3D printing service portland oregon

Portland 3d Printing, Portland finest 3D printing services

3D Printing With Us

We specialize in quickly manufacturing and iterating prototypes to create your products faster and at lower cost.

Do you have a part or assembly that's ready to move from drawing to prototyping?

Portland 3D can help you quickly create inexpensive working prototypes using a wide variety of materials and manufacturing technologies.

Our rapid prototyping services will 3D print your design in your choice of plastic, metal or composite in just 1 to 10 days.

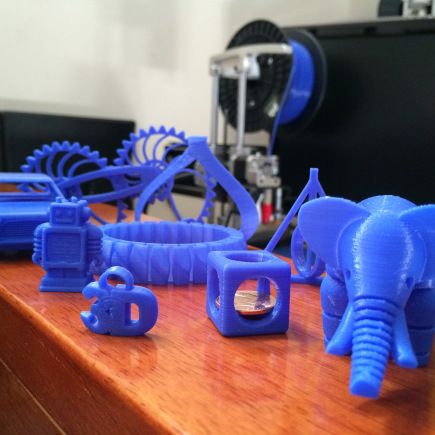

3D Printing Services

Fused Filament Fabrication

Fused Filament Fabrication (FFF), also known as fused deposition modeling, creates 3D printed plastic parts by extruding thermoplastic filaments in successive layers. FFF 3D printing provides high dimensional accuracy and consistency on every part. Because of the strength and durability of industrial thermoplastics like ABS, PC and Ultem, it is ideal for fixtures, stamping tools, mechanical prototypes, form-fit-function models and small-batch production.

3D printed plastics are durable, inexpensive and quick to produce.

Reimagine Manufacturing with HP Multi Jet Fusion 3D Printing

Have you ever heard the old adage which says that you can do something quickly, cheaply, or well, but not all three?

The HP Multi Jet Fusion produces the least expensive, most durable and fastest 3D printed nylon parts on the market.Portland 3D uses the HP Multi Jet Fusion 3D Printer to provide our customers with better products, faster and at less cost. Set your production free from the design limitations of traditional manufacturing

render intricate shapes with precision and durability every time.

When complexity, performance, and cost are all essential, there’s no need to compromise.

Quick Quote

We ensure a 24 hour response time and usually respond to inquiries within 1 hour. You can always call us for quicker response 503-536-5471

Featured Products

Sign up to hear from us about upcoming 3D events in Portland.

Email Address

3D Printing Company, Thermoforming & Machining in Portland

3D Printing and Manufacturing Services

Utilizing cutting-edge technology to rapidly engineer, prototype, and manufacture custom products.

Our Capabilities

From engineering and design to manufacturing and rapid delivery. We empower your business with instant online quoting and ordering.

We empower your business with instant online quoting and ordering.

Industries We Serve

We have custom manufacturing solutions for every type of industry. We provide on-demand manufacturing for businesses around the world.

Automotive

Simplify your supply chain and speed up prototyping, parts supply, and custom assembly.

Electronics

Utilize anti-static materials in custom electronic parts and assemblies.

Energy

Custom tooling and rapid prototyping. Quick production for repair or replacement.

Industrial

Custom prototyping, manufacturing, and finishing processes for unique applications.

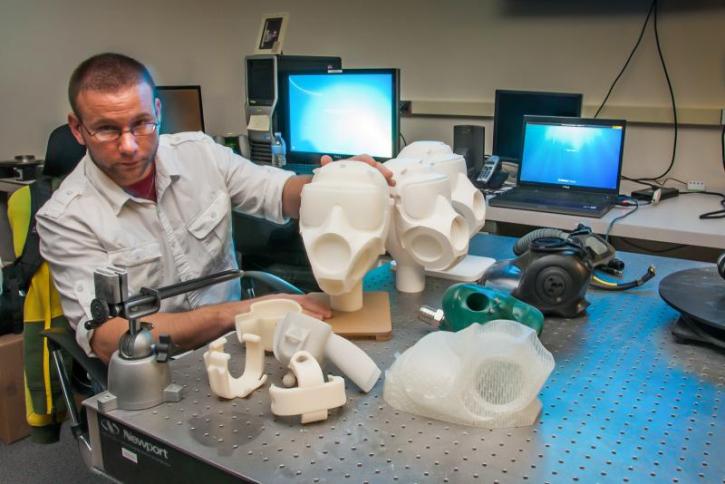

Medical

Rapid manufacturing for medical devices, surgical, and diagnostic equipment providers.

