Silicone 3d printing material

Can You 3D Print Silicone? Best Silicone 3D Printers and Alternatives

Silicone is a synthetic rubber that boasts several appealing characteristics for manufacturing. Its chemical structure is amazingly versatile, making it possible to adapt its chemical formula to fit diverse industrial applications from seals to joints, wearables, medical devices, robotic grippers, cooking utensils, thermal and electrical insulation, and more.

Most silicone products today are produced with injection molding, compression molding, or casting. With advancements in 3D printing, many people ask the question, “can you 3D print silicone parts?”

The answer is yes, with some important caveats. Silicone has a very high viscosity, making it difficult to 3D print with it precisely. It cannot be heated and extruded or cured with UV light like photopolymer materials. This means that 3D printing silicone requires highly specialized 3D printers, of which there are only a few inaccessible options available on the market today. However, there are many 3D printing processes that offer 3D printing materials with silicone-like properties, and 3D printing can also be used to create molds for molding silicone parts, bringing many of the benefits of 3D printing to traditional silicone manufacturing methods.

In this comprehensive guide, learn about the different options for silicone 3D printing, its alternatives, and how additive manufacturing supports traditional silicone manufacturing processes.

Silicone 3D printers and their alternative solutions can be divided into three categories:

-

Direct silicone 3D printing: There are silicone 3D printers on the market, but they are still far from being commercially viable or available to the average business.

-

3D printing using materials with silicone-like properties: Common polymer 3D printing processes offer various materials with silicone-like material properties that can serve as alternatives for certain applications.

-

Casting or molding silicone using 3D printed molds: Rapid tooling with 3D printing can bridge the gap between prototyping and mass-producing silicone parts with traditional manufacturing methods.

While most 3D printing technologies have been around for many years or even decades, silicone 3D printers are still a relatively new and experimental field due to the complexity of printing with silicone. Over the last few years, some companies have brought silicone 3D printers to the market, but these solutions all have certain limitations alongside excessively high costs, which means that they’re not suitable for most businesses and applications.

One of the first solutions for direct silicone 3D printing was a drop-on-demand deposition process developed by the German company ACEO. The drop-on-demand process involved the deposition of small amounts of silicone onto the build platform and the use of UV light to cure them into a finished part. However, this solution failed to find its niche in the market and was discontinued in 2021.

However, this solution failed to find its niche in the market and was discontinued in 2021.

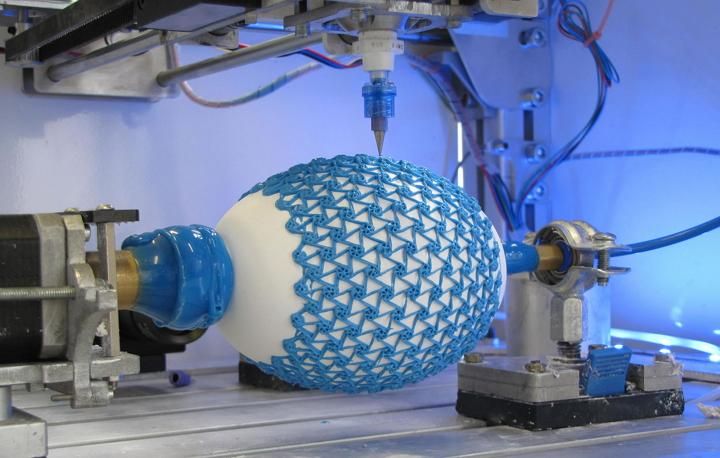

Liquid additive manufacturing (LAM) is another form of silicone 3D printing developed by InnovatiQ (formerly known as German RepRap) that involves dispensing liquefied silicon onto the build platform using an extrusion process that is similar to fused deposition modeling (FDM) 3D printing, and then curing the material with the combination of UV light and heat to form the finished product. However, with this solution, the design options and the quality of the parts are limited, and the printer costs $120,000.

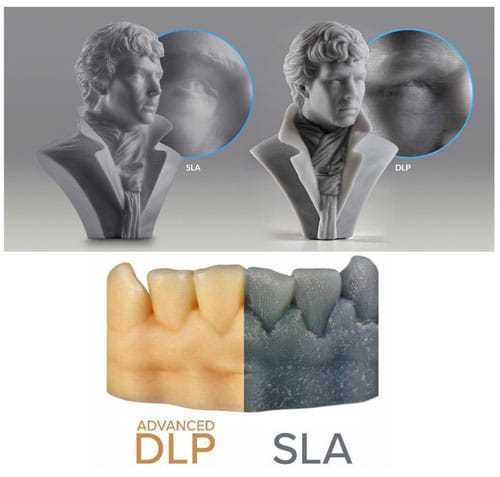

The silicone additive manufacturing technique developed by Spectroplast works similarly to resin 3D printers and turns silicone materials curable by light.

The latest example of silicone 3D printers is the silicone additive manufacturing (SAM) technique developed by Spectroplast. The SAM process is similar to the vat photopolymerization technique known from stereolithography (SLA) and digital light processing (DLP) 3D printers. Normally, silicone materials cannot be light-cured, but the company uses a proprietary process to turn them light-sensitive. This emerging technology promises to provide the same high degree of design freedom as other resin 3D printing technologies, for a starting price of around $100,000.

Normally, silicone materials cannot be light-cured, but the company uses a proprietary process to turn them light-sensitive. This emerging technology promises to provide the same high degree of design freedom as other resin 3D printing technologies, for a starting price of around $100,000.

Some of the primary reasons why manufacturers choose silicones are the elasticity and flexibility of these materials that empower a wide range of applications.

Silicones generally fall between 10A and 80A Shore durometer hardness. Common polymer 3D printing processes like FDM, SLA, and SLS offer various materials in this hardness range, with various degrees of likeness in other important material properties of silicone such as durability, thermal stability, UV resistance, food safety, biocompatibility, as well as color and translucency options.

