Kodak full body 3d scanner

Twindom and Kodak Announce the KODAK Full Body 3D Scanner

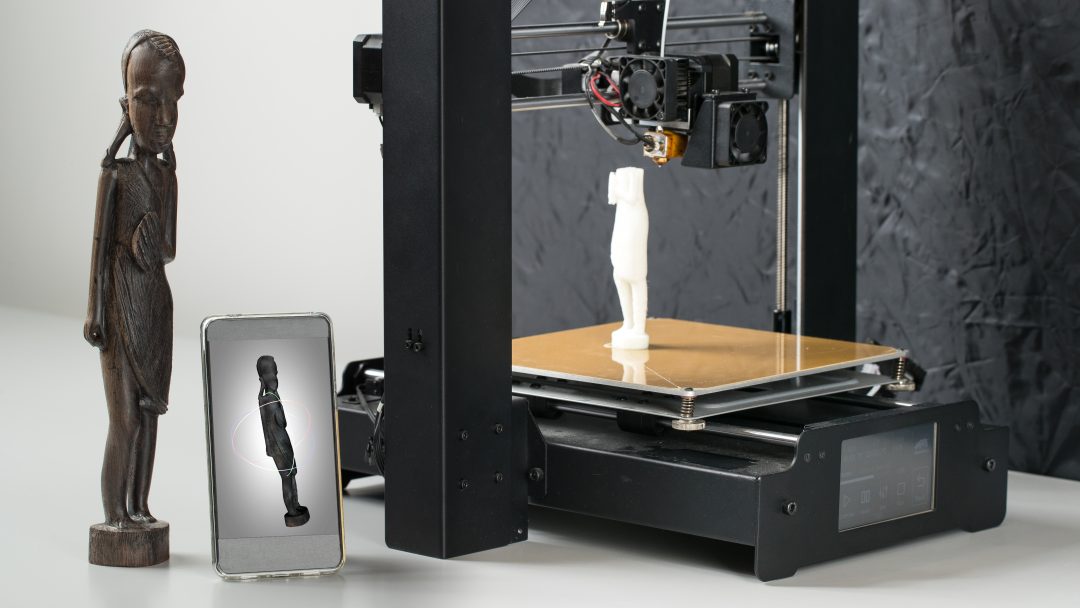

Today the Eastman Kodak Company and its brand licensee, Twindom, announced the KODAK Full Body 3D Scanner, a simple, powerful and mobile solution designed for the fast-growing 3D printed figurine market.

The new offering utilizes Twindom's industry-leading hybrid 3D scanning technology to produce high resolution 3D scans that in turn are made into 3D printed figurines on a full color 3D printer. A cloud service makes it easy to manage by automatically processing the 3D scans from the KODAK Full Body 3D Scanner and routing them to a full color 3D printing facility. Each 3D printed figurine is shipped to a customer's home address 1-2 weeks after being ordered. The KODAK Full Body 3D Scanner is well suited to be set up in a variety of locations, including at events with heavy foot traffic.

"We're delighted to be working with Kodak to bring 3D body scanning and 3D printing to customers everywhere," said Will Drevno, co-founder of Twindom.

"The 3D market is a dynamic and growing category," said Joel Satin, VP Brand Licensing, Kodak. "3D scanning and 3D figurines are important sectors to us. The KODAK Full Body 3D Scanner's ease of operation, mobility and competitive pricing positions it as an incredibly exciting and fun application for both professional and consumer applications."

The KODAK Full Body 3D Scanner and other Kodak products will be on display at the 2018 Consumer Electronic Show held in Las Vegas (LVCC South Hall 1, Booth #20612).

About Twindom

Founded in 2012, Twindom is a global leader in 3D body scanning technology with customers in 17 countries. Our full body 3D scanners are primarily used by 3D portrait businesses to make 3D printed figurines and R&D labs. We believe everyone in the world will, one day, have a 3D model of themselves as part of their digital identity for applications in online shopping (virtual fitting), virtual reality (be yourself), gaming (play as yourself), health and fitness (monitor your body image) and much more. We are focused on building tools and services that empower all of these applications. For more information, please visit http://web.twindom.com.