Robotics

Scale your manufacturing and innovate faster with rapid prototyping and critical flexibility.

Our Reviews

I've used RapidMade for YEARS now. They started out as a complement to the standard rapid prototyping online companies. They have consistently been the best for price, quality, and lead time. Their sales help is fast and responsive. Highly recommend RapidMade for prototypes and low volume MJF production parts!

They have consistently been the best for price, quality, and lead time. Their sales help is fast and responsive. Highly recommend RapidMade for prototypes and low volume MJF production parts!

Rapid Made in very responsive and always a pleasure to work with. I highly recommend for all your 3D projects.

Quick turn around, Super easy website interface to upload drawings & then get an instant quote. Saved us a ton of money & lead time not having to send it out to a machine shop. Best website interface I have ever seen. Will continue to use their services.

Online instant quote was quick. Uploaded my native solidworks files. Super easy and very reasonable prices. This will make iterating a prototype very easy! Will order again.

We are very pleased with the previous order of 200 parts in gray Nylon12. Ordering more for a continuous production run of 2,000 pieces. Part quality is wonderful, strong and consistent. Thank you for the excellent service and communication!

Great parts, super fast quoting!

Just a quick note regarding our first order with you. The parts came back great, I'm very pleased with the quality and finish straight out of the machine. They are painting great and will work wonderfully for our product. I look forward to doing a lot of business with you guys. Thanks again!

The parts came back great, I'm very pleased with the quality and finish straight out of the machine. They are painting great and will work wonderfully for our product. I look forward to doing a lot of business with you guys. Thanks again!

RapidMade Inc. was a great company to work with and exceeded our expectations! Thank you, Micah and the whole RapidMade Team for working with a sense of urgency and helping us meet our deadline. You Rock!

They have been wonderful to work with. As their name states, they have a fast turn around! Their engineers are helpful and give great suggestions for the designs. Micah Chaban responds quickly and has been a great resource for us. Thank you!

Our Rapid Manufacturing Process

01

01Request Quote

Get started with your project today by requesting a quote or giving us a call. We even offer instant 3D printing quotes for our most popular 3D printing services.

02

02Engineering

With our in-house engineering and product design services, we can work with your team to ensure product viability and successful production and finishing.

03

03Production

RapidMade uses the latest technologies and materials to help you supercharge your product development cycles with our rapid prototyping and manufacturing services.

Made in the USA

We provide all engineering, design, and product manufacturing services at our location in Portland, OR. Our team is large enough to handle complex and fast-production orders but small enough to maintain a customer and quality-focused approach.

Trusted by Over 5,000 Businesses Worldwide

Contact our Team

503-943-2781

RapidMade, Inc.

15883 Southwest 72nd Ave

Tigard, OR 97224

United States of America

Now Hiring: Finisher/Shop Technician

May 3, 2022

Press Release: Celebrating our 10 Year Anniversary

September 1, 2021

RapidMade Masks Help You Face Flying

August 5, 2020

Because One Size Doesn’t Always Fit All

July 6, 2020

RapidMade is fabricating High-Quality PPE for COVID-19 – Masks, Filters & Face Shields

April 9, 2020

RapidMade is Hiring…

February 25, 2020

Join Oregon Chapter of Women in Manufacturing Networking Night

November 11, 2019

Check Out Our New 3D Printing Guide

October 30, 2019

Increased 3D Printing Capacity Is Here

September 3, 2019

We’re Doubling Our MJF 3D Printing Capacity

August 12, 2019

Oregon Chapter of Women in Manufacturing Shares Safety & Ergonomics Best Practices

June 27, 2019

Instant Quotes Now Available for 3D Printed Projects!