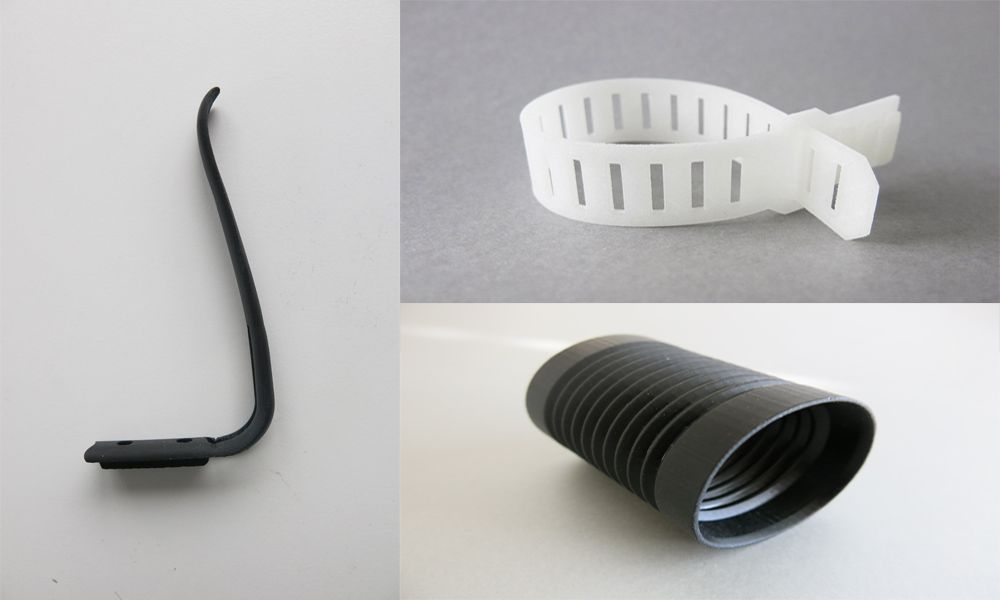

For fused deposition modeling, elastomers such as thermoplastic polyurethane (TPU) and thermoplastic elastomer (TPE) are the most flexible materials that can offer an alternative to silicone. These materials are commercially available at Shore 45A to Shore 90A hardness, which covers part of the silicone hardness range, except for the softest materials.

These materials are commercially available at Shore 45A to Shore 90A hardness, which covers part of the silicone hardness range, except for the softest materials.

The pros associated with these alternatives are the general affordability of FDM 3D printers and materials. Conversely, the cons include lower precision and dimensional accuracy, low resolution, quality, and part strength, and limited design freedom that all restrict real-world usability. Silicone-like FDM materials are generally less durable than standard silicone, not food-safe, have lower temperature resistance, and offer limited color and no real translucency options, but they can be biocompatible and skin-safe.

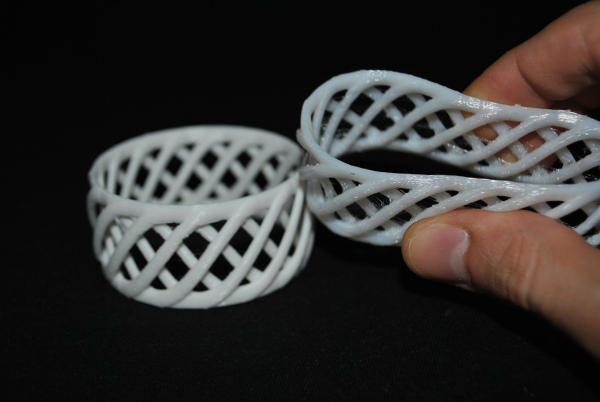

Stereolithography 3D printing is popular among professionals for its high precision and wide range of material options. SLA 3D printing offers multiple alternatives to silicone that empower manufacturers to prototype silicone-like parts or even manufacture end-use parts with the flexibility, elasticity, and durability of silicone. SLA parts offer the smoothest surface finish and a higher degree of design freedom than FDM.

SLA parts offer the smoothest surface finish and a higher degree of design freedom than FDM.

Silicone-like flexible 3D printing resins are generally also less durable than standard silicone, not food-safe, not biocompatible (but can be skin-safe), and have lower temperature resistance. Silicone-like SLA materials can be translucent and can also be dyed to different colors.

SLA 3D printing offers multiple alternatives to silicone that can be used to prototype silicone-like parts or even manufacture end-use parts.

The specific material availability is dependent on the printer model, but generally falls within the 30A and 90A Shore durometer hardness range. Alternative materials to silicone among Formlabs’ SLA 3D printing materials include:

-

Elastic 50A Resin is a soft material that’s suitable for prototyping parts normally produced with silicone. This 50A Shore material is ideal for parts that will bend, stretch, compress, and hold up to repeated cycles without tearing, and spring back quickly to their original shape.

Choose Elastic 50A Resin for applications like wearables (straps), stretchable enclosures and casings, compressible buttons, or soft tissue anatomy in healthcare.

Choose Elastic 50A Resin for applications like wearables (straps), stretchable enclosures and casings, compressible buttons, or soft tissue anatomy in healthcare. -

Flexible 80A Resin is a stiff soft-touch material with an 80A Shore durometer to simulate the flexibility of hard silicones, as well as rubber or TPU. Balancing softness with strength, Flexible 80A Resin can withstand bending, flexing, and compression, even through repeated cycles. It is ideal for prototyping applications like handles, grips, overmolds, cushioning, damping, shock absorptions, seals, gaskets, and masks, or cartilage, tendon, and ligament anatomy in healthcare.

- While slightly beyond the hardness range of silicone materials, Rebound Resin is an 86A Shore elastic 3D printing material that offers unique properties for end-use applications. With five times the tear strength, three times the tensile strength, and two times the elongation of other production-grade elastomeric materials on the market, Rebound Resin is perfect for 3D printing springy, resilient parts.

Rebound Resin’s high elongation makes it perfect for tactile, stretchy parts such as handles and grips. It is strong enough to handle constant compression or tension, which is ideal for manufacturing complex gaskets and seals that last.

Rebound Resin’s high elongation makes it perfect for tactile, stretchy parts such as handles and grips. It is strong enough to handle constant compression or tension, which is ideal for manufacturing complex gaskets and seals that last.

New Balance shoes incorporating Rebound Resin are already on the market and worn around the world. Rebound Resin withstands the elements, enduring daily use in all weather conditions to outperform and outlast traditional materials.

Sample part

See and feel Formlabs quality firsthand with a Elastic 50A Resin or Flexible 80A Resin silicone-like 3D print. We’ll ship a free sample part to your office.

