Shipping container 3d printer

This 3D printing 'factory' is being built into a shipping container for the US Department of Defense

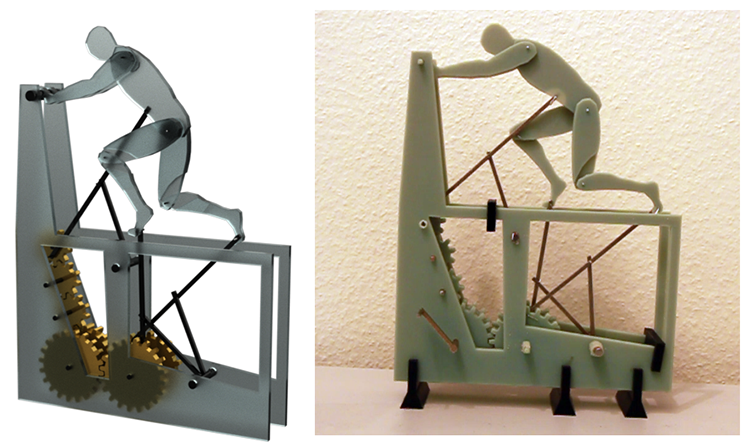

The products that come out of 3D printers can already be found in vastly different settings, ranging from hospital rooms to buried one hundred meters under the ground, or inside the world's largest particle detector. The US Department of Defense (DoD), for its part, is interested in bringing the technology into yet another setting: the battlefield.

Additive manufacturing company ExOne has been awarded a $1.6 million contract by the DoD to develop a fully operational, self-contained 3D printing "factory" that could be transported in a 12-meter-long shipping container. The technology could be easily deployed in the field via land, sea or air, to manufacture, at pace, the parts needed by military personnel carrying out an operation.

3D Printing

- The best 3D printers: From FDM to resin

- These are the most googled 3D printing questions of 2022, answered

- A 3D printed orthotic device made from castor oil

- This device recycles plastic water bottles into 3D printing filament

Whether intervening in a conflict zone or carrying out disaster relief, soldiers would be able to use the mobile factory to print broken or damaged parts in less than 48 hours, where traditional manufacturing methods typically requires four to six weeks. No tools would be necessary to build the parts, apart from the digital file for the finished product, as well as the material needed to print.

SEE: Hiring Kit: Computer Hardware Engineer (TechRepublic Premium)

This means that, instead of keeping racks of spare parts in storage, troops would only need to save a digital library of parts for 3D printing; when faced with a previously unseen technical issue, they could design a new digital file and print it as needed.

Aircraft ducting, replacement lens caps, advanced electronics or medical equipment: there are many examples of products that military personnel are likely to need urgently when in the field, and 3D printing those parts could significantly reduce downtime in a crisis.

The technology could be easily deployed in the field via land, sea or air, to manufacture, at pace, the parts needed by military personnel carrying out an operation.

Image: ExOneExOne, which spun out of MIT in the early 1990s, has an exclusive license to use a specific method for 3D printing called binder jetting. Instead of using a laser or nozzle to melt and weld material together, the company's printers inject a liquid binder on successive thin layers of powdered material to form the product. The concept is similar to traditional paper printing: the binder functions like the ink as it moves across the layers of powder, forming the final product.

Instead of using a laser or nozzle to melt and weld material together, the company's printers inject a liquid binder on successive thin layers of powdered material to form the product. The concept is similar to traditional paper printing: the binder functions like the ink as it moves across the layers of powder, forming the final product.

More than 20 materials, including metal and ceramic, are compatible with the company's method. "Binder jet 3D printing is a critical manufacturing technology for military use because of its speed, flexibility of materials, and ease of use," said John Hartner, ExOne's CEO. "We're excited to collaborate with the U.S. Department of Defense and other partners to make our 3D printers more rugged for the military (…). Most importantly, we know that years from now, our technology will play an important role in filling critical needs quickly."

Although the technology is already tried and tested, more work needs to be done to fit ExOne's 3D printers into robust shipping containers that can be reliably flown, shipped, or driven around. The contract with the DoD will initially focus, therefore, on improving the ruggedness of the printers to make sure that they can withstand a wide range of operating conditions.

The contract with the DoD will initially focus, therefore, on improving the ruggedness of the printers to make sure that they can withstand a wide range of operating conditions.