We are focused on building tools and services that empower all of these applications. For more information, please visit http://web.twindom.com.

About Kodak

Kodak is a technology company focused on imaging. We provide — directly and through partnerships with other innovative companies — hardware, software, consumables and services to customers in graphic arts, commercial print, publishing, packaging, entertainment and commercial films, and consumer products markets. With our world-class R&D capabilities, innovative solutions portfolio and highly trusted brand, Kodak is helping customers around the globe to sustainably grow their own businesses and enjoy their lives. For additional information on Kodak, visit us at kodak.com, follow us on Twitter @Kodak, or like us on Facebook at Kodak.

Media Contacts

Will Drevno

Twindom

510-397-9455

Nicholas Rangel

Director of Communications, Eastman Kodak Company

nicholas. [email protected]

[email protected]

+1 585-615-0549

Twindom and Kodak Introduce Full Body 3D Scanner Together at CES 2018 - 3DPrint.com

Everyone who’s anyone in the 3D printing technology world is at CES 2018 in Las Vegas this week. We’ve been following the pre-show announcements for weeks, and now that the show has officially opened today, there are bound to be more, including a big one from Kodak and its brand licensee Twindom this morning.

Kodak, which is already busy showcasing its new Portrait 3D printer at the trade show this week, and 3D body scanning technology provider Twindom, creator of the popular and portable Twinstant Mobile instantaneous full-body 3D scanning system, together announced their new KODAK Full Body 3D Scanner on the opening day of CES 2018.

Twindom Co-Founder Will Drevno said, “We’re delighted to be working with Kodak to bring 3D body scanning and 3D printing to customers everywhere.”

Headquartered in California, Twindom was founded in 2012, and its full body 3D scanners are mainly used by 3D portrait businesses to make 3D printed figurines. The company’s belief is that someday, every person in the world will have a 3D model of themselves, to use as part of a digital identity for such things like gaming, online shopping, and health and fitness. Twindom works to build services and tools that will, as the company puts it, “empower all of these applications.”

The company’s belief is that someday, every person in the world will have a 3D model of themselves, to use as part of a digital identity for such things like gaming, online shopping, and health and fitness. Twindom works to build services and tools that will, as the company puts it, “empower all of these applications.”

“The 3D market is a dynamic and growing category. 3D scanning and 3D figurines are important sectors to us,” said Joel Satin, VP Brand Licensing, Kodak. “The KODAK Full Body 3D Scanner’s ease of operation, mobility and competitive pricing positions it as an incredibly exciting and fun application for both professional and consumer applications.”

The powerful KODAK Full Body 3D Scanner is completely mobile, and was designed for the growing 3D printed figurine market. This new offering, which can be taken to and set up at retail locations and events, uses Twindom’s leading hybrid 3D scanning technology in order to take high resolution 3D scans of people, which are later made into figurines on a full-color 3D printer at one of Kodak’s approved 3D printing partners. Then, once the 3D printed figurine is complete, it’s shipped out to the customer’s home address 1-2 weeks after it’s been ordered.

Then, once the 3D printed figurine is complete, it’s shipped out to the customer’s home address 1-2 weeks after it’s been ordered.

Thanks to a cloud service, which automatically processes the 3D scans and sends to them a 3D printing facility, and the 3D scanner’s ease of use, anyone can manage the system. It takes one person only seconds to fold, and unfold, the 3D scanner, and roughly 30 minutes to set the system up; then, a high resolution, full body scan is just a few mouse clicks away. Then users can review, share, and order 3D printed figurines, 3D portraits, and 3D selfies on-site at the event, or online. According to Kodak, more products, like 3D crystals and busts, will be coming later.

The startup costs are low, and 3rd party financing is available for the KODAK Full Body 3D Scanner. The system comes with marketing built right in, as you can automatically share every 3D scan across social media, and the KODAK system can capture groups of up to 14 adults, kids, and even pets.