Request a Free Sample Part

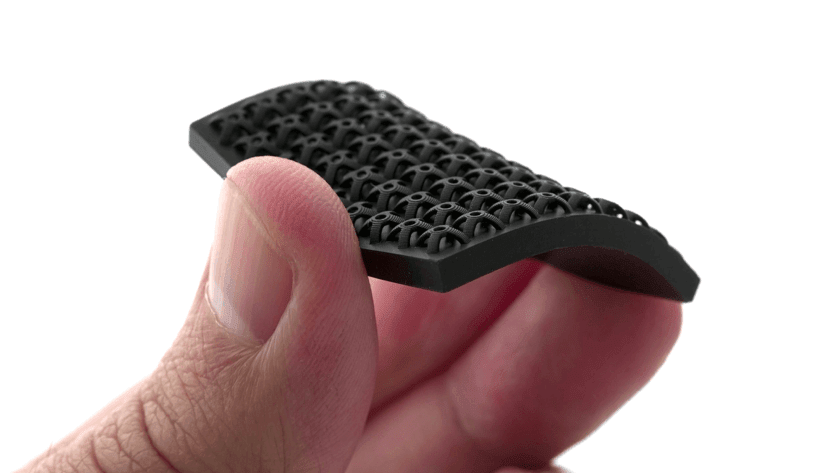

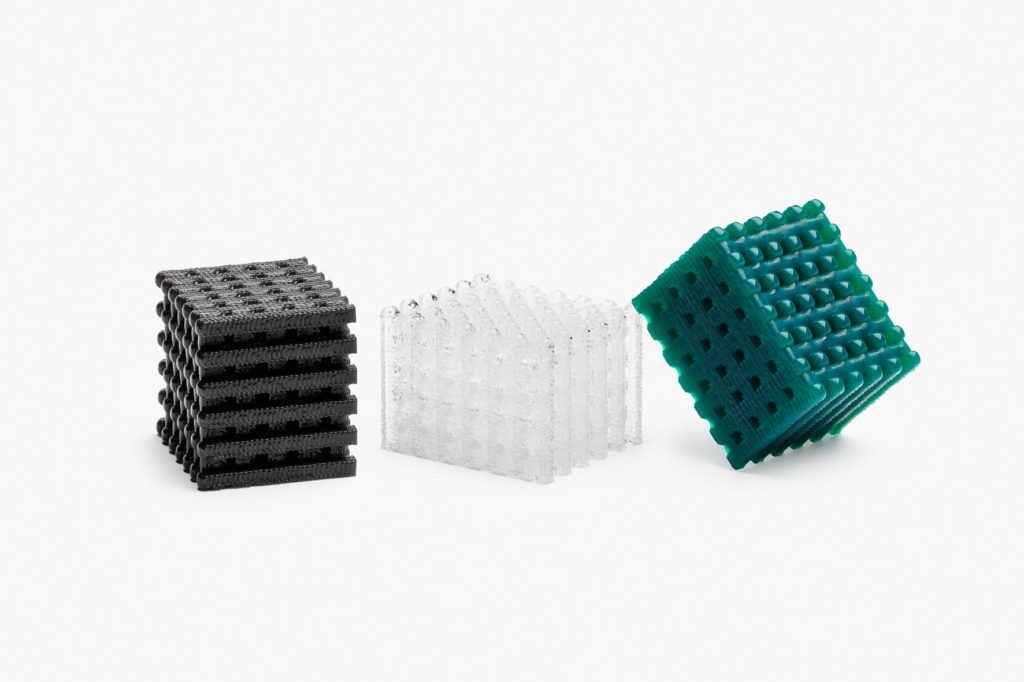

Selective laser sintering (SLS) 3D printing is the most common additive manufacturing technology for industrial applications. It offers high accuracy, high throughput, and almost limitless design freedom as the unfused powder supports the part during printing and eliminates the need for dedicated support structures.

SLS materials with silicone-like properties include TPU, TPE, and TPA, offering hardness ranges between 45A and 90A Shore. The exact availability is dependent on the printer model.

Parts produced with silicone-like SLS materials are accurate, durable, abrasion and wear-resistant, and have the highest temperature resistance of the three plastic 3D printing processes. They can be biocompatible, skin-safe, and also food-safe after post-processing. On the downside, SLS printing offers limited color and no translucency options, and designs with thin walls may warp while cooling down.

For those looking to produce real silicone parts, 3D printing can also help bridge the gap between prototyping and mass-producing silicone parts with traditional manufacturing methods.

Injection molding, thermoforming, compression molding, and silicone casting all make use of molds to create the finished silicone product. However, tooling comes with high upfront costs and weeks or months-long lead times from service providers, slowing down product development and extending the time it takes to get a product to market.

Incorporating in-house rapid tooling into the product development process empowers businesses to validate the design and material choice before transitioning to mass production and provides an affordable means to produce custom or limited series of end-use parts.

White Paper

In this white paper, learn how to combine rapid tooling with traditional manufacturing processes like injection molding, thermoforming, or casting.

Read the White Paper

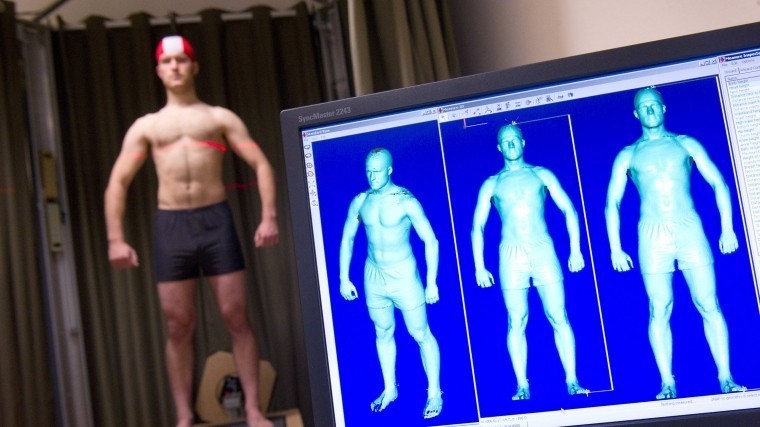

Google’s ATAP team used 3D printed stand-ins or surrogate parts instead of overmolded electronic sub-assemblies for the initial tool tuning at the factory.