SEE: How 3D printing is helping CERN scientists upgrade the world's largest machine

ExOne said that it is developing a special military edition of its 3D printers, with a new body style and features that will be up to military standards. The company is collaborating with materials engineering company Dynovas and engineering firm Applied Composites – San Diego, both of which have extended experience in developing defense systems.

Another key part of the project, according to ExOne, will consist of simplifying the use of the technology in the field with software and training. The goal is to ensure that the 3D printing factory can be used with minimal technical knowledge.

The DoD's interest in 3D printing is not new: efforts to use additive manufacturing can be traced back to 2012, when it emerged that the US military was developing backpack-sized 3D printers designed to print spare parts for soldiers in the battlefield. The same year, the DoD created a $30 million center dedicated to harnessing the potential of 3D printing for the military.

The same year, the DoD created a $30 million center dedicated to harnessing the potential of 3D printing for the military.

Many initiatives have followed since, including the opening of a center for advanced manufacturing in collaboration with the Army Research Laboratory, as well as the launch of the AMNOW program, which seeks to assist the US army in the deployment of additive manufacturing technologies.

Last month, a special office within the DoD that is dedicated to defense manufacturing technology released an additive manufacturing strategy, designed to establish a common vision for the use of 3D printing, which was described as a "game-changing technology" with the potential to create new products on-demand, while bolstering the lifespan of legacy systems.

Innovation

▷ shipping container 3d models 【 STLFinder 】

Shipping Container

sketchfab

Maersk inspired shipping containere. Quite worn. Modelled in Maya and textures done in Substance Painter. ...Higher res renders and turntable available at: https://www.artstation.com/artwork/2xVoke

Quite worn. Modelled in Maya and textures done in Substance Painter. ...Higher res renders and turntable available at: https://www.artstation.com/artwork/2xVoke

Shipping Container

thingiverse

Here's a 40' shipping container model that is sized for an N scale model railroad. The design was done in OpenSCAD. The size is 76 mm long by 17 mm high by 15 mm wide. Instructions I used the...

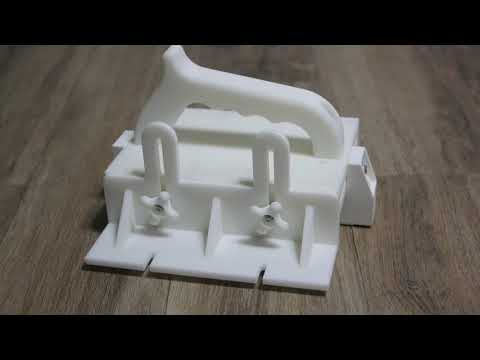

Shipping Container

thingiverse

Hi There.

Some time ago I was looking for a model of a shipping container with a sliding cover, but couldn't find any I liked, so y made one myself. The print you can see is at 60% scale of de model.

... Anyway, I made the model in Fusion 360 so you...

The print you can see is at 60% scale of de model.

... Anyway, I made the model in Fusion 360 so you...

