

Artec Eva and Artec Space Spider help restore confidence in breast cancer survivors

A prosthetics professional needed a way to create a custom-fit external breast prosthesis for post-mastectomy cancer patients, and to make it long lasting, lightweight, and comfortable.

Artec 3D launches the 2022 Artec Leo with twice the power and even greater precision

Upgraded multi-core processing and increased accuracy make the new Leo the most powerful and user-friendly wireless handheld 3D scanner yet.

3D scanning for traffic accident reconstruction: How Origin Forensics uses Artec Leo

Every time forensic accident reconstruction expert Jarrod Carter, Ph. D., steps up to a twisted wreck, he sees a book of stories waiting to be told...

D., steps up to a twisted wreck, he sees a book of stories waiting to be told...

Creating a one-of-a-kind prosthesis with Artec Eva and Geomagic Freeform

When a German prosthetics firm needed to create a unique lower-leg prosthesis for their patient, they understood that traditional tools and methods wouldn’t be up to the task, so they reached for their 3D scanner.

New Video: Introducing a new way to work, with Artec Cloud

Find out how Artec Cloud has taken the kinks out of the 3D data workflow and made it easier for teams to work faster, better, and, more importantly, to work together.

Items per page: 10203050

1 - 20 of 394 items

News 3D Blocks

When you buy a 3D scanner, you are sure to be faced with a variety of choices in the current market with dozens of different solutions. In our article, we will help you choose effective equipment and talk about common misconceptions that prevent you from making a choice.

In our article, we will help you choose effective equipment and talk about common misconceptions that prevent you from making a choice.

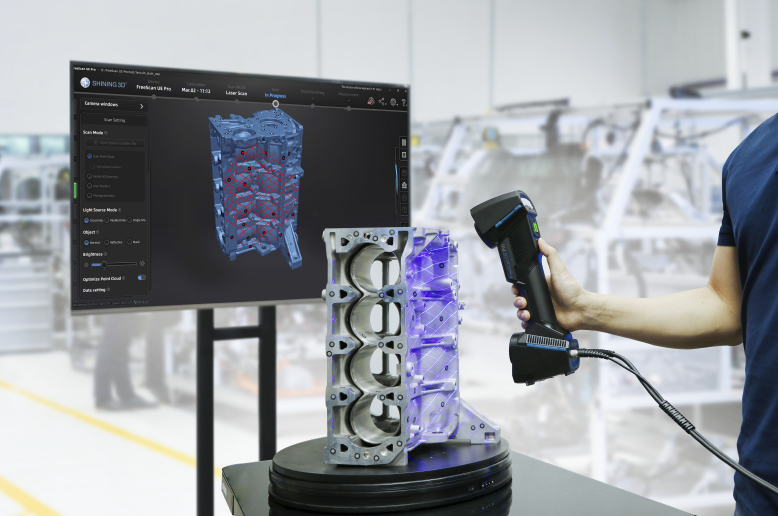

Today, 3D scanning plays an important role at the beginning and end of the production process, as well as during operation. Engineers, designers, developers, designers, and others use a 3D scanner to start creating a digital model of a part, relying on an already created part (reverse engineering), using bionic shapes, or digitizing complex curved surfaces.

After production, 3D scanning can be used to evaluate the accuracy of the resulting part by comparing the mathematical model of the part with the scan. During the operation of the part, a 3D study will help to assess wear and deformation, and make the right and timely decision to repair or replace the part.

Basic applications.

Reverse engineering - Solving the problems of digitizing originals. This is necessary if the drawings are lost, or some changes have been made to the part and it is necessary to take them into account in the part model. Possibility of industrial design, digitization of complex surfaces obtained by hand when finalizing the part in place. The main criteria are ease of use, accuracy and resolution. For such tasks, it is worth considering stationary solutions with an automated turntable. If your parts are up to 1 m in size, you want to automate the work as much as possible.