Designers at the Google Advanced Technology and Projects (ATAP) lab were able to cut costs by more than $100,000 and shorten their testing cycle from three weeks to just three days using a combination of 3D printing and insert molding. Google ATAP’s team found that by 3D printing test parts, they could save time and money over using expensive electronic parts that had to be shipped in from a supplier.

Dame Products, a Brooklyn-based startup, designs products for the health and wellness industry. They employ silicone insert molding to encapsulate internal hardware for customer beta prototypes. The Dame Products product line incorporates complex ergonomic geometries fully encapsulated in a layer of skin-safe silicone in vibrant colors.

Dame Products employs silicone insert molding to encapsulate internal hardware for customer beta prototypes.

Silicone insert molding is also ideal for manufacturing low volumes of end-use parts. Advanced prosthetics manufacturer Psyonic uses the process to create fingers for prosthetic hands that have a hard 3D printed core overmolded with silicone, while Robotics manufacturer RightHand Robotics uses the same process to create grippers for robots.

Psyonic uses silicone insert molding to create fingers for prosthetic hands.

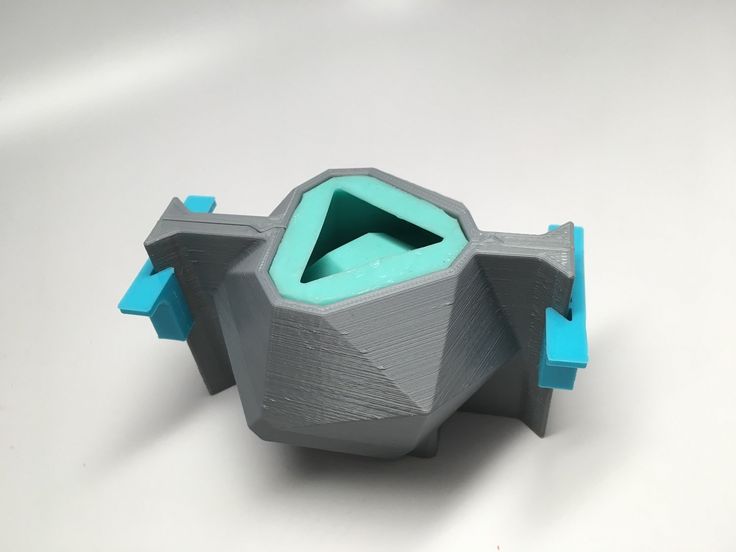

3D printed rapid tooling for compression molding can be leveraged for the production of thermoplastic, silicone, rubber, and composite parts. Product developers at kitchen appliance manufacturer OXO use 3D printing for prototyping rubbery components such as gaskets by compression molding two-part silicone using 3D printed molds.

Product developers at kitchen appliance manufacturer OXO use 3D printing for prototyping rubbery components such as gaskets by compression molding two-part silicone using 3D printed molds.

3D printing is a fast and cheap method for creating molds for compression molding.

White Paper

Download this report for case studies featuring OXO, Tinta Crayons, and Dame Products that illustrate three different implementations of silicone molding for product design and manufacturing, including overmolding and compression molding.

Download the White Paper

Casting is also a popular method for producing silicone and plastic parts for medical devices, audiology, food-safe applications, and more.

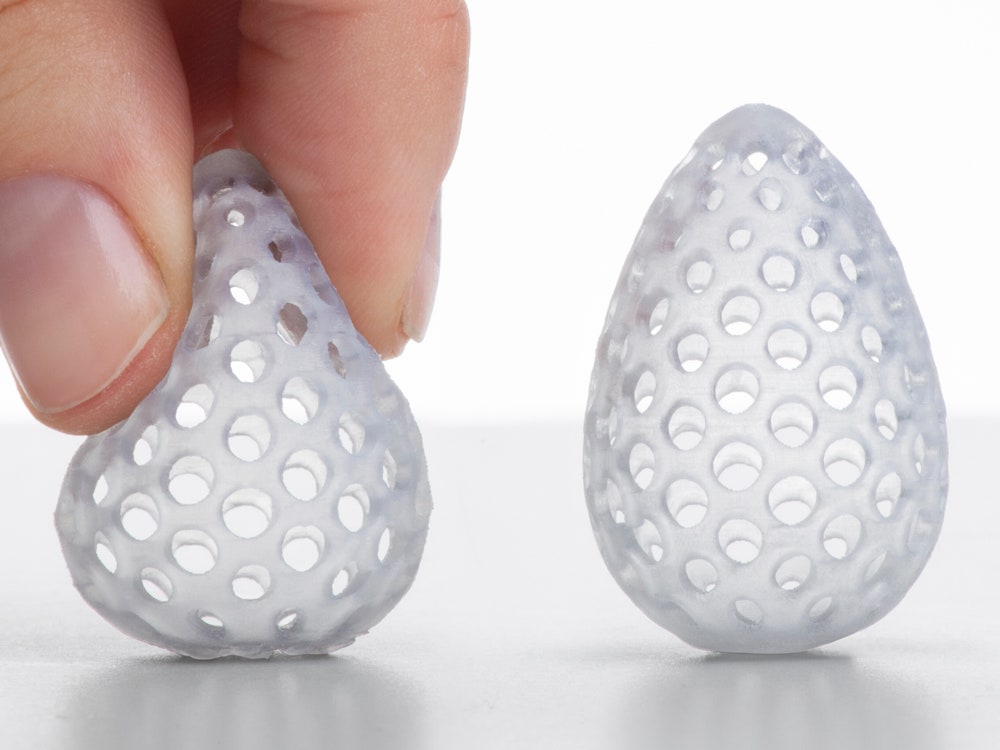

Medical device company Cosm manufactures patient-specific pessaries for patients with pelvic floor disorders. They 3D print molds on an SLA 3D printer and inject biocompatible, medical-grade silicone into it to create the part. Rapid tooling with 3D printing allows them to create custom parts without the high costs of traditional tooling.

Rapid tooling with 3D printing allows them to create custom parts without the high costs of traditional tooling.

Patient-specific pessaries, produced by silicone casting.