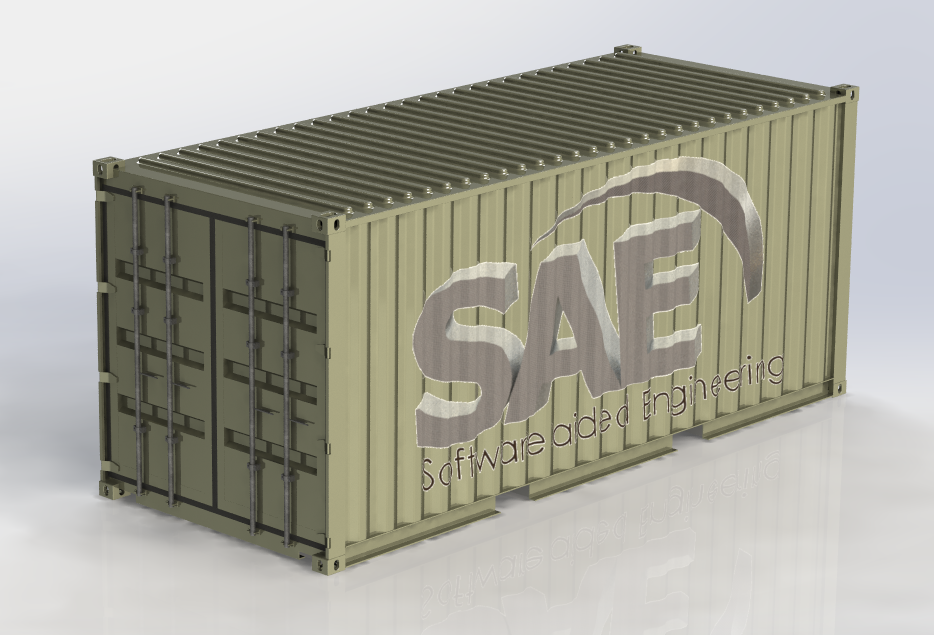

Shipping container

grabcad

software- solid works 2013Rendering- Keyshot 5

Shipping Container

sketchfab

Low poly shipping container model

Shipping Container

sketchfab

Again, materials won’t work properly on sketchfab Render: https://prnt.sc/g4l3di

Shipping container

grabcad

a container go beyond just providing shock and moisture protection for the contents.

Shipping Container

grabcad

Shipping Container

Shipping Container

3docean

The model was created in blender and exported in format(.obj). Also you can find included in the file the low-poly version of the model so that you can apply a modifier to change the level of details. Format:(.obj) .obj:Face(408089)/Verts(411330) ...

Shipping Container

myminifactory

A simple shipping container designed for use as terrain in a tabletop game with a cyberpunk/urban theme. ... I designed it around a 50mm x 100mm base to fit with the other terrain pieces but printed it smaller to reduce printing time.

... I designed it around a 50mm x 100mm base to fit with the other terrain pieces but printed it smaller to reduce printing time.

Shipping Container

3docean

A 3D model of orange and blue shipping containers with all details all used materials are included all parts are separatelly made to be able to move them files included: .3ds/.skp/.obj/.fbx/.dxf/.dwg

Shipping Container

grabcad

A nice detailed model of a shipping container

Shipping Container

thingiverse

Laser cut 3mm MDF

50x50x130

i needed some shipping containers for a game table i'm building. edit: removed the logos from the file

you can find them at this guys work if you like.

... https://www.thingiverse.com/thing:3646078

edit: removed the logos from the file

you can find them at this guys work if you like.

... https://www.thingiverse.com/thing:3646078

Shipping container

thingiverse

This thing was made with Tinkercad. ...Edit it online https://www.tinkercad.com/things/7dLFP6EnRE9

Shipping Container

sketchfab

It is a container

Shipping Container

sketchfab

Only the outside. ... Not sure in what categorie it fits :D

Shipping Container

grabcad

Shipping ContainerWith doors on both endsBrand: MaloyNo single dimension is off by more than 1/8"

Shipping Container

grabcad

This is a prop I made for one of my Star Wars scenes.

Shipping container

sketchfab

Quick photogrammetry of a shipping container. ...16 k textures and simplified.

Shipping Container

sketchfab

Low poly model of shipping container with nice detail.

Shipping Container

sketchfab

No description provided.

Shipping Container

grabcad

Hi , This is a 3D container made on Nx.

Shipping container

thingiverse

Easy to print shipping container with opening doors. No need any supports, brims or raft. Ready to print on nano 3D printers (min. required printing area 80\*80\*75mm). This toy fits all our ship and train models (see:...

Shipping Container

grabcad

Shipping container modeled using the most accurate dimensions I could find.

Shipping_Container

sketchfab

Shipping Container Project

Shipping Container

sketchfab

This is meant for a quick and easy 3D game. ...It’s not too detailed and it works for easy implementation.

...It’s not too detailed and it works for easy implementation.

Shipping Container

sketchfab

Semi-Futuristic Shipping Container

Shipping Container

3docean

This model created in blender. Texture color code: 373737 Photoshop texture included. blend. 3ds. obj. fbx. formats are available. If you have any problem don’t hesitate to contact with me. ... Email: [email protected] Facebook:...

Shipping Container

3docean

A very accurate model of a 40 Feet Shipping container . The model has the interior modeled, and there is a sixth archive with a .blend with the doors open. The model comes in five formats: -.blend, animated and rigged, rendered with cycles,...