Possibility of industrial design, digitization of complex surfaces obtained by hand when finalizing the part in place. The main criteria are ease of use, accuracy and resolution. For such tasks, it is worth considering stationary solutions with an automated turntable. If your parts are up to 1 m in size, you want to automate the work as much as possible.

If the dimensions of your parts are from 10 centimeters to 12 meters, a handheld 3D scanner can serve as a good solution.

Geometry Inspection - Solving problems of optical non-destructive control of the geometry of a part immediately after production or during operation. Comparing a scan with a mathematical model, obtaining surface deviation values or checking given dimensions and tolerances for compliance.

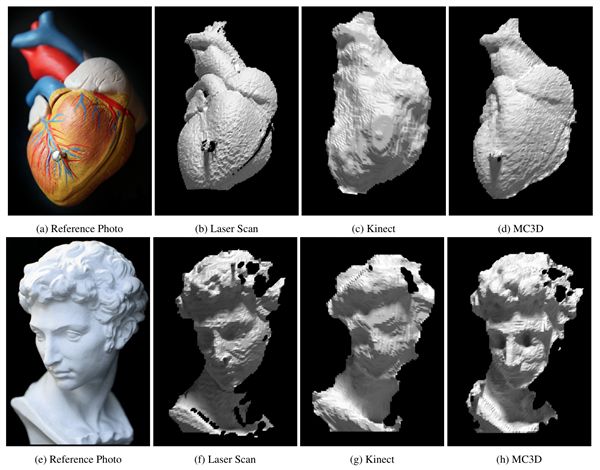

The main criteria - accuracy, resolution, ease of use. Historically, this area of problems was solved by stationary 3D scanners with structured light technology, but it was difficult to control large parts. Now there are mobile hand-held scanners that allow you to control parts with dimensions up to 12 meters./cdn.vox-cdn.com/uploads/chorus_asset/file/11731097/CT_1.jpg)

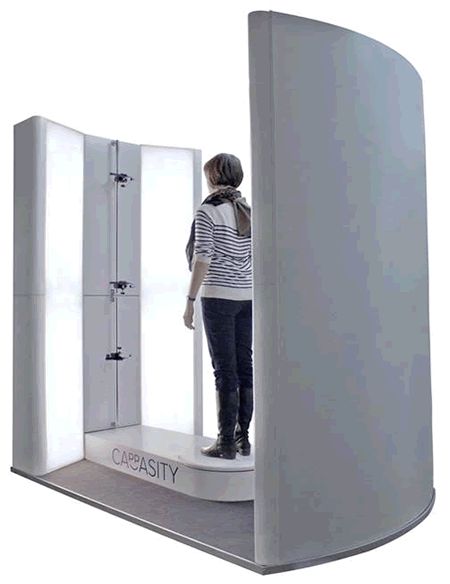

Rendering - Solve problems by quickly digitizing existing parts to create a model on the screen. Allows you to add the appearance of your product to the site, presentation, virtual tour\museum.

The main criteria are ease of operation, speed of operation and the ability to scan in color. Handheld 3D scanners with the ability to scan in color are suitable for this task. You can also use small stationary devices, this will help save.

Archiving - Ability to save the geometry of an object for further analysis when needed.

The main criteria are ease of operation, speed of operation, accuracy. The task can be solved by stationary 3D scanners for parts up to 2 meters in size. For work with large parts, we recommend manual solutions

Once you have decided, you can contact the i3D team for help in selecting equipment. We are ready to offer different options based on the criteria listed below.

Feedback form with a request for the selection of equipment.

Key criteria for choosing a 3D scanner

Below we list the main criteria that will help you in choosing equipment.

Accuracy is the key to any professional 3D scanner. The value of this parameter is indicated in microns (microns). For stationary scanners - as a constant value for a certain field of view, and for hand-held scanners, in general, as a value depending on the dimensions of the object. A 3D scanner with high accuracy will allow you to get the right measurements, high-quality data. Quality data, obtained the first time, will allow you to quickly get results. Scanning accuracy can be improved using a photogrammetry system.