Manufacturing custom ear molds with 3D printing has also revolutionized the audiology space, for applications like hearing aids, noise protection, and custom-fit earphones. Digital manufacturing provides greater control and accuracy compared to traditional mold production, significantly reducing the number of errors and remakes.

The step-by-step process of making custom-fit ear tips using silicone ear molds.

White Paper

Walk through a step-by-step guide of the process for affordably producing custom silicone ear molds using a Formlabs 3D printer and Formlabs’ Standard Clear Resin.

Download the White Paper

Silicone casting is also used in the entertainment industry. Jaco Snyman, founder of the award-winning practical prosthetic make-up effects and prop-making company Dreamsmith Studio, used a variety of these techniques for the sci-fi series “Raised by Wolves”. Leveraging the large build volume of the Form 3L SLA 3D printer, Snyman created a hyper-realistic silicone replica of an actress’s body, silicone masks for actors, human-size dummies, and more.

Leveraging the large build volume of the Form 3L SLA 3D printer, Snyman created a hyper-realistic silicone replica of an actress’s body, silicone masks for actors, human-size dummies, and more.

Making a hyper-realistic silicone replica of an actress’s face, with molds digitally designed and 3D printed on the Form 3L.

Conversely, silicone materials can also be used to create molds for molding various materials. Read our guide to learn how to make silicone molds.

| Direct Silicone 3D Printing | FDM 3D Printing | SLA 3D Printing | SLS 3D Printing | Casting or Molding Silicone Using 3D Printed Molds | |

|---|---|---|---|---|---|

| Accuracy | ★★★☆☆ | ★★★☆☆ | ★★★★★ | ★★★★★ | ★★★★★ |

| Surface Finish | ★★★☆☆ | ★★★☆☆ | ★★★★★ | ★★★★☆ | ★★★★★ |

| Design Freedom | ★★★☆☆ | ★★★☆☆ | ★★★★☆ | ★★★★★ | ★★★☆☆ |

| Ease of Use | ★★★☆☆ | ★★★☆☆ | ★★★★★ | ★★★★☆ | ★★★★★ |

| Materials | Silicones | TPU, TPE | Proprietary resins | TPU, TPE, TPA | Silicones |

| Hardness | 20A to 60A Shore | 45A to 90A Shore | 30A to 90A Shore | 45A to 90A Shore | 10A to 80A Shore |

| Price | Starting around $100,000 - $120,000, depending on the solution. | Budget printers and 3D printer kits start at a few hundred dollars. Higher quality mid-range desktop printers start around $2,000, and industrial systems are available from $15,000. | Professional desktop printers start at $3,750, and large-format benchtop printers at $11,000. | Benchtop industrial systems start at $18,500, and traditional industrial printers are available from $100,000. | Same as SLA 3D printing for the printer. Other costs depend on the manufacturing process. |

| Pros | Uses real silicones | Affordable Can be biocompatible | Great value High accuracy Smooth surface finish Easy to use Can be durable and wear-resistant Can be translucent and colored | Durable and wear-resistant Design freedom No need for support structures Can be biocompatible and food safe | Uses real silicones Affordable |

| Cons | Expensive machinery Low accuracy Low details Limited material options | Low accuracy and resolution Limited design freedom Limited material options | Limited material options | Limited material options Rough surface finish | Labor-intenseve workflow |

| Ideal for | Niche applications | Prototyping simple parts | Functional prototyping Moldmaking End use parts | Functional prototyping End use parts | Functional prototyping End use parts |

While direct silicone 3D printers are not yet easily accessible, there are many ways to leverage the benefits of 3D printing to produce silicone or silicone-like parts.

SLA 3D printing is ideal for prototyping parts with silicone-like properties and creating molds for molding real silicone parts.

Request a free sample of our flexible and elastic SLA materials or speak with a 3D printing expert today to find the right solution for your application.

Request a Free Sample Part

Is 3D Printing with Silicone possible? – Beamler

One of the greatest breakthroughs in the field of 3D printing materials in recent years was the launch of a process that makes 3D printing with silicone possible. Learn more about this exciting development.

Throughout history, inventions and breakthroughs in the field of material science have influenced the development of societies. And it is not very different nowadays. The likelihood of these breakthroughs having a significant impact on our technological future is extremely high.

Take 3D printing as an example. New material discoveries allow us to produce tools, mechanical parts or even functional prototypes in a completely new way. But not only that, it also unlocks a new level of freedom for the manufacturing industry to design and innovate.

But not only that, it also unlocks a new level of freedom for the manufacturing industry to design and innovate.

In the end, having a wide range of 3D printing materials available makes the product development easier than ever before. Especially when these materials mimic their traditional counterparts but have had certain properties adjusted to fit new applications.

3D Printing Silicone is now possible

One of the most recent developments in additive manufacturing was the emergence of a new technology that enables the use of silicone as a 3D printing material.

The announcement brought excitement to the industrial 3D printing community.

After all, 3D printing with silicone, and by that we mean real silicone, is a game changer.

It serves so many markets: medical, automotive, consumer products. We can safely say that it is one of those breakthroughs that will truly impact our technological future.

ACEO 3D Models in Silicone

Before that, producing silicone parts was only possible through injection molding, casting and compression molding. An extremely expensive process due to the high cost of molds.

An extremely expensive process due to the high cost of molds.

Clearly not suitable for the creation of prototypes, bio-models or small batches of products.

Ironically, the reason why silicone was so attractive as a 3D printing material was also what made it not a viable option.

It is not possible to melt silicone by exposing it to heat and then print a 3D object layer by layer like it is with plastics or metals.

For those reasons, several companies have attempted to develop materials that would simulate silicone although it was never truly the same.

The new technology, developed by ACEO ®- the brand for 3D printing with Silicones from the German chemical giant WACKER – have made it possible to create 3D objects from silicone materials without thermal changes.

The technology is a variation of the Material Jetting process based on a “Drop-on-Demand” principle. Basically, the print head deposits single silicone voxels on the build platform.

How does ACEO®'s 3D printer for Silicone work?

According to WACKER, their 3D printer for silicone functions just like an inkjet printer. The workspace and a robot are within a glass case.

The workspace and a robot are within a glass case.

One by one, tiny droplets are rapidly extruded from the nozzle onto to the printing area until a fine line is created.