June 18, 2019

Join WiM Oregon for a Lively Discussion on Workplace Safety & Ergonomics

June 12, 2019

Affordable 3D Printed Parts for the Agriculture Industry

June 10, 2019

Cast Silicone Medical Device Saves Oreo the Goat

June 4, 2019

3D Printing Art History

May 23, 2019

April News: Design for Additive Manufacturing Workshop, New Online Resources, and More

April 26, 2019

Why Design for Additive Manufacturing (DfAM)?

April 23, 2019

Design for Additive Manufacturing Workshop with HP and RapidMade

March 25, 2019

Oregon’s Chapter of Women in Manufacturing Tours Johnson Controls

March 22, 2019

Defox, LLC and RapidMade show how 3D printing can help small businesses

March 8, 2019

Join Women in Manufacturing’s Oregon Chapter at Johnson Controls Tour & Networking

March 5, 2019

3D Printing vs. Injection Molding | Cost and Quality Analysis

Injection Molding | Cost and Quality Analysis

February 27, 2019

RapidMade Sales Reps Provide Local Services, Now with More Midwest!

February 19, 2019

Oregon Business Magazine’s Manufacturing Issue Highlights Gender Gap

November 12, 2018

Women in Leadership Forum Prompts Lively Discussion

November 9, 2018

RapidMade CEO to Speak at University of Portland’s Women in Leadership Forum

October 31, 2018

RapidMade Presents at NW Electronics Design & Manufacturing Expo

October 4, 2018

RapidMade’s Manufacturing Team Expands with Summer Heat

July 12, 2018

Dragons Return to Merry Ole England, Thanks to 3D Printing

July 10, 2018

Join Women in Manufacturing Oregon Chapter’s Workshop/Networking Event

May 31, 2018

RapidMade CEO Promotes STEM Careers to Skyview High School Students

April 16, 2018

K9 Helm Shields Hard-Working Dogs from Serious Injuries

March 9, 2018

3D Printing Advocate Shares “The Practice of Innovation”

March 8, 2018

Women in Manufacturing is Coming to Oregon!

February 22, 2018

Women in Manufacturing Launching Oregon Chapter to Support, Promote & Inspire

November 28, 2017

HP Jet Fusion Delivers Injection Mold Quality without the Mold

November 17, 2017

Businesses Celebrate Holidays with Custom 3D Printed Gifts & Promotionals

November 13, 2017

RapidMade Attends Operations & Technology Management Symposium

October 25, 2017

RapidMade Clients Named PBJ Small Business & Innovation Award Winners

October 4, 2017

RapidMade Featured in U. S. News Article on 3D Printing

S. News Article on 3D Printing

June 21, 2016

RapidMade Expands Services Offered

January 22, 2016

RapidMade Selected One of Oregon’s Top Manufacturers by Portland Business Journal

October 27, 2015

What Manufacturers & Developers Should Consider when Investing in 3-D Printing

August 17, 2015

RapidMade Hosts 3D Printing Summer Camp Students

July 22, 2015

Learn Laika’s Lessons for Full-Color Printing

June 26, 2015

3D Scanning Insures Access to Critical Spare Parts

May 29, 2015

“CROWD COW” Project “Udder” Fun for RapidMade

May 5, 2015

Son Helps Father Get a 3D Printed Face

April 29, 2015

RapidMade Adds New Fortus 250mc For Faster ABS Print Turnaround

April 8, 2015

Please vote for RapidMade…

February 16, 2015

RapidMade is Featured in Oregon Business Magazine’s May Issue

April 30, 2014

Portland-based Hilos creates sustainable 3D printed shoes - see how it's done

now, yes, shoes today printed on a 3D printer. And it's being done right here in downtown Portland by a company called Hilos, which won Best in Show at Austin's South by Southwest last spring.

It goes something like this: A computer-generated shoe design is sent to a 3D printer the size of a small car, specifically a Hewlett Packard MJF 5200. The nearly 2,000-pound printer runs all night to create about a dozen pairs of shoes (shoe insole and heel) . Local designers collect all the details and send the shoes directly to the buyer. Shoes are made only after an order has been placed.

3D printing technology allows Hilos to produce shoes on demand, helping to reduce overproduction, a major problem in the fashion industry.