Resolution is an important parameter. It determines what is the minimum size of an element that will be clearly visible on our 3D scan. It is very important to understand that the resolution value can be worse than the precision value and these are not linearly dependent parameters. Processing high-resolution scans is a laborious and time-consuming task. Therefore, many devices allow you to make scans with different resolutions, using a software or hardware solution, in order to optimize the value of this parameter for your task.

Therefore, many devices allow you to make scans with different resolutions, using a software or hardware solution, in order to optimize the value of this parameter for your task.

The price of equipment - immediately after the main technical characteristics comes economic. Depending on the technical characteristics, ease of use, convenience, brand awareness, the price of the device is formed. A proper understanding of the tasks and operating conditions of the equipment will help you choose the most cost-effective solution.

Scanning speed is a combination of the speed of data collection, their transfer to a computer and the speed of data processing algorithms to obtain the final result. Make sure that the scanner comes with software that is easy to use. The very process of the 3D scanner is only the beginning, to obtain the final result, processing in the software supplied with the scanner will be required. The functionality and user-friendliness of the software interface are just as important to the overall scanning speed.

Dimensions of the scanned part - a parameter that determines the convenience of using a particular system. For parts smaller than half a meter, stationary systems with a turntable are ideal. For parts with dimensions up to 8 meters, hand-held 3D scanners are suitable. If you need to scan parts with dimensions up to 12 meters, you can use the handheld 3D scanner + photogrammetry kit. To scan parts with large dimensions, you can also use a stationary 3D scanner + photogrammetry kit, but manual solutions are more effective.

The external environment - it is very important to understand who/where will use the measuring equipment when choosing it. Factors such as light, humidity, temperature, vibration, dust affect the operation of different systems in different ways. Some scanners are designed to work only under strictly controlled conditions, while others are specifically designed for field (workshop) work. Determining the place and working conditions is extremely important for the correct selection of equipment.

Ease of use – technology is rapidly evolving and new solutions are coming to the market, making it imperative for scanner vendors to offer training for your staff on how to use the equipment. However, even after training, people need time to get used to the equipment, gain experience to work effectively with it. The simplicity of the software, the ease of use of the scanner itself is very important for the user and his adaptation to new equipment.

Ability to scan color - for visualization and design tasks, not only the shape, but also the color of the object is very important. Correct color reproduction can be a decisive factor in solving the problems of creating a virtual museum, store, presentation and commercials of your products.

Source: https://i3d.ru/

News

NewsShare with friends

Blog

Accurate measurement of Tesla with KSCAN

3D scannerFebruary 25, 2021

3D scanning technology is widely used in many industries, with the automotive industry being a typical example.

Blog

Automotive parts inspection made as efficient as possible

February 25, 2021

The automotive industry is a highly competitive industry. A car is made up of many important components, including the body, chassis, wheels and tires, interior and exterior parts, engine and gearbox, electronics, mirrors, seals, and more.

Blog

Creating databases with 3D scanning

February 25, 2021

Environmental Invisible Automotive Film is a thermoplastic urethane, often self-healing, film applied to new or used vehicle paint surfaces to protect the paintwork from stones, scratches, crushed insects and minor damage.

Blog

Universal 3D Medical Solution

February 25, 2021

An experiment was recently conducted at Manchester General Hospital using the iReal 3D scanner to reconstruct and reshape the face.

Blog

Case 2. Correction of the spine

February 24, 2021

The Kunming Center for Digital Orthopedic Medical Technology used the iReal 3D Scanner in scoliosis correction procedures.