Technical specifications for the KODAK Full Body 3D Scanner include:

[Image: Kodak]

Scan speed: 1/4 of a second- Model resolution: 400k – 2 M

- Geometric Accuracy: ~1cm

- 30 day premier setup support

- 12 month defective parts warranty

- 17 scanning poles, 16 LED light strips

- 89 camera sensors, 25 LED projector sensors, 1 calibration sensor

Space requirements to set up the KODAK Full Body 3D scanner are 10′ x 10′, and a 120 V circuit; in addition, it should be place in a well-lit area with no direct sunlight. All 3D scanners require a cloud subscription in order to process the data into 3D models, and in addition to the 3D scanner itself, the system includes a capture laptop and a tools and spare parts kit.

It’s easy to set up the KODAK Full Body 3D Scanner in a variety of different locations, even events with heavy foot traffic, such as CES 2018.

Drevno told 3DPrint.com, “We will be demoing the new scanner throughout CES and will be also be doing some live streams on social media.

”

At CES this week, you can see the KODAK Full Body 3D Scanner, the Kodak Portrait 3D printer, and other Kodak products at its booth #20612 in the South Hall of the Las Vegas Convention Center. 3DPrint.com will also be at CES, bringing you all of the latest product and technology news right from the showroom floor.

Discuss this and other 3D printing topics at 3DPrintBoard.com or share your thoughts in the Facebook comments below.

[Images provided by Twindom]

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d full body scan • 3d printed figurines • CES 2018 • cloud services • full body 3d scanner • full body 3d scanning • full body scanner • full color 3d printer • full color 3d printing • high resolution • kodak • KODAK Full Body 3D Scanner • mobile scanning • twindom

Please enable JavaScript to view the comments powered by Disqus.

Metrology Grade 3D Scanner | effective for high volumes

Designed for large-scale projects

Specially designed for 3D measurement of large-scale objects, the 3D Global Scanners have an integrated photogrammetry system that provides metrological-level 3D solutions without the use of additional devices. Scanning area and volumetric accuracy are inevitable issues when conducting a 3D inspection of a large-scale project, but this type of 3D solution benefits from the innovative technology of an embedded photogrammetry system that provides ultra-wide scanning area and accurate data collection, improving the efficiency of high-quality 3D modeling and speeding up the 3D process. digitization.

AXE-B17 3D Scanner

Built-in photogrammetry allows large-scale measurement with just one handheld 3D scanner. When working with Scantech's automatic 3D system, the AX 3D scanner will carry out continuous online batch 3D inspection.

Accuracy

0.020 mm resolution

0.025 mm

Learn more >

AXE-B11 3D Scanner

With the AXE-B11 3D Scanner, you can experience smooth 3D scanning of large complex parts with metrological accuracy, and obtain real 3D models for numerical simulation to help manufacturers solve complex manufacturing problems.

Accuracy

0.020 mmResolution

0.025 mm

Learn more >

Which 3D solution is best for your needs?

We provide you with an individual solution for 3D measurement

CONTACT OUR SPECIALISTS

| 3D scanner AXE-B17 | |

|---|---|

| Precision | Up to 0.020 mm |

| Scan speed | Up to 1,300,000 measurements / s |

| Scan area | Up to 550 mm × 600 mm |

| approval | 0.025mm |

Collaborate with the leading supplier of 3D scanners

Allows you to measure and scan anything

FREE DEMO NOW

Scantech's global 3D scanner solution designed for the unique needs of various industries.

Find out how our global 3D scanner can help.

Quality Control

Full inspection of large scale machines is considered an important issue. The project shows how to use a handheld 3D scanner with an accuracy of 0.020mm to check quality.

Quality control

The traditional measurement is that the steel sheet is placed on the inspection tool, quantitative analysis is carried out using a calibrated plug. However, how can a steel sheet be tested in 10 minutes? by 3D scanning.

Quality control

Advanced method NDT SCANTECH at sea. The size of the wheel hub of a wind turbine is too large, so how can you efficiently obtain accurate 3D data on both the inside and the outside?

New.