A computer gives the exact coordinates in order to form the desired shape. The area is then exposed to UV Light which causes the silicone to immediately vulcanise.

The process is repeated until the object is formed.

Once solidified silicone does not come back to its liquid state, so the final objects are – just like traditionally produced silicone parts – heat resistant.

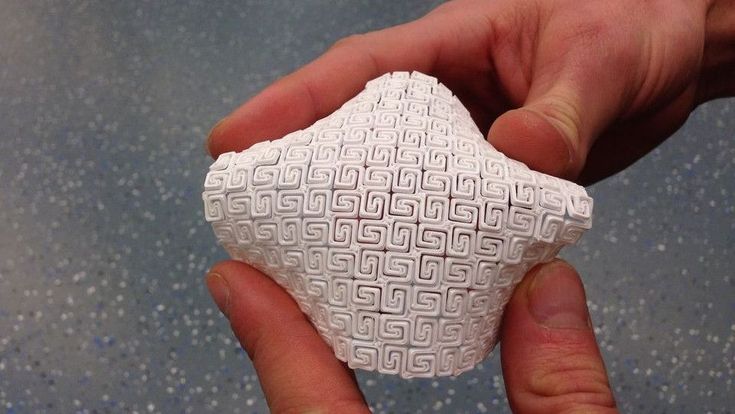

Important to mention is the impressive precision with which the robot lays down the droplets to form extremely fine structures.

We have seen structures where the width of the silicone strip was just 0.6mm and half the thickness.

ACEO®'s Silicone material properties

Silicones manifold properties make it suitable for the most diverse applications:

- Temperature and radiation stability, allows it to be exposed to temperatures that vary from -55 to +180 degrees

- It has impressive elastomer properties, with a high variation of hardness being suitable for applications where a low compression set or high flexibility are required.

- ACEO®’s silicones have been tested for biocompatibility, making it a good option for several applications in the medical field.

- It is an insulating material that can be used for sealings in the automotive industry and other hydraulic applications where flow of fluids needs to be secured.

- ACEO® also offers a special grade of silicones that is electrically conductive and can be used in multi-material prints to provide conductivity and resistance for electrical components such as heat pads.

- Available in different colours but also translucent.

Can I buy Silicone filaments and resins?

At the moment, Silicone filaments and resins are not available for the market as most 3D printers for Silicone have been developed by companies that are not machine manufacturers.

On the other hand, silicone filaments and resins that can be found online are not the real deal – so be very careful.

The best way to 3D print in silicone is still through a silicone 3D printing service.

How to start 3D Printing in Silicone?

If you are looking for a silicone 3D printing service, you have come to the right place.

The first step to start 3D printing in silicone is to have a STL or OBJ file of the object you want to print. We prepared this silicone design guideline to help you make sure your part is 3D printable without further modifications.

You can upload your file to Beamler’s platform and our team will provide you with a quote as soon as possible. Don’t worry, all uploads are secure.

3D Printing in Silicone | SLA | 3D Print Service

3D printing in Silicone Silicone is an elastic material with outstanding mechanical, chemical and thermal properties. A higher degree of customisation and precision is achievable

Read More »

3d printer for silicone molds and products

With a 3D printer, you can create many complex and unusual products from various materials. In recent years, silicone 3D printing has become increasingly popular, which allows you to create implants, organ prototypes, and other useful products. Let's take a closer look at silicone printing, products that can be created with its help, the necessary equipment and the prospects for the development of new technology.

Let's take a closer look at silicone printing, products that can be created with its help, the necessary equipment and the prospects for the development of new technology.

What is 3D printing silicone?

Silicone is a polymer that consists of chains of alternating silicon and oxygen atoms. This material is resistant to various temperature ranges and various chemicals.

In 2016, Wacker Chemie found the most efficient way to 3D print silicone products. Based on this technology, Fripp Design, Envisiontec, Carbon 3D developed and produced equipment and materials that made it possible to work with silicone on a 3D printer.

Silicone is most often used in the medical industry to create objects that are resistant to changing environmental conditions. Until 2016, it was possible to create medical objects from silicone only with the help of injection molding of thermoplastics (injection molding). However, the new technology of additive 3D printing allows you to create smaller parts at an acceptable cost compared to injection molded products.

3D silicone printing technology

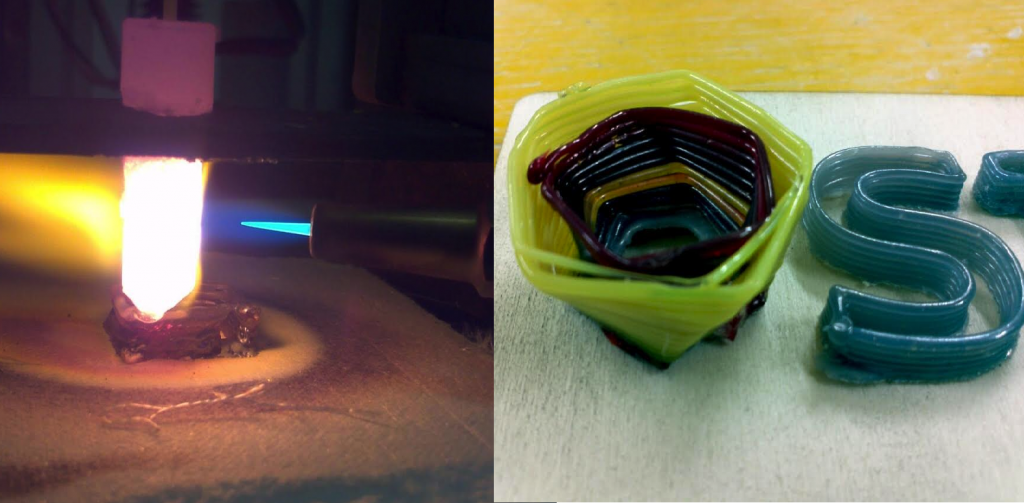

3D printer, which can print silicone products, has the same principle of operation as an inkjet printer. Liquid molten silicone is fed through the extruder in small droplets that are superimposed on each other, forming layers. The printer software is responsible for the correct formation of lines and shapes as a whole.

The curing process is required for the silicone to cure. It is performed using ultraviolet radiation, which forms cross-links between sections of the polymer chain. Due to this, the silicone is strengthened and becomes heat resistant.