“With our newly developed shoe molds specially adapted for 3D printing, we can go from idea to reality on the market in just 90 days. Traditionally, brands need 18 months,” said Elias Stahl, CEO and co-founder of Hilos. “With the speed and flexibility of this technology, we can significantly lower entry barriers while increasing a more sustainable outcome for the industry.”

“With the speed and flexibility of this technology, we can significantly lower entry barriers while increasing a more sustainable outcome for the industry.”

Shoes are also notorious for being thrown into landfills and beaches. Hilos shoes are therefore specially designed to be recyclable at the end of their life. The company encourages customers to send old pairs for recycling. The bonus for this is a 15% discount on your next purchase at Hilos.

“The real beauty of this design, in my opinion, is that it is also fully rounded,” said Gaia Giladi, co-founder and chief creative officer of Hilos.

“3D printing allows us to create the internal channels you see here,” Giladi said, pointing to a hole in the sole of one of the shoes. “You can assemble the shoe in a whole new way by cutting through the upper without glue so you can easily cut through the wire, skin the platform and completely recycle every component. You can't do that with traditional production. "

"

Giladi and Stahl hope to make their mark on the industry by collaborating with other brands. Hilos recently partnered with Helm Boots, an Austin-based men's shoe company, to create a custom design using Hilos' 3D printing technology.

“We came to Portland to start this company because Portland is the shoe capital of the US,” Stahl said.

At the same time, Stahl also acknowledges that Portland is at the crossroads of footwear and technology, where many well-known companies are based.

“With 3D Systems and HP and Autodesk located here, there is an incredible technology base and product experience that we think will change the retail landscape,” he said.

Hilos makes everything from strappy sandals and clogs to mules and chunky heels. Prices range from $175 to $375.

Source:

MX3D printed on the 3D printer of the Steel Dragon Steel

News

Subscribe to

Subscribe

I do not want

1 9000 project - a ten-meter bench called "Oregon Dragon", made using a 3D printer using the technology of electric arc deposition of metal wire.

MX3D is one of the leading companies in the field of WAAM, that is, additive manufacturing by electric arc welding. There are already several interesting projects in the MX3D piggy bank, the most famous of which is the first of its kind 3D printed bridge made of steel and installed in the center of Amsterdam ( in the illustration below ).

Due to the long development of the technology, the reconstruction of the canal, and then the pandemic, the project dragged on for a long time, but last year the four-ton structure was finally put in place, and the ribbon was cut under the watchful eye of Queen Maxima of the Netherlands by a robotic arm. This is quite symbolic, because MX3D additive systems are also built on the basis of multi-axis robots.

The bridge is twelve meters long, and the new creation is limited to "only" ten, but its shape is even more squiggly. This bench is located in front of the main entrance to the Nike headquarters in Beaverton, Oregon. The consumable material was Duplex 2209 stainless steel welding wire, the topologically optimized design reaches ten meters in length, three in width, and two and a half in height.

The consumable material was Duplex 2209 stainless steel welding wire, the topologically optimized design reaches ten meters in length, three in width, and two and a half in height.

The object has been named "Oregon Dragon" as it continues the "dragon" series of 3D printed benches created by designer Joris Laarman since 2014. In fact, the 3D printing technology itself was worked out on the original "dragons" by the method of electric arc deposition.

As for the MX3D, exactly one year ago the company released a more compact and convenient version of its additive system under the M1 index. Large-sized metal structures cannot be printed on it, but such a task is not worth it: M1 3D printers are designed to produce relatively small parts for the automotive industry, the oil and gas sector, and the like. Most importantly, since 2019, the company has been offering dedicated Metal XL control software, built on the basis of experience gained.

More information about MX3D technologies and projects can be found on the official website.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

MX3D WAAM bench Oregon Dragon

Follow the author

Follow

Don't want

1

More interesting articles

7

Subscribe to the author

Subscribe

Don't want

The F2 Gigantry system will allow manufacturing companies, in particular aerospace companies, to...

Read more

5

Follow the author

Subscribe

Don't want

Scientists from the Perm National Research Polytechnic University have designed an exp.