The model has the interior modeled, and there is a sixth archive with a .blend with the doors open. The model comes in five formats: -.blend, animated and rigged, rendered with cycles,...

Shipping container

myminifactory

A futuristic conex, I know the internet is full of examples of these but I decided to make my own. What sets my design apart is that it has relatively simple geometry so it can be printed for much smaller scale minis, most of my things are made for a...

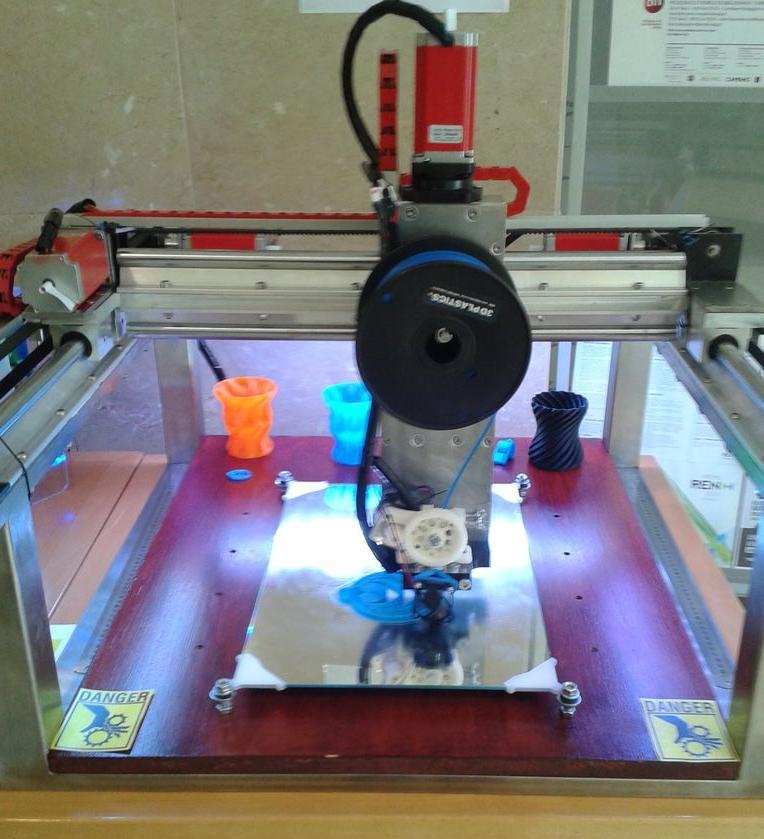

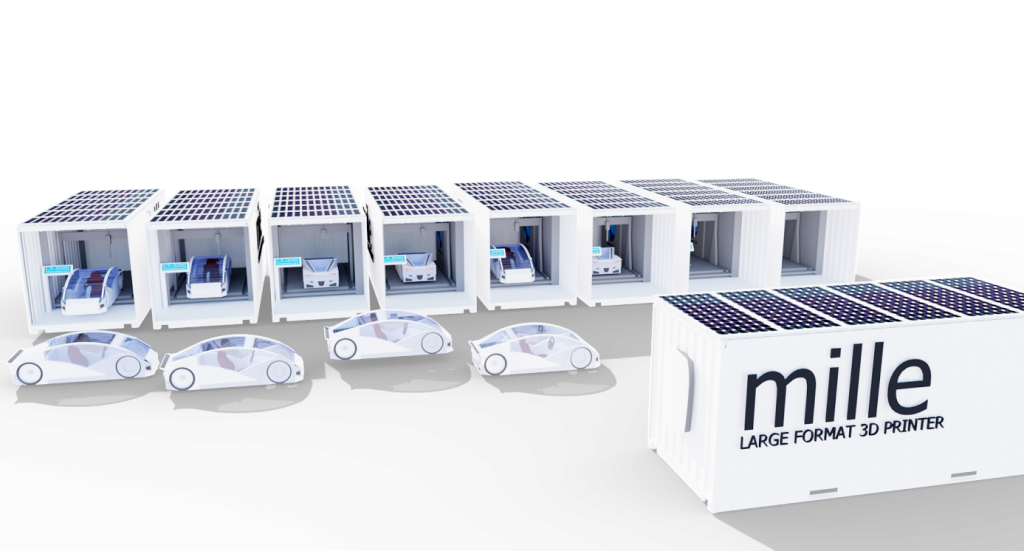

Mille Multifunctional Large Format 3D Printer Fits in Shipping Case

News

Millebot Inc. demonstrated its own multifunctional industrial 3D printer "Mille" at the Maker Faire in Orlando. The unit has a large working area and fits in a standard shipping container.