3D printed silicone inside a microgel

Silicone 3D printed inside a microgel was developed at the University of Florida. This technology makes it possible to create more durable, but at the same time flexible and comfortable implants. At the same time, the cost of their production will be significantly lower, as well as the final cost for buyers. In the future, silicone printing inside the microgel will allow the creation of various therapeutic devices and very complex structures, such as human organs and tissues.

This 3D printing method allows you to create individual products of various shapes. The printing nozzle moves along a predetermined path and extrudes liquid silicone drop by drop onto the microorganic gel substrate. Depending on the complexity of the finished product, the printing process can take from several hours to several days.

Application of silicone mold printer

3D silicone mold printer is applicable to the following industries:

- Medicine. Silicone is biologically compatible with the human body, does not have a toxic effect on it and is resistant to the influence of an aggressive environment. Thanks to this, the material is used for the production of:

- individual implants;

- respiratory masks;

- hearing aids;

- ear prostheses;

- training preoperative organ models;

- spectacle nose pads;

- contact lenses.

- Automotive industry.

Due to the resistance of silicone to extreme temperatures and solar radiation, it is used for the production of automotive plugs, hose. The presence of waterproofing properties also allow the use of silicone for the manufacture of seals in hydraulic systems and materials for sealing automotive joints.

Due to the resistance of silicone to extreme temperatures and solar radiation, it is used for the production of automotive plugs, hose. The presence of waterproofing properties also allow the use of silicone for the manufacture of seals in hydraulic systems and materials for sealing automotive joints. - Manufacture of everyday or sports articles. The elasticity of silicone and the safety of its use makes it possible to produce insoles for running shoes, ear plugs for headphones, and wristbands.

- Manufacture of souvenirs and jewelry.

Which 3D printer is suitable for silicone products?

What to look for when choosing?

When choosing a 3D printer for printing silicone products, you should pay attention to three main parameters of the device:

- Extruder. It must be inkjet, as liquid silicone is used for printing.

- Integrated heater and pump. To prevent liquid silicone from cooling down during printing and not clumping, the printer must have a heater that will constantly maintain the same temperature.

It is also important to have a pump. It will help to evenly supply liquid filament to the work surface from the extruder.

It is also important to have a pump. It will help to evenly supply liquid filament to the work surface from the extruder. - Closed print area. It is necessary for the vulcanization of the printed blank. An ultraviolet emitter is located in the printed area, and the area itself is closed with a darkened glass dome.

German RepRap LAM PRE-SERIES 3D printer

Ideal for printing silicone products. It adopts FDM technology, in which two-component liquid silicone rubber (LSR) is mixed by a pneumatic piston and extruded by an extruder. Then each layer of material is thermally cured under the action of an infrared rod.

The FDM technology used by the printer has increased print speed, reduced waste during production, completely eliminated post-processing of the product and accelerated its time to market.

The operation of the device is controlled using the touch screen. The printer uses Simplify3D software to process 3D models.

3D printer German RepRap LAM PRE-SERIES

- Base platform heated

- The weight 80

- Material LC-3335

- Seal FDM

- Working chamber area 390 x 400 x 330 mm

- Speed 6000 mm/m or 100 mm/s

- Number of print heads 1

- Layer thickness from 100 µm

- Nozzle diameter, mm 0.

4

4

Go to product

Top 9 Silicone 3D Printers0021

The following professional silicone 3D printers have proven themselves in the market:

- EnvisionTEC - printing medical and dental parts (Perfactory Micro, Vida HD CROWN & BRIDGE and Xede 3SP Ortho lines).

- Structo - creation of dental products (OrthoForm, DentaForm series).

- Total Z - printing of advertising, souvenir, layout and educational products (Anyform line).

- Stratasys - creation of parts for the automotive, aerospace, defense industries (Connex Objet series), printing of dental products (J720 Dental line).

- 3D Systems - printing of souvenirs, models, promotional items and educational products (sPro series).

- Sinterit Lisa Set is a system for creating advertising, souvenir, mock-up and educational products.

- Intamsys FUNMAT PRO 610 HT is an industrial printer for printing large items and testing functional parts under critical conditions.

3D printer Intamsys FUNMAT PRO 610 HT

- Software IntamSuit, Simplify 3D, Cura

- Control connection interfaces WiFi, Internet, USB

- Material PEEK, PEKK, PEI, PPSU, PC, Nylon, ABS, PLA, PVA, TPU, Carbonfiber Reinforcement

- Seal FDM

- Supported file formats STL, OBJ

- Z-axis resolution 0.0016 mm

- Resolution X and Y 0.016 mm

- Platen Temperature 300°C

- Extruder temperature 500°C

- Working chamber area 610 x 508 x 508 mm

- Number of print heads 2

- Layer thickness from 50 µm

- Thread diameter 1.

75

75 - Nozzle diameter, mm 0.4 (0.25, 0.5, 0.6, 0.8, 1.2 mm)

- Display 7" color touch screen

Go to product

Sinterit Lisa Set

- Control connection interfaces WiFi

- Laser IR 5W

- Maximum Layer Height 0.15 mm

- Maximum consumer power 24 W

- Maximum build chamber temperature 105 °C

- Maximum platform temperature for printing 190 °C

- Max extruder temperature 275 °C

- Material PA12 smooth, flexa Black

- Minimum Layer Height 0.

06 mm

06 mm - Seal SLS

- Food 110/120 V or 220/230 V

- Supported software Sinterit Studio 2016

- Dimensions (mm) Sinterit Lisa - 650x550x450; Sinterit Sieve - 600x340x330; Sinterit Sandblaster - 480x370x360

- Accuracy along X, Y axes, mm 0.1

- Speed 15 mm / hour

- Layer thickness from 75 µm

- Weight, kg Sinterit Lisa - 35;Sinterit Sieve - 22.

5;Sinterit Sandblaster-15

5;Sinterit Sandblaster-15

- Data output format STL, OBJ, 3DS, FBX, DAE, 3MF

- Max workpiece size PA12: 90x110x130 mm, flexa Black: 110x130x150 mm

- Print area Sinterit Lisa - 150x200x150 mm; Sinterit Sandblaster - 410x310x200 mm

- Operating system Microsoft Windows

Go to product

The future of silicone 3D printing

Silicone printing was originally developed for medical applications. Therefore, the most promising goal is the development and creation of silicone tissues and human organs that imitate real ones with great accuracy.