Blog

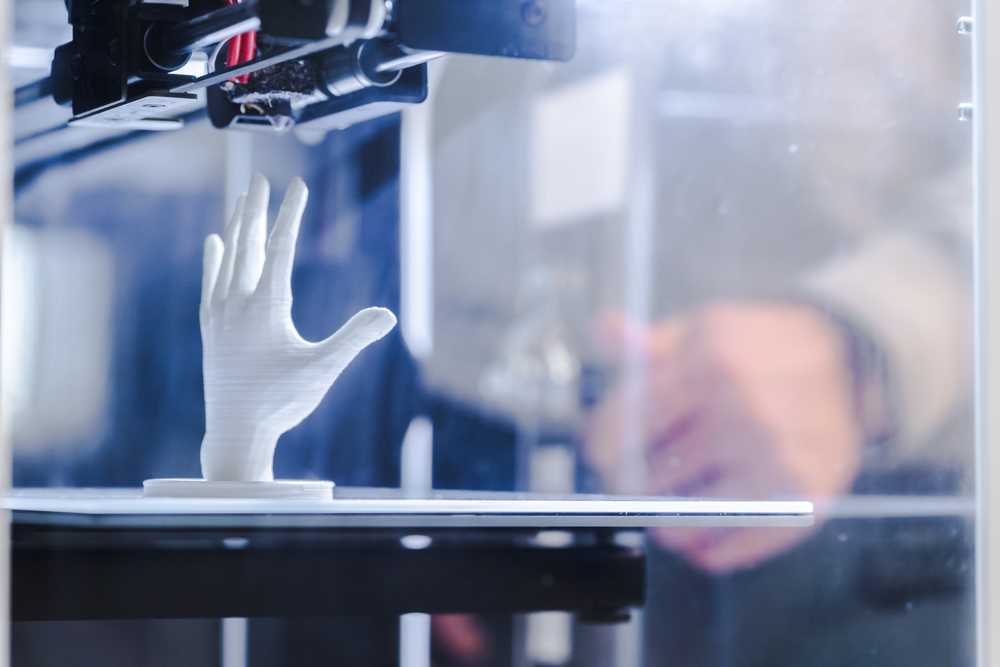

Case 3. Application for the manufacture of prosthesis

February 23, 2021

Prosthetics is an area where 3D scanning has been used for a long time.

Blog

Case 4: All-In-One 3D Physiotherapy Solution

February 22, 2021

The solutions provided by ScanTech are not limited to 3D scanning services. We pay more attention to secondary design after scanning. This aspect also excites our clients. 3D data can be easily imported into 3D printer, reshaping software, providing a complete solution for physiotherapy clients.

We pay more attention to secondary design after scanning. This aspect also excites our clients. 3D data can be easily imported into 3D printer, reshaping software, providing a complete solution for physiotherapy clients.

Significant events

Entry of Scantech scanners into the register of measuring instruments

April 10, 2020

range updates

New Scantech

devicesApril 10, 2020

KScan 3D scanner at Metalworking 2019

June 7, 2019

At the Metalloobrabotka-2019 exhibition held in May, Terem3D presented the innovative 3D scanner KSCAN manufactured by ScanTech at its booth for the first time in Russia.

New 3D Scanner KScan: new possibilities for 3D scanning

May 23, 2019

ScanTech has introduced a new portable 3D scanner KScan, operating in two modes - red and blue laser.

Hardware overview: Scantech PRINCE 775 handheld 3D scanner

April 19, 2019

We talk about the unique handheld 3D scanner Scantech PRINCE 775 and demonstrate its operation in both modes - red and blue laser.

Where and how ScanTech and Thor3D 3D scanners are used

February 25, 2019

At the Conference on 3D equipment for Russian suppliers, held on February 1, 2019, Georgy Kazakevich, a representative of Terem3D, told visitors about the technologies, tasks, brands and applications of 3D scanning, and also demonstrated the operation of one of the best handheld 3D scanners in the world.

Scantech and Thor3D 3D scanners at Interplastica 2019

February 19, 2019

At the exhibition Interplastica 2019, held from January 29 to February 1, 2019, Terem 3D presented the latest 3D scanning solutions to visitors.