Universal 3D Scanner Peel

Universal 3D Scanner Peel Toggle Nav

Back

November 18, 2021

Today we will tell you about the Peel 3D line of portable 3D scanners from the leading Canadian manufacturer Creaform. Peel handheld scanners are great for reverse engineering in a wide variety of industries and have a number of advantages, the main of which is an affordable price combined with high quality.

The line includes several modifications of 3D scanners using structured white illumination technology, which is completely safe for the eyes. The equipment is supplied complete with software that allows you to significantly simplify and speed up the work with 3D scanning data.

Scanners fit easily in your hand and are comfortable to use even for long periods of time. Calibration is not difficult, just place a special plate with dots on the table or on the floor, place the scanner next to it and slowly move it back until a notification of successful hardware setup is received. Recalibration is not required, just set up the scanner once.

Recalibration is not required, just set up the scanner once.

In what areas can Peel 3D be used?

- Industry;

- Design and art;

- Architecture;

- Medicine;

- Science and education;

- Preservation of cultural and historical heritage;

- Digitization of the human body.

Features and Benefits

- There is no need to prepare the equipment beforehand. Peel 3d devices provide fast, accurate 3D scan data: a high level of detail is achieved through automatic shape recognition.

- It is possible to work with objects from different materials and with any type of surface, including clay, ceramics, porcelain, leather.

- Position markers not required.

- Preparation for work takes no more than 1 minute thanks to automatic calibration of the equipment.

- Accuracy up to 100 microns.

- High speed.

- The kit includes software with a set of necessary tools for processing 3D data and exporting files.

- Significantly simplifies and speeds up the process of creating 3D object models.

Key features

peel 1 3D scanner. The junior peel 1 is the most affordable of the entire product line. The compact handheld scanner is capable of capturing objects ranging in size from 0.3 m to 3 m and accurately scanning even and smooth surfaces.

peel 2 3D scanner. This model can capture the texture of the surface, conveying information about the color of the object. With peel 2, you can scan even products with complex geometries.

3D scanner peel 2 CAD. An easy-to-use, accurate and fast scanner that allows you to complete reverse engineering tasks in just a few minutes. You will get a high-quality result without prior preparation and equipment setup.

You will get a high-quality result without prior preparation and equipment setup.

peel 2-S 3D scanner. New for 2021, the peel 2-S is designed specifically for measuring small and small objects from 5 to 50 cm. It provides the most realistic color reproduction and high scanning accuracy - even human faces and body parts can be measured with it.

peel 2 CAD-S 3D scanner. An improved model that guarantees even higher detail of small objects up to 50 cm in size. Users will have at their disposal a set of all the necessary tools for fast and high-quality processing of a 3D object model.

Scanner Real Cases

So let's take a look at Creaform's range of affordable handheld 3D scanners in action. To test the equipment, several tests were carried out on objects of varying complexity and size.

To begin with, we scanned a copy of the torso of the sculpture "Diadumen" by Poliklet, presented in the Louvre. The height of the model was only 35 cm, its surface is smooth with large smooth details. Scanning was carried out without marks, and the whole process took about 2 minutes 30 seconds. After processing the received data, the 3D model practically did not need to be cleaned.

The height of the model was only 35 cm, its surface is smooth with large smooth details. Scanning was carried out without marks, and the whole process took about 2 minutes 30 seconds. After processing the received data, the 3D model practically did not need to be cleaned.

Left to right: 3D printed replica of the Diadumen torso - test result 1A - test result 1B / Photo: 3dprintingindustry.com

Next, a more complex object with small uneven elements and a partially reflective surface was taken for testing. The digitization of Augustin Pajou's sculpture "The Head of a Bearded Old Man" was also quite successful. Some hard-to-reach areas in the neck area had to be reconstructed after the scan was completed, however, the time spent on digitizing the object was no more than 2 minutes.

Left to right: 3D printed copy of "Head of a bearded old man" - test result 2A - test result 2B / Photo: 3dprintingindustry.com

The biggest challenge was digitizing the 3D printed copy of the bust of Costanza Buonarelli.

:quality(80)/images.vogel.de/vogelonline/bdb/1696600/1696673/original.jpg)