Help.

The first attempts to create a human organ from a silicone filament were made at the Federal Institute of Technology Zurich. The artificial heart in design and movement completely imitated the real one. However, the silicone model takes only 3,000 strokes to wear out, which is equivalent to a lifespan of less than one hour.

In 2021, only training and demonstration organs are printed from silicone, which help to study human physiology during training in medical specialties. The first experimental implants and prostheses also began to be developed.

Silicone 3D printing with silicone is a new, emerging technology. It is considered very promising due to the ease of use of the material, its high elasticity, wear resistance, resistance to radiation and aggressive chemical environments.

- March 14, 2021

- 6905

Get expert advice

Making a silicone lamp with a 3D printer / Sudo Null IT News0001

Is plastic printing boring? Me too, so today I will tell you my idea of how to make silicone products on a regular 3D printer.

Now I am involved in one project of interior things - we are experimenting with different technologies for the production of objects. Almost everything is initially designed in 3D, so 3D printing is a key technology.

But 3D printing itself has limitations. When we print using FDM technology (conventional 3D printers), then, accordingly, we find ourselves limited in the choice of materials, surface quality, and print time.

So the challenge has been long overdue: to bypass some of the limitations of FDM 3D printing with minimal effort.

Idea

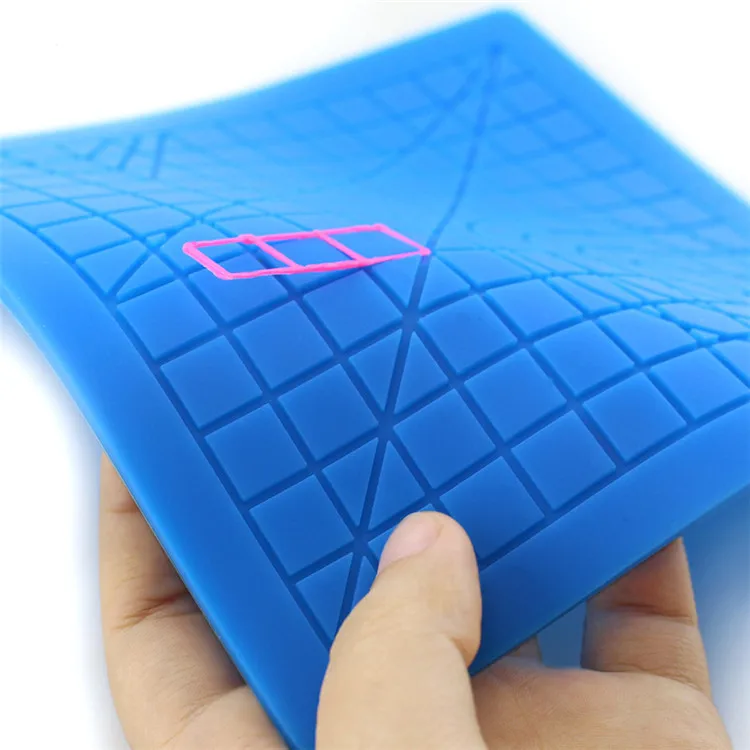

The essence of my idea is this: get a product from molded silicone, but pour it directly into the printed mold!

Where is the innovation here? And the fact that usually a silicone mold is created for this, and it is removed from the master model. That is, if silicone is poured directly into the printed mold, then we save ourselves from the cost of mold casting, and in fact the mold sometimes requires several times more silicone than the product itself. Let's get started with the implementation.

Let's get started with the implementation.

Realization of the idea of molding into a printed mold

I forgot to say - now we are experimenting with the manufacture of lamps. Therefore, the first thing to consider is how our product should function and how the silicone will be poured. As a result of taking into account all the nuances of printing and casting, the designer created the following 3D model of the lamp:

This model is also a model for printing a mold, here is such a trick. A cavity is clearly visible inside which we will pour the material

The object turned out to be medium in size - 23 cm high and 11 cm in diameter. Let's finally print.

We decided to print on our large 3D printer, because it had a 1.0 mm nozzle - so printing was fast, and the form turned out to be strong, albeit only 1 wall thick. Material - ABS. Naturally, we print only the walls - no filling.

By the way, here is a photo of this Tsar Printer:

Its print area is 1. 2 m x 1.2 m, so printing such a small thing is of course a bit ridiculous. If someone is interested, I will write an article about him, he is almost finalized and has very interesting features.

2 m x 1.2 m, so printing such a small thing is of course a bit ridiculous. If someone is interested, I will write an article about him, he is almost finalized and has very interesting features.

So, the shape is received:

Below you can see how thick the line width is. The spout at the top is specially elongated so that it can then be cut evenly.

In general, it turned out great the first time. Now you need to pour silicone inside. Do not forget to seal the form by sealing all small holes, for example, with hot glue.

Unfortunately, the casting process could not be removed, because. silicone gets very dirty, but it was impossible to hesitate.

Then the silicone hardened and a day later we broke the mold, taking out the silicone product.

According to the designer's idea, it should be a lamp with translucent spikes. But we did not pour spikes and decided to just print. To insert the spikes, holes were made in the silicone.

Next, we inserted a light bulb and now you can evaluate how it turned out.

Result

This is a lamp, for example, for a bar. As planned, he is not alone and is in a similar interior.

The surface completely repeated the texture of layer-by-layer 3D printing, but since the layer was thick - about 0.6 mm, it is distinguishable by the eye and shimmers interestingly. It feels very unusual to the touch - it is soft, but it seems to be printed from black plastic.

As a result, the design idea was realized. In terms of time and money, it turned out quite economically, but the most important thing is that another way to use 3D printing has been tested, which means that more ideas can be realized.

Offtopic

As for printing from plastic, we also have a lamp that is completely printed. It takes a very long time to print, it probably weighs a kilogram. Here it is:

Its height is about 30 cm, so it is quite large. It shines well and draws an interesting pattern on the walls.

:quality(80)/images.vogel.de/vogelonline/bdb/1696600/1696673/original.jpg)