Interestingly, the printer does not just fit into a container, but uses it as a chassis. All main elements are mounted directly on the floor and walls of the steel box. The flip-down side panel makes it easier to access the gears and the large work platform, but the most obvious benefit is the frame savings. The container has an anti-corrosion coating and is completely sealed, ensuring the safety of delicate equipment during transportation.

All main elements are mounted directly on the floor and walls of the steel box. The flip-down side panel makes it easier to access the gears and the large work platform, but the most obvious benefit is the frame savings. The container has an anti-corrosion coating and is completely sealed, ensuring the safety of delicate equipment during transportation.

“The shipping containers act as a heavy-duty chassis. When building large machines, one of the most expensive items is the frame. Mille solves this problem by using an airtight container. The entire hardware of the 3D printer is bolted directly onto the steel walls. Since the internals and external dimensions are standardized, almost any container can be converted,” says the head of the company, Andy Tran.

In addition to choosing a container of the required size, various additional modules can be ordered, such as Tesla Powerwall batteries, solar panels, a conveyor work platform, a 3D scanner, a shredder for processing plastic waste into raw materials for 3D printing and various post-processing nozzles.

All in all, this is a true multifunctional CNC manufacturing system. Various replaceable nozzles allow printing with polymers, clay and building mixtures, laser and plasma cutting, drilling, milling, etc. The construction is made of aluminum and hardened steel, and the repeatable positioning accuracy reaches 25 microns. The size of the workspace directly depends on the size of the container and the wishes of the customer.

The developers are positioning the machine as a tool for building temporary shelters, prototyping large items, manufacturing components for the automotive and aircraft industries, making props for films and productions, etc.

According to the information on the company's website, Mille units will be available for purchase and rental. Whether the drawings will be made public or available under a commercial license, the team has not yet decided. Additional information on the project is available on the Millebot Inc. website.

website.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

Follow the author

Follow

Don't want

8

More interesting articles

ten

Subscribe to the author

Subscribe

Don't want

Igor Kostusev, an employee of the Arktika shipbuilding enterprise, received the Lomo Regional Prize...

Read more

eight

Follow author

Follow

Don't want to

The F2 Gigantry system will enable manufacturing companies, in particular aerospace companies, to. ..

..

Read more

56

Subscribe to the author

Subscribe

Don't want

Dear friends!

3D printers, makers and just caring people in Russia connect...

Read more

STL file Desktop scale shipping container ASSEMBLY・Model for download and 3D printing・Cults

Tank with robotic arm

18.87 €

RC / Smartphone Contolled Car / Can - Am Inspired Design

18.87 €

Mold for concrete planters Improved version

1.94 €

Best 3D Printer Files in Architecture Category

Winterfell

Free

Kingdom Center -Saudi Arabia-

Free

Grand Castle Generator

Free

Pen Holder M1

Free

London City - skyscrapers

0. 99 €

99 €

Burj Al Arab

Free

motorbike with sidecar

2,50 €

Generative Design / Topology Stool & Furniture Brackets

2.65 €

Bestsellers in the category Architecture

Scale pallets HO

1 €

Transformer oil

1.91 €

Crane for axle capra

2.76 €

Warhammer 40k Crane

1.89 €

Space Launch System (SLS): NASA Artemis I Lunar Rocket with Platform. STL-OBJ file for 3D printer

2.90 €

OBELISK

2.42 €

Christmas house

0. 62 €

62 €

Airbus A330-200 1:500

0.50 €

Elven High-Castle

3.98 €

EMPIRE STATE BUILDING - NEW YORK

2.99 €

King Kong at the Empire State Building - New York

3.42 €

Leaning Tower of Pisa

2.50 €

disney princess offer

2.50 €

Cessna 172 Skyhawk 1:72

2 €

NEW YORK - CITY OF MANHATTAN

2.99 €

Giant wheel / ferris wheel / grande roue / 1 meter

8 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so it is very easy to support us in maintaining activities and creating future developments.